-

Posts

916 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by aydingocer

-

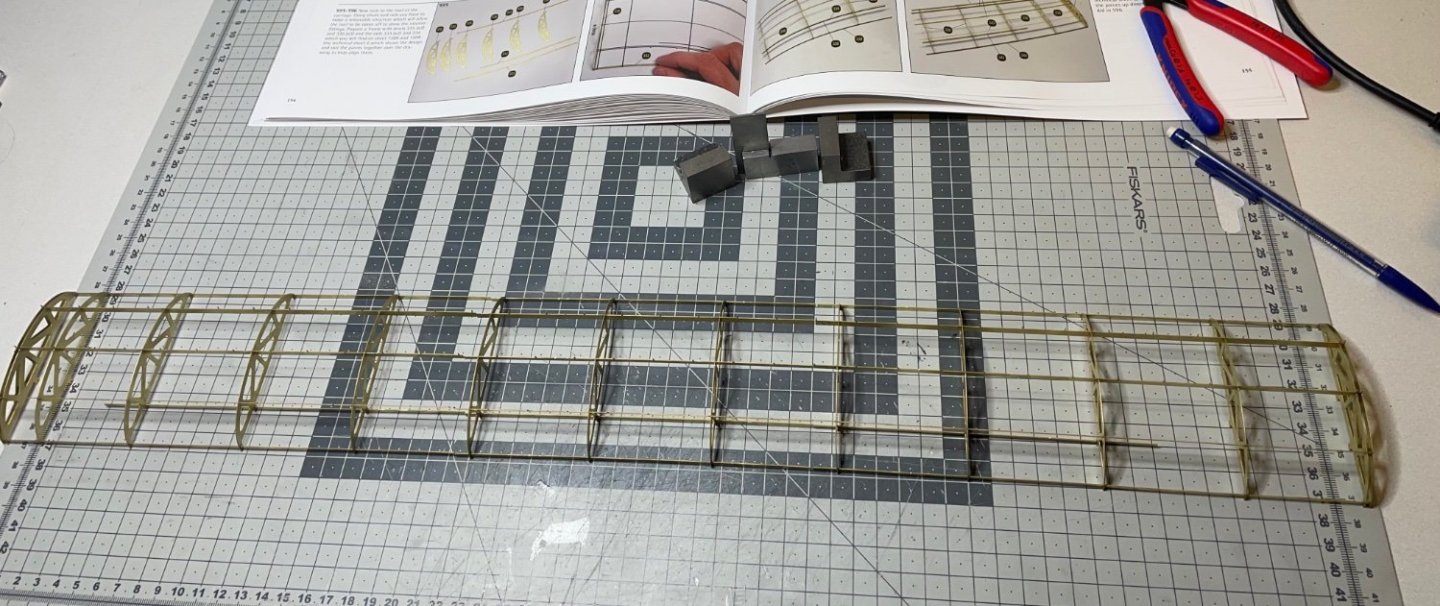

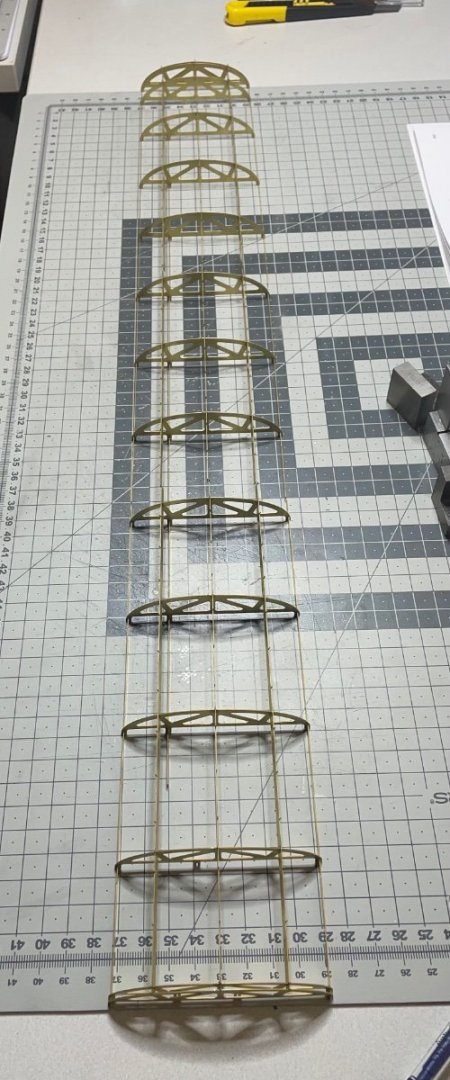

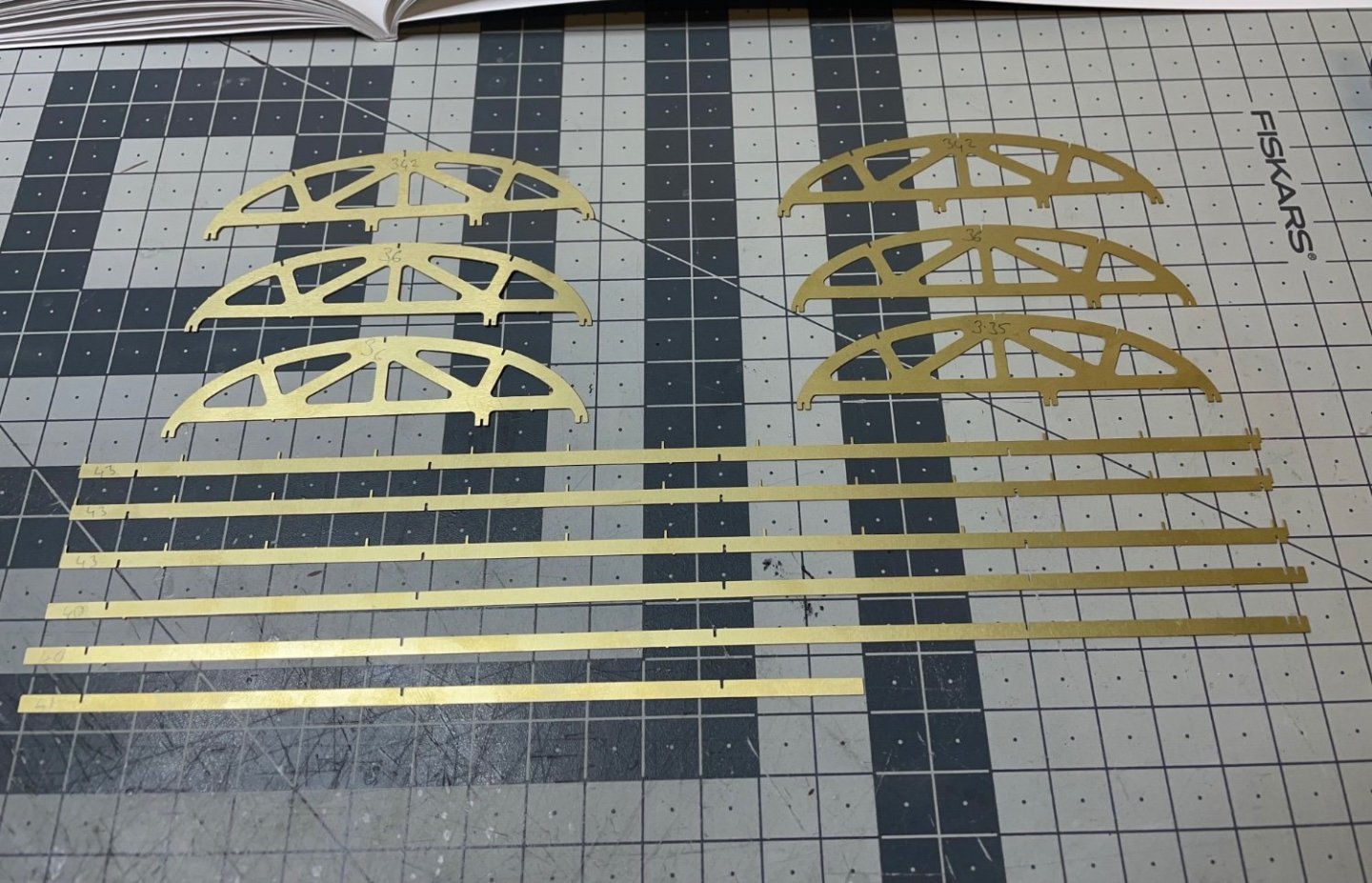

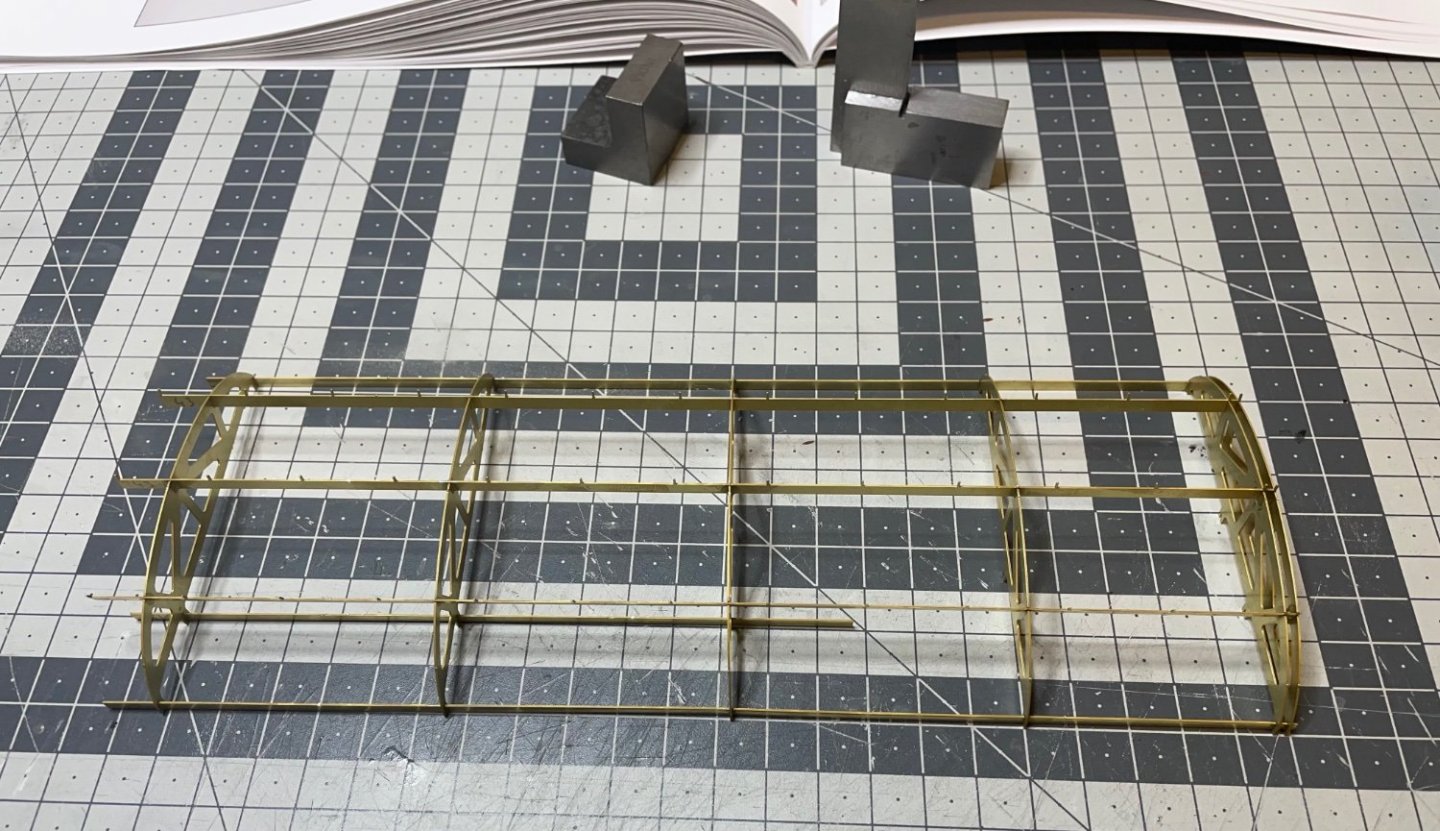

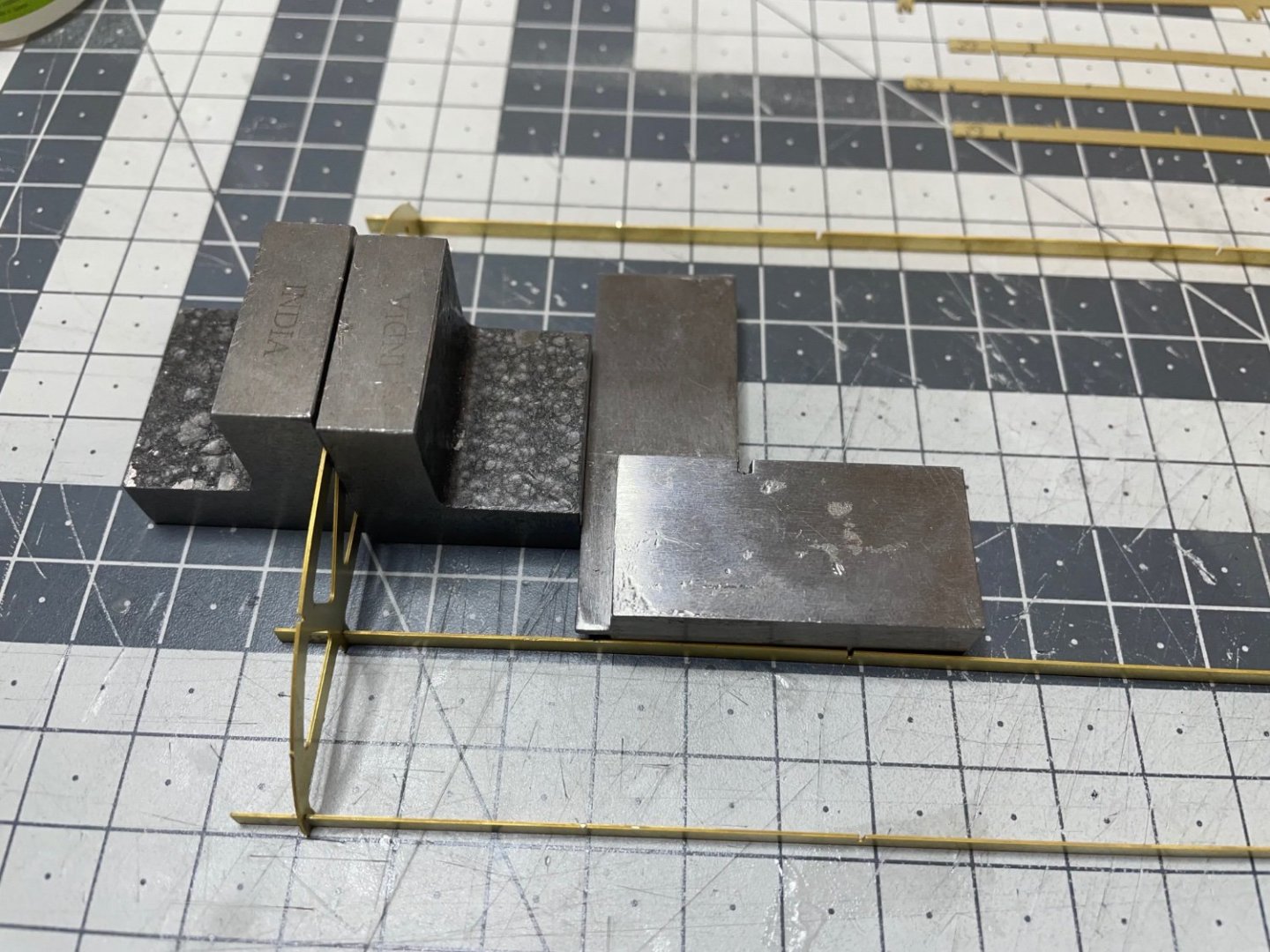

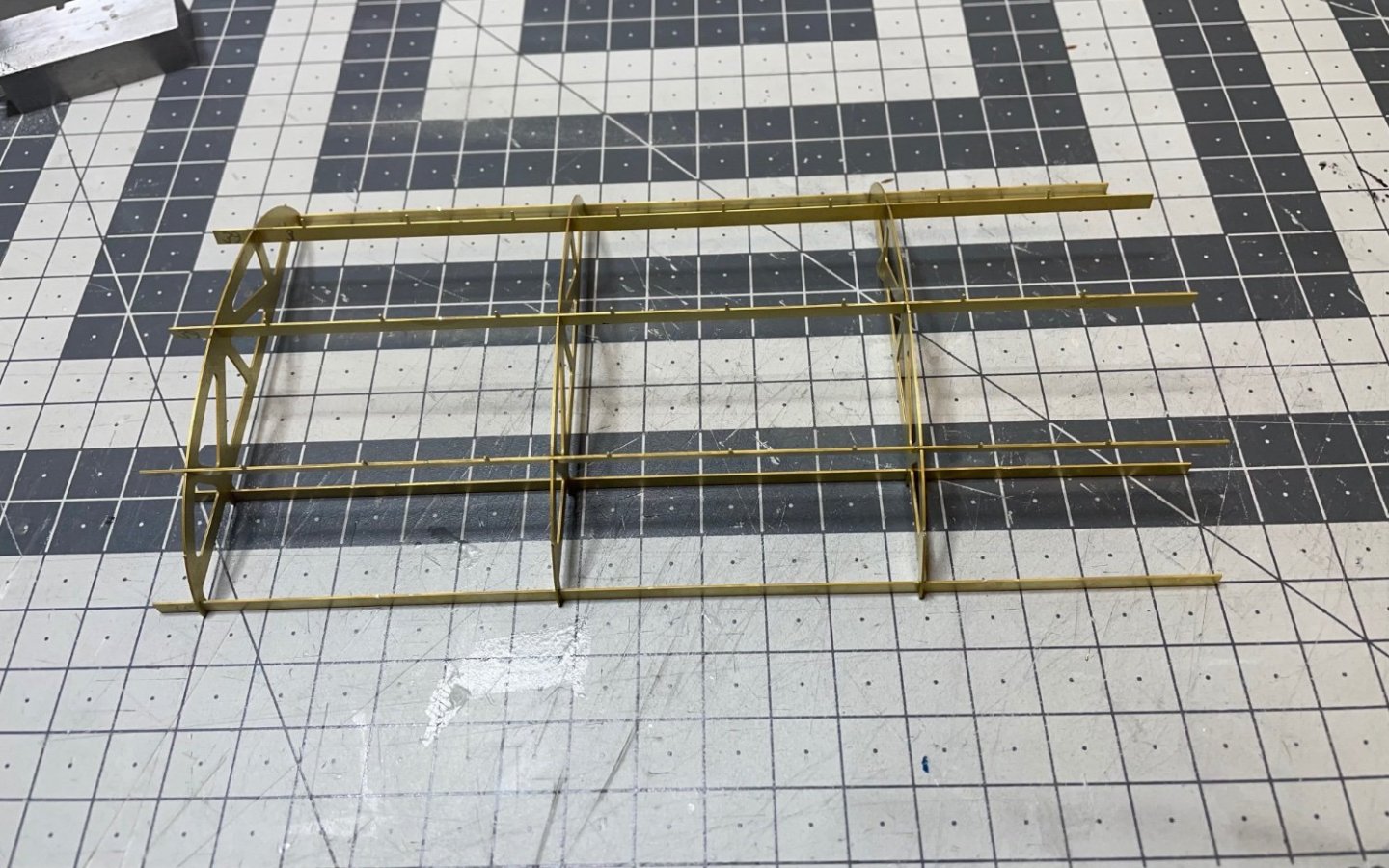

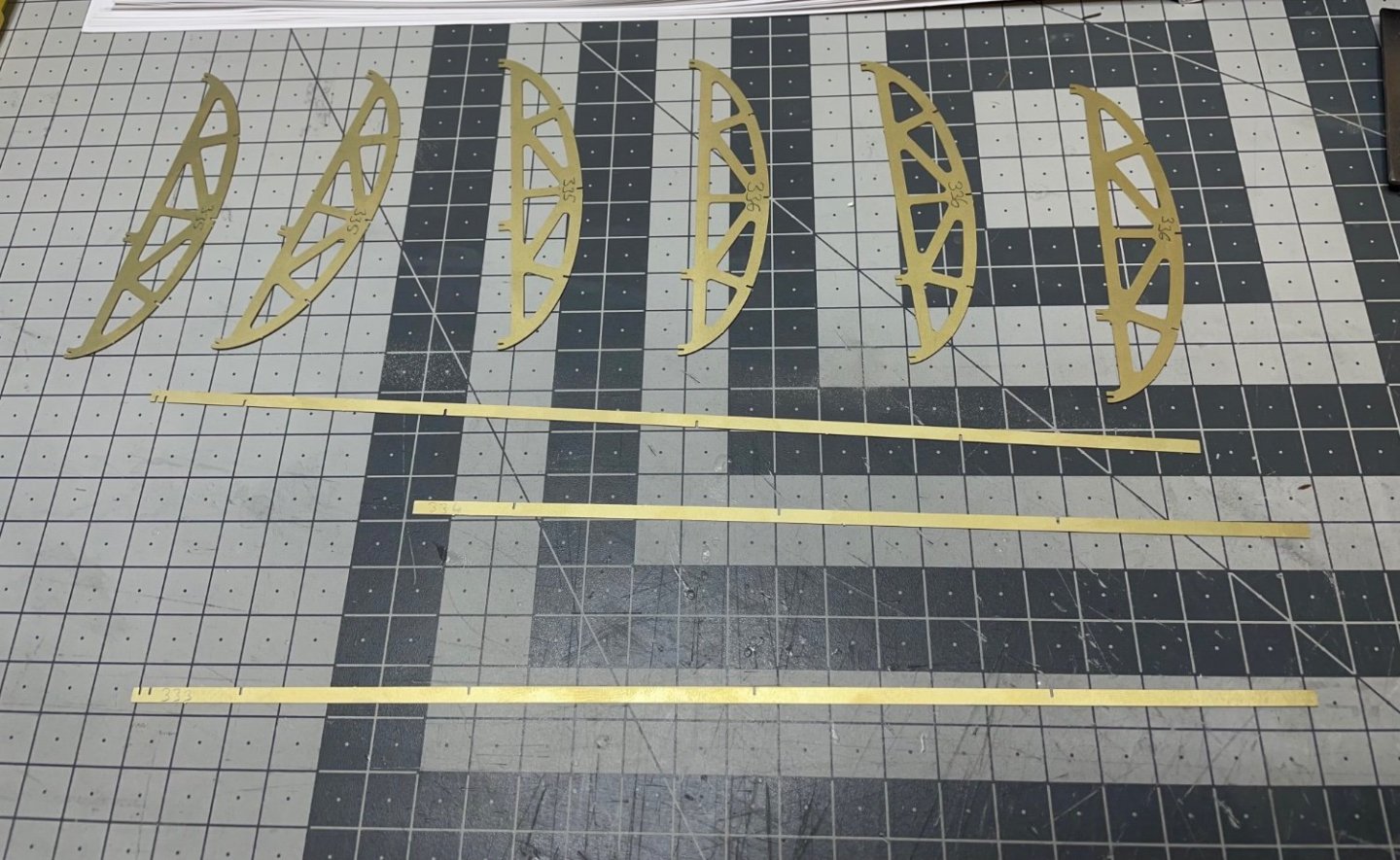

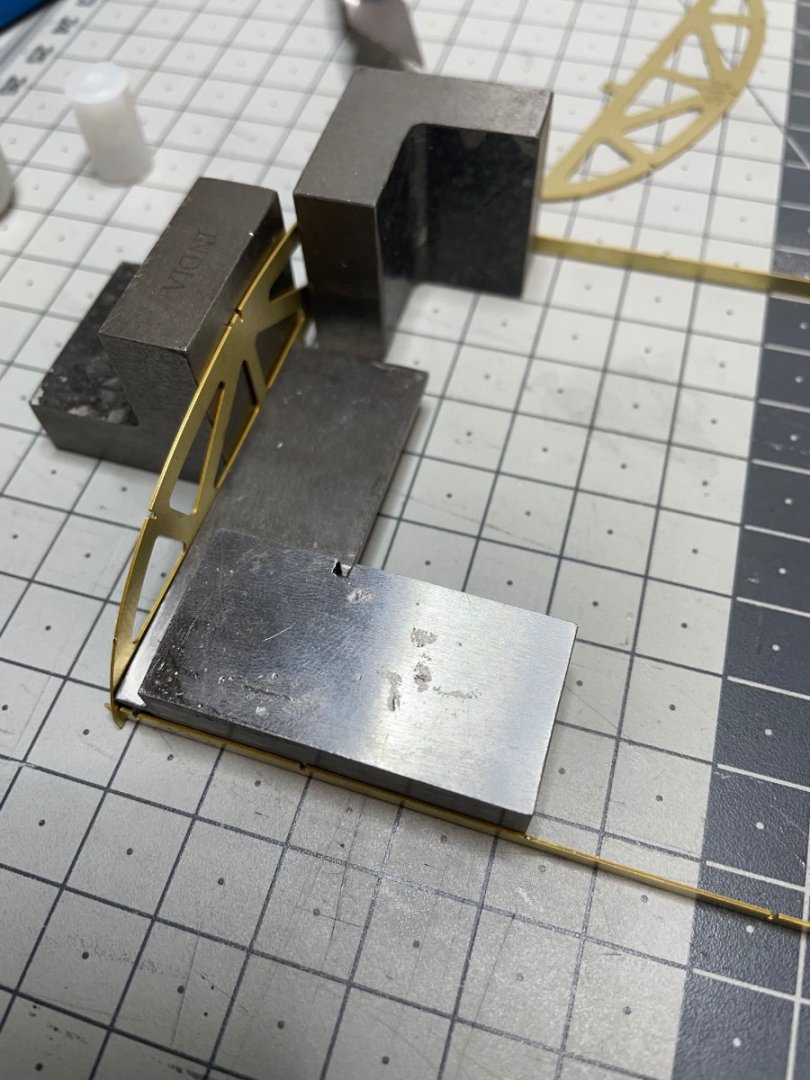

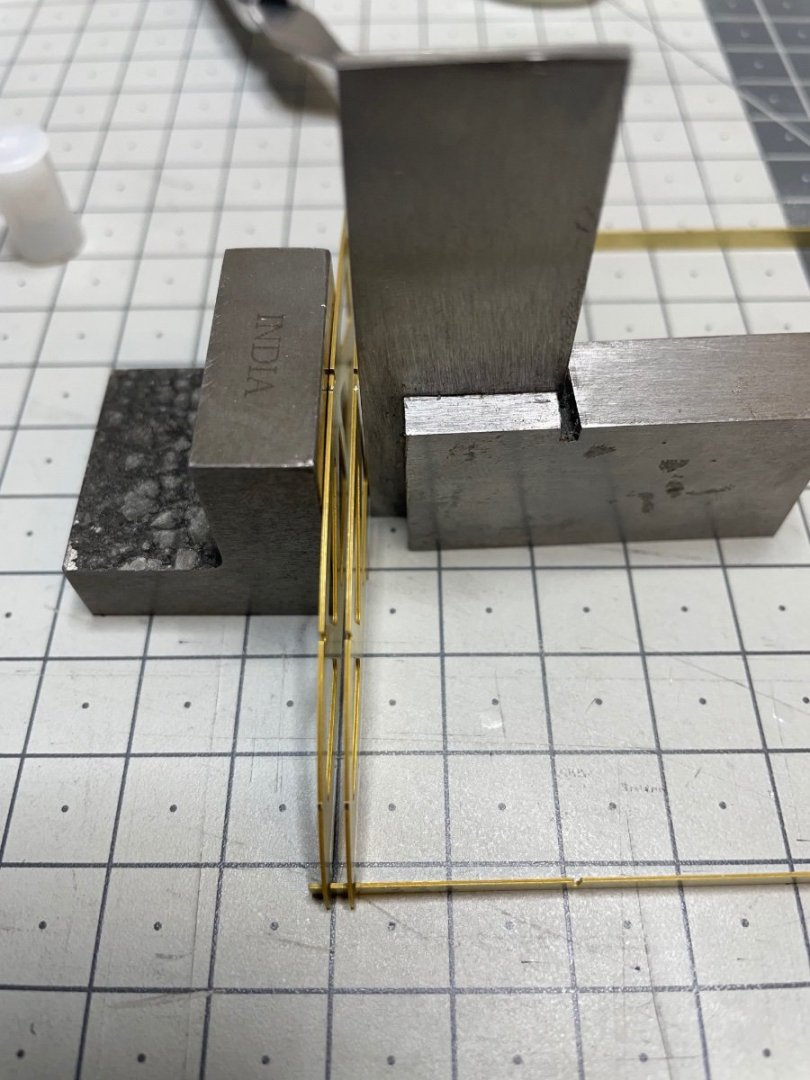

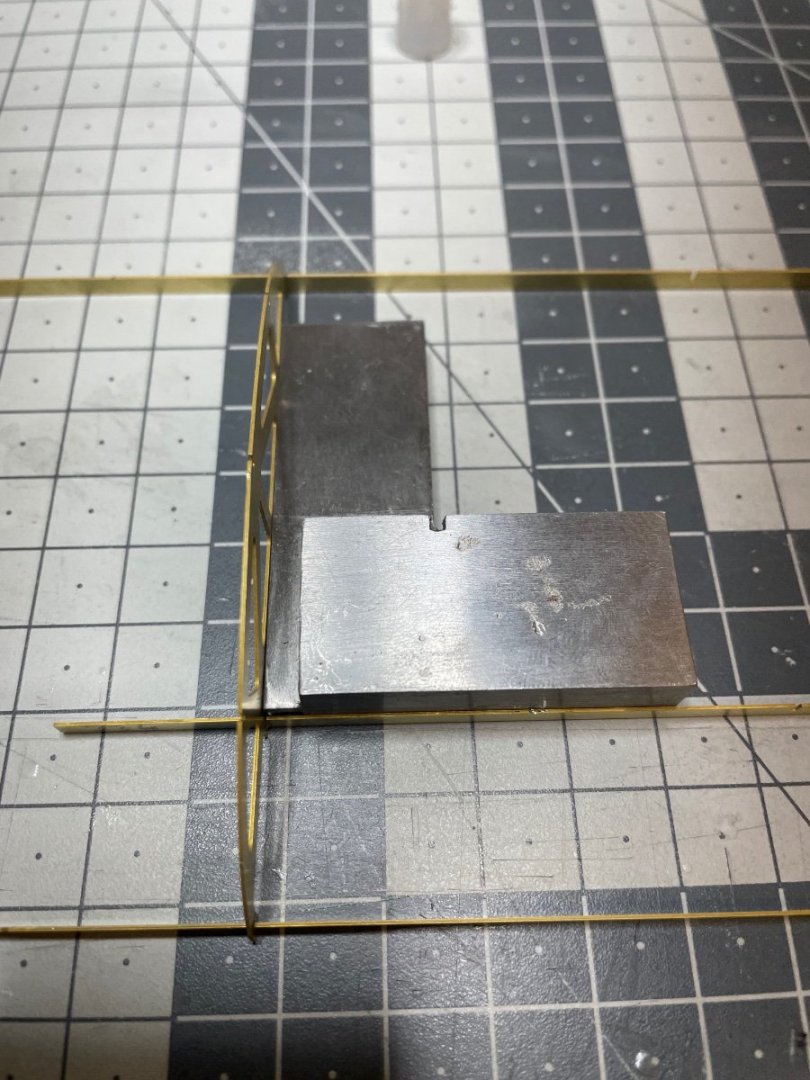

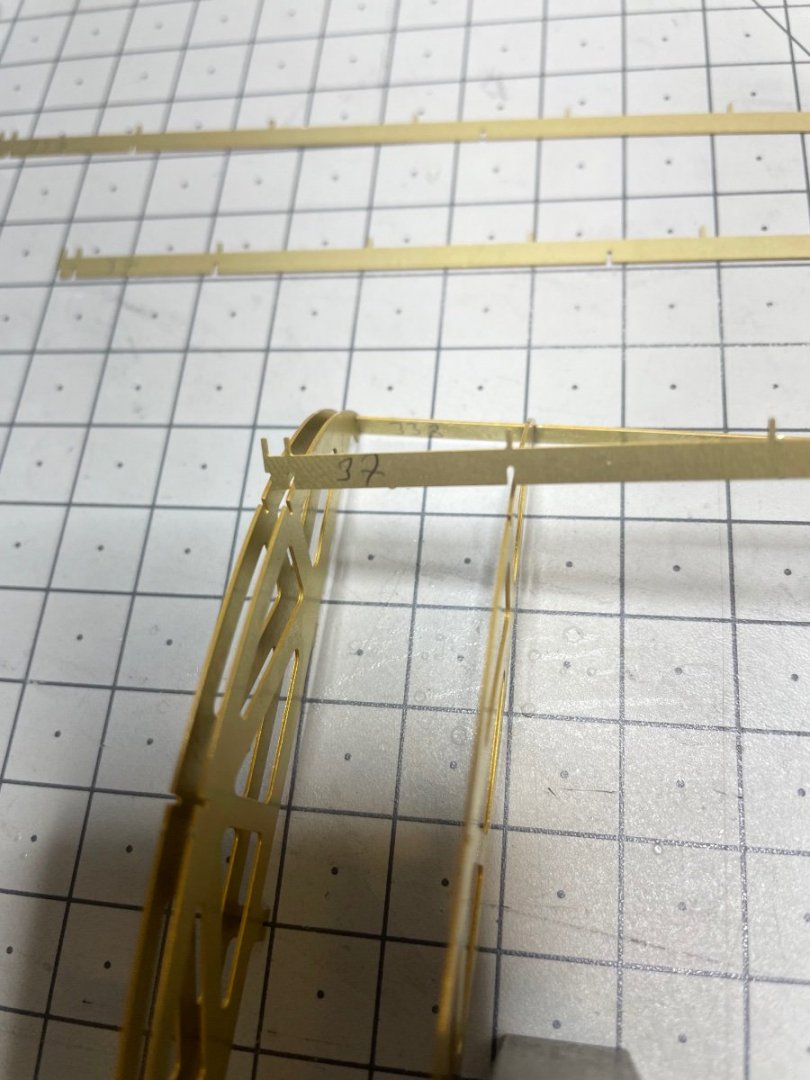

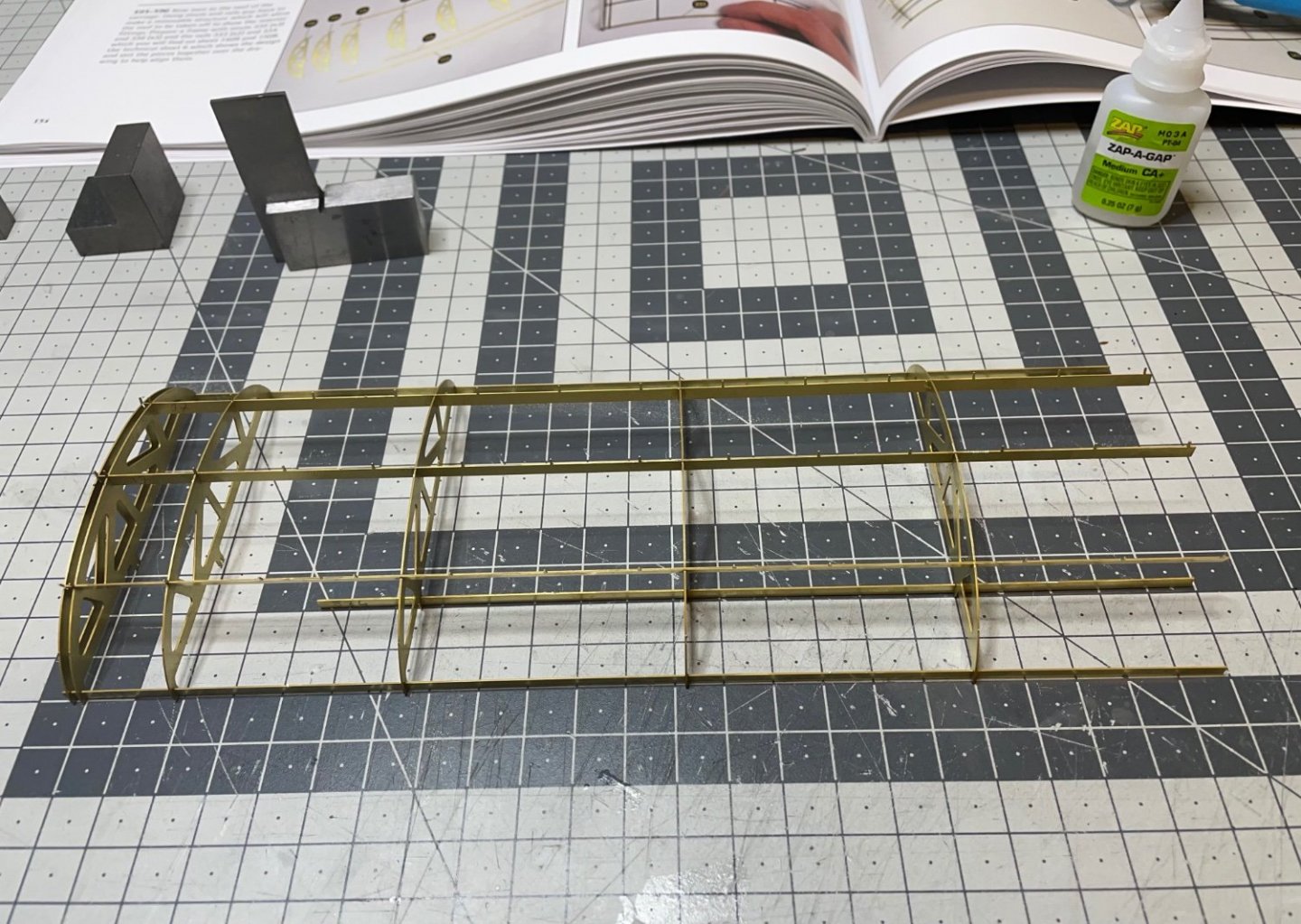

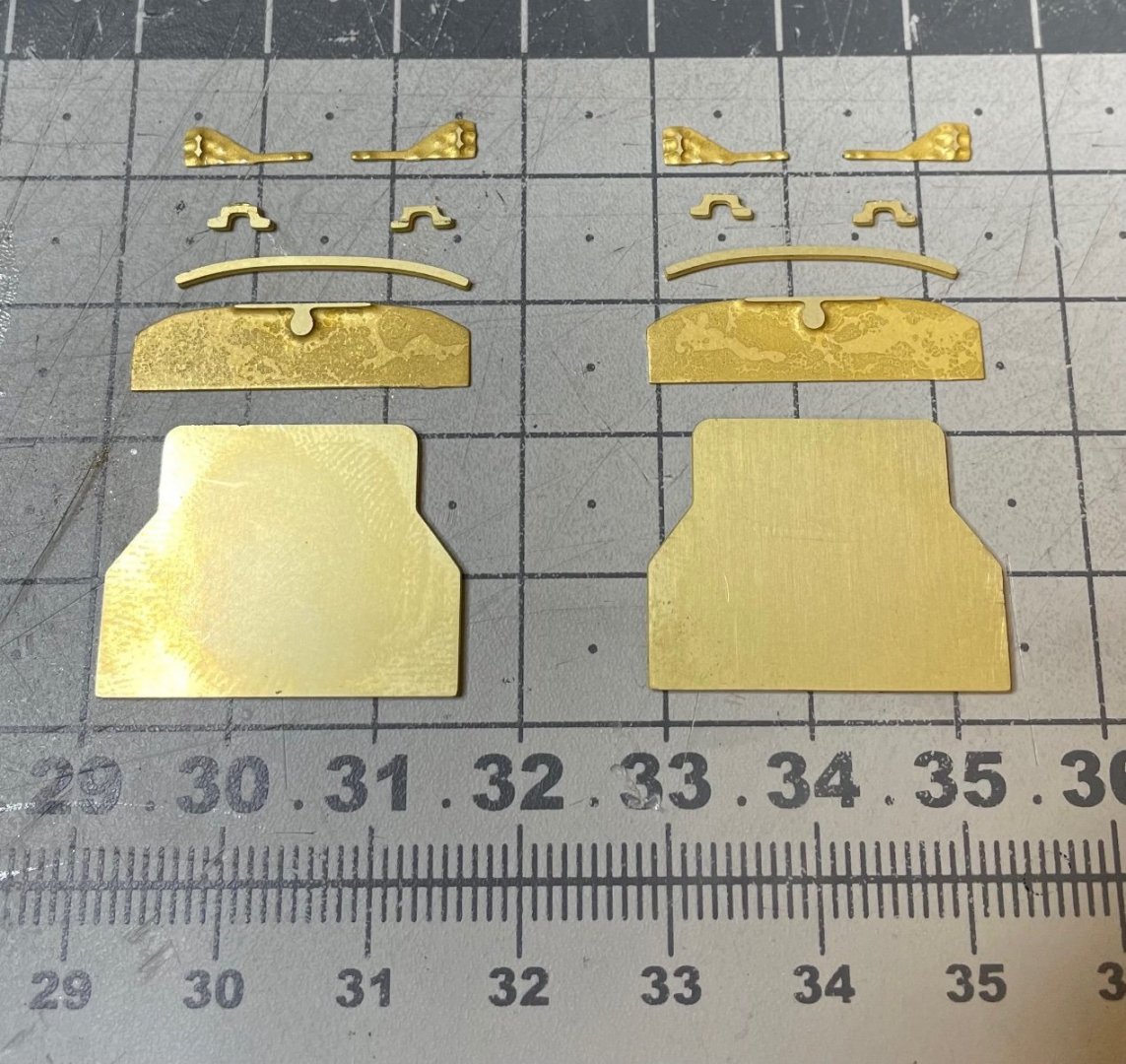

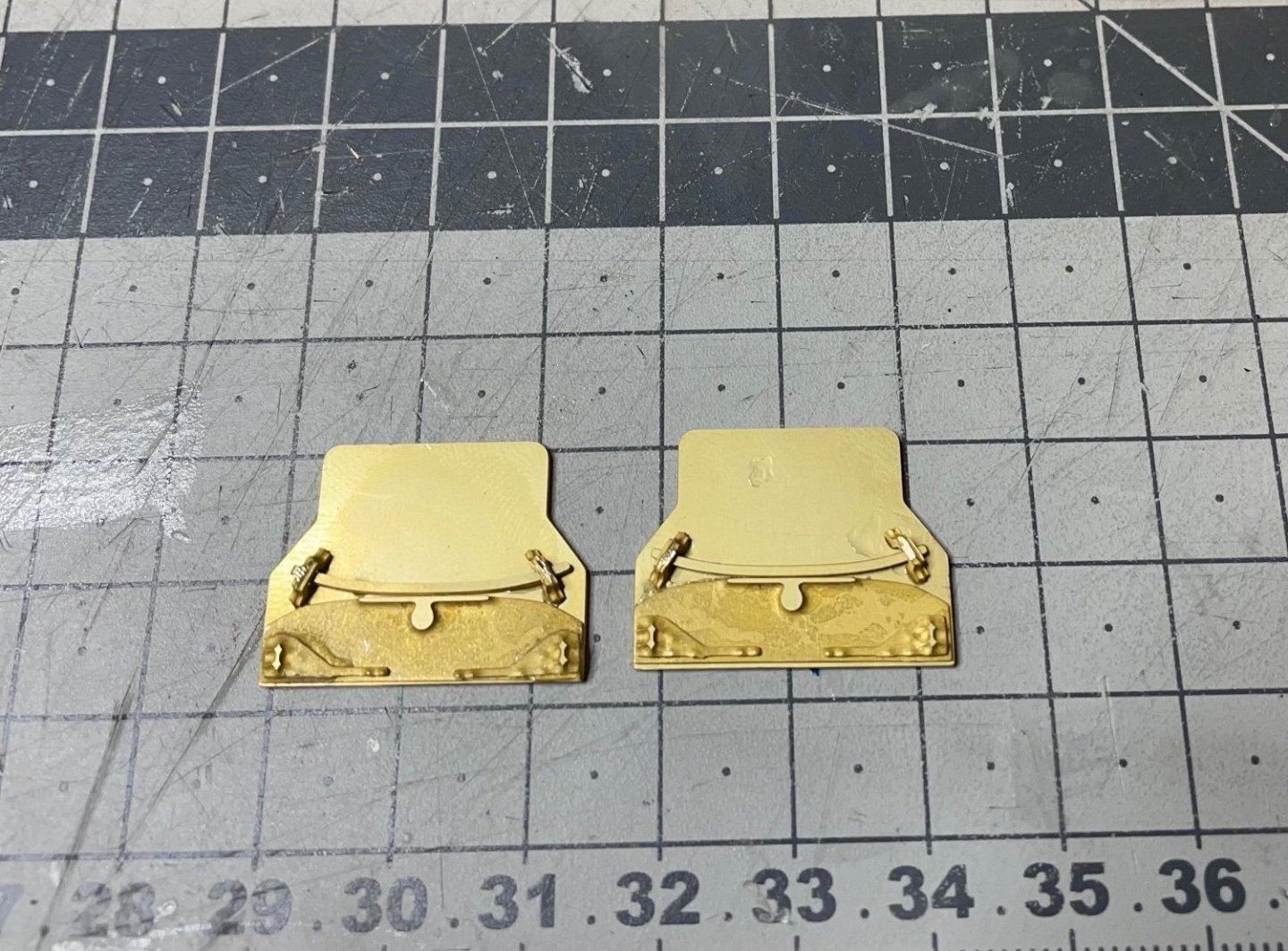

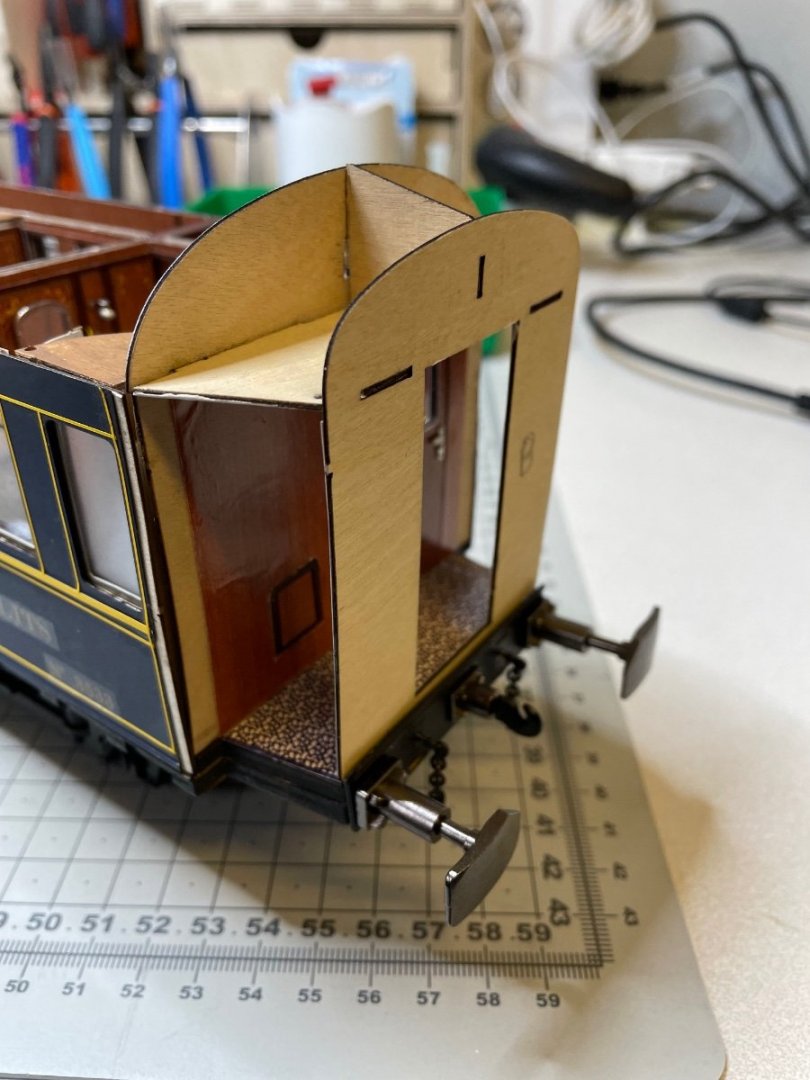

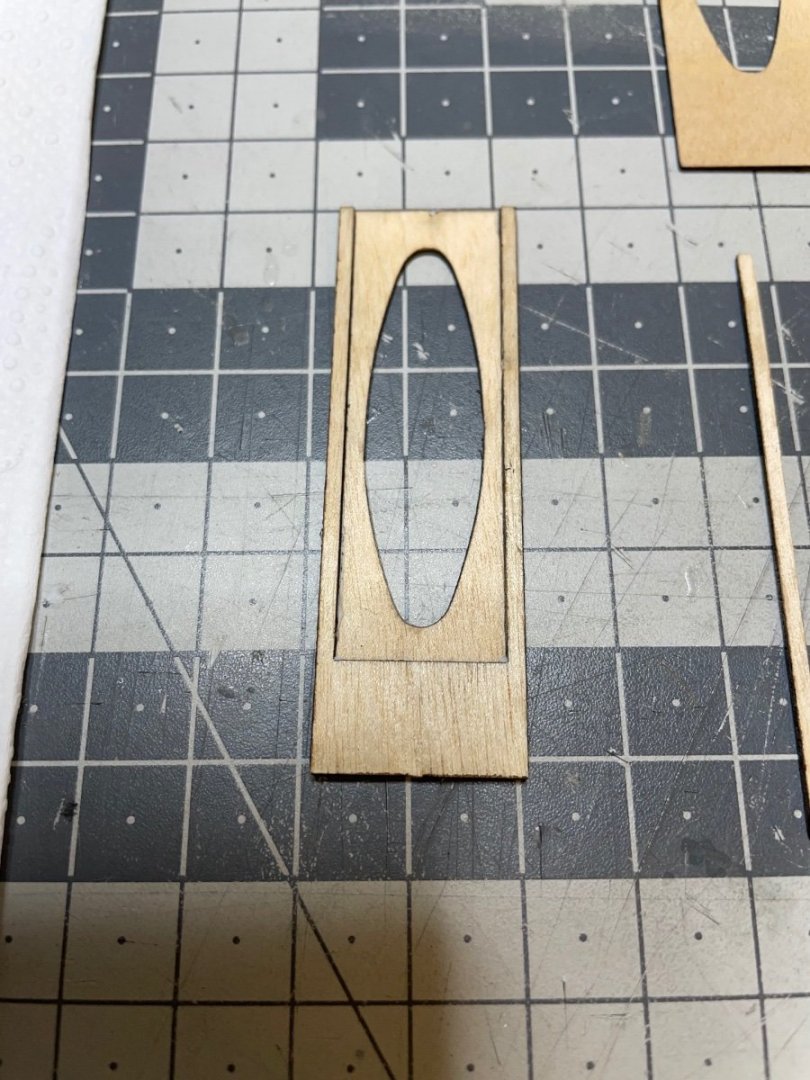

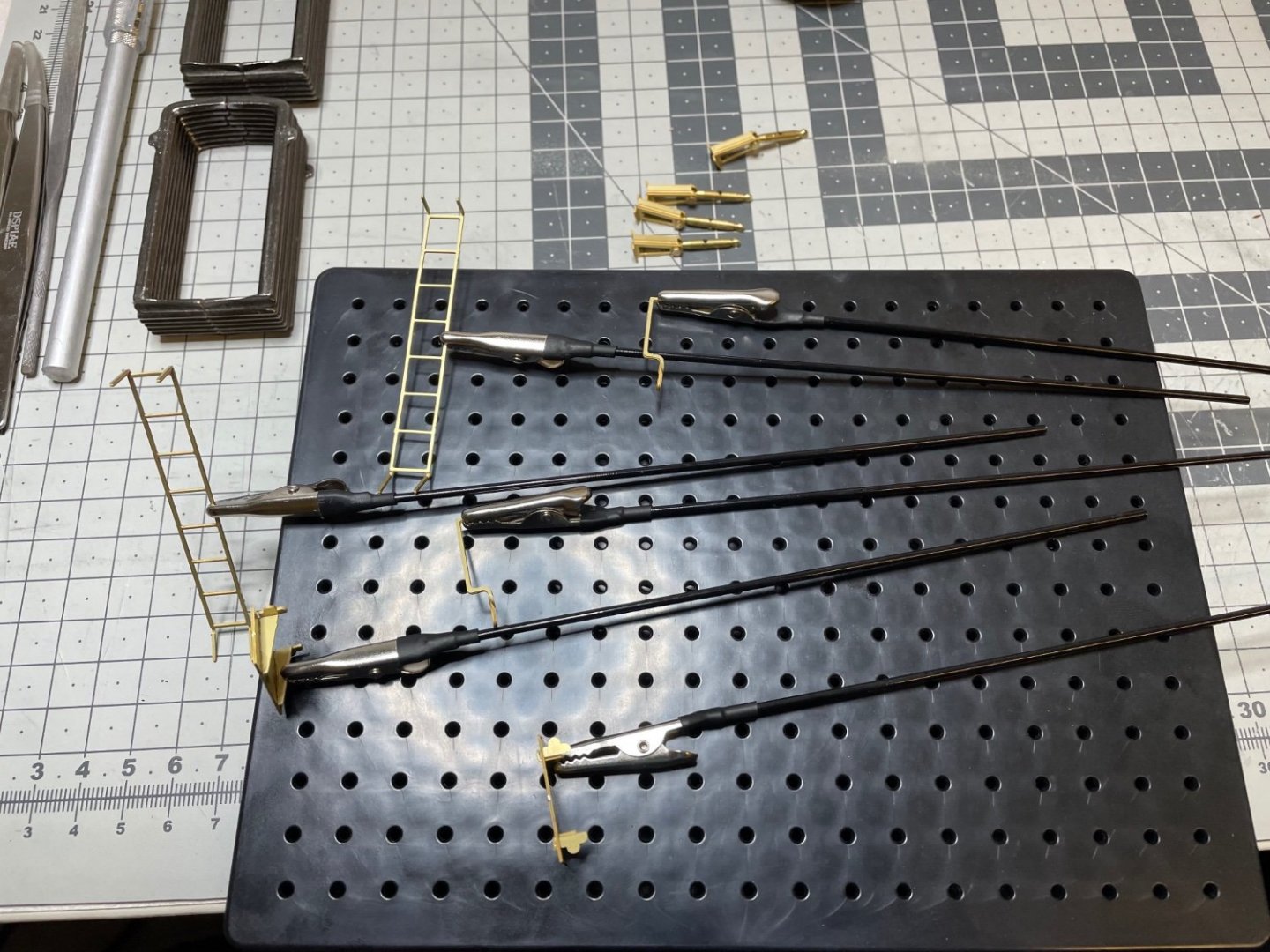

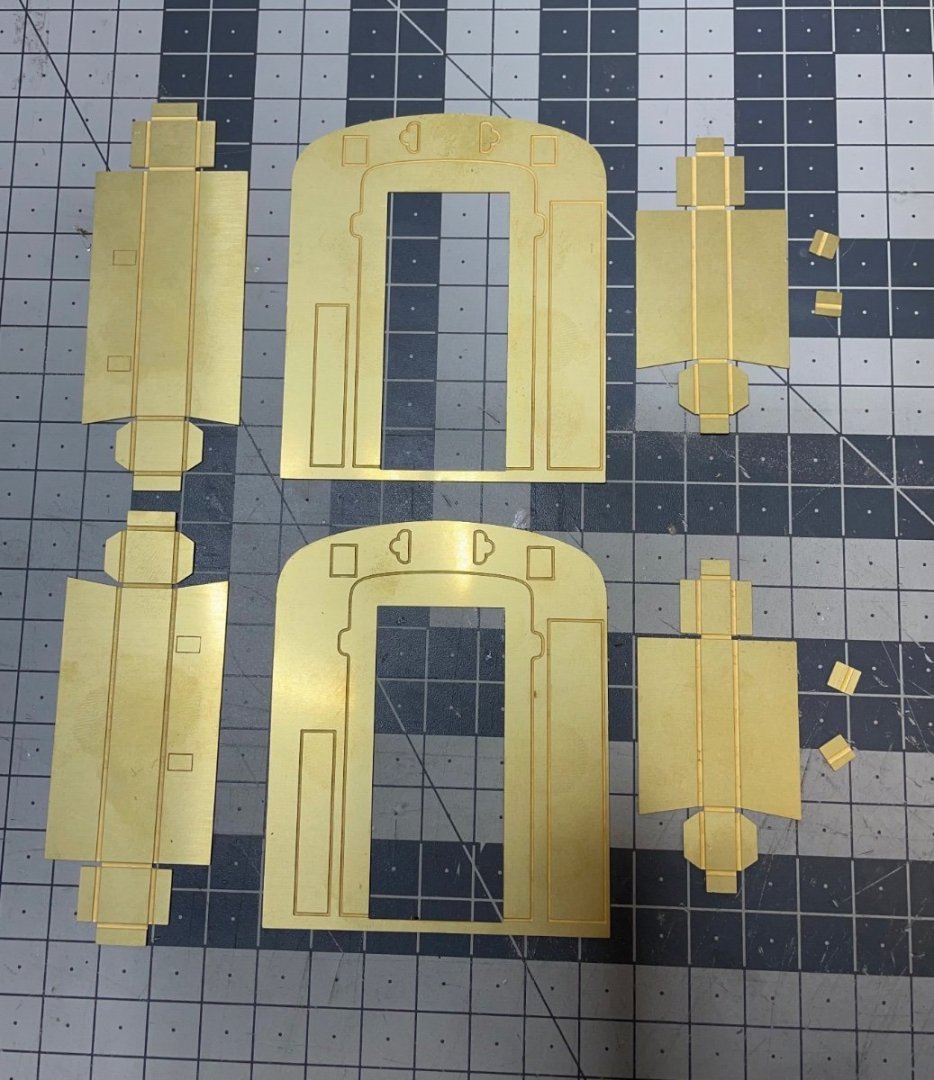

Roof is a combination of three constructions, which will be finally assembled together on common rails. The completed roof structure will not be glued to the carriage, instead it will be removable to make it possible to show the inside to your friends. Figures 401-407: The first construction. The parts are very precise and they fit perfect. I used CA glue all the way, using different viscosities depending. Paying attention to alignments is the key in achieving a correct structure, hence I took my time with ensuring right angles.

-

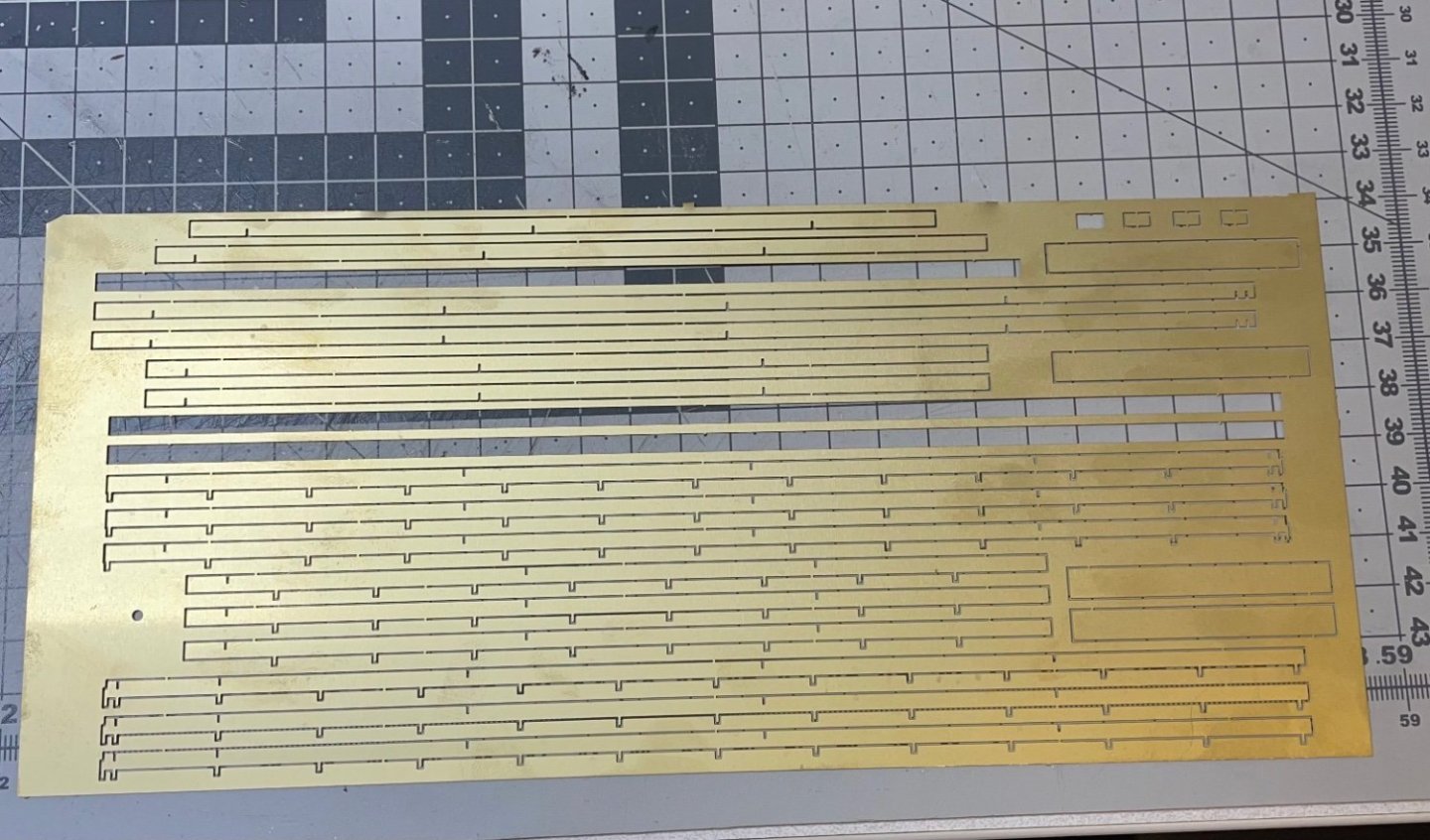

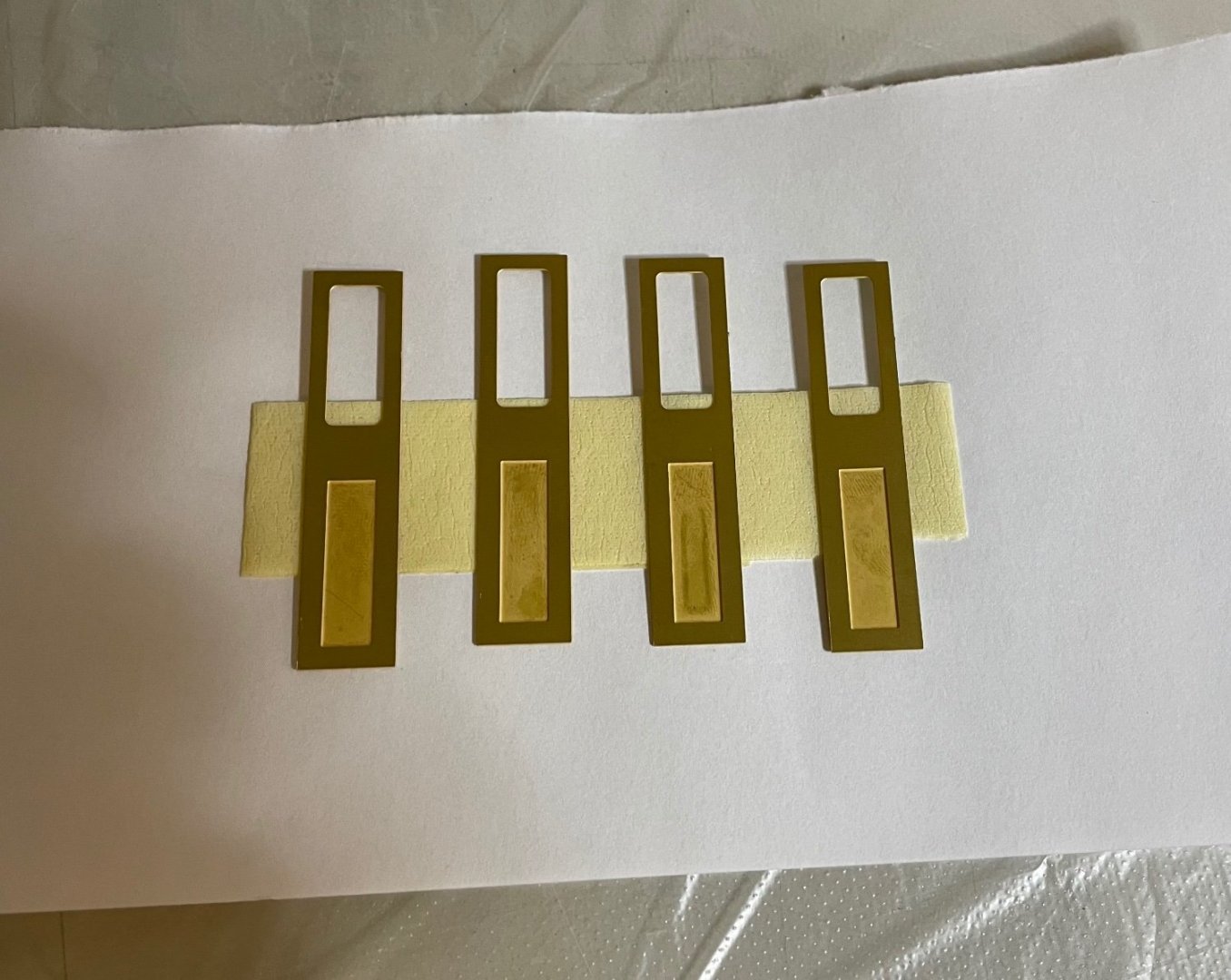

BUILD DAY 39 / 2.5 hr / (TOTAL: 101 hrs) I ruined my good old airbrush a few days ago. While waiting for the new (and the better) one to arrive, I continue with the roof construction. Figure 401 : One of the etched sheets of roof parts. You really want to number and remove each part from the sheet one by one as you go along in order to avoid finding out you glued the wrong piece .

-

That could have worked, too, I guess. I do have Gorilla Glue actually but it didn't occur to me. Though, there is very limited possibility to clamp anywhere on the structure it would be very difficult to keep the parts squeezed until the glue has cured. But anyway, now I did it this way and the result was satisfactory enough 🙂.

-

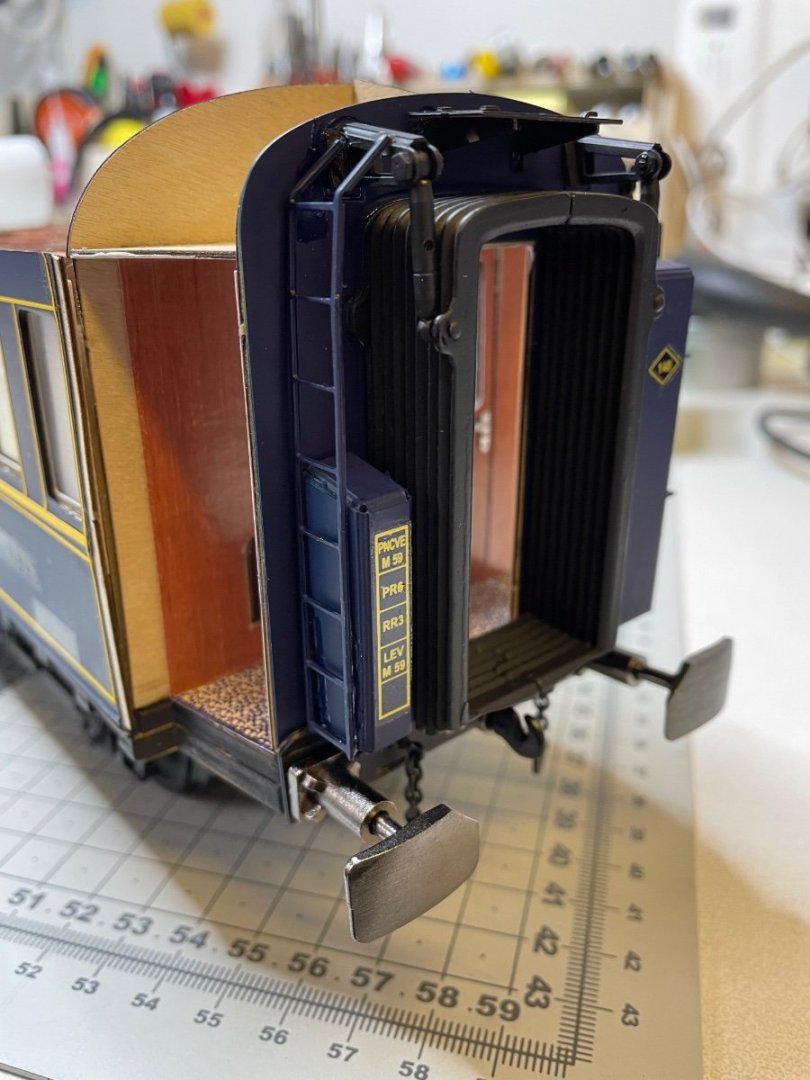

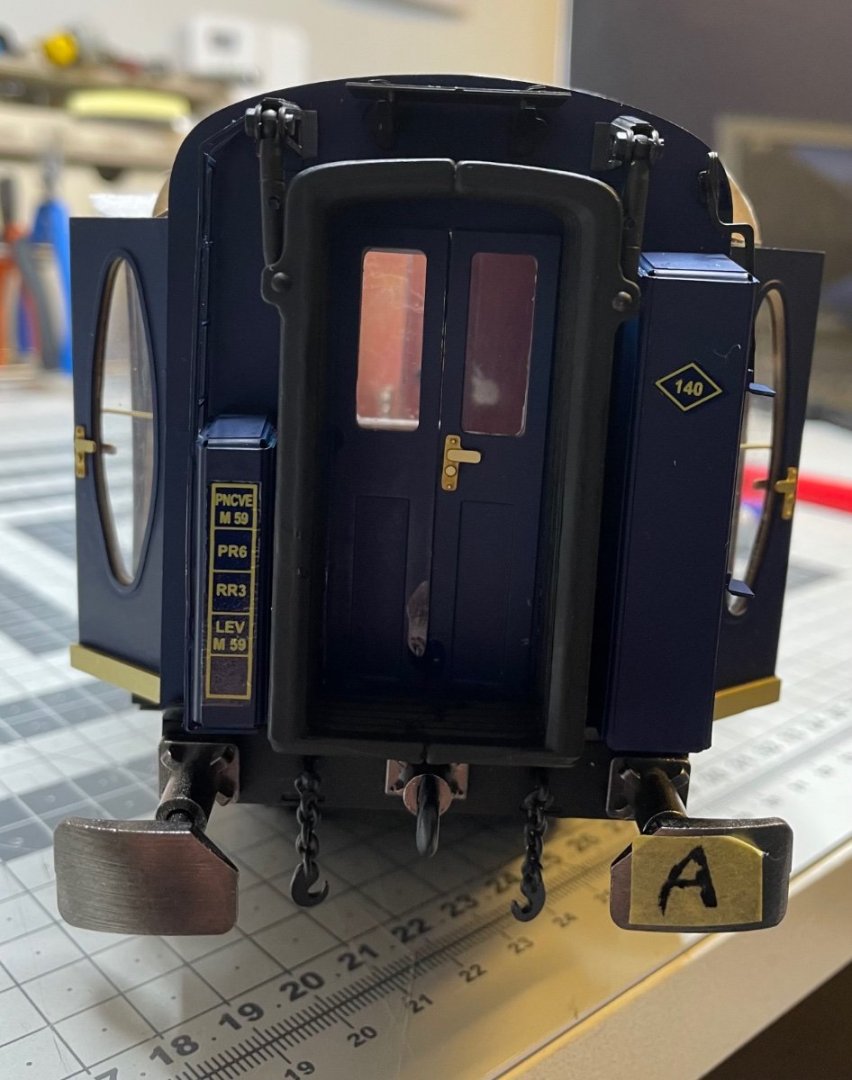

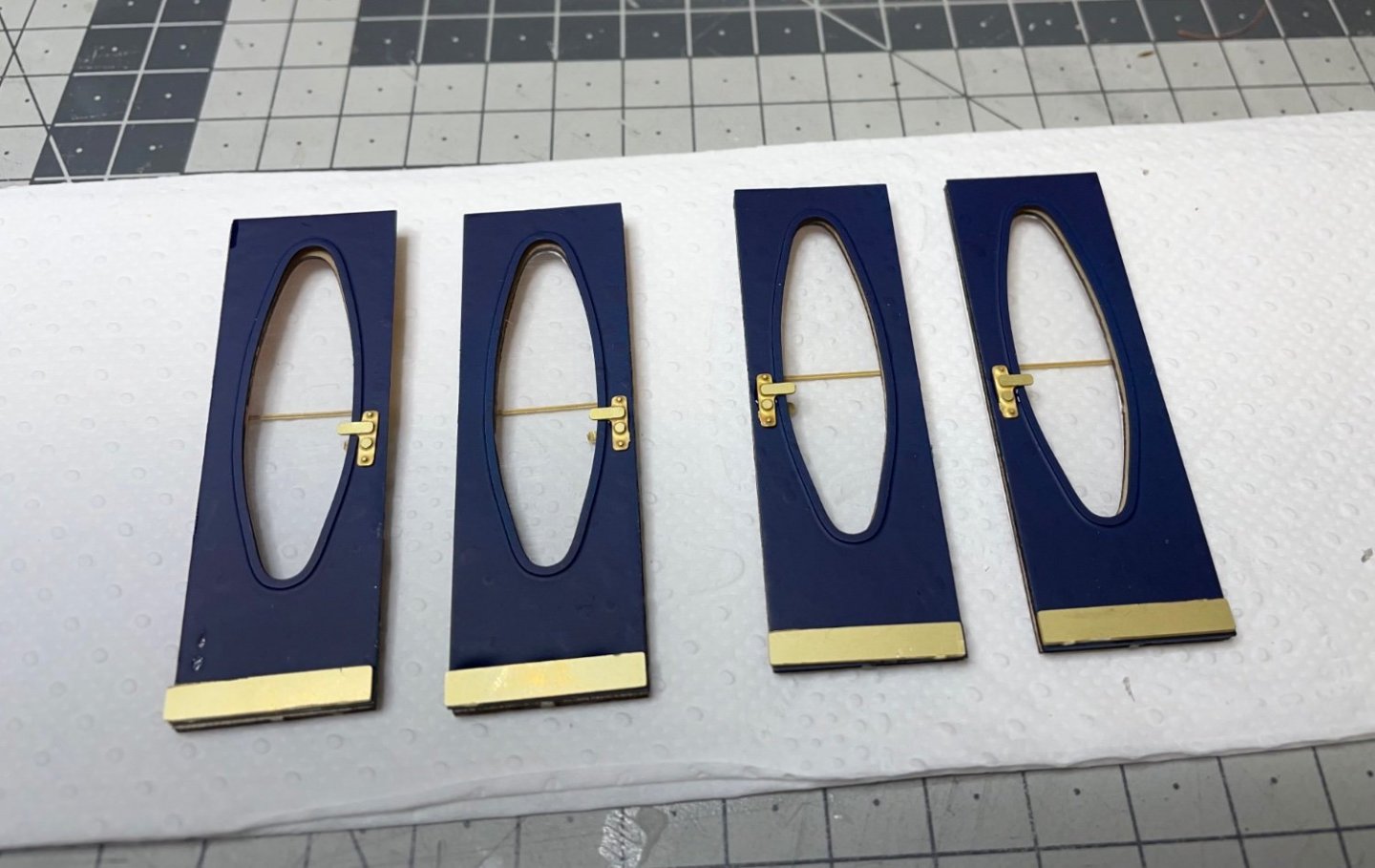

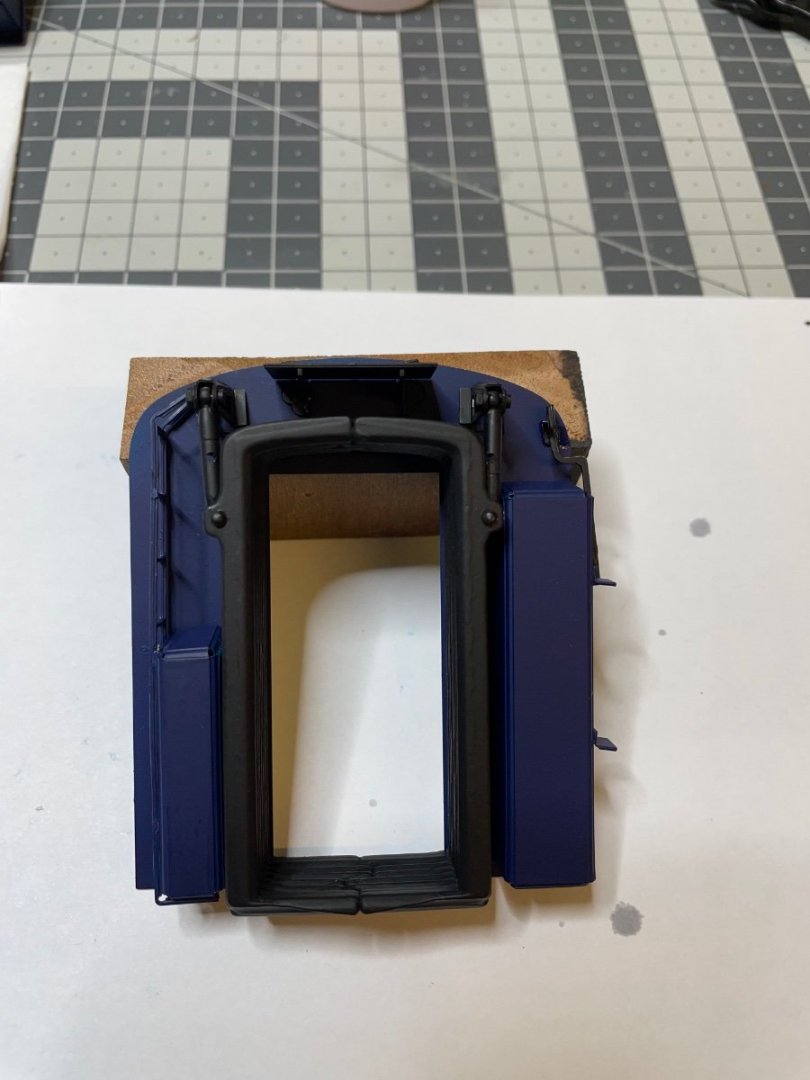

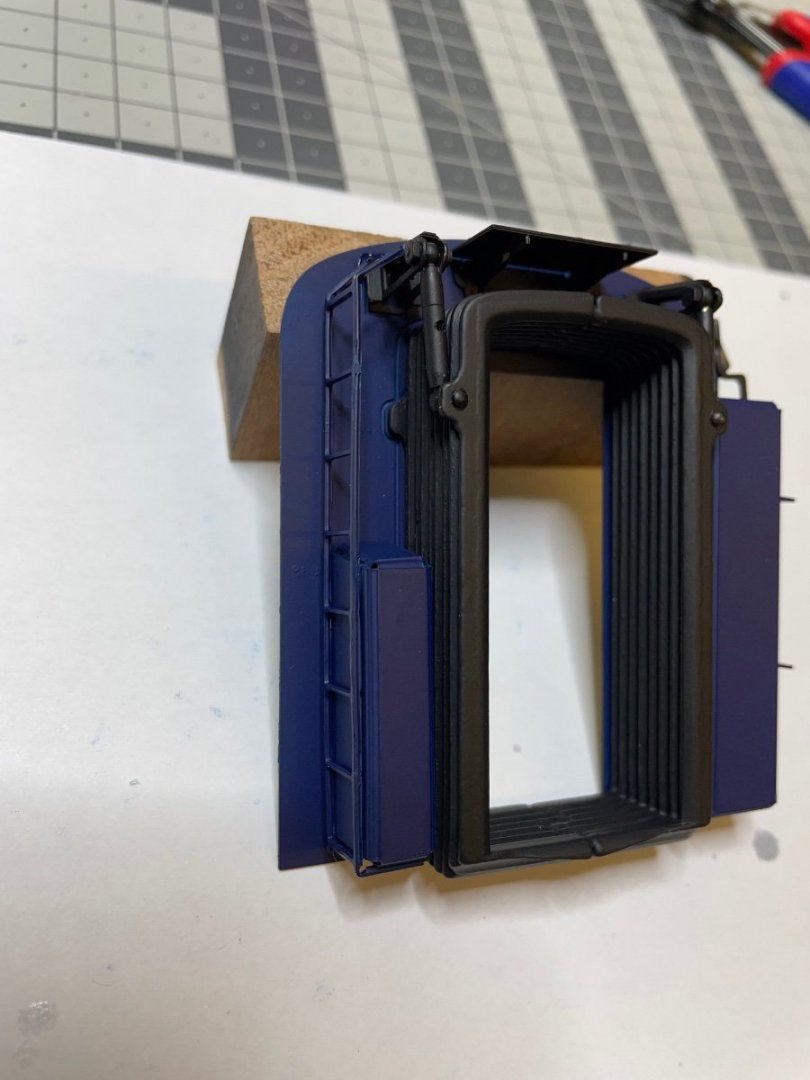

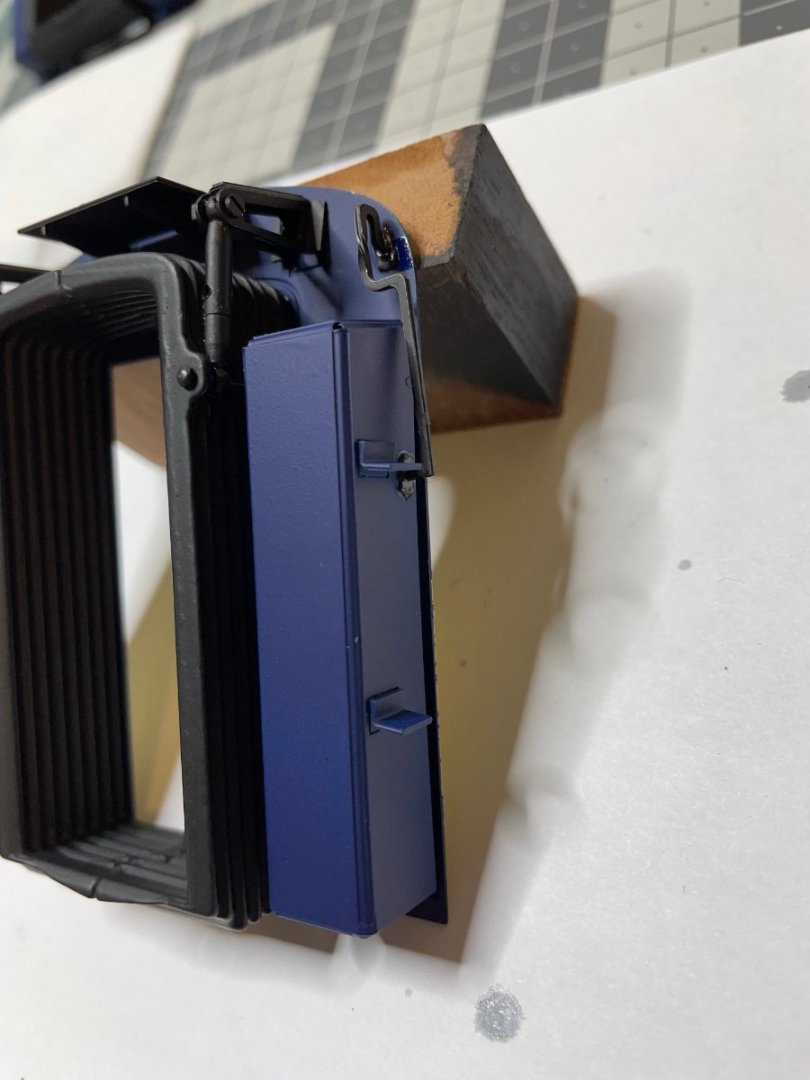

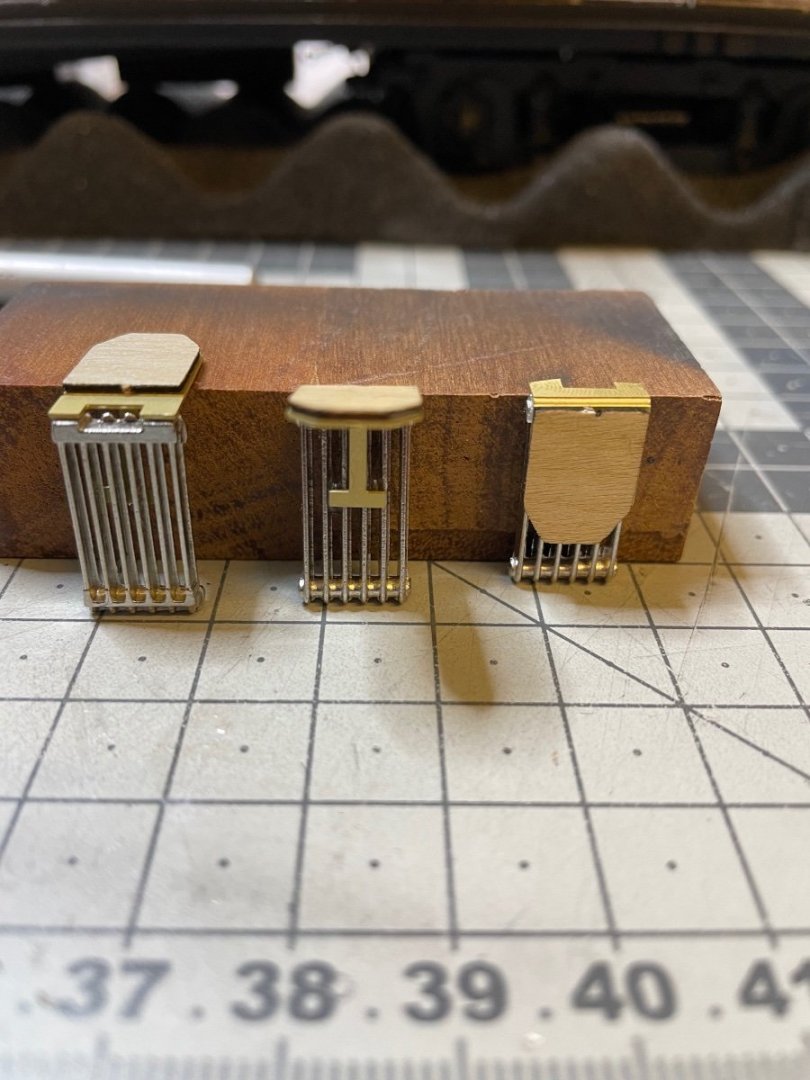

Assembling the head ends (with bellows) as well as the swing doors and lobby doors I had prepared earlier. The swing doors on either side of the bellows, as the name suggests, swing open and close, with the help of a copper bar. The small doors inside the bellows are fixed. There will come a folded iron plate glued on them later. That plate is supposed to be opened to form a "bridge" between the wagons to allow passage, when the doors are open. Figures 391-397: This is all for now. Thanks for watching!

-

BUILD DAY 37 / 2 hr / (TOTAL: 98 hrs) The decals on carriage and head ends are ready, now finally it is time to assemble the carriage walls on the structure. A very delicate work where you use CA glue on a rather long structure and get the positioning right at first try. I dry tested and tested and tested and finally got the courage to do it. The idea of laying it on its side on a soft sponge helped get it done more easily. Below some photos showing the progress and the end result. Figures 385-390:

-

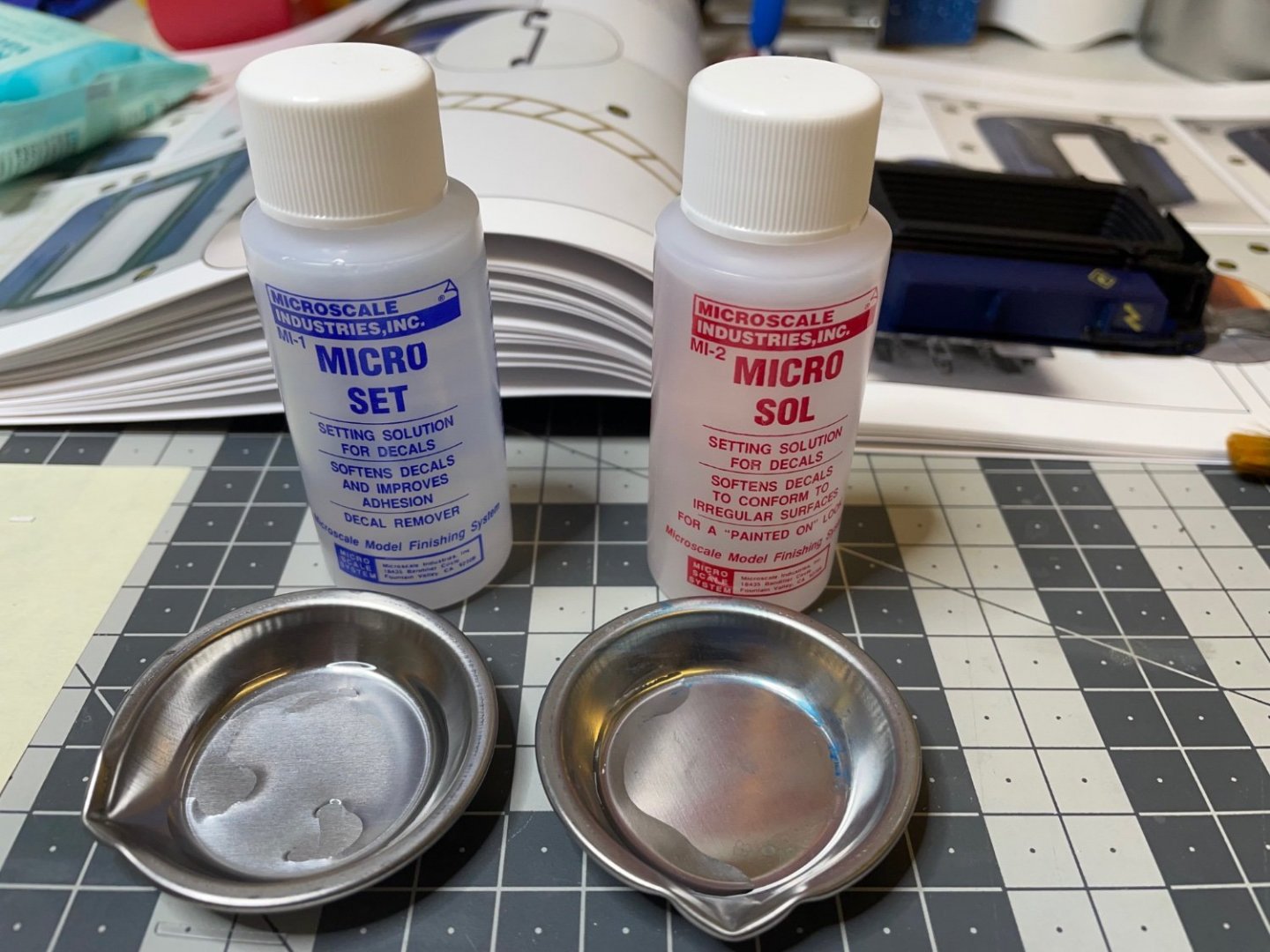

Figures 380 - 384: Now I try the Micro Set and Micro Sol chemicals for the first time. Overall they look much better than standard decal application and I am pleased with the result. The Micro Sol solution is mainly aimed for further softening the decal to better adapt to uneven and irregular surfaces. Even though the surfaces on this train are plain flat, I still used it since it helps them look more like a layer of paint than a sticker. I dropped a small amount of each on separate cups and used separate brushes for application. I didn't want to dip the brush directly into the bottle. For detail instructions visit this document from the manufacturer: http://www.microscale.com/Merchant2/graphics/Instructions/MSISysteminstr.pdf This is all for now. Thanks for watching!

-

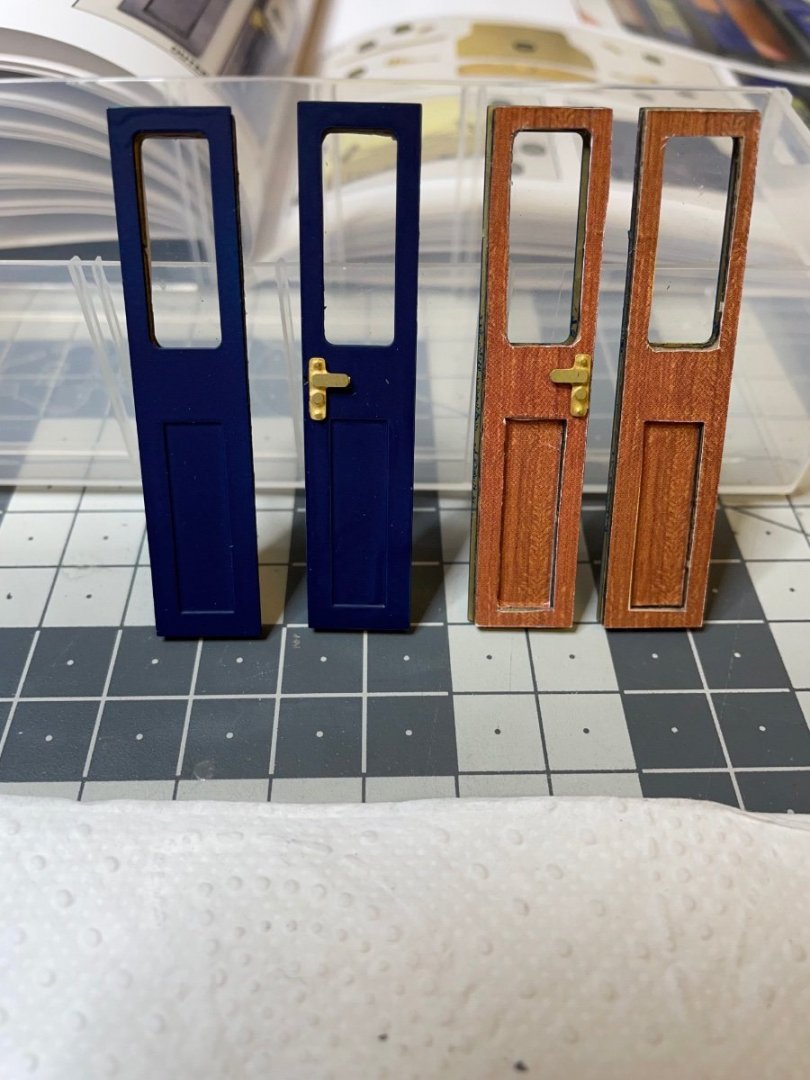

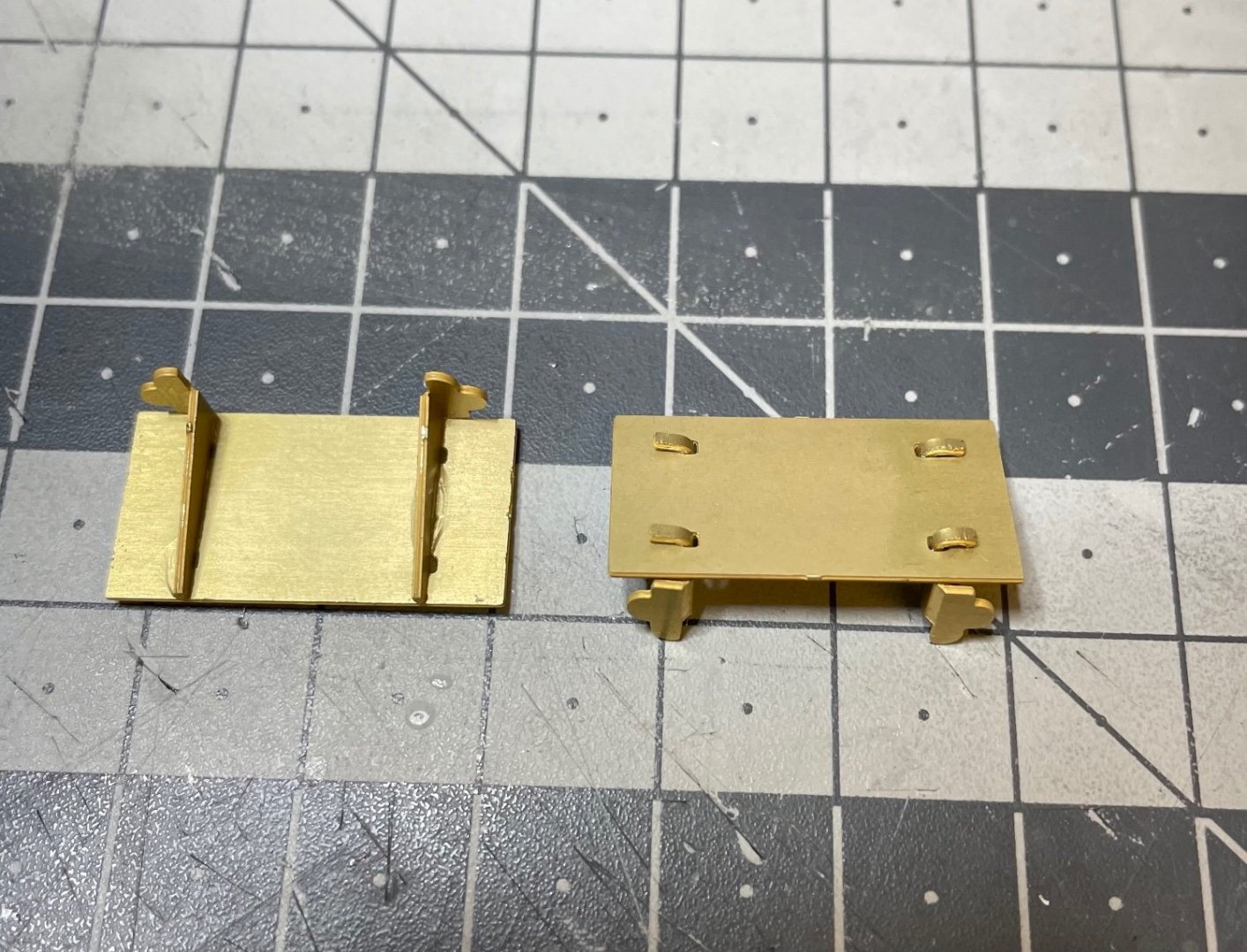

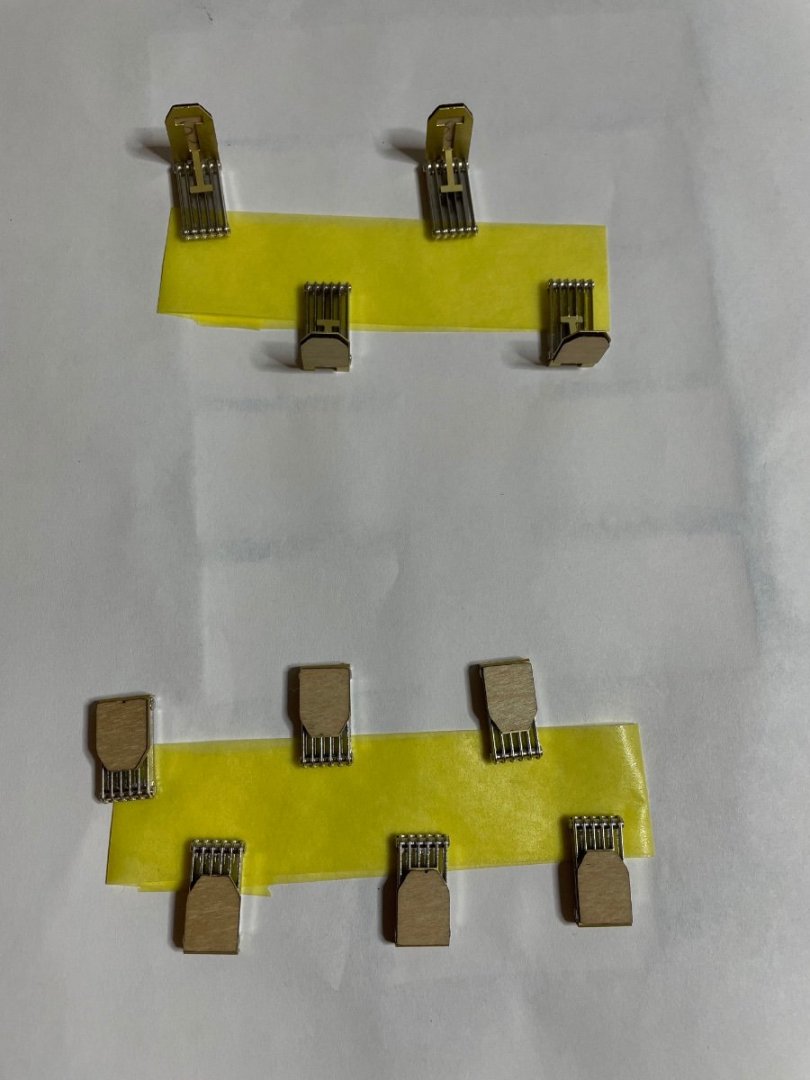

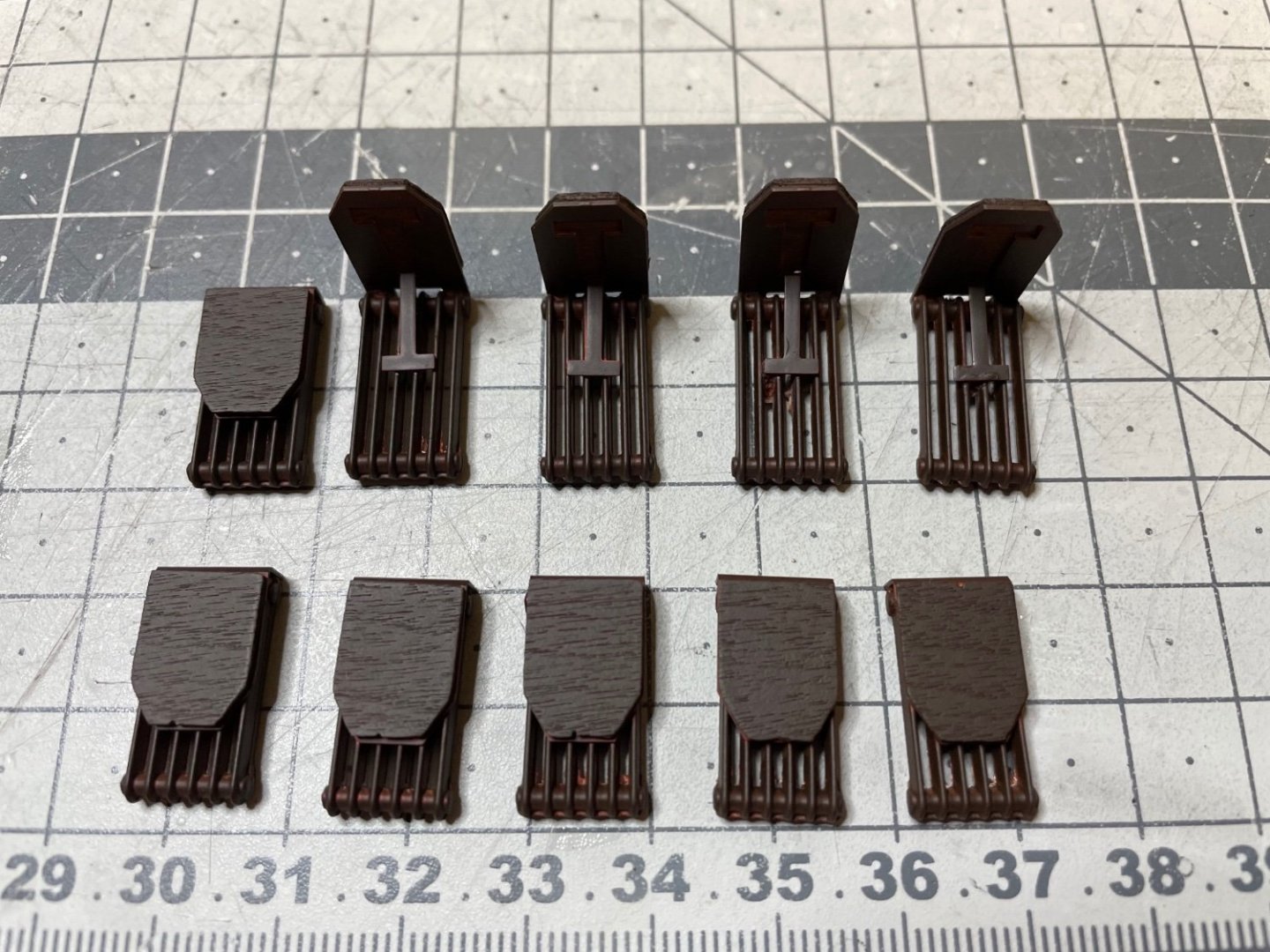

BUILD DAY 36 / 3 hr / (TOTAL: 96 hrs) Decal chemicals have arrived and I will start applying the decals. I have also ordered a new decal sheet from Amati (at a cost). I will replace some of those I had already applied and not looking great this time using the chemicals. Today's work also includes lobby doors and swing doors. - Swing doors, the slimmer ones, will be mounted on the head ends above. They are fixed. - The lobby doors, the wider ones, are to be placed on both sides of each end of the carriage (total of 4). In addition, it will be possible to open/close the lobby doors. Figure 369 - 374 : Starting with the lobby doors. Each door is composed of 5 main parts (including the glass) plus the ornaments. No big surprises in building therefore not much to comment, so I just post here the pictures from the construction.

-

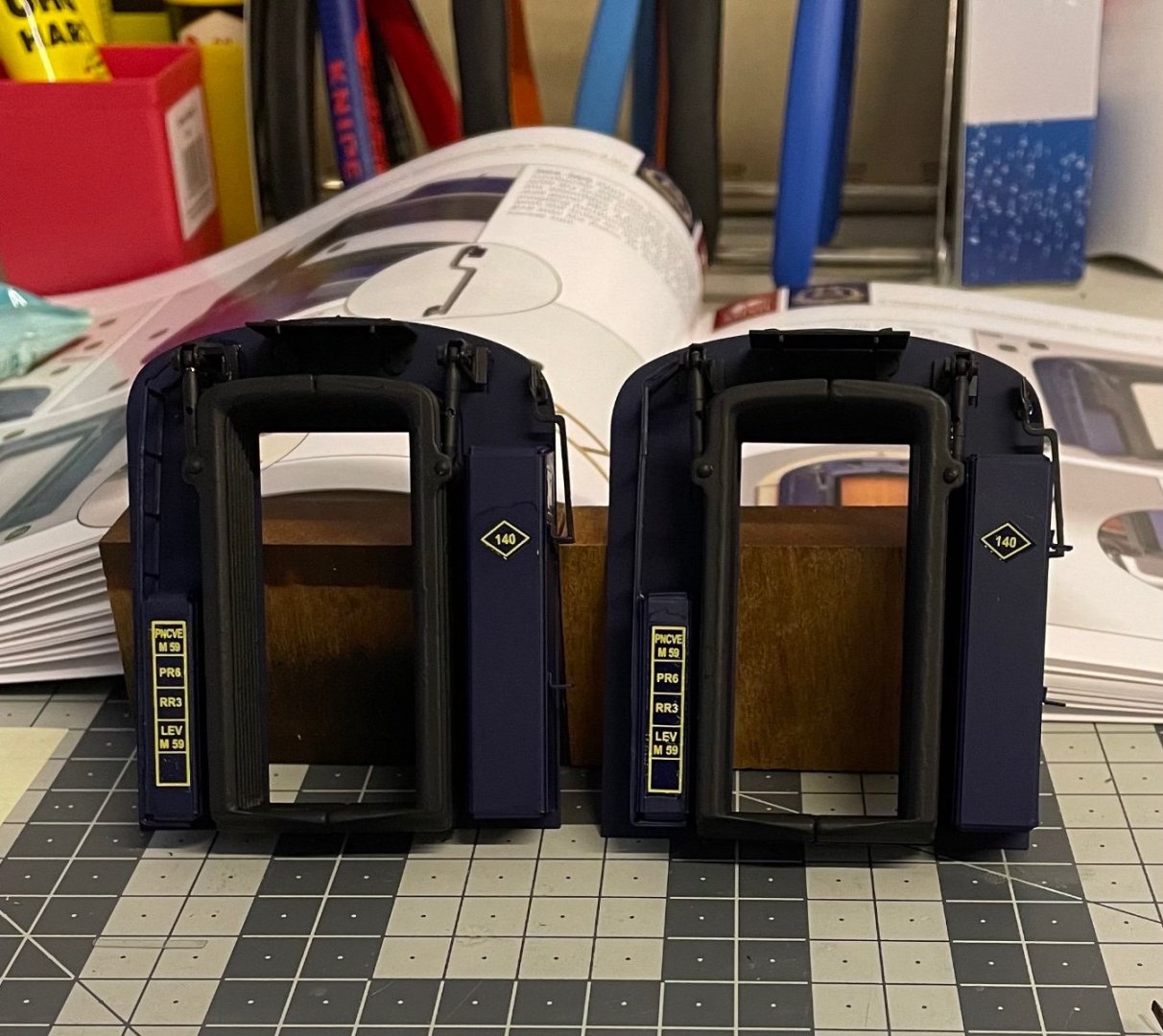

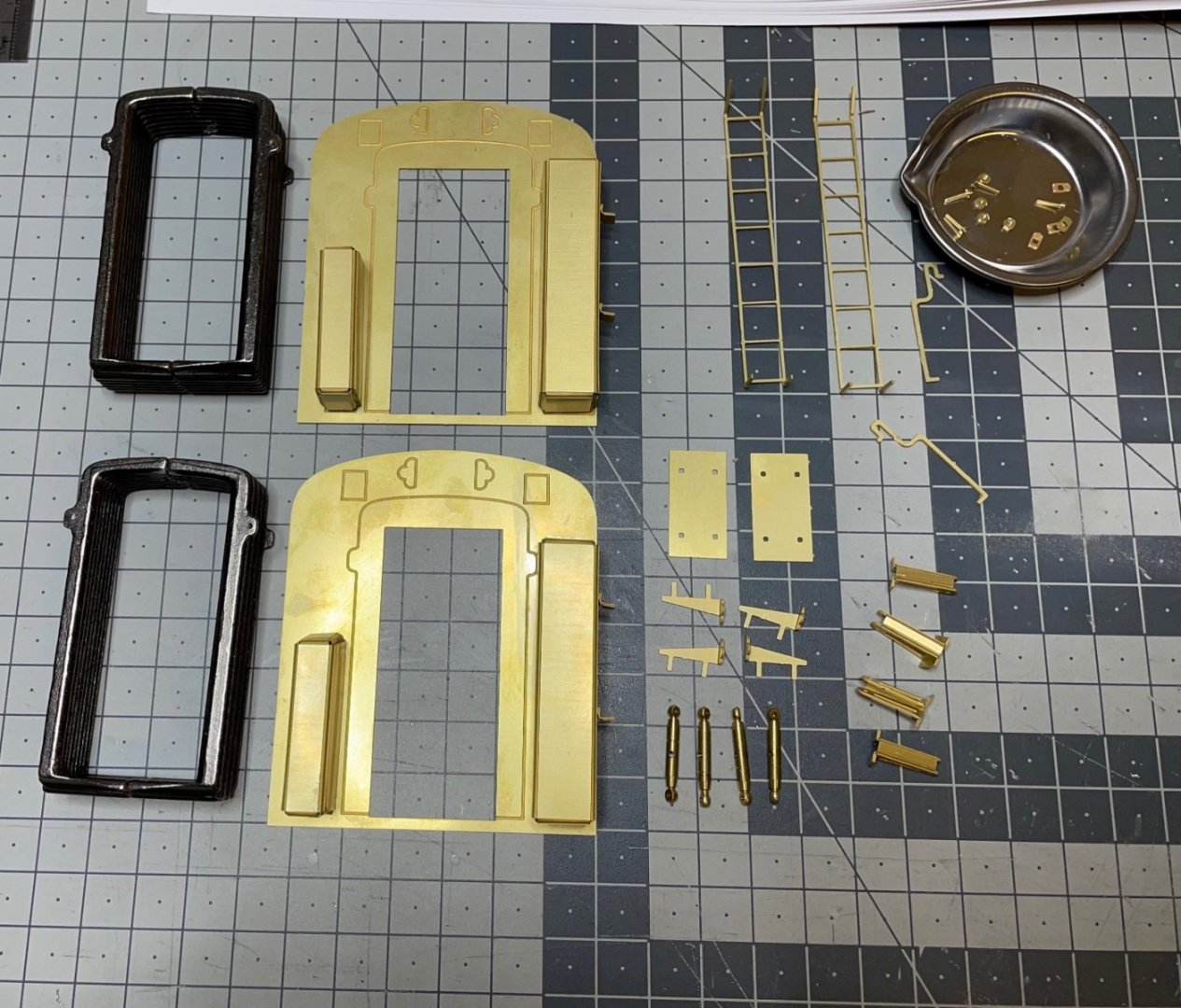

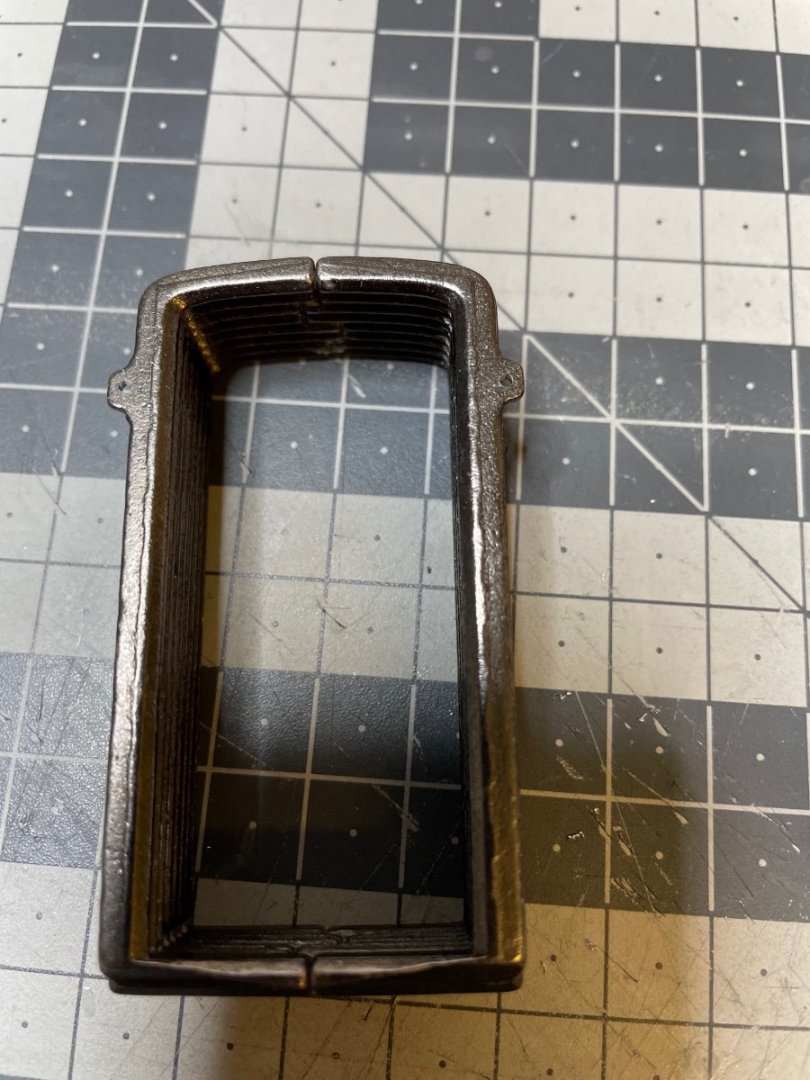

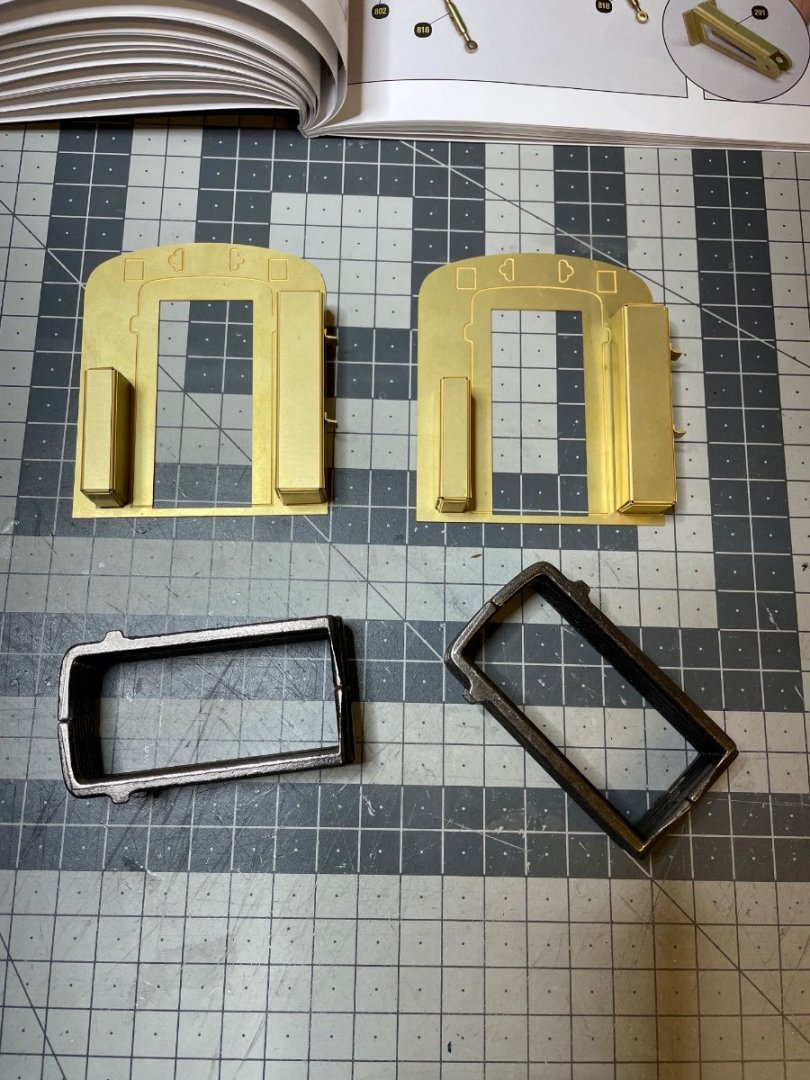

BUILD DAY 35 / 3 hr / (TOTAL: 93 hrs) While waiting for the decal chemicals in the mail, I proceeded with then next step: the head ends. Figures 358-359: They are identical at both ends of the wagon. The black parts in the photos are bellows, made of iron cast. They are made of two parts which you glue together. They take some amount of filing before they fit each other properly.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.