-

Posts

916 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by aydingocer

-

Amati Riva Aquarama Transmission and RC

aydingocer replied to tomsimon's topic in RC Kits & Scratch building

Hi Tom! Check my log for some hints on RC. The RC section should start somewhere here: -

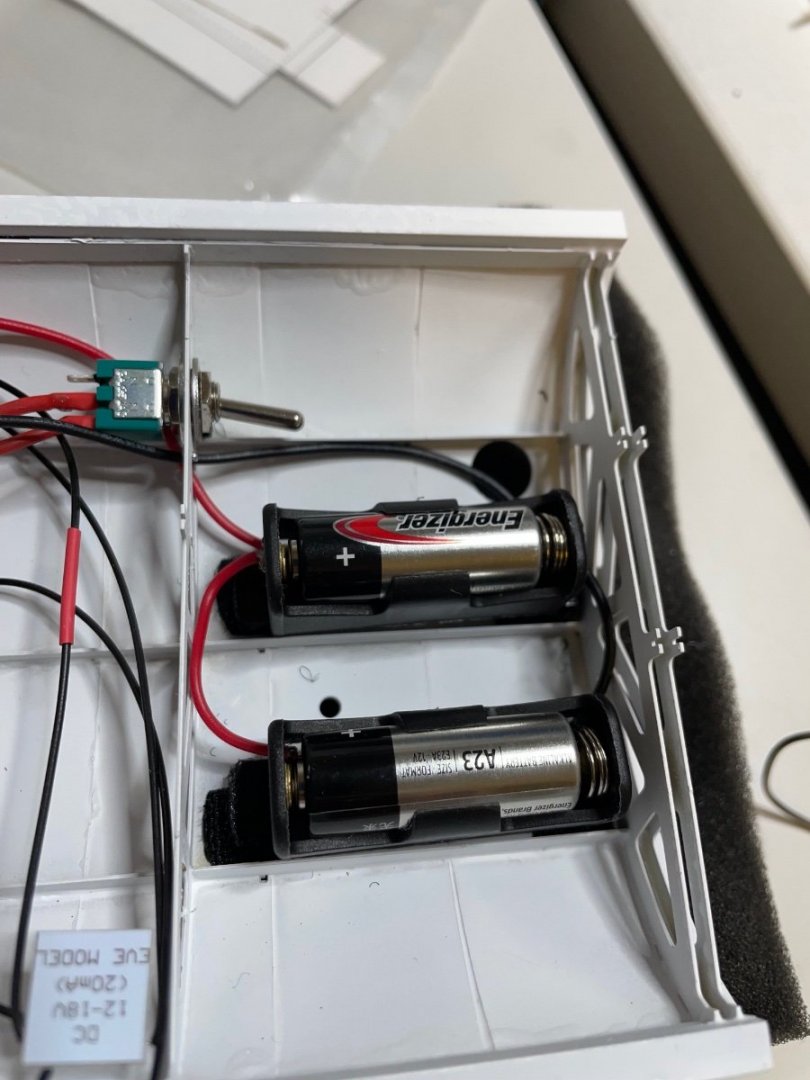

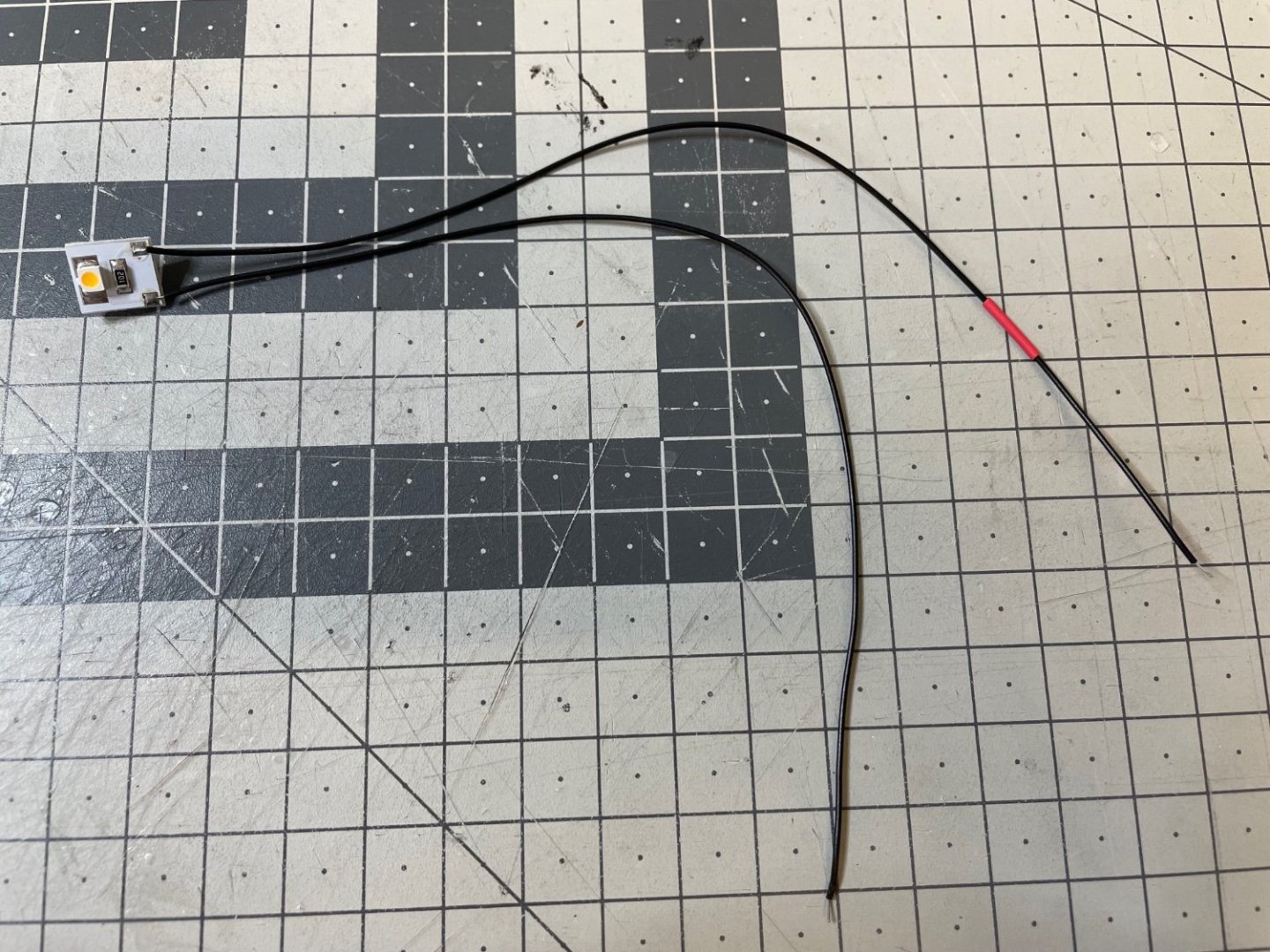

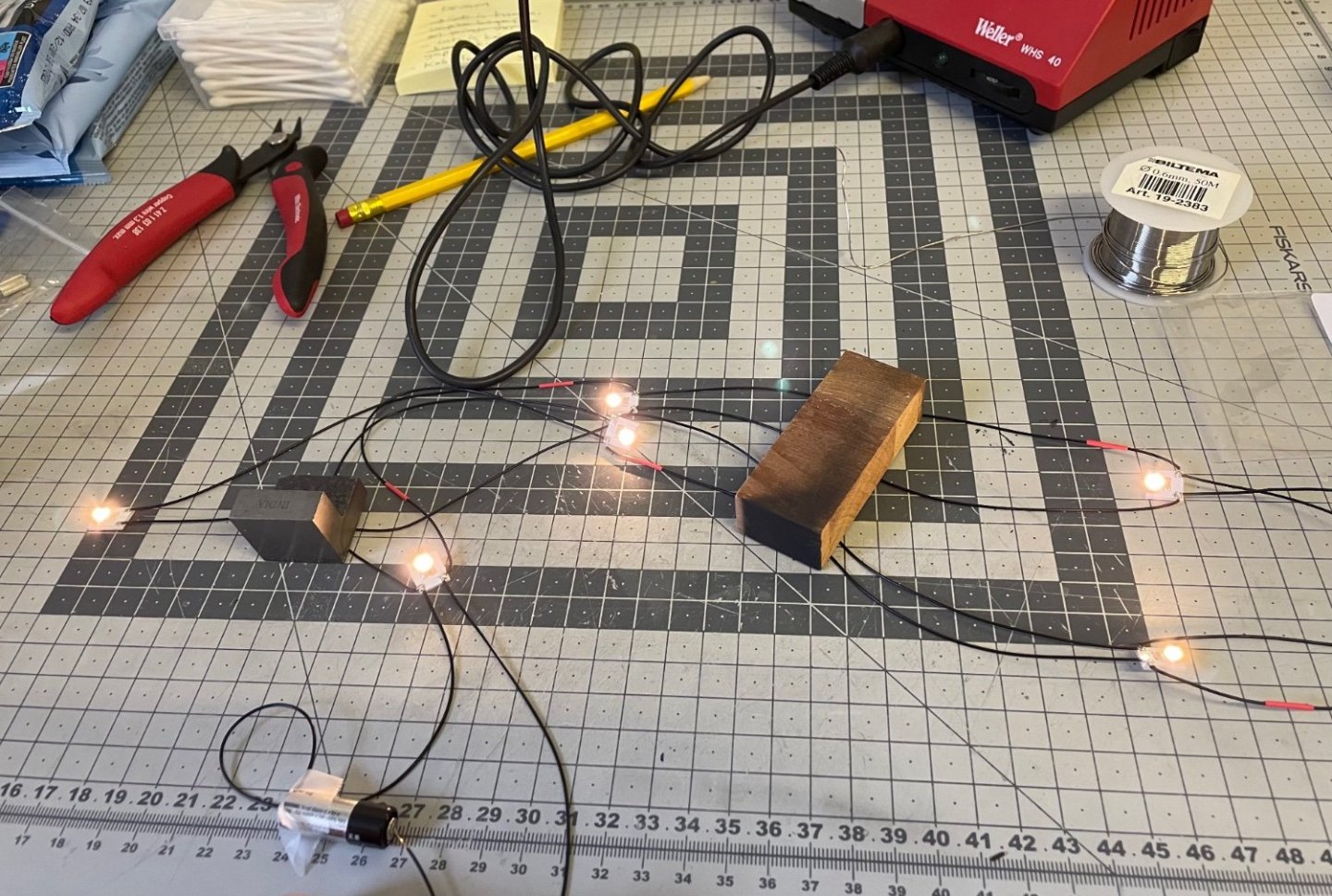

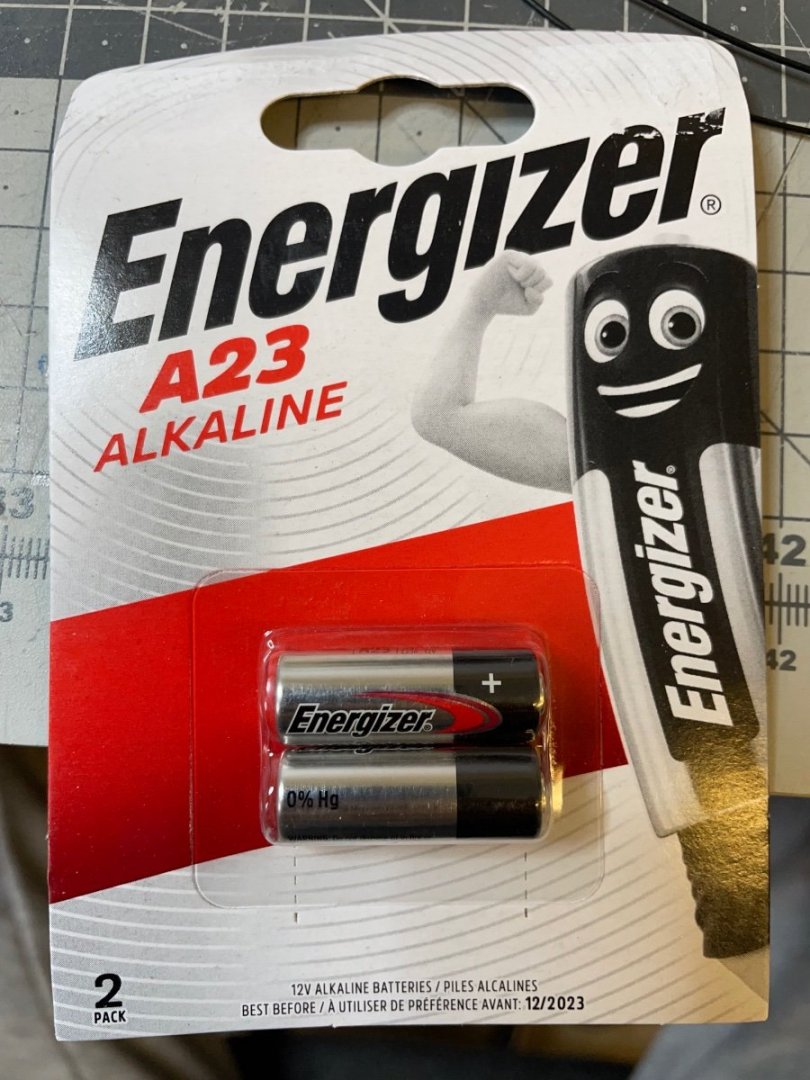

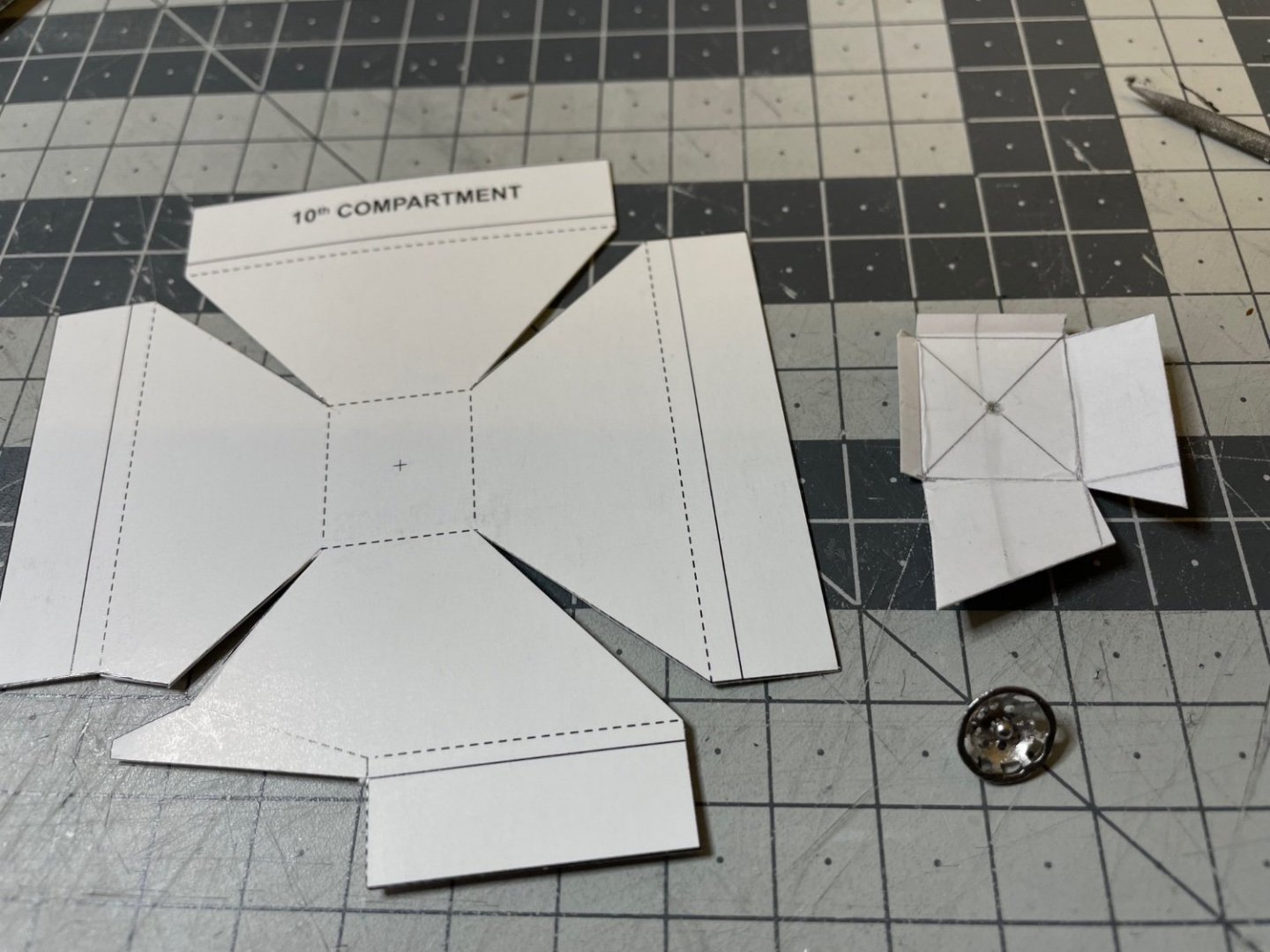

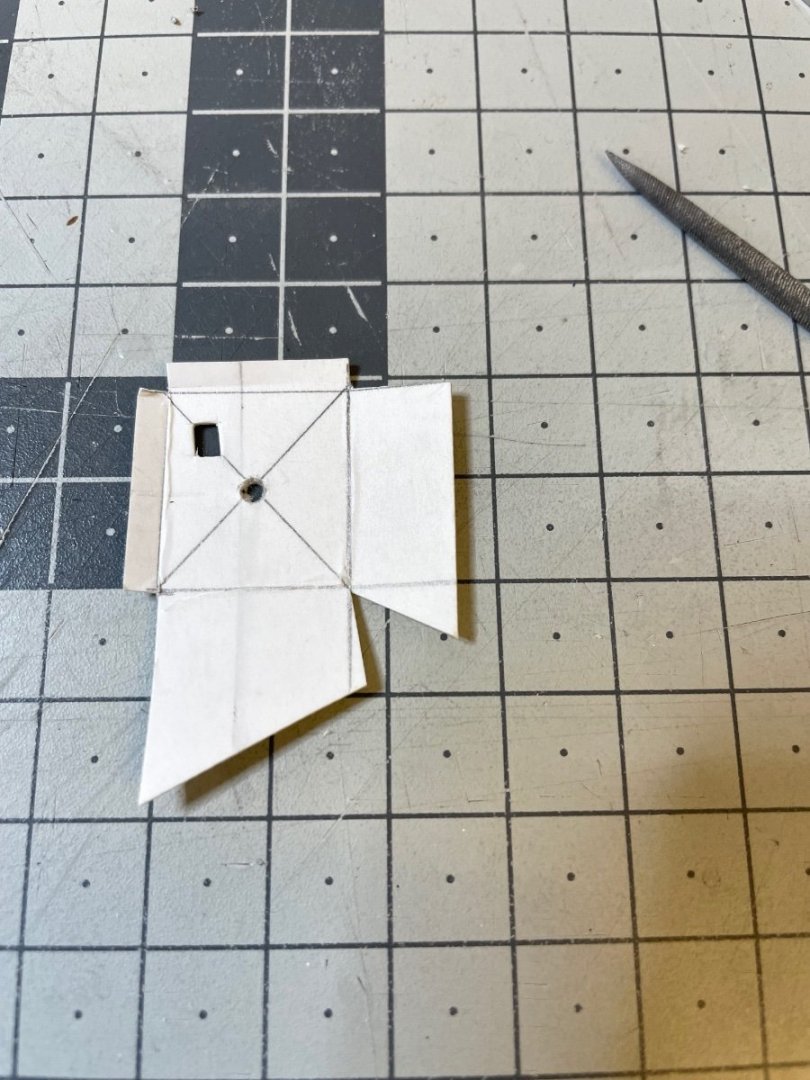

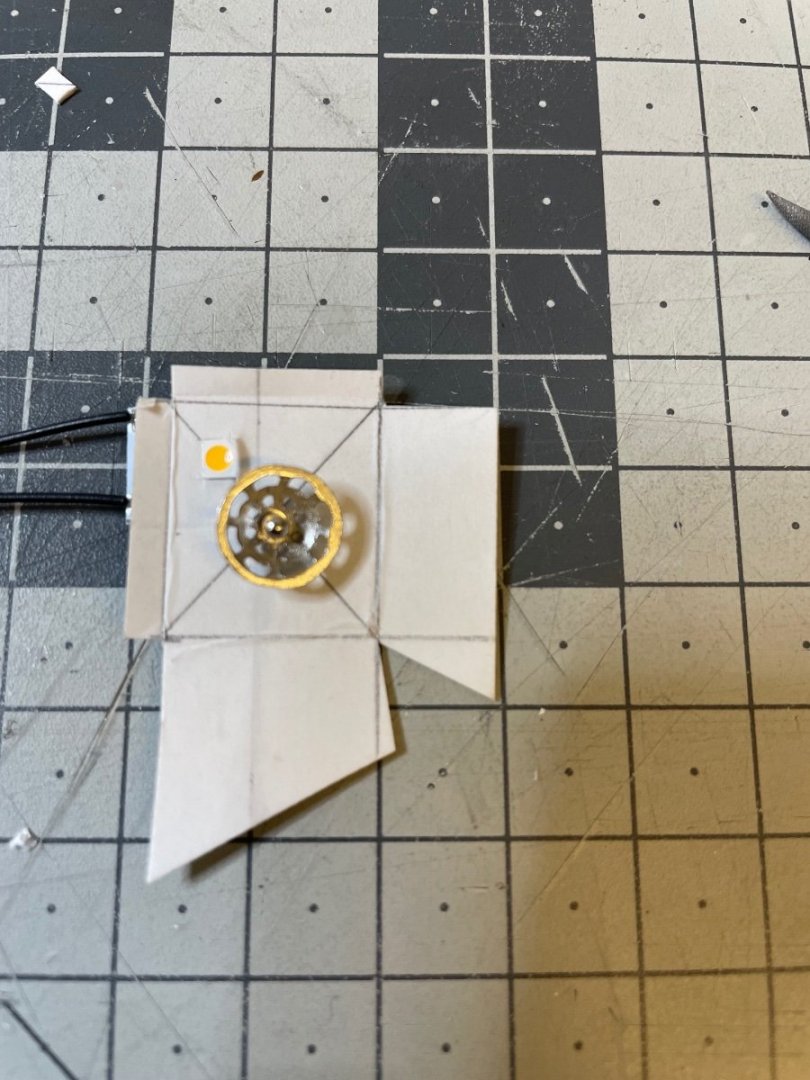

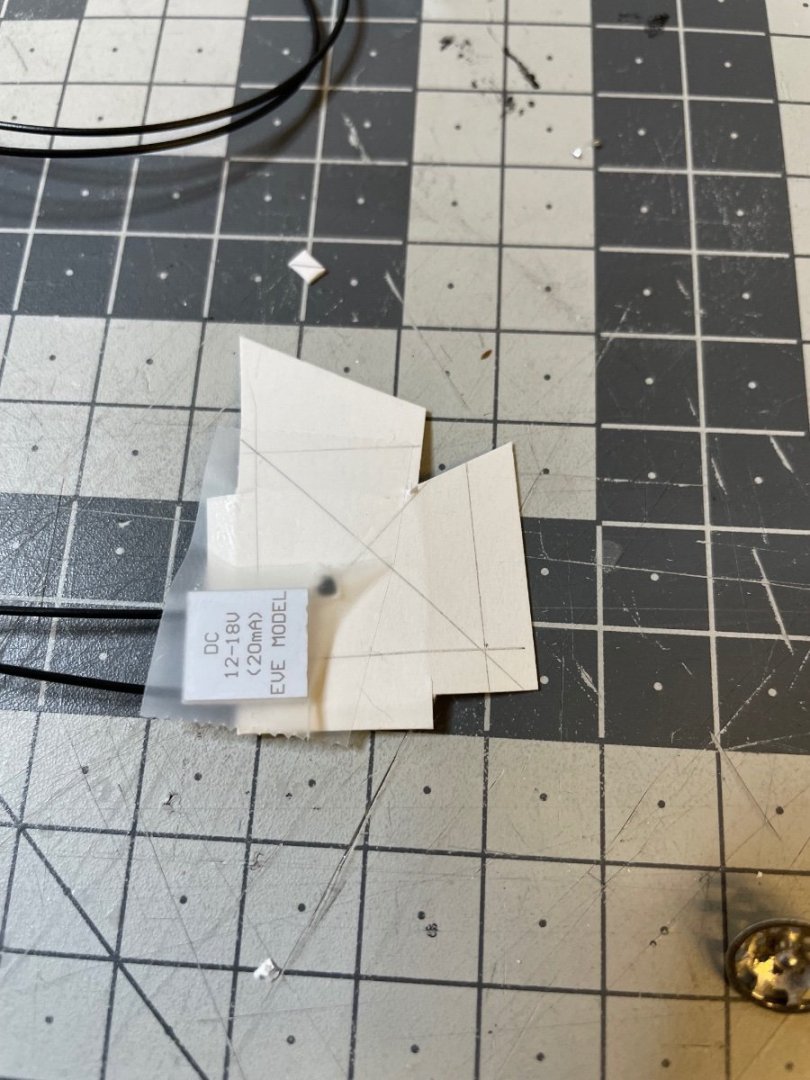

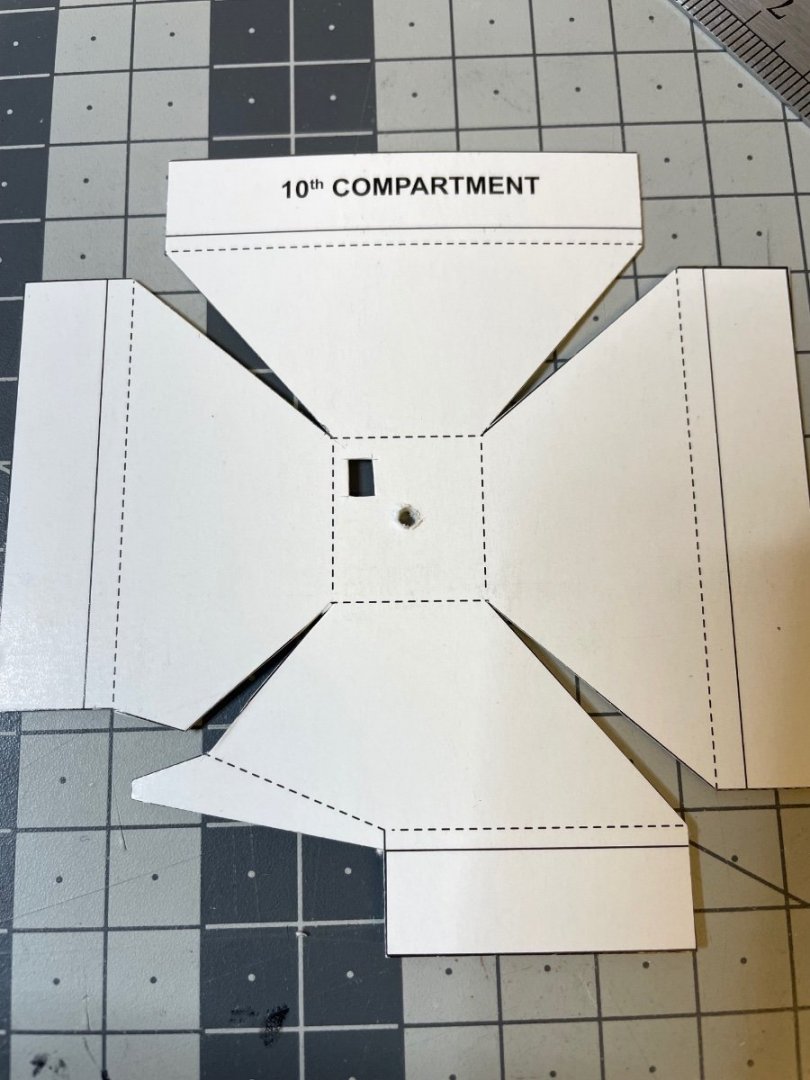

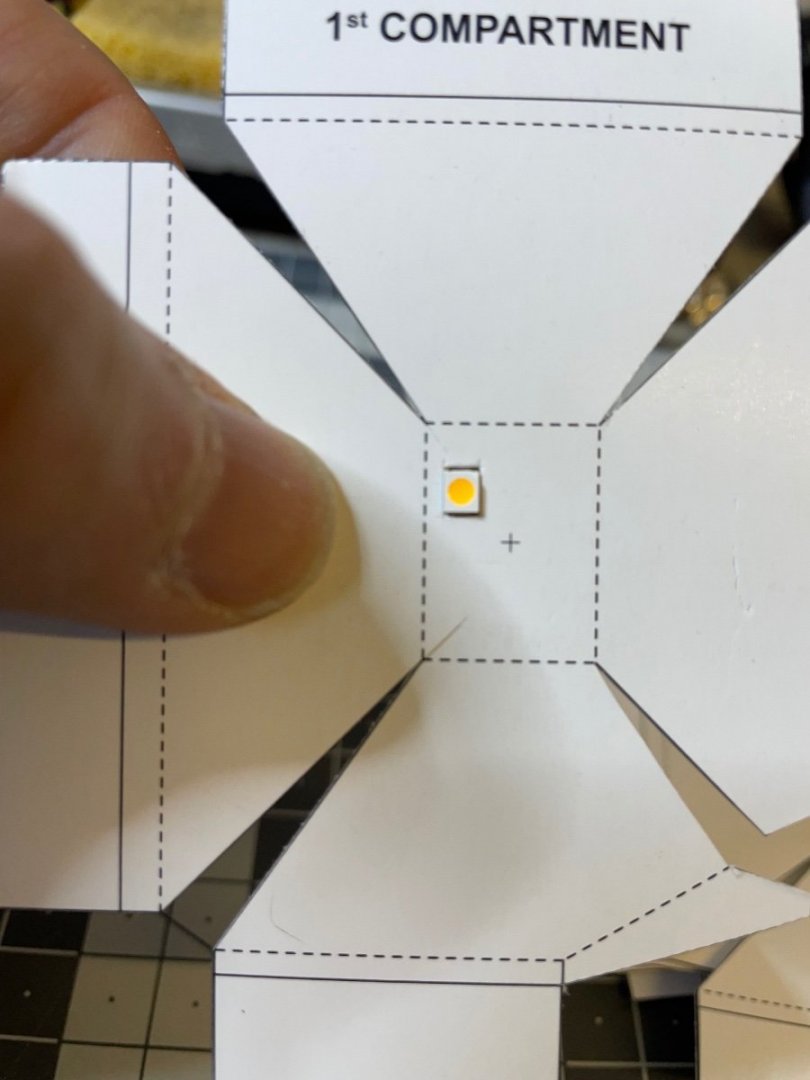

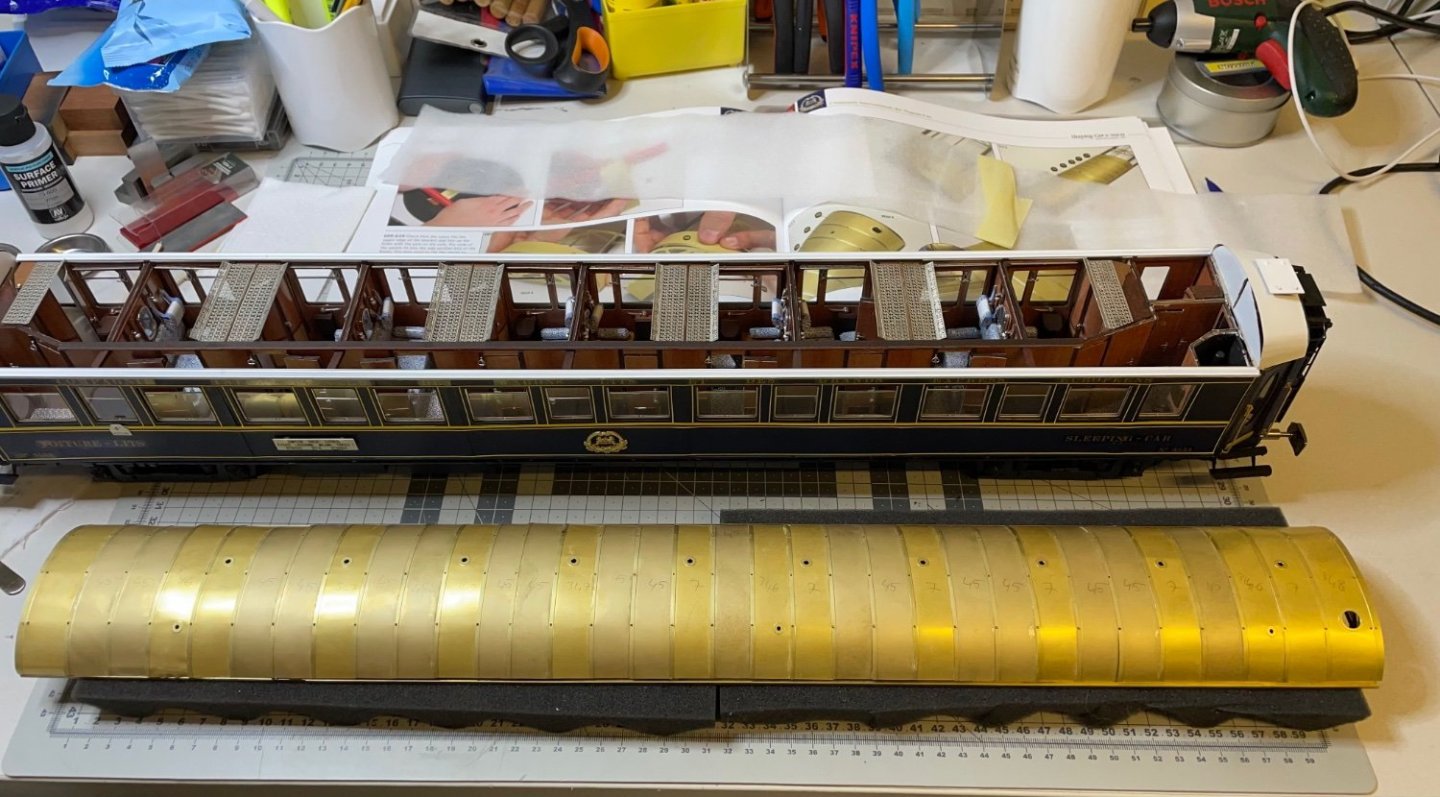

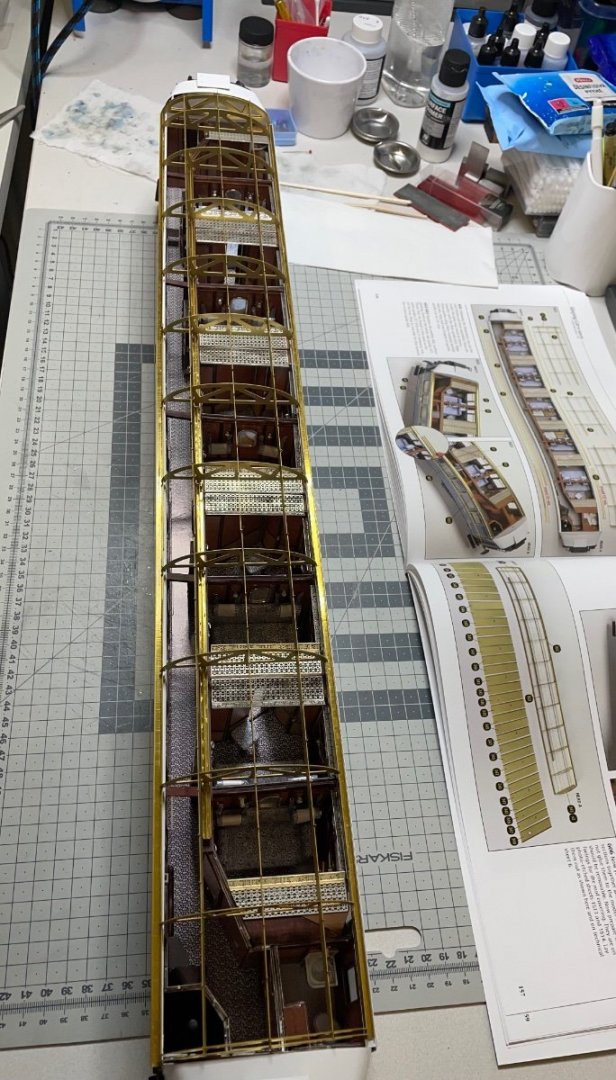

BUILD DAY 45 / 6 hrs / (TOTAL 115 hrs) It has been a while since my last build post. I have been traveling and time to time investigating how to install lighting on the ceiling. As I wrote earlier it had to be close to original lighting with at least one per compartment, not just some spots here and there. I also wanted to fit all the lighting elements (i.e. incl batteries, switch, wires) into the roof structure to avoid hanging of wires around and be able to remove the roof freely without any obstacles. Here in this post I will show my ceiling structure and light installation. Finally I was able to find led lamps, small batteries and switch with suitable specs. LEDs: They are 12 volt and resistors already soldered on the PCB board. They are from a small supplier in UK, https://www.smallscalelights.co.uk. The owner of the webshop, Jennifer, is the same person who is actually producing most of the nice railroad lighting items. Not all the countries are available for shipment, I sent an email request and she sent my order to Finland. So, if you like something on her webshop but your country is not in the list, it may be worth sending an email to her! Switch: Simple small size 1-pole toggle switch. Battery: A23 12 volt batteries. Here I installed two of them in parallel. So, still 12 volts but more power to light all 12 leds. Figure 458: Here is a single LED. It is ready to use if you just hook it up to a 12V battery source. Figure 459: Here I soldered them to each other in parallel to make a strip of 12 leds, with enough cable in between for installation. Test with the battery looks good. Figure 460: These are the batteries I use. Figures 461-464: Experimenting the installation on a scrap test piece (on the right) Figures 465-466: Testing the installation on the real ceiling piece. I think it looks pretty OK like this

-

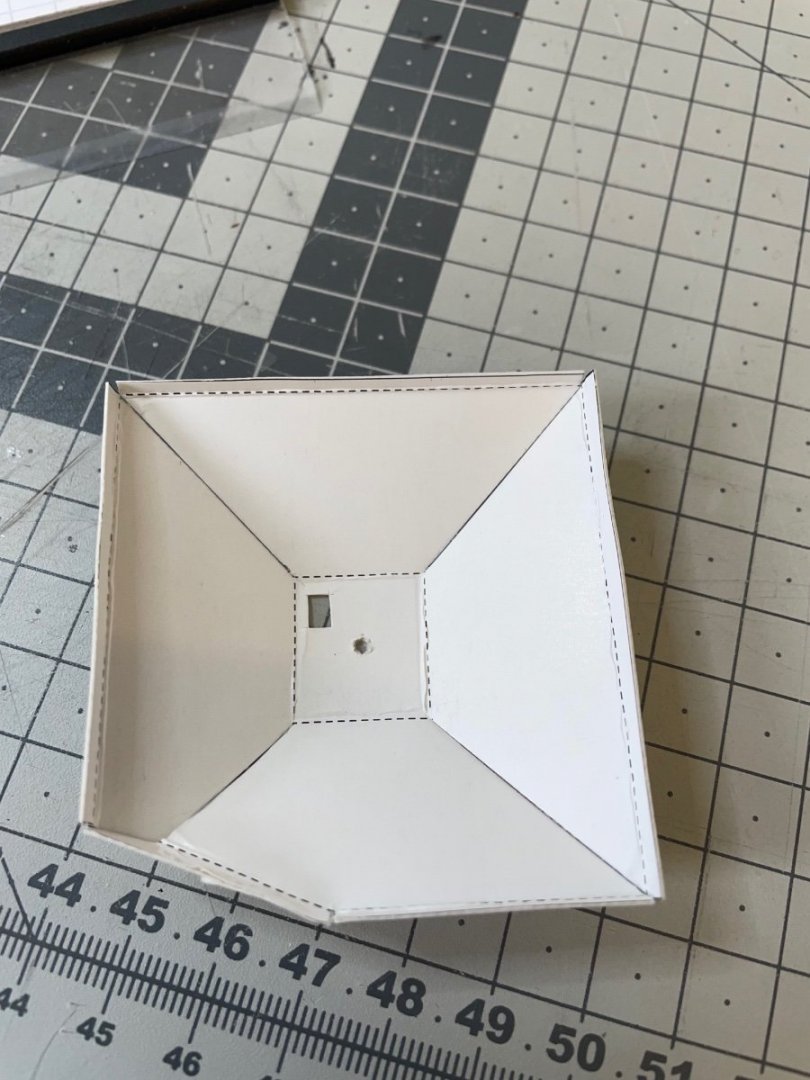

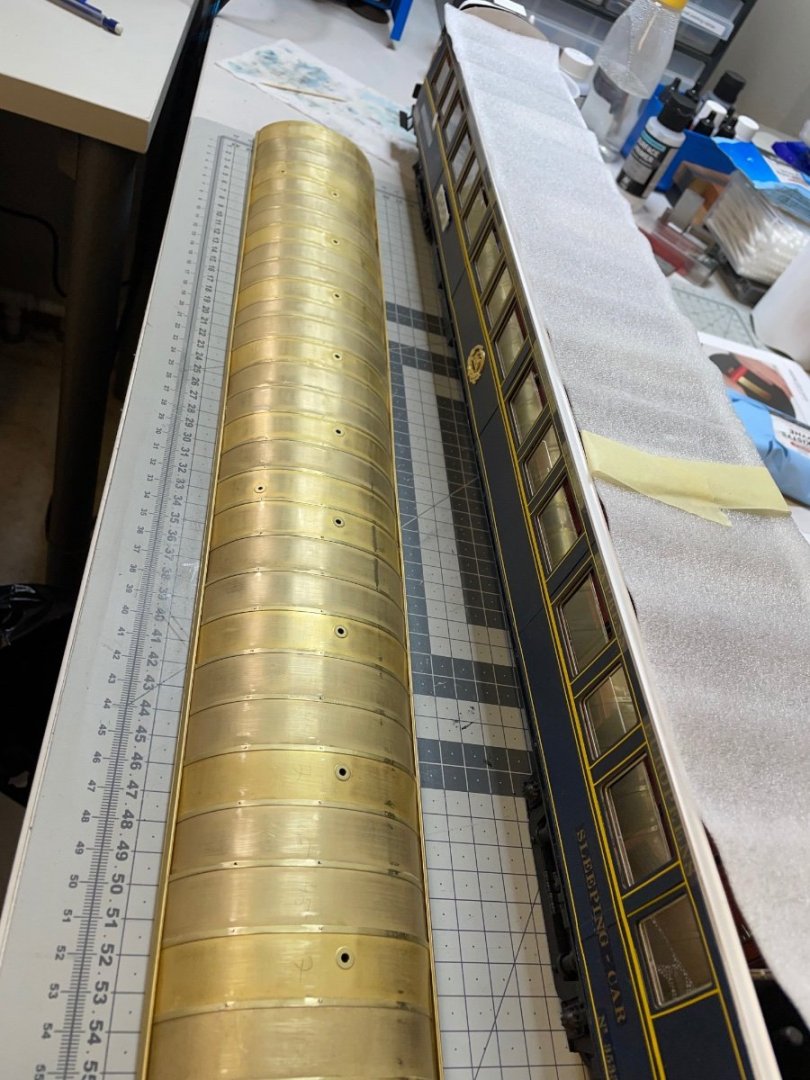

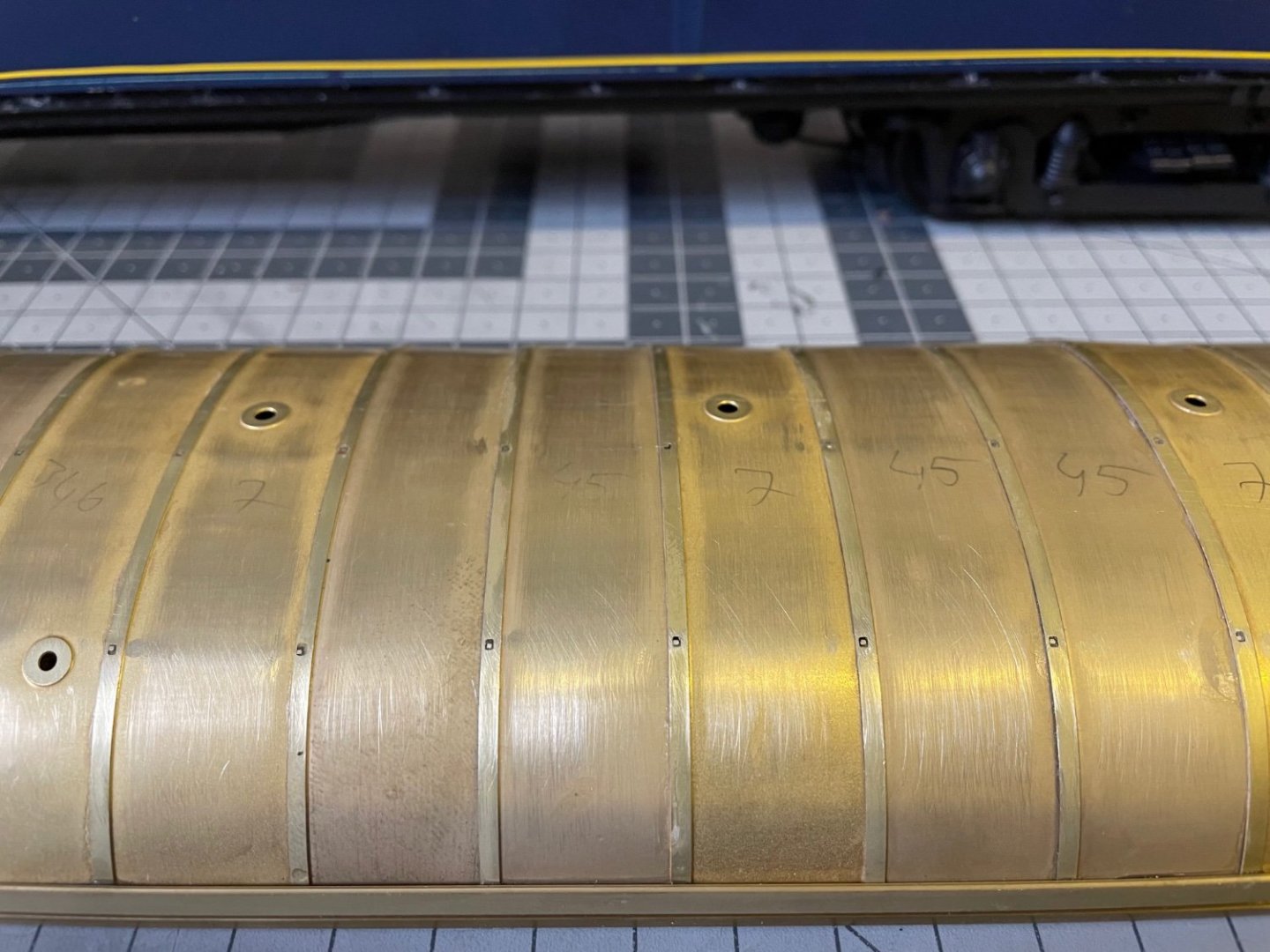

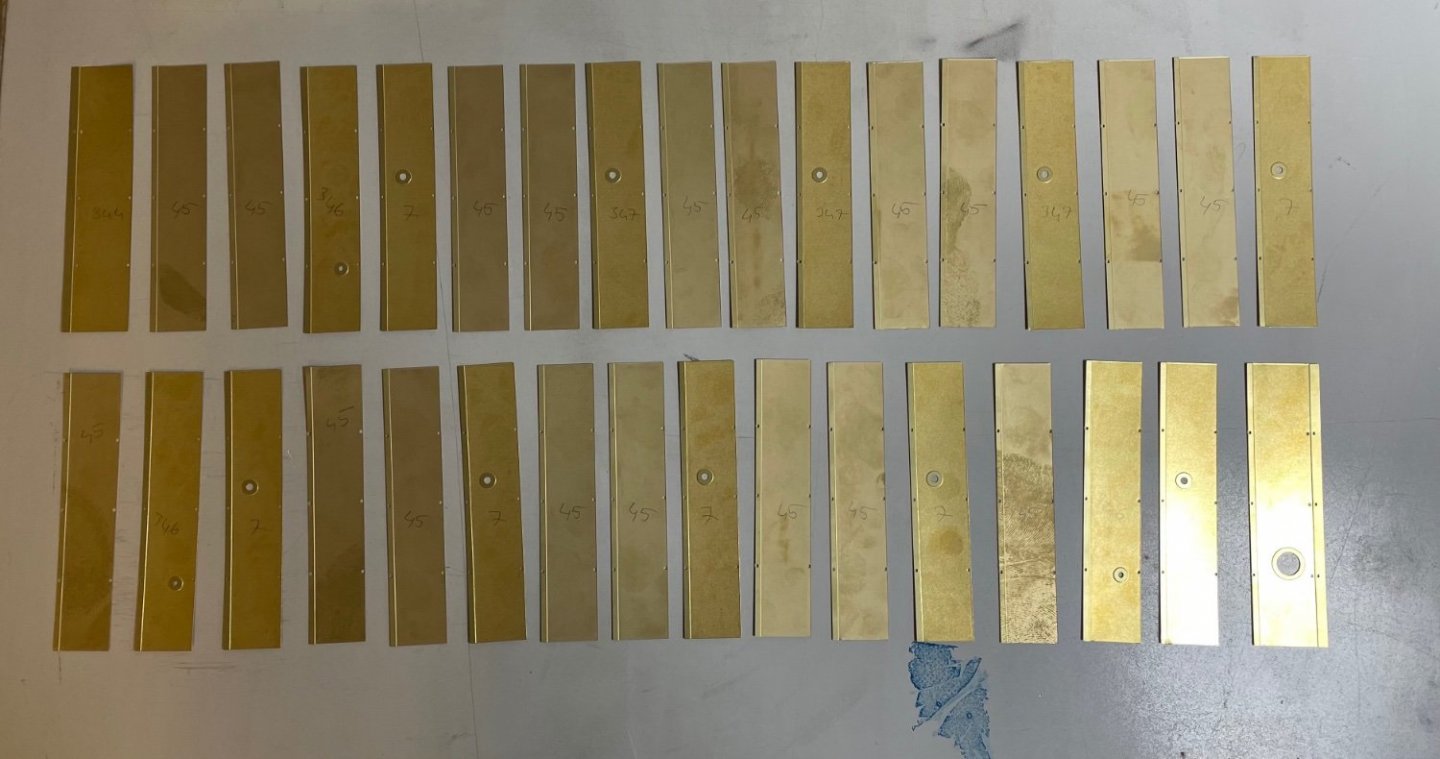

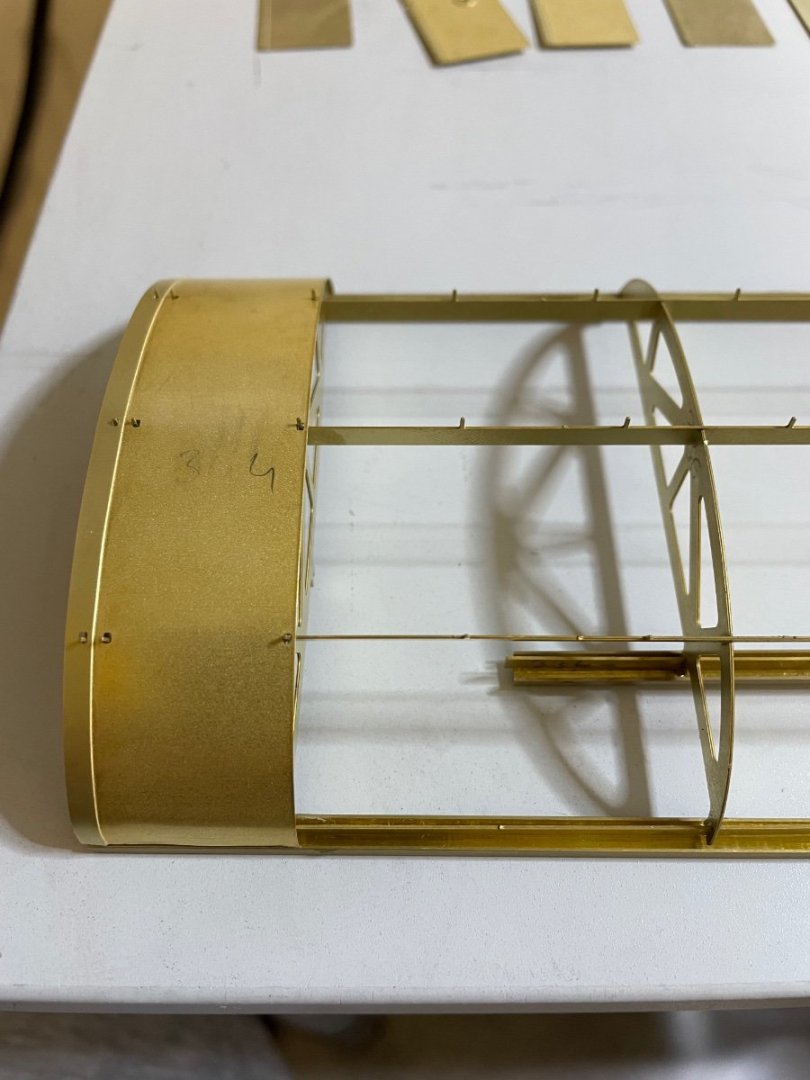

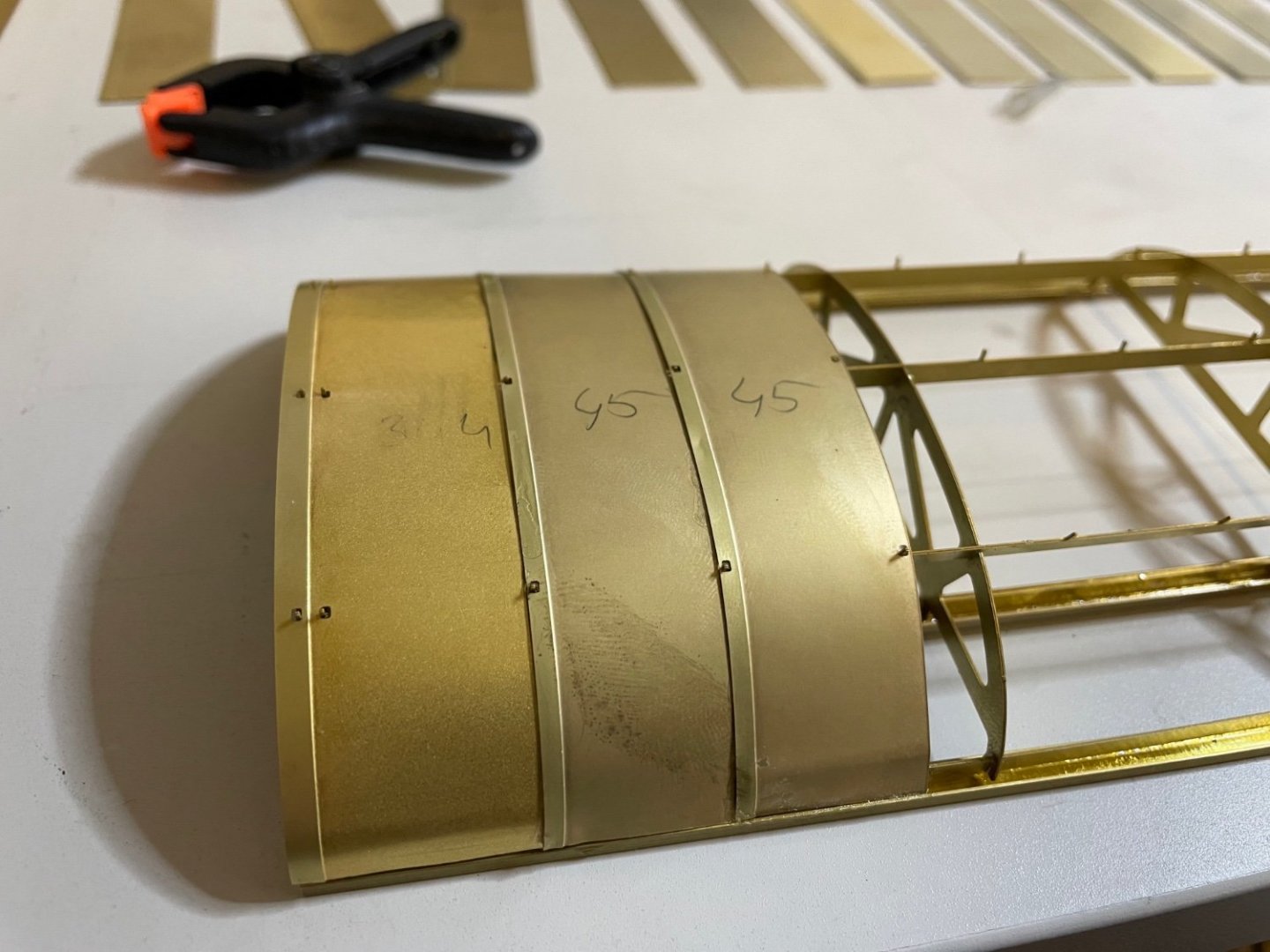

BUILD DAY 44 / 2.5 hrs / (TOTAL 109 hrs) Figures 451-457: Here is a series of photos from the roof construction. Overall it went smoothly. Once all parts glued, the next task was to do some surface finishing: remove the spikes coming out of the roof and smoothen the surface using sandpaper and file, especially to get rid of any glue residue. It was pretty much like finishing the hull planking of a ship model. That's all for now. Thanks for watching!

-

Though I am not a big fan of "bringing a model to life" (e.g. with human figures, lights, sounds etc), I am considering to add leds to this model, only if I am truly convinced with the possible options. I will try to plan the lights at as accurate as their original spots, such as one on the ceiling of each compartment and a few on the corridors, if this approach works. That would mean I will not install just one or two lights to give a general illumination. For this purpose I ordered the special leds below: https://www.smallscalelights.co.uk/product/3528-12-18v-chip-leds-on-pcb

-

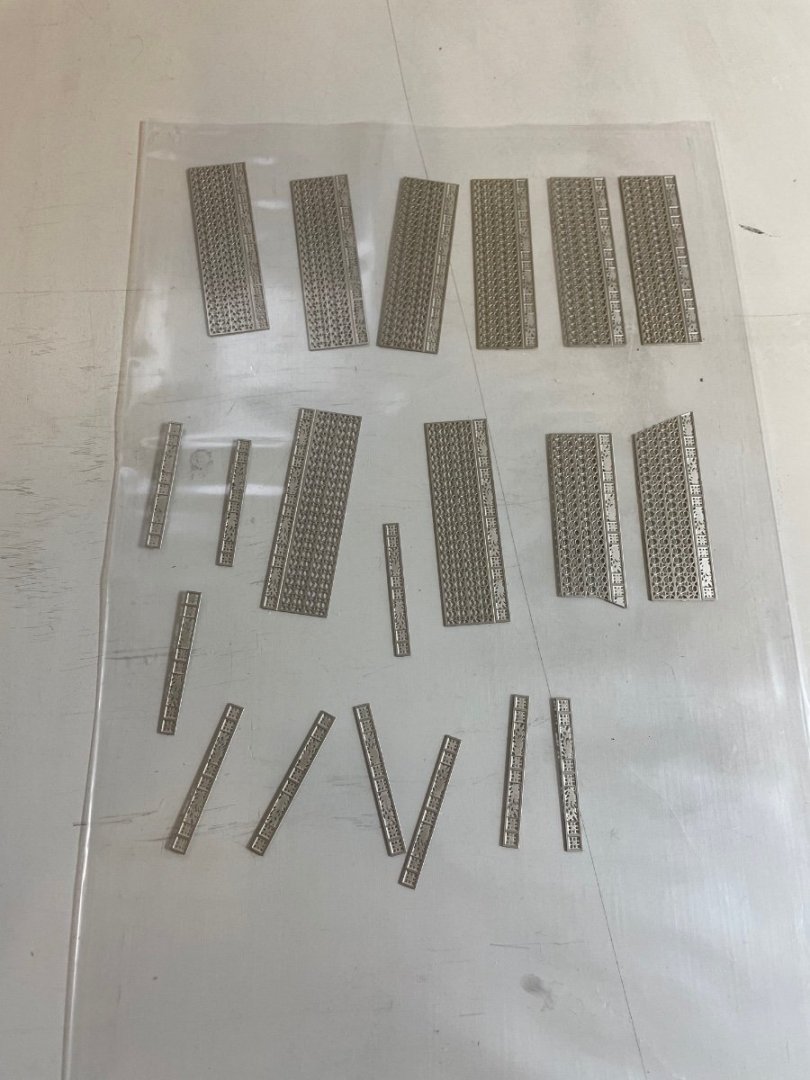

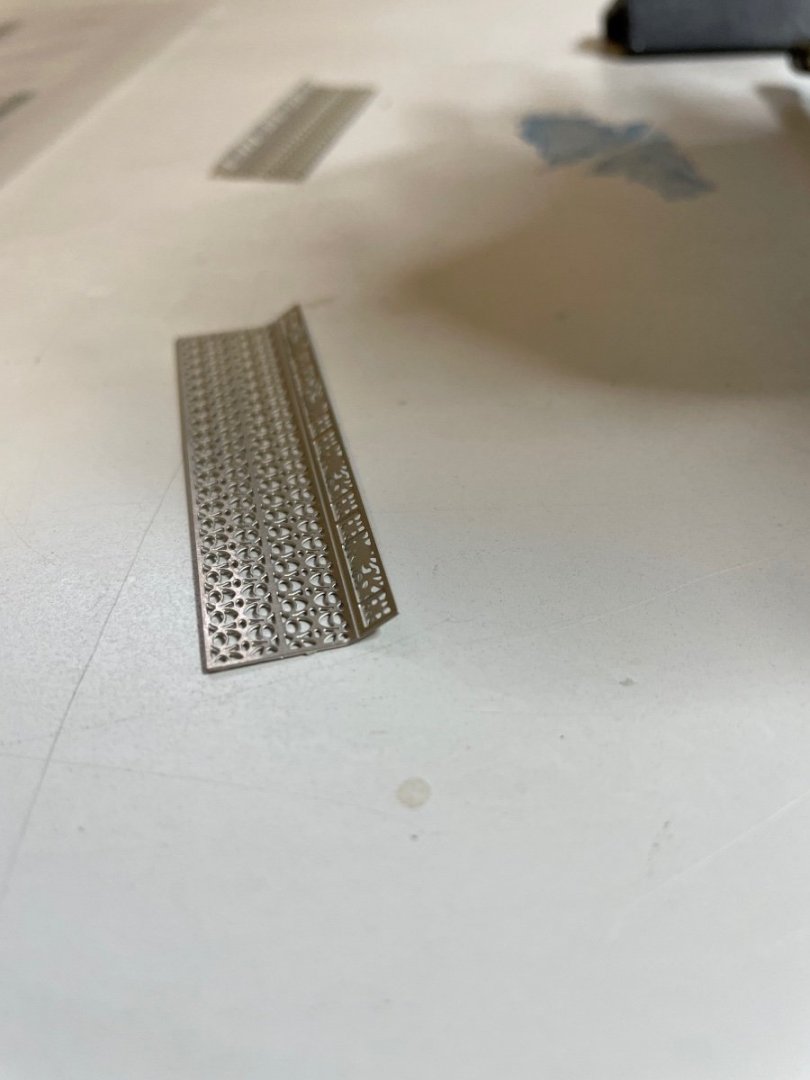

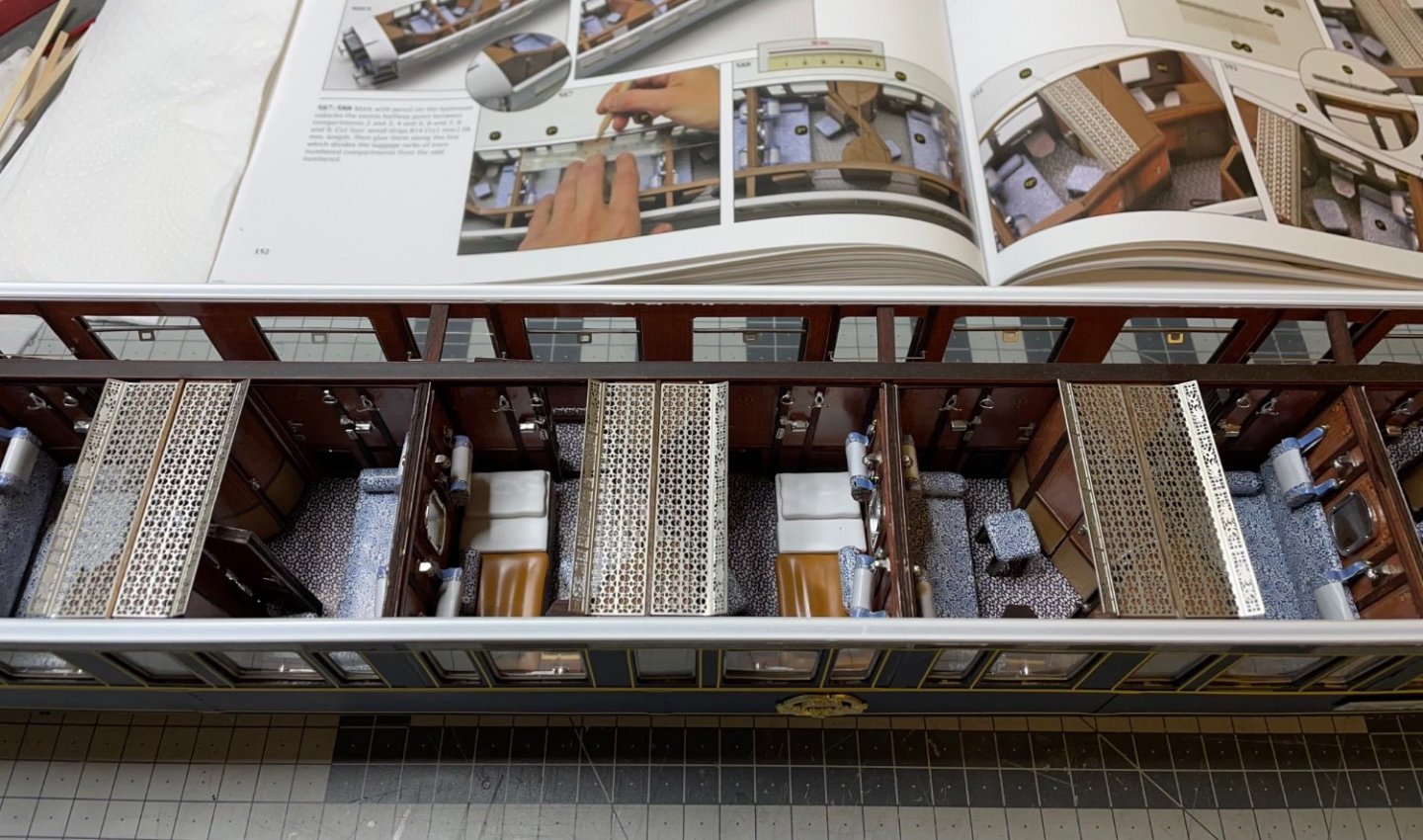

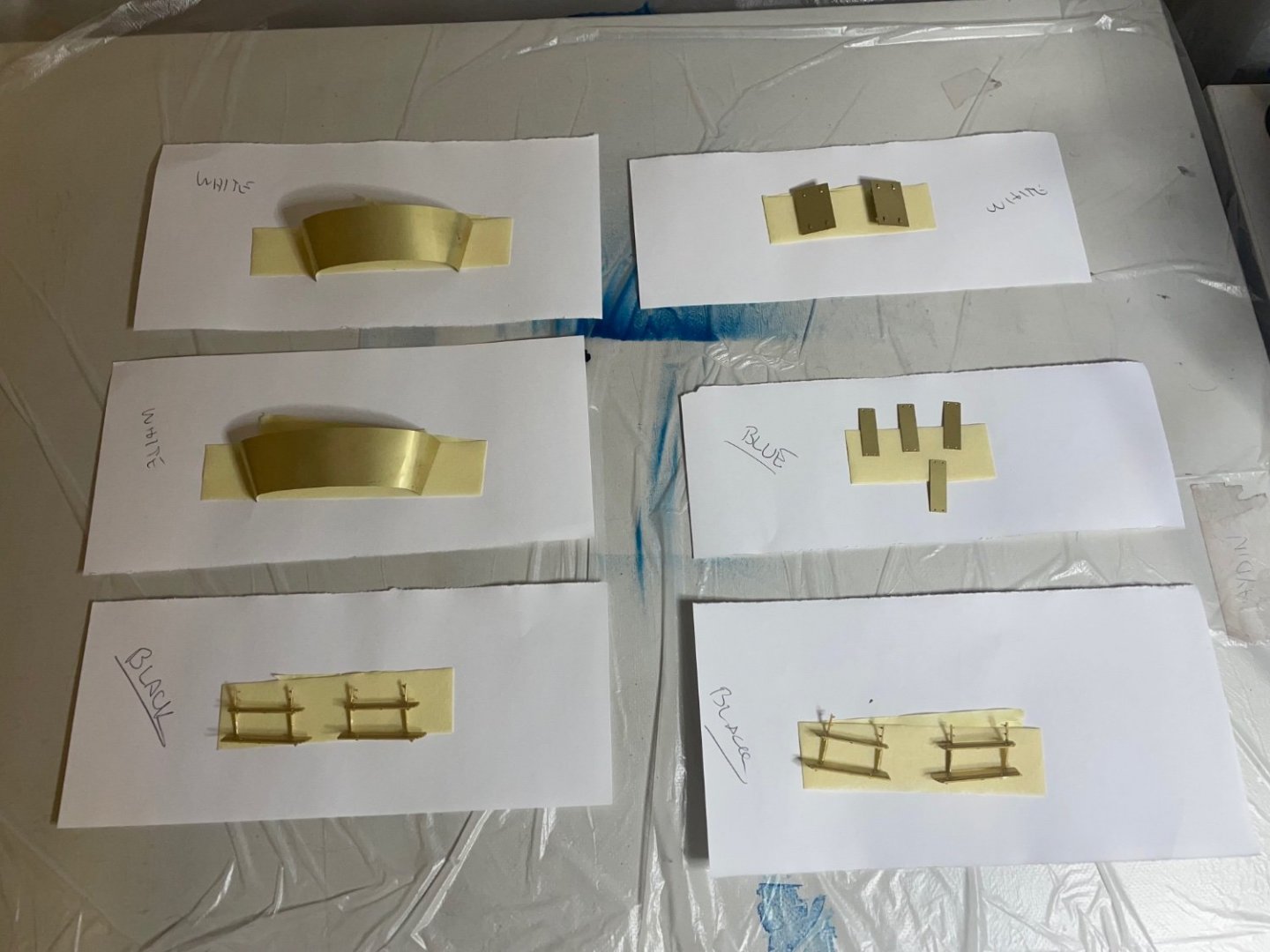

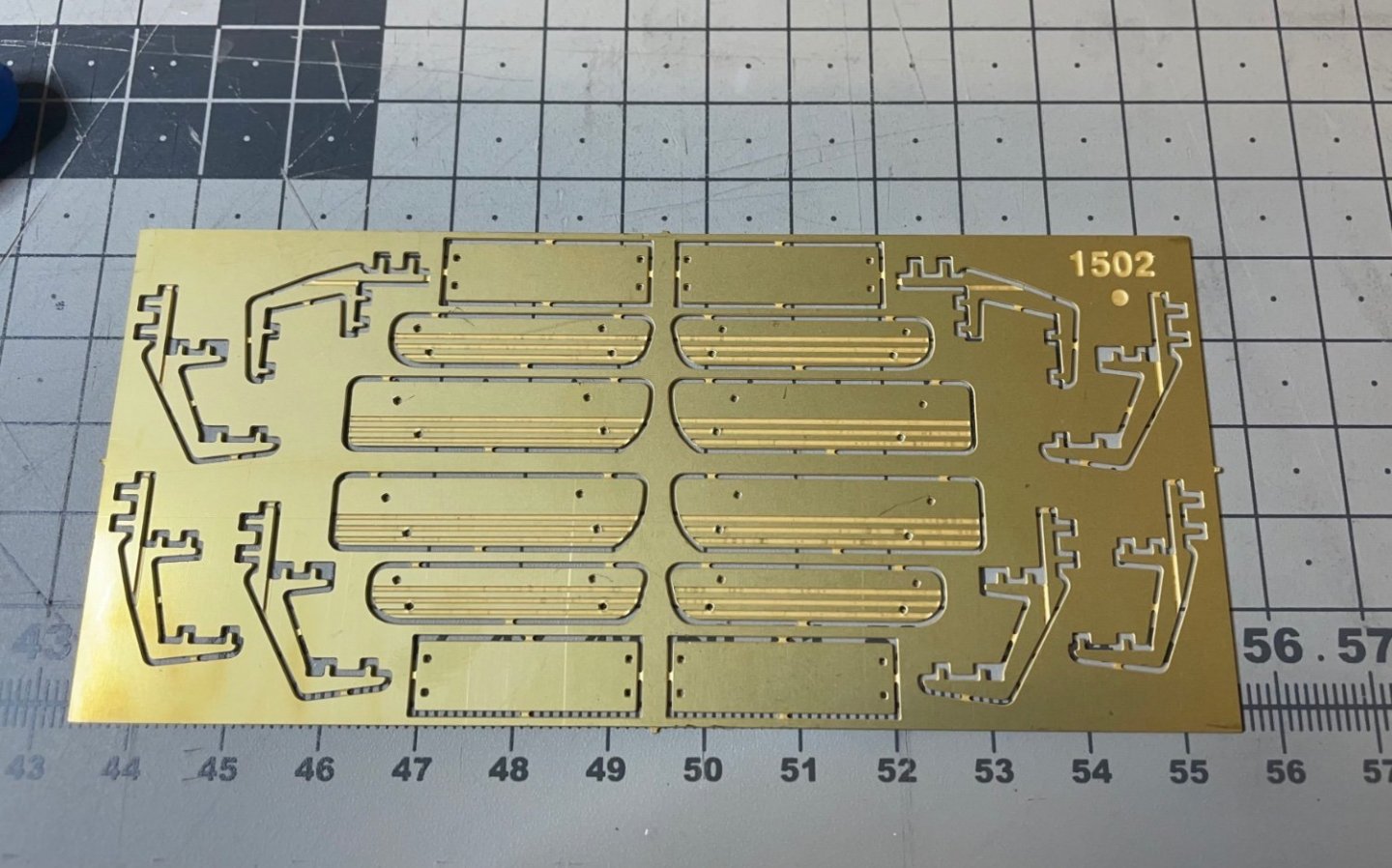

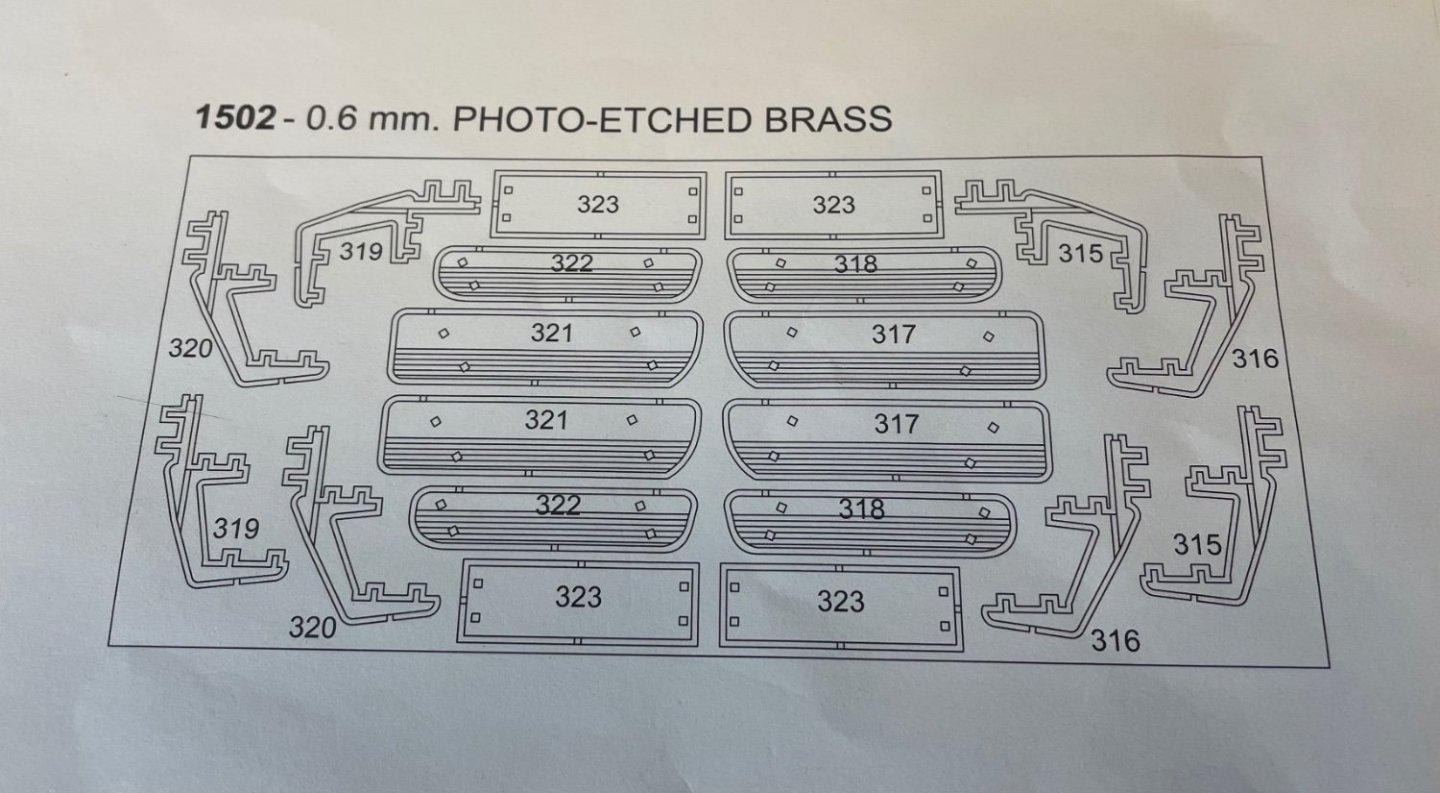

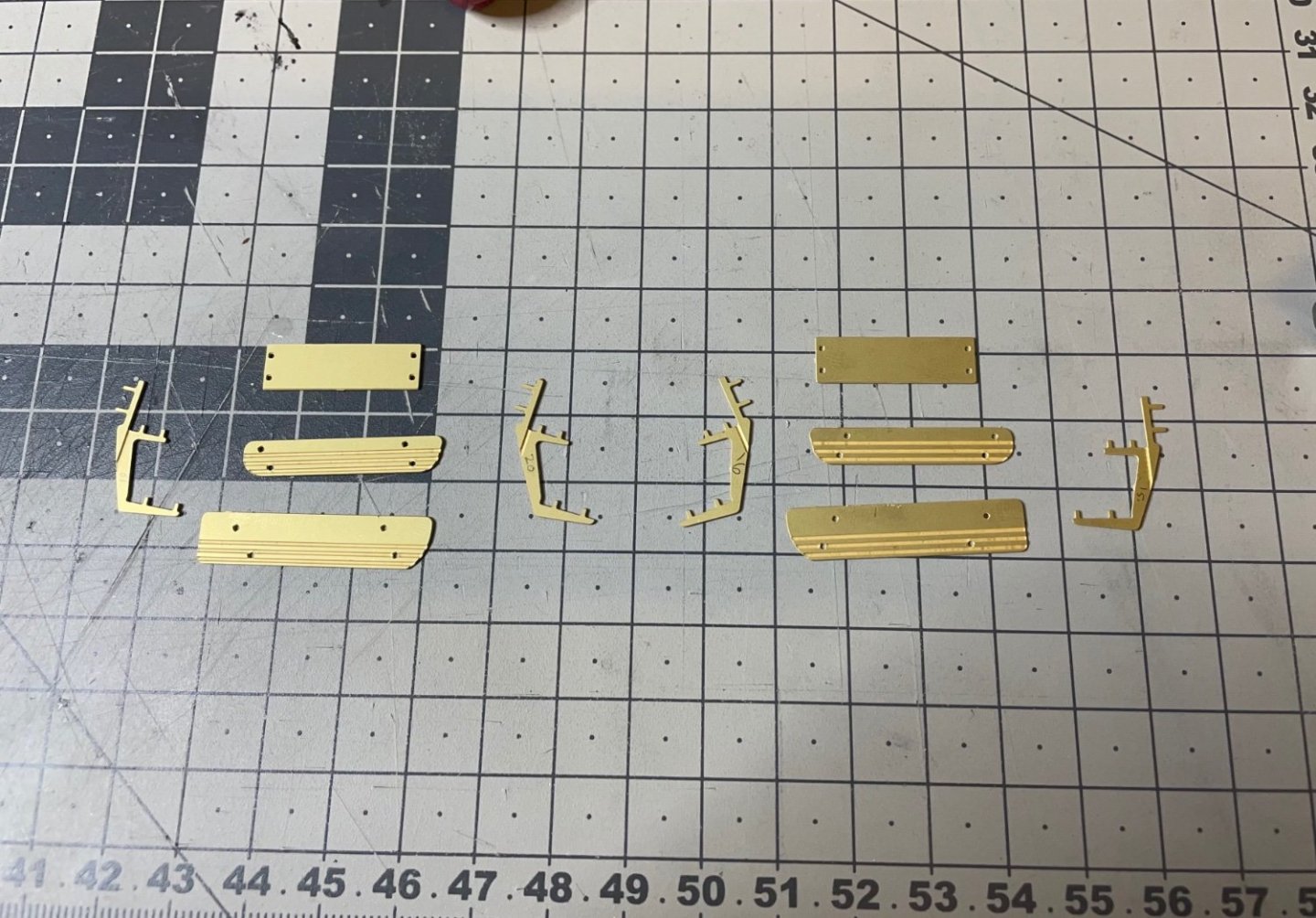

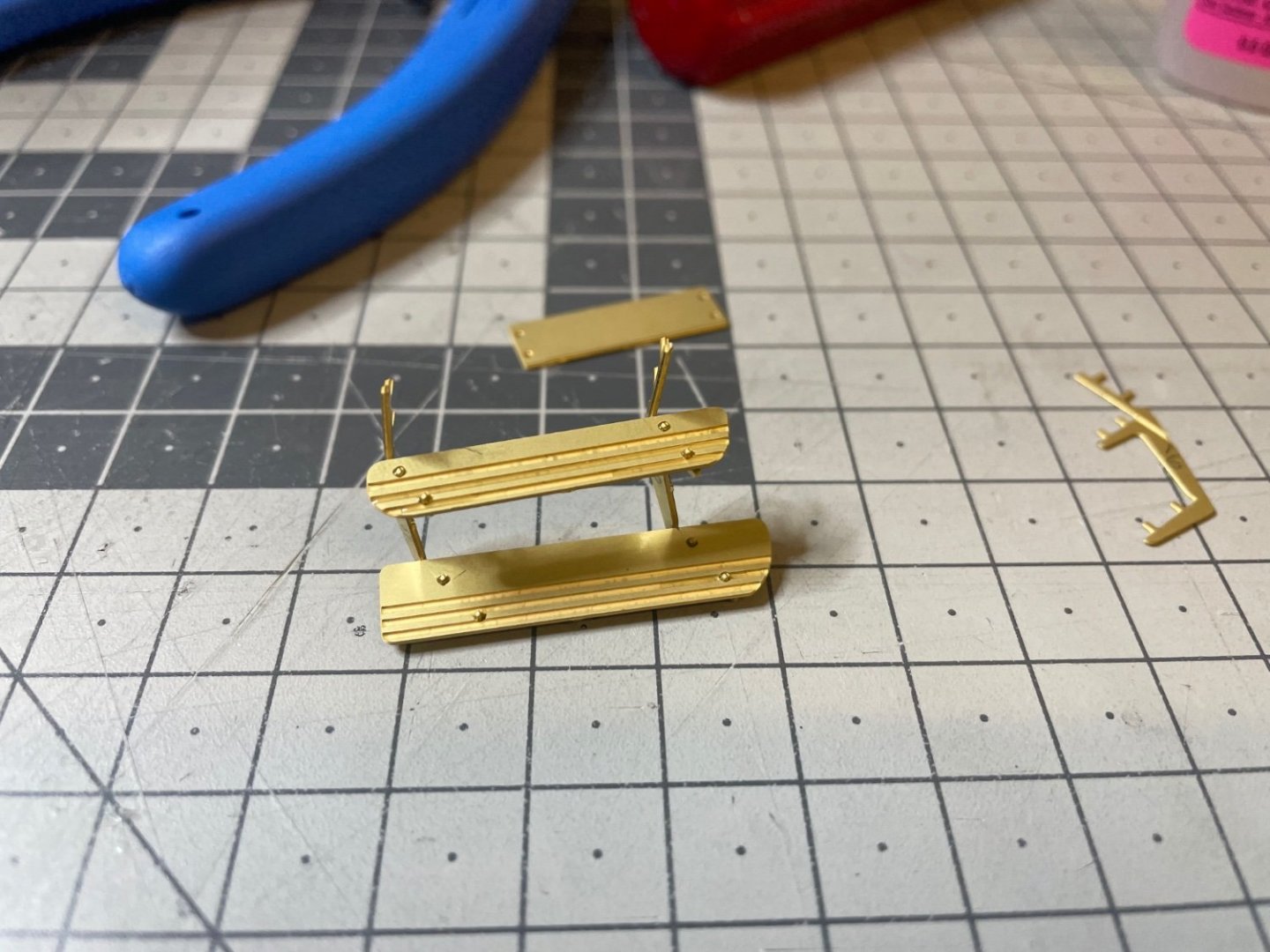

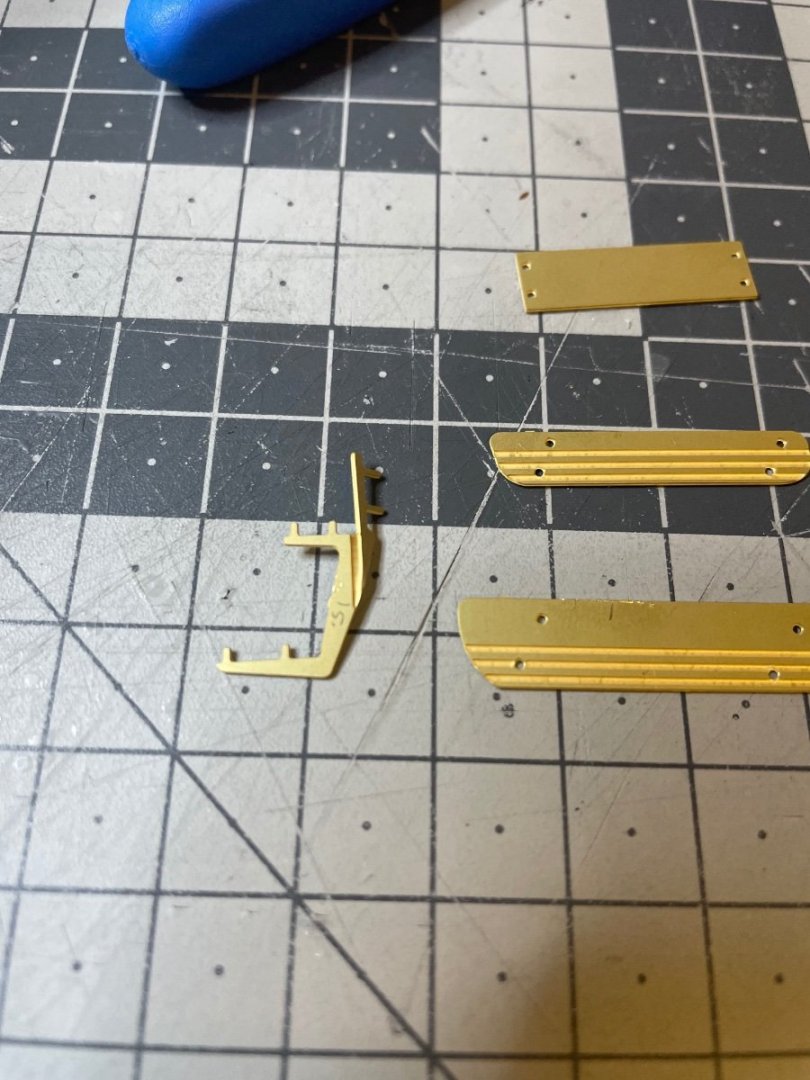

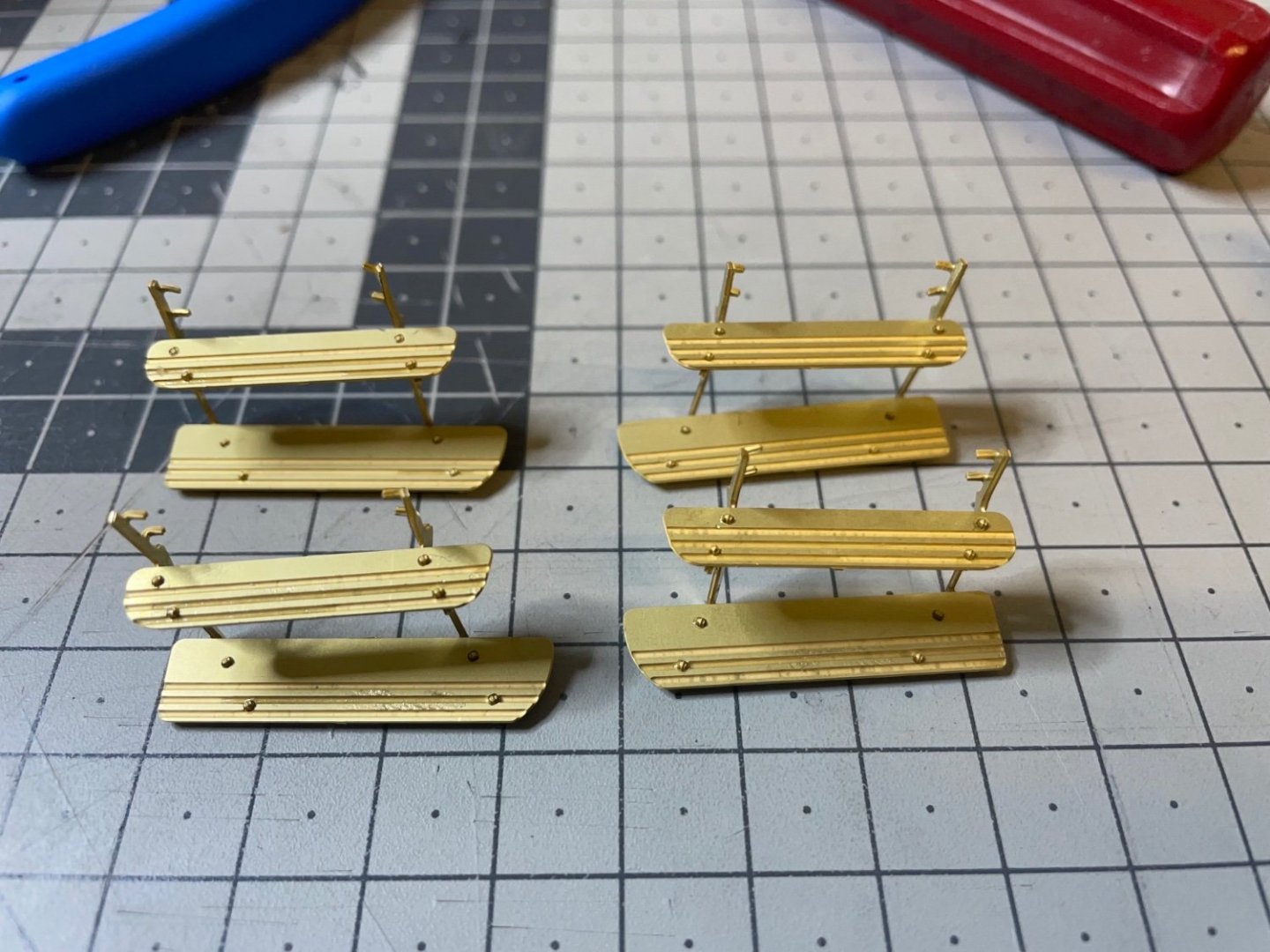

Figure 439: Overhead luggage/hat shelves. One for each compartment. The shelves for the 1st and 10th compartments are slightly different shape. The thin shelves are to be placed over the windows. Figures 440-441: The overhead shelves are bent around 30 degress on the compartment side, in order to prevent the stuff from sliding and falling. Figures 442-443: Some photos showing the shelves in place.

-

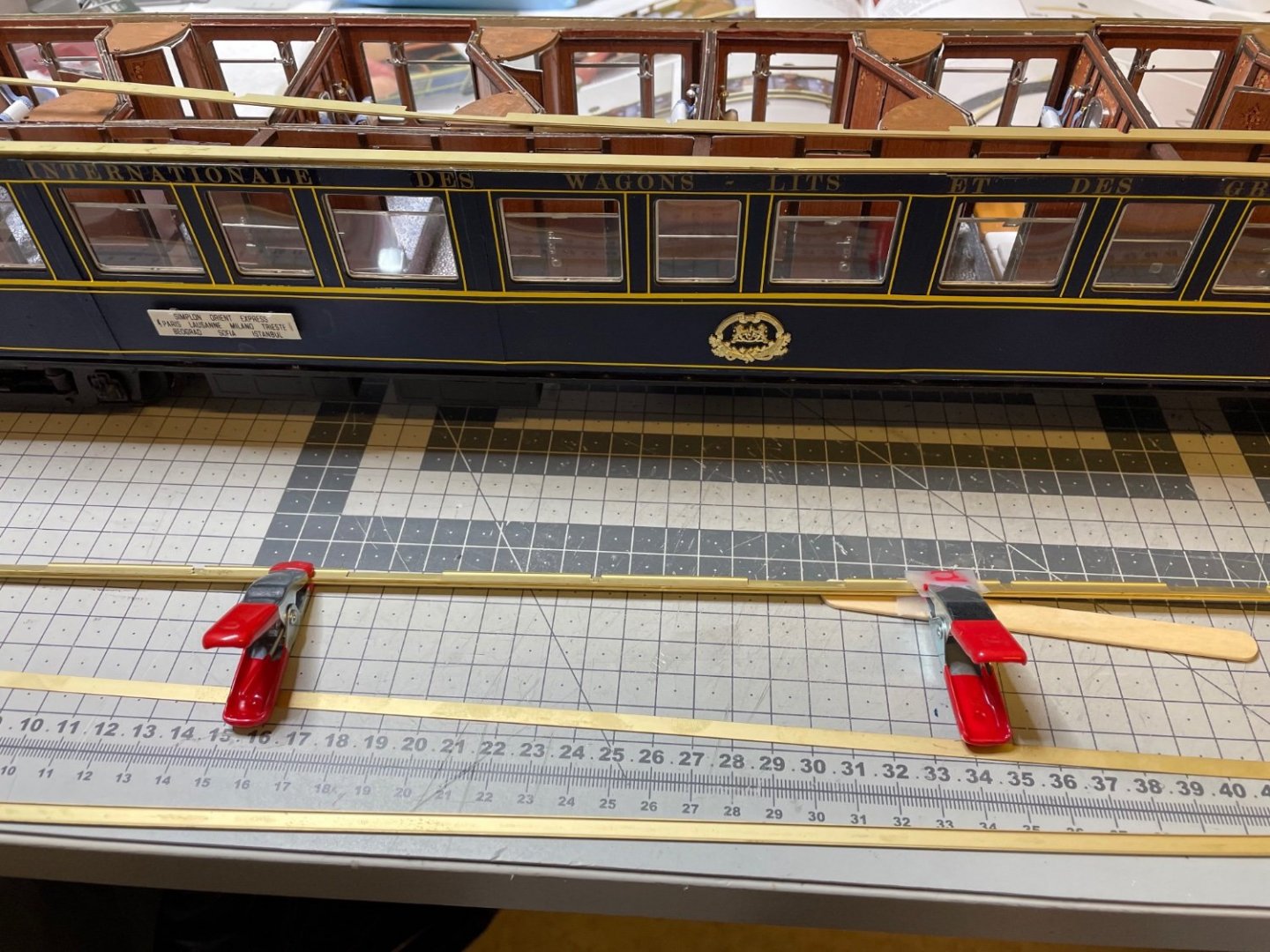

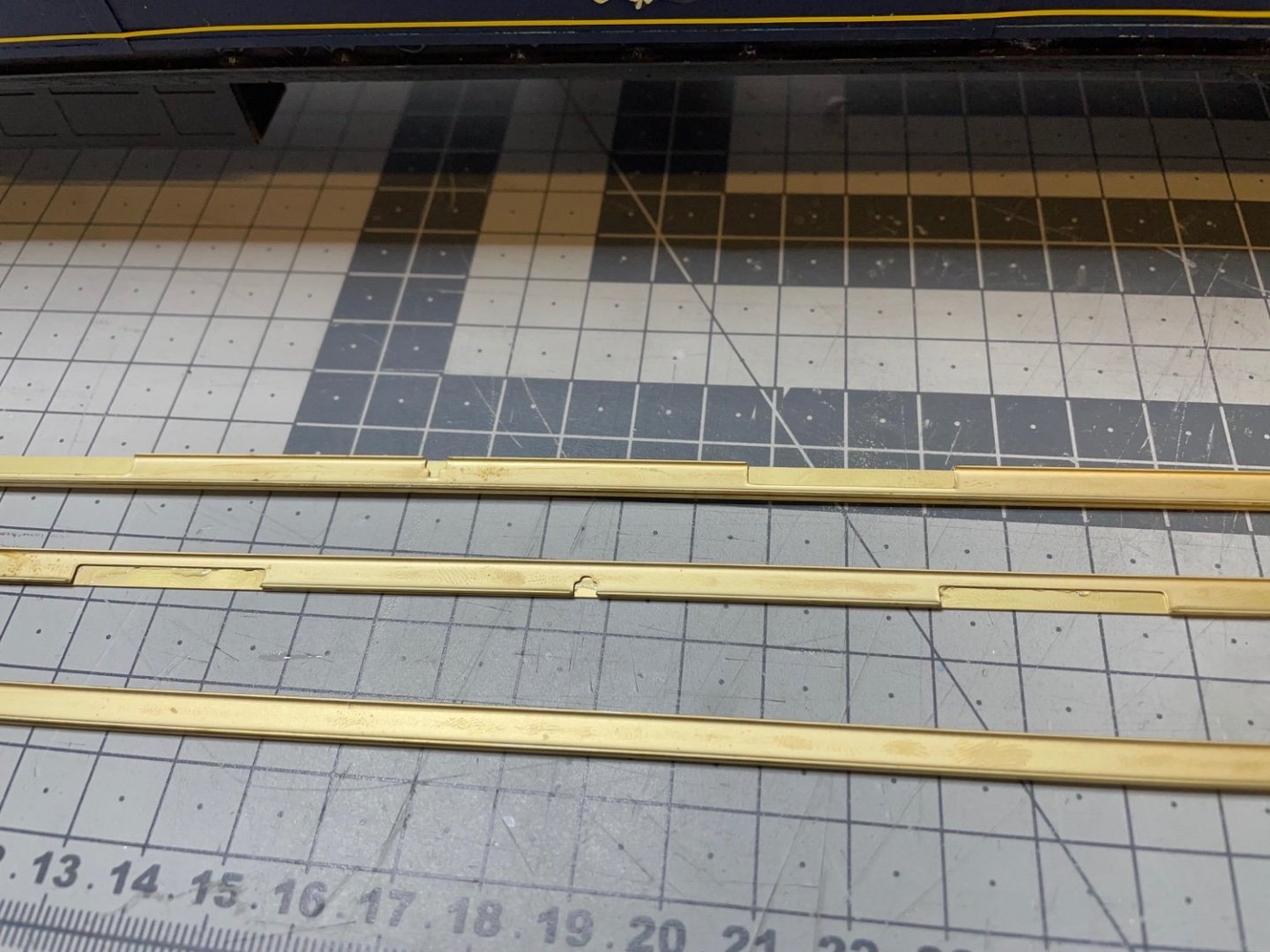

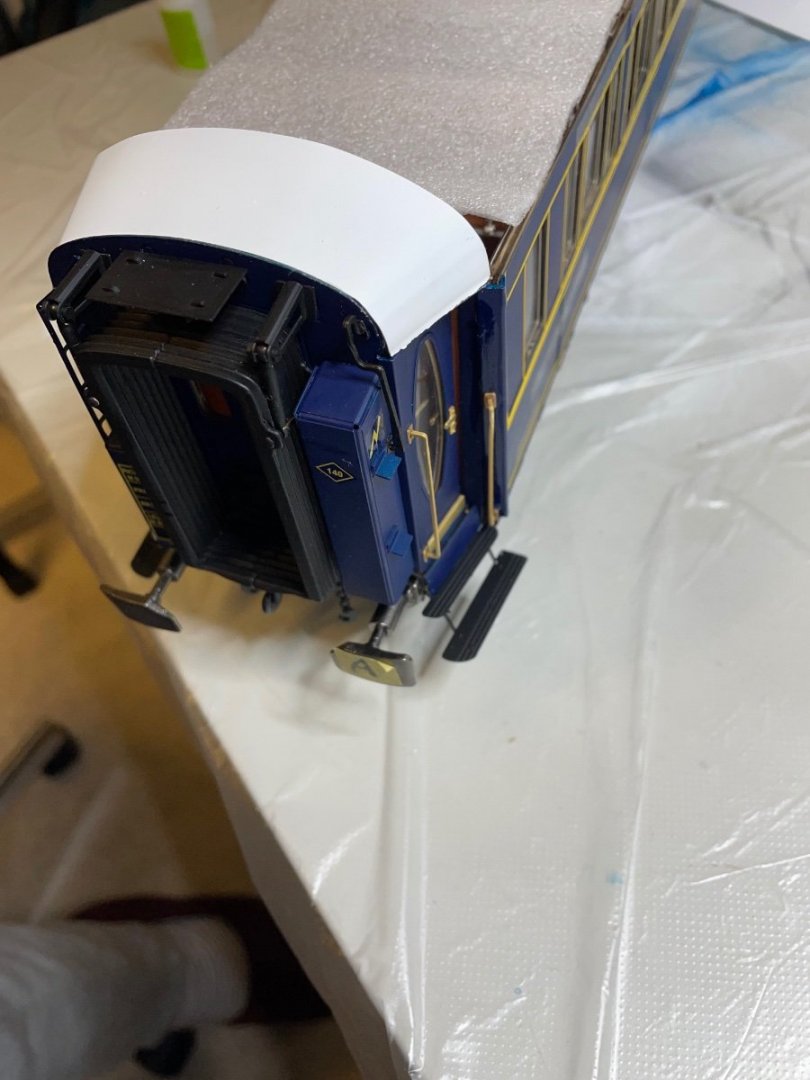

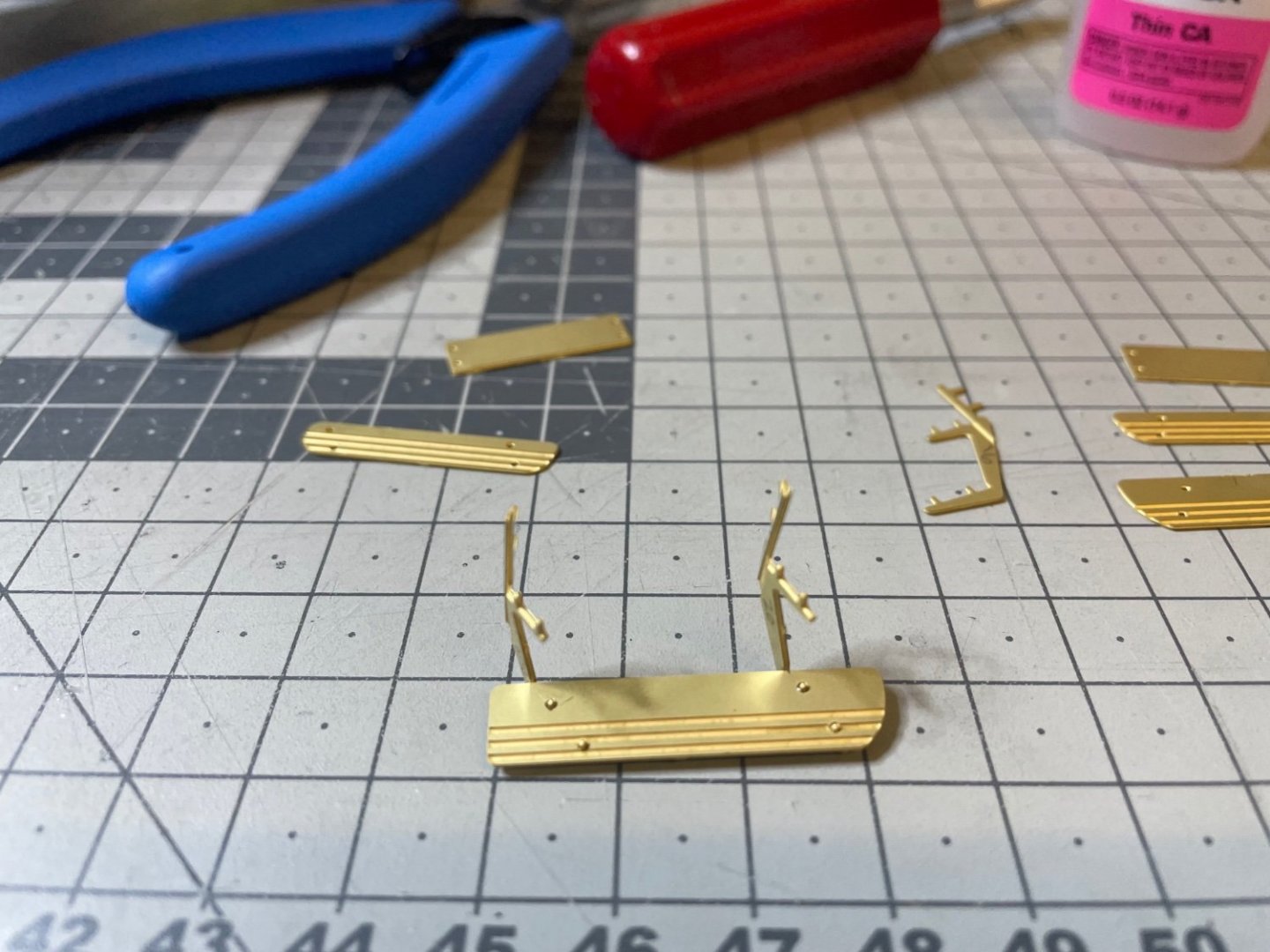

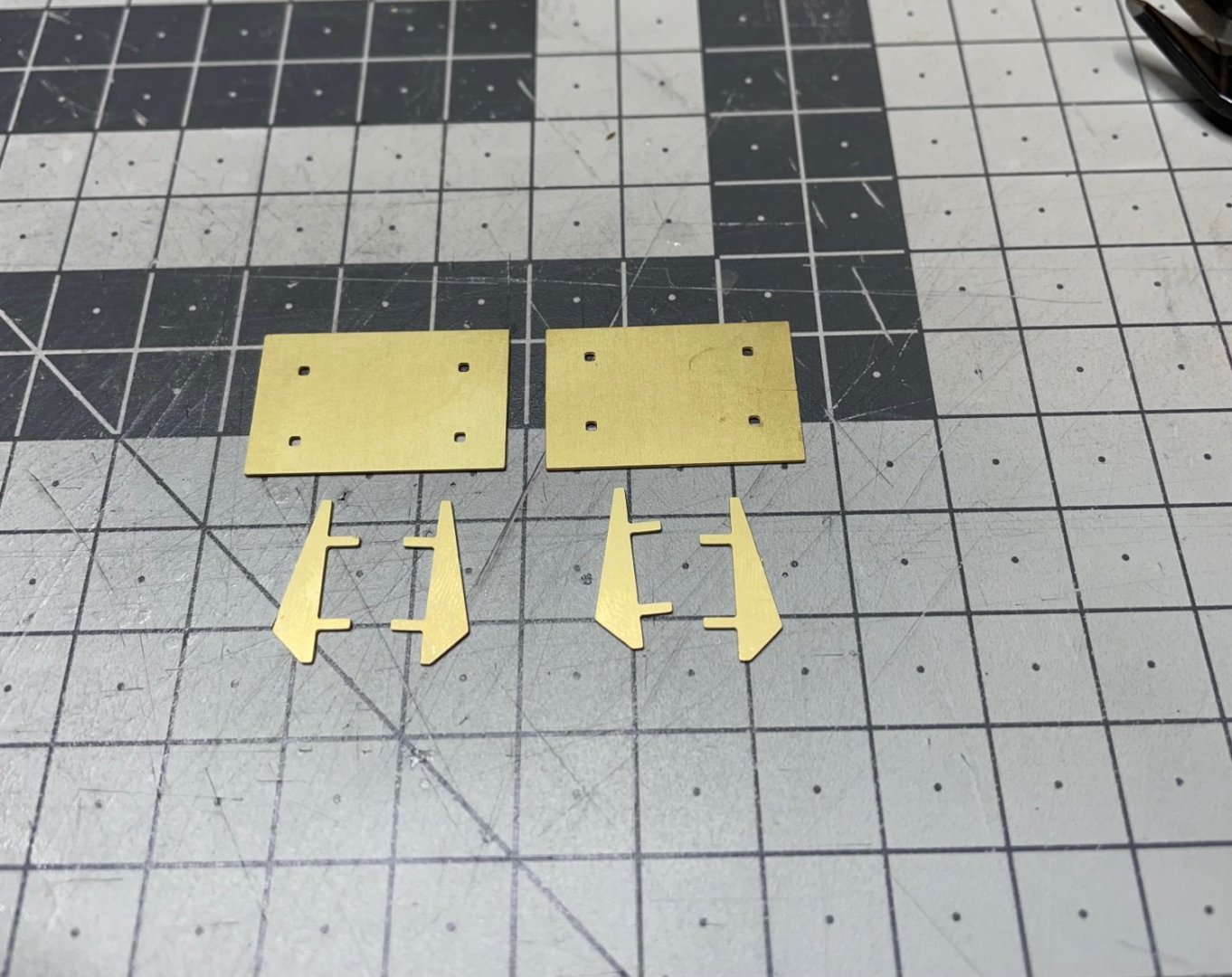

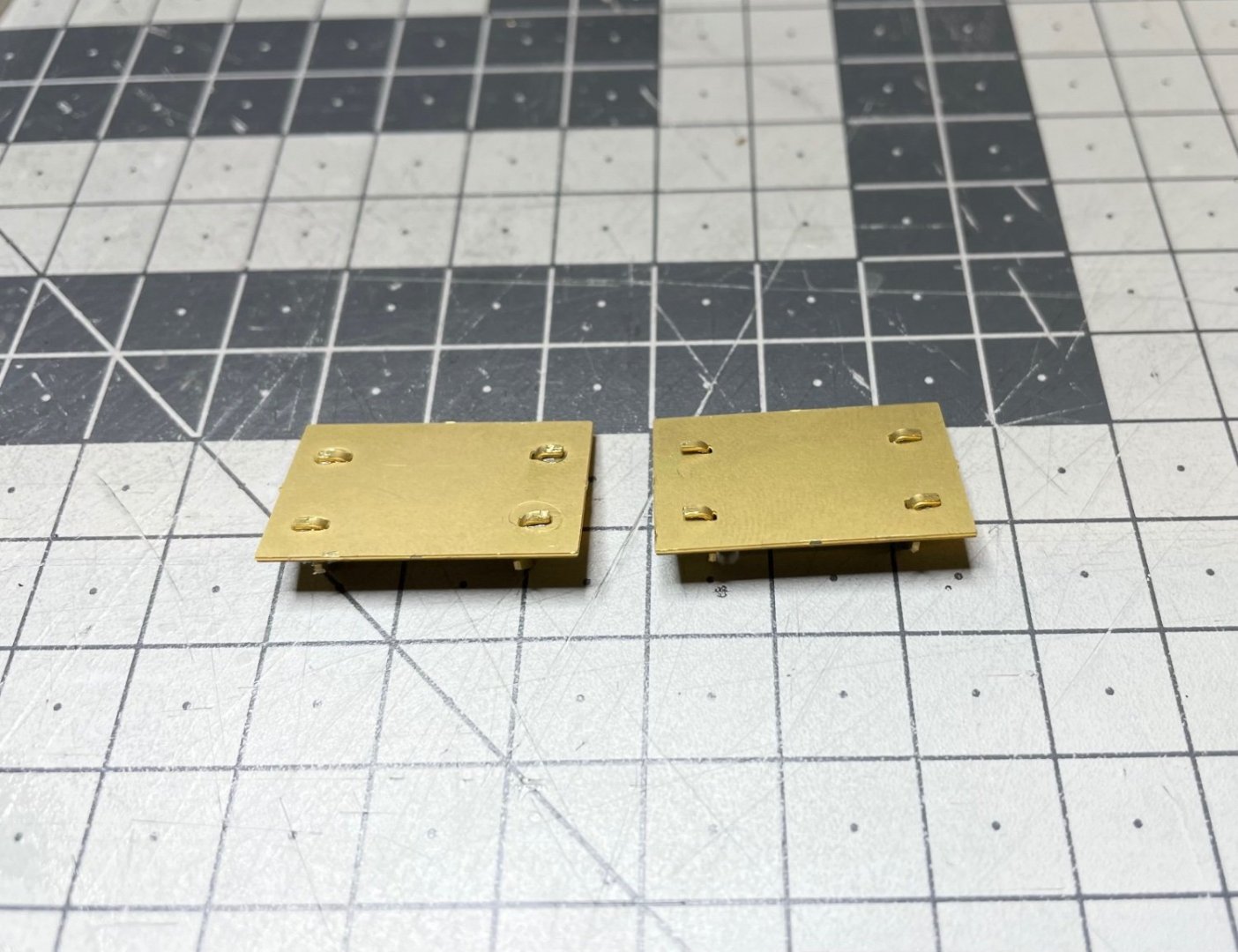

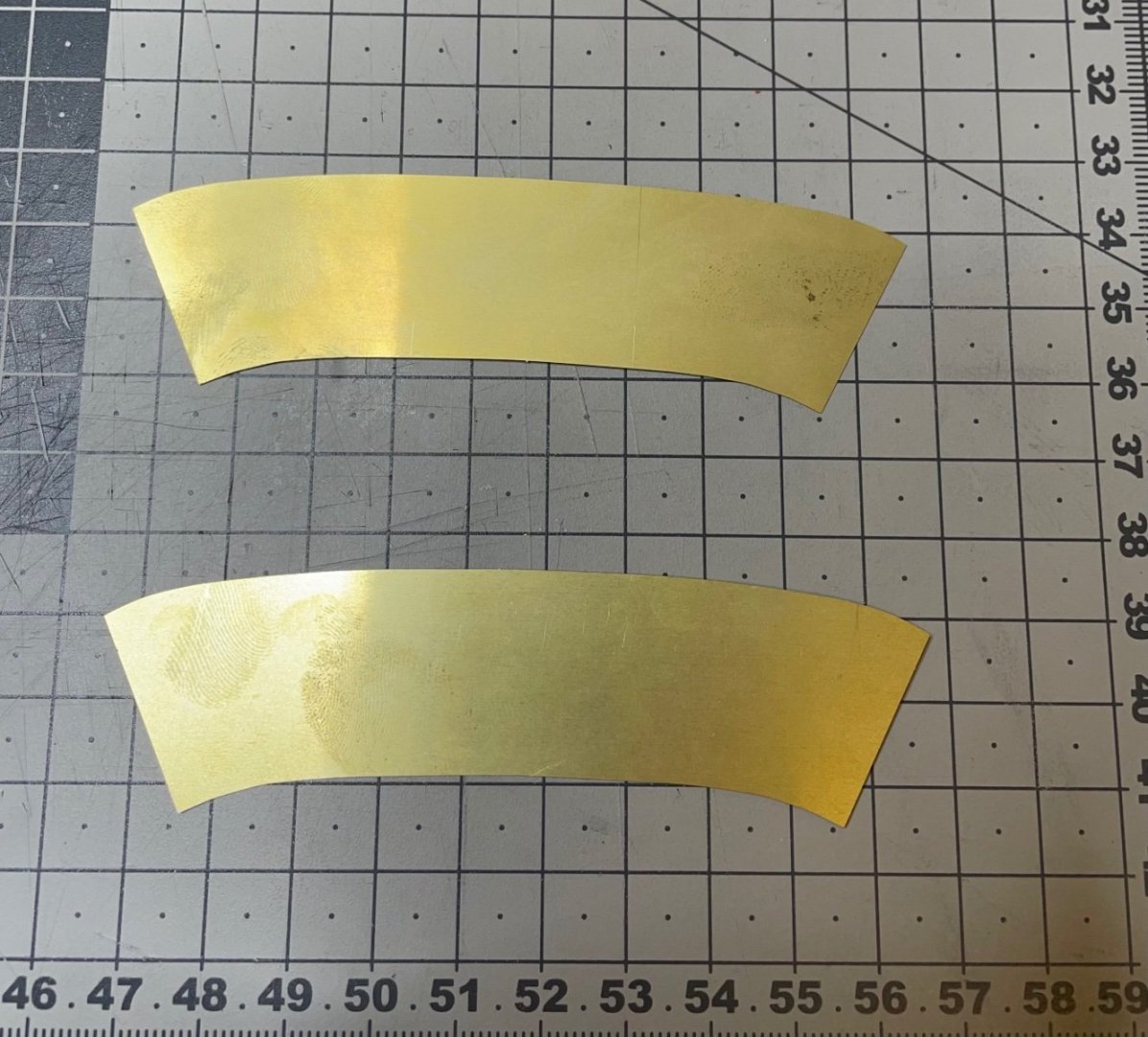

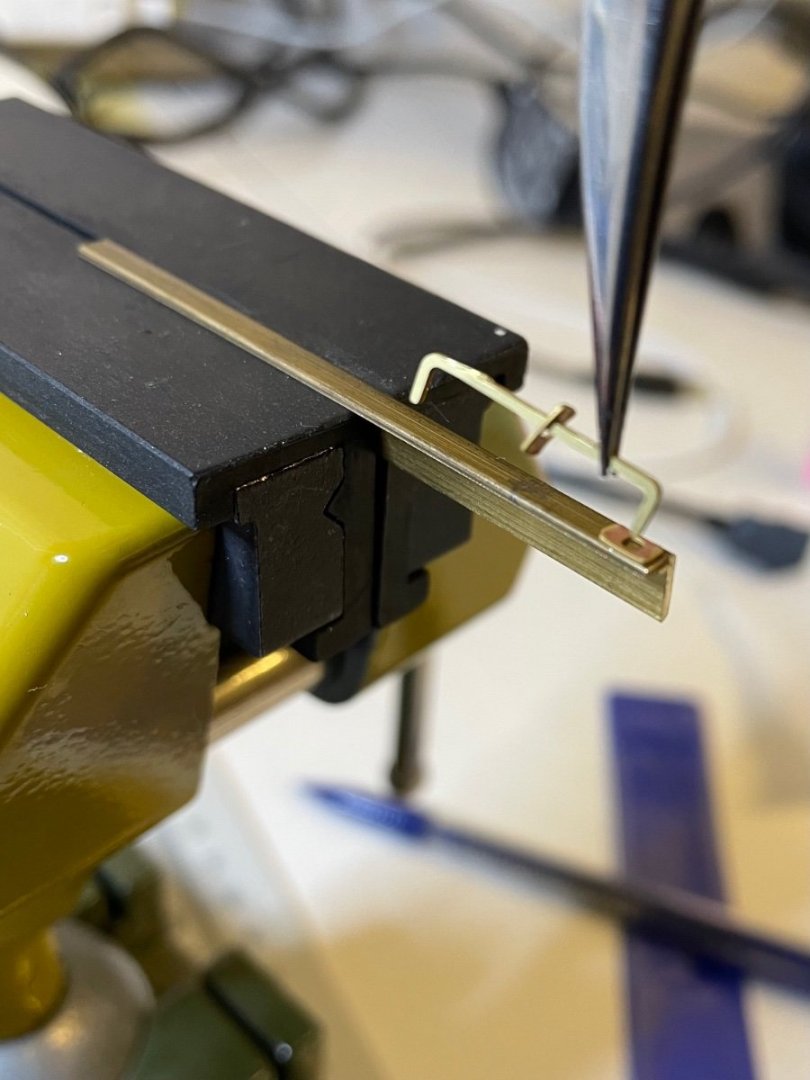

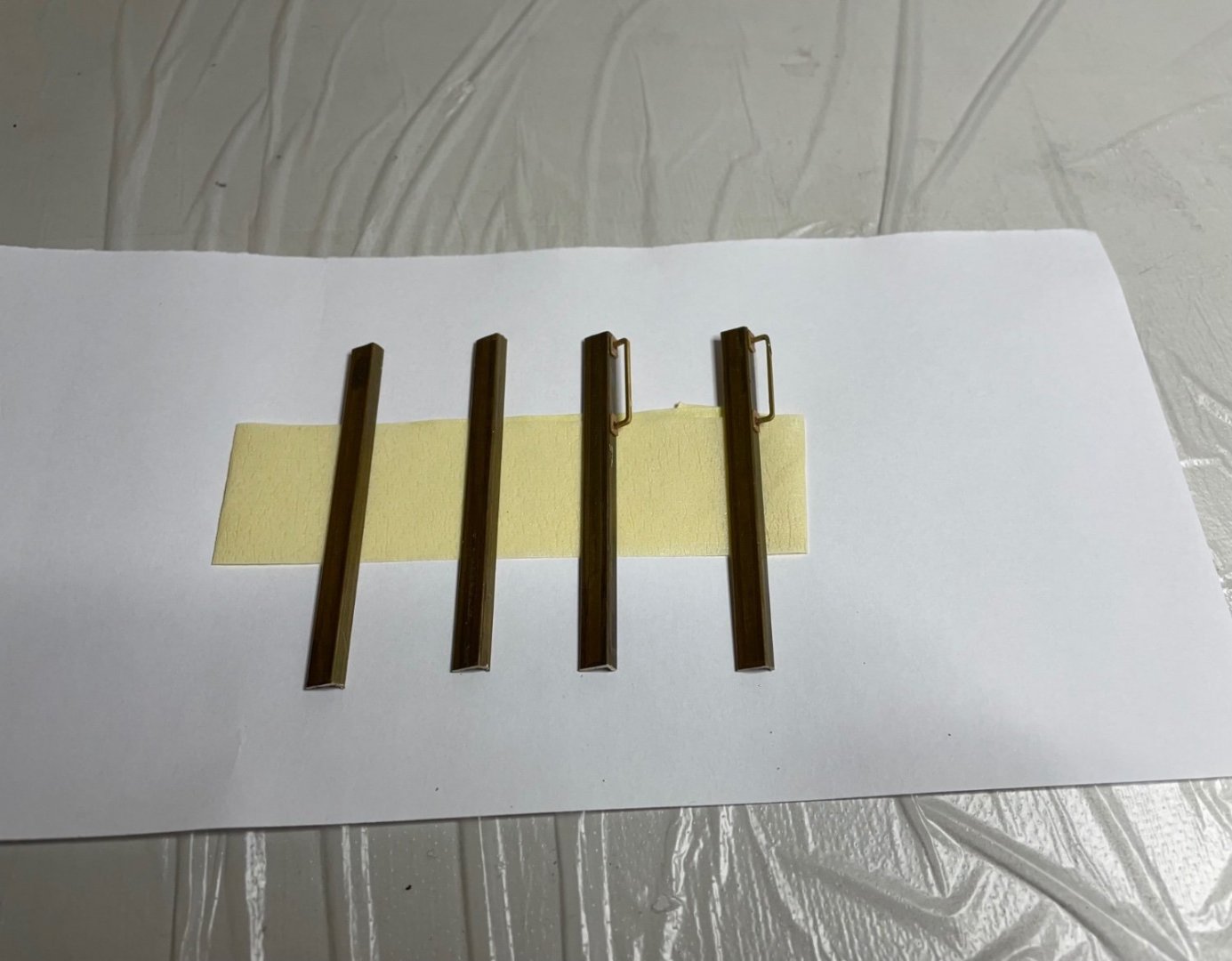

BUILD DAY 42 / 2 hrs / (TOTAL: 106 hrs) Figures 433-438: Rails for sitting the roof on. There are 3 rails: 2 on the sides and one going over the compartment doorline. The latter is to be painted in brown while the two on the sides will be white. The rails are composed of two pieces each. The lower part has grooves to fit the structure while the upper part is flat to accomodate the roof structure.

-

If they drop some day, then I think I will just glue them back. When it comes to soldering, although I am familiar with soldering electronic parts, I still don't dare to do it in this model. For the purpose of the handles, it would also create other challenges such as isolating the handle while painting the bar in blue, since any soldering should be done before paint.

-

BUILD DAY 40 / 1 hr / (TOTAL: 102 hrs) Handles on door sides. They are to be installed without any painting. There is also an additional handle in body color on the ladder side. Photos showing my way of gluing the handles. - First I glue one of the "hinges" on its place. - Then I insert the handle to other hinge - Then I glue the handle at both ends. - Finally I move the second hinge and glue it in position. This way all three parts are aligned perfectly. Figures 414-415: --------- Figures 416-417: Parts ready for paint and in place.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.