-

Posts

916 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by aydingocer

-

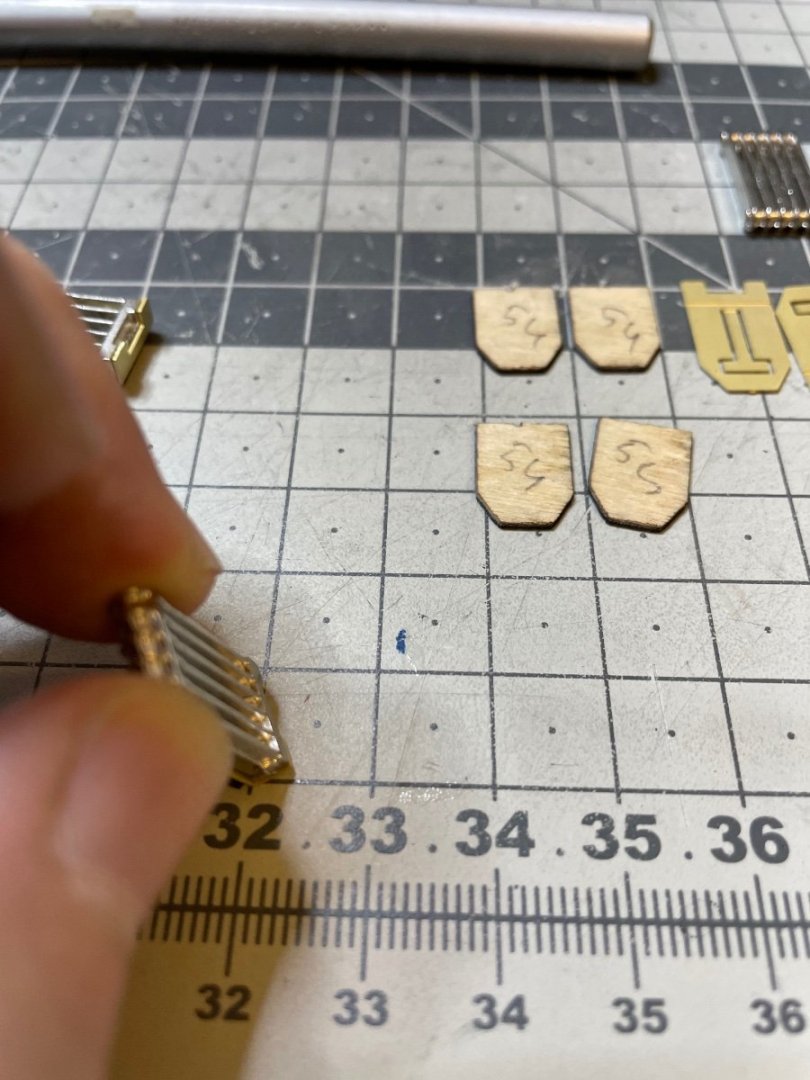

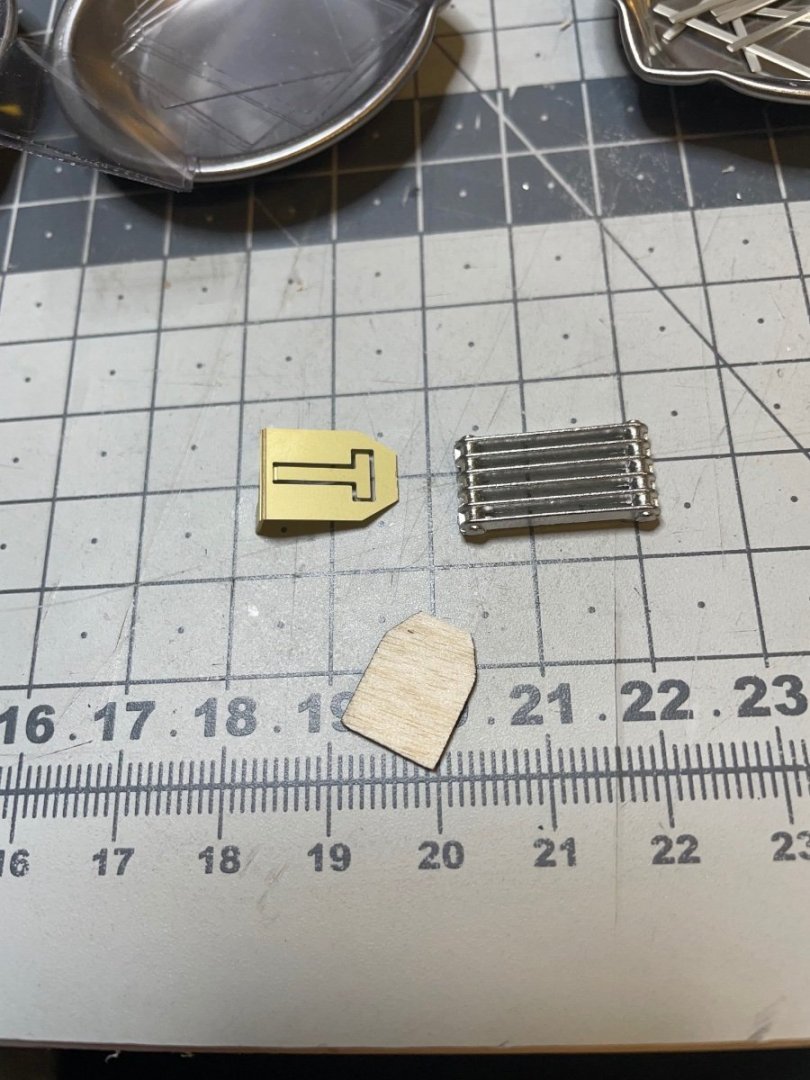

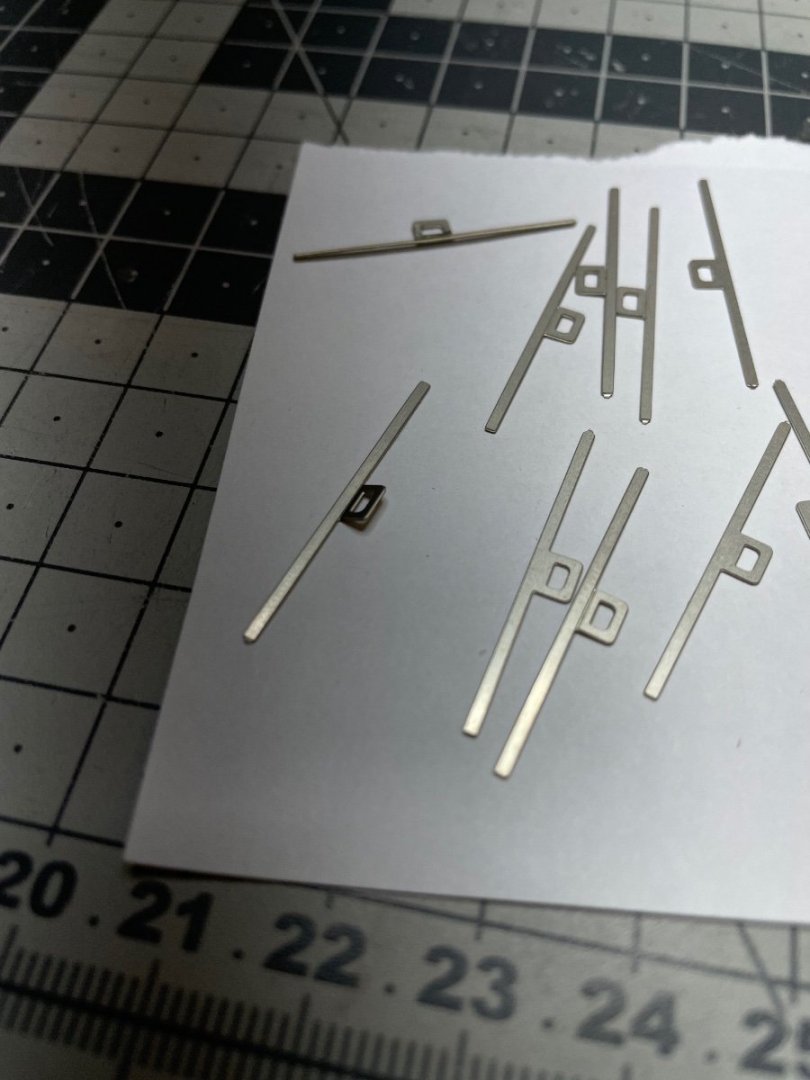

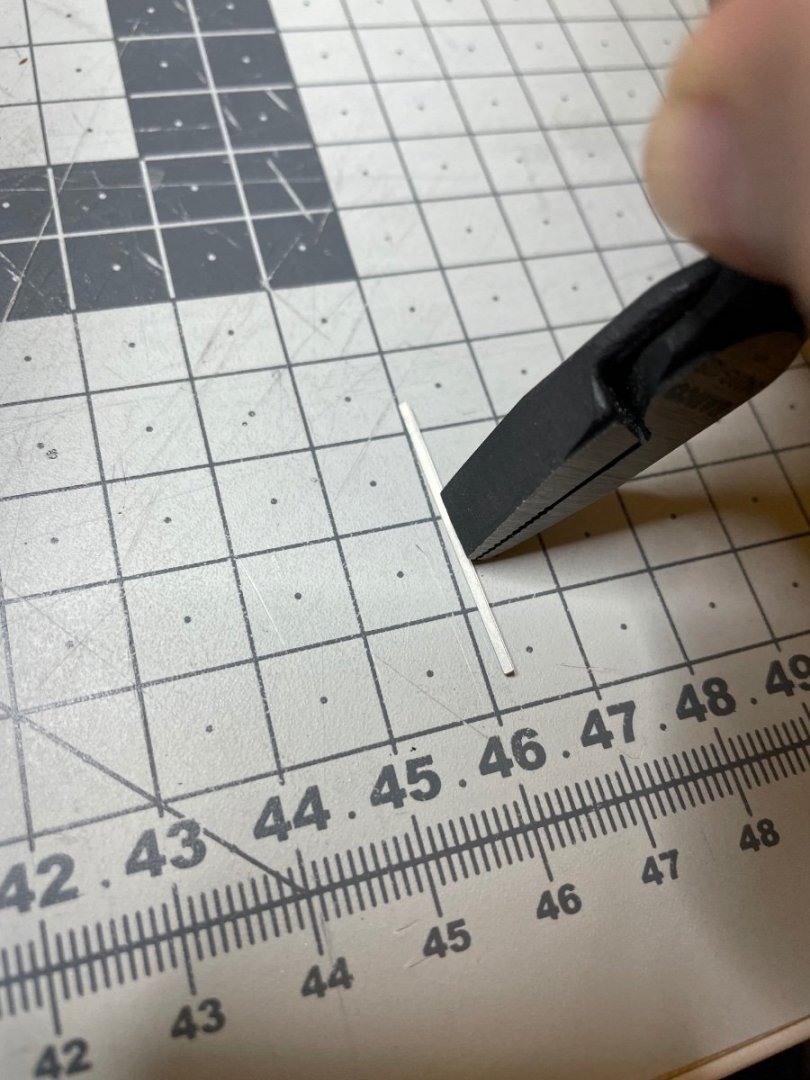

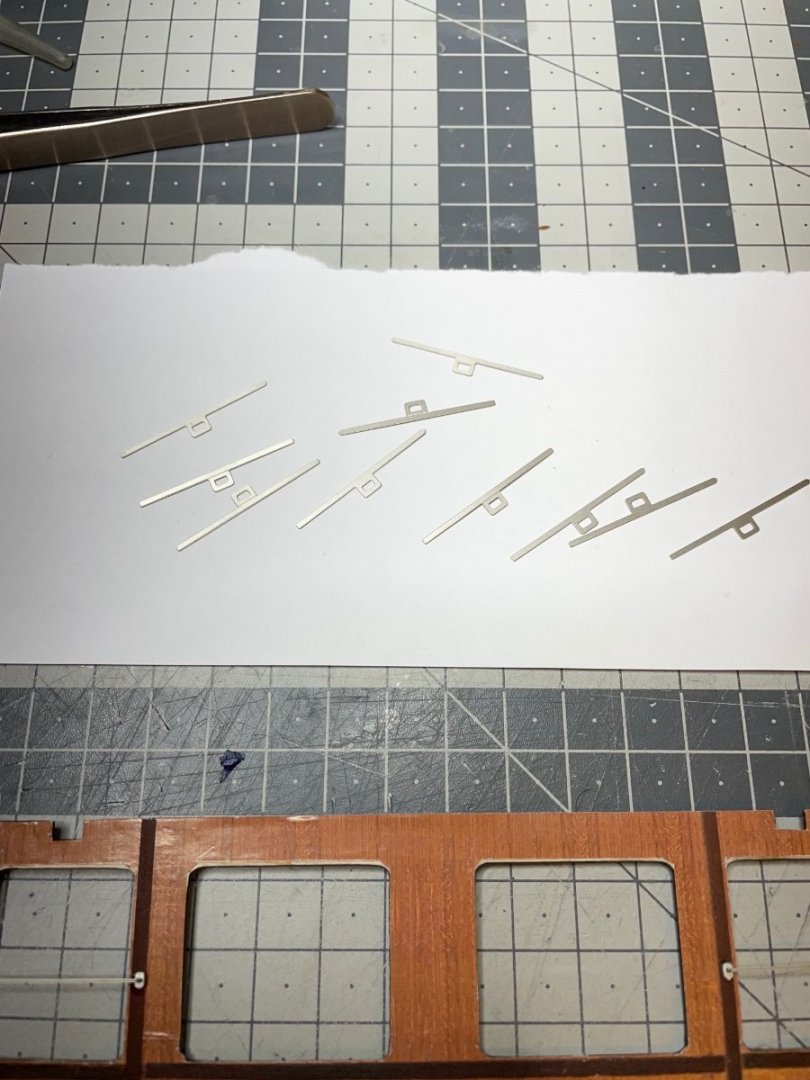

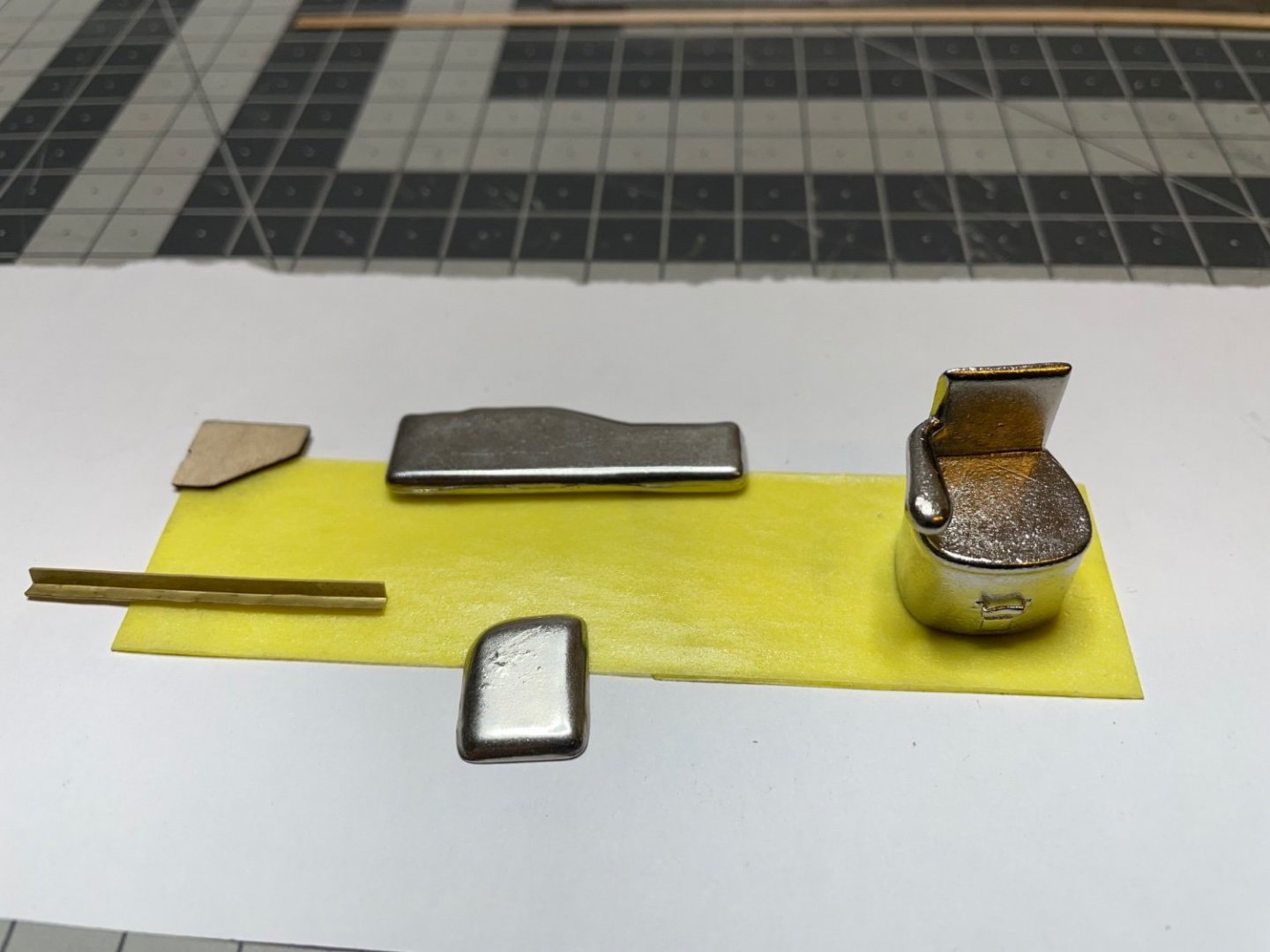

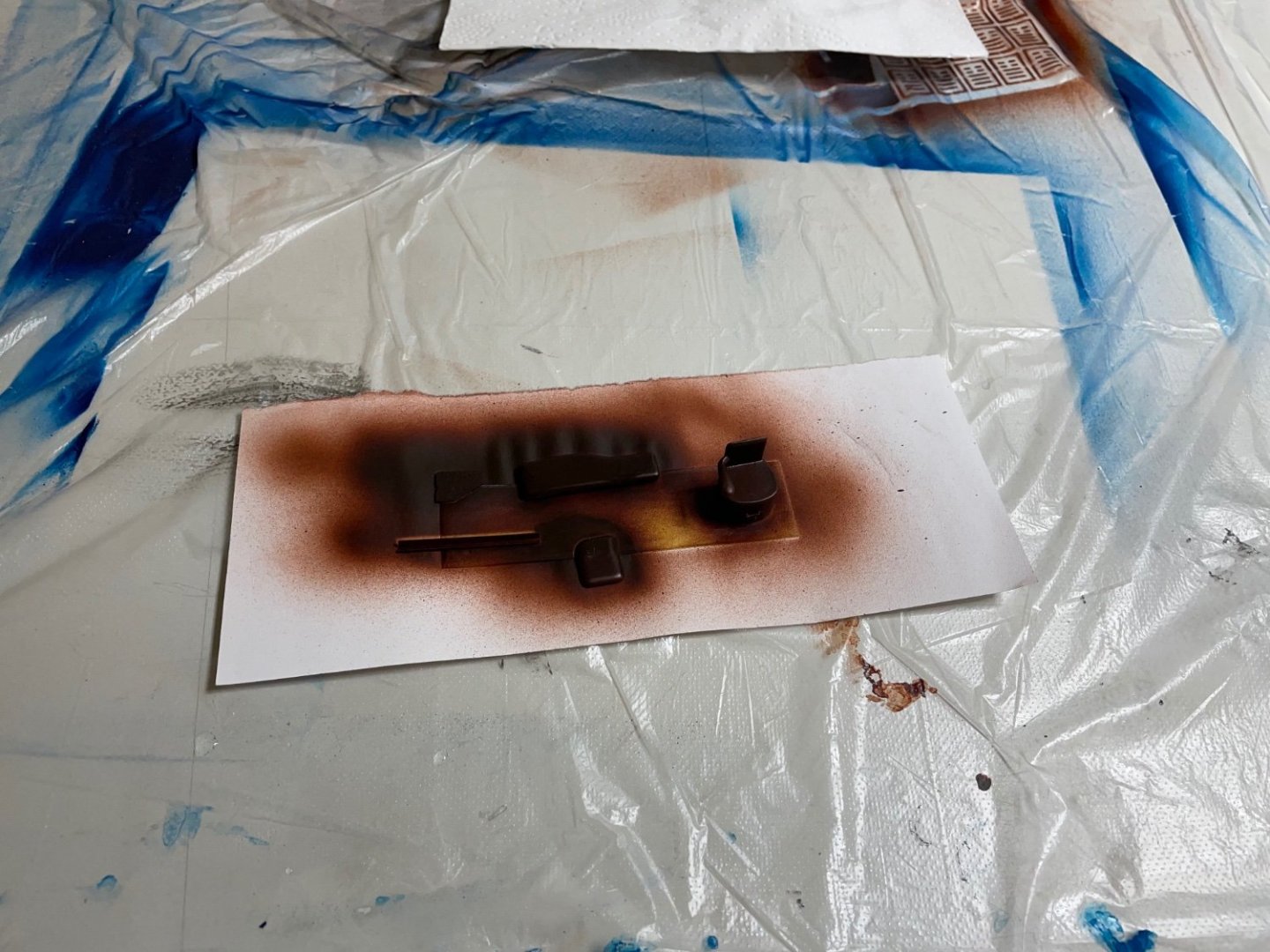

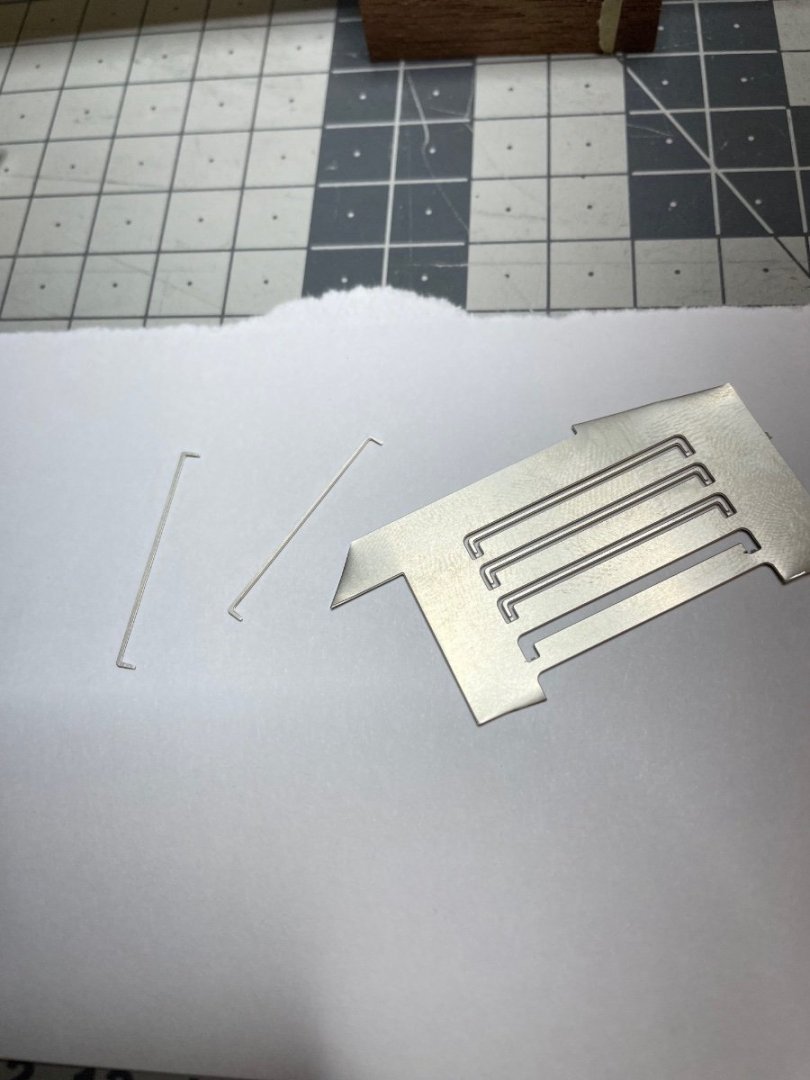

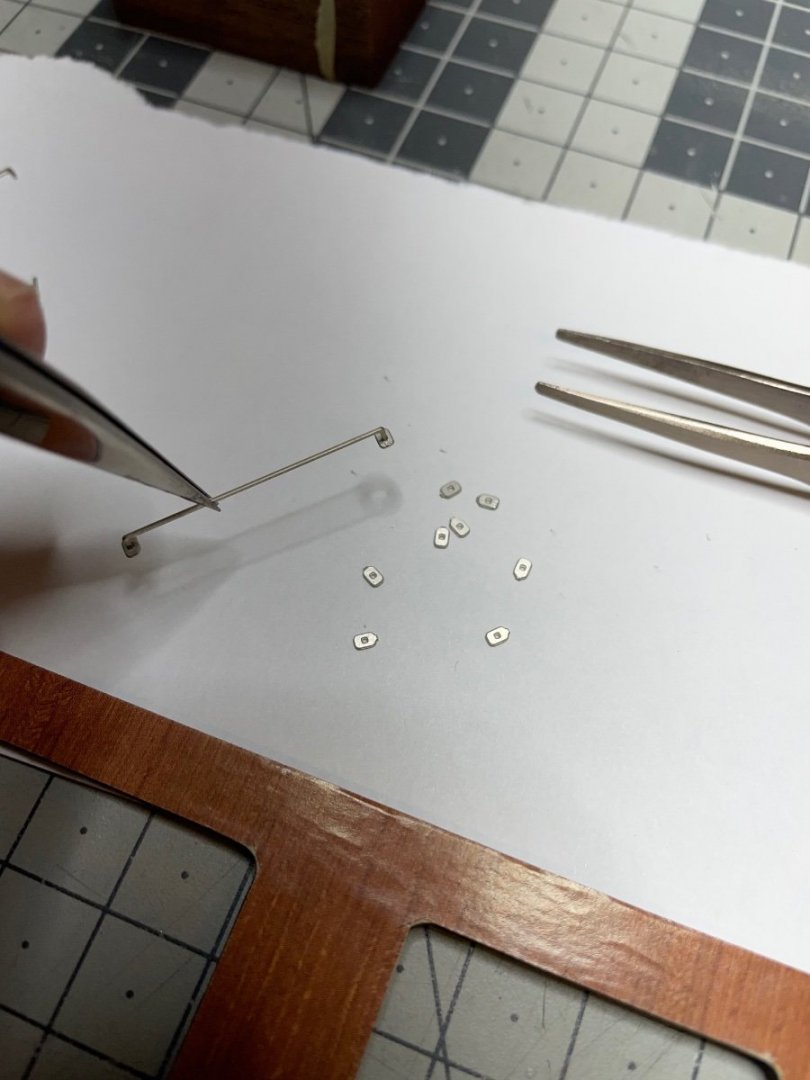

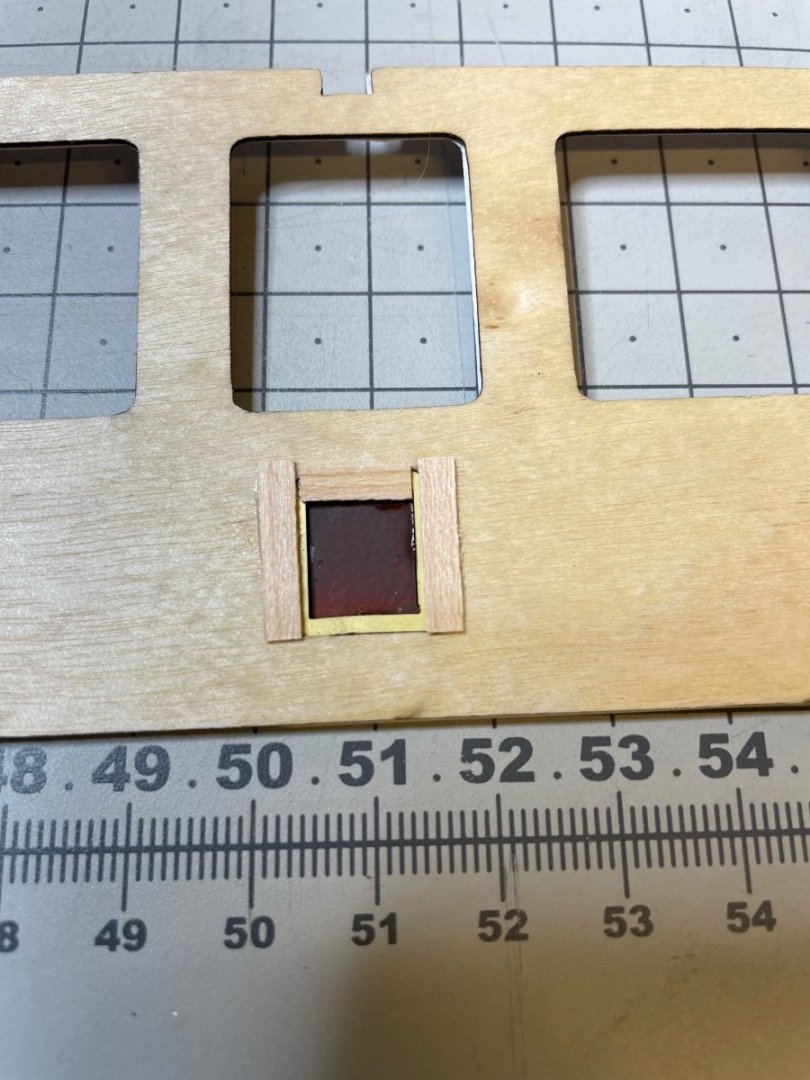

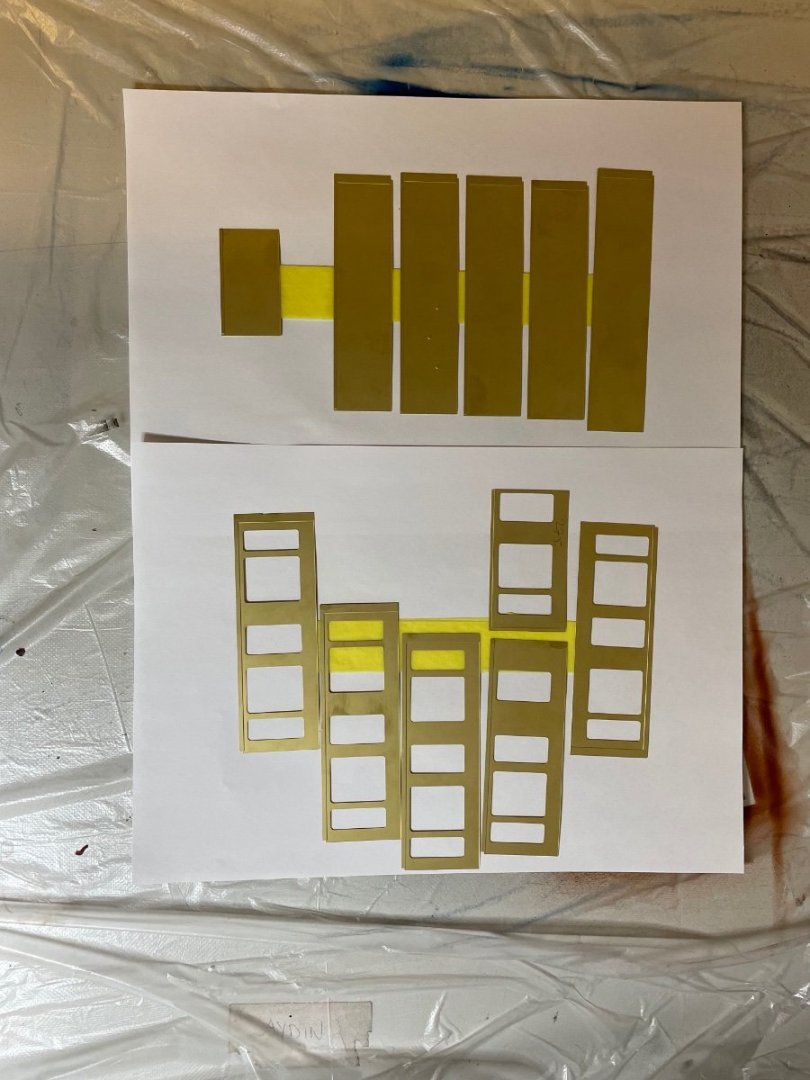

Continuing with the radiator/folding table combination. Tables can be set folded or open. It is up to the builder to decide how many of which to build. I checked carefully with each compartment to ensure that the compartment furniture (such as freely placed the stools) won't obstruct the open table and decided to build 4 of them open and 6 of them folded. Figure 350: The radiator, (metal), wooden table surface (wooden). Figure 351: First folded table ready.

-

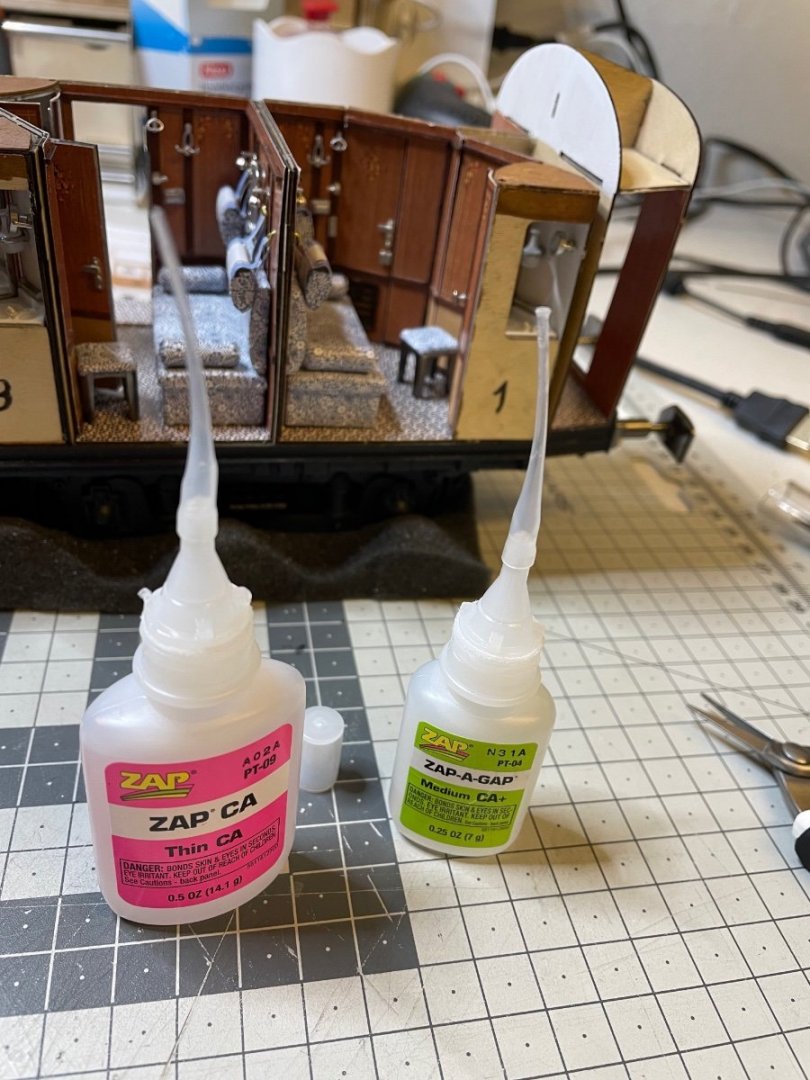

BUILD DAY 34 / 1 hr / (TOTAL: 90 hrs) Figures 348-349: A recommendation before I start this day's log. I have been using these medium and thin CA glues in this kit. The disposable flexi-tip nozzles fit both viscosities perfectly. No glue stain anywhere else than exactly where you need it to be. Highly recommended.

-

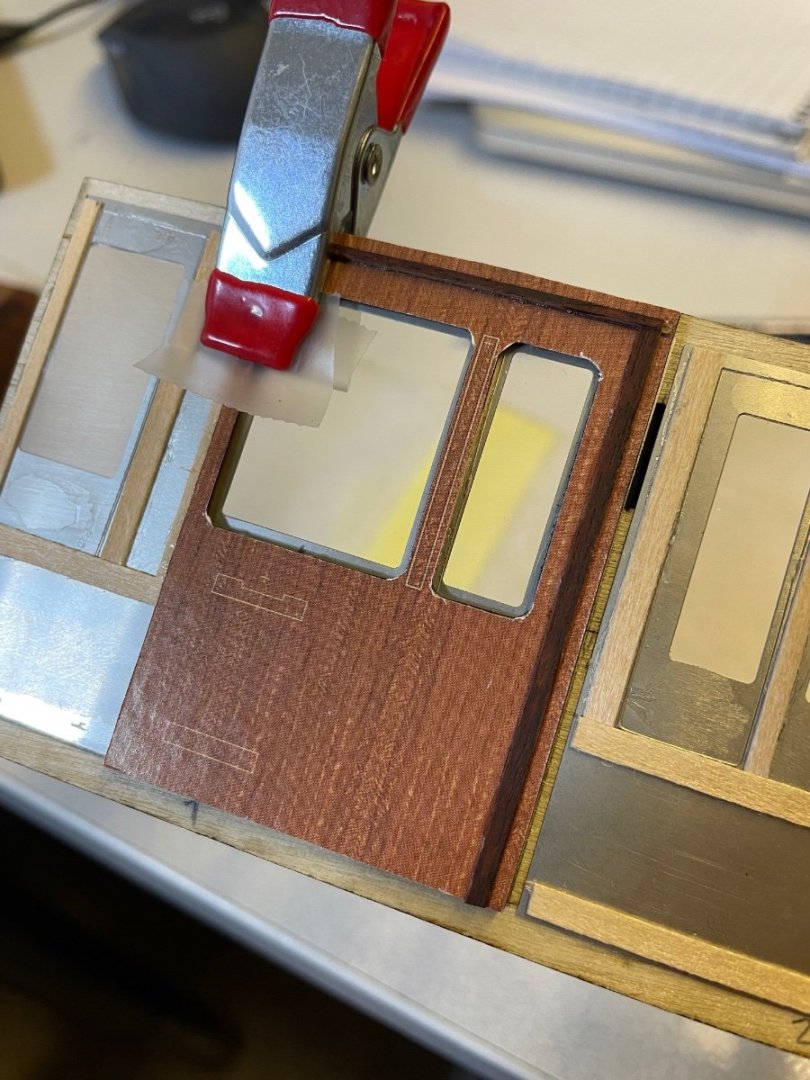

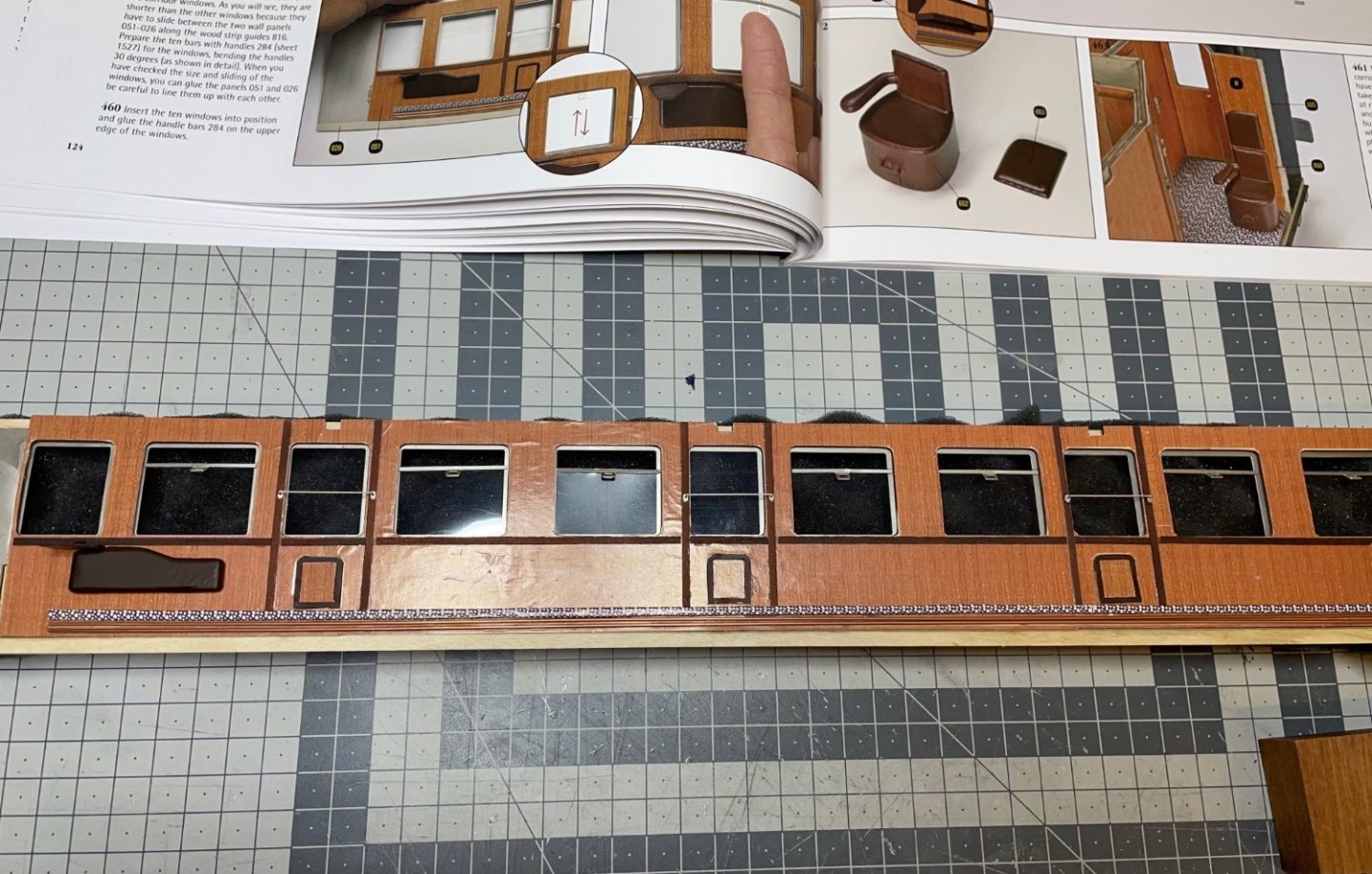

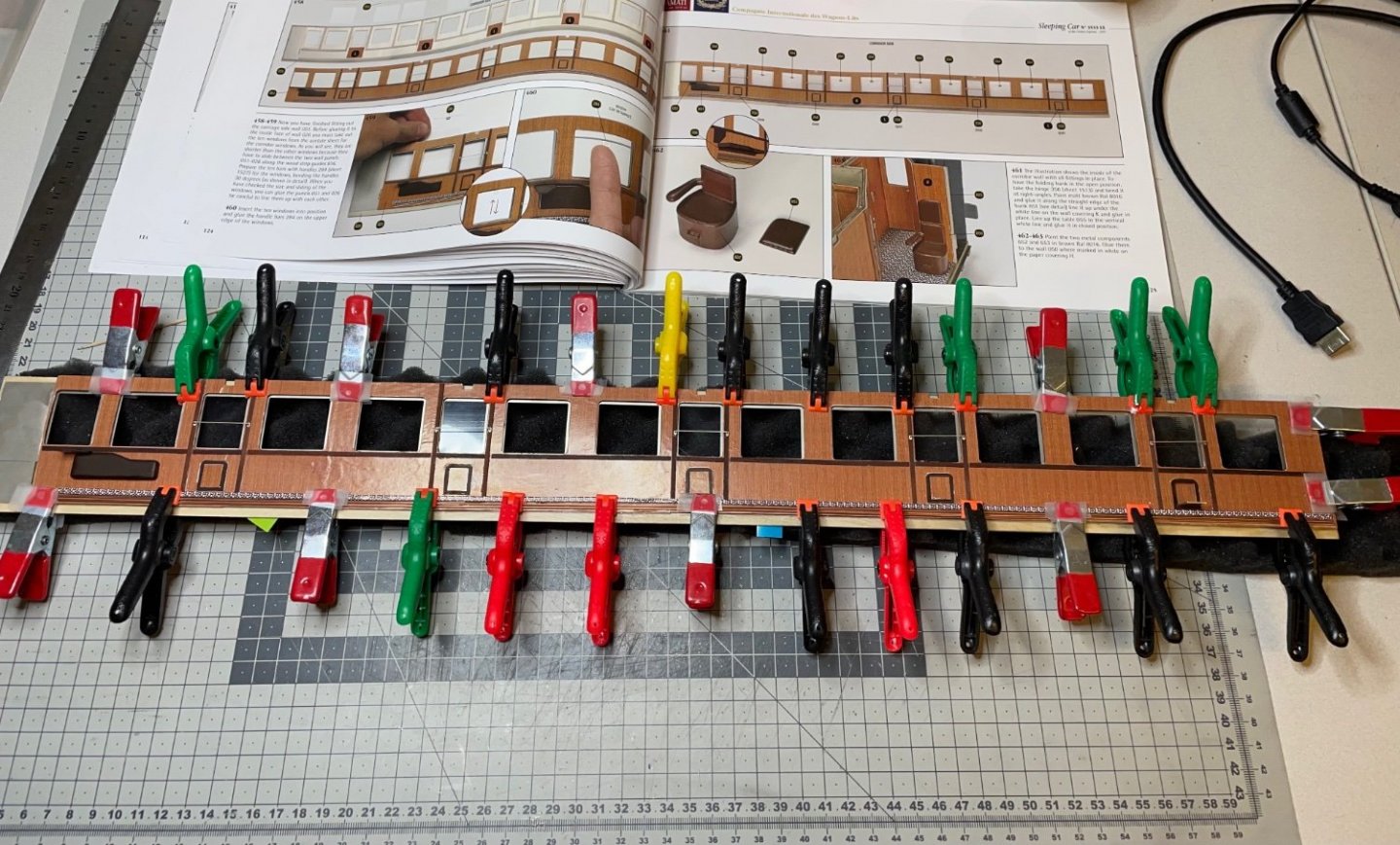

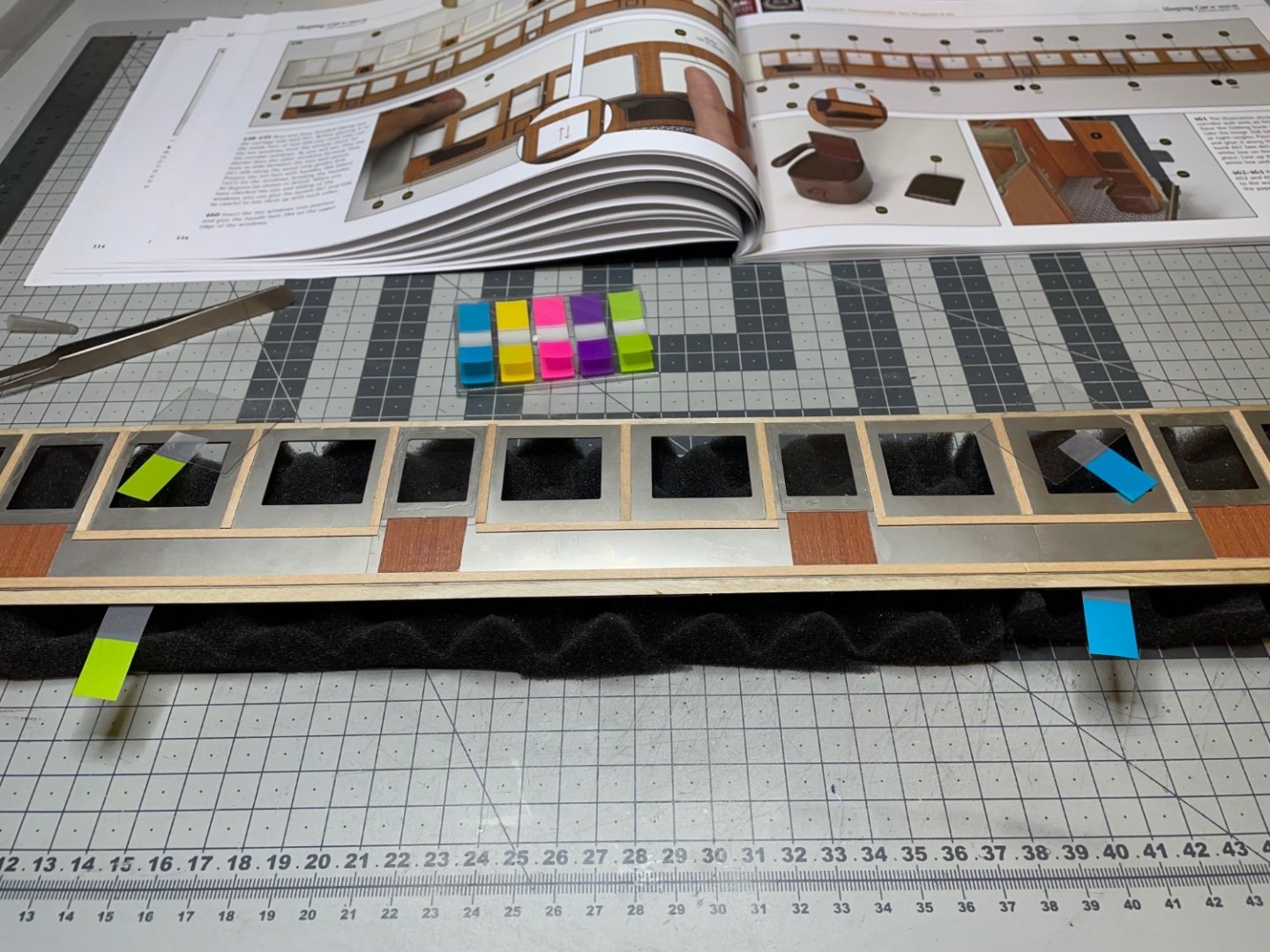

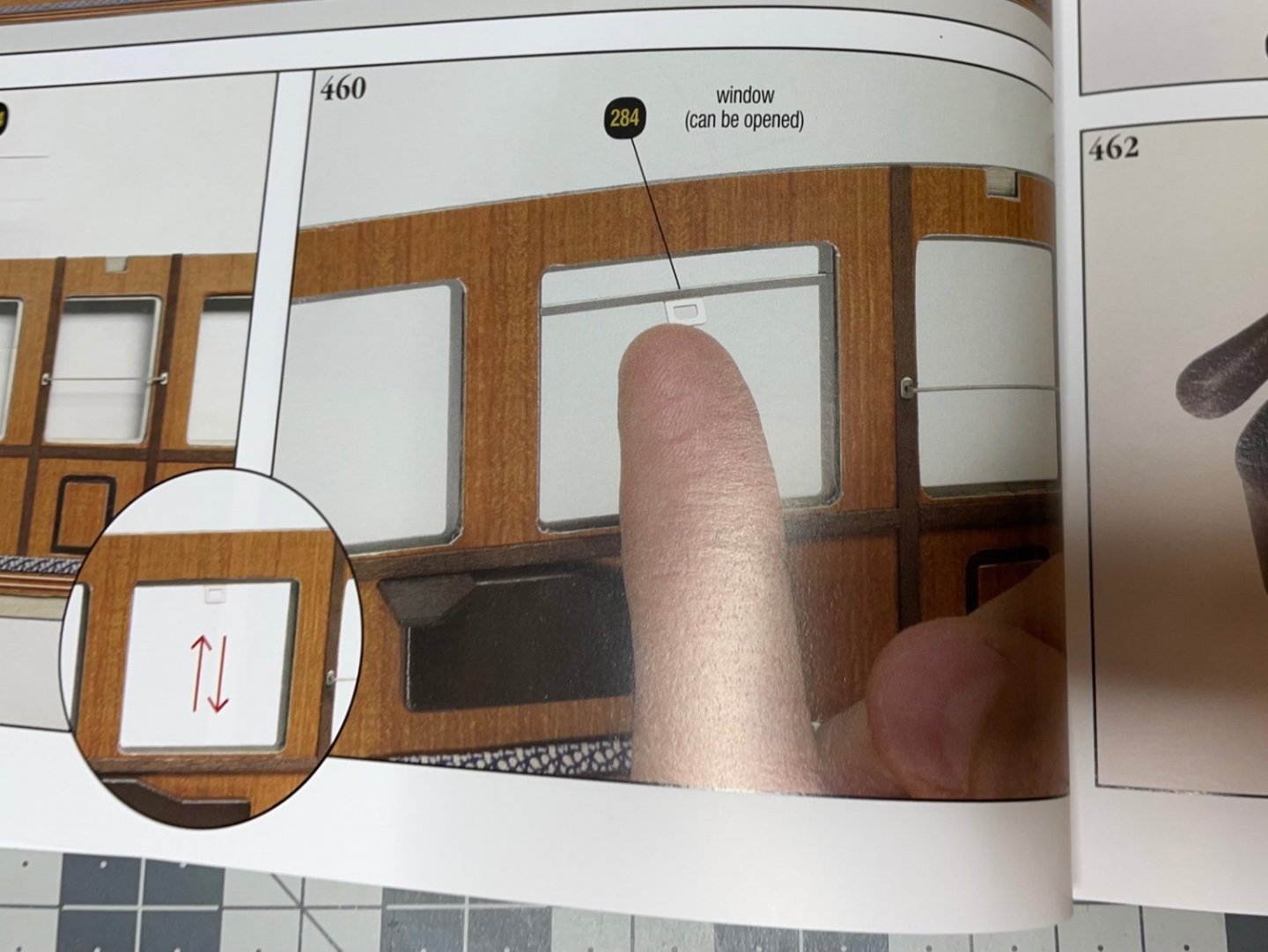

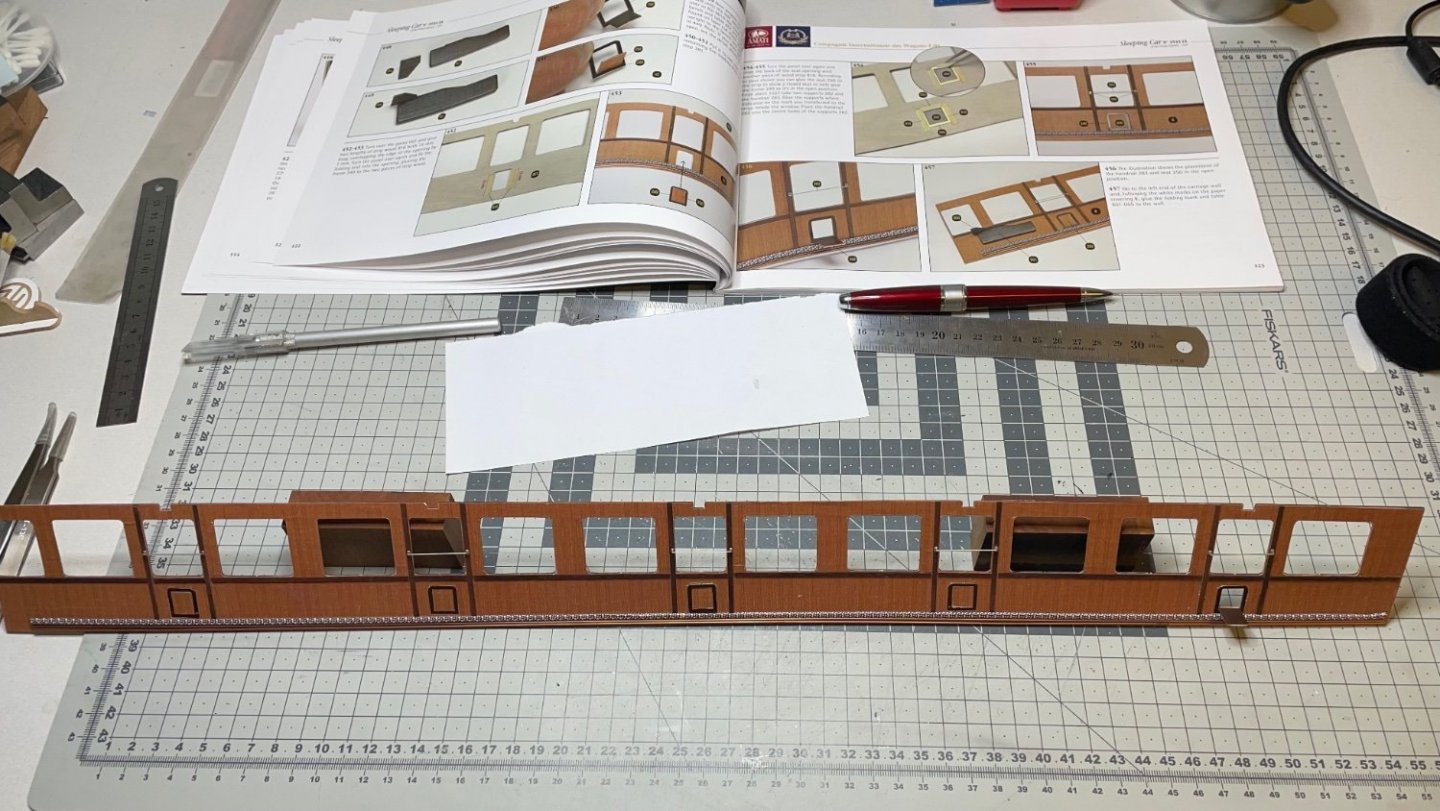

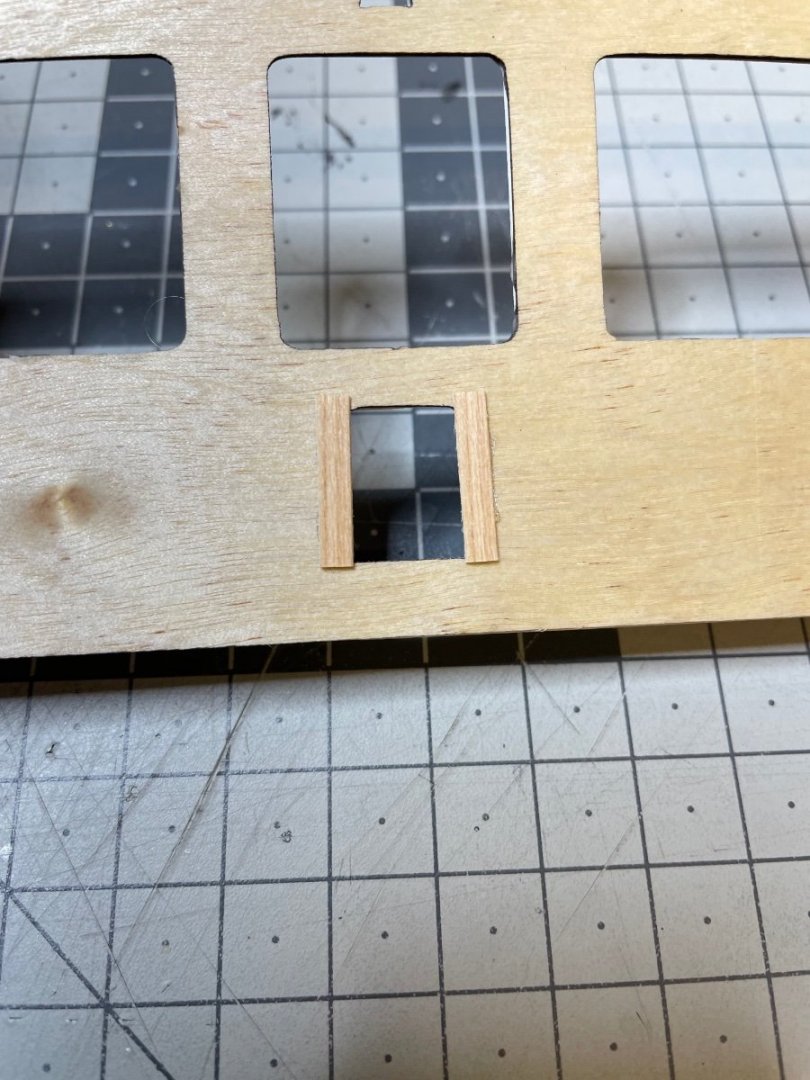

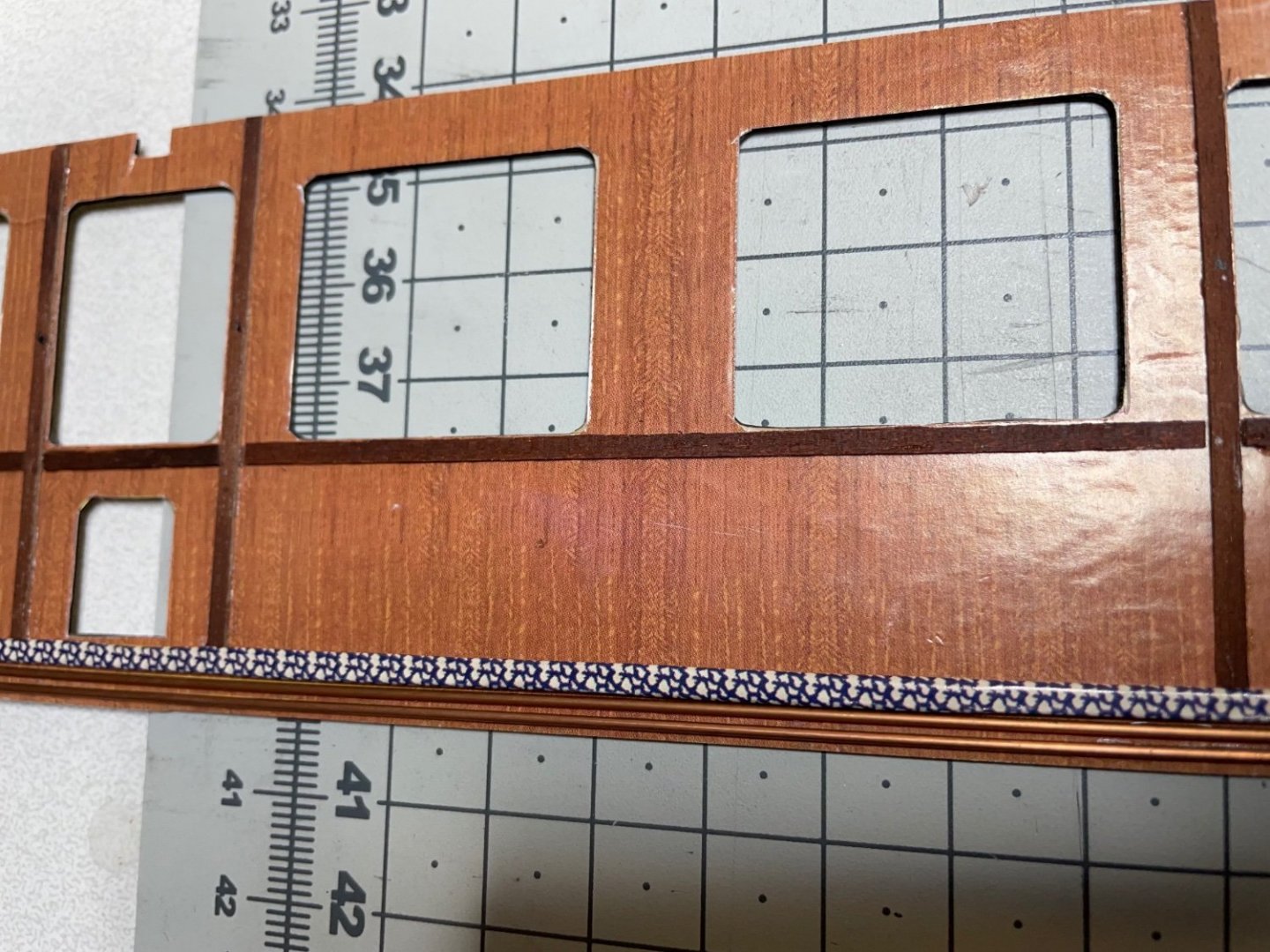

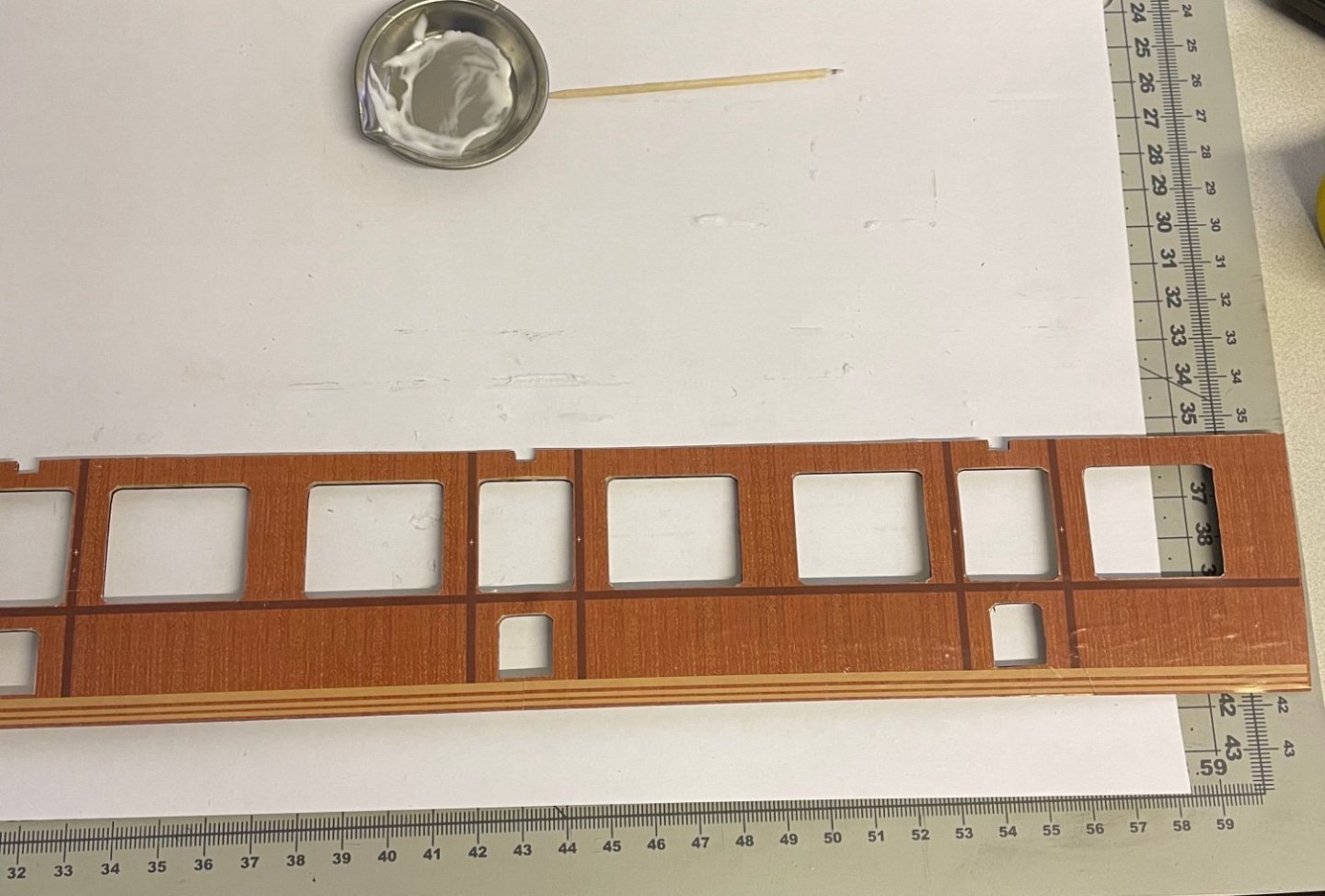

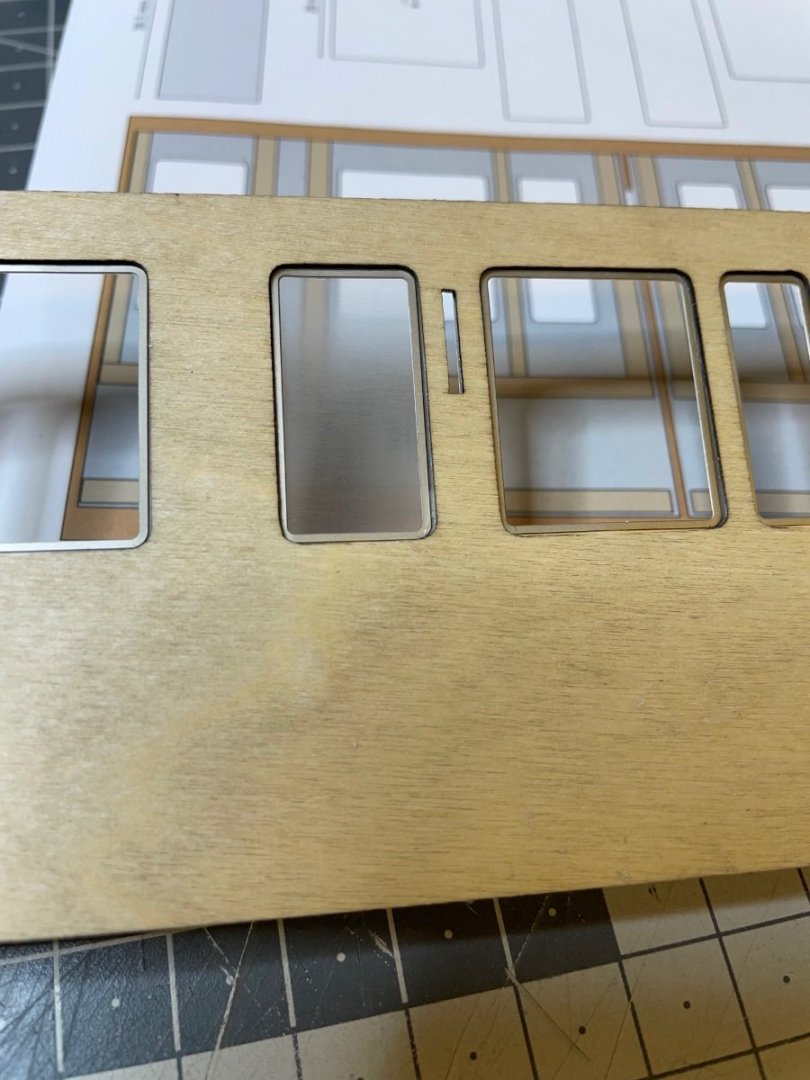

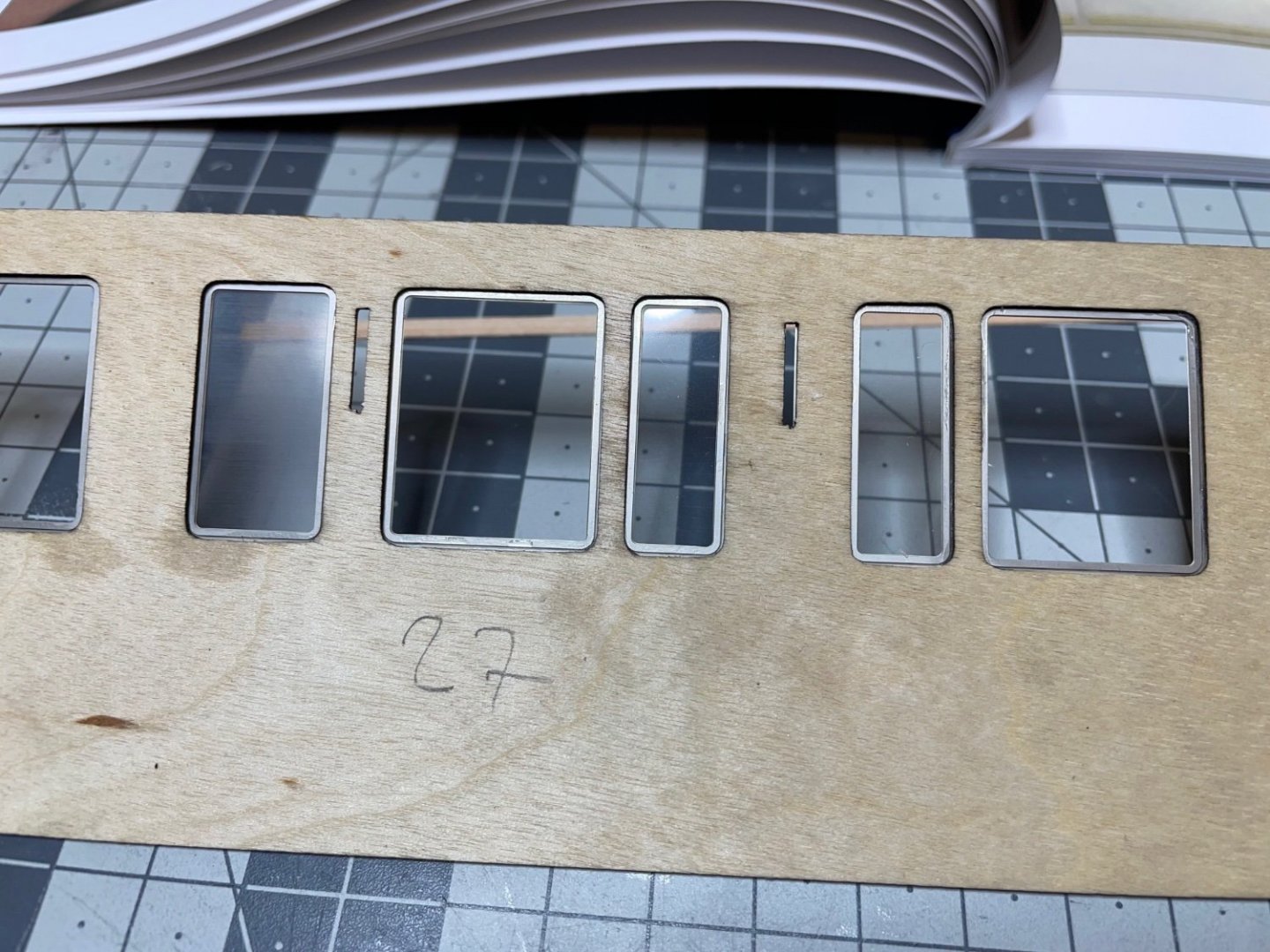

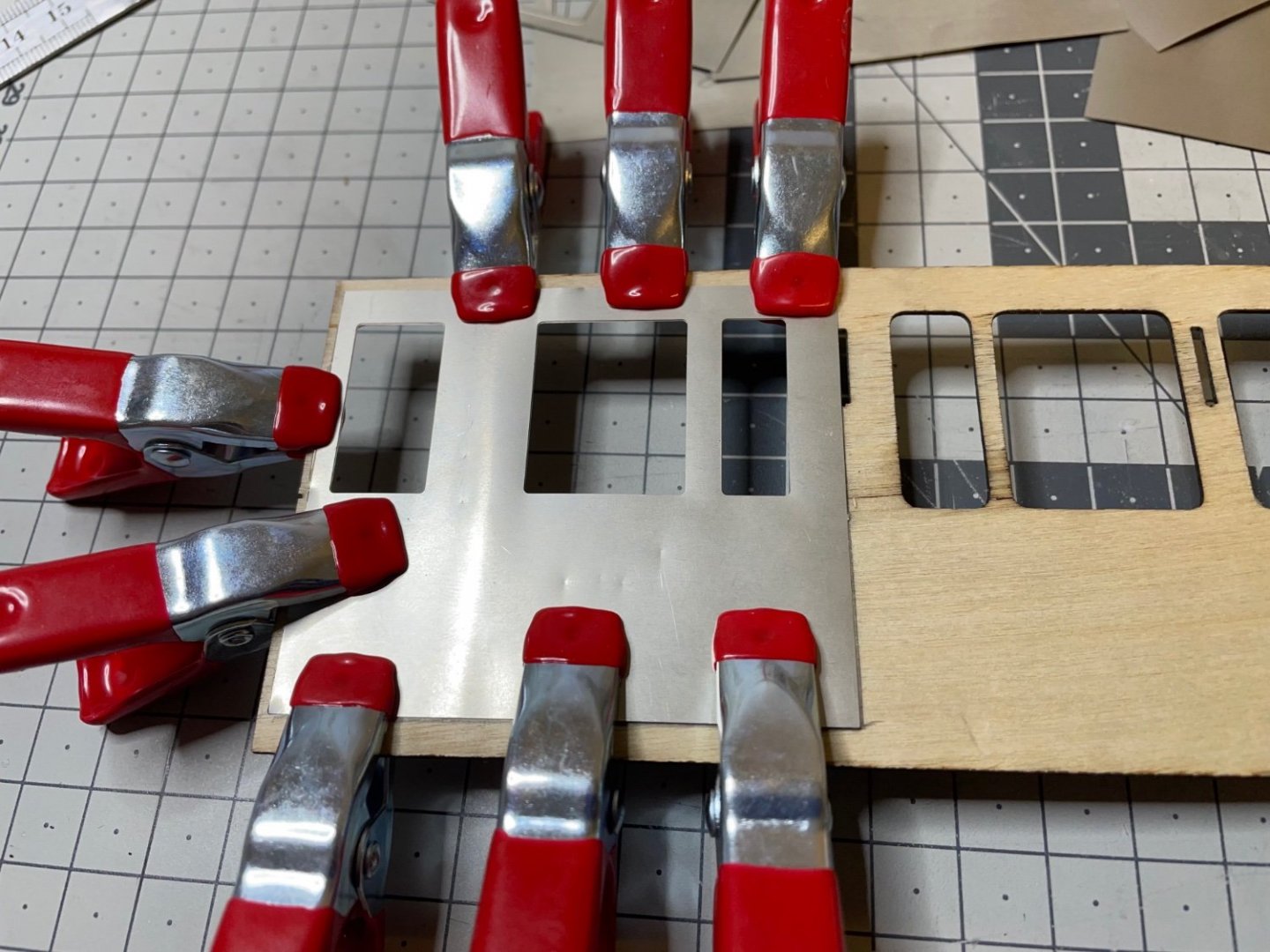

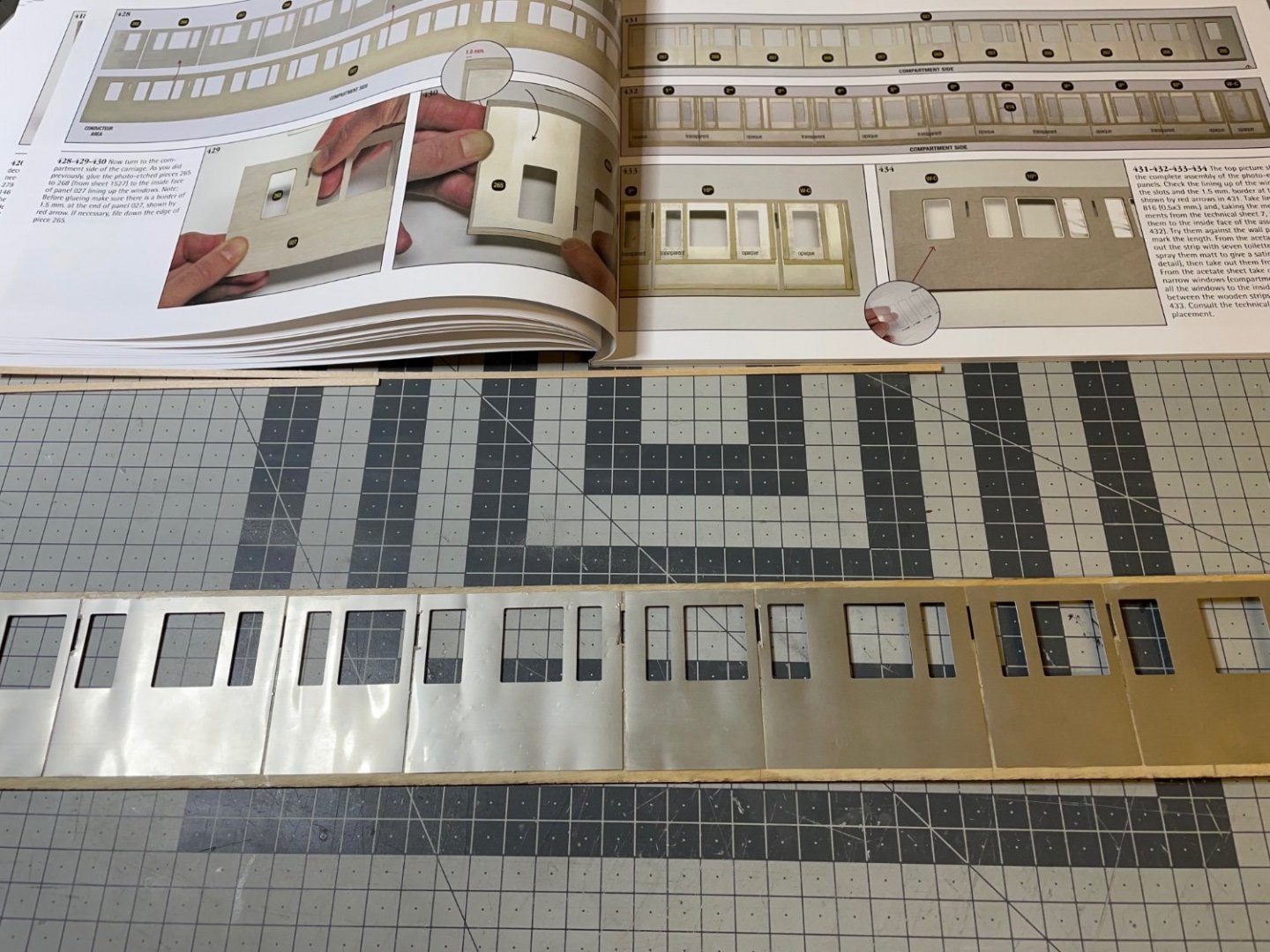

BUILD DAY 33 / 2 hrs / (TOTAL: 89 hrs) Now it is time to do the compartment side carriage wall. Here the inner walls for each compartment is separate and therefore it is a bit trickier. According to the instructions you first dry fit the inner walls and make the necessary trims and adjustments, then glue all of them to their place on the outer wall. And then you glue the whole thing to the wagon, hoping that all the sockets, walls and whatnot will just fit and snap nicely 😆. I am sure that it won't be the case for me so I decided take a different approach. If an inner wall requires trimming and adjustment, I will glue them directly to the carriage thereby reducing the risk of preventing a good installation. Figures 345-347: Some photos below showing my progress of dry fitting the inner walls. Before gluing the inner walls to their place, I will need to install on them a few things like the folding table, heating radiator, window stoppers and jacket hook. Figure 348: Parts for constructing the folding tables and radiators. That's all for now. Thanks for watching!

-

Figures 321-324: Installing the foldable wall seats, prepared earlier. You glue two pieces of wooden strips at the back in order to support them. You can leave as many open or closed (folded up) as you like. I chose to leave one of them open, just to show. Otherwise I bet they had always been folded up while not in use.

-

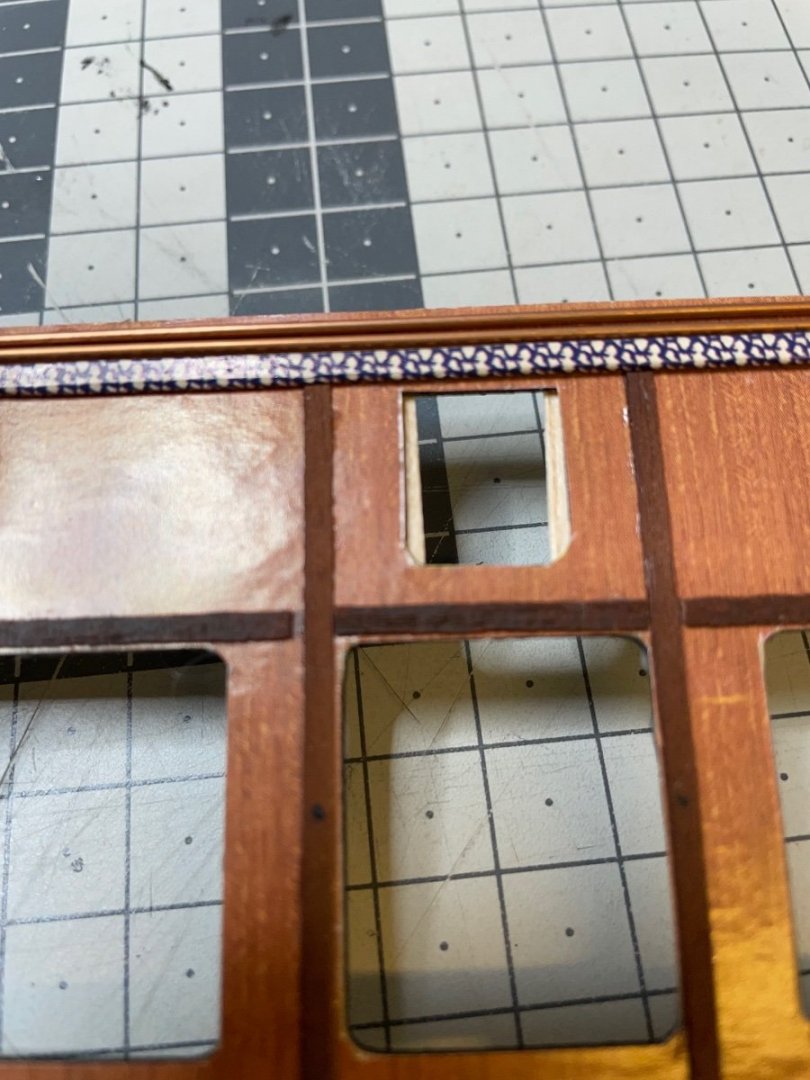

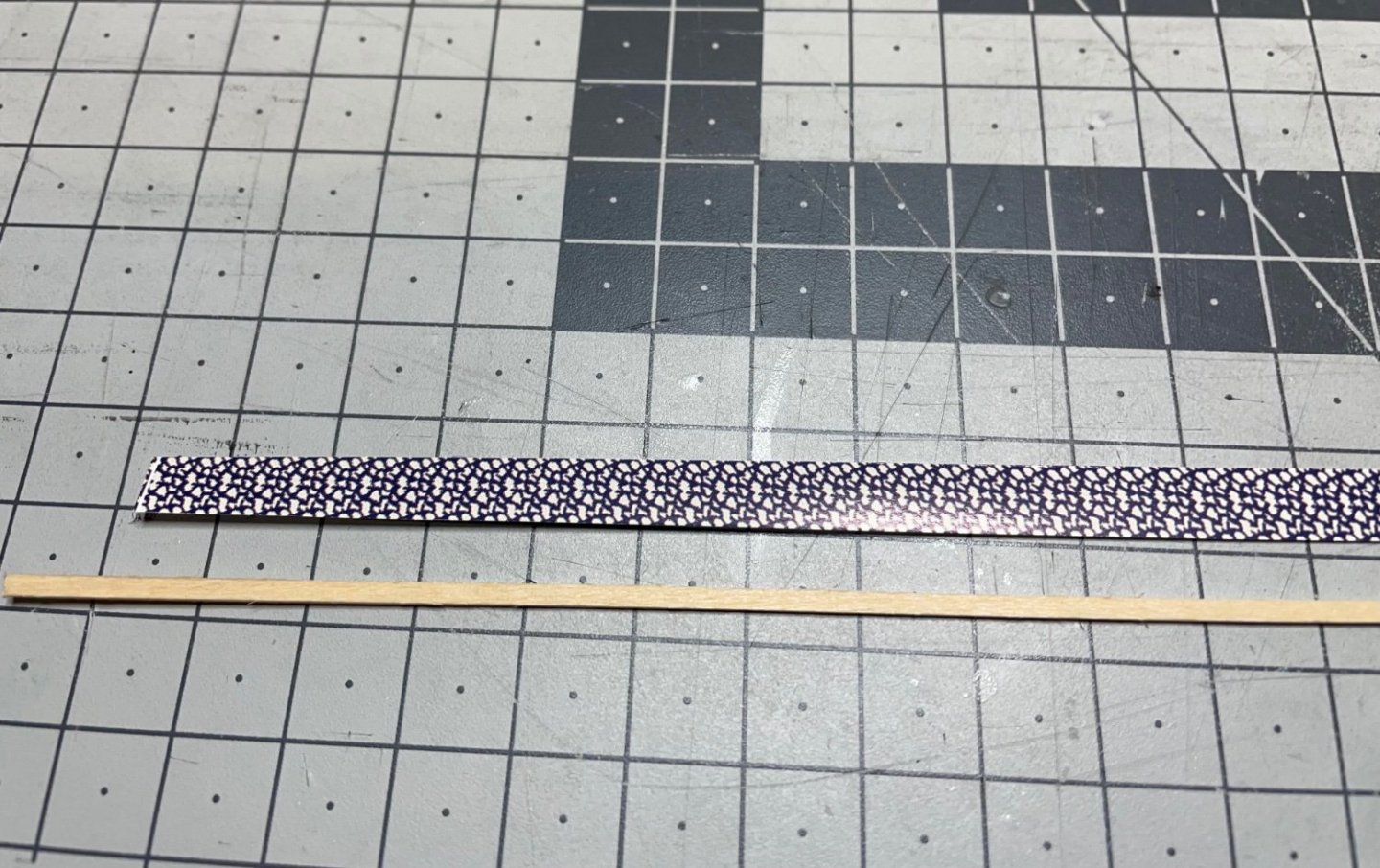

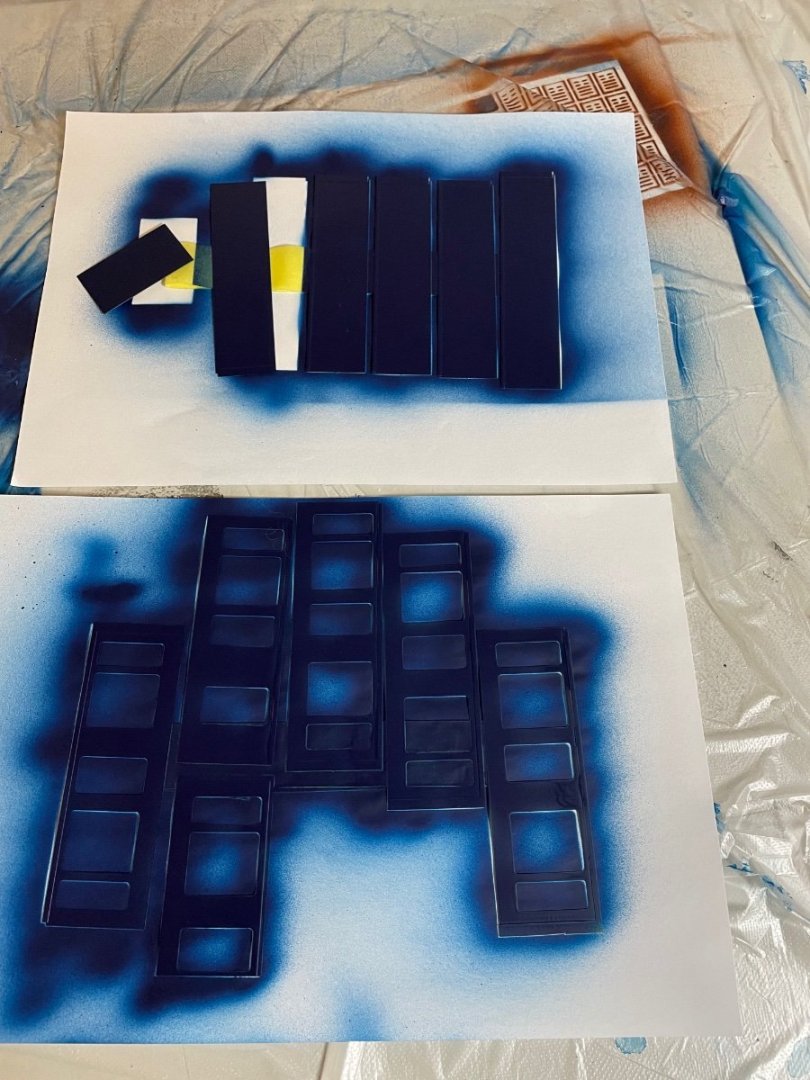

BUILD DAY 31 / 2 hrs / (TOTAL: 83 hrs) Figure 315: Blue plates and pinstripes are in place. Similar work as that of the corridor side carriage and no surprises hence I don't have many photos nor much to tell. Pinstripe trims on an ice cream stick. I have less than 10cm left of the 0.5mm stripes after the work. It was getting scary towards the end. Amati could have put one more line of cut on the sheet (which would not cost them anything). But anyways I survived. Waiting for the Micro Sol decal setters from the mail before I apply the decals.

-

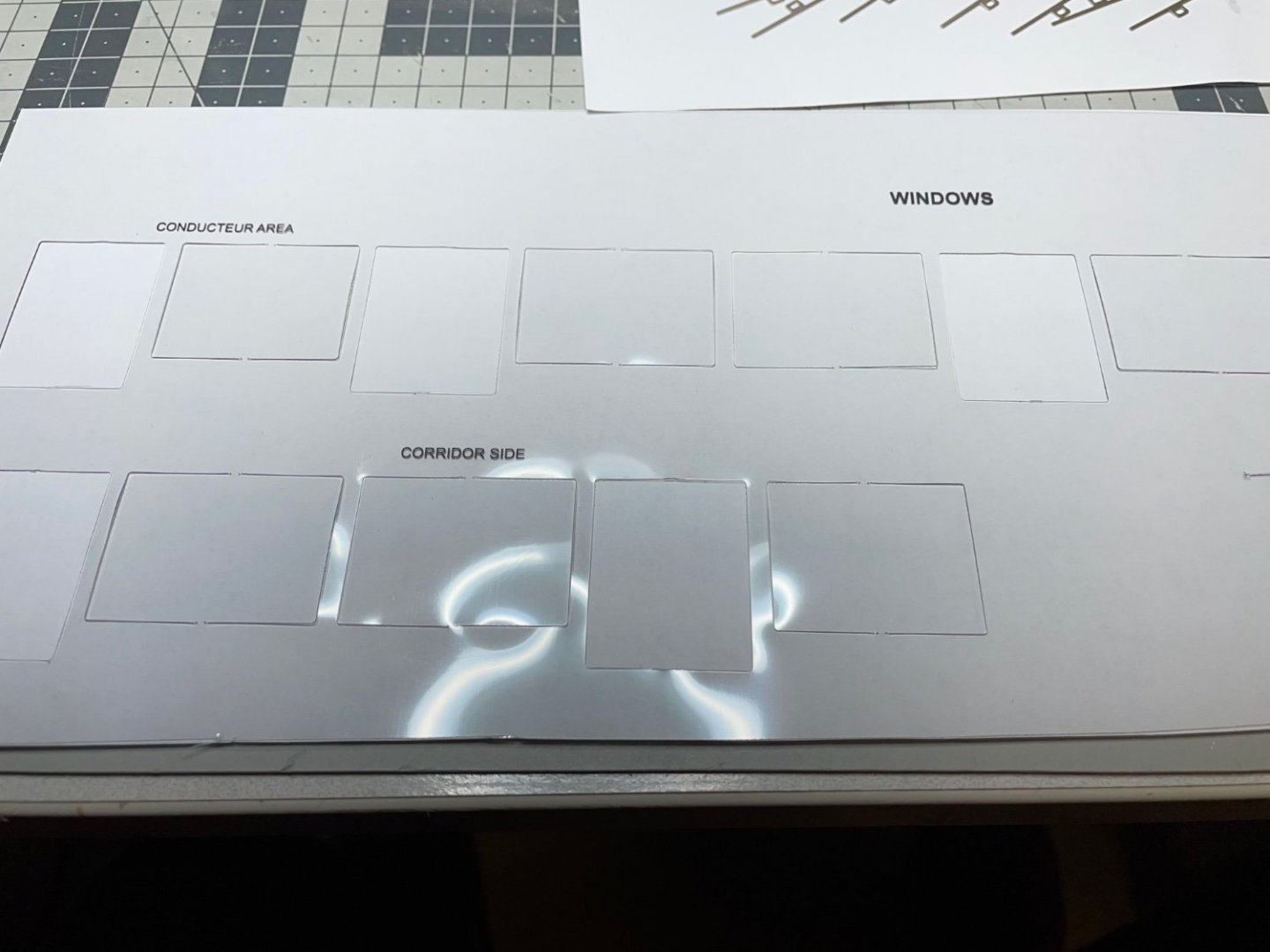

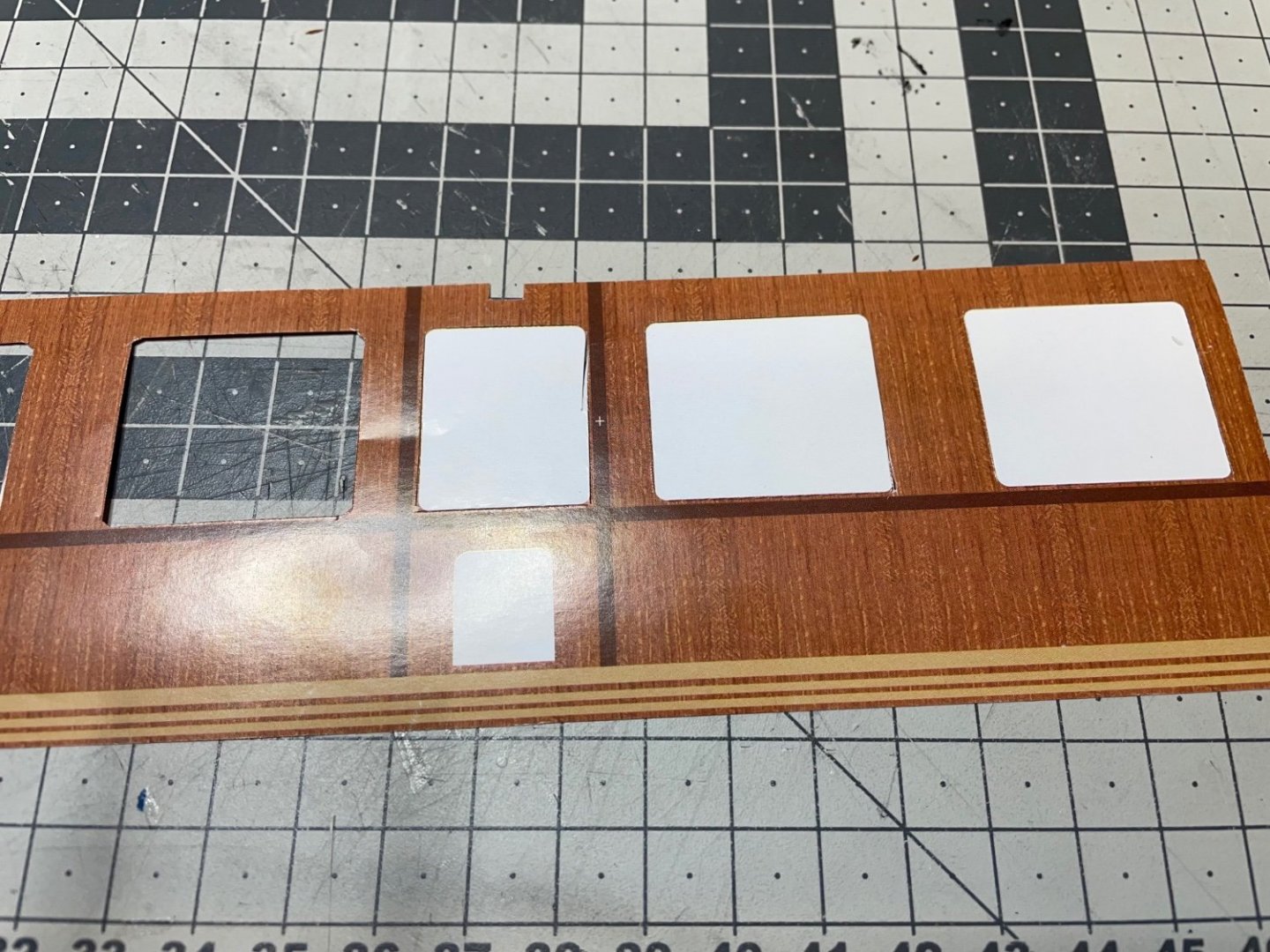

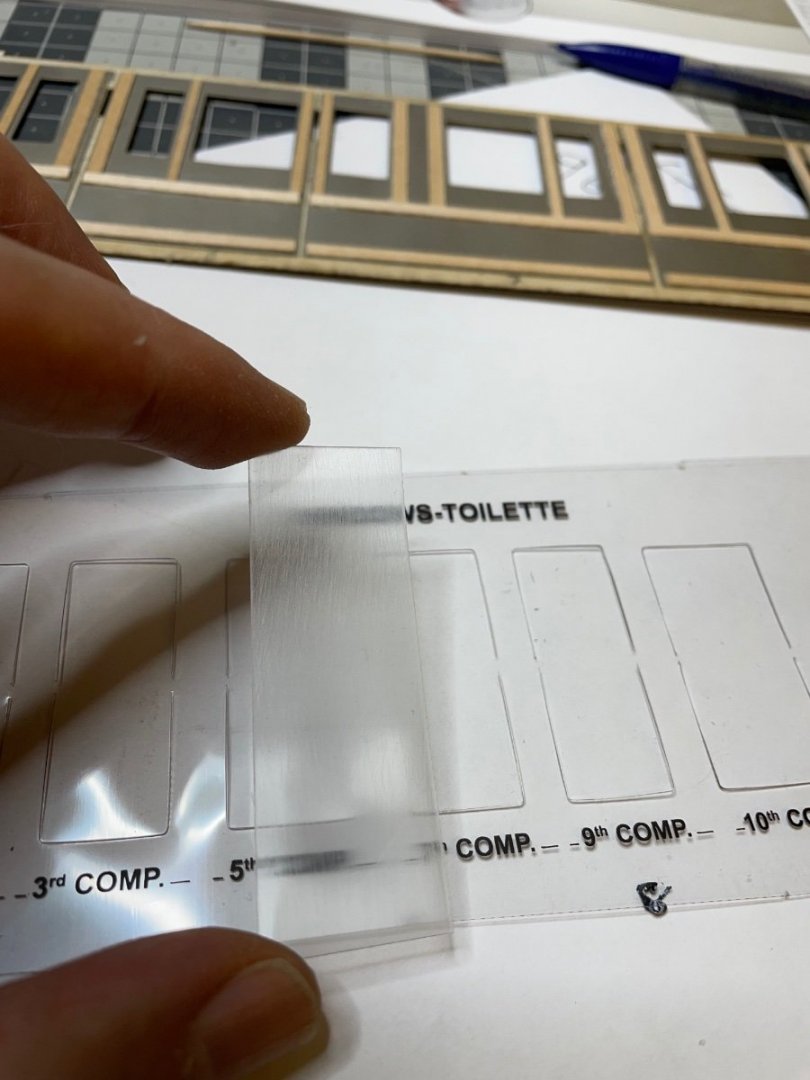

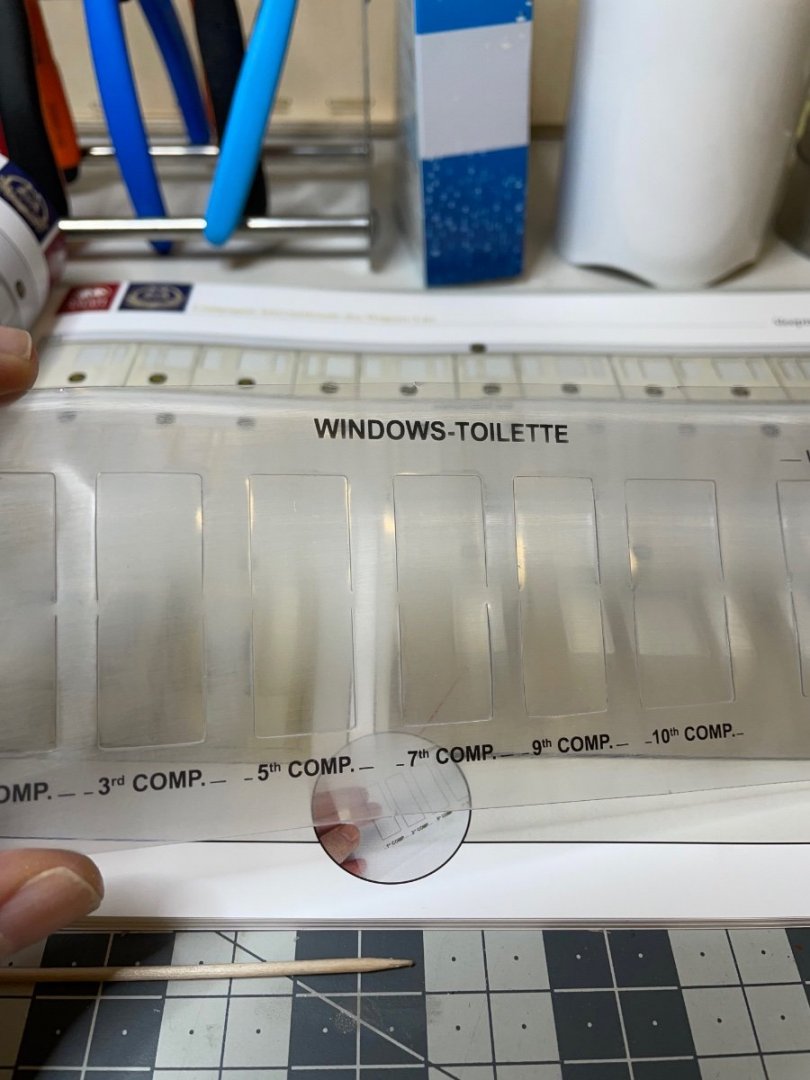

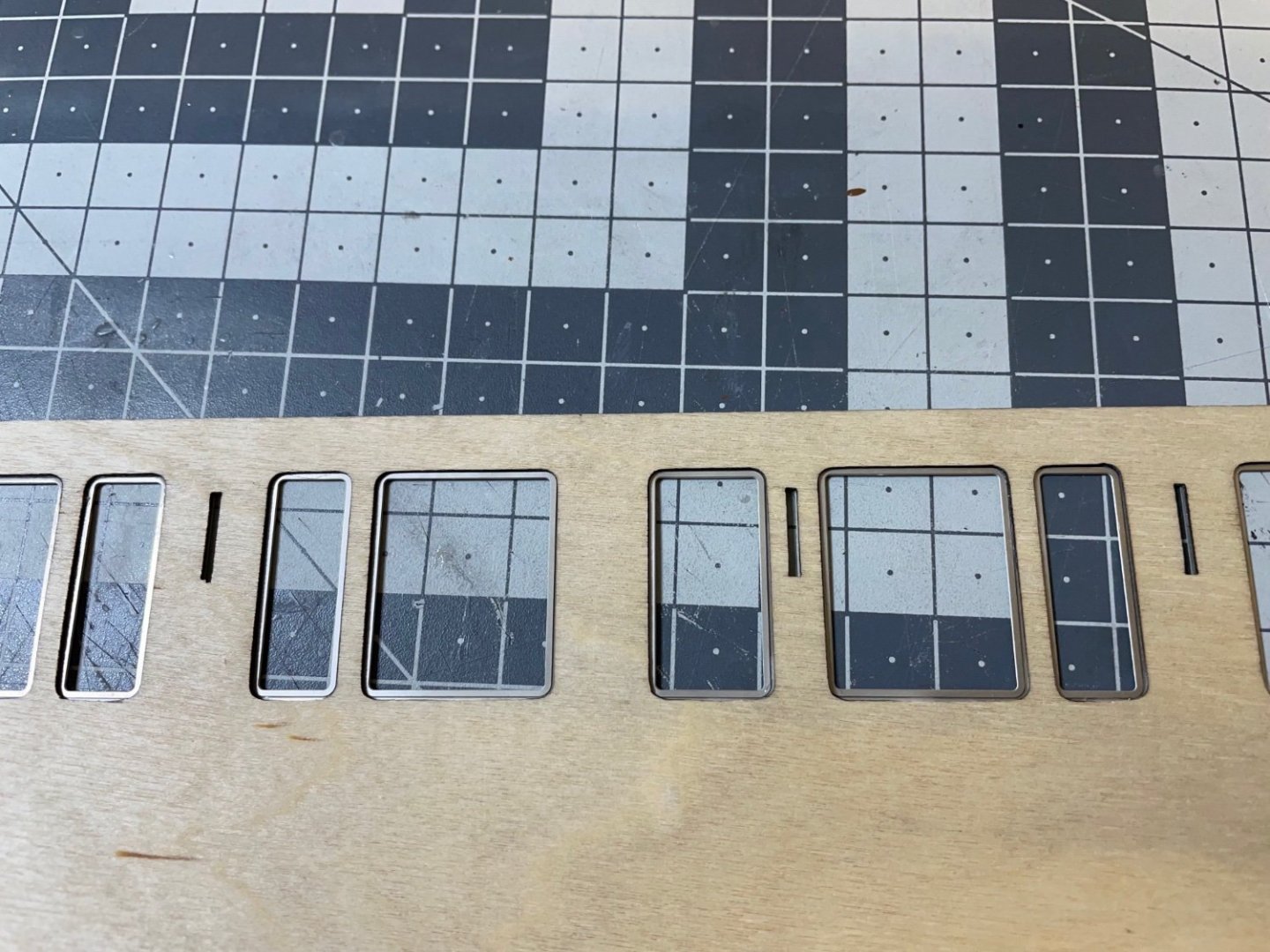

Figures 308-311: The toilet windows have to have some degree of opacity. After all it is a toilet, right? In order to achieve this, the instructions recommend to spray matt varnish on them. I tried it on a scrap piece but the result was awful. Instead I rubbed them a few times with fine grade sandpaper. Turned out not too bad.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.