-

Posts

916 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by aydingocer

-

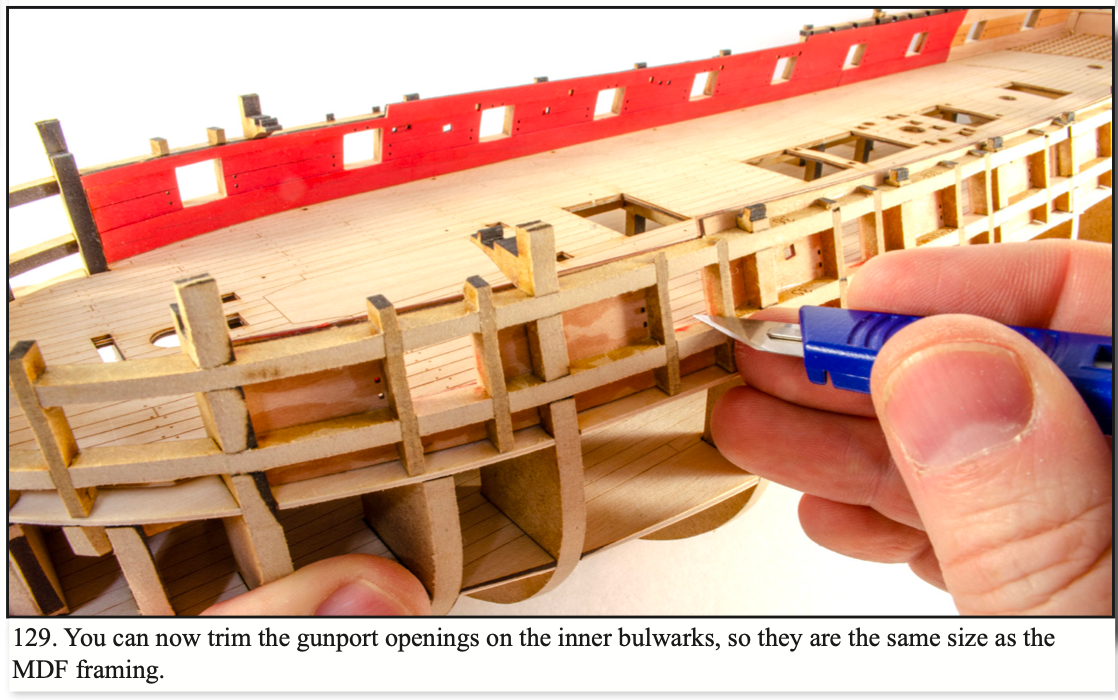

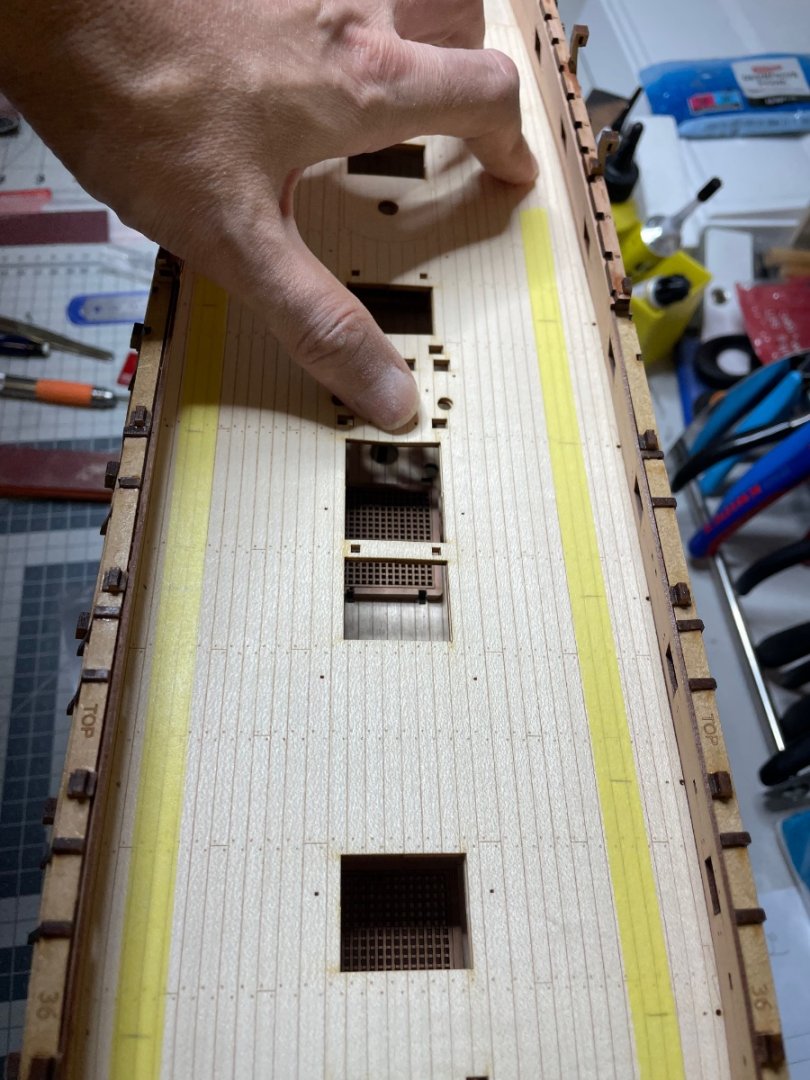

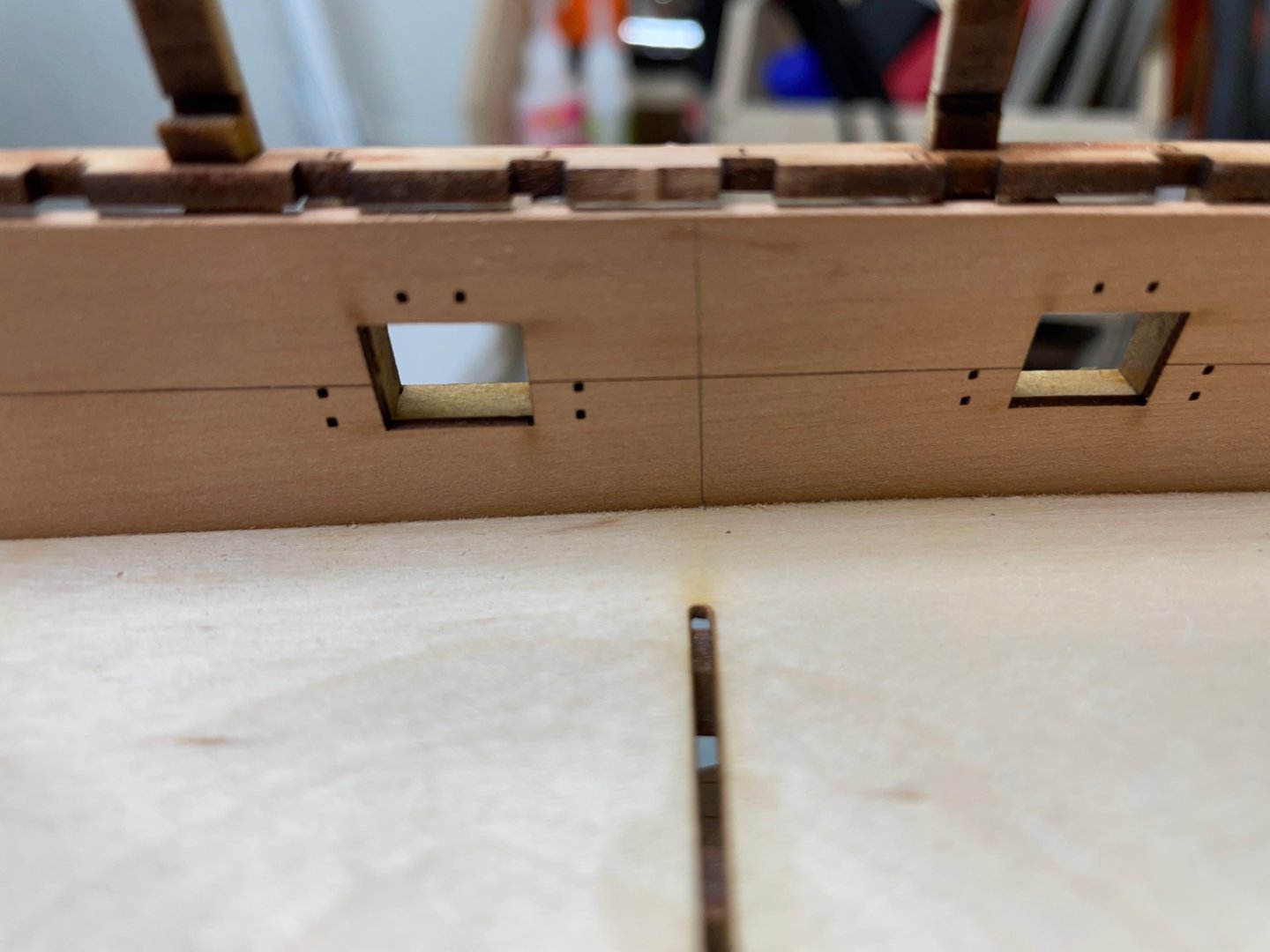

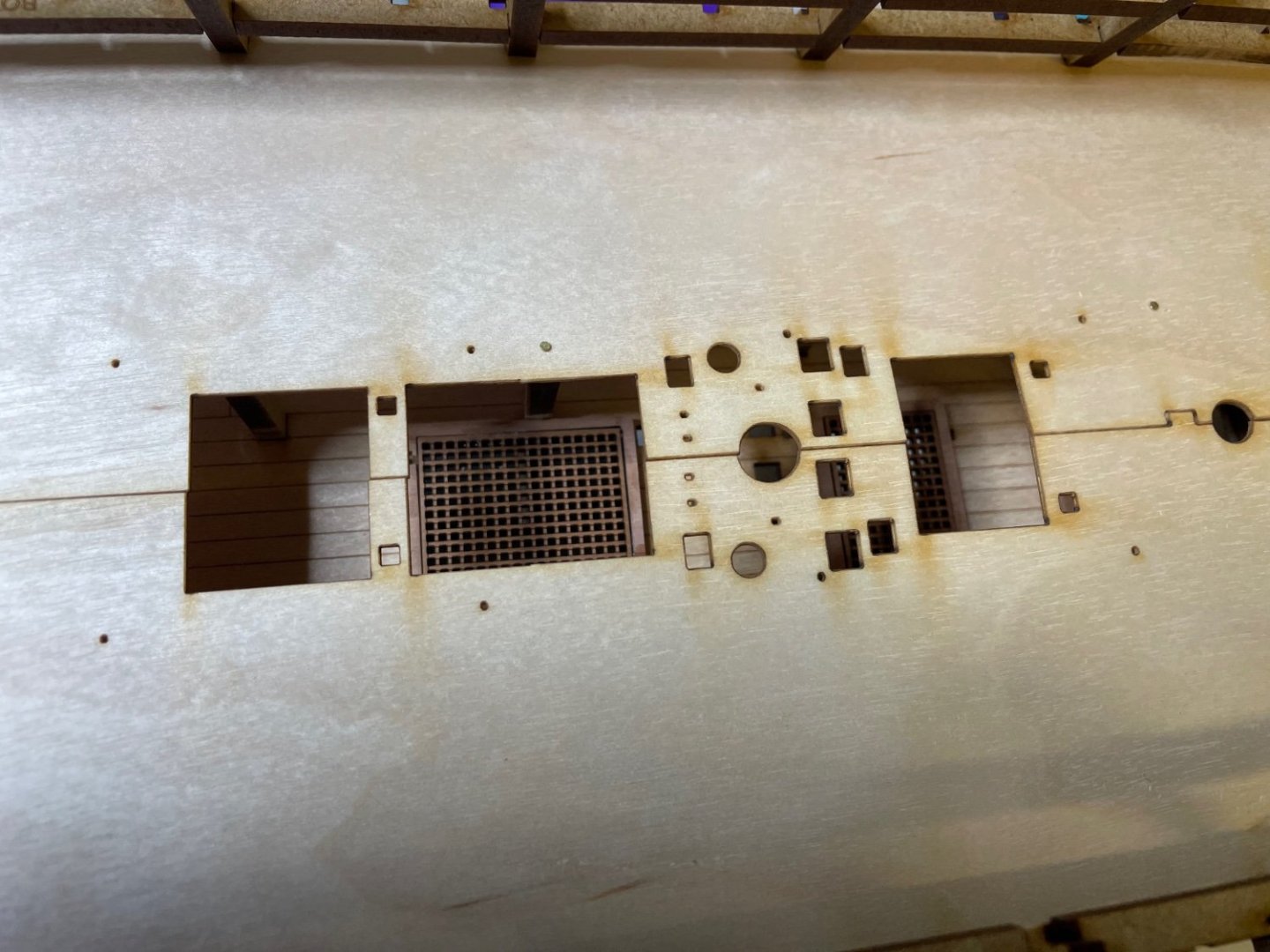

A question one step before planking: How necessary is it to trim the gun port openings to same size as the MDF frames? Is it only for visual historical accuracy or will it be crucial to fit something later? I am just concerned I can't get perfect identical square shapes when viewed from the deck side and I don't want them to look worse than they are at the moment.

- 426 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

Thanks for the advice. I will follow that. I think I can manage.

- 426 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

I have no idea why I did it like that 🤨. I think I somehow thought of my earlier builds where the planks from each side meet at the front and are glued to to each other. Damn. In your photo it is obvious that the central keel should be left as it is. I should have followed the photos more carefully. What do you suggest I do now? Sand it totally flush, cut a similar piece from a scrap MDF and glue it there? Or will I have still a chance to rectify it when I glue the prow pattern?

- 426 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

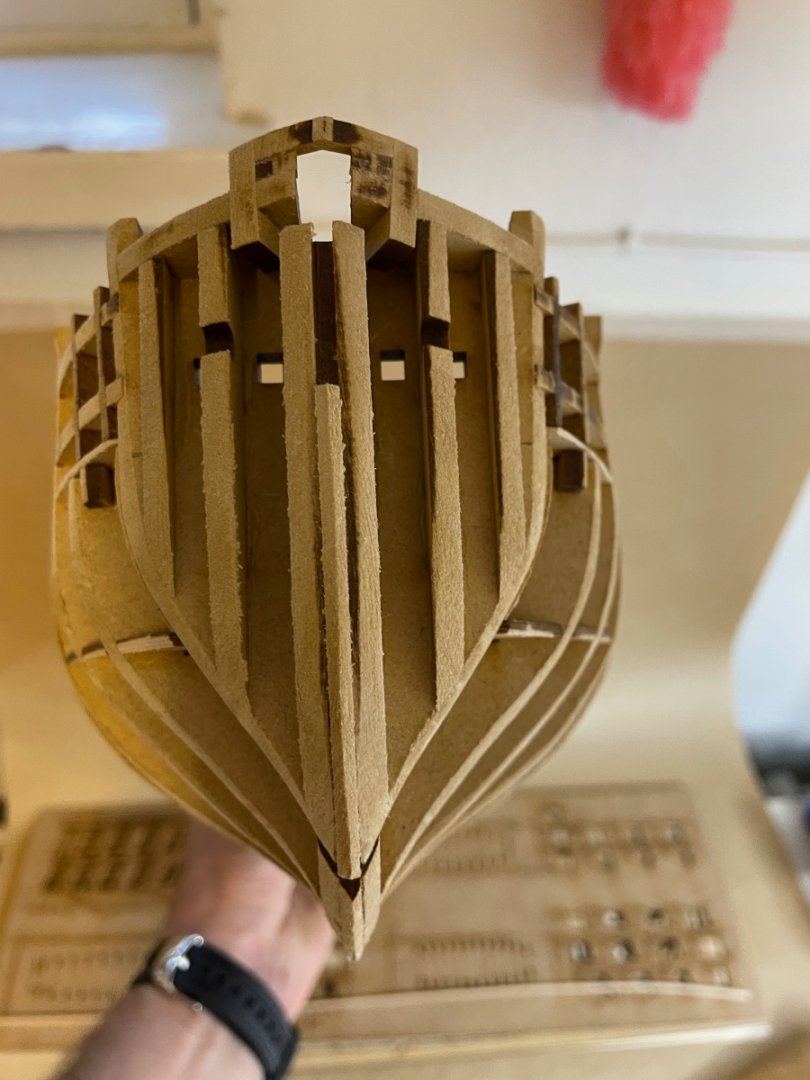

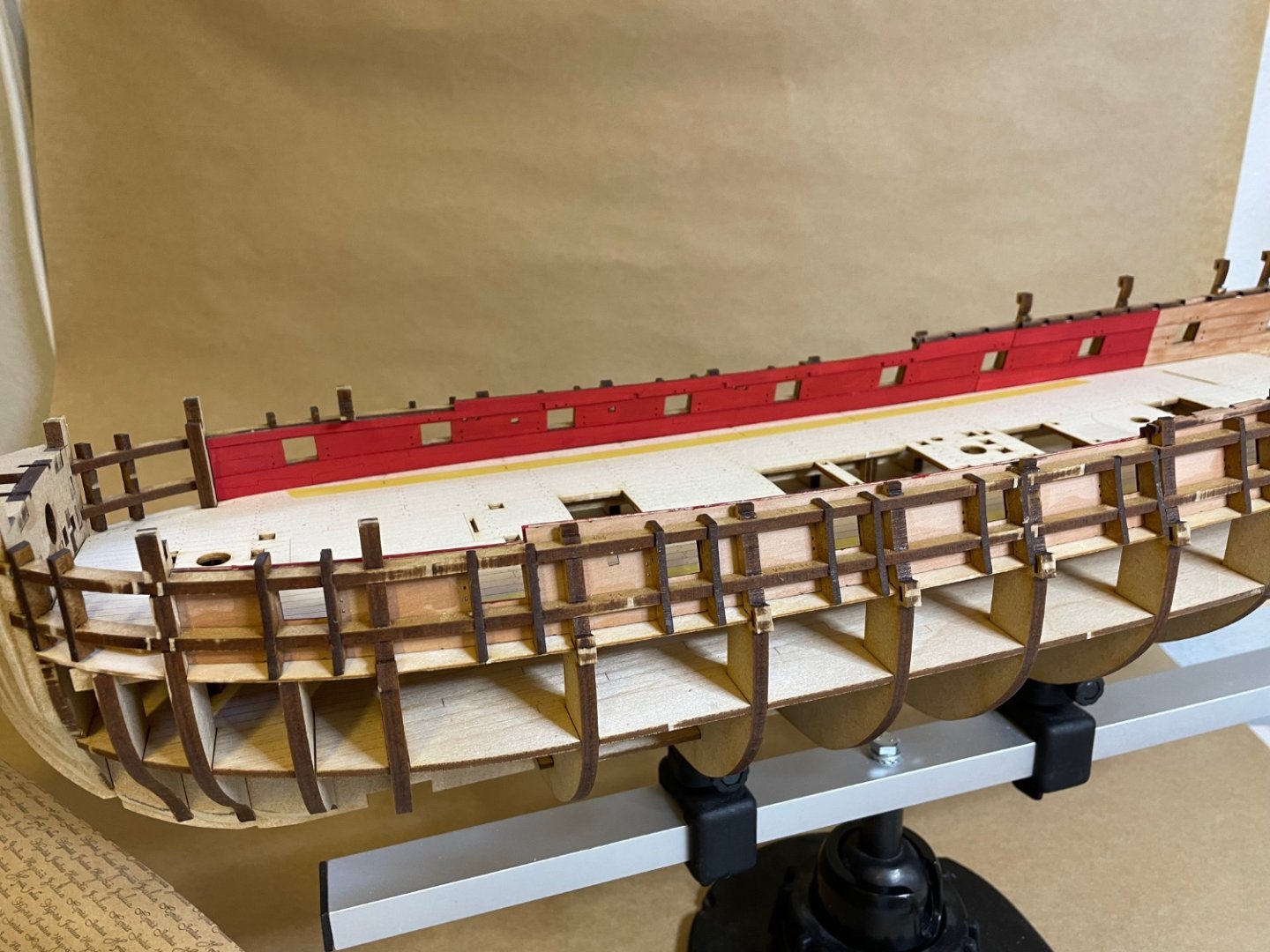

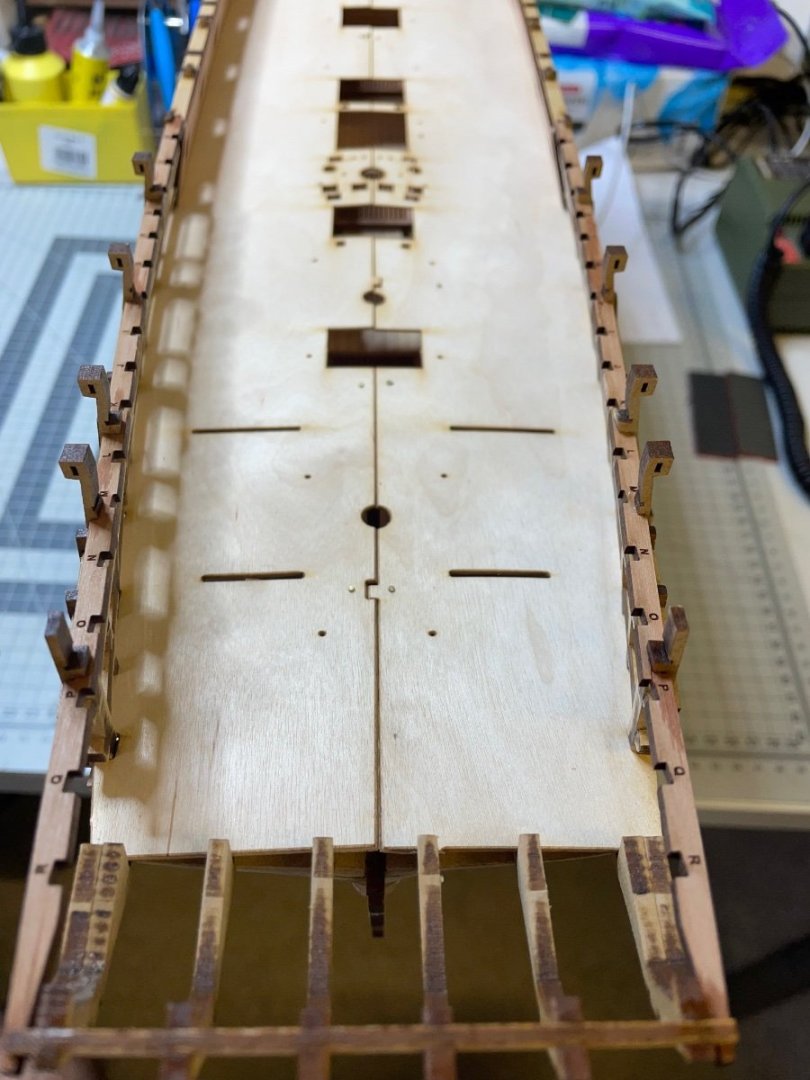

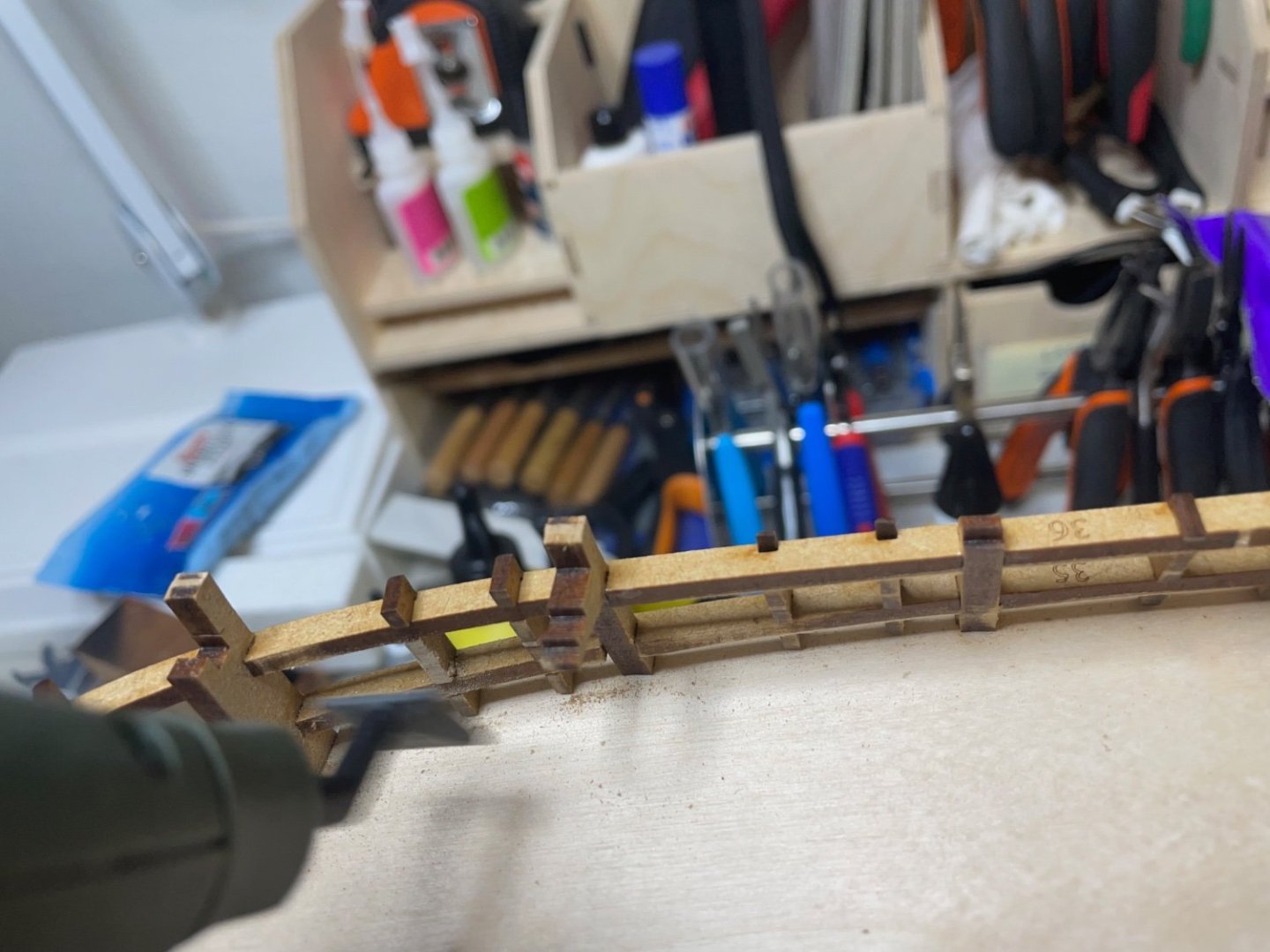

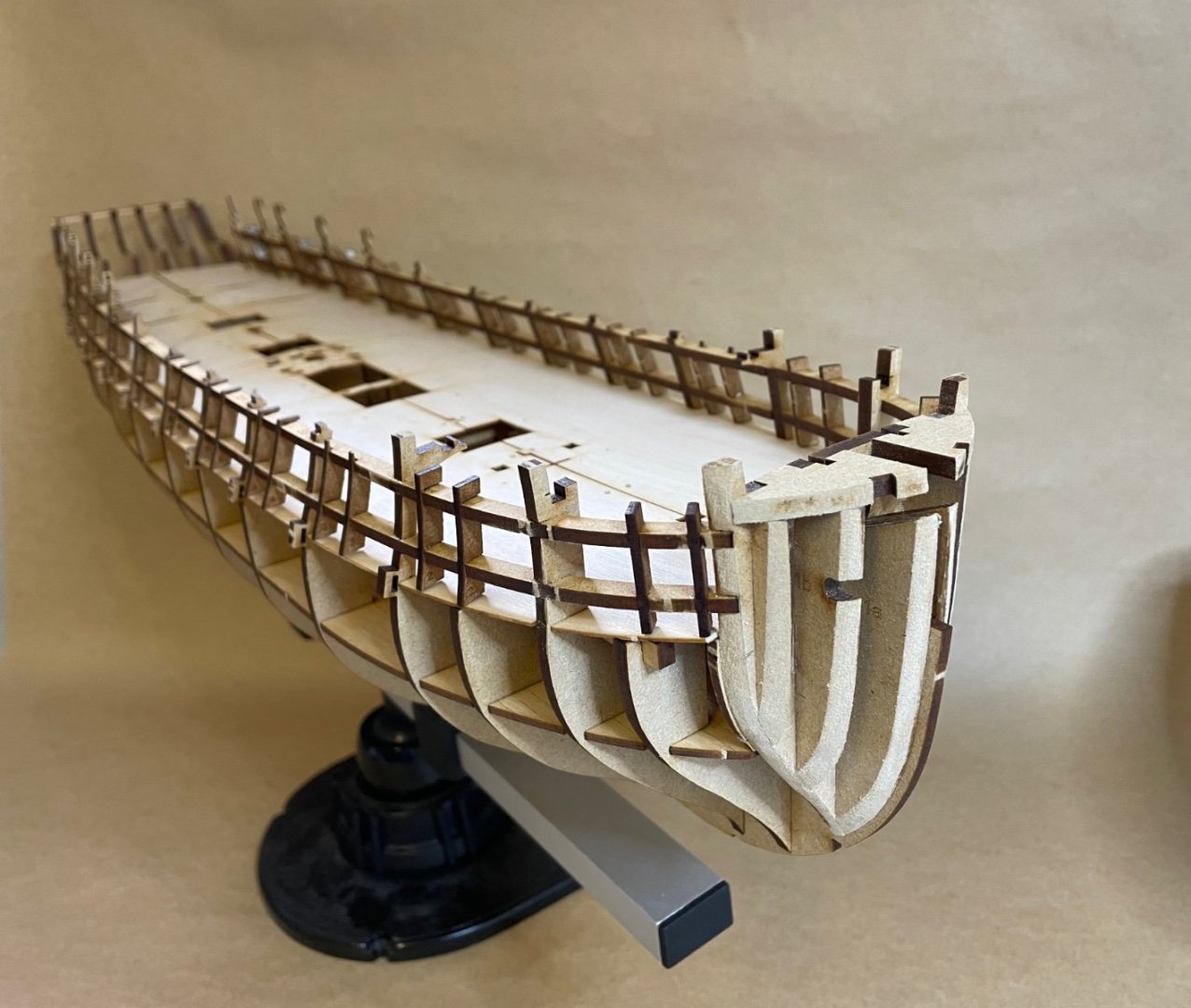

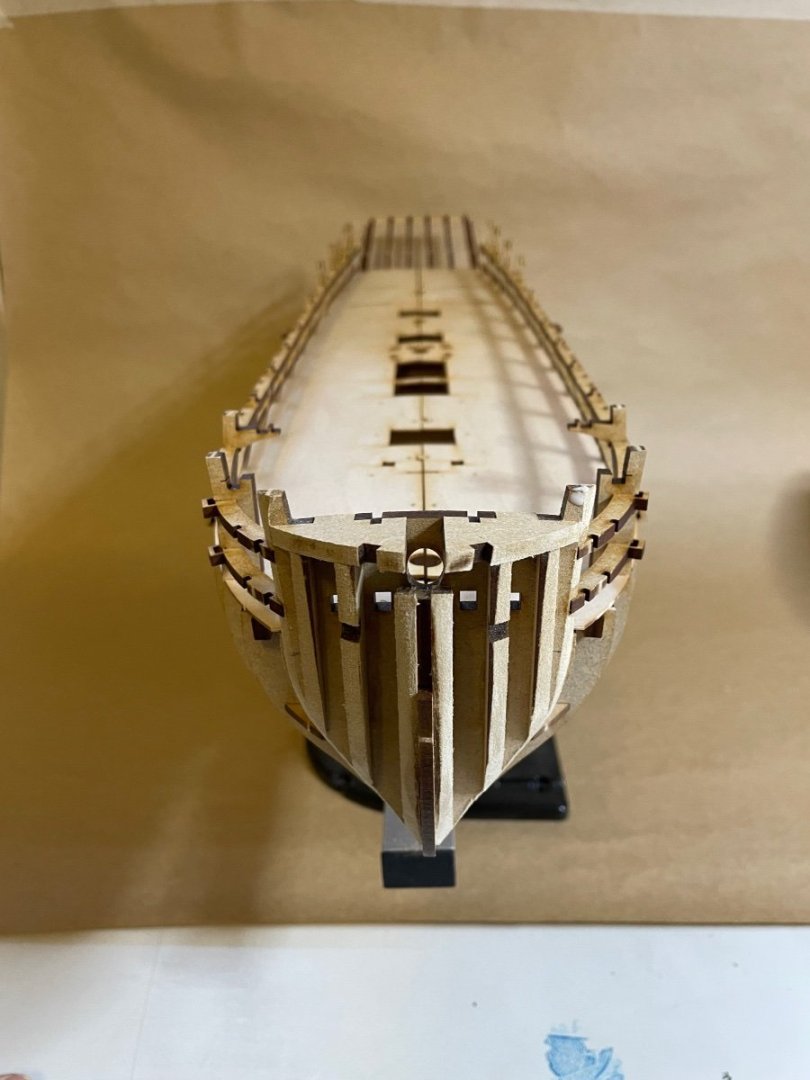

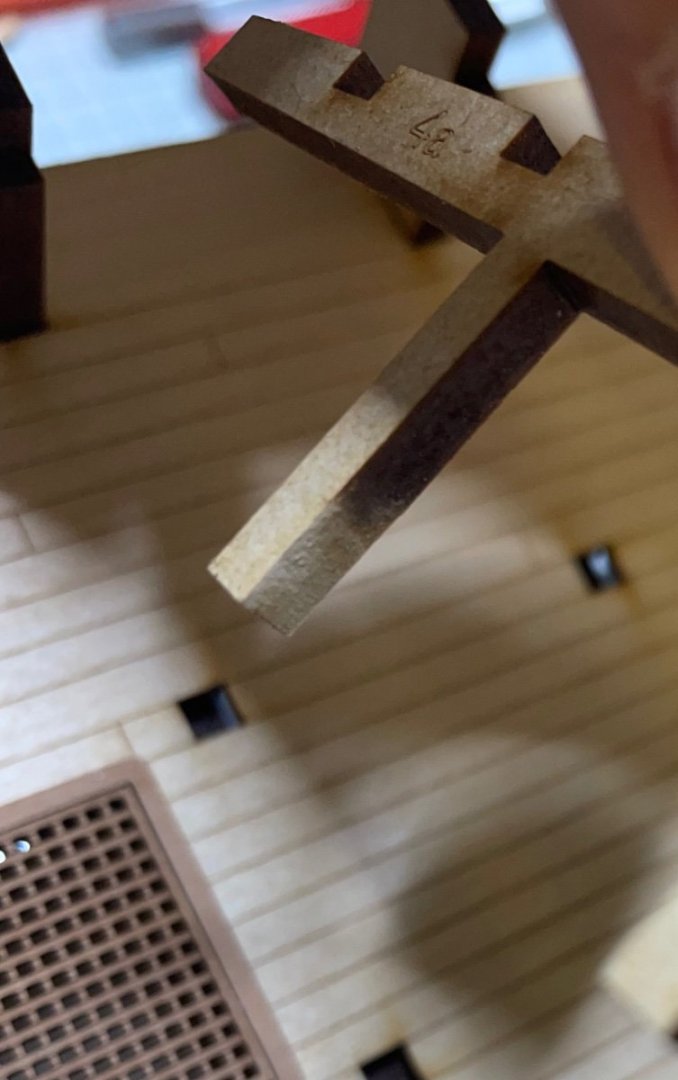

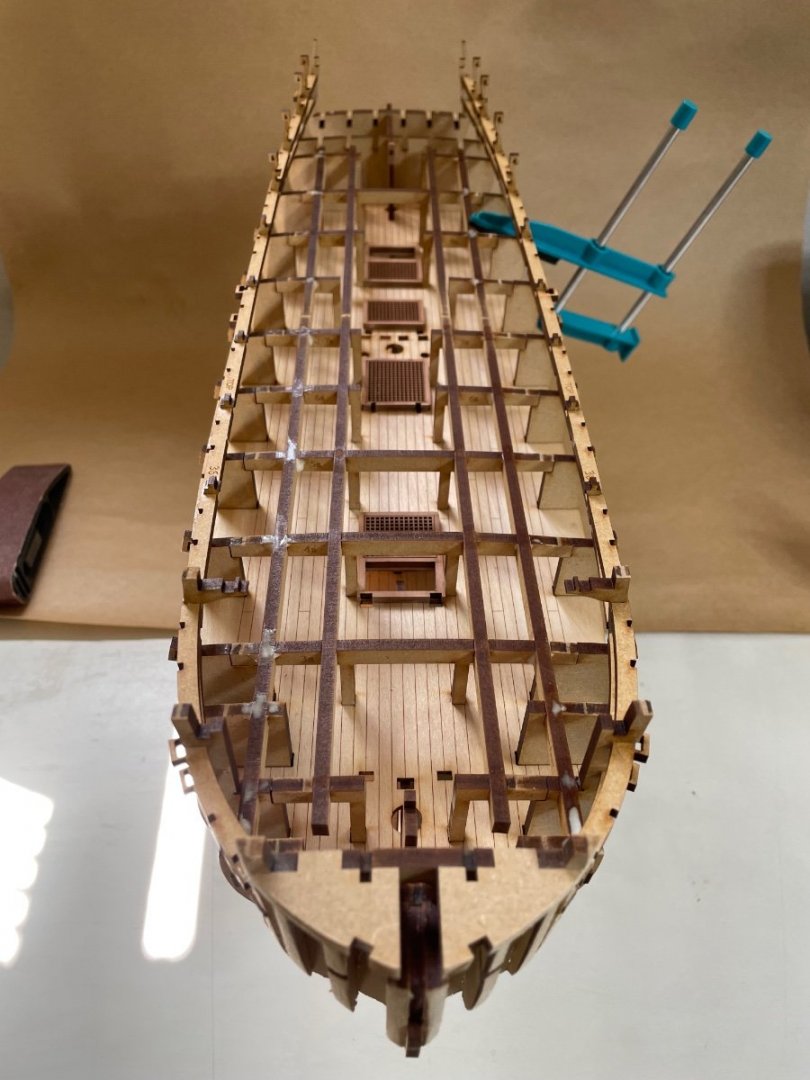

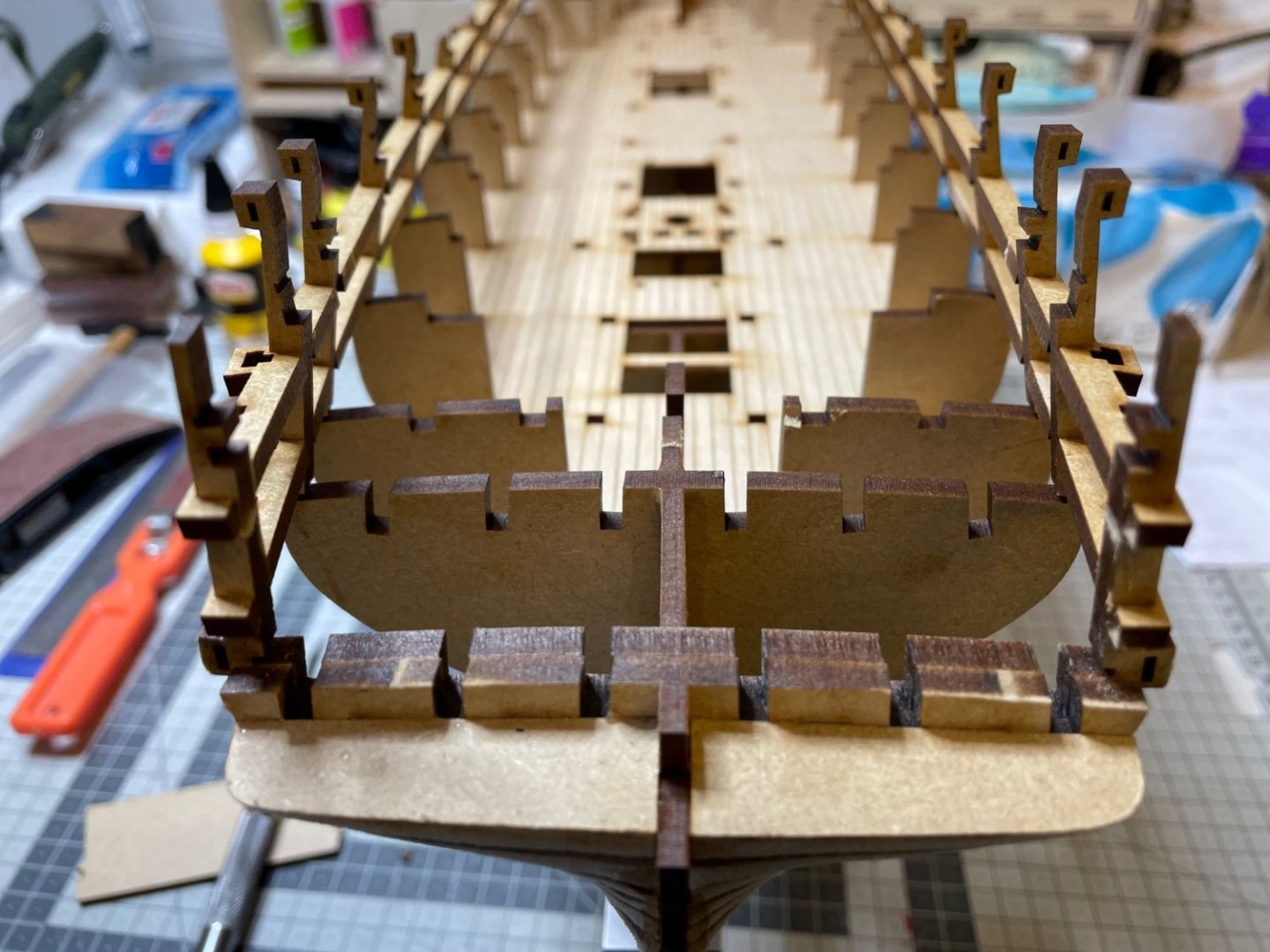

BUILD DAY 11: 2 hours / Total: 20 hours It was a great sunny day today here, I took the opportunity to hull fairing outside in the yard. Before that I built the jigs. These are designed to maintain the width between bulwarks whilst adding external faces and planks etc. First time I have ever seen these in any model I built before and that's another proof of how well this kit has been designed to help the builder minimize errors during construction. 💯 Photos 153-155: Jigs carefully glued and temporarily placed in their positions. You do not glue them to hull. Photos 156-157: Two shots showing bow and stern after sanding. Sanding took about an hour. I tested with a planking strip on the way and paid attention that both sides are symmetrical. I can't say it is perfect, but mainly looking precise enough. I can make small sanding adjustments in individual spots during actual planking if need be. Photo 158: I didn't touch here... yet. I am sure there is a reason the bulkhead extends below that notch. Future steps will show what to do with it.

- 426 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

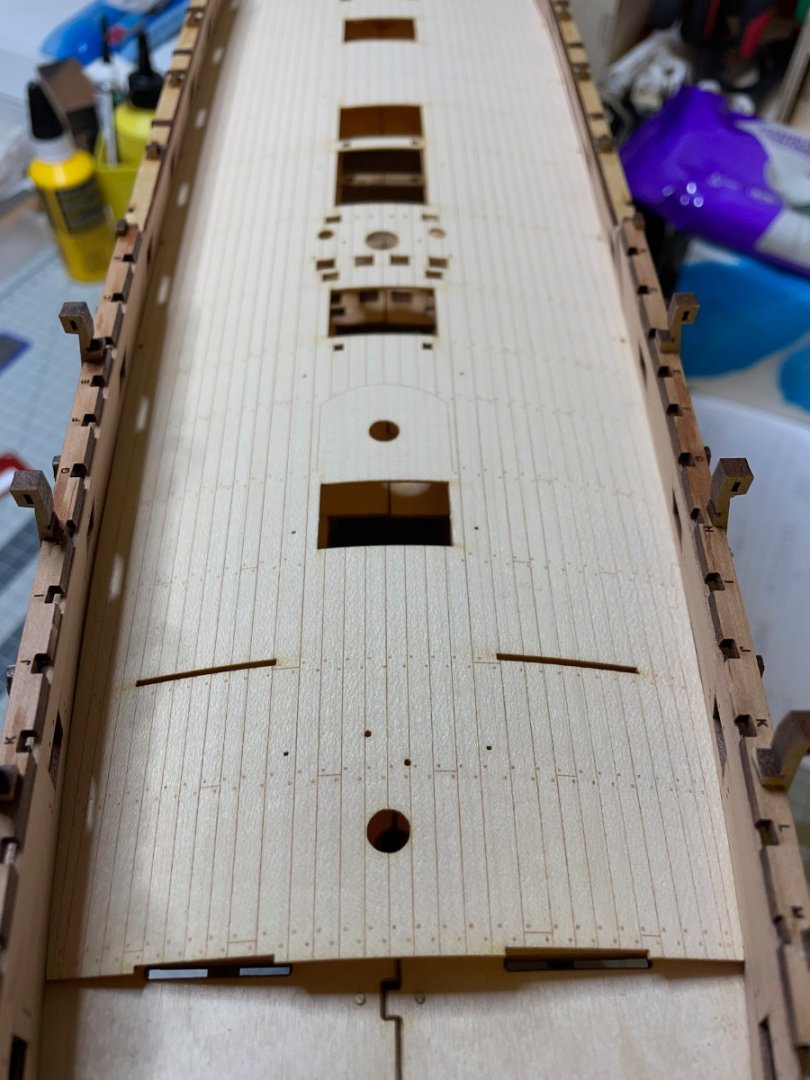

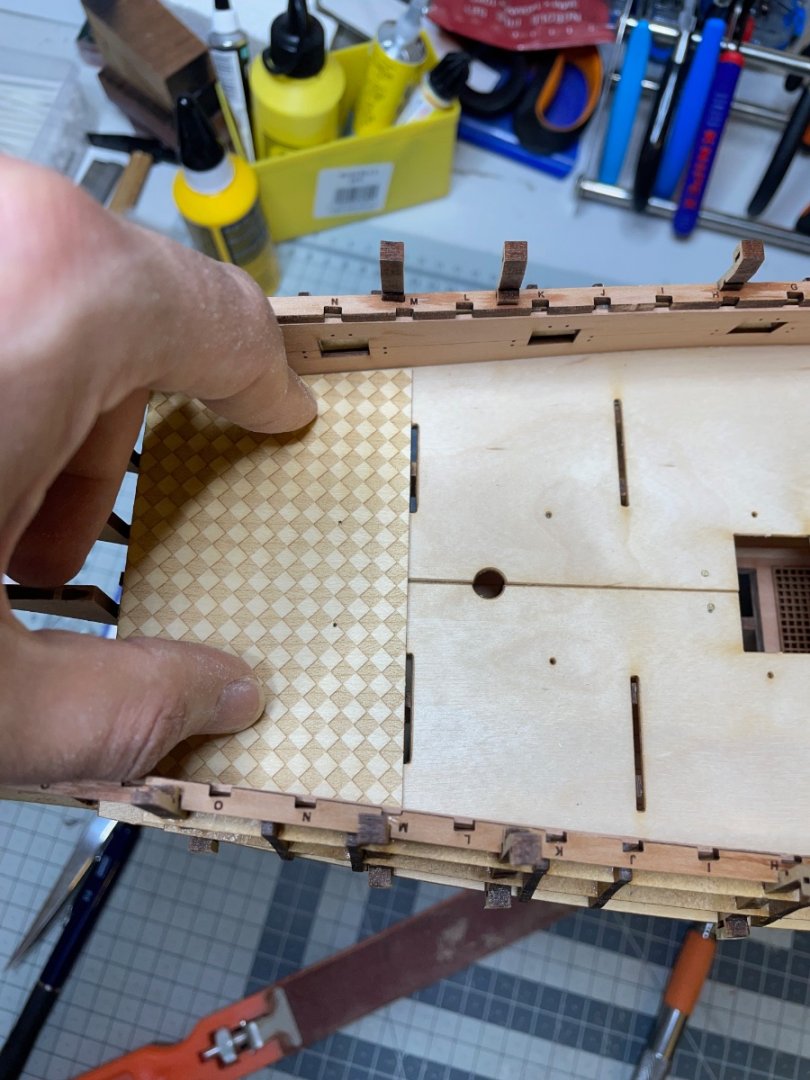

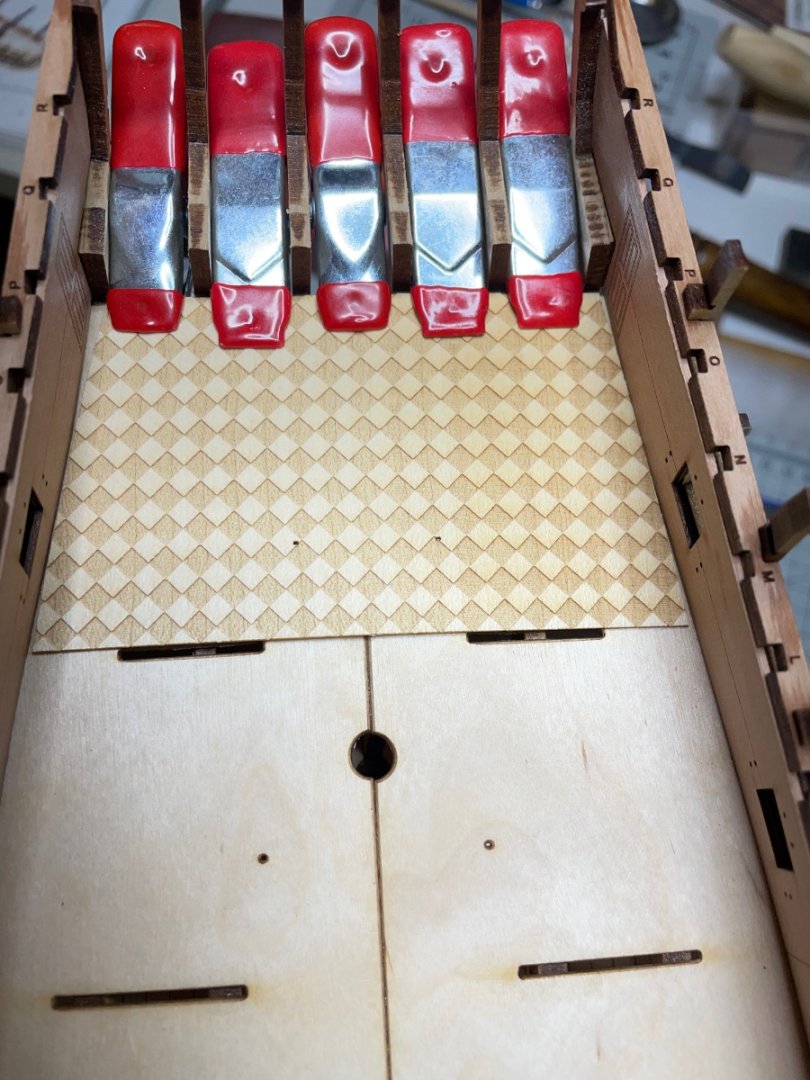

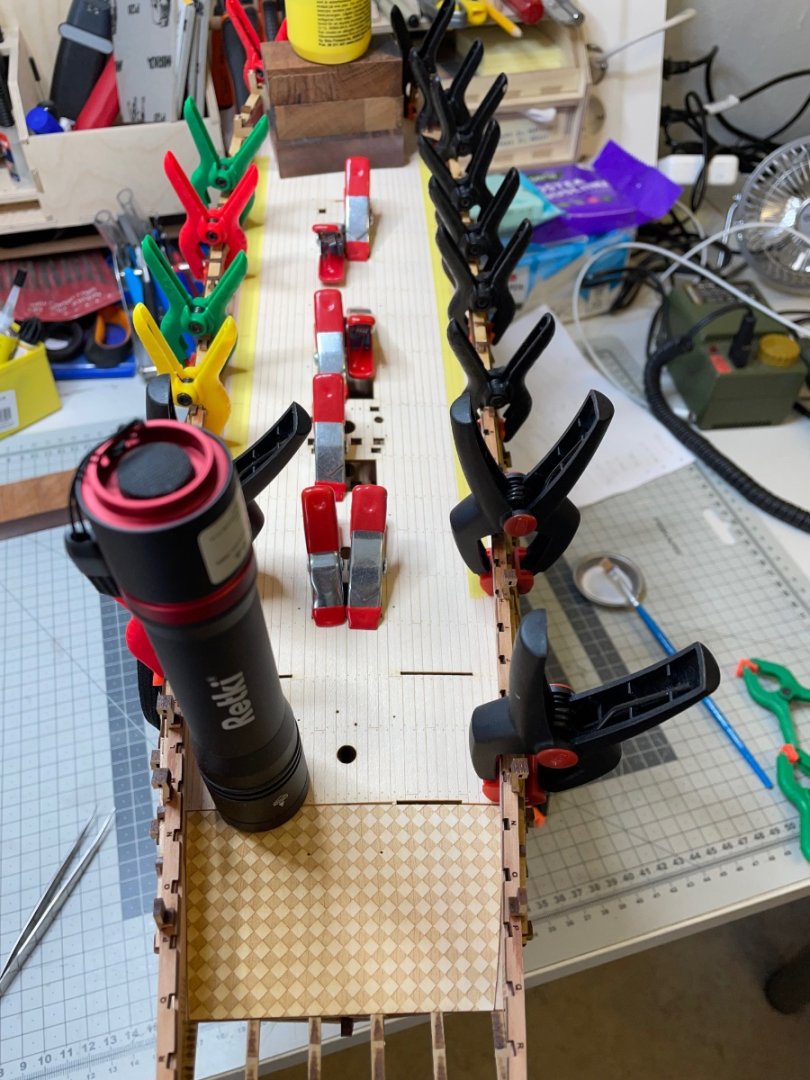

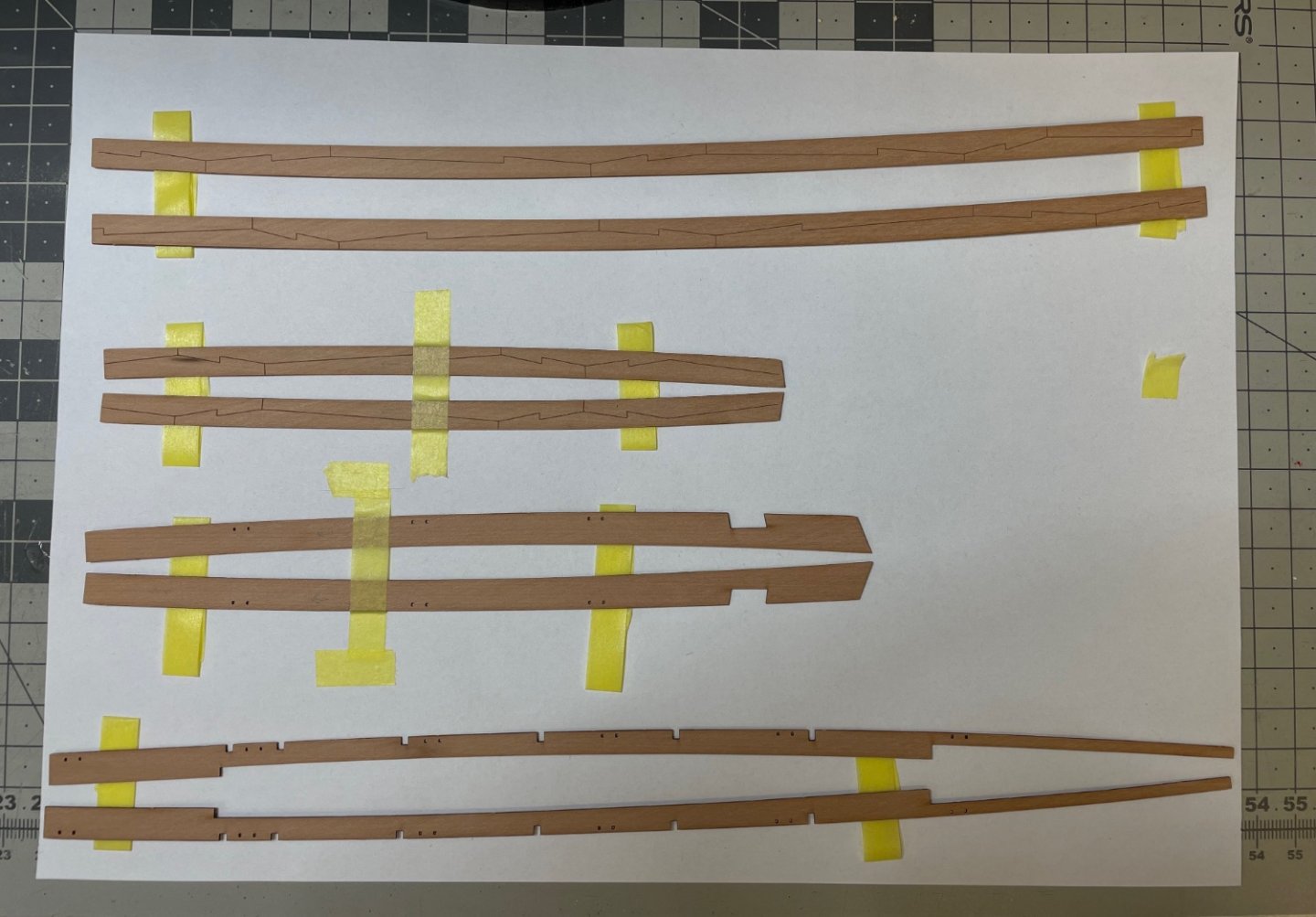

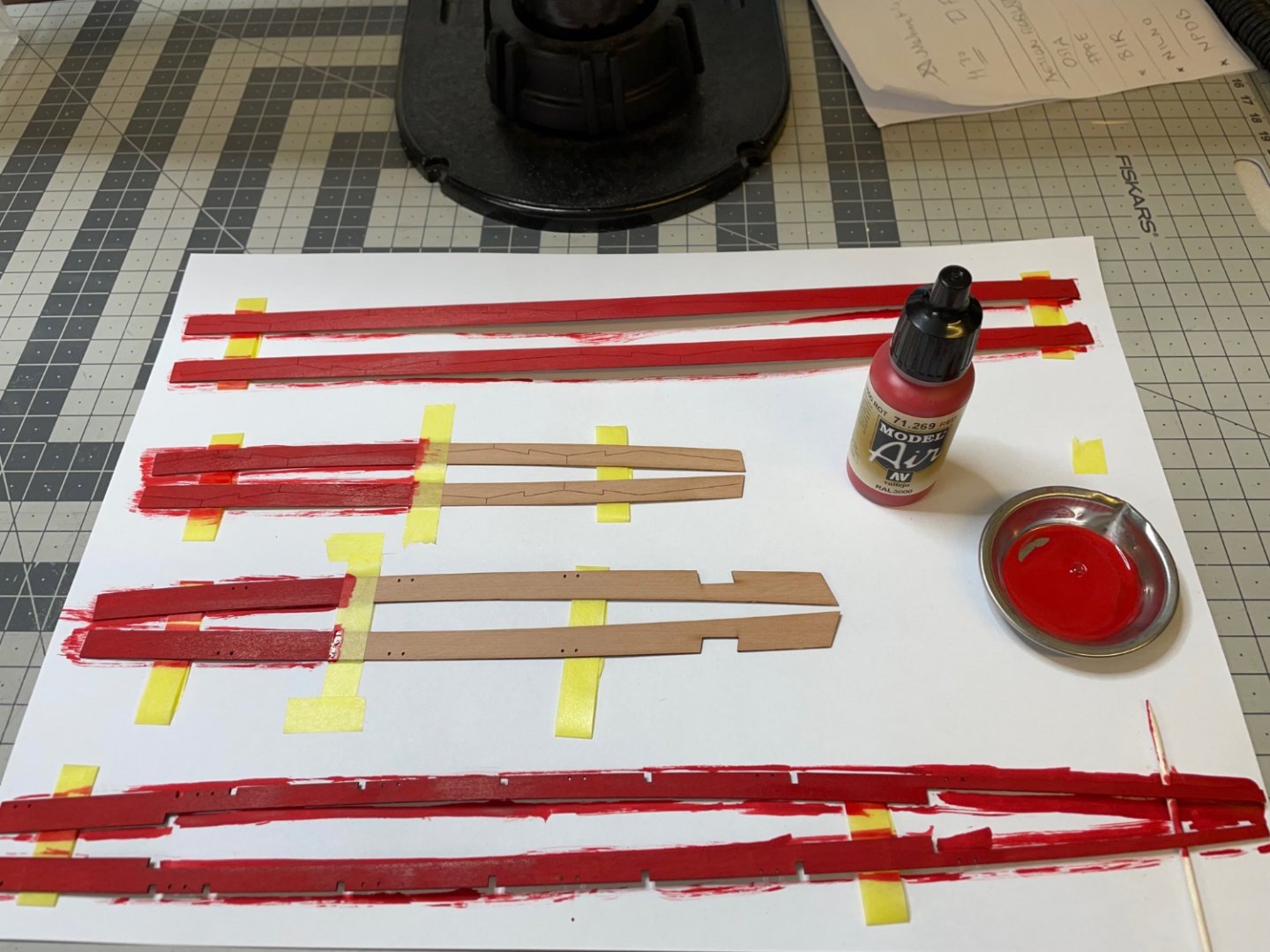

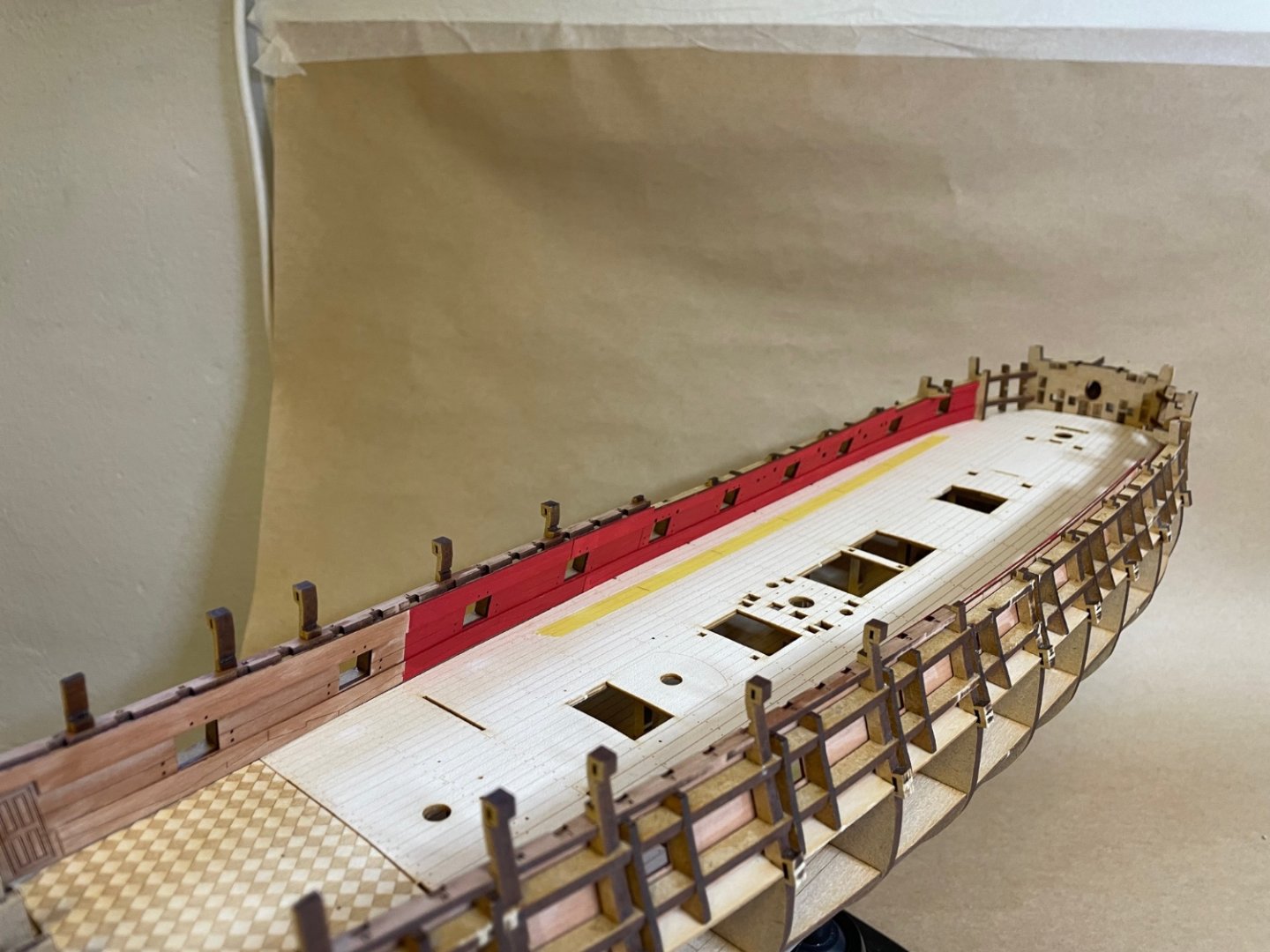

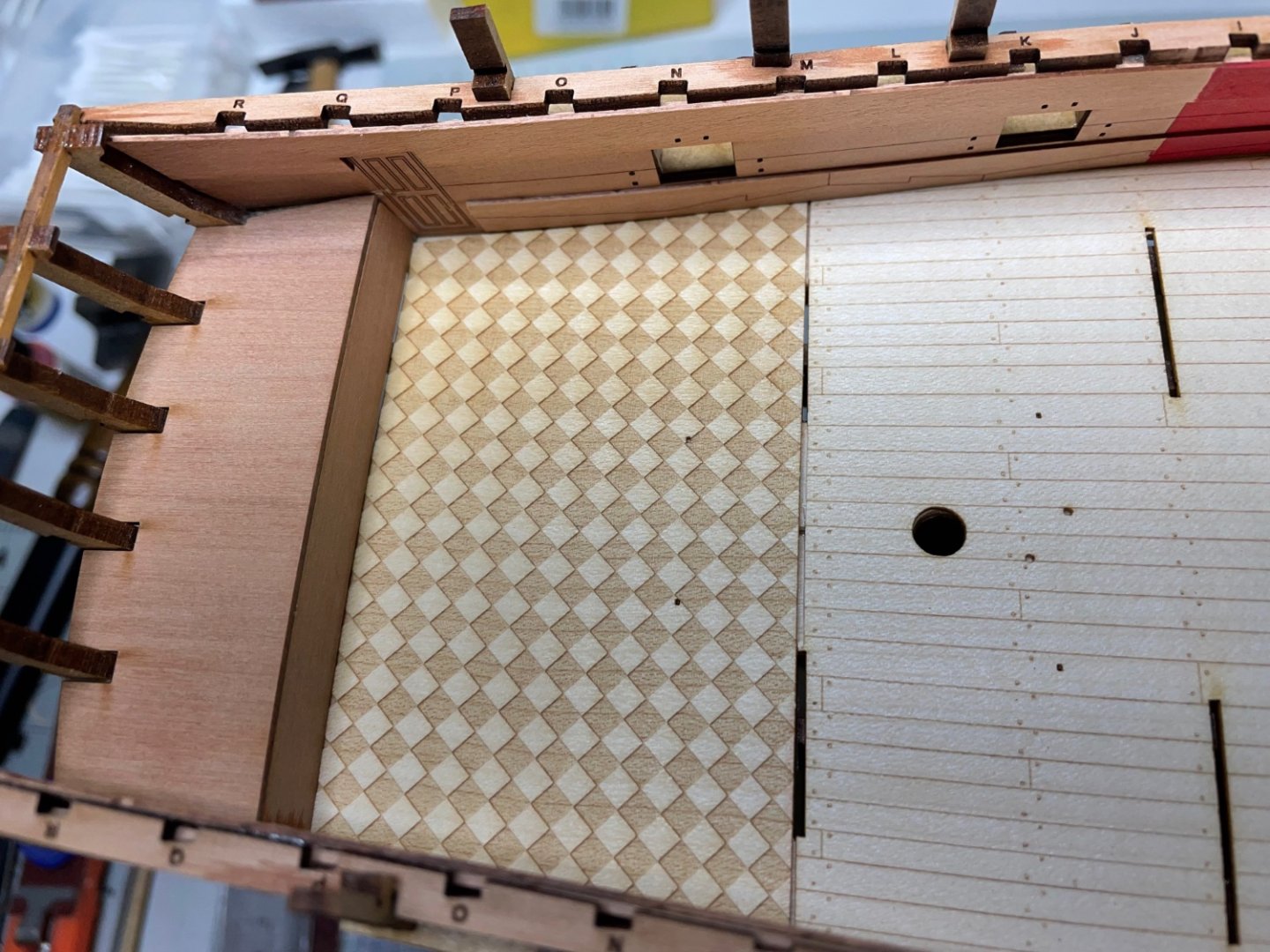

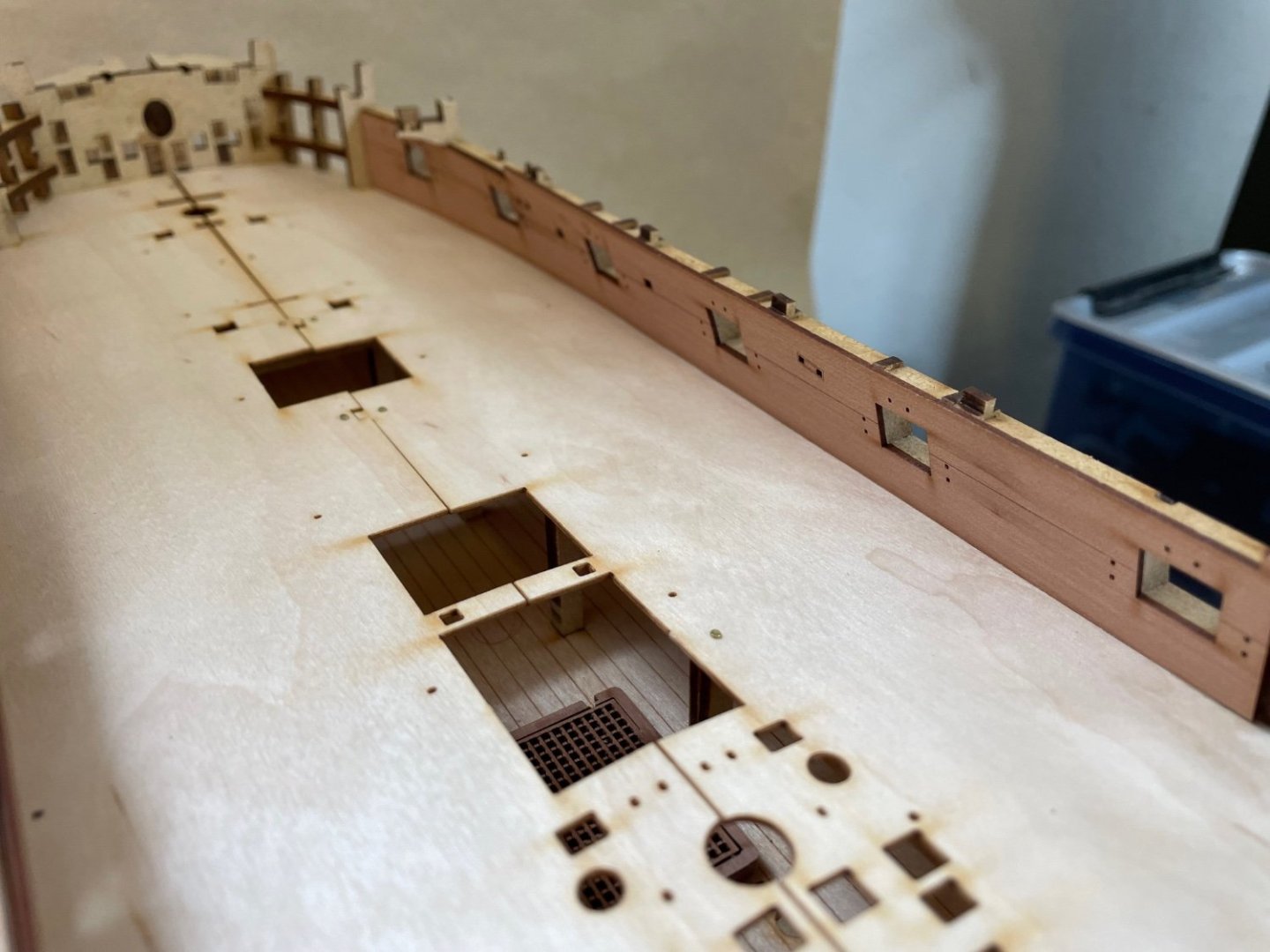

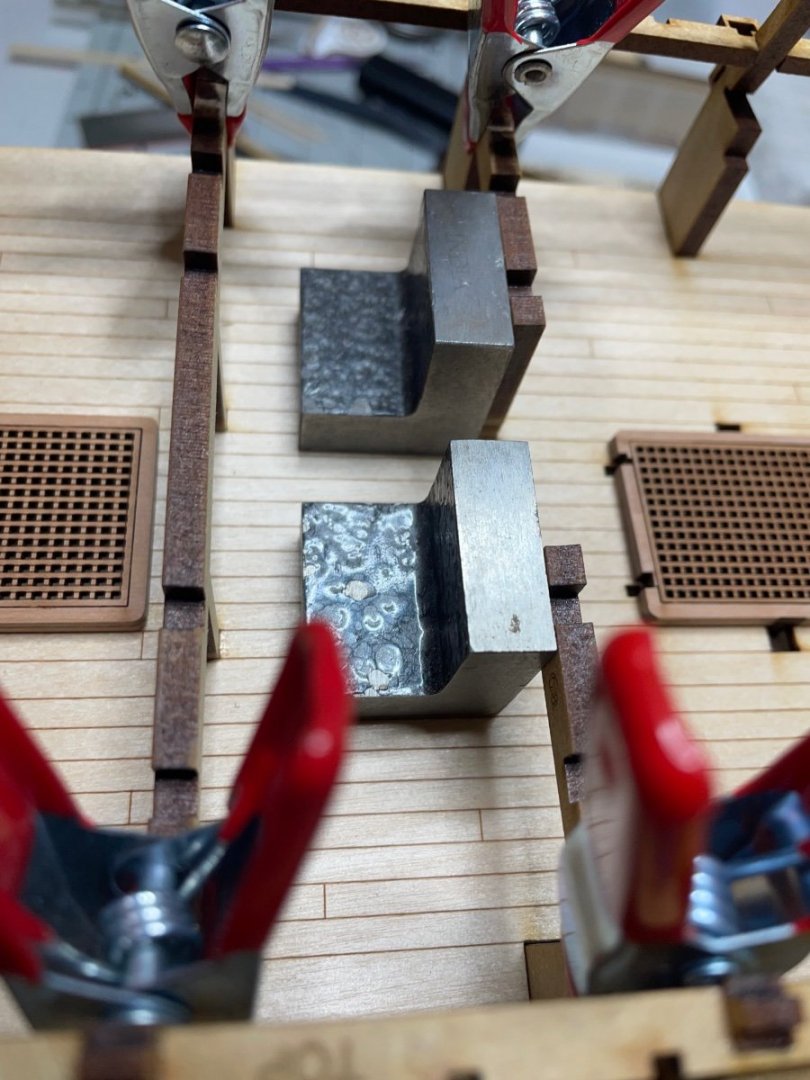

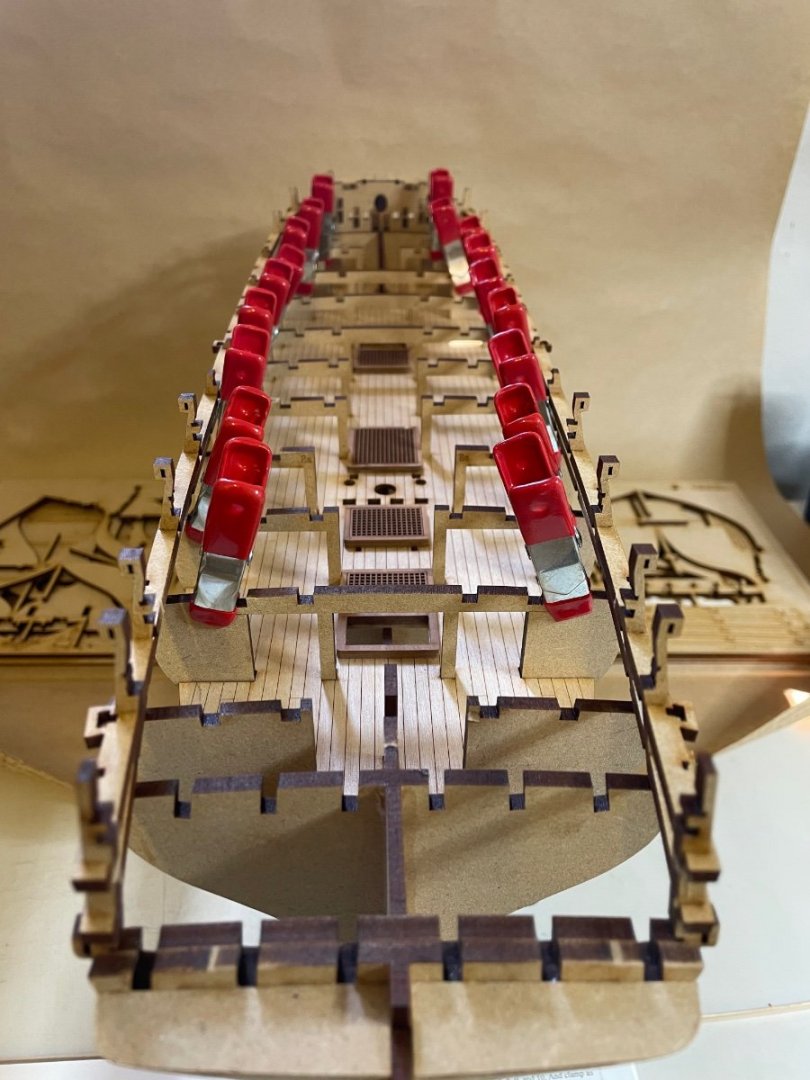

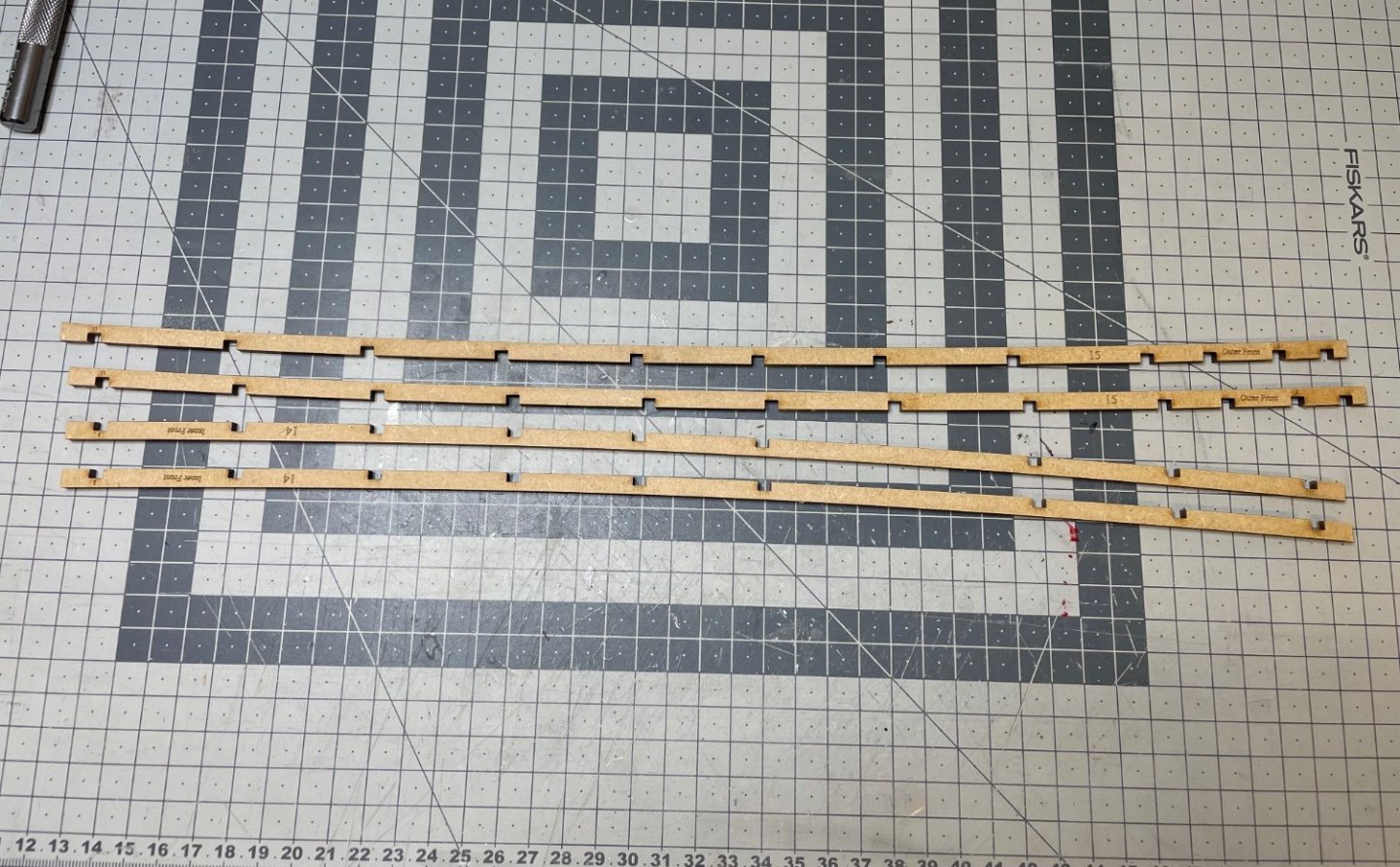

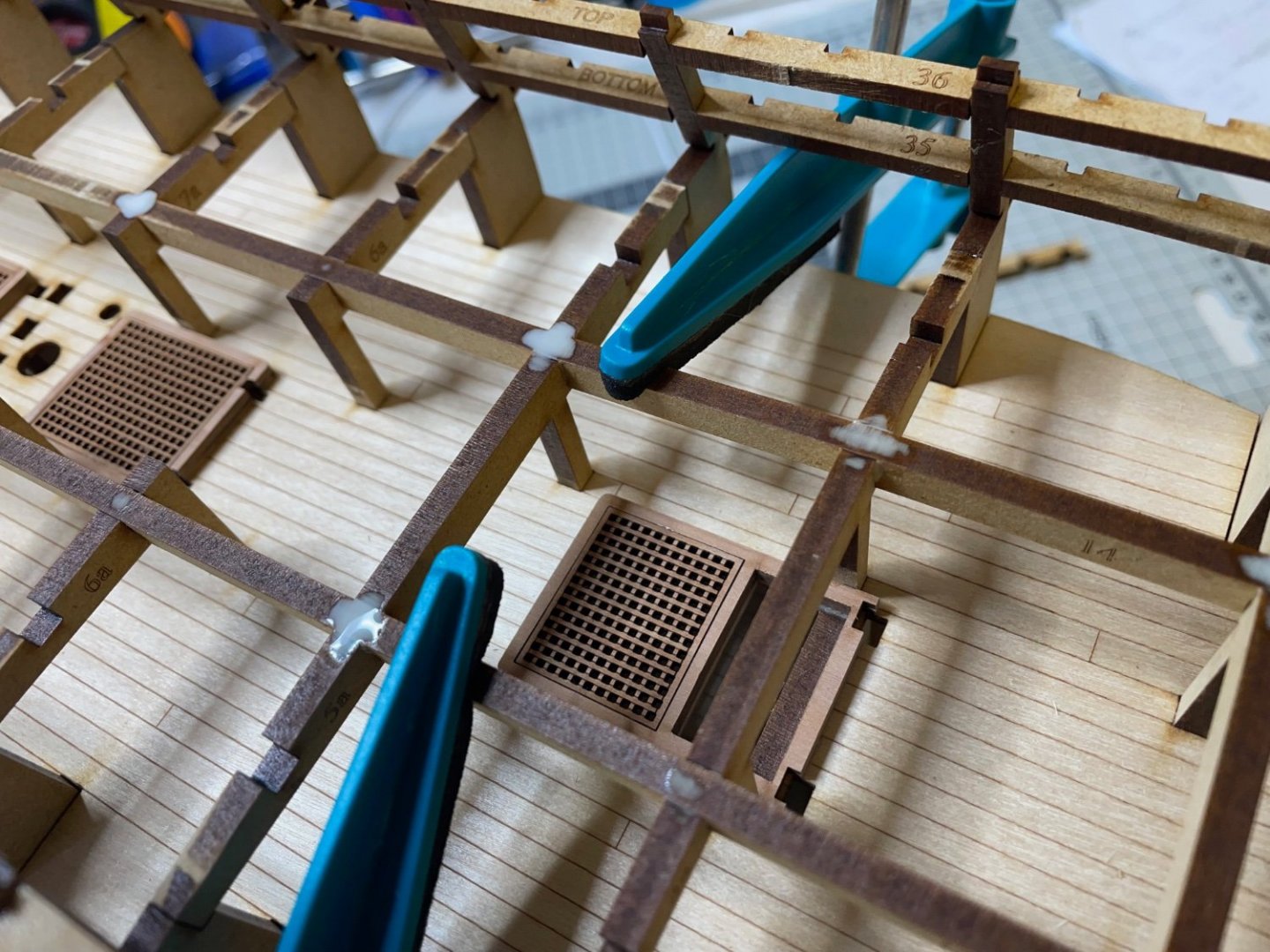

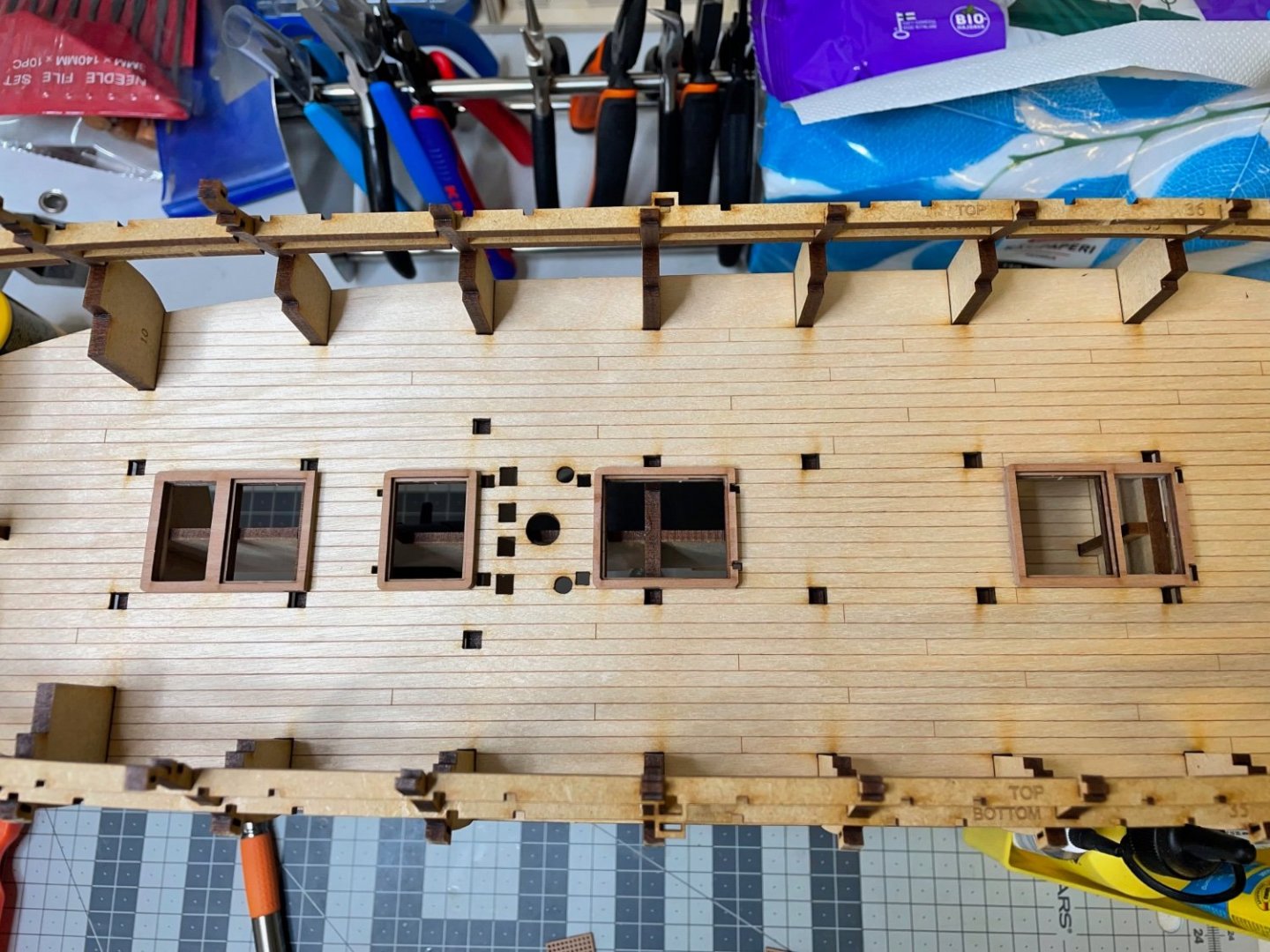

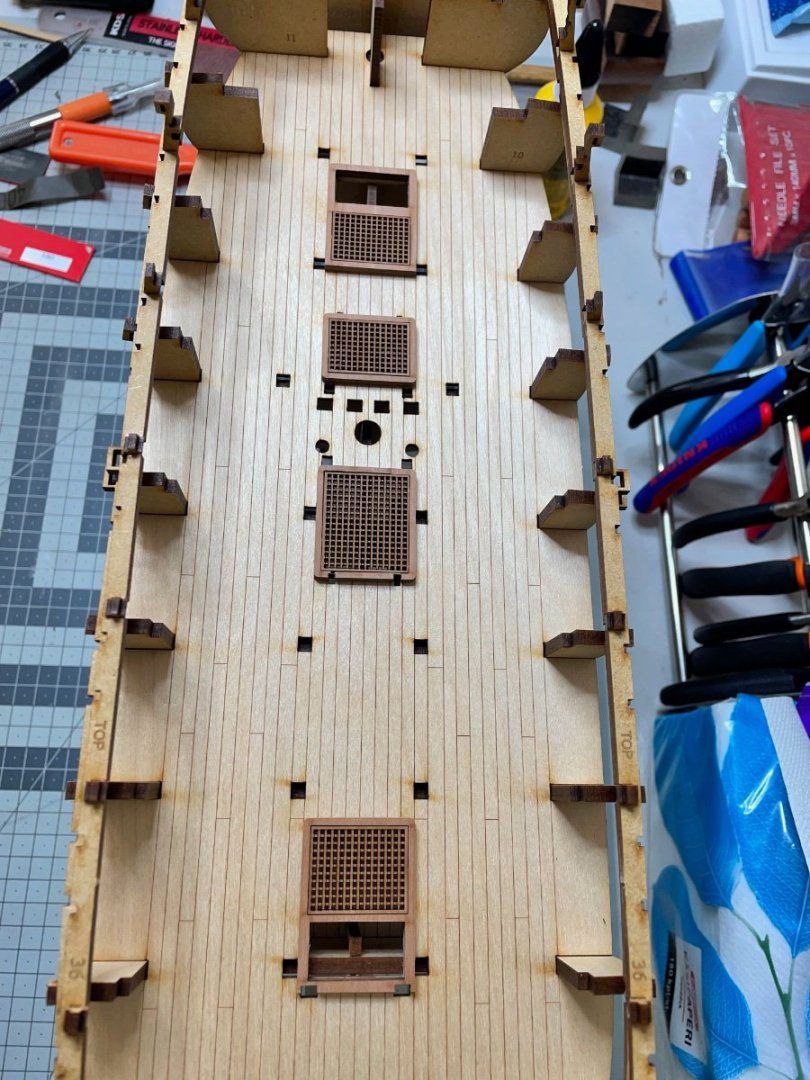

BUILD DAY 10: 4 hours / Total: 18 hours In this slightly longer build day I went through Gun Deck Pattern, Checker Pattern, bulwarks painting, Lower Spirketting, Deck Clamp Patterns, Stern Cabin Bulkhead Pattern and the Stern Cabin Seat Pattern installations. Photo 141: As it is, Gun Deck Pattern forms a bow on my model and therefore needs trimming from the edges in order to fit firmly. This is also instructed so in the manual as an expected situation. Photo 142: After several rounds of sanding and trimming I finally fit it in place. But you see the small sequence of holes close to the edge are almost already at the edge. It makes me wonder if I didn't install the Inner Bulwark Gundeck Patterns with full contact to the bulkheads, thereby narrowing the width. But they look alright. Though I don't worry too much, as the deviation is only about 1mm at worst. If I guess right those holes will probably be used for rigging. I marked across their locations on a masking tape as seen in the photo, in case I need to know later. Photo 143: Checker Pattern dry fit in place after slight sanding. Photo 144: Marked the red paint border. Photo 145: Checker Pattern glued. Photo 146: Gun Deck Pattern. I brushed diluted glue to entire deck surface below and then placed this part on top of the deck, supported with clamps and whatever small weight I find on my table. Photos 147-148: Lower Spirkettings and Deck Clamp Patterns. Painted. By the way I tried Vallejo Model Color Flat Red (70.957) and Vallejo Model Air Red 71.269 on a scrap pearwood and I decided to go with 71.269. It looked better on pearwood to my eye than the flat red. Photos 149-150: Current status. Photos 151-152: Stern Cabin Bulkhead Pattern (197) and the Stern Cabin Seat Pattern (198) glued in position. That's all for today. Thanks for watching!

- 426 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

Definitely too small error to worry about and so far my experience with the manual's visual and explanatory qualities as well as guidance to the builder have been great. 💯 In the beginning of my log I wrote as the first impression that this manual ranks all time 2nd best after Amati Orient Express manual but as I am building it, it is likely that my ranking will change at the end. 😃

- 426 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

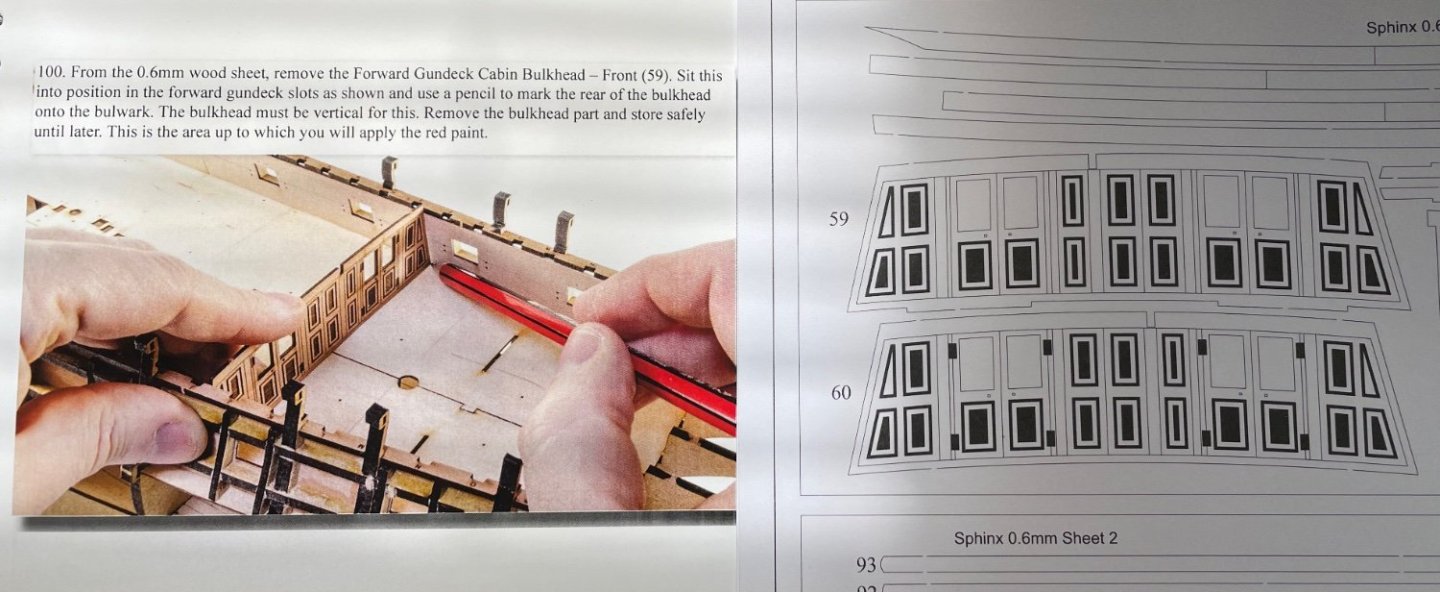

By the way here in the text it reads part #59 for marking the paint border but in the photo it is clearly the part #60 (which actually makes more sense, as that's the backward facing surface of the Forward Gundeck Cabin wall) A small error to correct in the online manual.

- 426 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

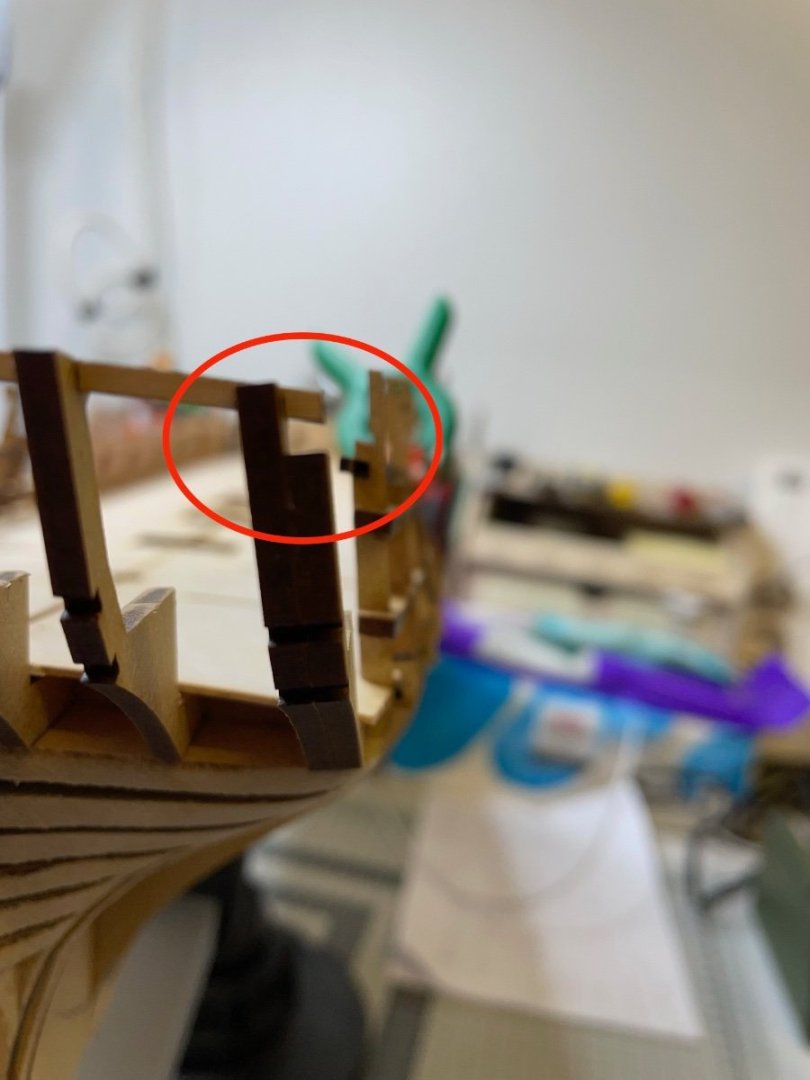

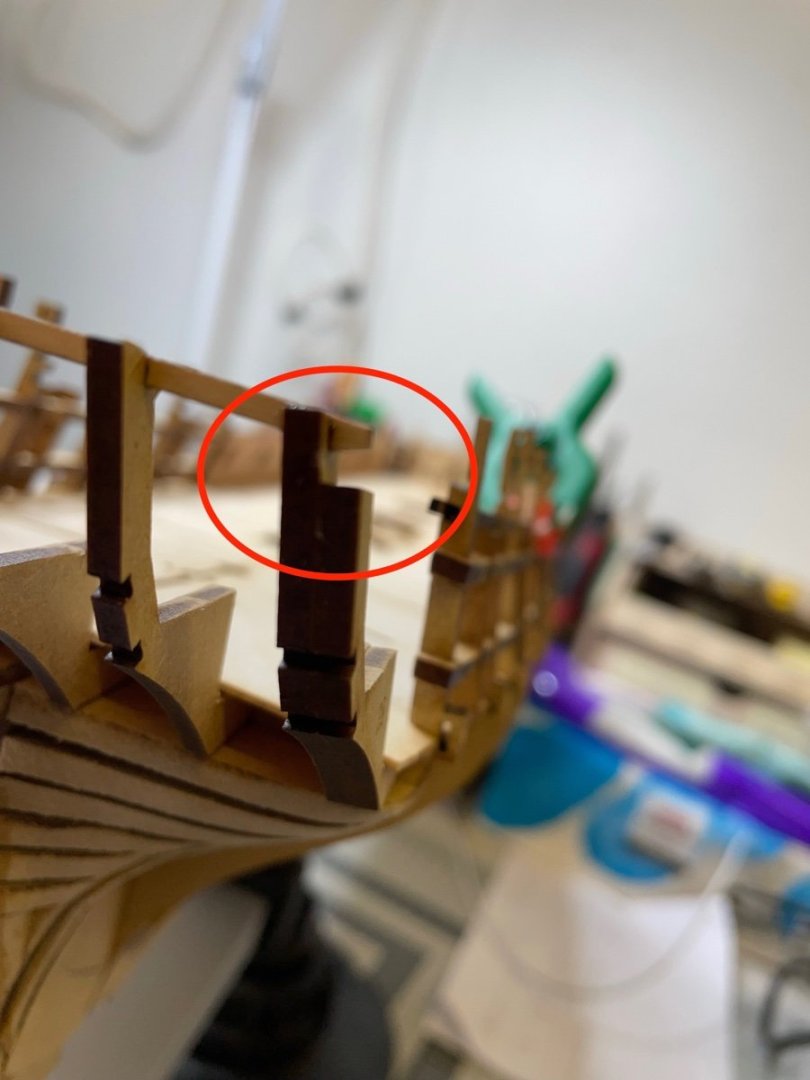

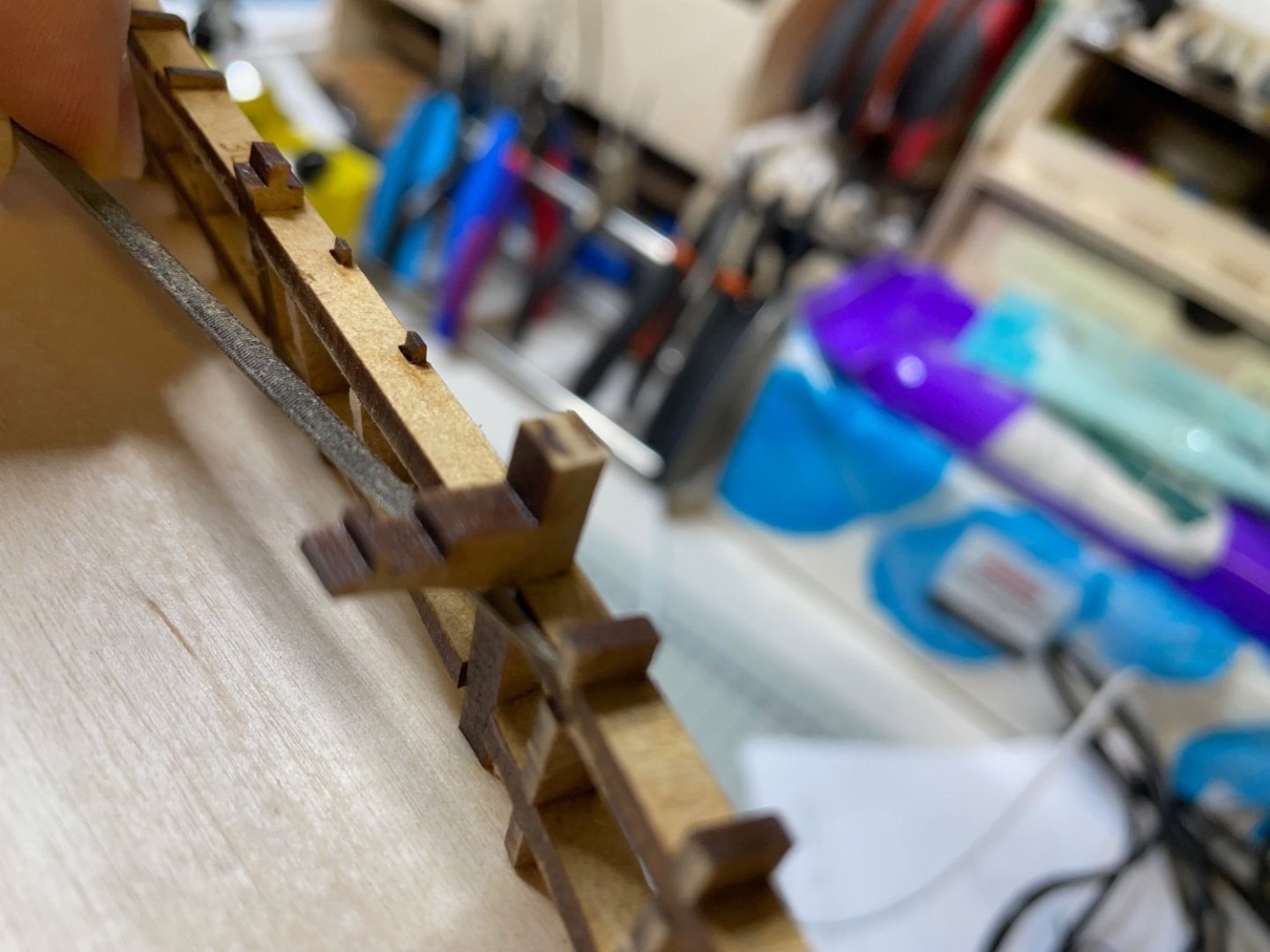

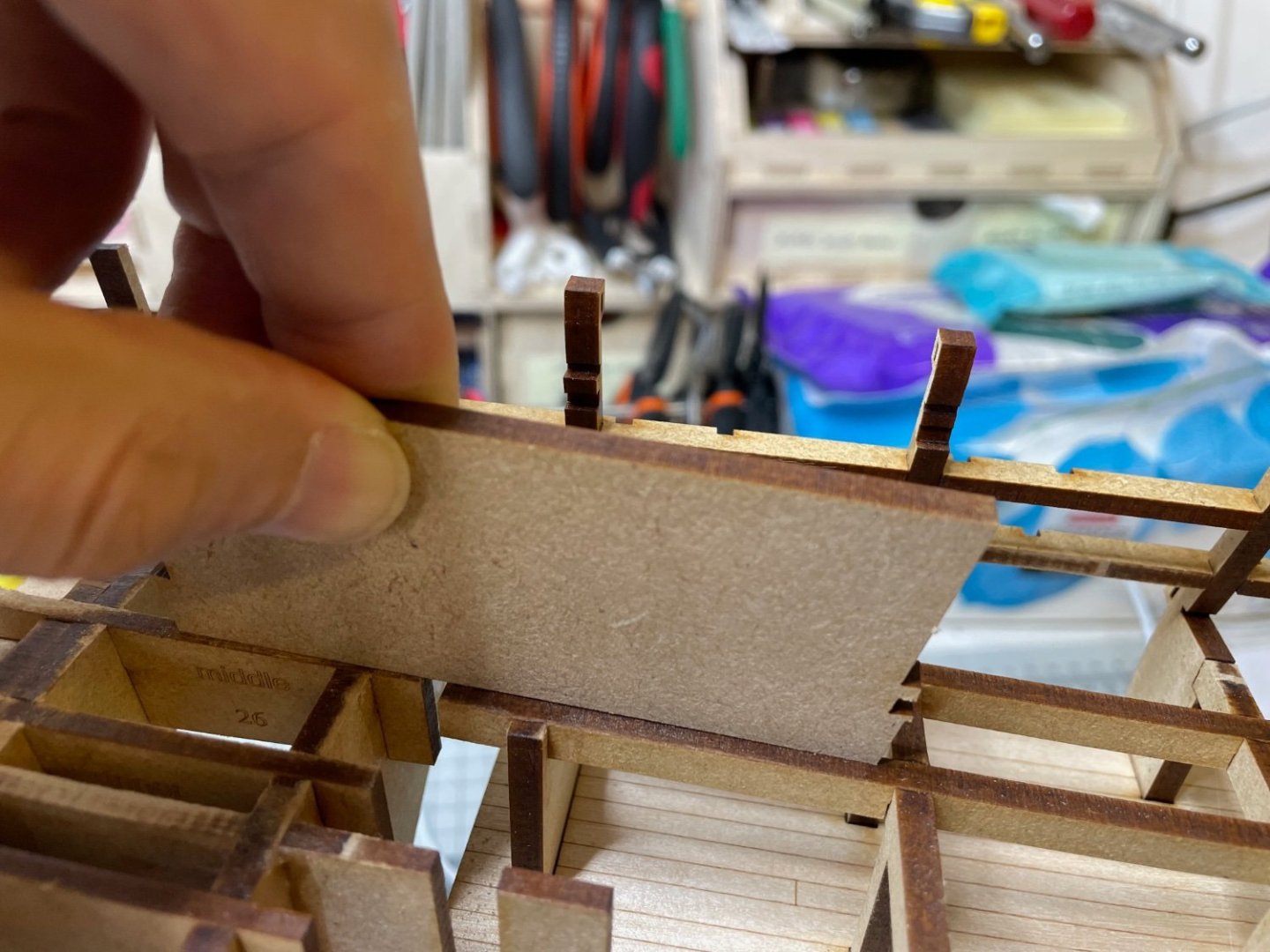

BUILD DAY 9: 1,5 hour / Total: 14 hours Some details installing the Quarterdeck Beam Spacing Patterns. Photos 136-138: Their rear ends should slot into the timbers at the top of the stern. This needs a slight sanding to form a square opening at the end. The last photo is actually from the other side than the first two. Photo 139: Both Quarterdeck Beam Spacing Patterns installed. Photo 140: Next, Rear Inner Bulwark Gundeck Patterns. Installed the same way as the front ones, nothing special. Had to do small corrections using sanding block. In the photo the one on the right is ready and the one on the left is waiting for the glue to dry.

- 426 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

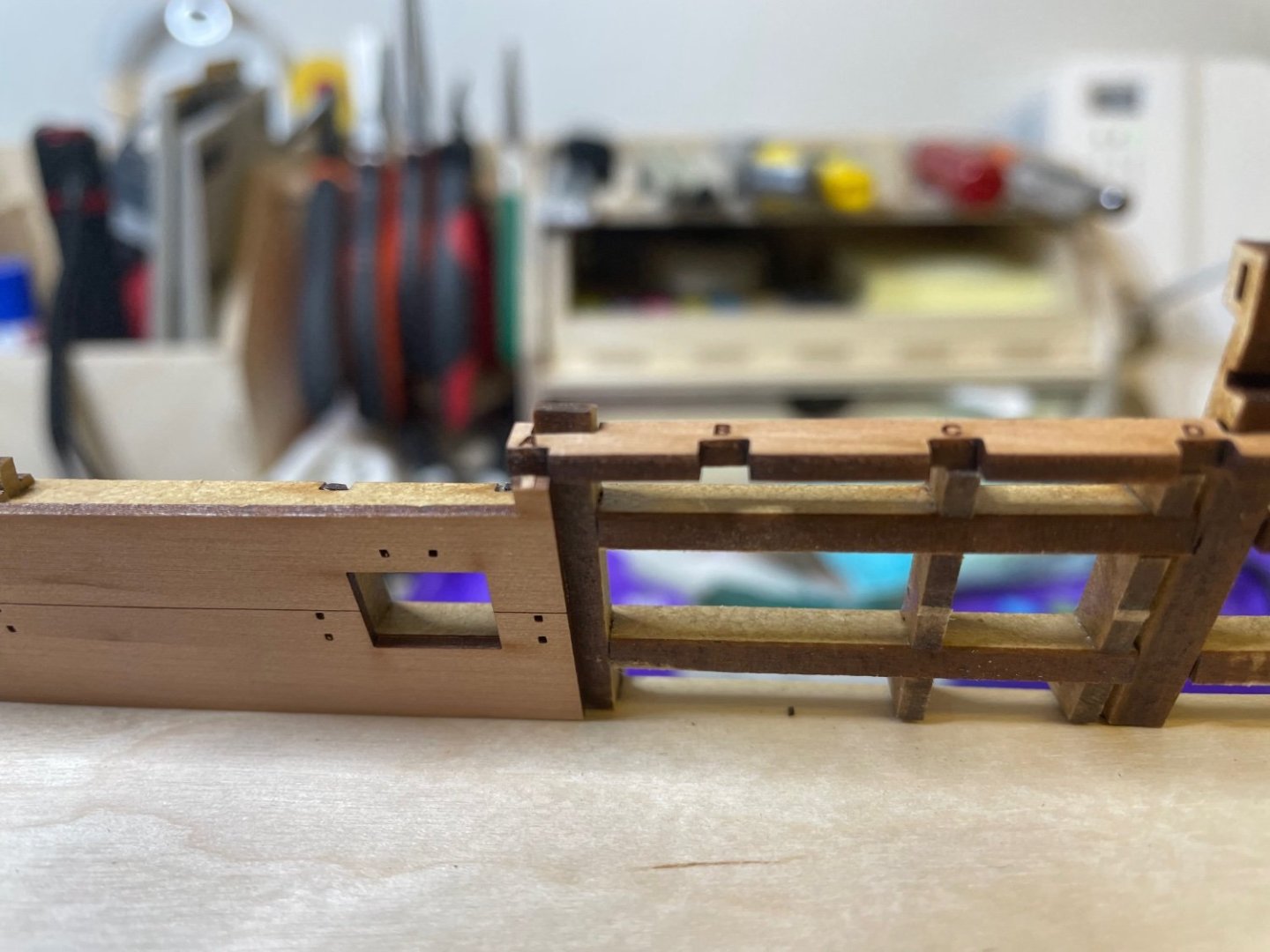

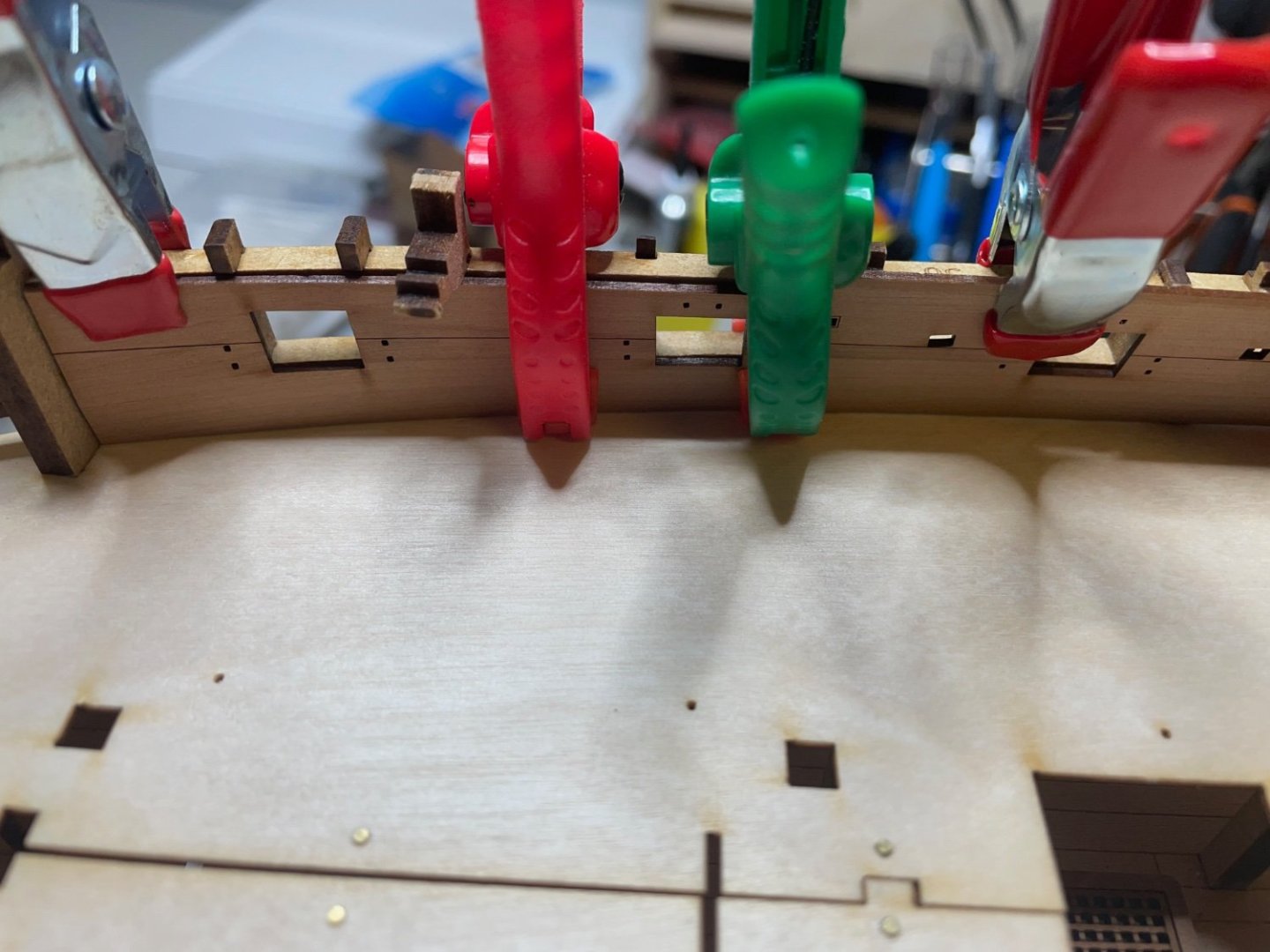

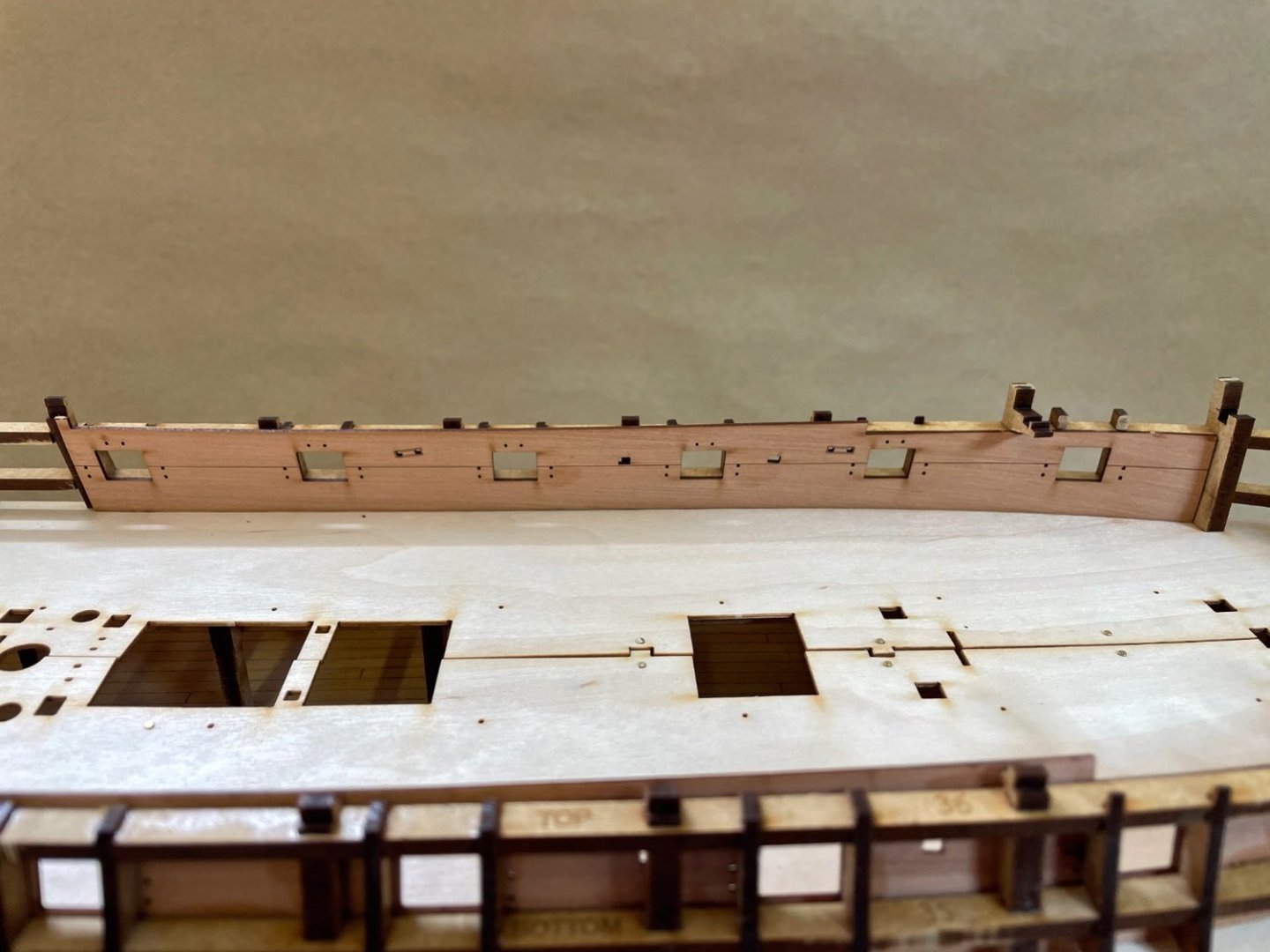

Time to glue the Inner Gundeck Bulwark Patterns, made from pearwood with nice laser details. Photo 128: I used my Proxxon mini sander to sand inside the frames where the bulwark patterns will fit. Photo 129: Here I dry-fit the Quarterdeck Beam Spacing Pattern (the part with A-B-C.. marks on the right) temporarily to take a good reference to fit the Gundeck Bulwark Pattern precisely. Photos 130-133: Photos showing the progress of the front Gundeck Bulwark Patterns. I brushed diluted glue here as well. I had to scrape below this bulkhead ear a little from under with a narrow file. This was pretty much the only correction I had to make. Photos 134-135: I am also glad that they sit perfectly in contact with the deck pattern, with no gaps.

- 426 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

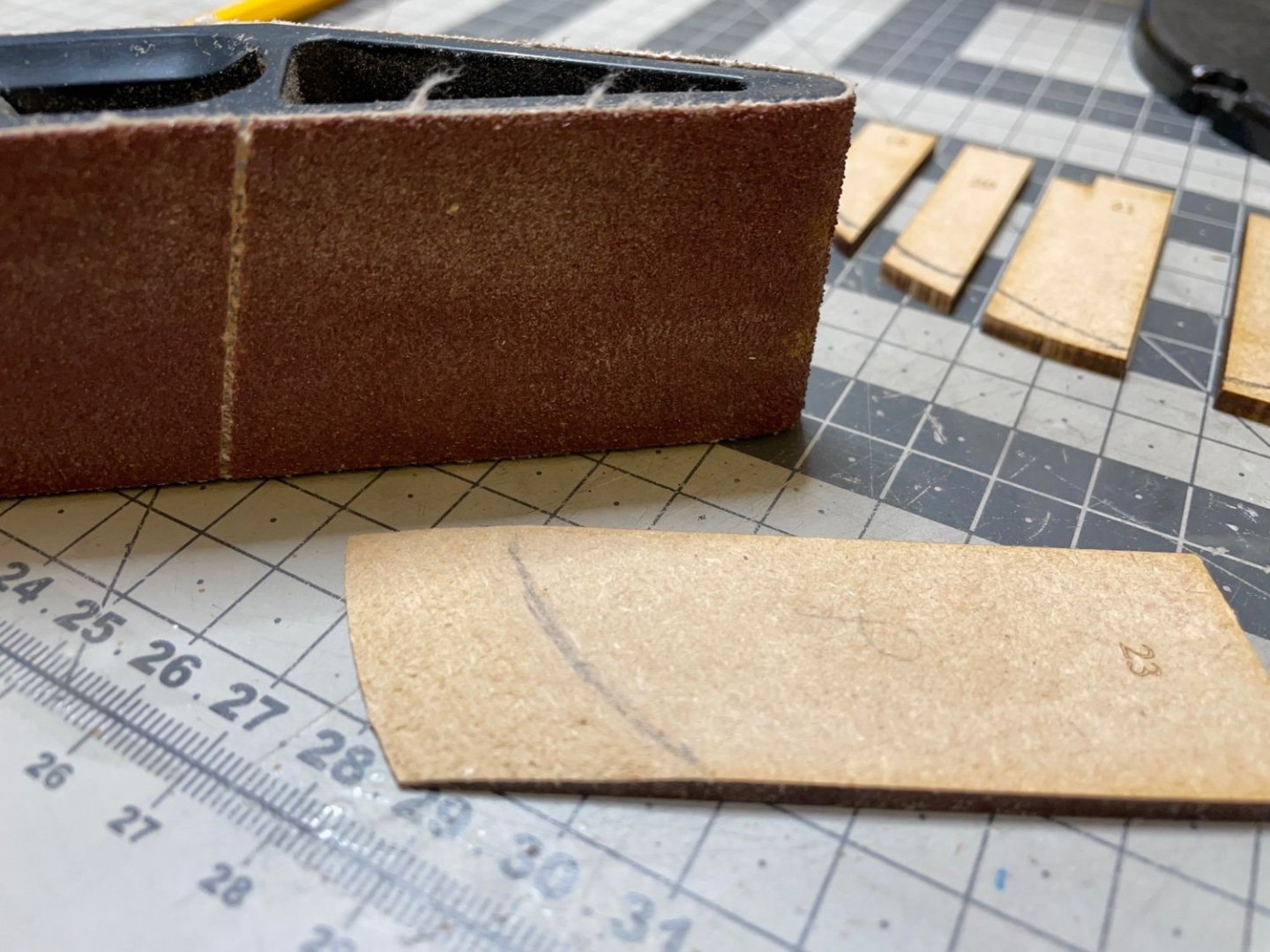

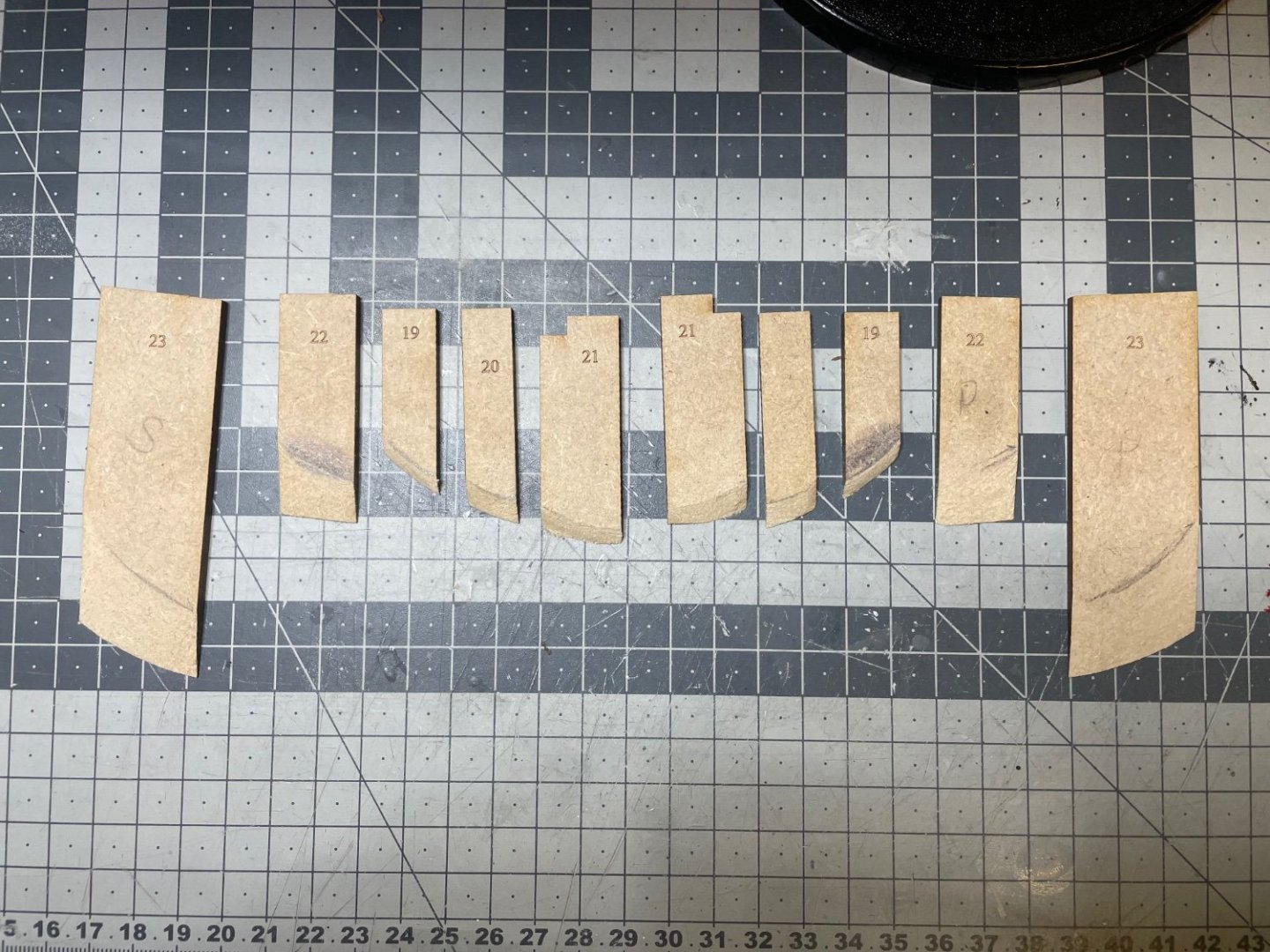

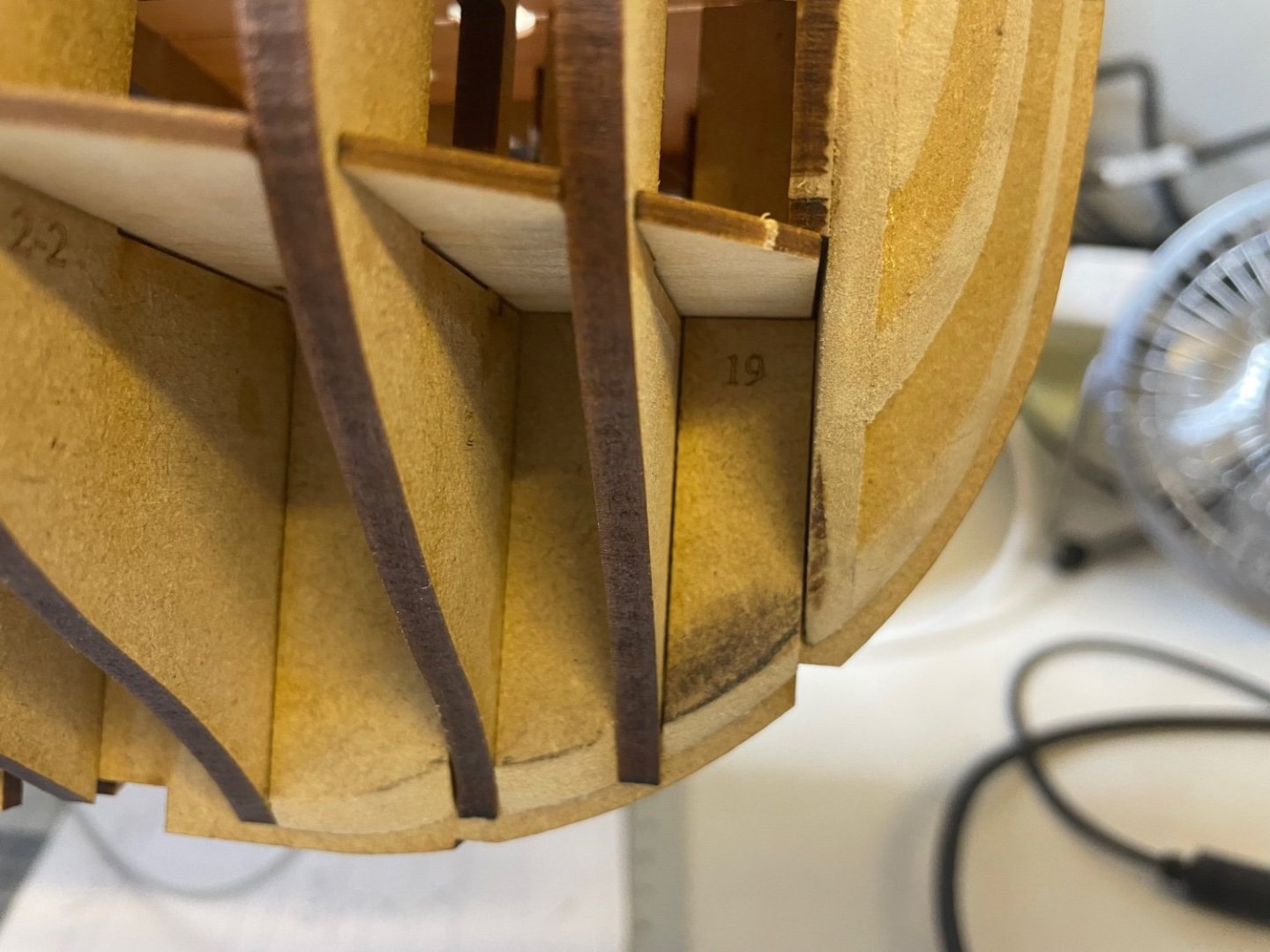

Photo 123: I used my coarse sanding belt (in the photo) for sanding them. Photos 124-127: Bow and Stern Planking Patterns are sanded and glued in their places. I used white wood glue here.

- 426 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

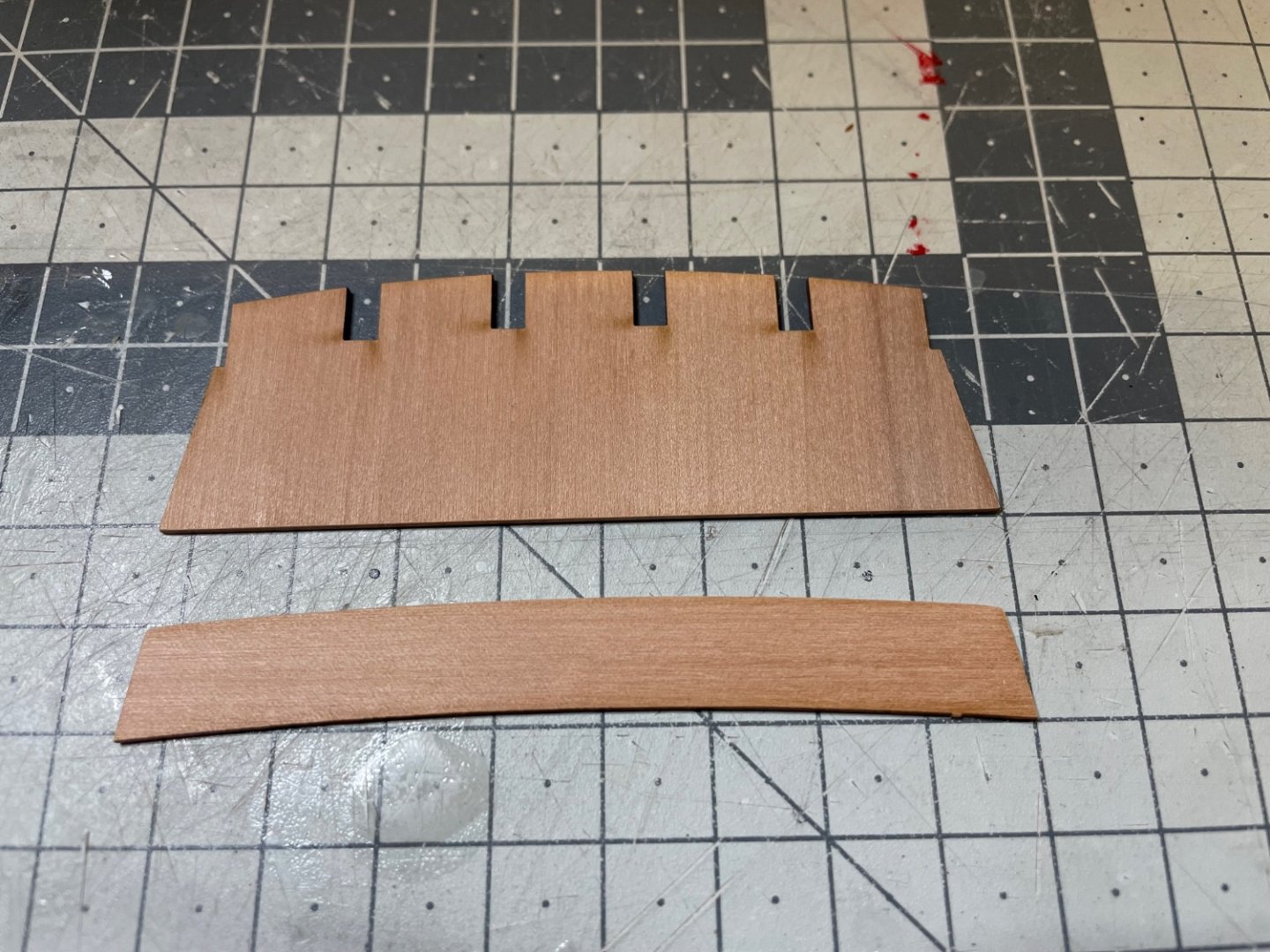

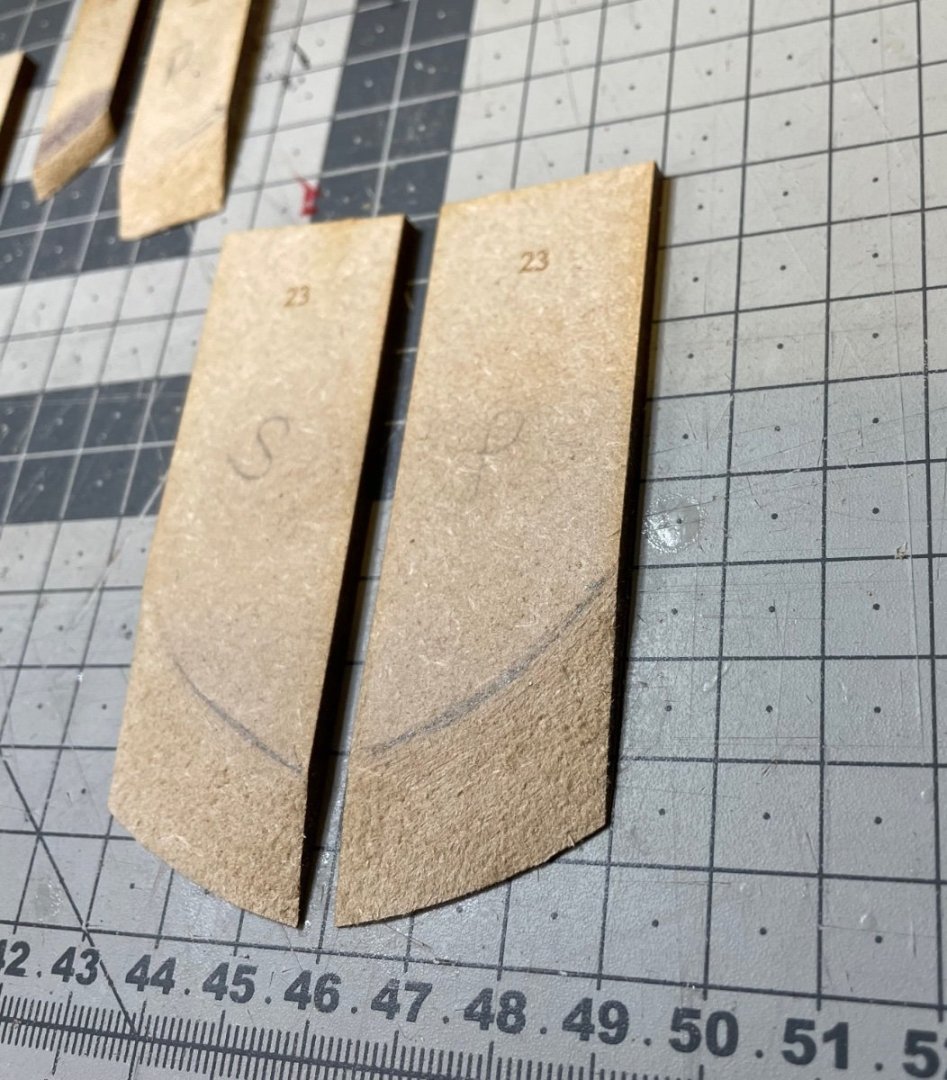

Photo 119: Bow and Stern Planking patterns. Photos 120-122: I marked them at the spot where the adjacent bulkheads are at the same level with them and combined the marks with a curvy line. Instructions do not mention where to mark the line but following the photos I had the feeling that's the right way to do.

- 426 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

- 426 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

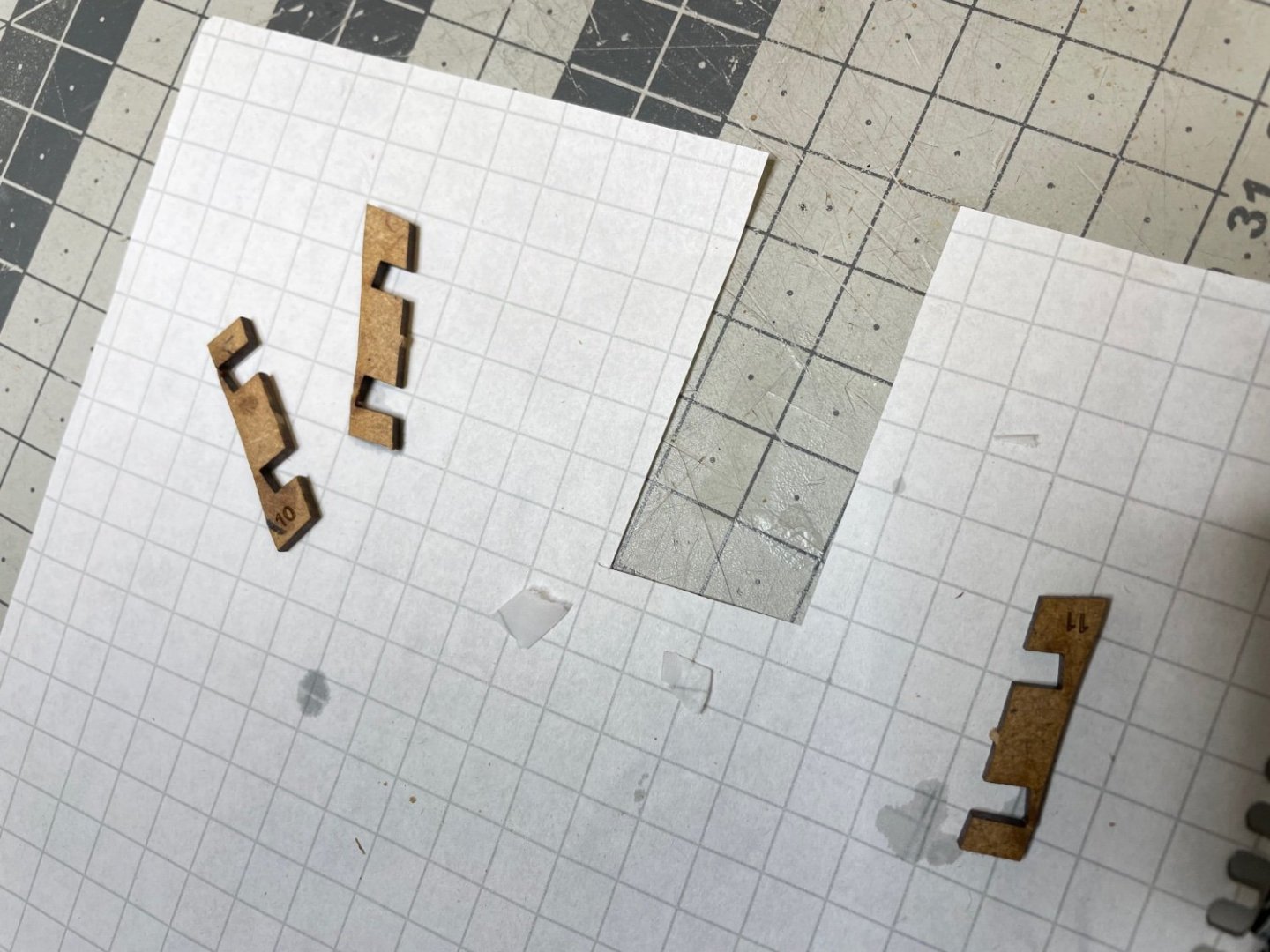

Photo 113: Status after Gun Deck Pattern installation. ---------- Photos 114-116: Vertical Gun Port Patterns. I broke 3 of them removing a bit carelessly from the board. Quite delicate those tiny necks. I fixed them by dropping a tiny drop of thin super glue and letting the paper below also stick to it and enforce. Photo 117: Waiting for the brushed glue to dry.

- 426 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

BUILD DAY 7 and 8: 3 hours / Total: 12,5 hours Today I am logging two days of work, it will be a long set of posts. Photos 106-108: Sanding the Stern Counter Frames to align flush with the rest of the deck elements at parts like marked in the photo. I used straight piece of wood and ruler during the progress to check. Photos 109-112: Installing the Gun Deck Pattern, coming in two pieces. I used this pin pusher I bought from Micromark. It grabs the pin perfectly and lets you make small-trip-at-a-time pushes that help you insert the nail more accurately and without risk of bending/twisting it. Recommended. I nailed it in the center edges and brushed diluted glue from the underside. I am satisfied with the result. There will still sit another layer on top of this, so I hope I will be able to correct the small misalignments visible in the pictures.

- 426 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

I thought the same about visibility, my main reason for considering was if varnish would be good for protecting the wood. But here I'll stick with your recommendation.

- 426 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

Question: Next step is to install the Upper Gun Deck patterns and this will block accessibility to most of the lower deck pattern. Does the lower deck need any treatment such as varnish before this step? Or shall I just leave it as it is? Any recommendation?

- 426 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

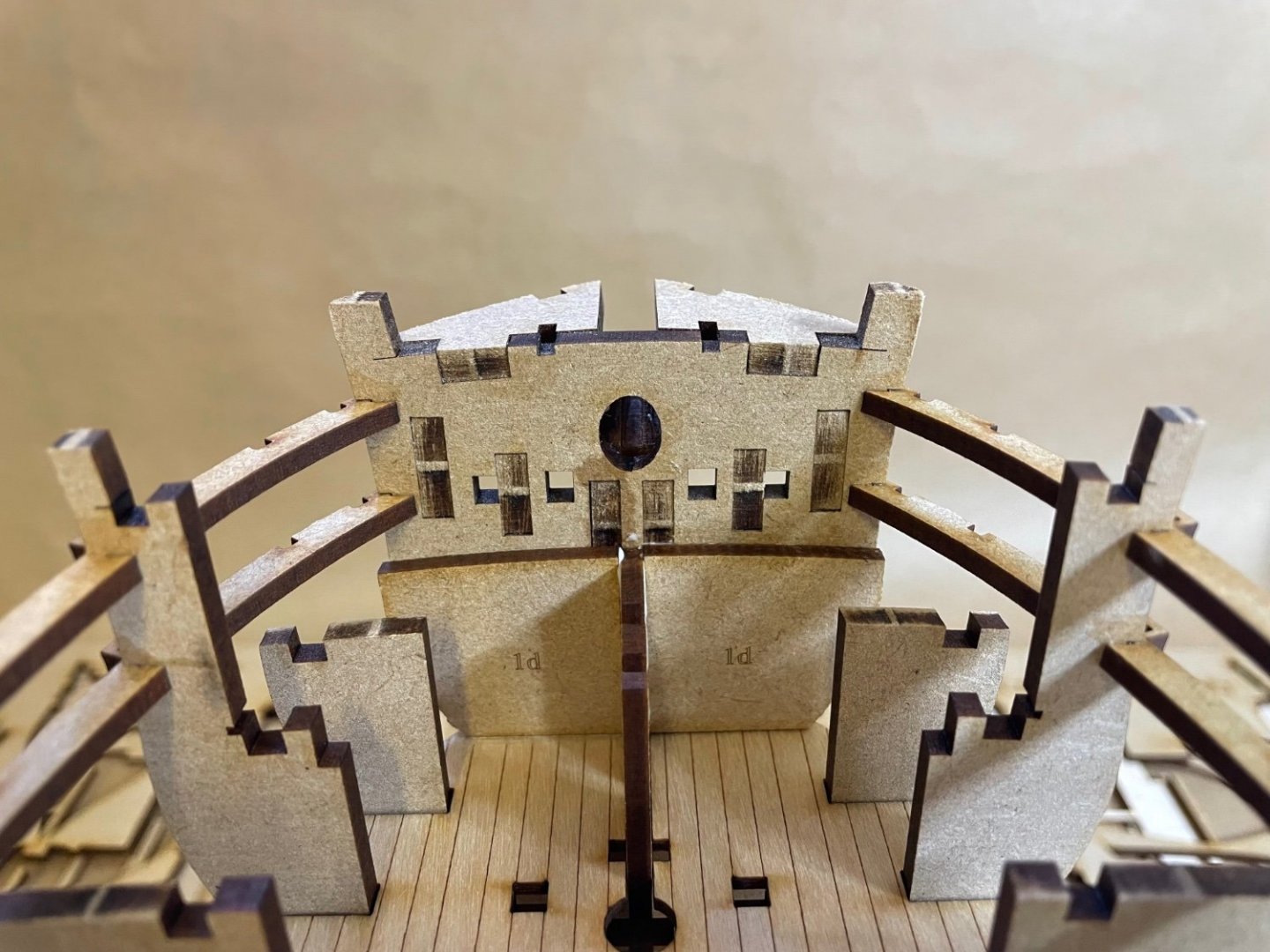

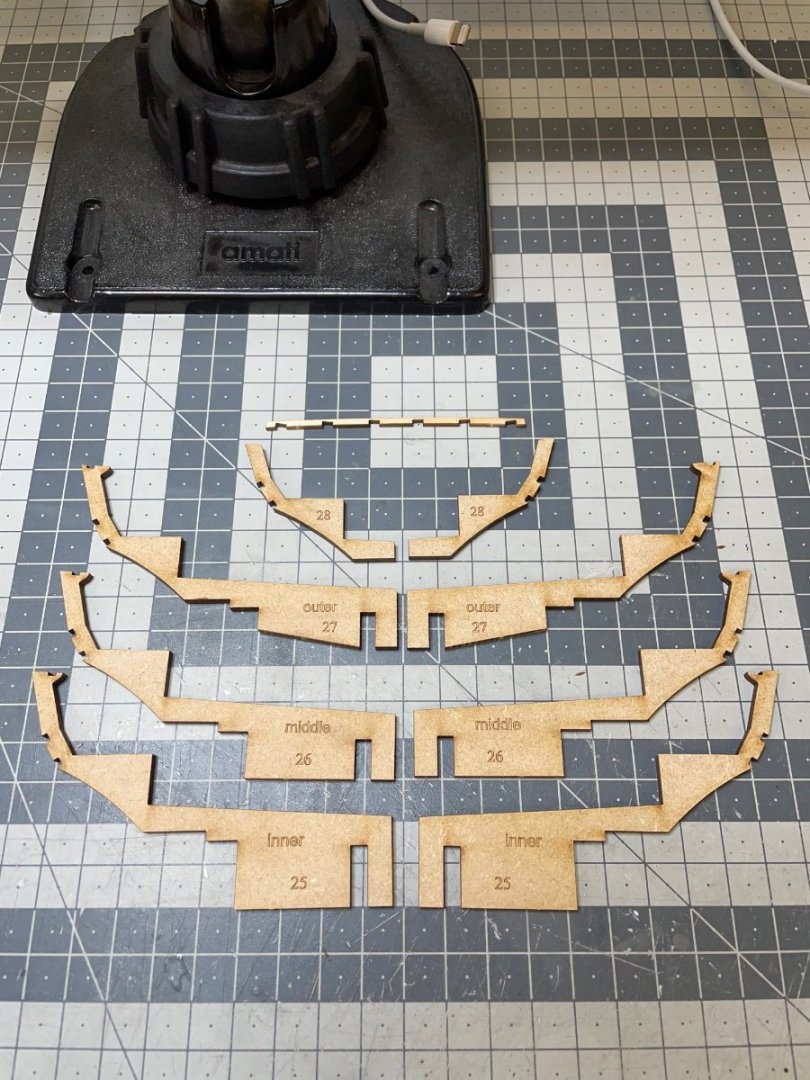

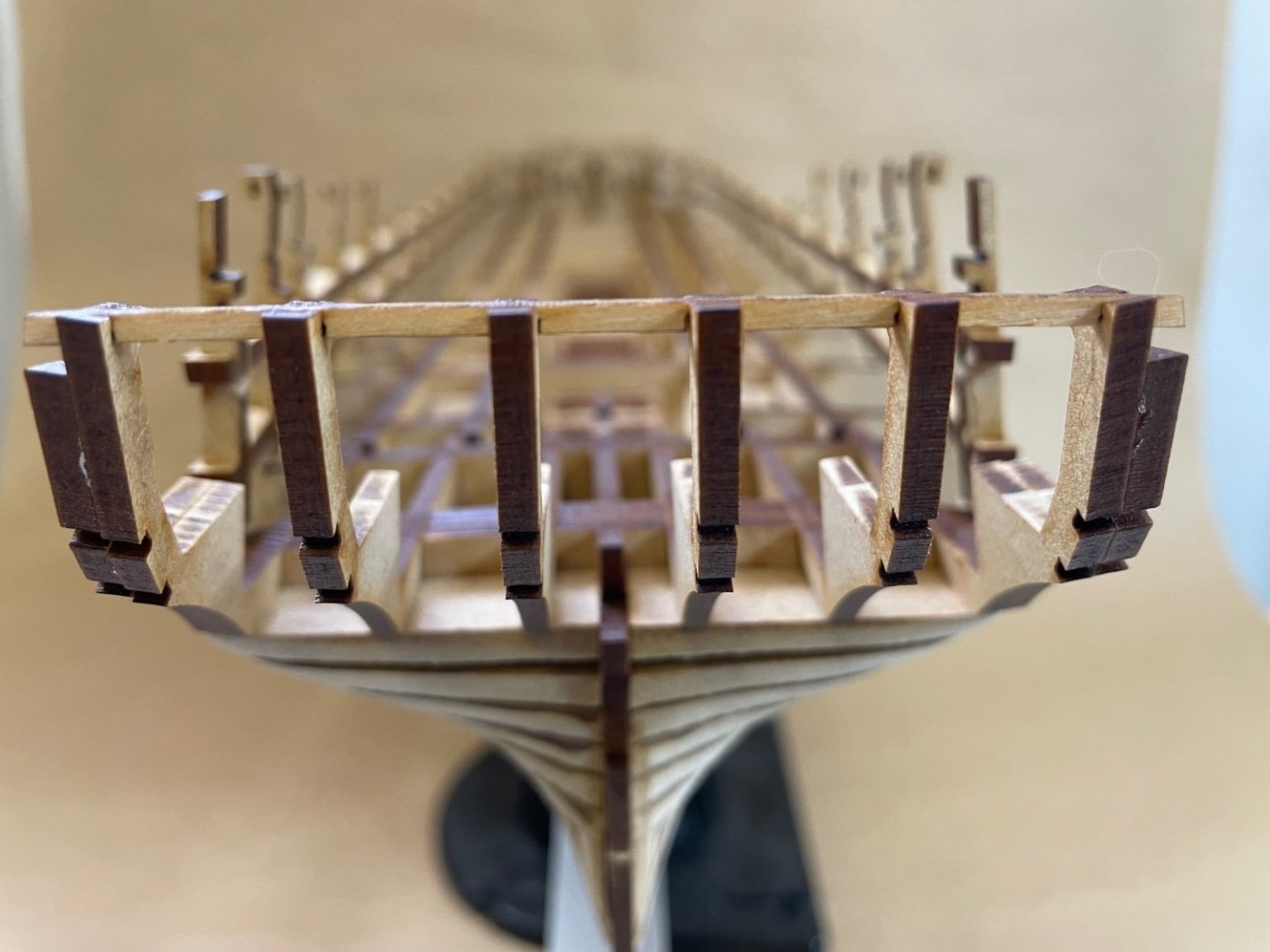

BUILD DAY 6: 2,5 hours / Total: 9,5 hours Photo 83: Gun Deck Support patterns (2 x #1d) in place. Photo 84: Gund Deck Support Beams. Photo 85: Time to time the parts needed slight sanding, just enough to remove the laser char, in order to fit their sockets. Photo 96: At some parts I used a right angle until glue is dry to ensure a vertical alignment. Photo 97: All support beams are in place. By the way I used UHU Hart glue at this stage. Photo 98: Longitudinal Deck Beams, which will sit on top of the support beams I installed above. They have accurately made slots. Photo 99: I brushed in diluted wood glue here in all joints. At some parts I used a soft clamp to keep joints completely in place while glue is drying. Photo 100: Yes! 100th photo of my build log! And this is how my model looks: Photo 101: Side view. Photo 102: Stern counter frames and their spacer. Their locations are clearly labelled on the MDF as inner, mid and outer. Photos 103-105: They fit nicely with only slight sanding time to time. I brushed diluted glue, except at parts #28 where I glued directly with UHU Hart. Note that these frames are not always vertical. They make a slight angle towards the keel. Therefore their horizontal surface is not flush with the bulkhead or the Longitudinal Deck Beams. You'll need to get them level by sanding before moving any further. This is explained clearly in the instructions.

- 426 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

Thanks Glen! I follow your build and I get lots of hints and inspiration from it!

- 426 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

- 426 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

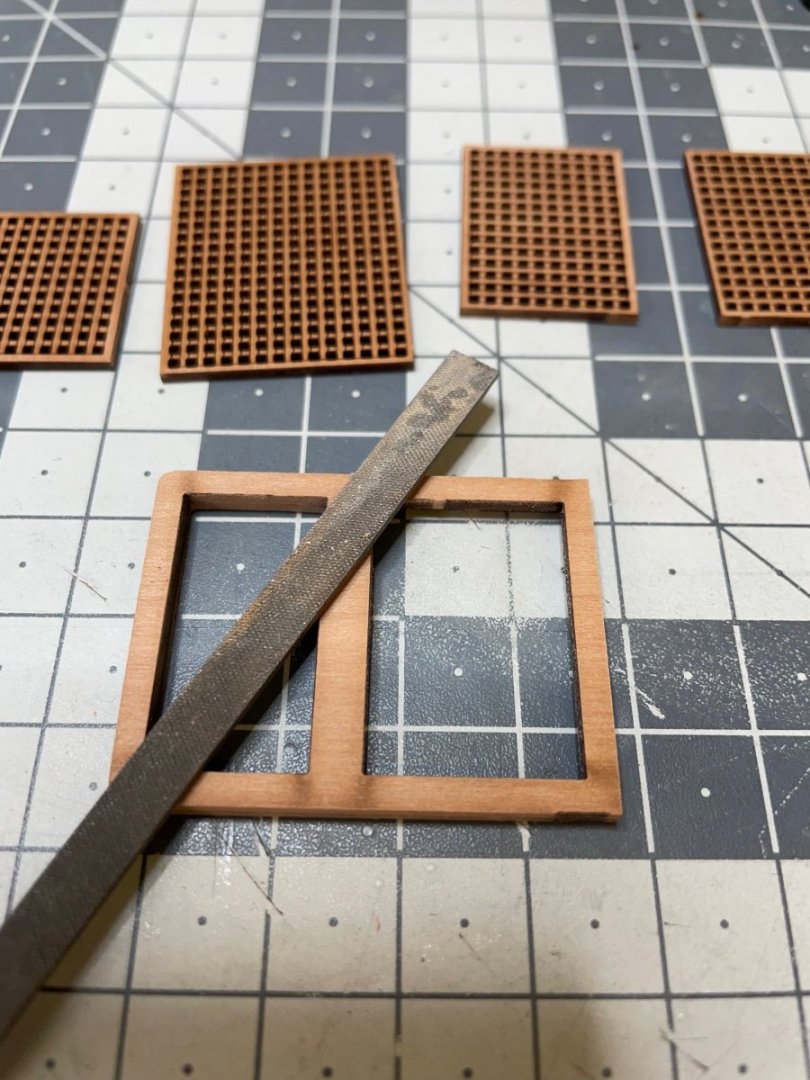

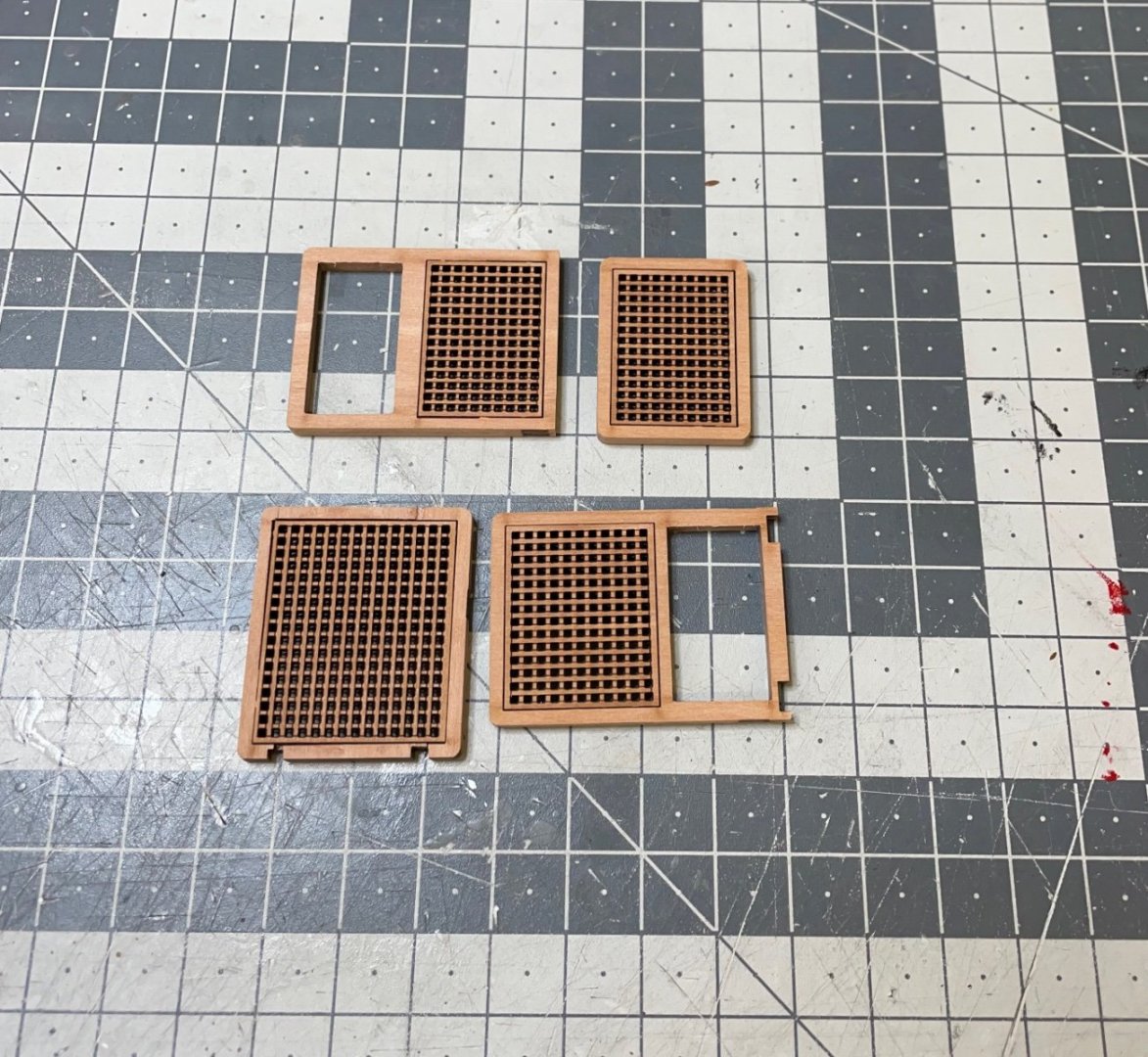

Photos 77-80: With the help of DSPIAEs and mini files where they won't fit, I sanded the surface and char where necessary. I also dry fit the gratings. You want to glue the frames (coamings) on the deck without the gratings first, so that you can easily align them in their places properly, and only after that, glue the gratings.

- 426 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

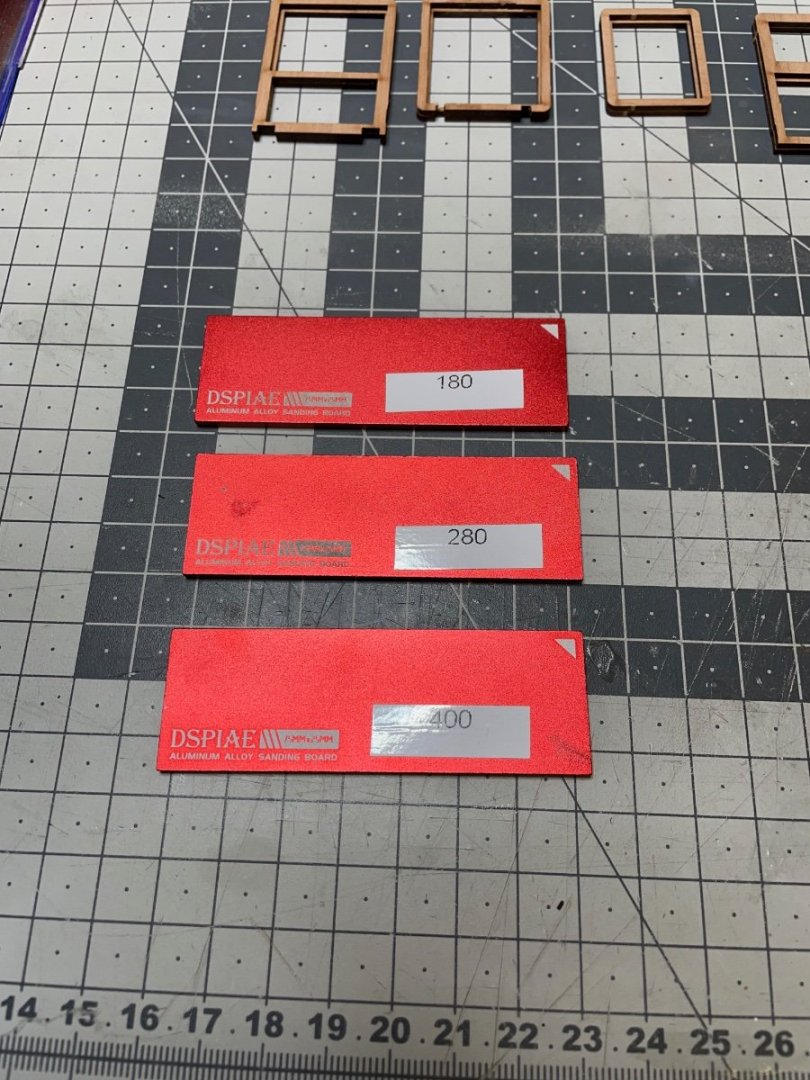

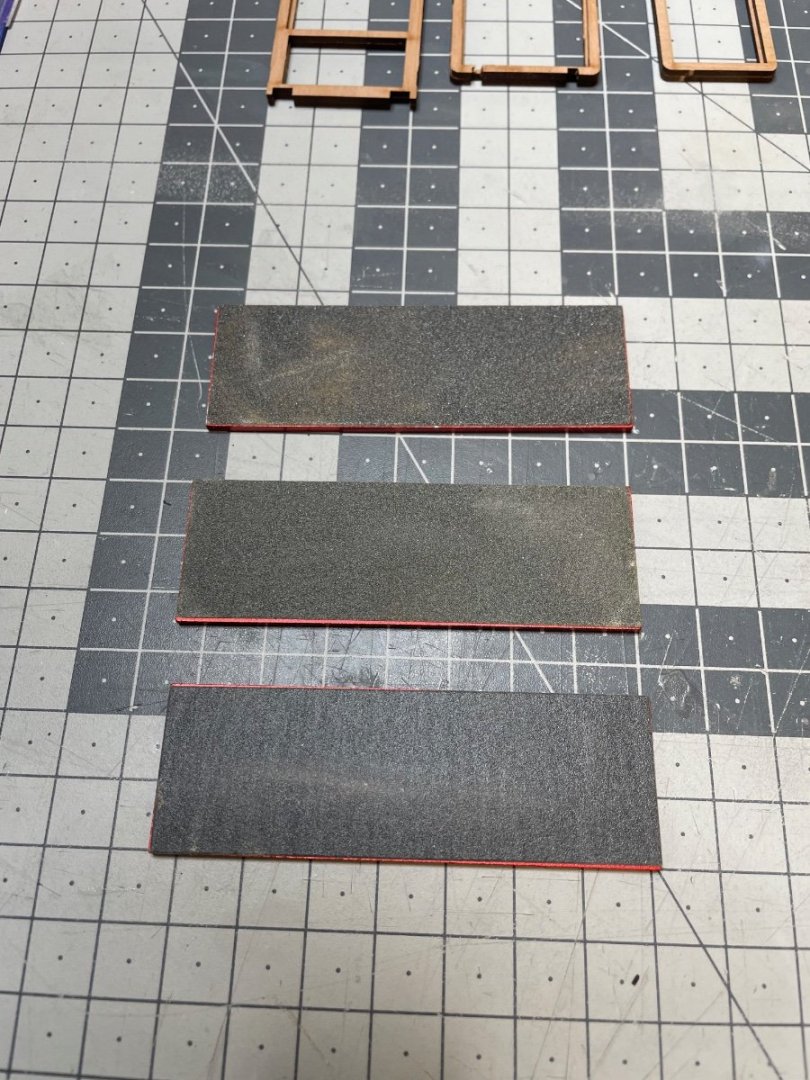

Photos 75-76: By the way I use these aluminum sanding boards from DSPIAE for precise sanding most of the time. They have their own self adhesive papers. I bought 180, 280 and 400 grit. I labelled the grits on the back of each board so that I can identify them easily. Very practical and highly recommended. I am not sure if these DSPIAE products are available everywhere and it is a shame because they really manufacture high quality stuff. I order them from a small online hobby shop located in the Netherlands.

- 426 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

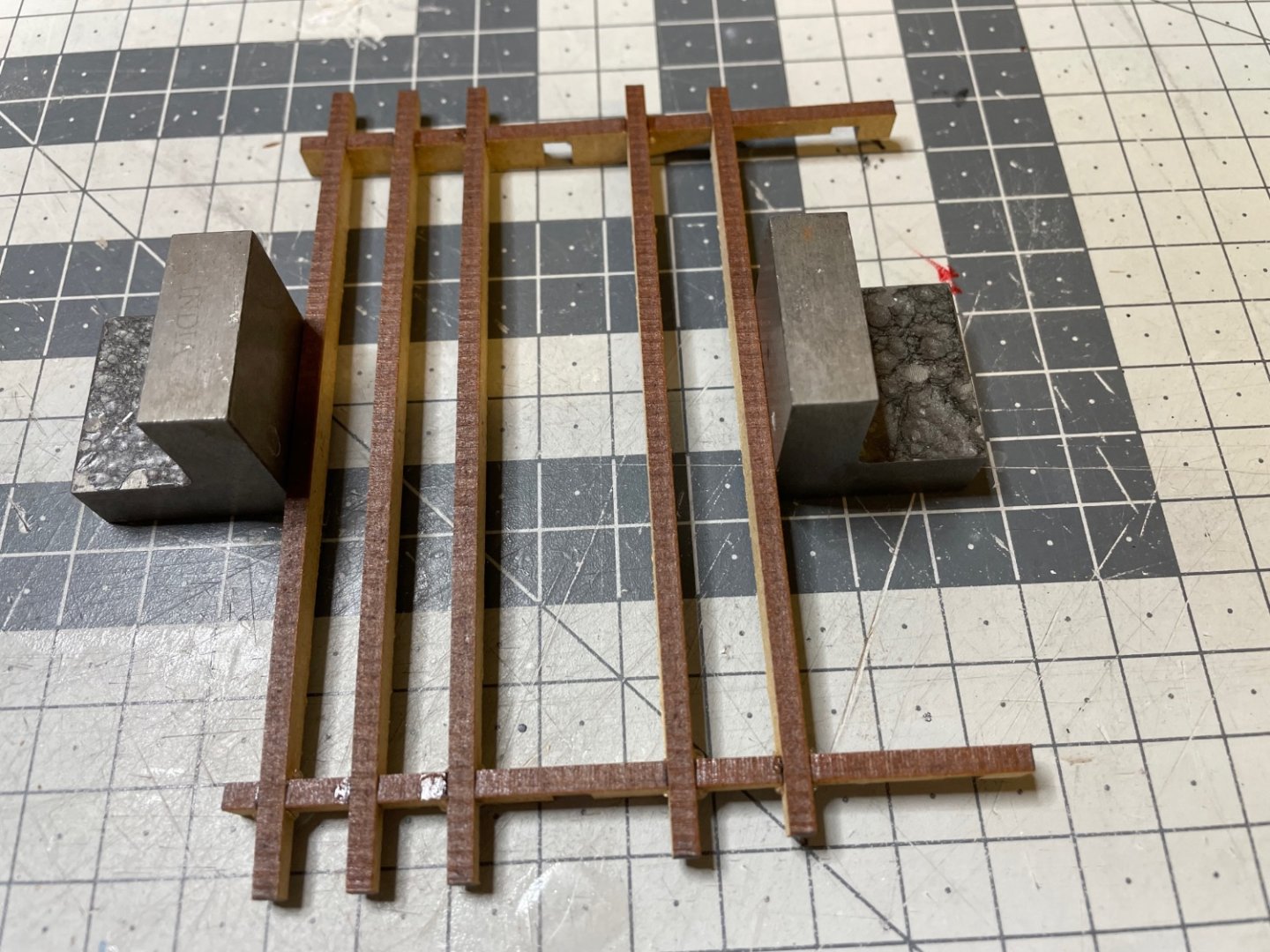

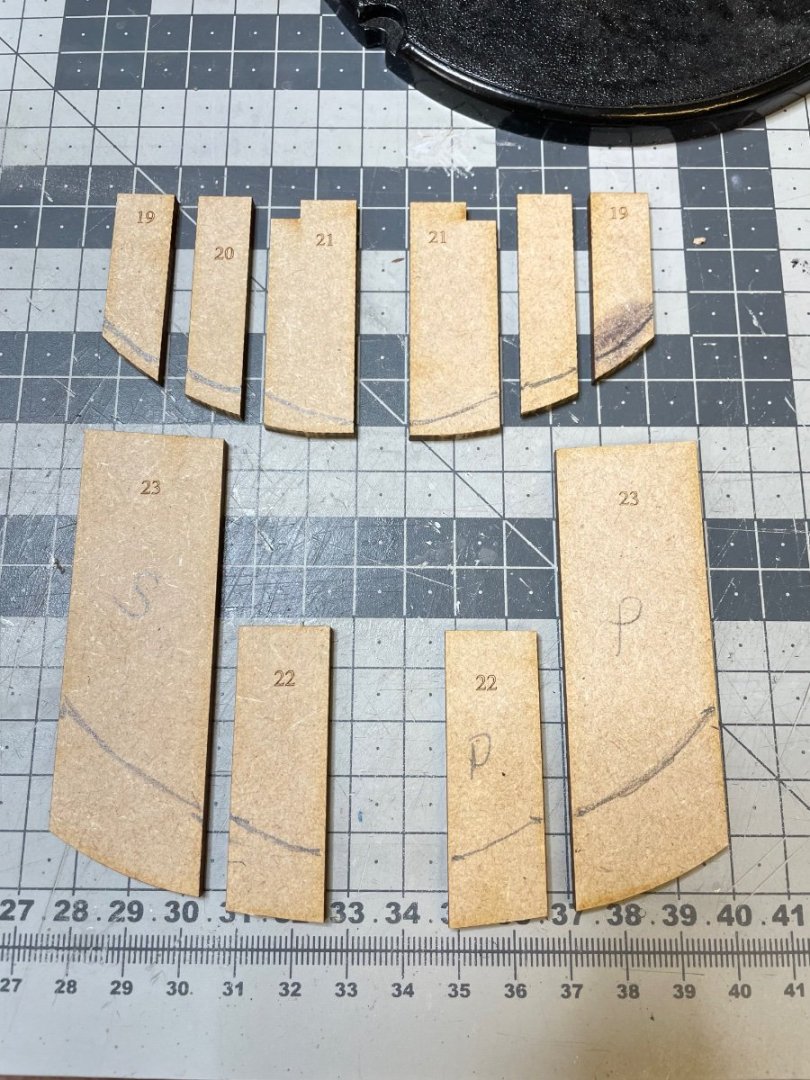

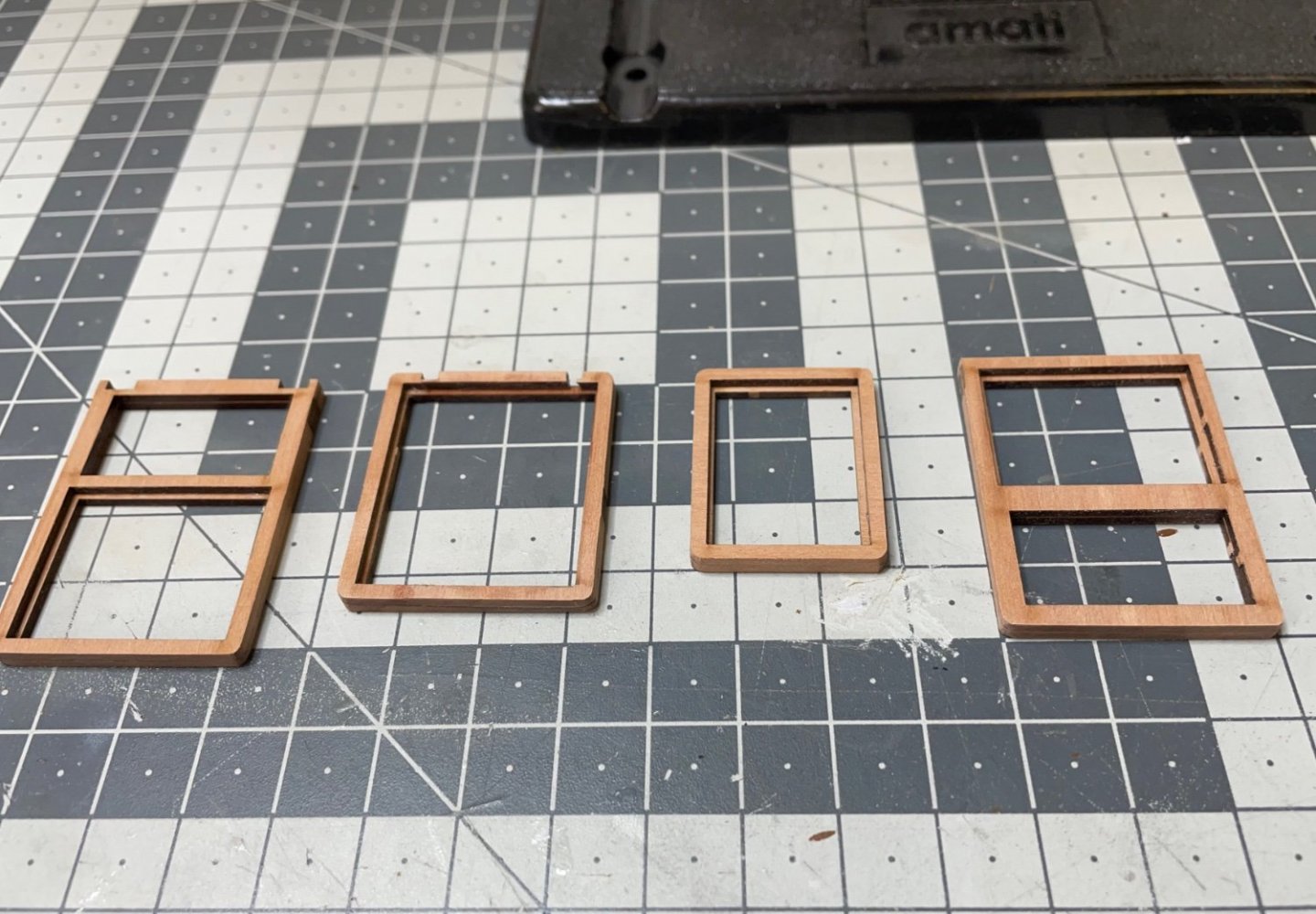

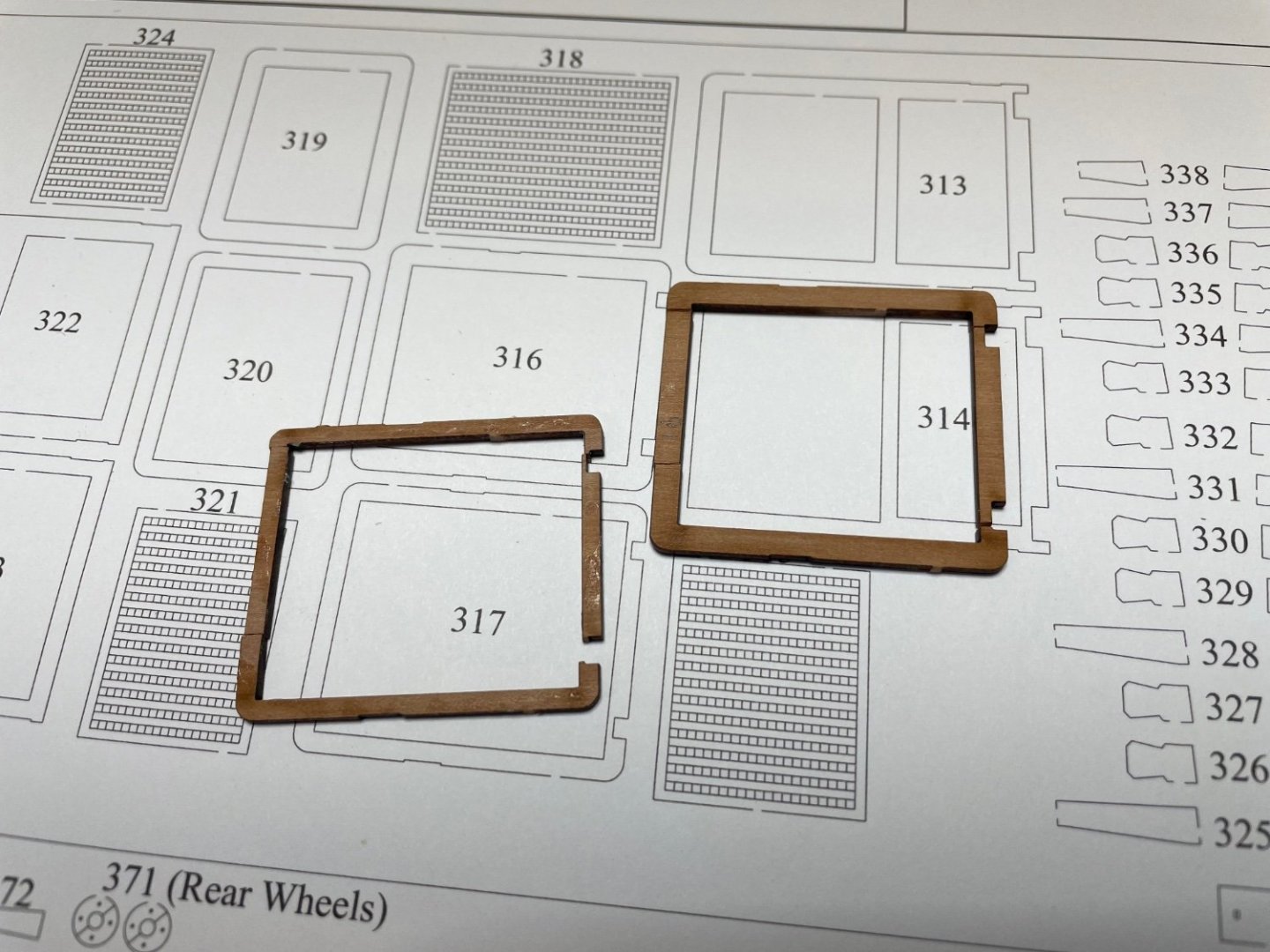

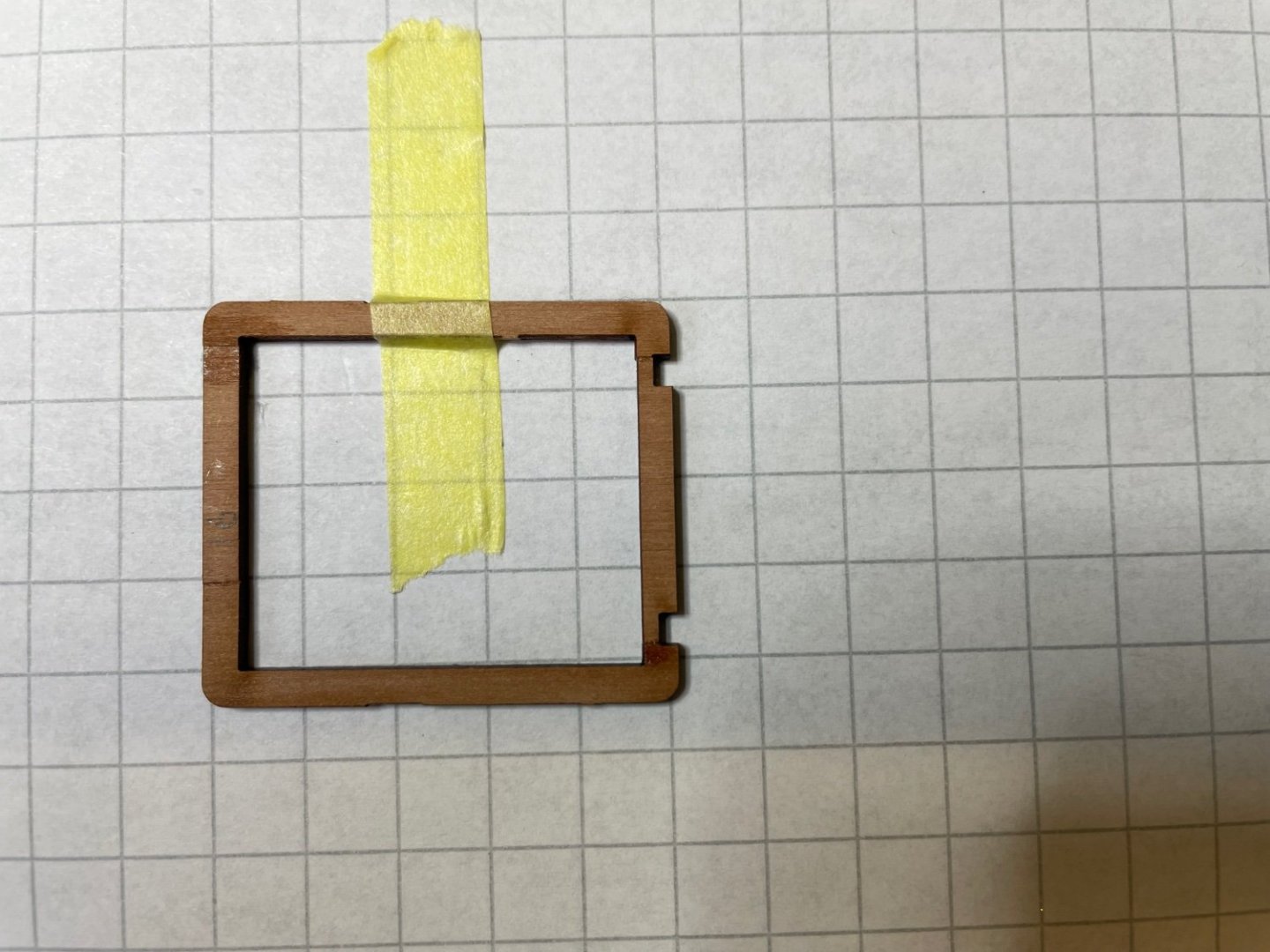

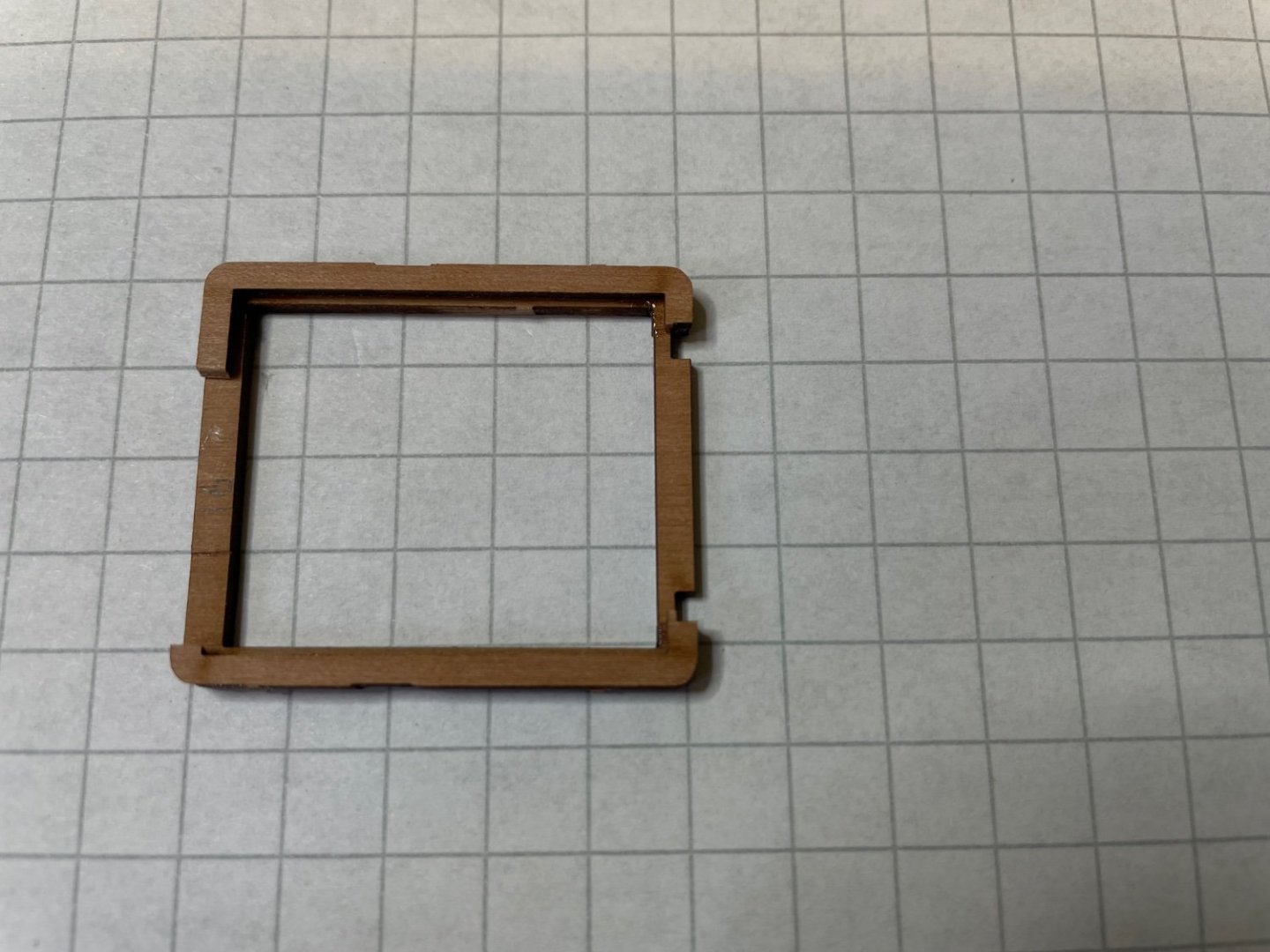

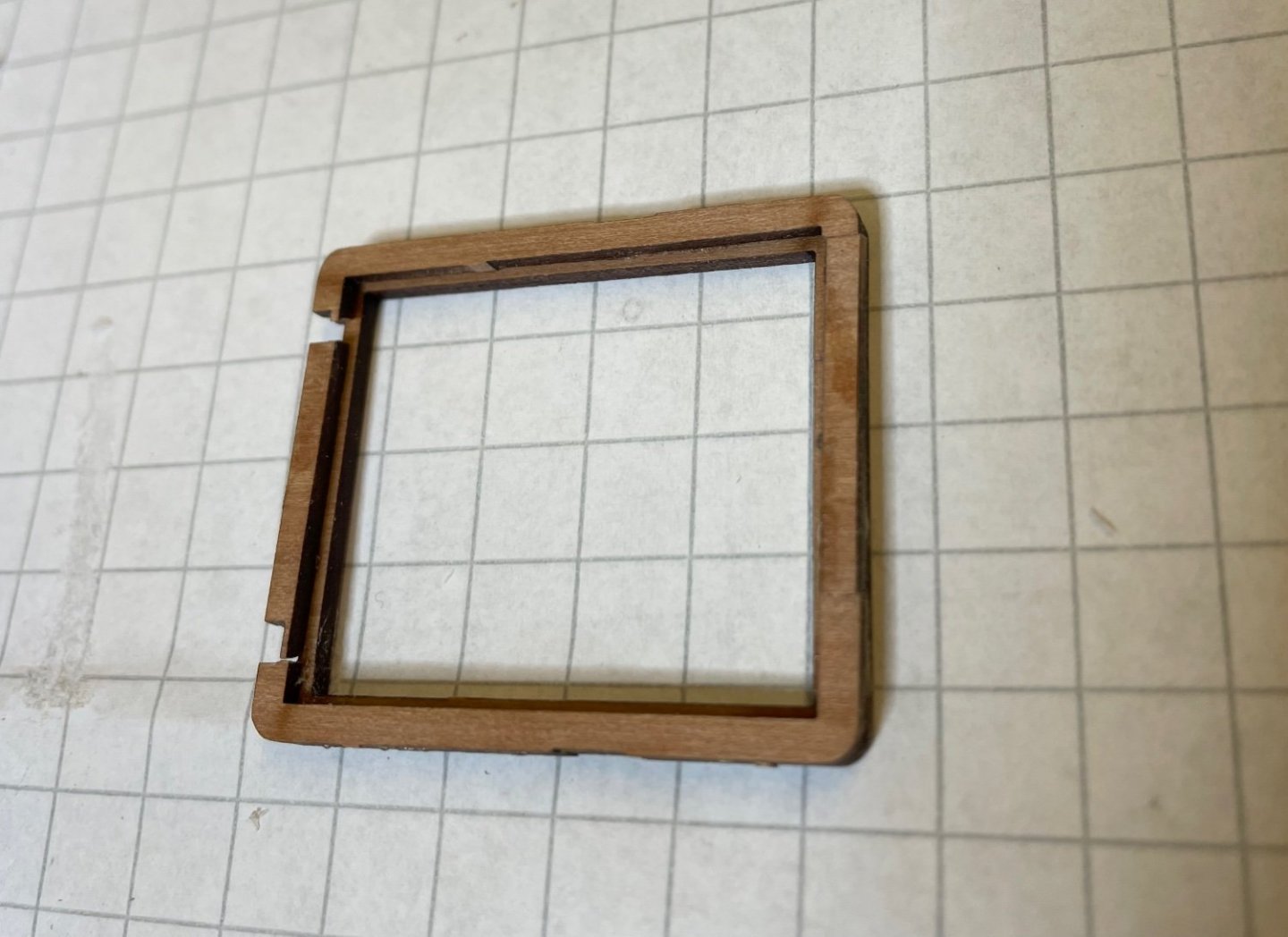

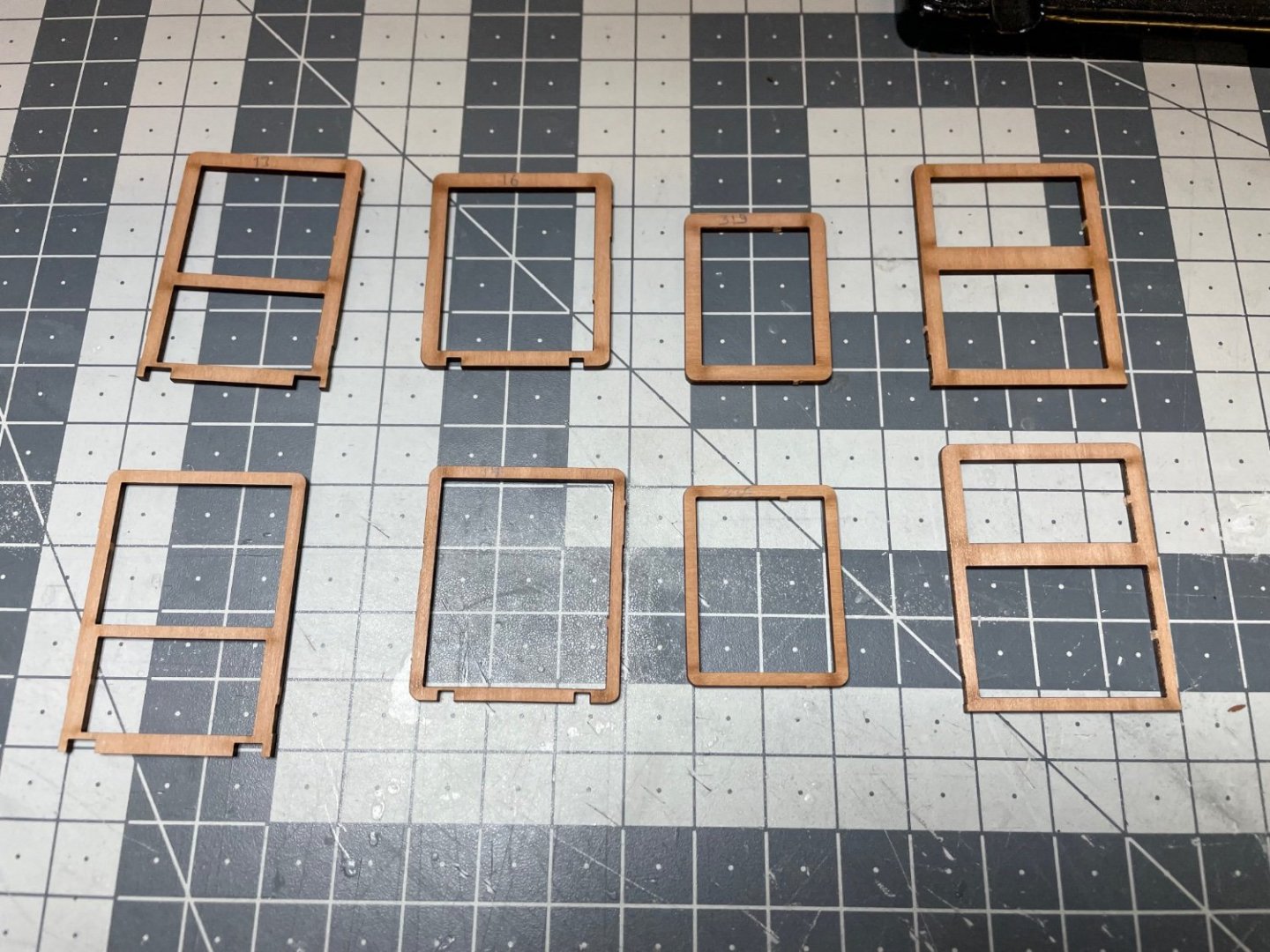

Photo 69: Well, a near small-disaster (or a small near-disaster if you will) 🤣. Today I learned to treat pearwood with respect. I had never handled pearwood until now and I didn't know they are so crispy. When I was gluing these two parts together I must have squeezed a bit too much and all of a sudden the whole thing broke into these many pieces! Parts flew all over on the table and on the floor. Luckily I was able to find all the pieces. In hindsight, I think it happened when I squeezed the assembly from the short edges with my thumb and index finger, where they are the weakest due to the notches, when I was trying to ensure their alignment. Photo 70: I used the plan to locate their places. It was like solving a jigsaw puzzle. The parts in question are #316 and #317. Photos 71-73: I decided to repair them together in their final assembly rather than restoring each frame individually. It felt easier this way. They will sit on top of each other anyway. I used a grid paper to help position them correctly and used thin super glue to fix first few pieces. Once dry, I used UHU Hart to finish the assembly. Photo 74: Overall the repair process worked fine, only setting me back for about half an hour. The repaired assembly is second one from the left. Hard to tell from the others if you don't know the story. With a little surface sanding it will look just like as if nothing has happened 😃.

- 426 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

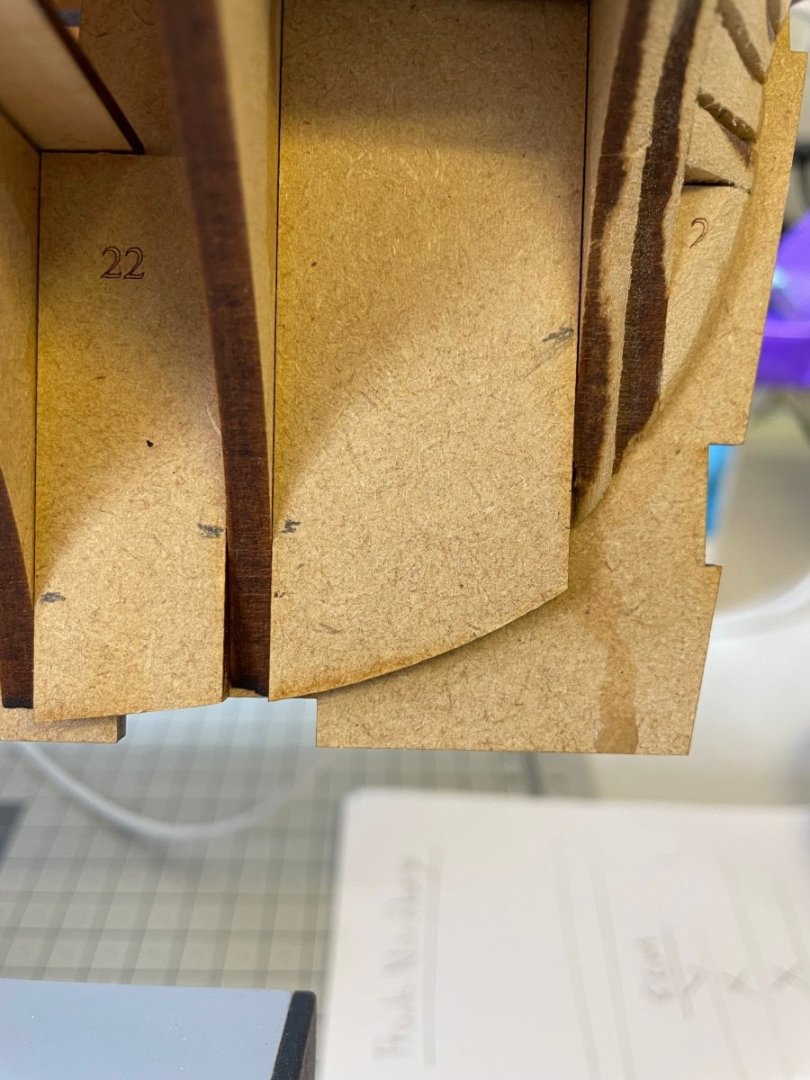

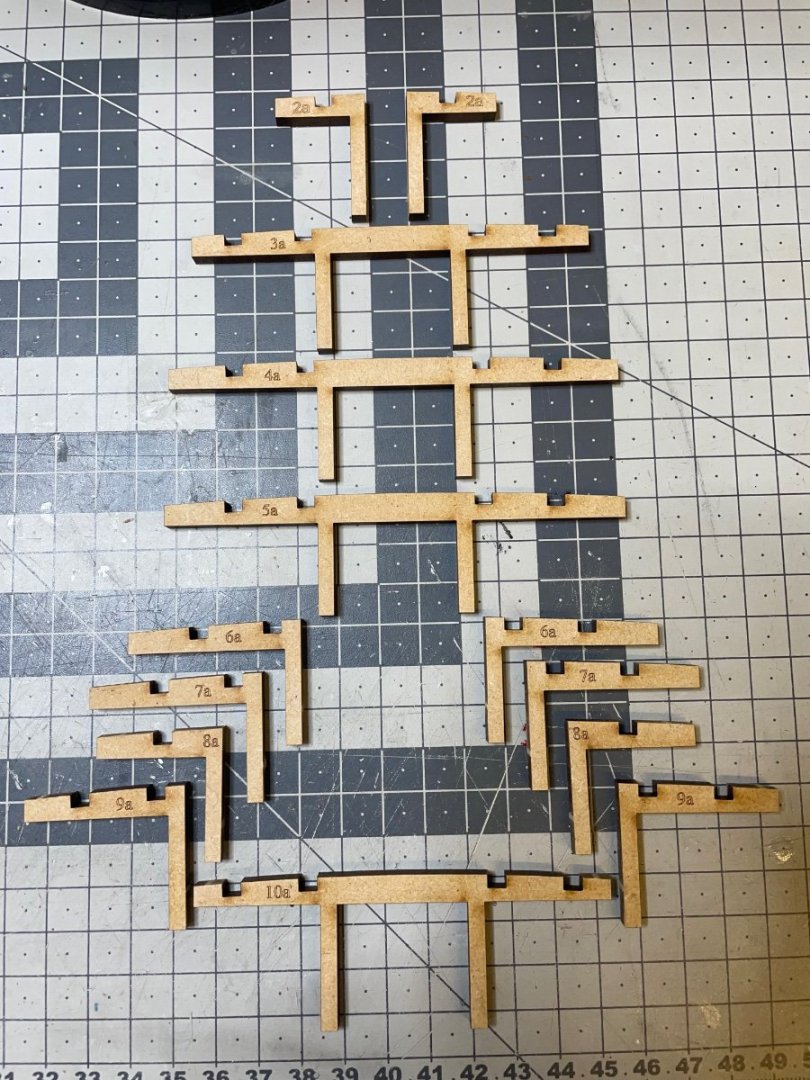

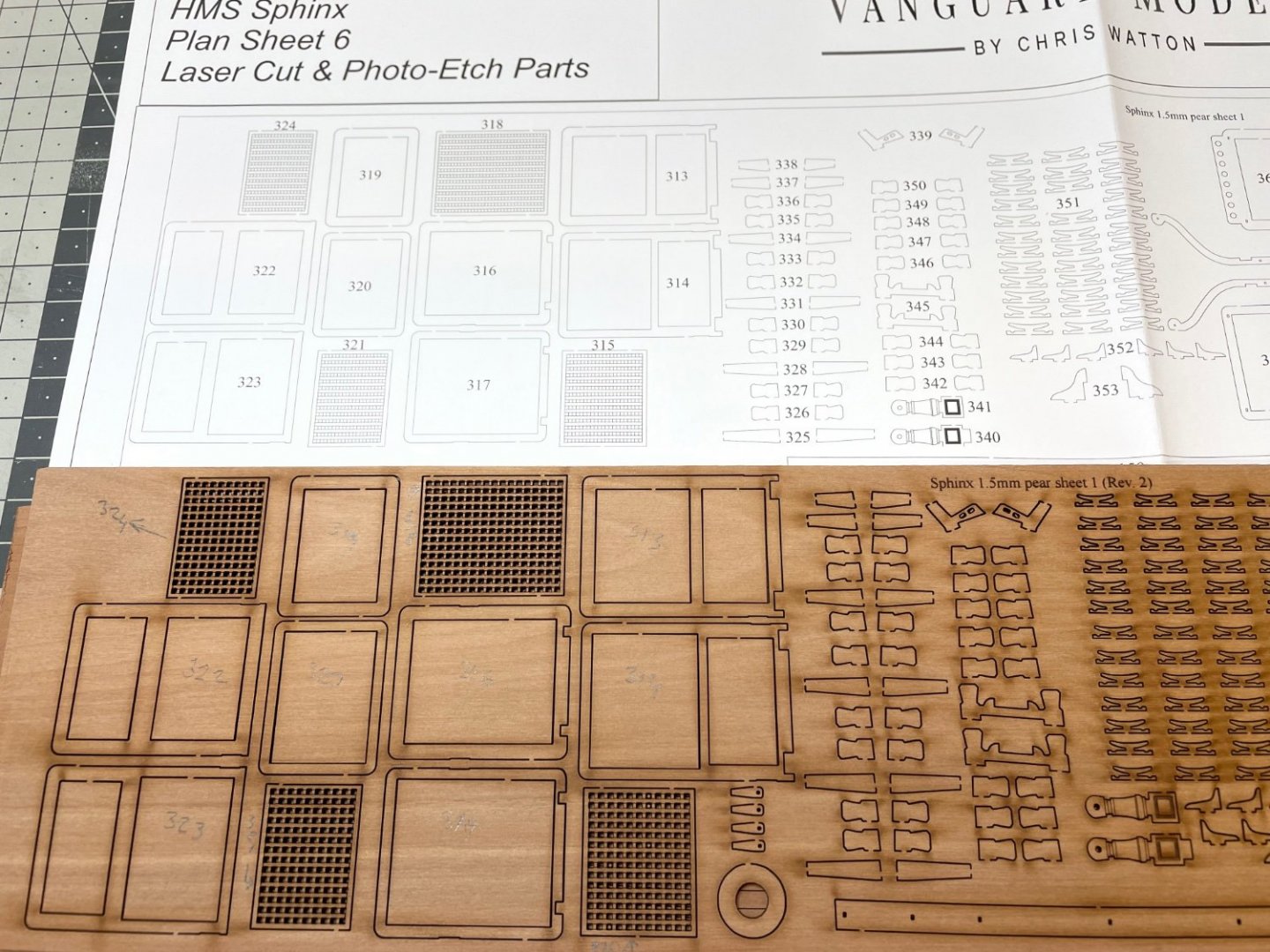

Next, lower deck coamings. Photo 67: The part numbers are not marked on the wood in these so I referred to the plan sheets. Photo 68: Frames removed and sorted. Those on the bottom row will be glued on top of those on the top row. Sounds easy.... wait until you see my next post 🤣

- 426 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

- 426 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

Photos 64-65: Having sufficient support from the port frames, the rectangular piece for protecting ears of Bulkhead #13 is now free to remove and discard. It took a few careful strokes on the two small tabs on just one side of the board and a few back and forth twists to do it.

- 426 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.