-

Posts

24 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by jsolka

-

-

I've found a nice link (IMHO) on traditional English Ships structure. I liked the drawings showing detail of framing.

http://www.cnrs-scrn.org/northern_mariner/vol03/tnm_3_1_1-43.pdf

One more link - a nice book, and free pdf download.

-

Lee Valley tools makes a set of miniature planes - low angle block and shoulder - that I've used successfully on my models. Even tho they are super small they have a very sharp edge and cut very well. See http://www.leevalley.com/US/gifts/page.aspx?p=70138&cat=4,104,53212,70138 and http://www.leevalley.com/US/wood/page.aspx?p=64300&cat=1,230,41182,64300 They also have a set of miniature chisels and spokeshake, both of which I have and use frequently. But they are miniature and holding them in your hand takes a little getting used to. They work just as well as their full sized models.

For finger planes you cannot beat Lee Valley I have some of there planes and think hey were worth every penny.

David B

"Supplied in a French-fitted embossed leatherette box" - hmm... Sounds a little effeminate:)

But seriously - I know Lee Valley, and their tools are very good. And what was I thinking to consider planes that cost $10 for three. Best to spend a bit more. One question - can you use a honing guide on their blades?

What do you think of those?

http://www.leevalley.com/US/wood/page.aspx?p=50232&cat=1,41182

There are some more, but don't won't to push the envelope. I think the most useful would be one with good square shape for shooting. The also have an edge plane. Okay, that's enough.

Thank you gentlemen.

-

I've read where some use old fashion carbon paper slipped between pieces during dry fitting to mark / highlight the bumps to sand.

It seems a good idea. And yeah, checking during the process... I know. Measure twice, cut once, I have to work on it.

Thanks

-

First mistakes - sanded too much, and now the pieces are a tad smaller than they appear on the plan (and surfaces weren't perfectly true). This could be not entirely me fault since the precut pieces didn't allow for sanding (perhaps?). While building from scratch this could be compensated by cutting pieces a bit larger. Also I think that when I would really like surfaces to be perfect, I may consider using planes for truing surfaces rather than sandpaper. Does anybody have any advise/recommendations about hand planes that can be used in model making. I've seem some cute brass and wood micro block planes, but wasn't fully convinced.

-

Very nice. A bit closer home that your other built in progress.

Thanks.

-

Your presentation is very good and detailed. Nice pics. Amazing job. I'm not there yet, so the most of it didn't really speak to me as it would, should I have been on that level. Thank you.

-

Thanks Brian and others.

The kit is called "Rowing Dinghy"

-

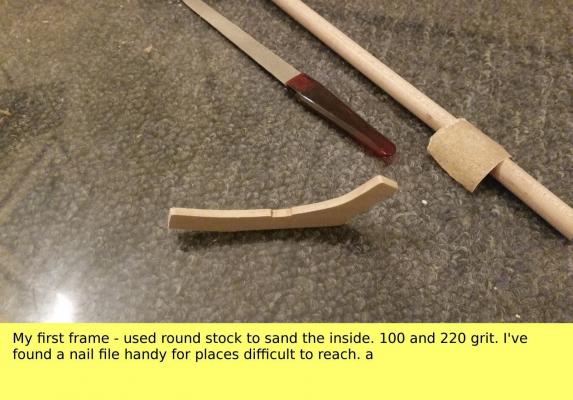

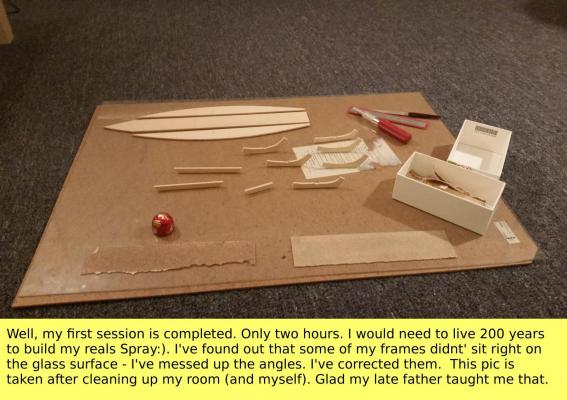

I want to learn gradually so I can eventually build my real Spray to travel the world round and round:).

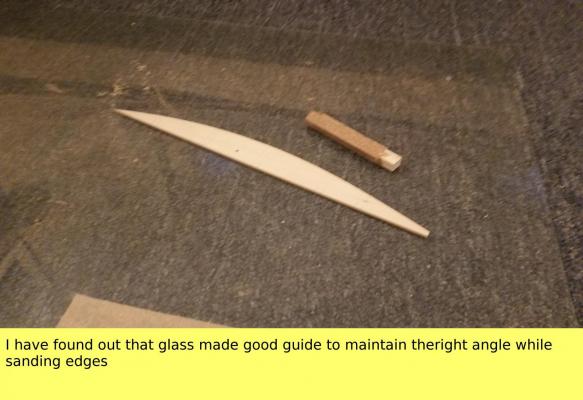

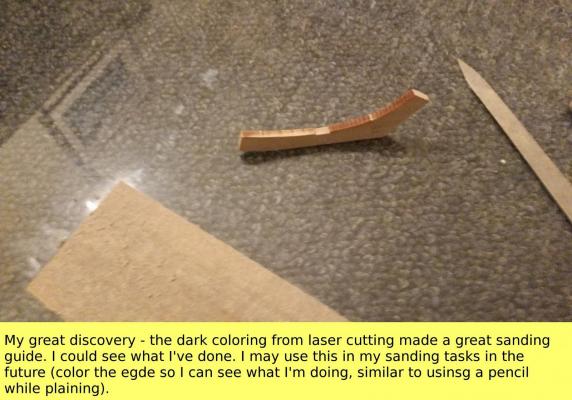

It is also a very basic guide on sanding for very basic absolute beginners.

I used a glass surface to guide my sanding block so it stays at the right angle. I also glued pieces of sandpaper to it so I could have more control over sanding.

-

Hi,

This is a very basic beginner's question. When I want to sand a narrow piece of wood (especially while making bevels) is there any technique (besides a steady hand) to maintain steady angle and flat surface on the sanded piece?

Thank you.

-

with mdf other than the chemicals off gassing I do wonder how it will last over a long time.

when the computer and music industry first came out with the CD-ROM and DVD-ROM it was thought that they would last forever as long as the disk did not melt or break. we now know that some disks can go bad in a few years depending on the material they are made from.

so will MDF last for say 50 or 100 years ?

You have a point. Wood has a proven record of lasting very, very long, at least in certain conditions. On the other hand, mdf is used now even in restoration projects in architectural woodworking. The rule is, mdf for stability, wood for strength.

Medium Density Fiberboard (MDF)

Moisture Resisitant, FSC Certified, No Added Formaldehyde (NAF)

Medex® is a sustainable, moisture resistant, medium density fiberboard (MDF) panel utilizing a formaldehyde-free adhesive system and pre-consumer recycled wood fiber. Medex® is engineered for interior high moisture areas in non-structural applications and is used in place of sanded plywood or solid wood. With the versatility of a superior composite wood panel and the enhancement of indoor air quality, Medex® has been specified in hundreds of commercial, institutional and conservator projects since the 1980’s.

- Medex carries an industry leading MR50 moisture rating

- We have upgraded our stocking program to Medex over the venerable Medite II

- SierraPine’s Medex MDF is produced with a No Added Formaldehyde resin and 100% post-industrial recycled wood fiber.

- FSC MEDEX MAY CONTRIBUTE FOR THE FOLLOWING LEED CREDITS

- Materials & Resources (4.1, 4.2, 7.0)

- Indoor Environmental Quality (4.4)

Stock Items 4' x 8' 4' x 10' 4' x 16' 5' x 8' 5' x 10'

1/4" ,3/8",1/2", 5/8",11/16",3/4",1" , 1-1/8" ,1-1/4" ,

-

Please tell. I was trying to get freebies pdfs but not very successful.

So long.

BTW I Got me a kit rowing model boat to follow Chapell's advice to start small t. If I succeed I will proceed further.

Thank you,

Secret Sharer Joshua Pascal M. Fitch Slocum the 3rd

-

-

Hi,

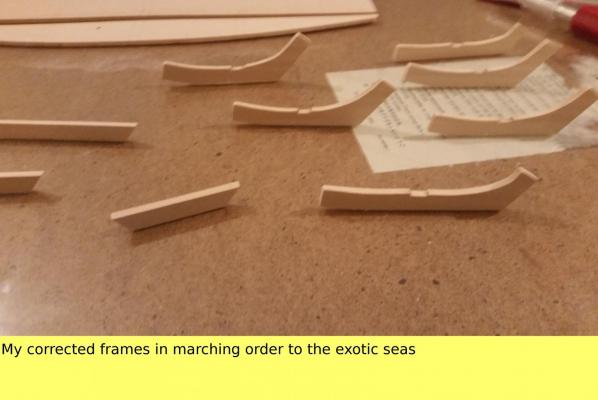

Here's a pic of traditional framing in which the frames (ribs) are not at the right angle to the keel (on the vertical plane). I was wondering what could be possible cons and pros for this kind of framing. I am interested in different approaches to framing and its history. I'm new to boat design, and maybe a tad anal. Anyway, as an absolute beginner, I've found it interesting.

Thank you.

-

-

-

Good one in medex, formaldehyde free mdf

-

I tried it and I think I've found some bugs. I couldn't trace on attached image, the image disappearing, and needed to be reloaded after each line (except with spline, but spline again had some other issues) I may try Autocad, since I may have an access. Thank you.

-

-

Hi,

I am in Architectural Woodworking business, and I've found DraftSight that is recommended as the closest software to Autocad. I was wondering if anyone used this program. I would like to learn it both for my ship model project and to improve my processional skill.

Thank you

PS I'm also considering Free Cad - any feedback?

-

Hi Cap'n'Bob,

I want to build Spray. Slocum is quite a personality, and so is his boat! I am an architectural woodworking estimator, and I wanted to kill 2 birds with 1 stone. I thought that I may want to learn auto cad. But... it turns out I can't get the license, and one is quite costly. Do you know if there is any open source software, I mean would you recommend any ( I know there are many)?

I will probably ask you many more questions, since my project will take me a while. It's just a goal that I want to keep in mind while learning and doing things. BTW I'm a newbie - you may check my post. Today is the first day of my new life:). Love this forum! And your build is awesome.

Thank you.

jsolka

-

-

-

Hi,

Art of shipbuilding.

Due to the lack of scientific methods of calculation and design of ships

ship building in the old days was a kind of art and everything depended on the experience of employee master of shipbuilding.

Gathered here from my archive of photos from various museums showing how ships were built centuries ago.

A few photos from the net is because old shipyards are still in the Navy possession or a ban on photographing in some museums.

Project.

Construction of a new ship ordered by the King was preceded by a performance of the model to the Admiralty can assess whether the project meets its requirements. Many of such models have survived to our time, they show the details of construction of the hull, we call it The Admiralty Models.

Because in those days there were no scientific method stability calculations all based on the experience of masters of shipbuilding.

Foto 1-3 Admiralty models

Foto 4-8 Assembly of Admiralty

Tadeusz

Gluing Techniques and Associated Information

in Building, Framing, Planking and plating a ships hull and deck

Posted

This is a great forum. I'm new to ship models, and didn't even know that there is the whole world of gluing products and techniques.