-

Posts

916 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by aydingocer

-

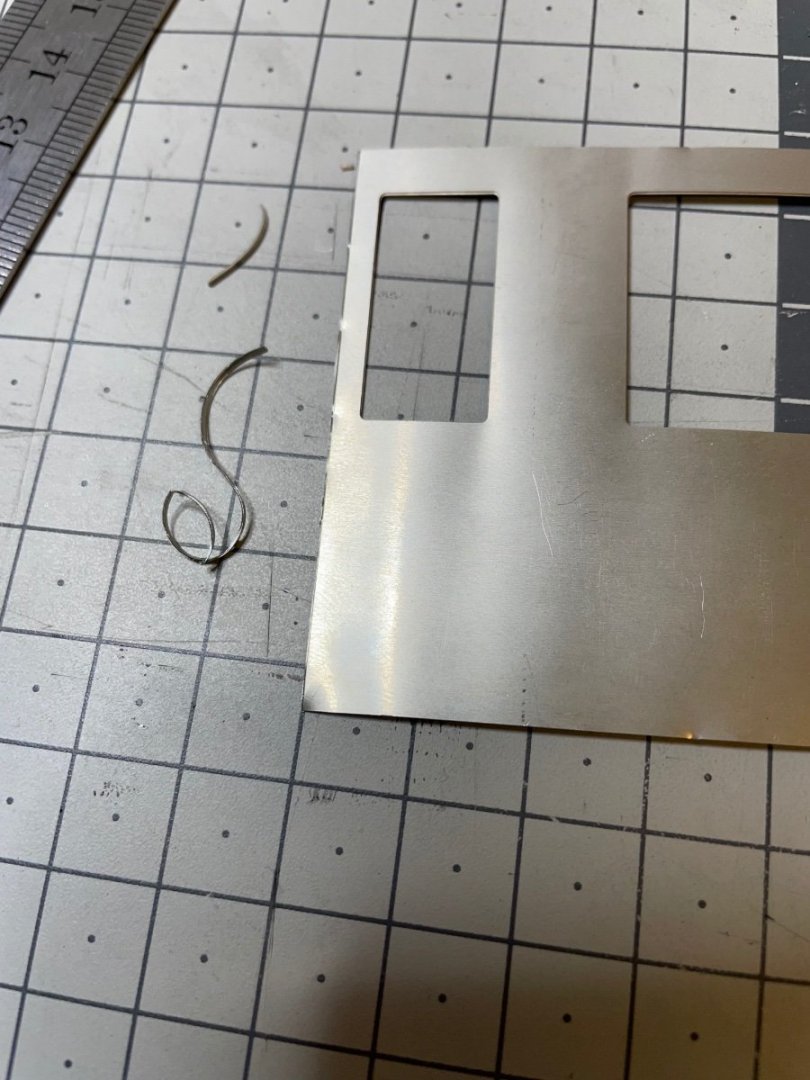

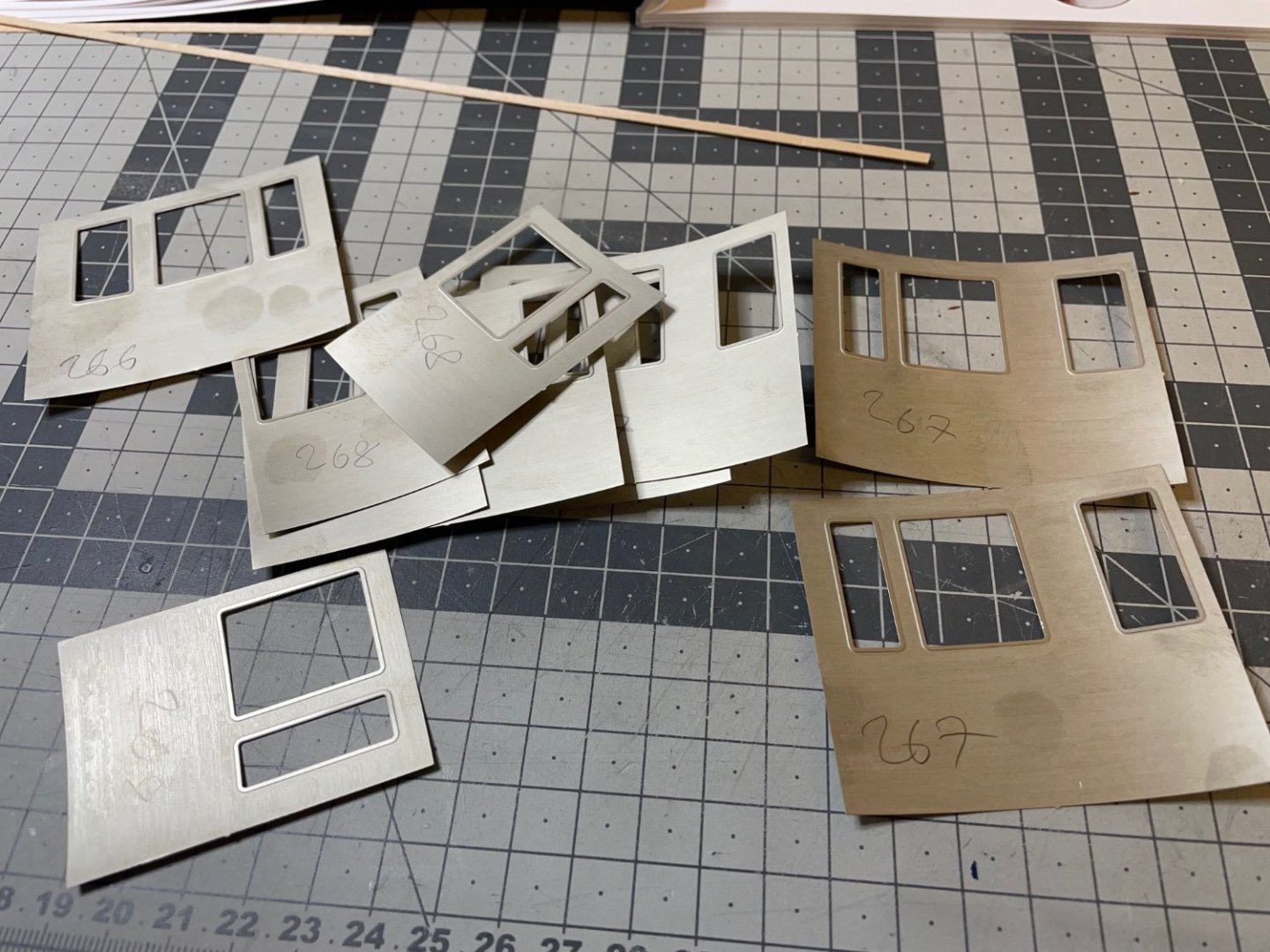

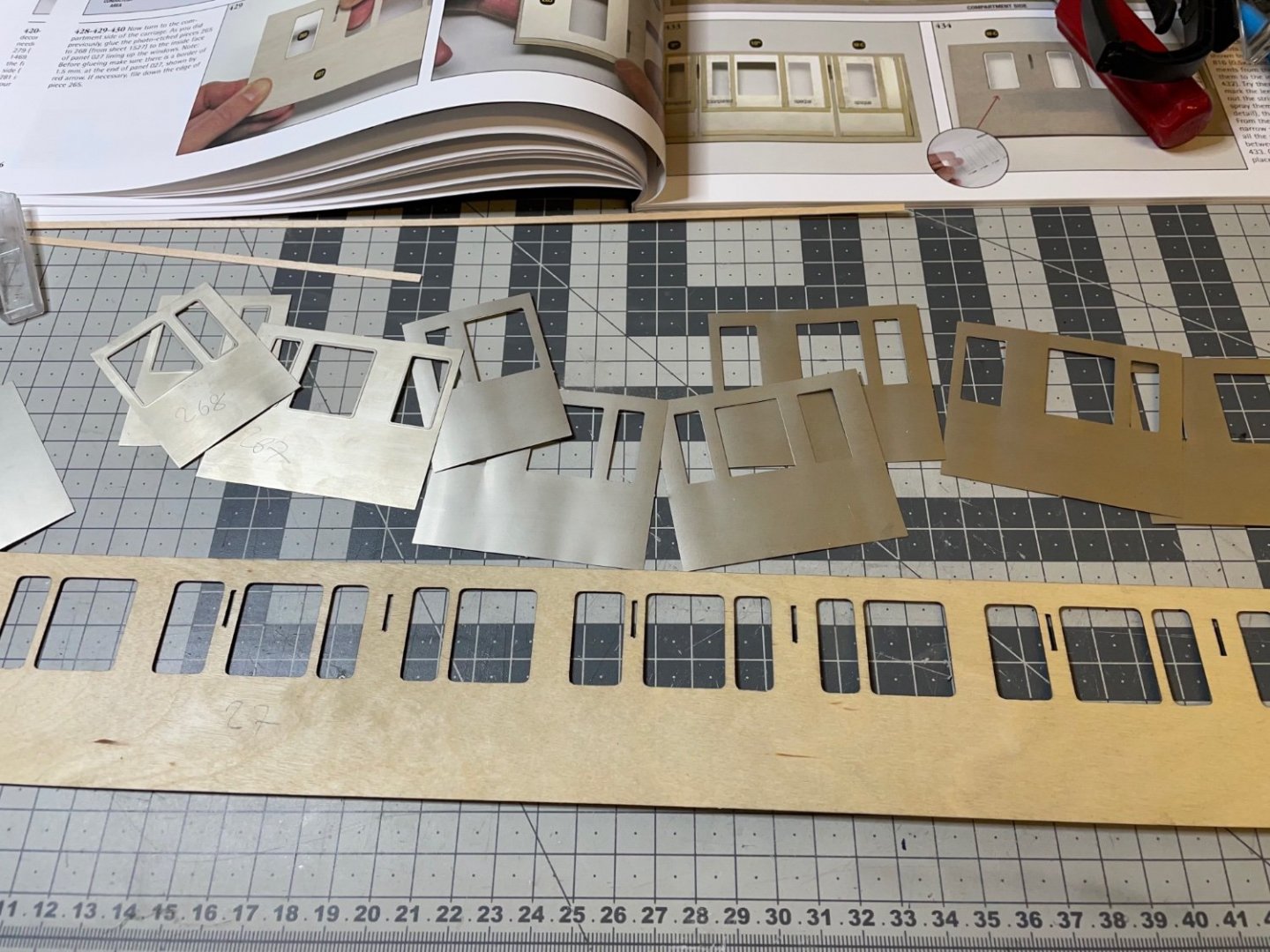

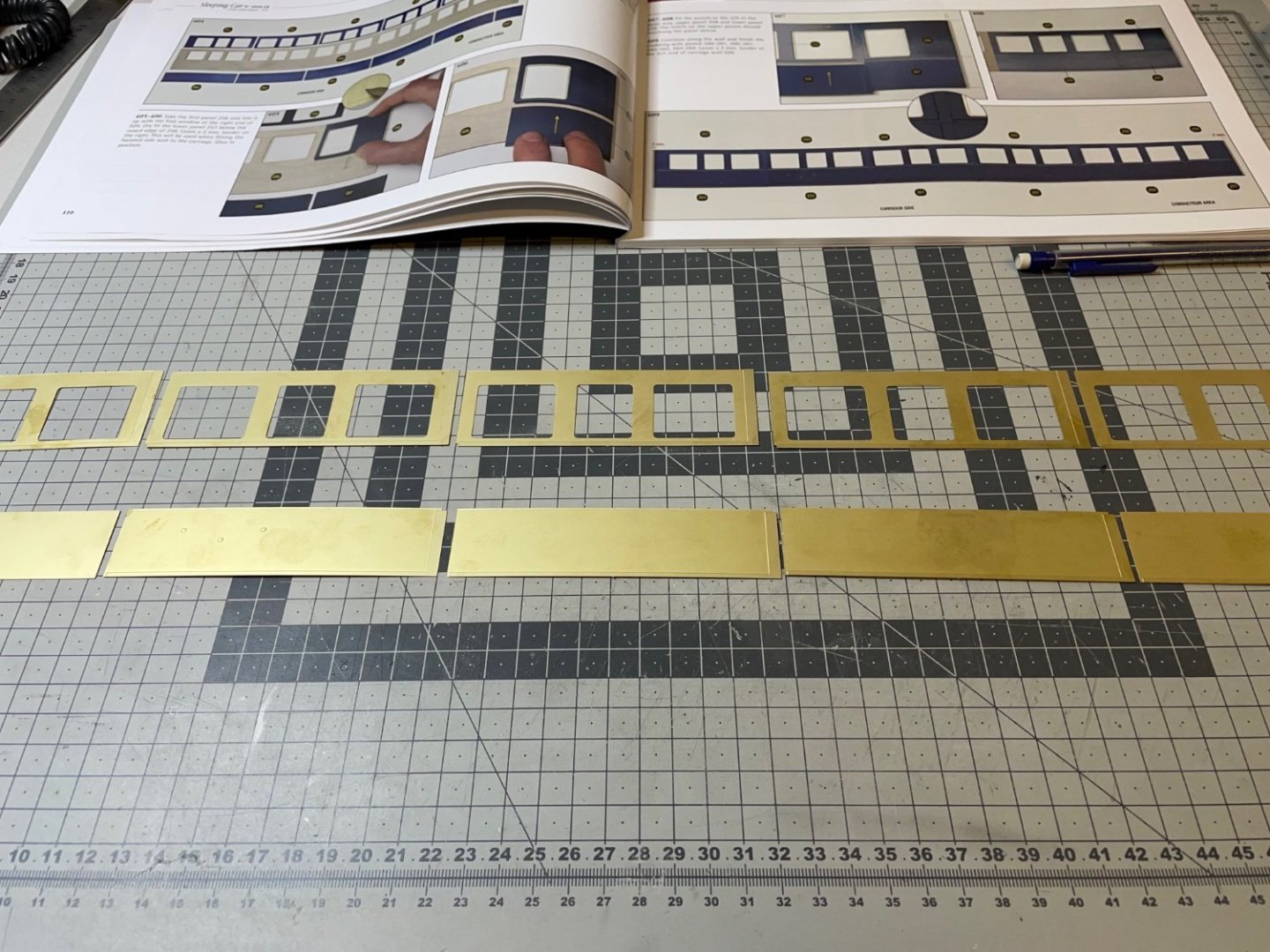

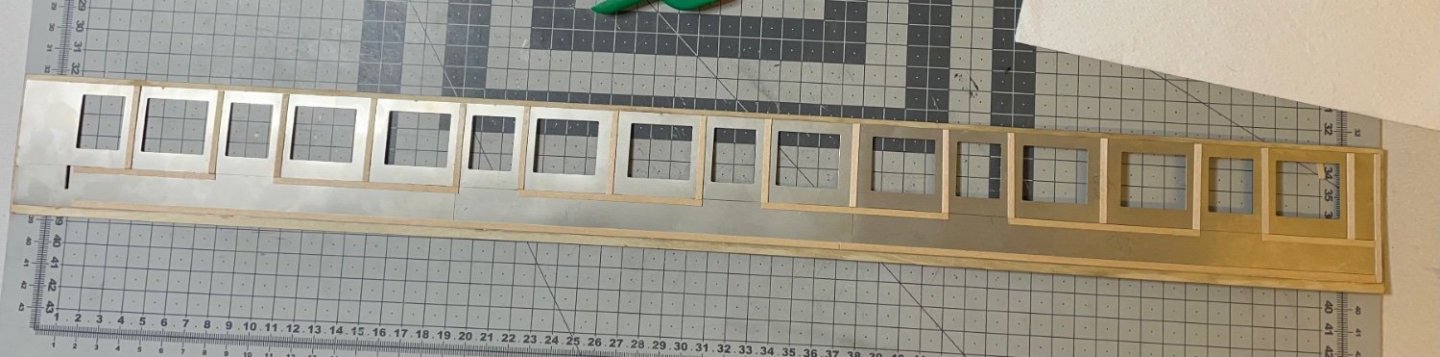

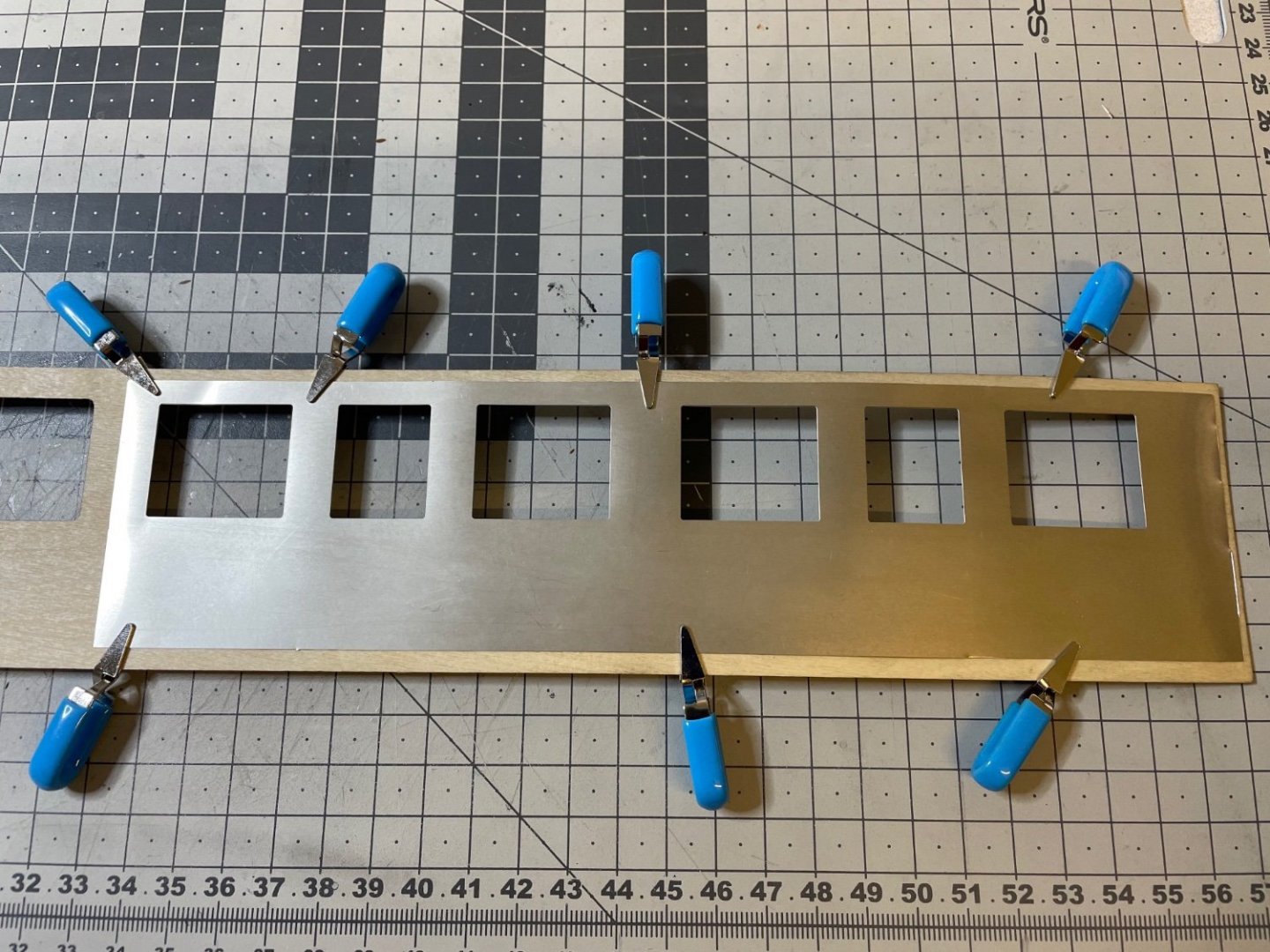

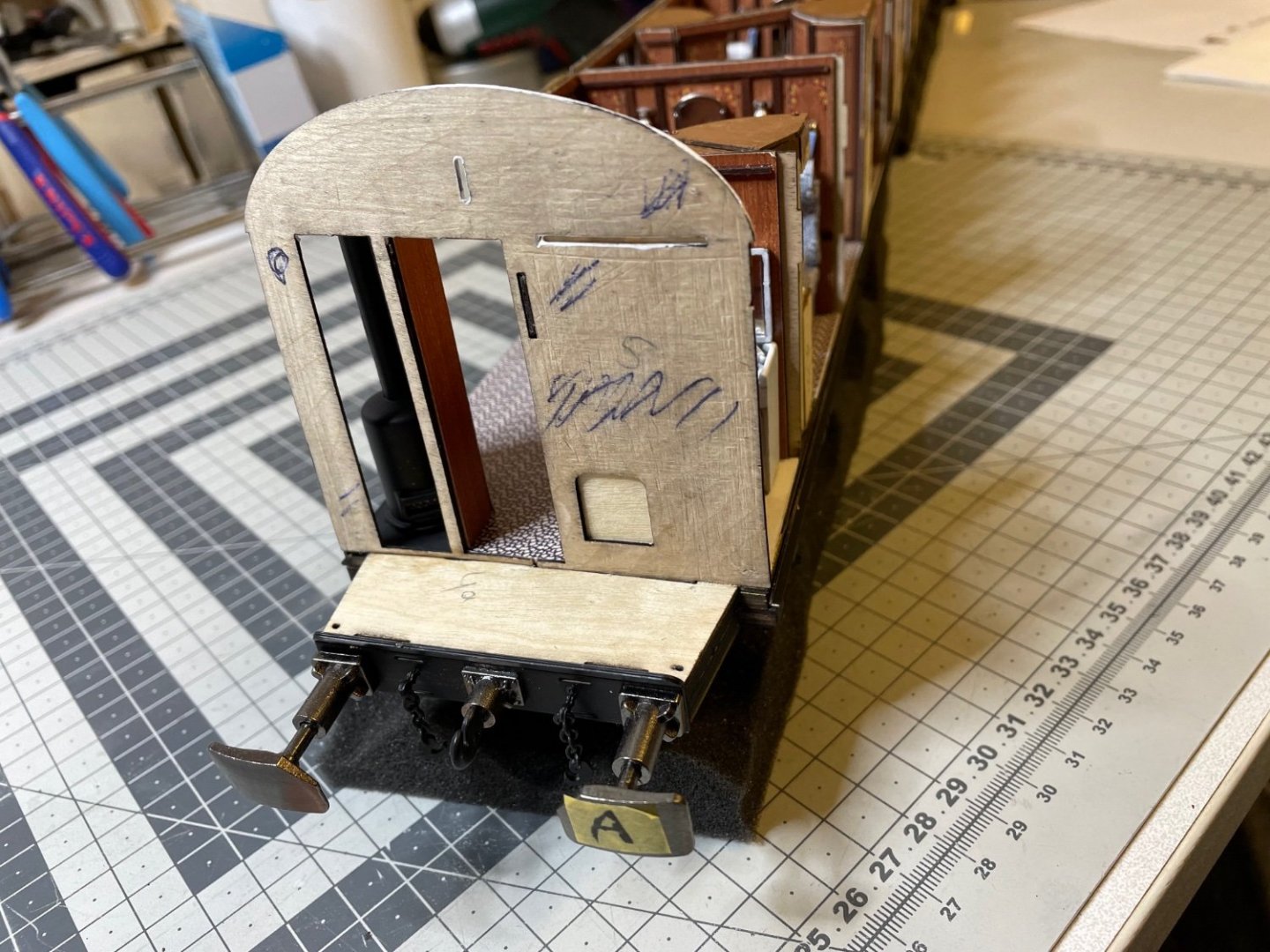

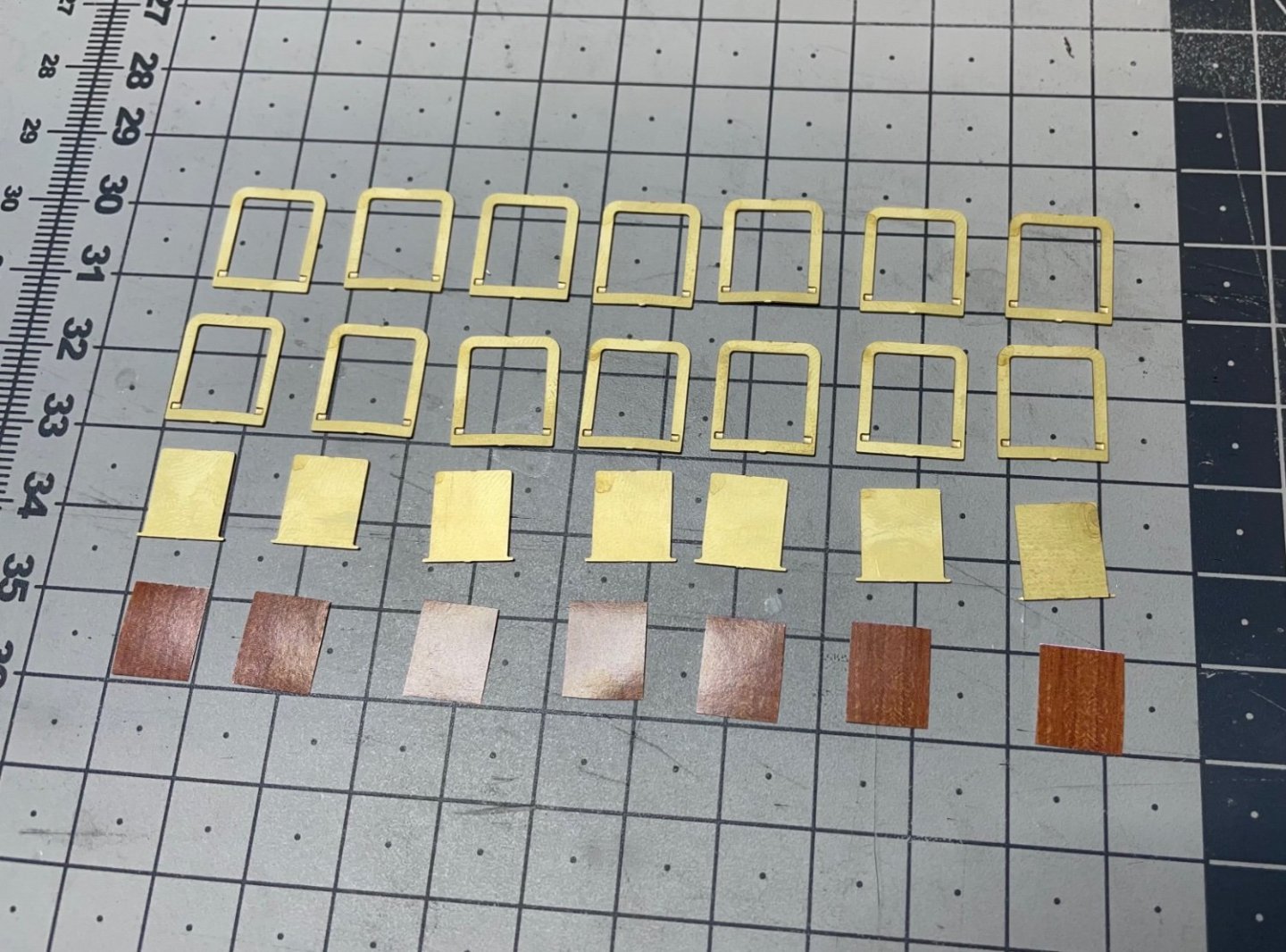

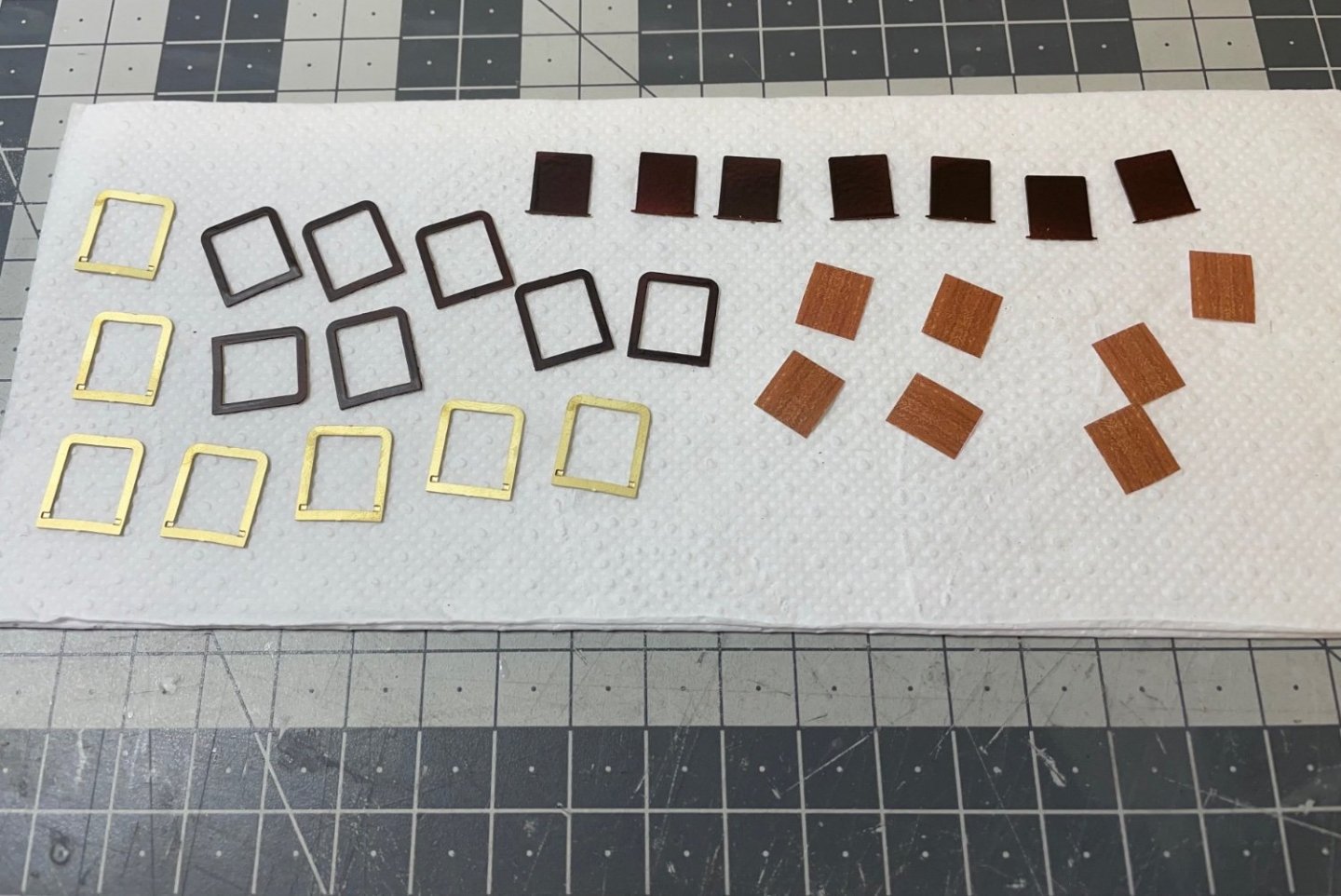

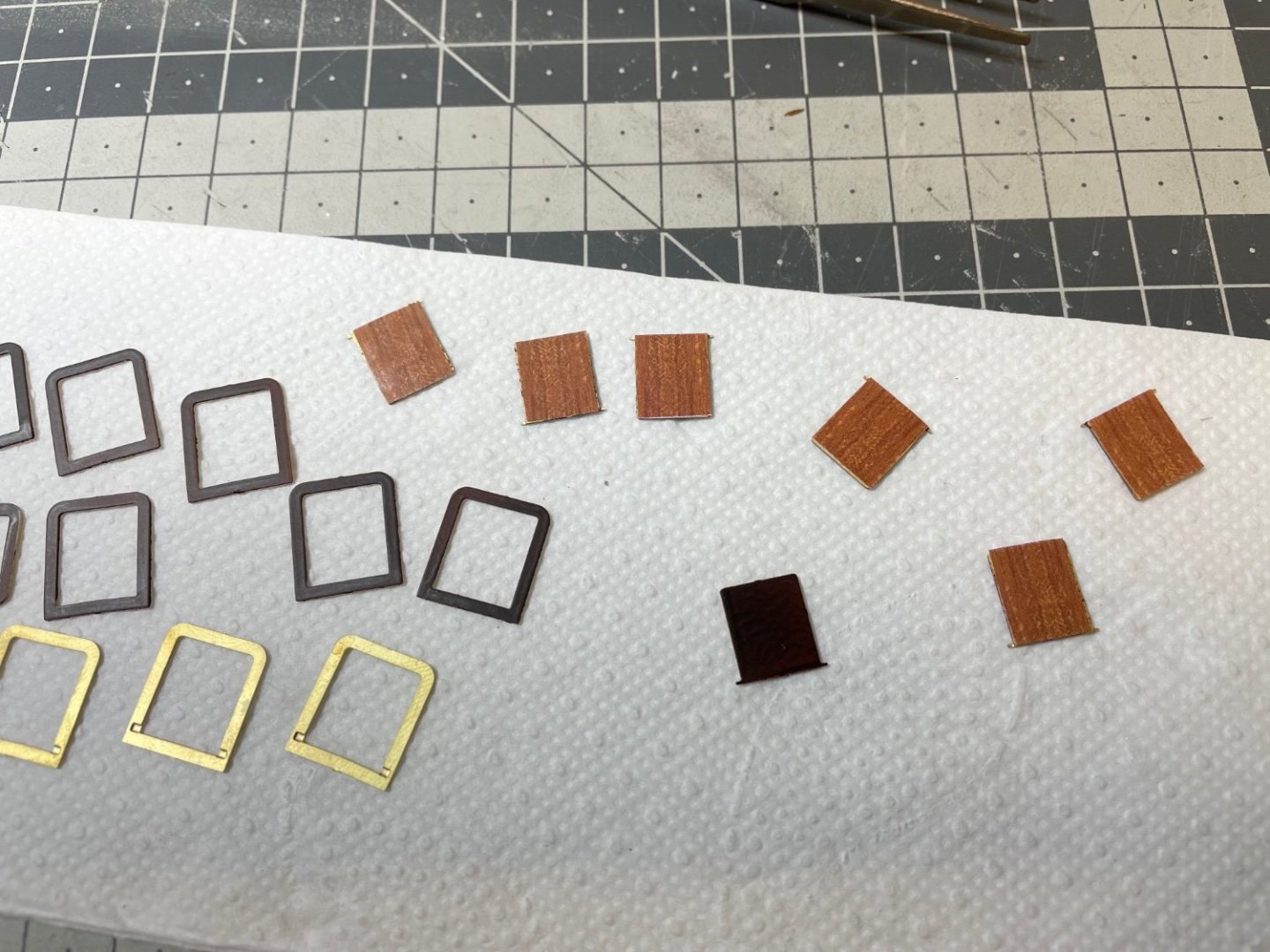

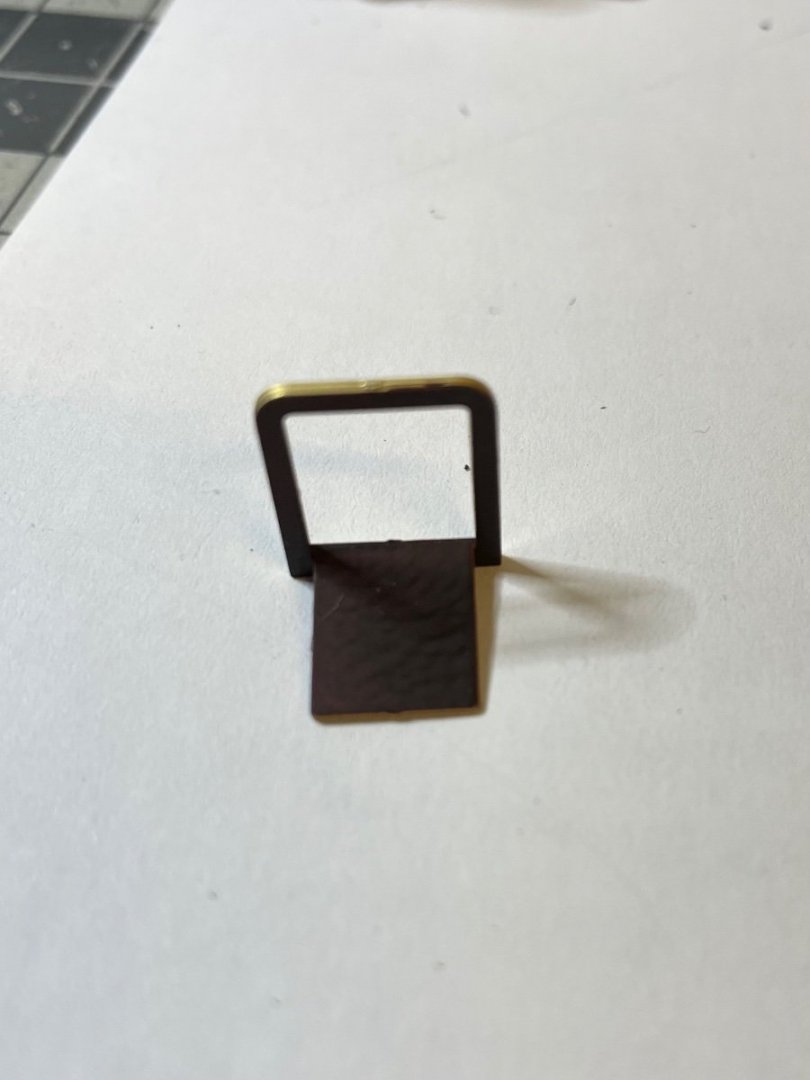

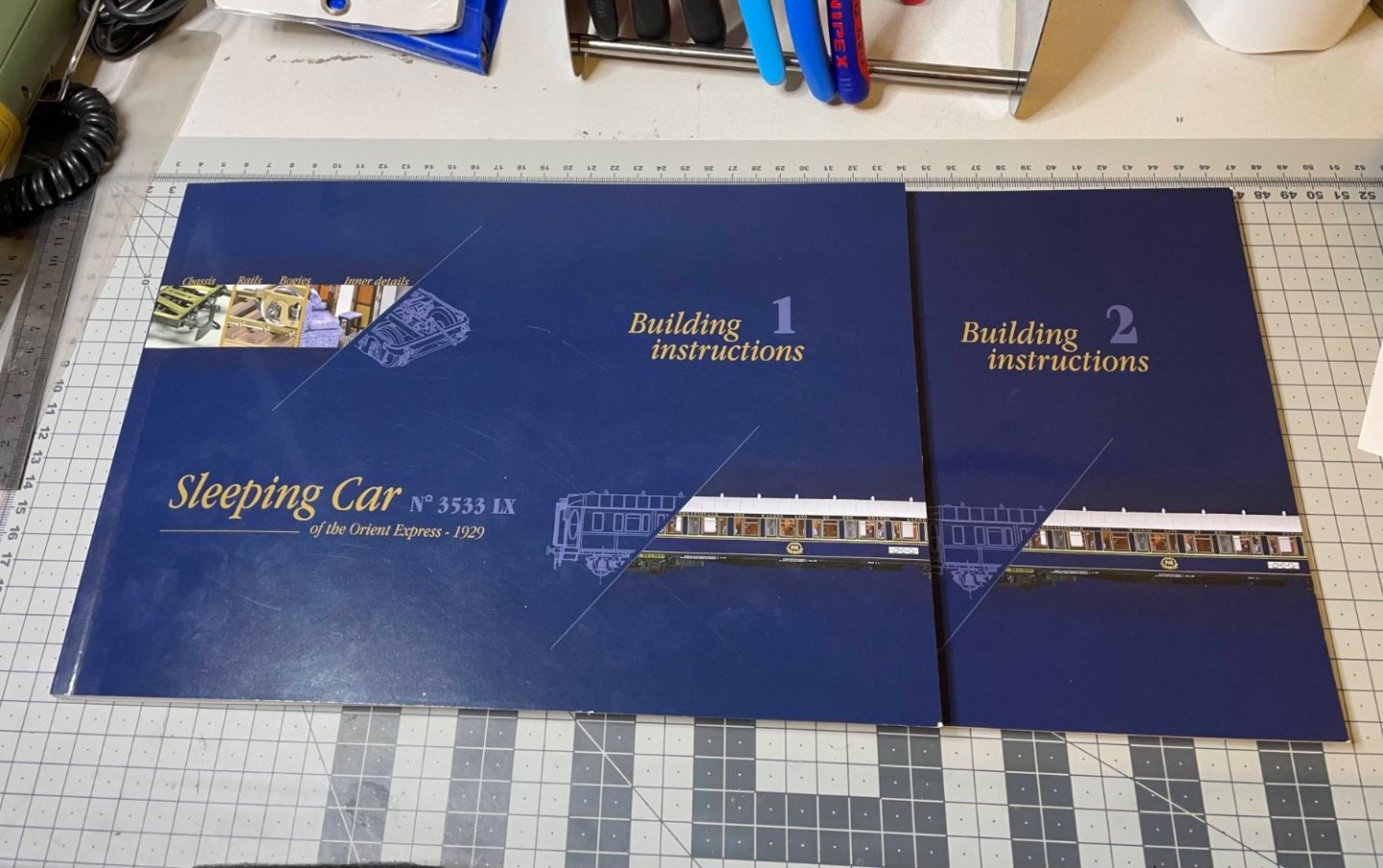

BUILD DAY 30 / 3 hrs / (TOTAL: 81 hrs) Continuing with the compartment side of the carriage. The work is pretty much the same as the other side. This has more windows. Figure 301: Nickel parts. They are also curved out of box. Now that I know they won't be visible, I use some force and hammer to flatten them enough. Figure 302: Here they are flat.

-

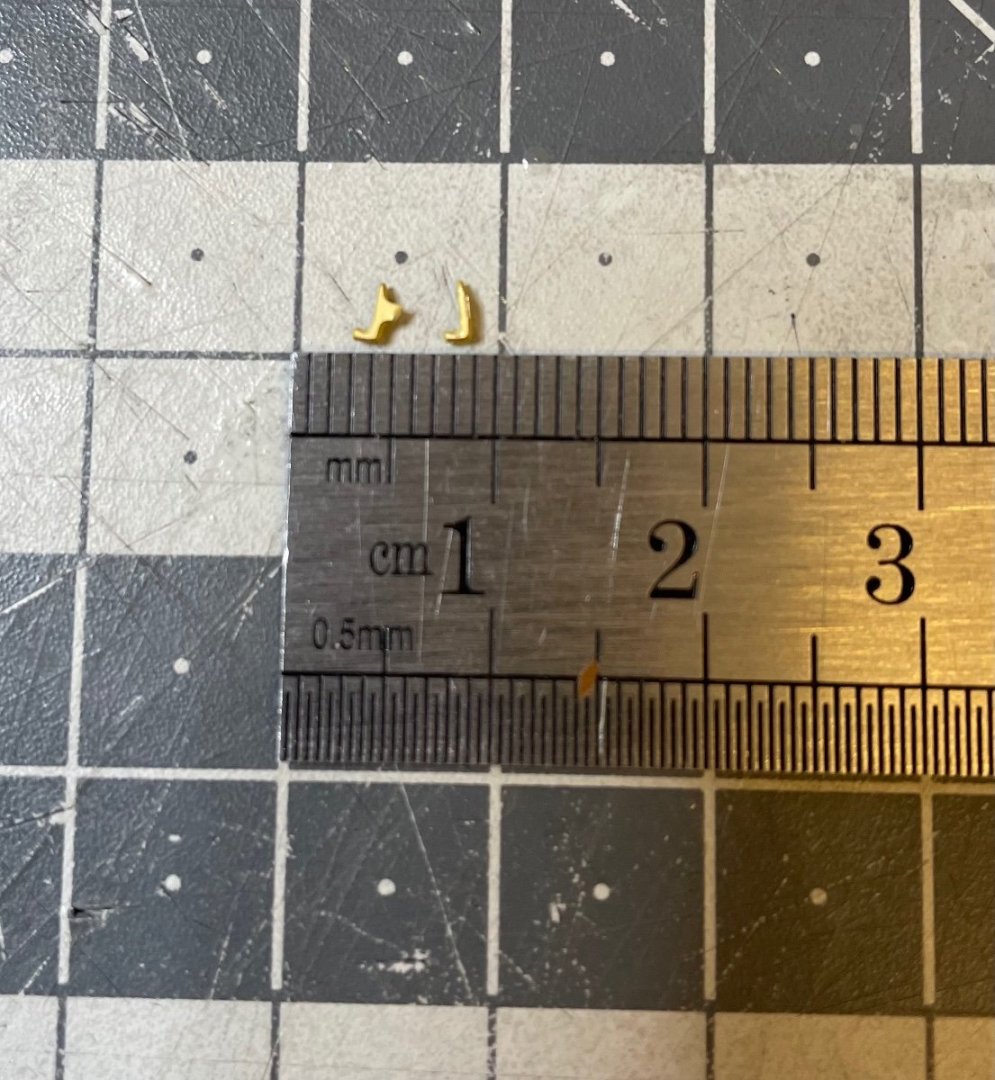

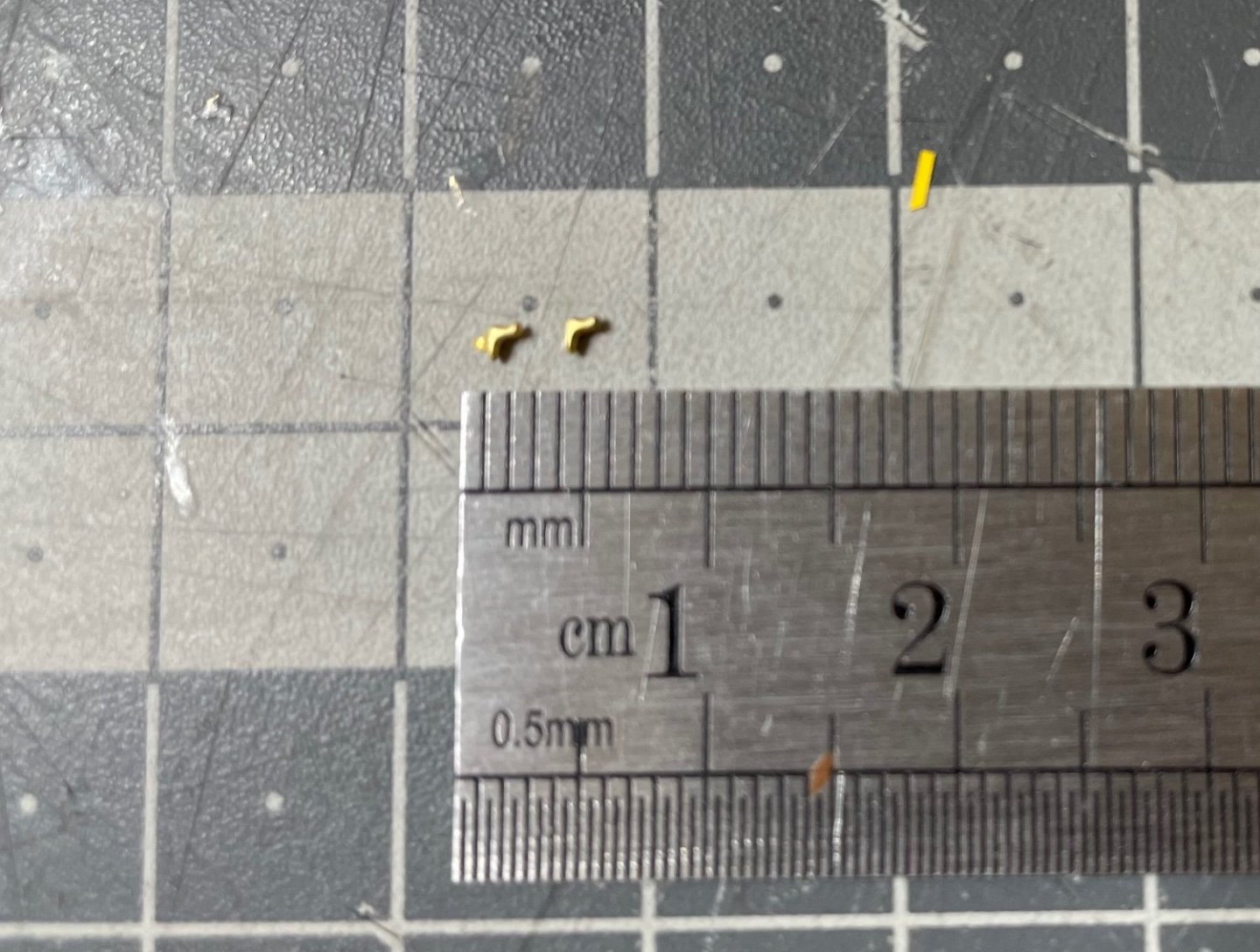

BUILD DAY 29 / 2 hrs / (TOTAL: 78 hrs) Logo, route nameplate, wagon number plate. Figure 296: These are the smallest parts in this kit. They are the hooks for hanging the route nameplate. After removing them from their brass sheet you'll need to trim and file them so that they stay on the wagon smoothly. Figures 297-298: In the two pictures below. Left: Just removed from its sheet. Right: trimmed and filed, ready to use.

-

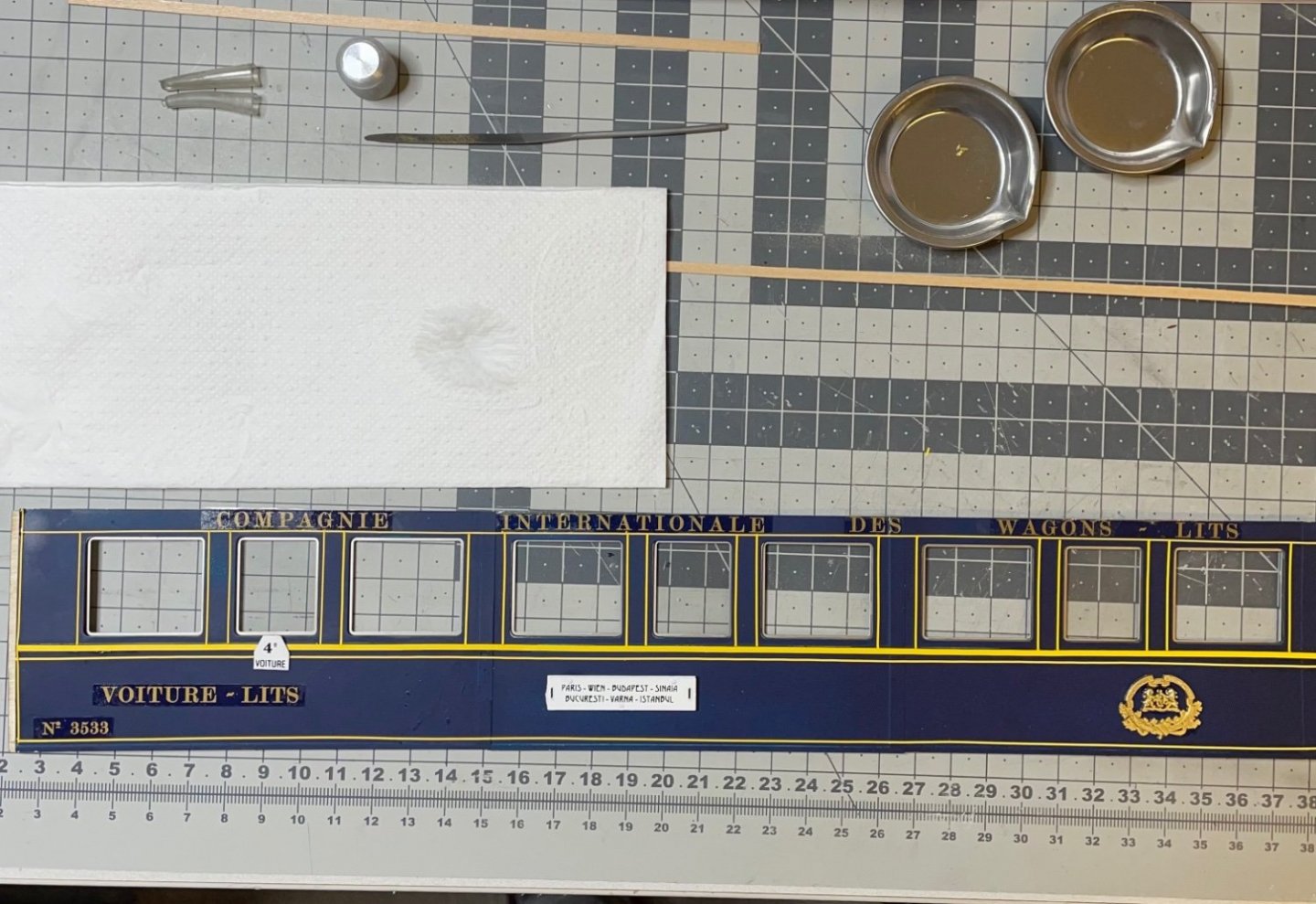

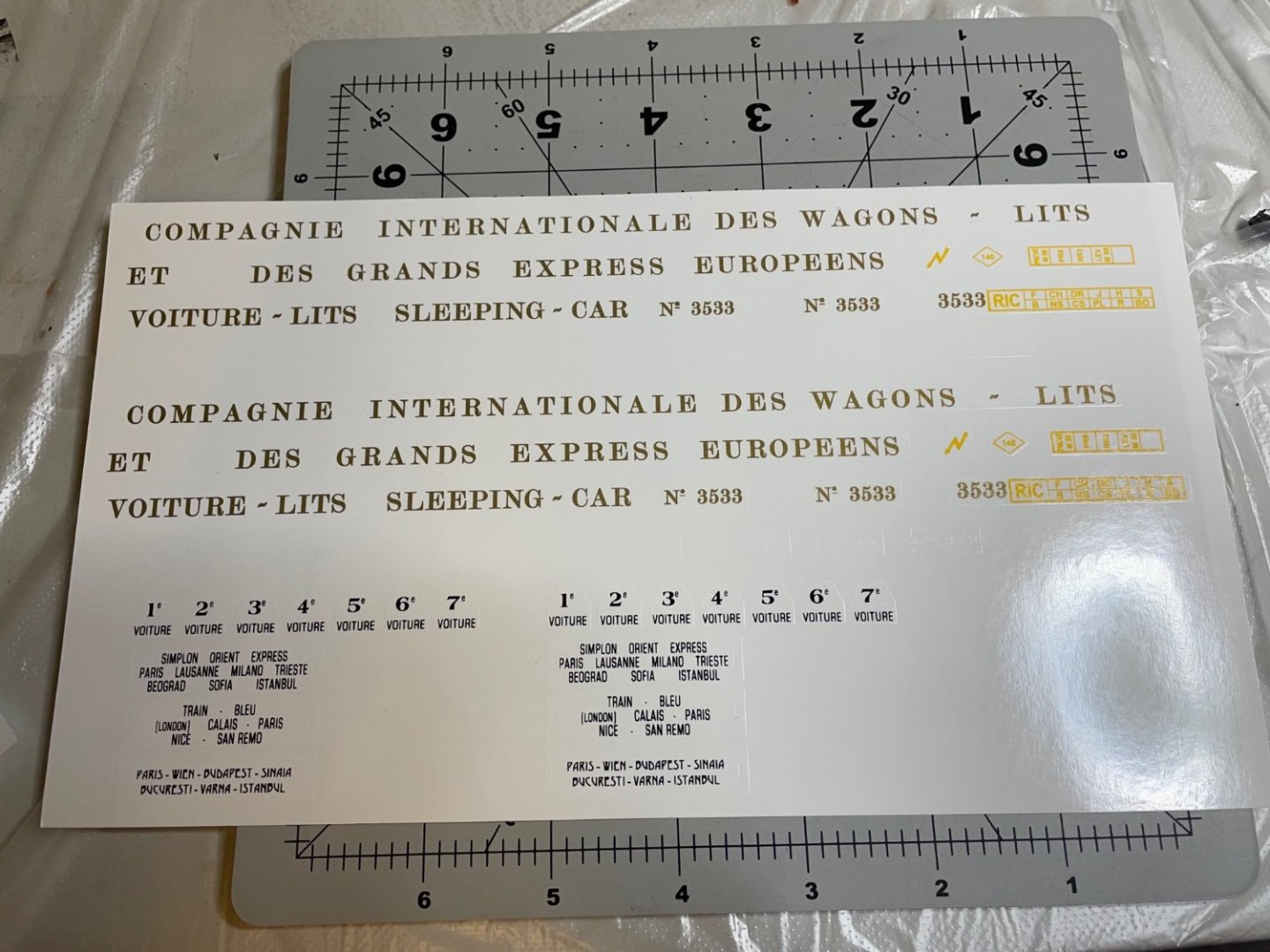

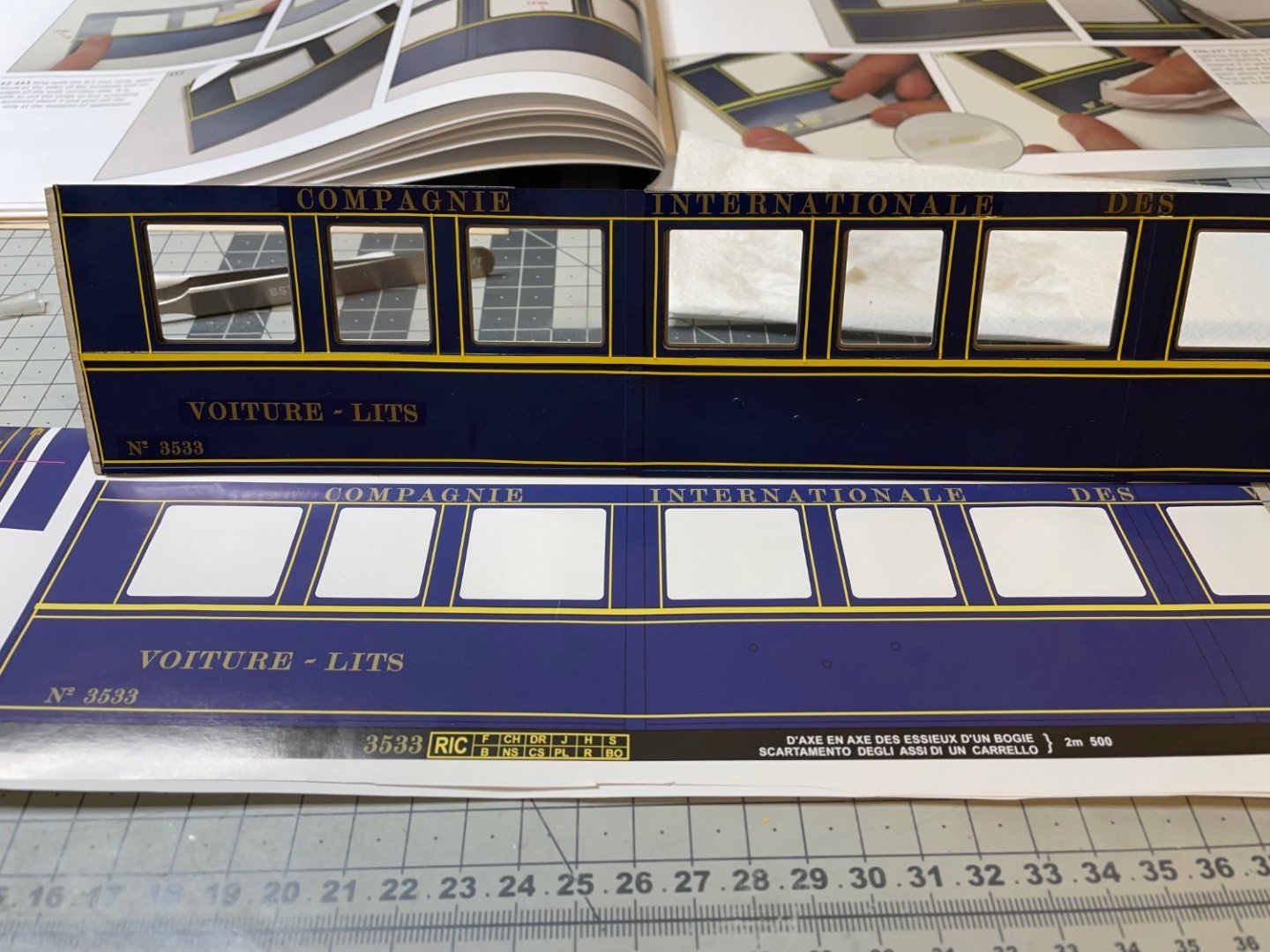

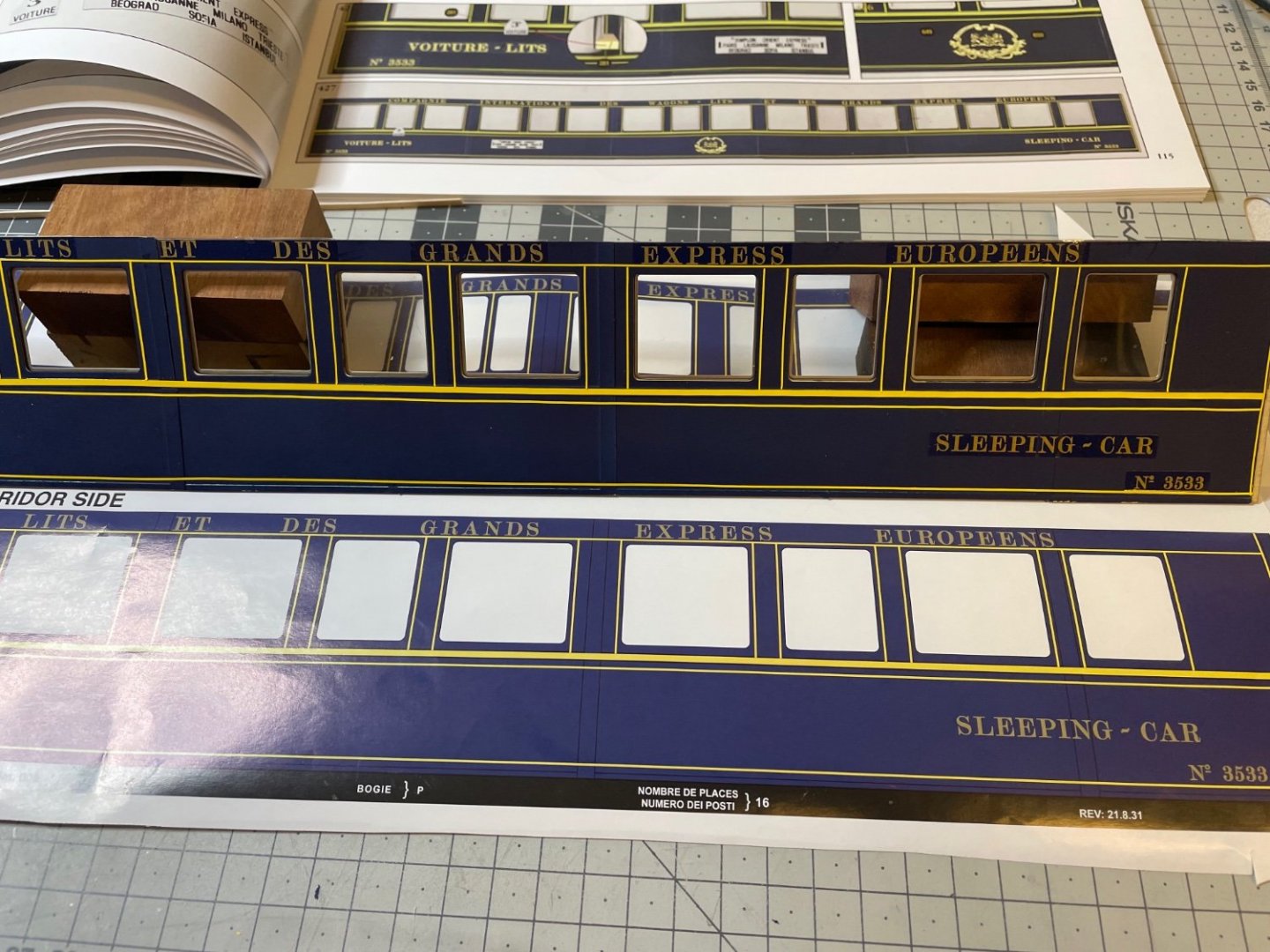

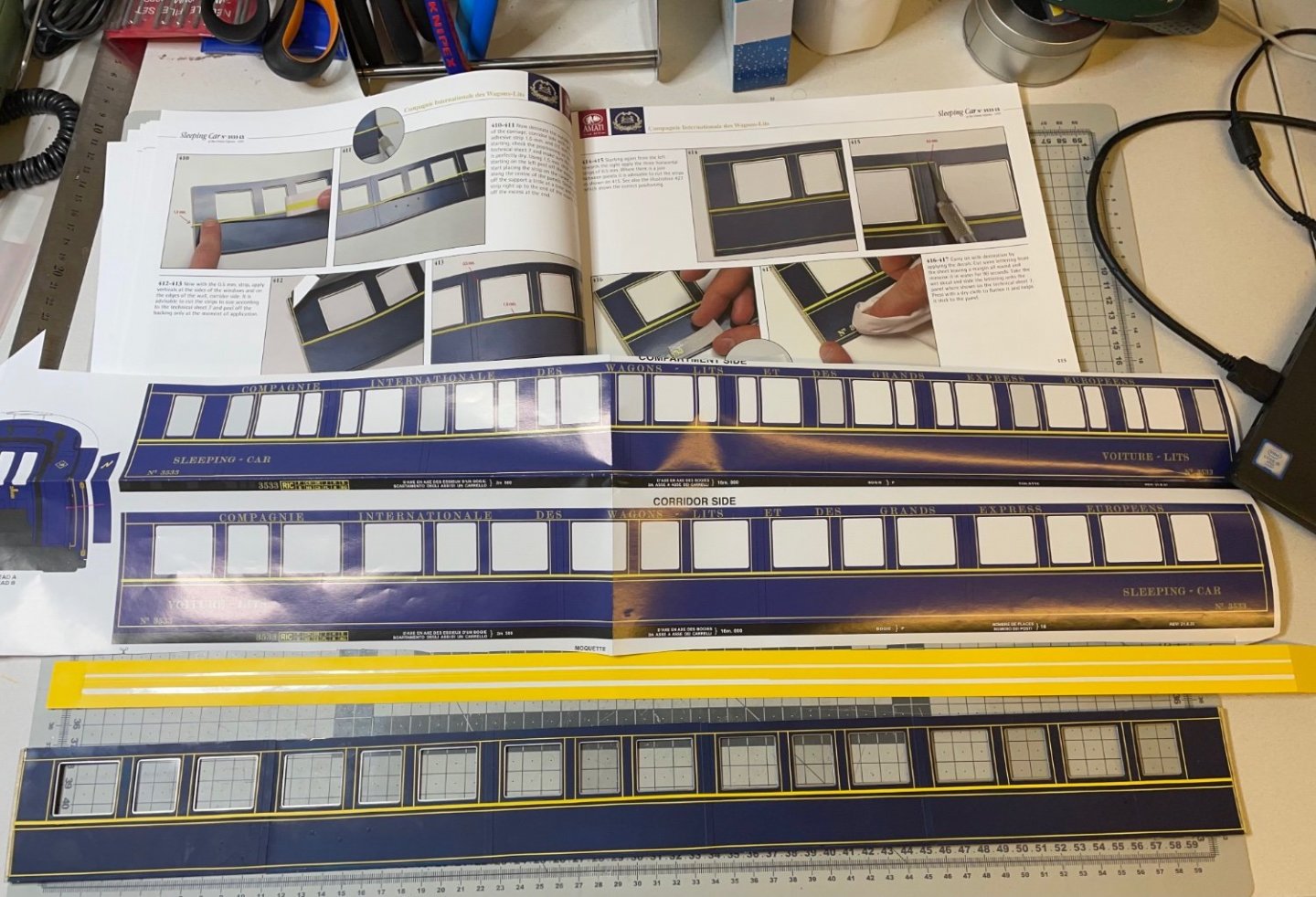

Figures 293-295: Decals. There are decals at some white parts of the sheet as well. They are white texts to be applied on the black metal structure. You use the printing as a guide for their location. Same goes for installation of the yellow lines. Note you can select the route among the available options. This is all for now. Thanks for watching!

-

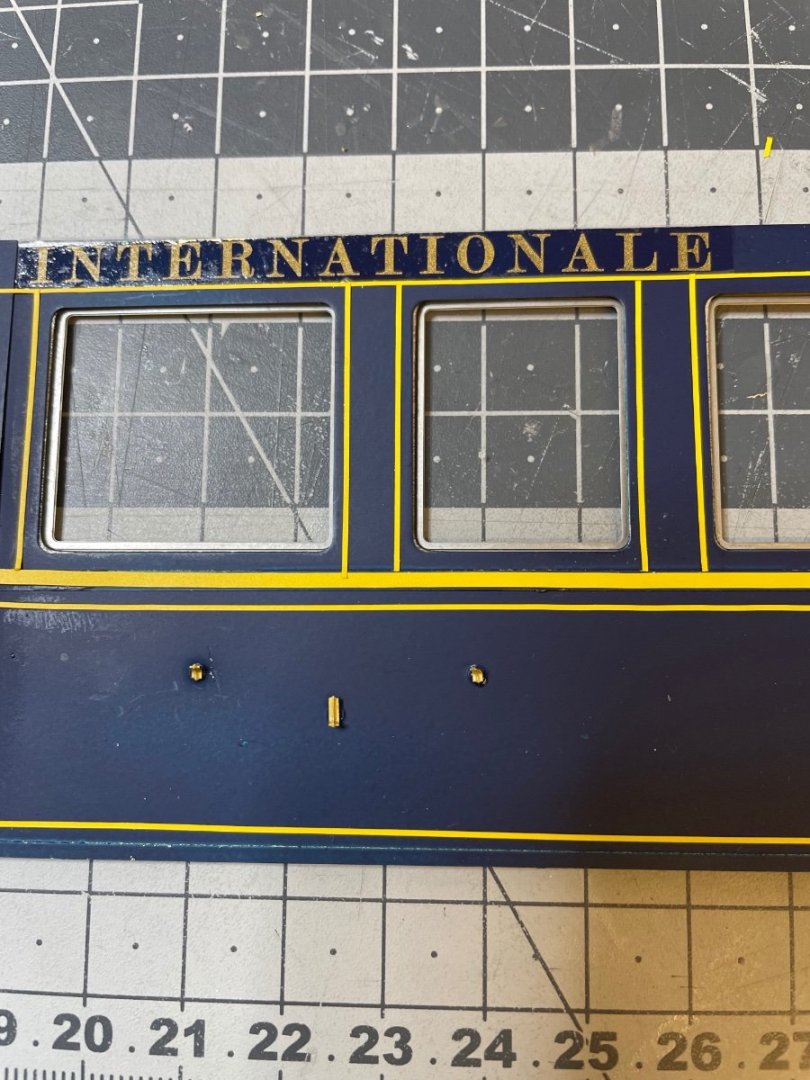

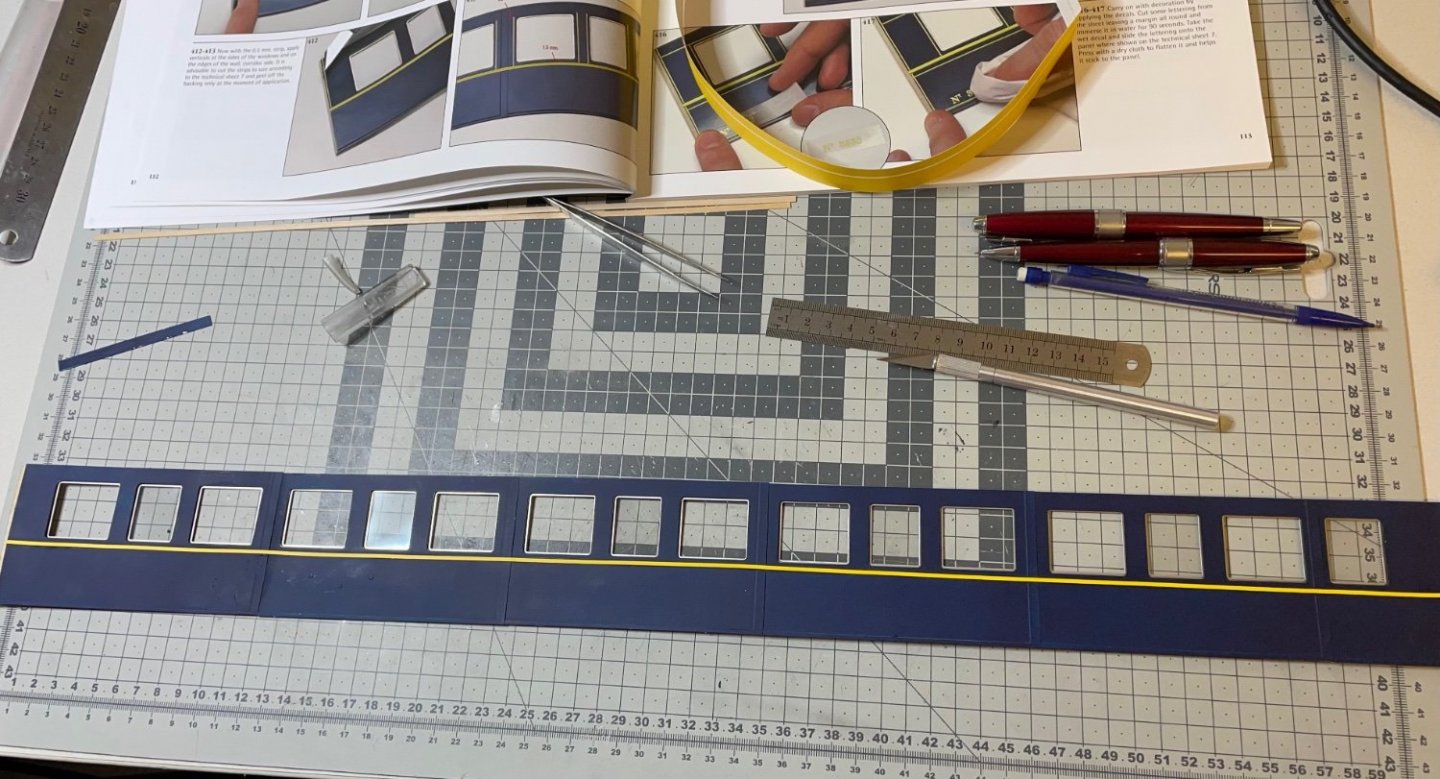

My hands are shaking 😄. This is the first time I have ever done a sticker work at this level of precision. Figures 288-291: These yellow lines are provided as elastic stickers, not decals (thanks God). They are in 1.5mm and 0.5mm thickness. From the back of the sheet I read it is a brand called Avery Dennison, in case anyone wants to find out more about them. Overall it went wery well and I am kind of proud of the work

-

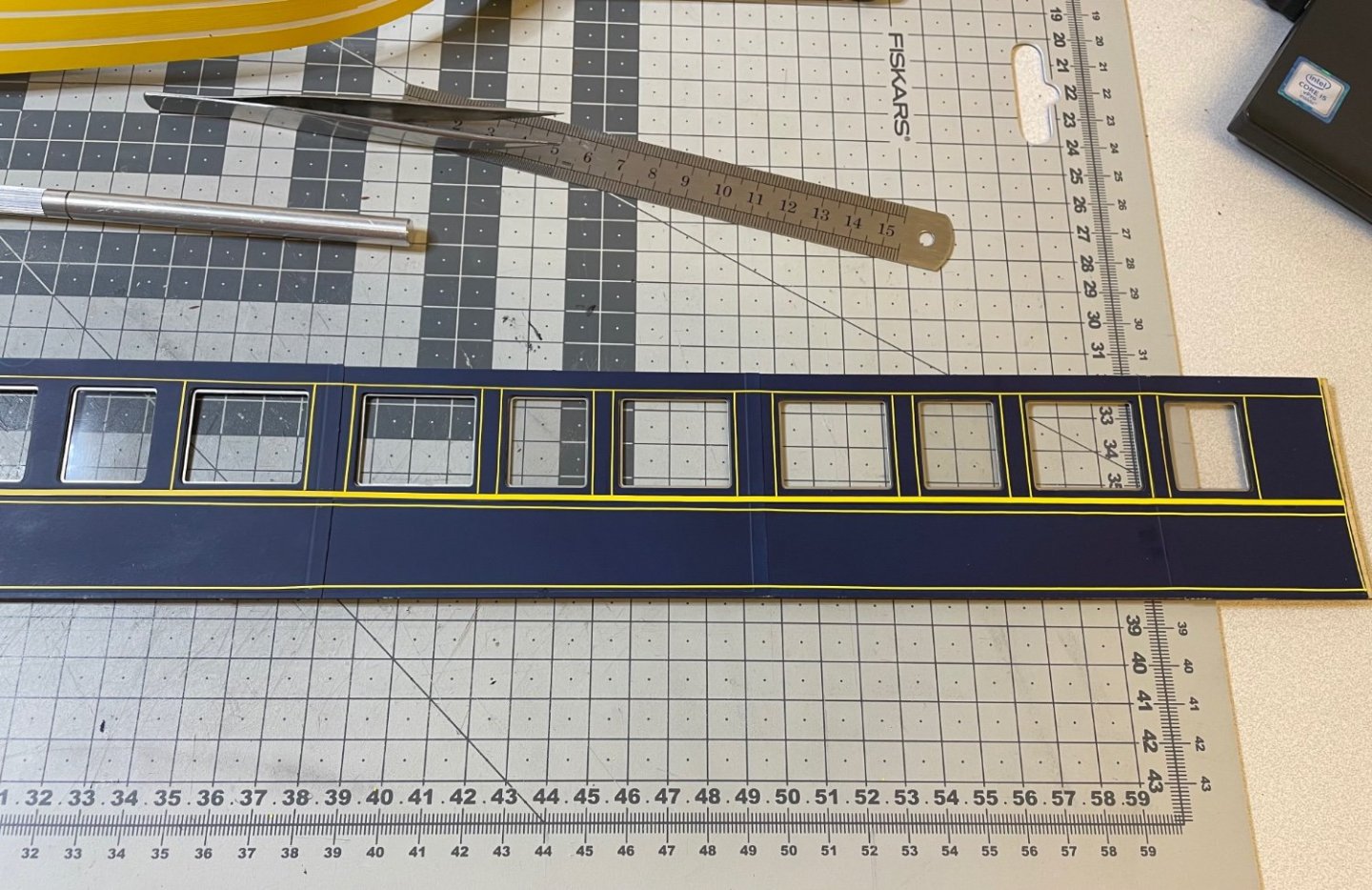

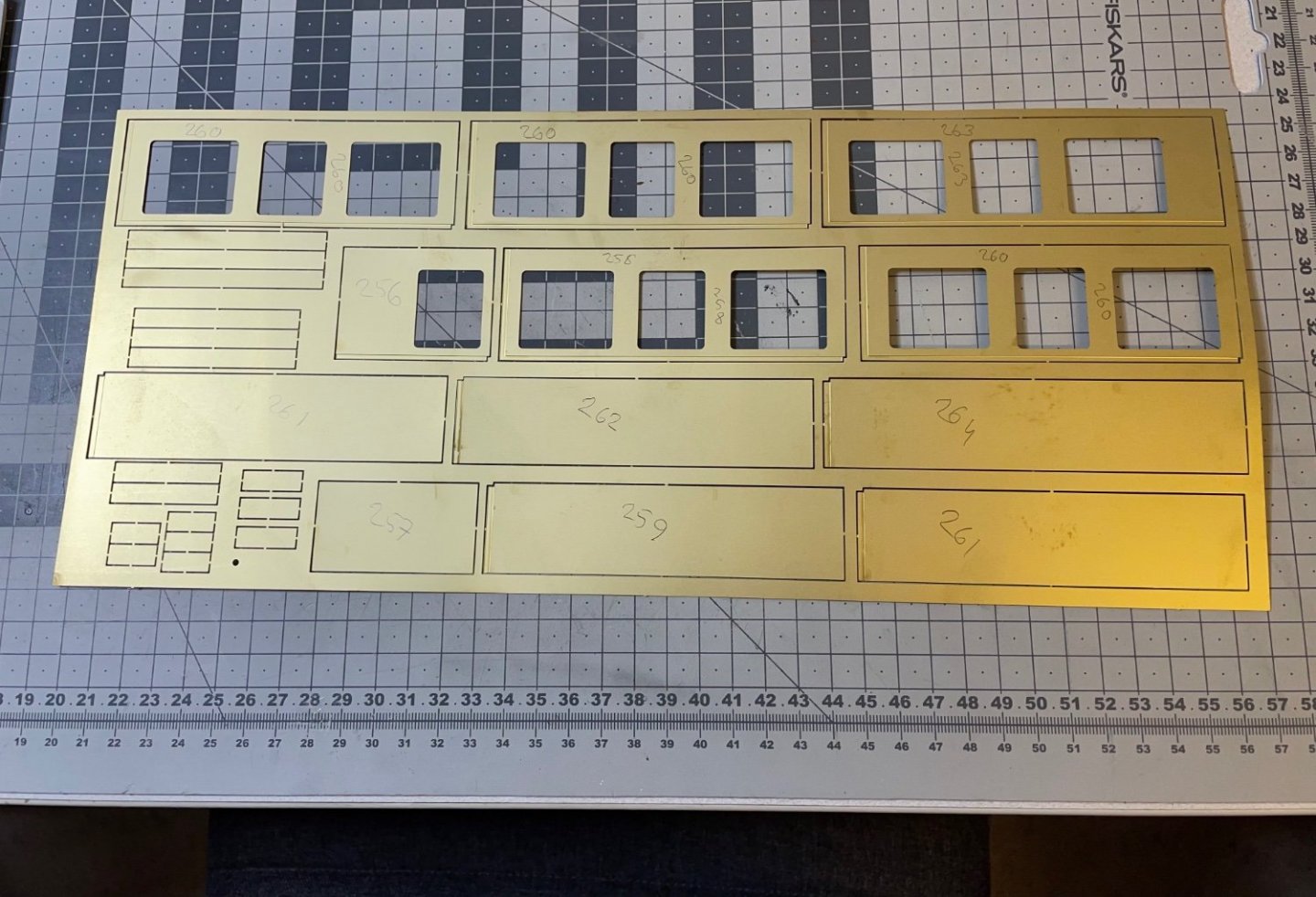

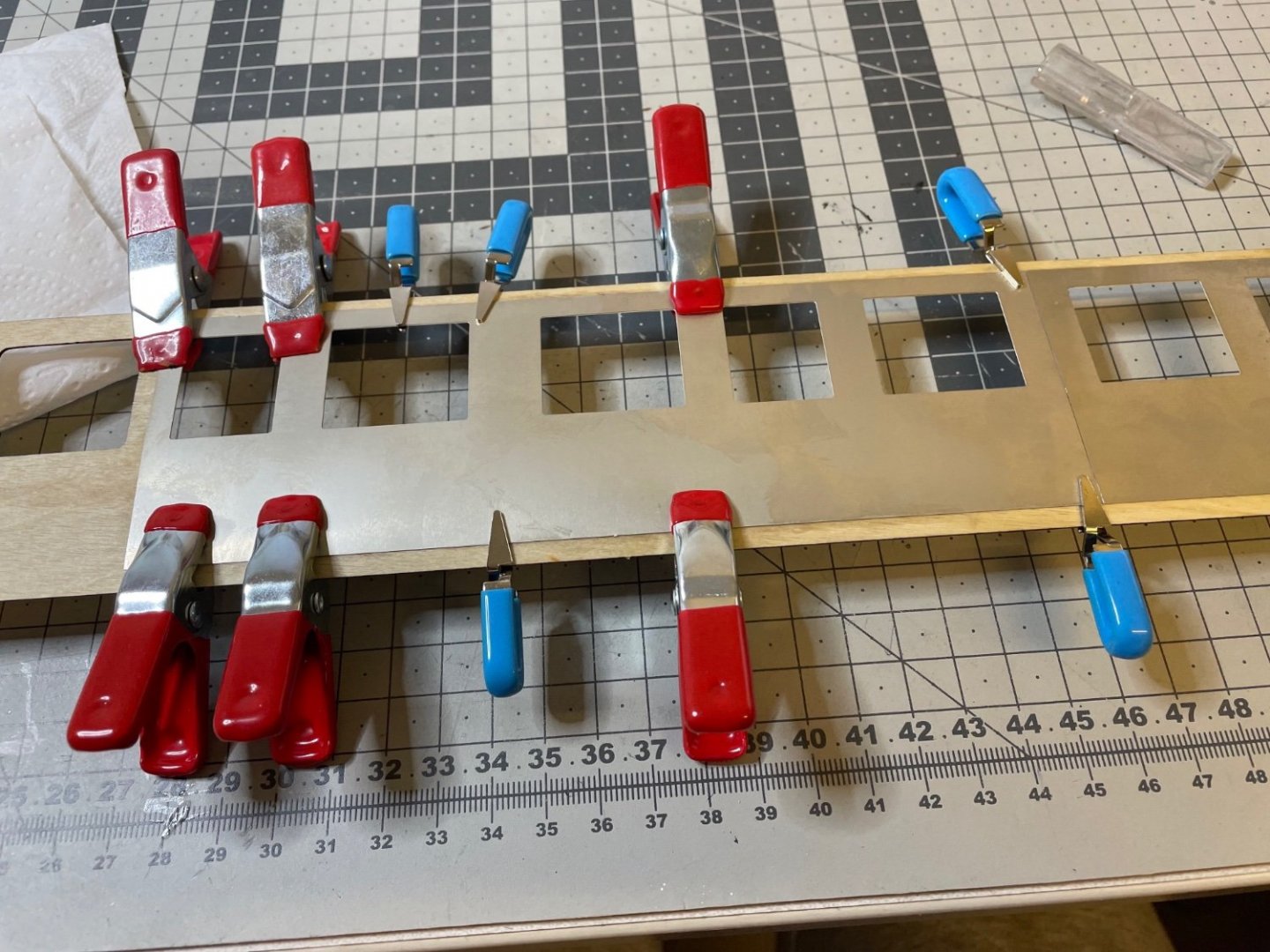

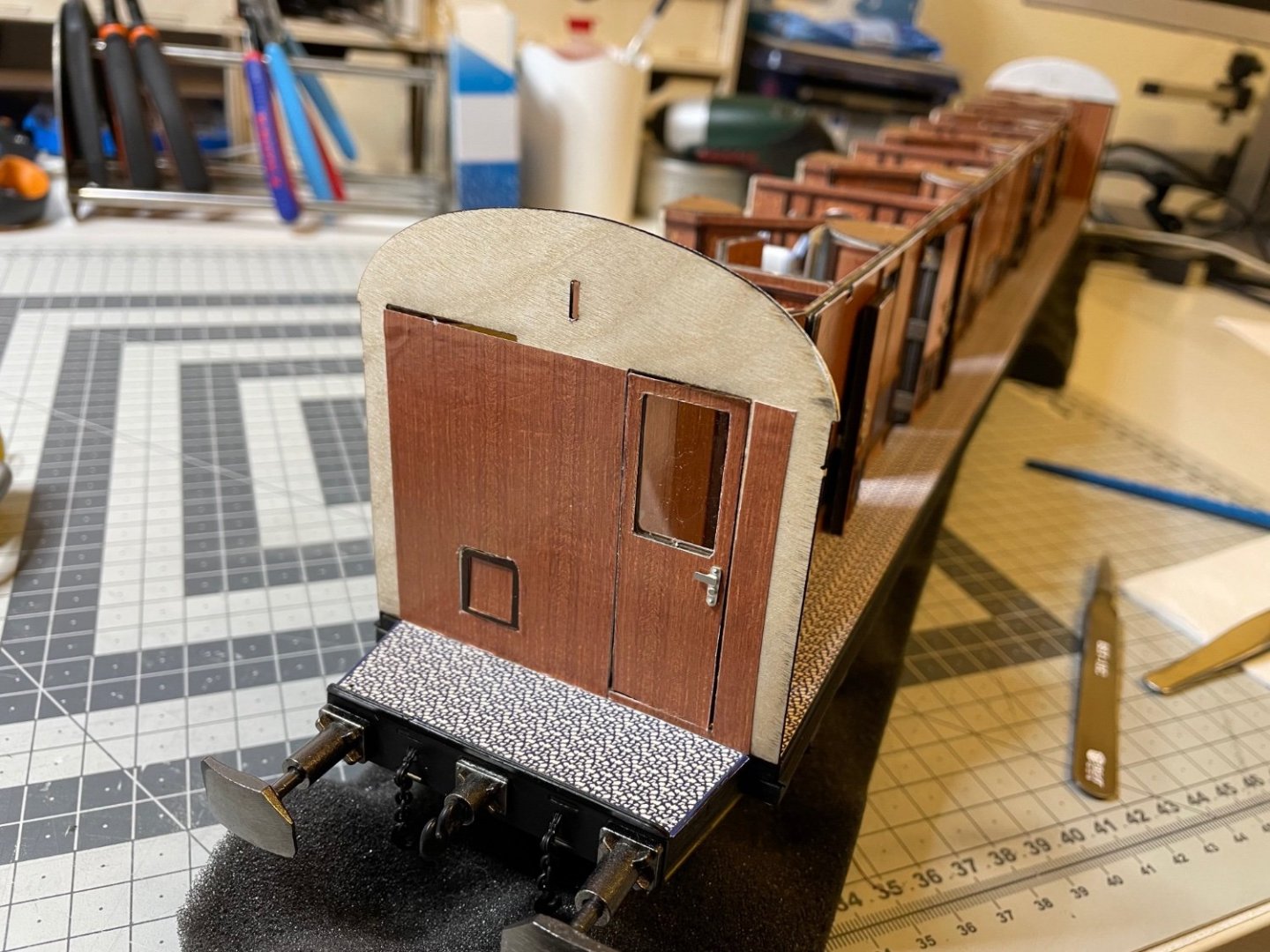

Figures 283-287: Next sequence of photos show the progress of aligning the photo etched parts, painting and gluing using the order in the instruction manual, with one exception: According to the instructions, starting from the rightmost end, you should first glue the upper panel and then slide the lower panel towards under the extrusion of the upper panel (i.e. the lower panel goes around 1.5mm underneath the upper panel). This does not always work. I tried it and especially with super glue, it caused a lot of problems, such paint strip off etc. Instead I glued the lower panel first and upper panel after it and it worked just fine. Color is Vallejo Steel Blue (see photo). I used airbrush.

-

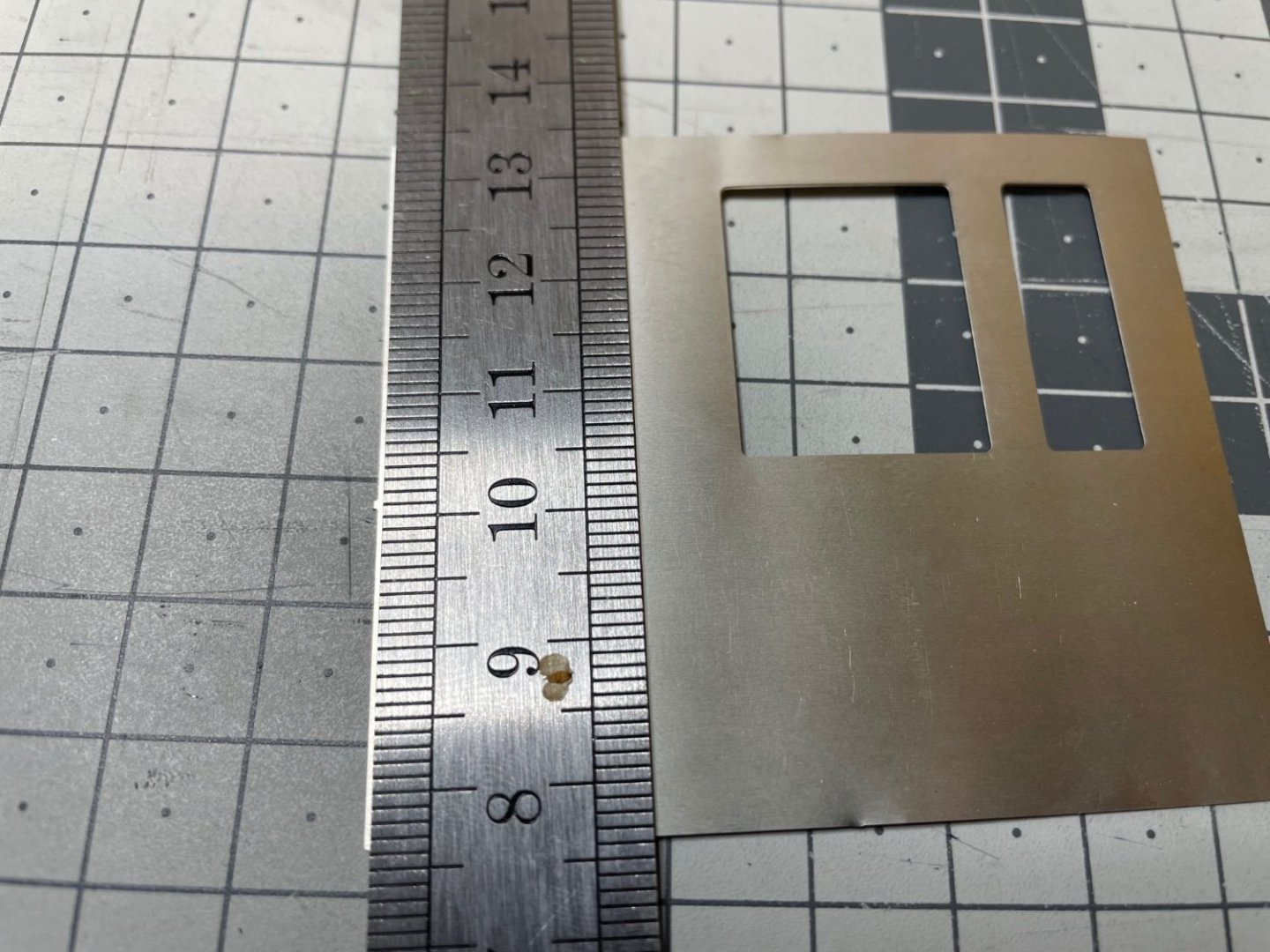

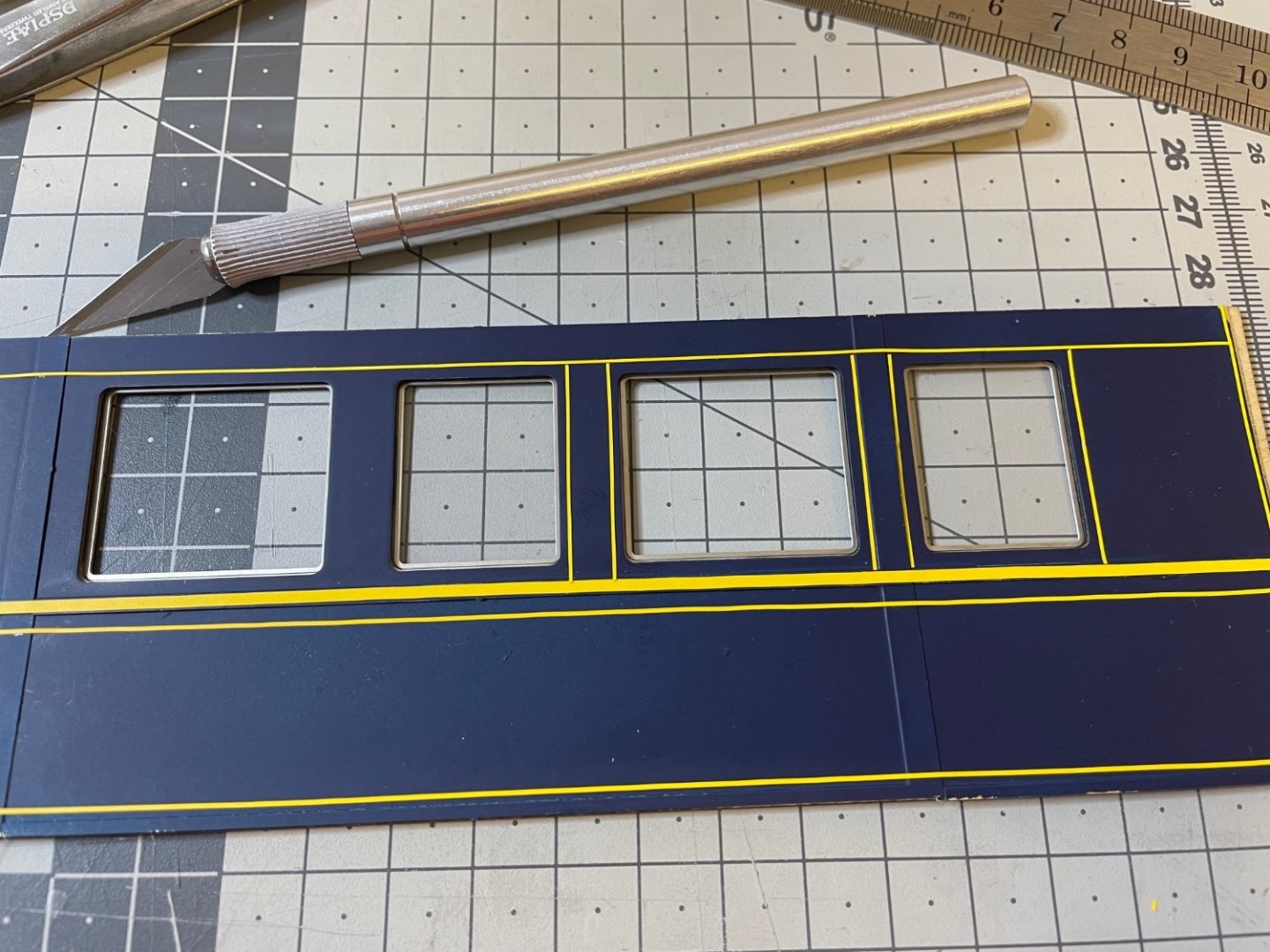

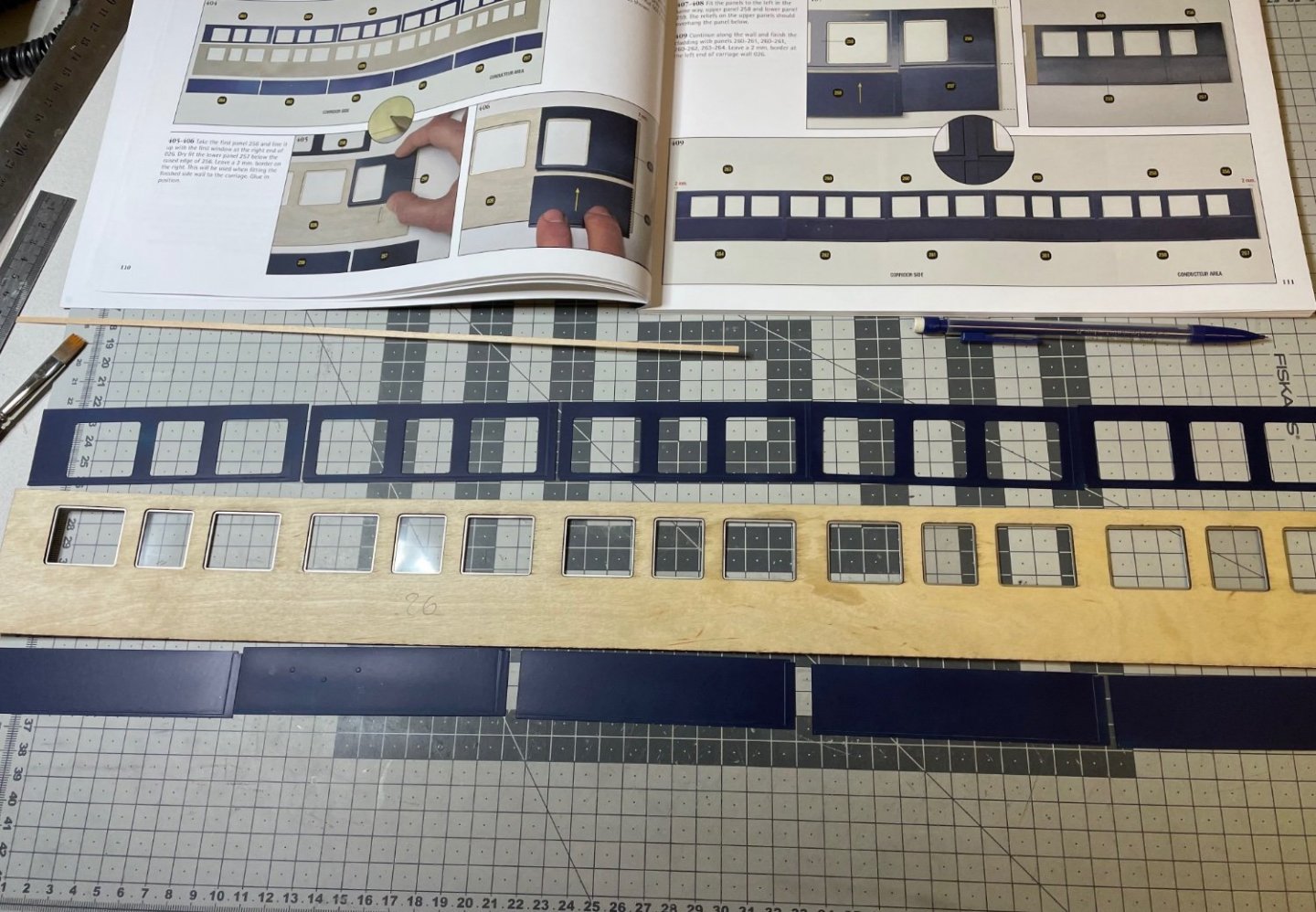

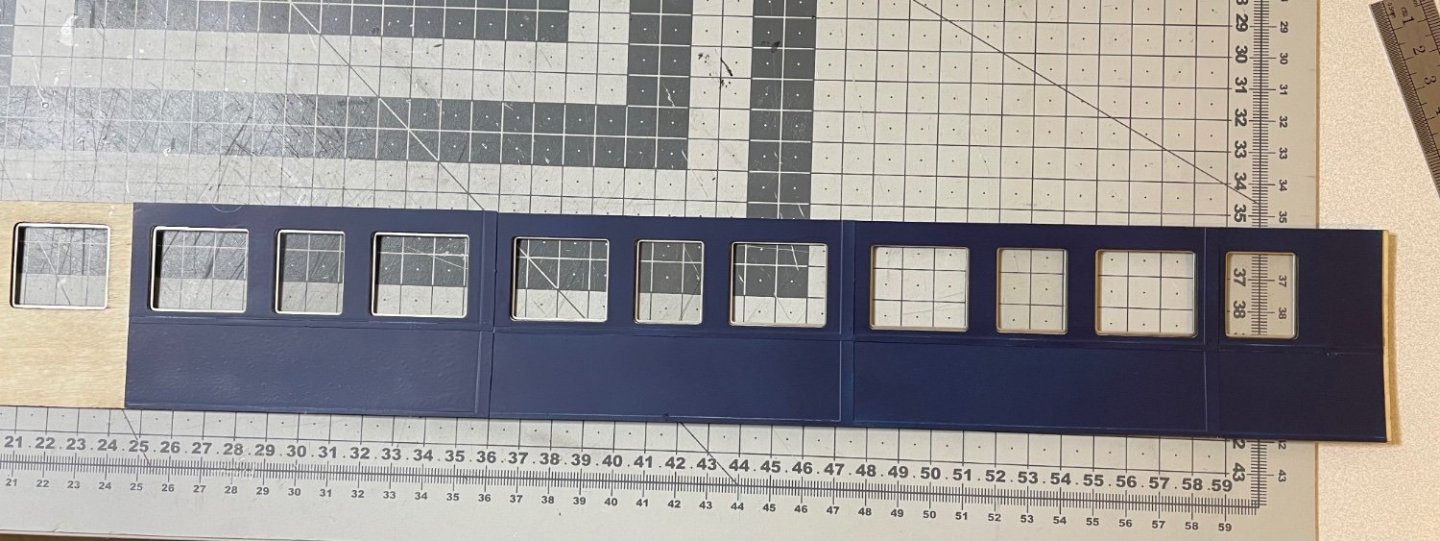

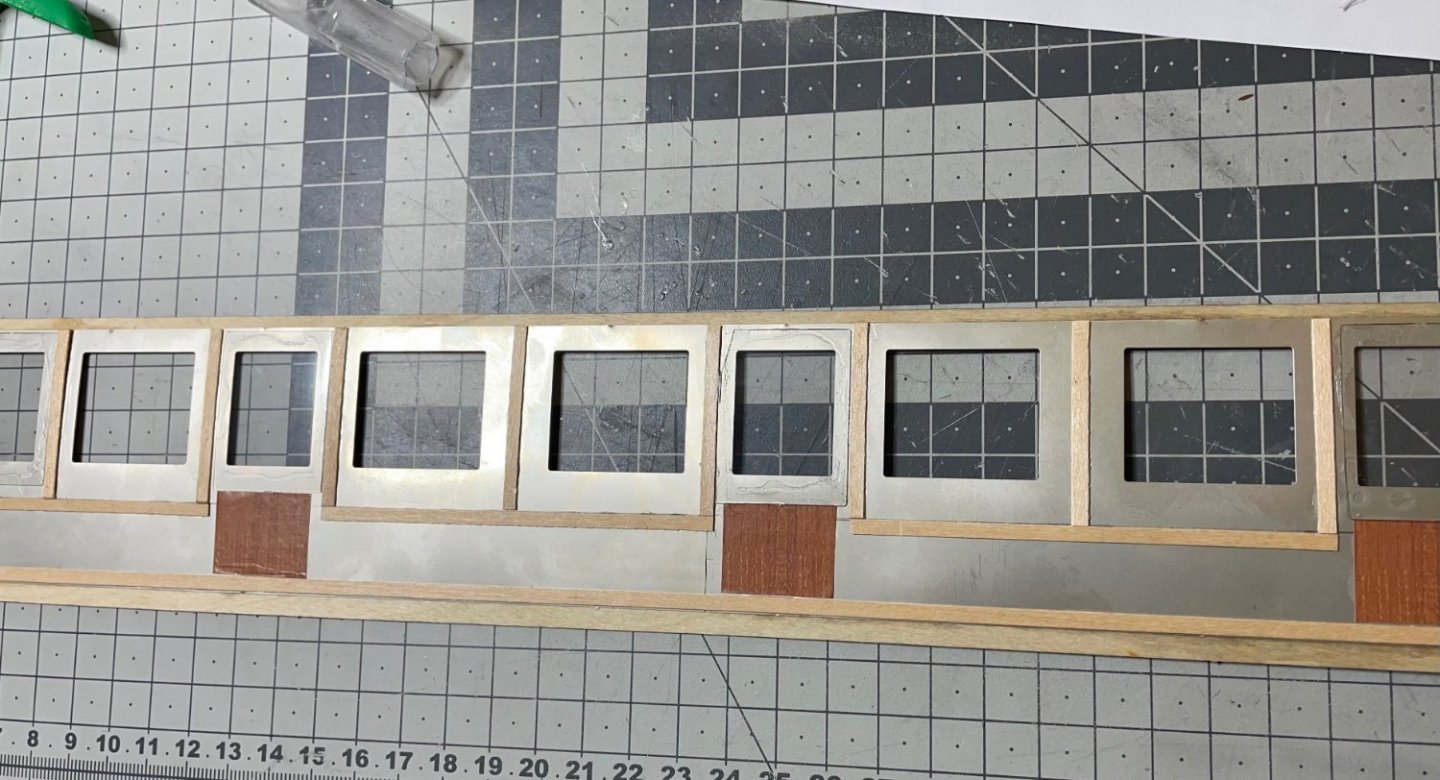

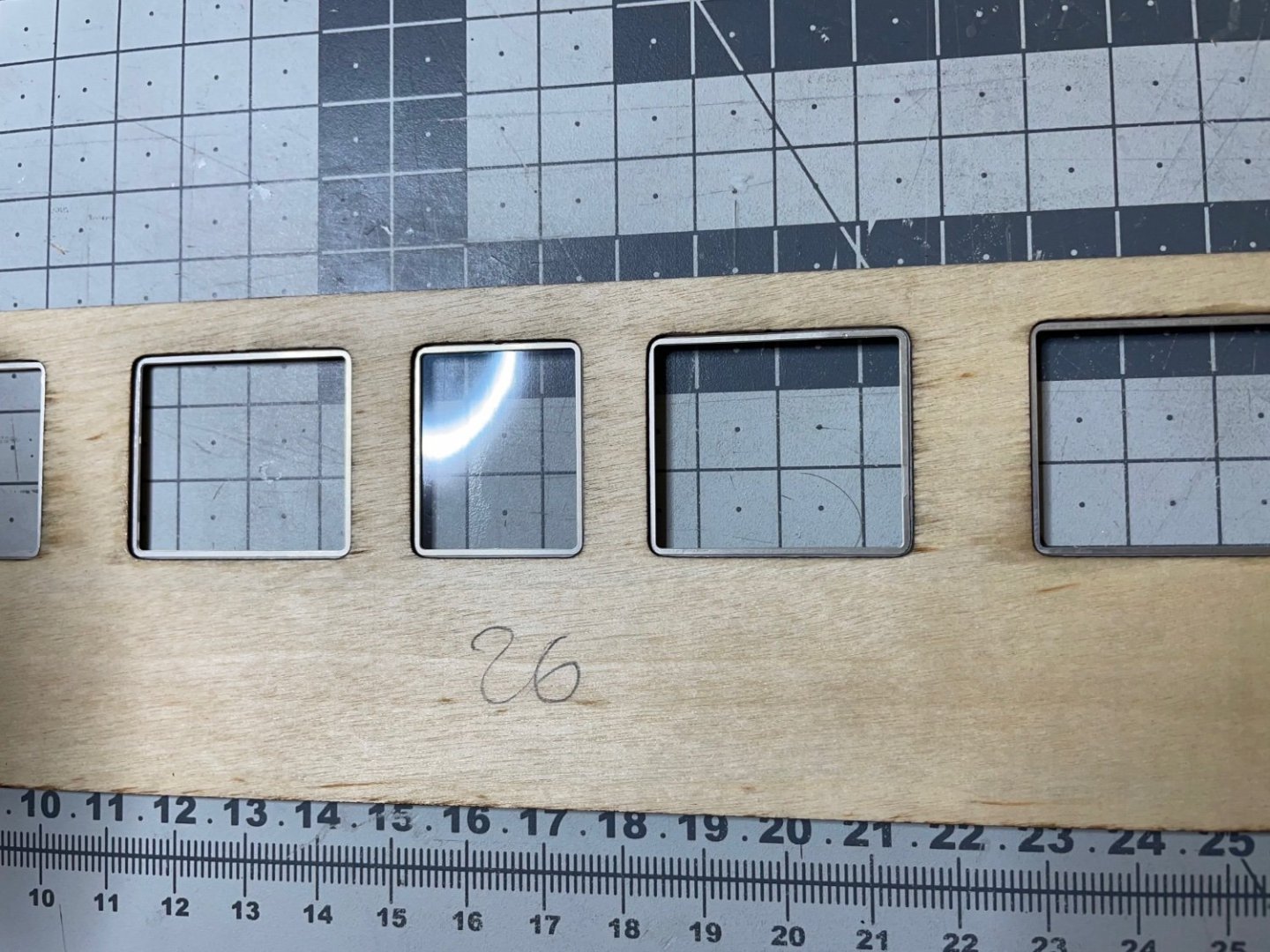

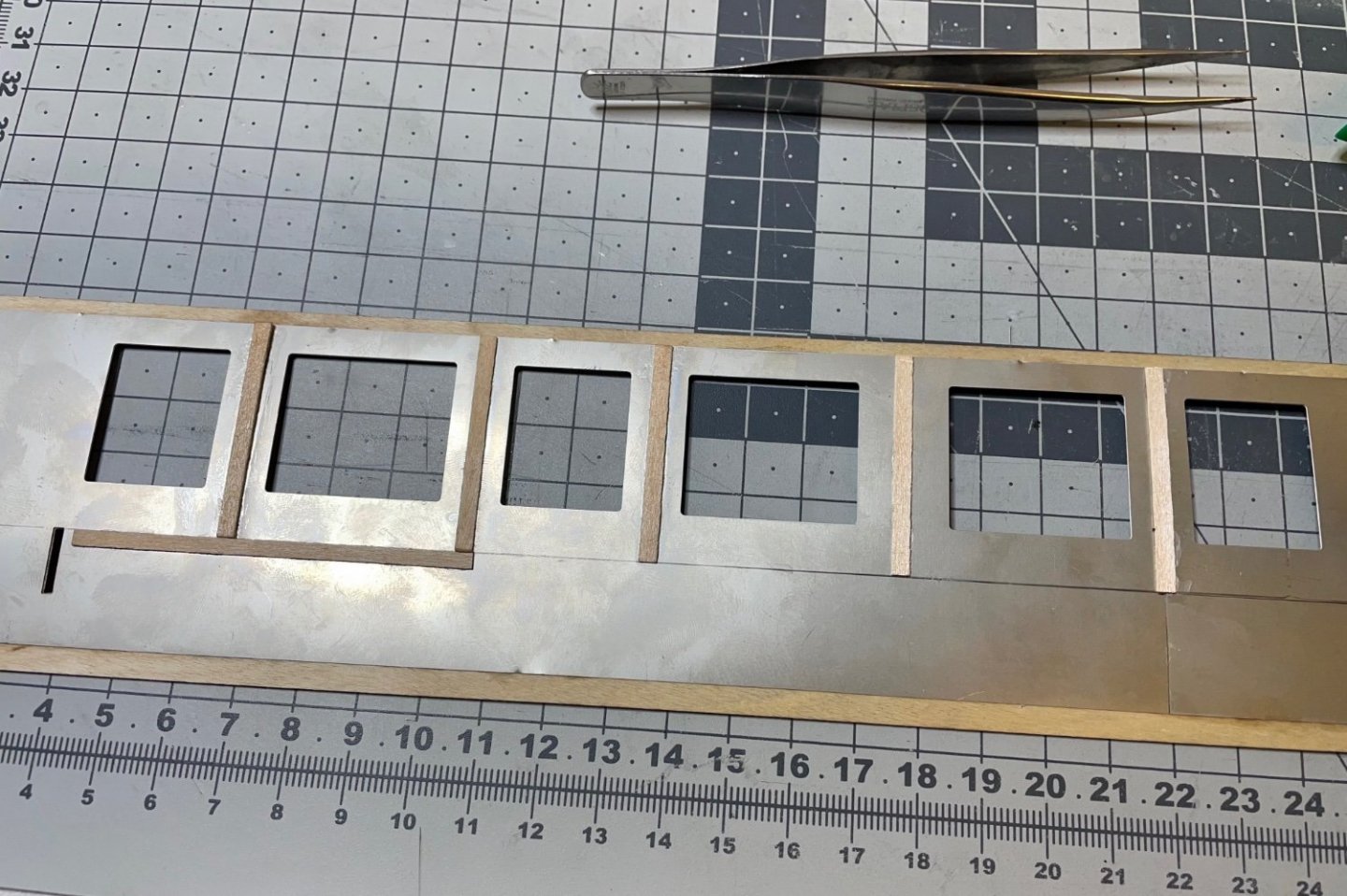

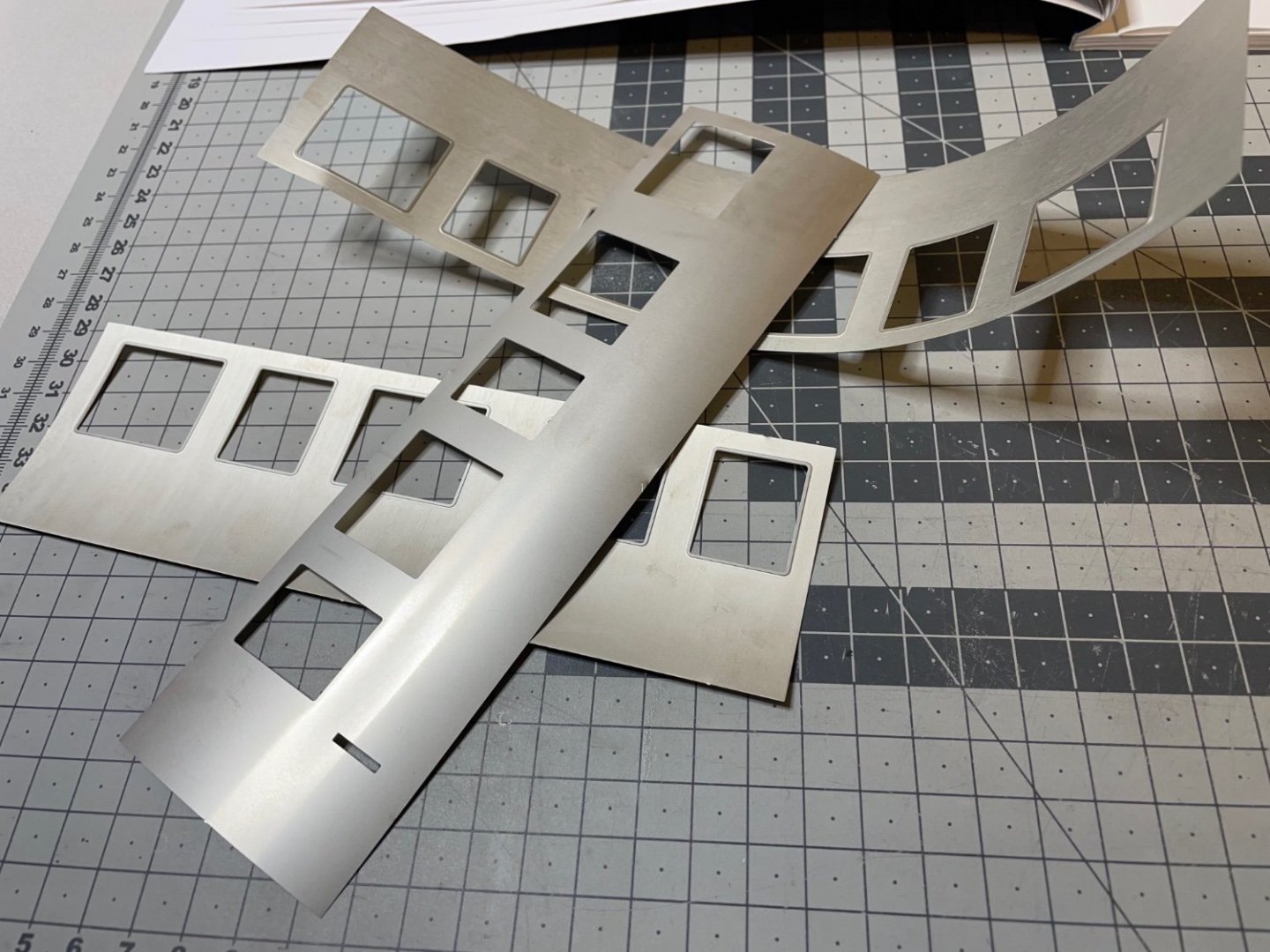

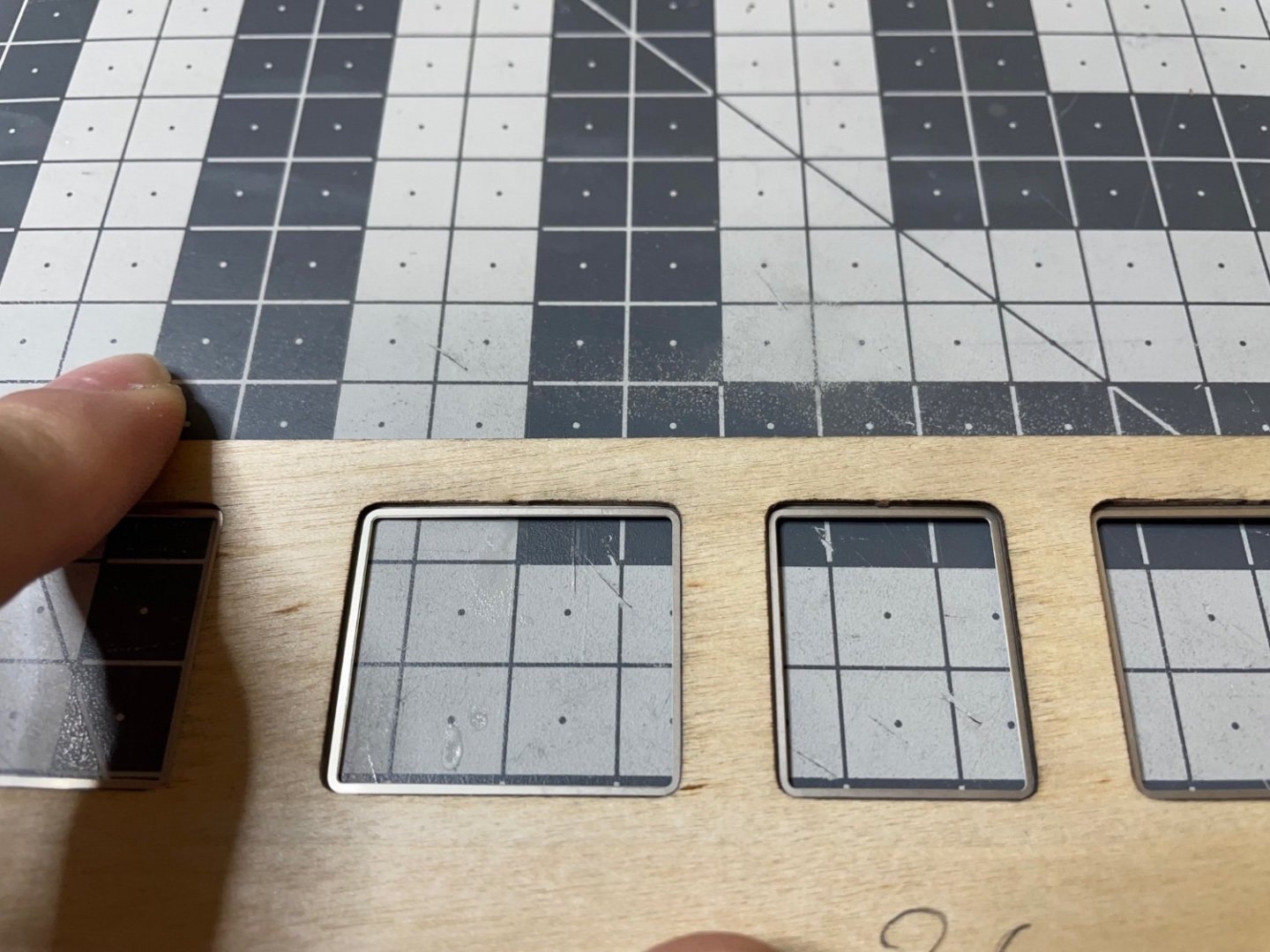

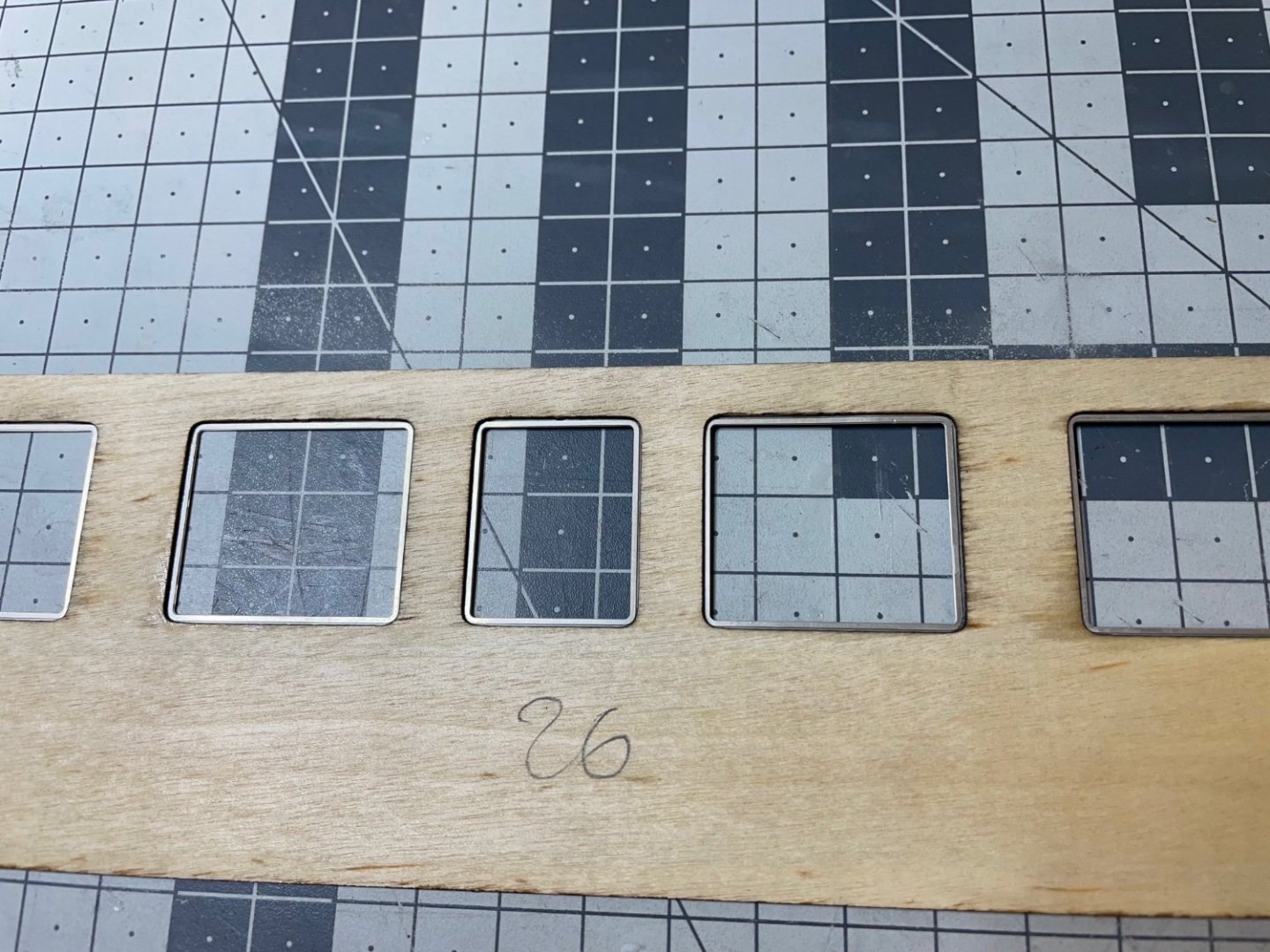

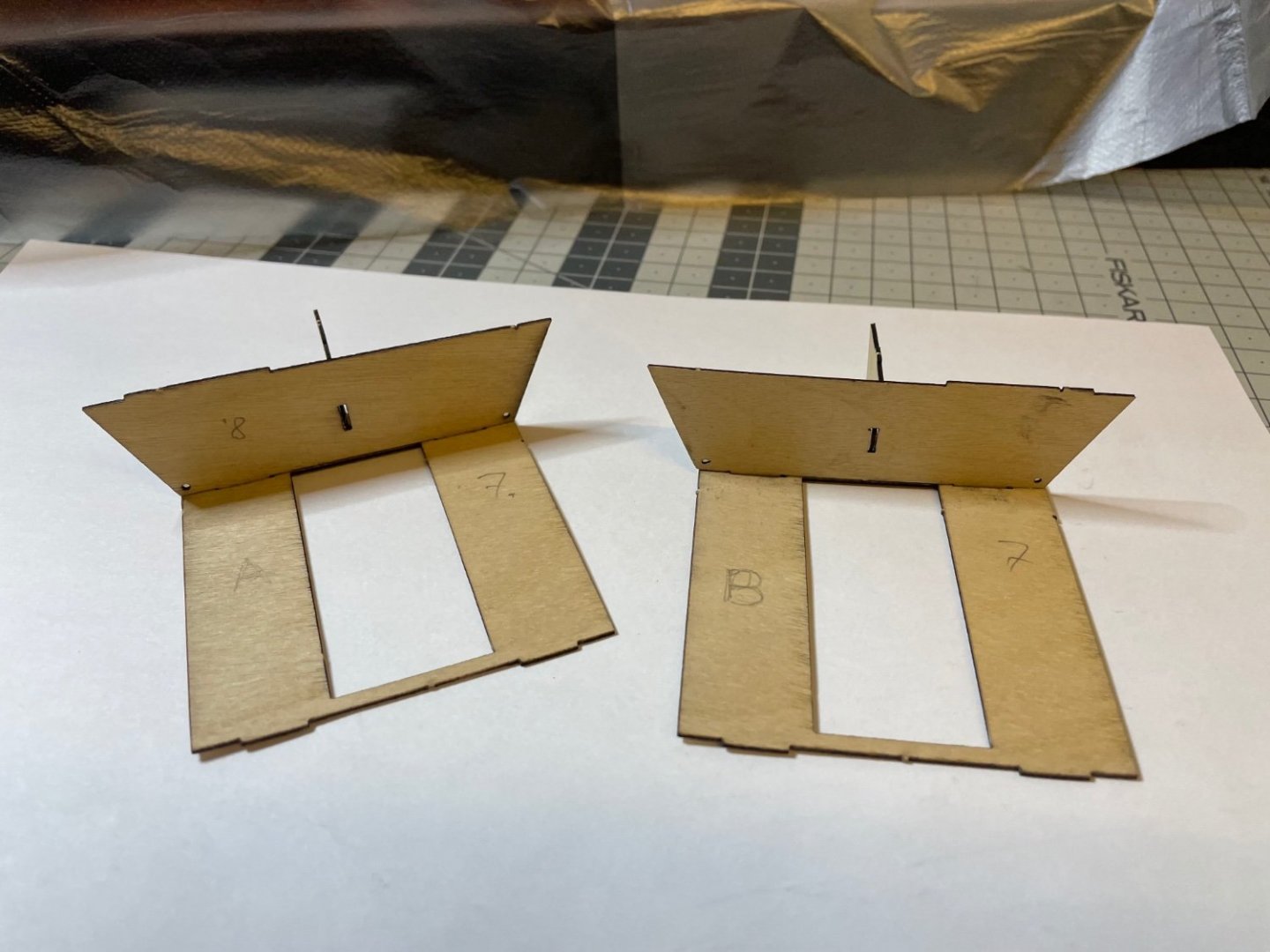

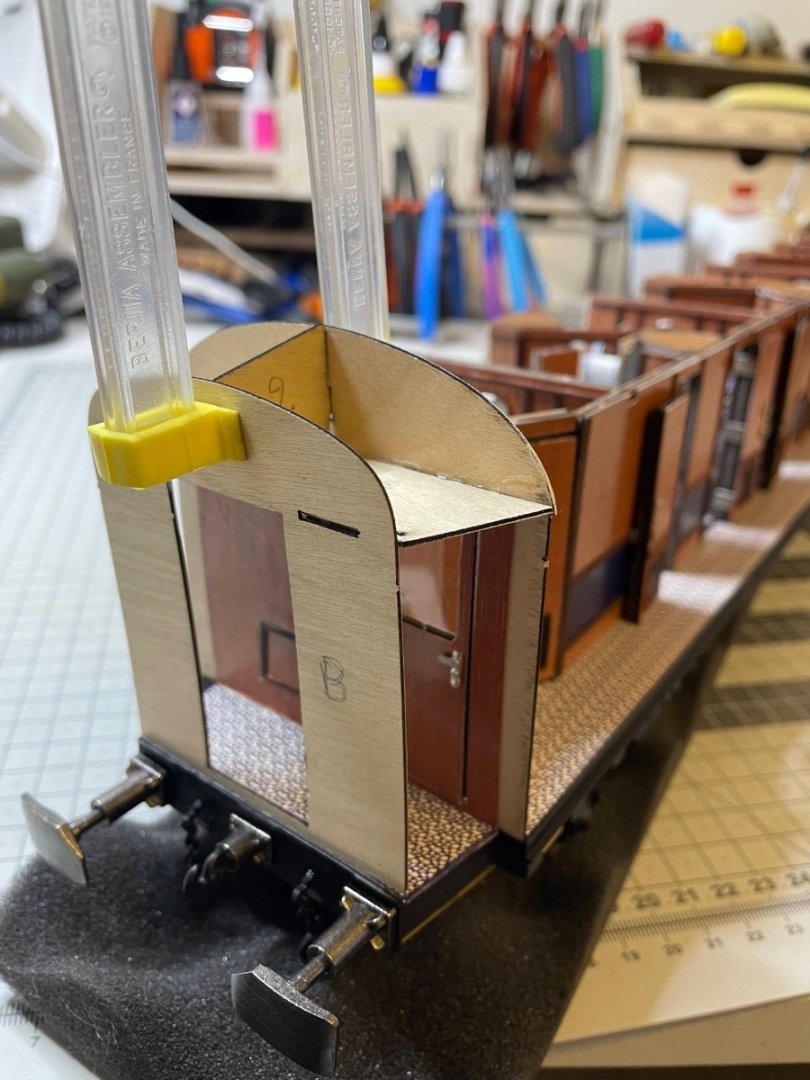

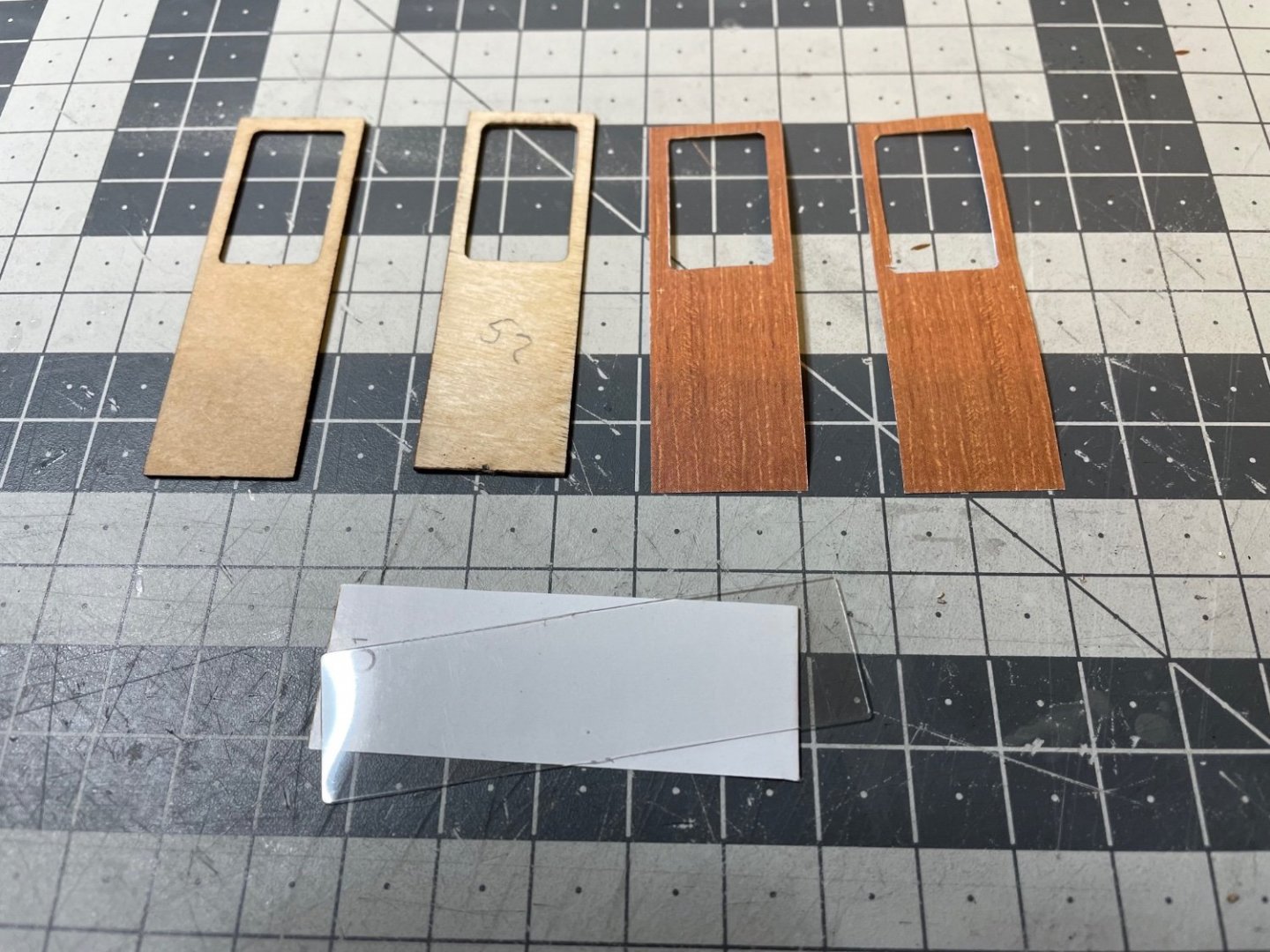

BUILD DAYS 27-28 / 5 hrs / (TOTAL: 76 hrs) Next in the line is construction of corridor side outer wall. The wagon structure will rest aside for a while. Figure 272: We start with photo etched the nickel panels, which will be glued on the plywood structure. In the photo you see how they came out of the box, even though they should be totally flat. When I press on them with my hand they bounce back to the same shape! I don't want to use tools to bend them as I am afraid of kinking them. I just hope they will remain flat enough when glued on the plywood. There will be also other components like wooden strips and another layer of photo etched panels to enforce the structure, so hopes are high. Figures 273-276: Aligning the window openings of the nickel sheet with that of the plywood. Nickel should form a thin frame of about 1mm wide from the wooden window.

-

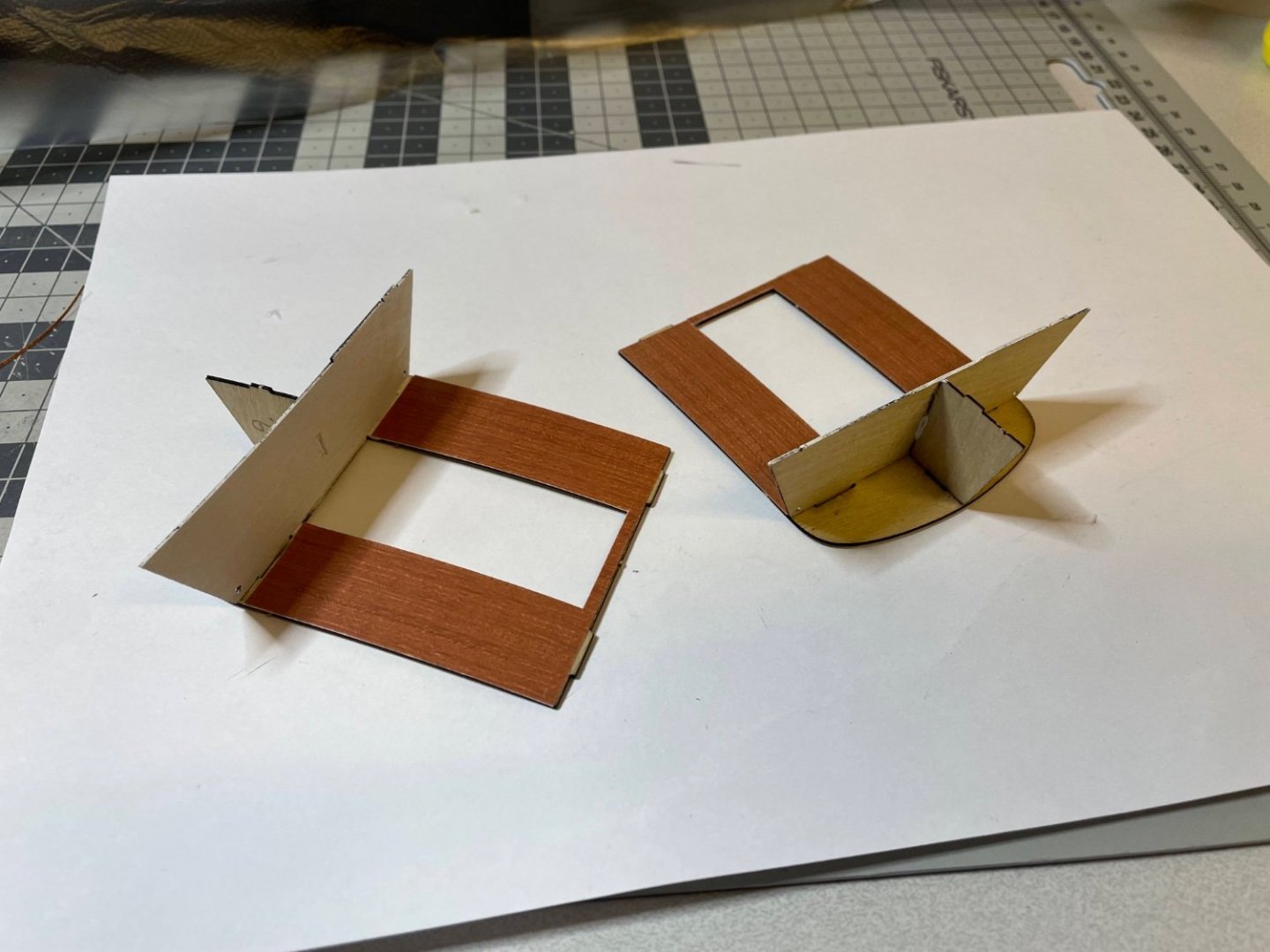

Figures 261-265: Folding chairs to be mounted on several locations on the wagon walls. They are designed to allow to move the seat up and down freely, though when you install them in the place you fix them in either closed or open position. There are altogether 7 of them. Some parts need painting, some paper decoration.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.