-

Posts

916 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by aydingocer

-

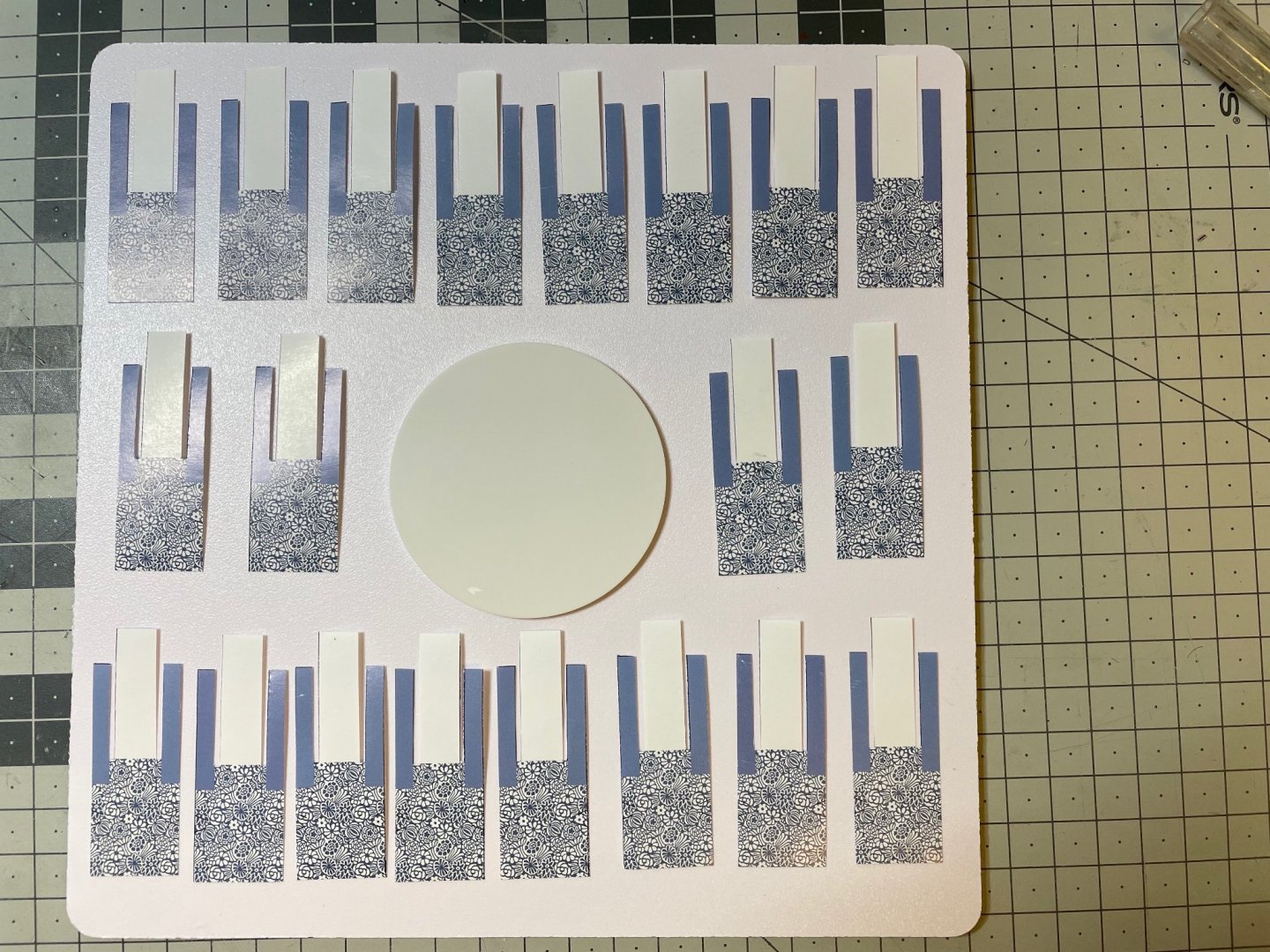

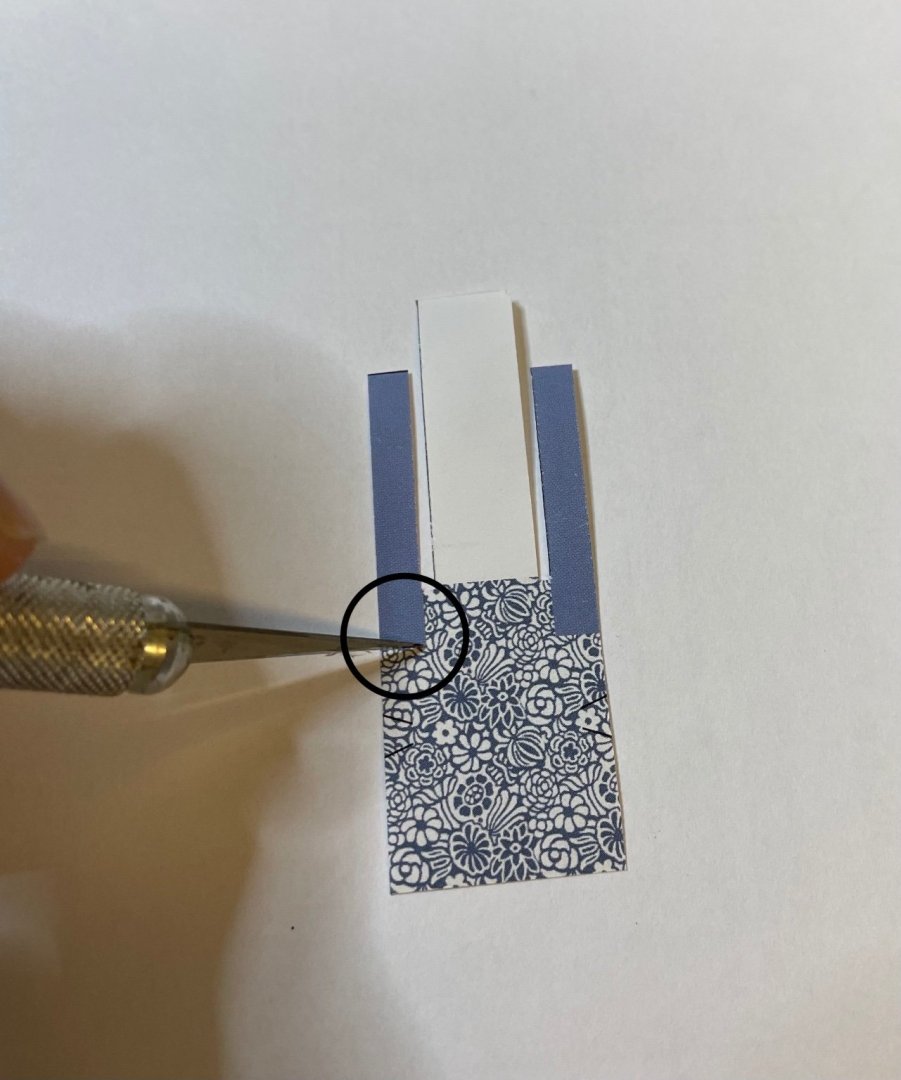

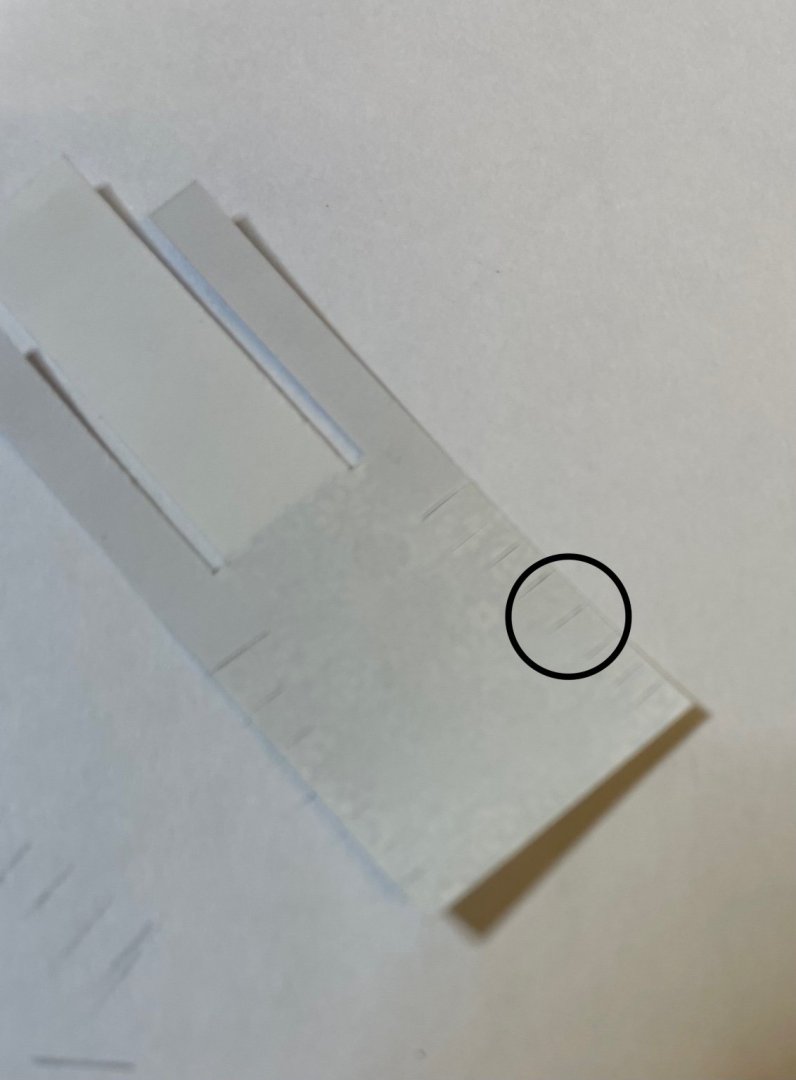

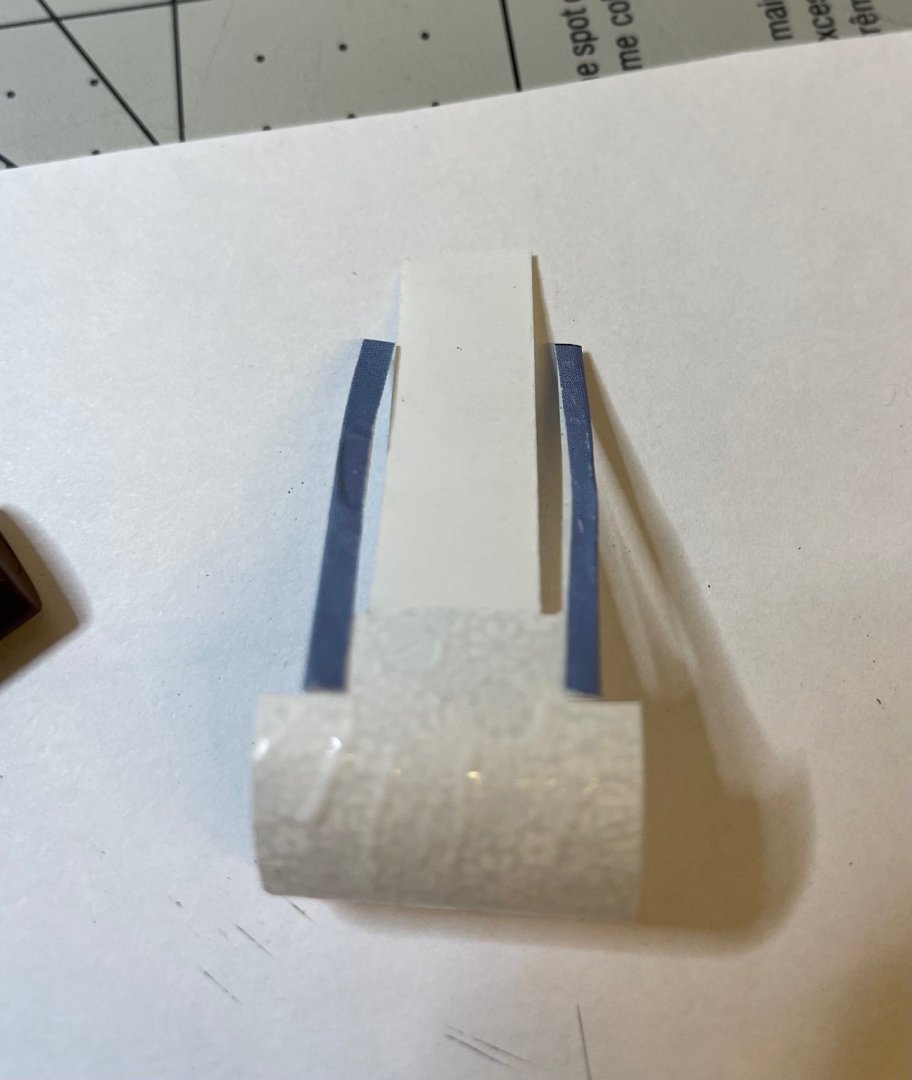

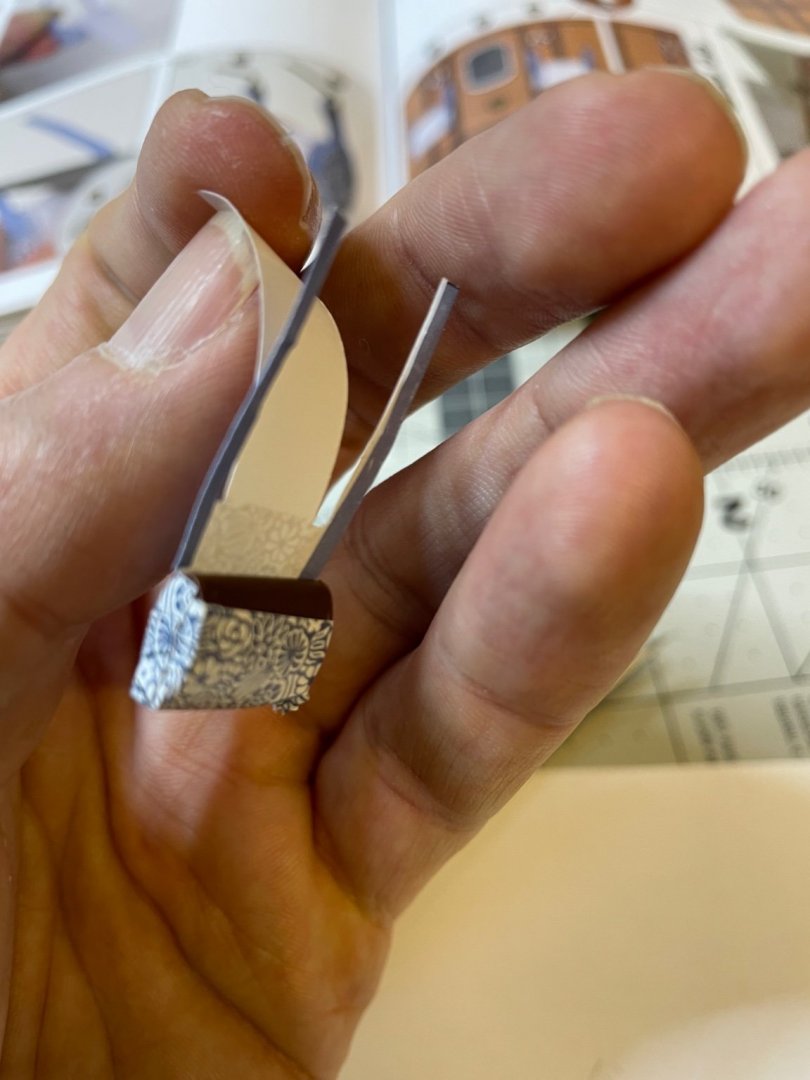

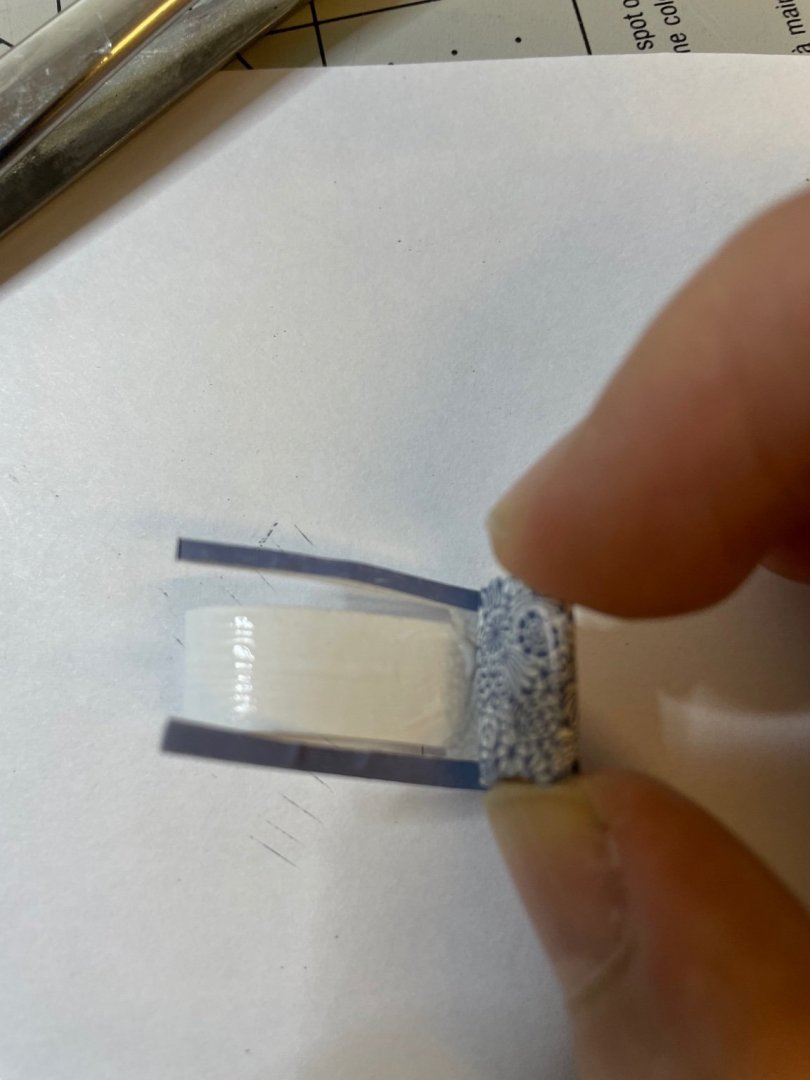

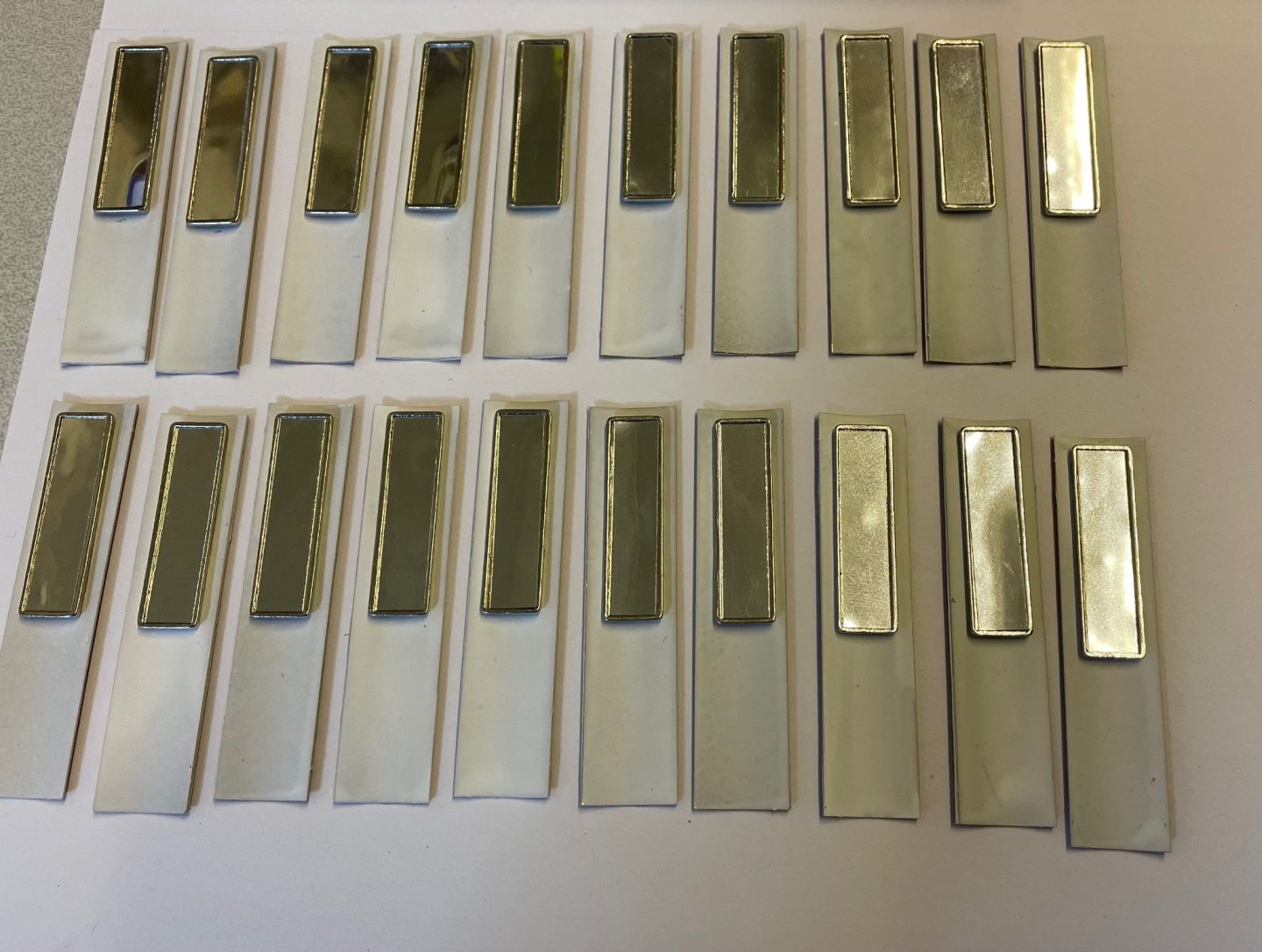

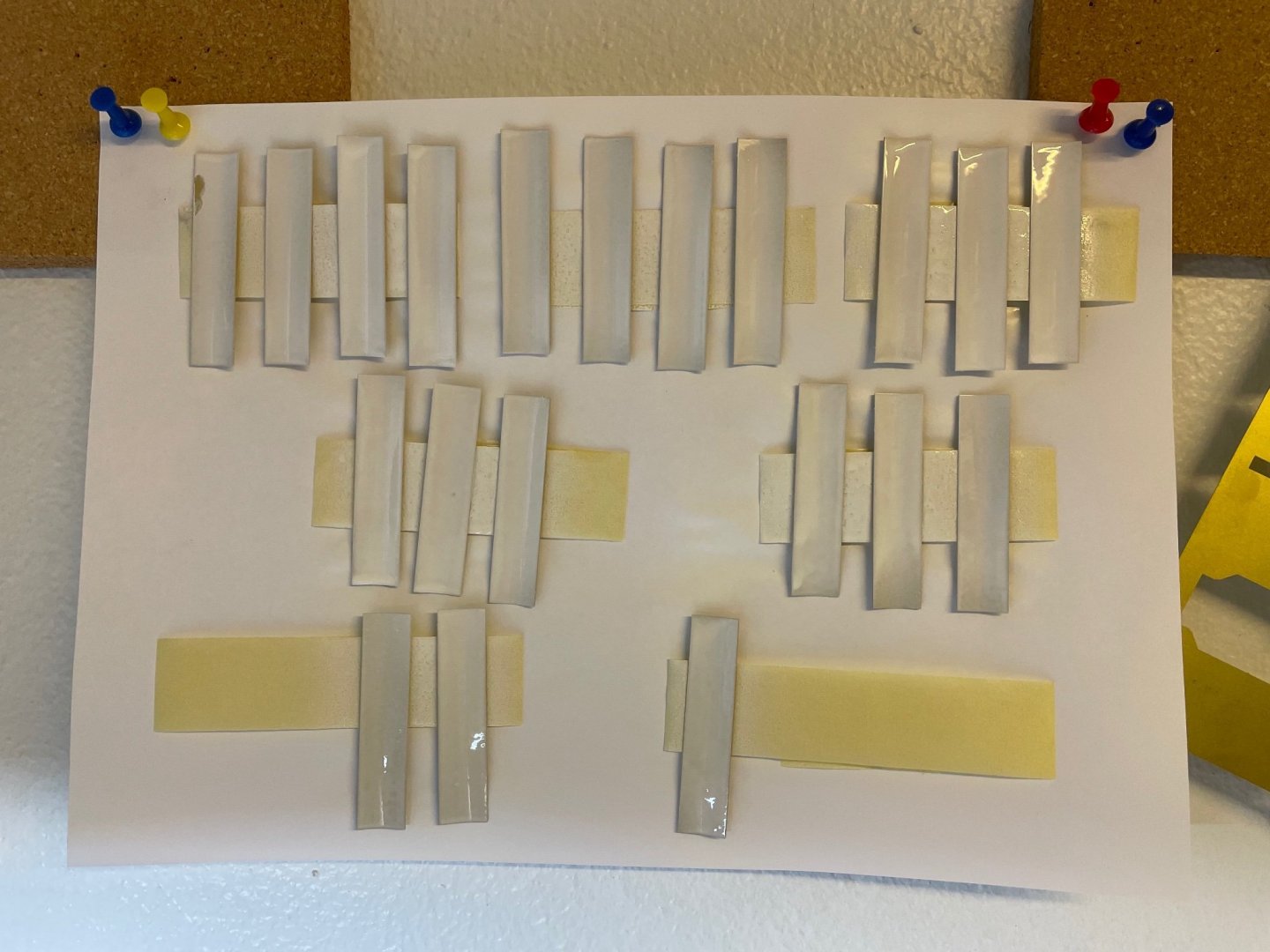

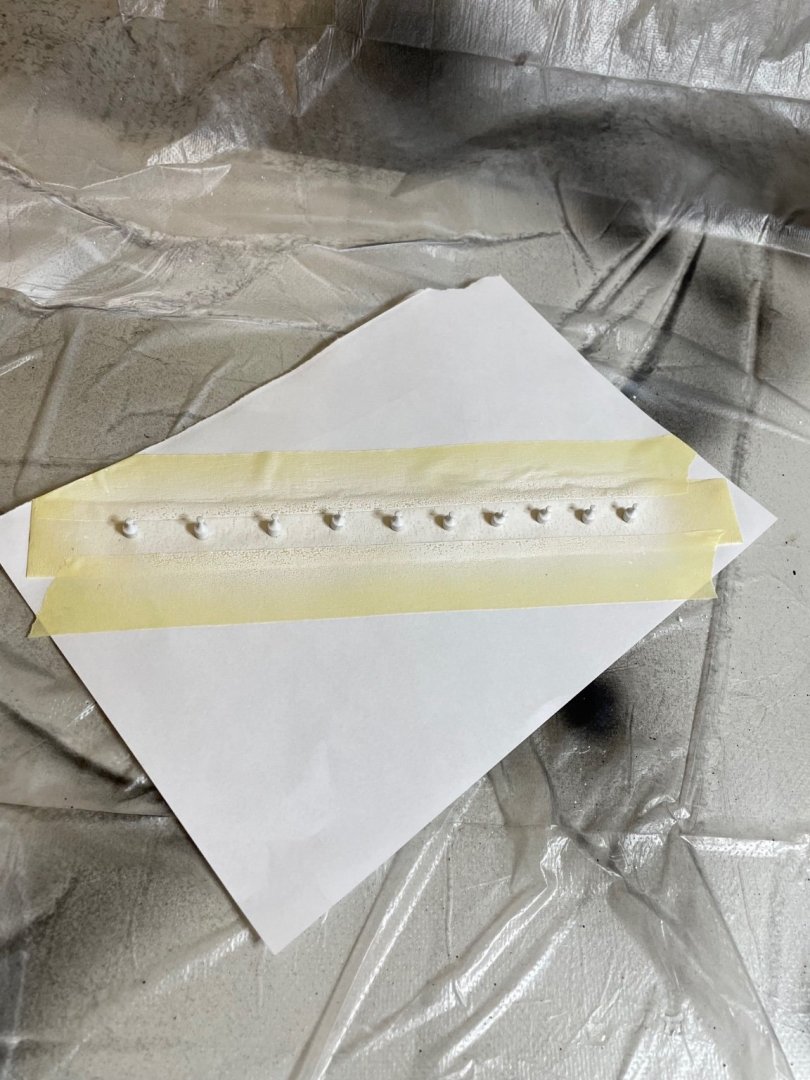

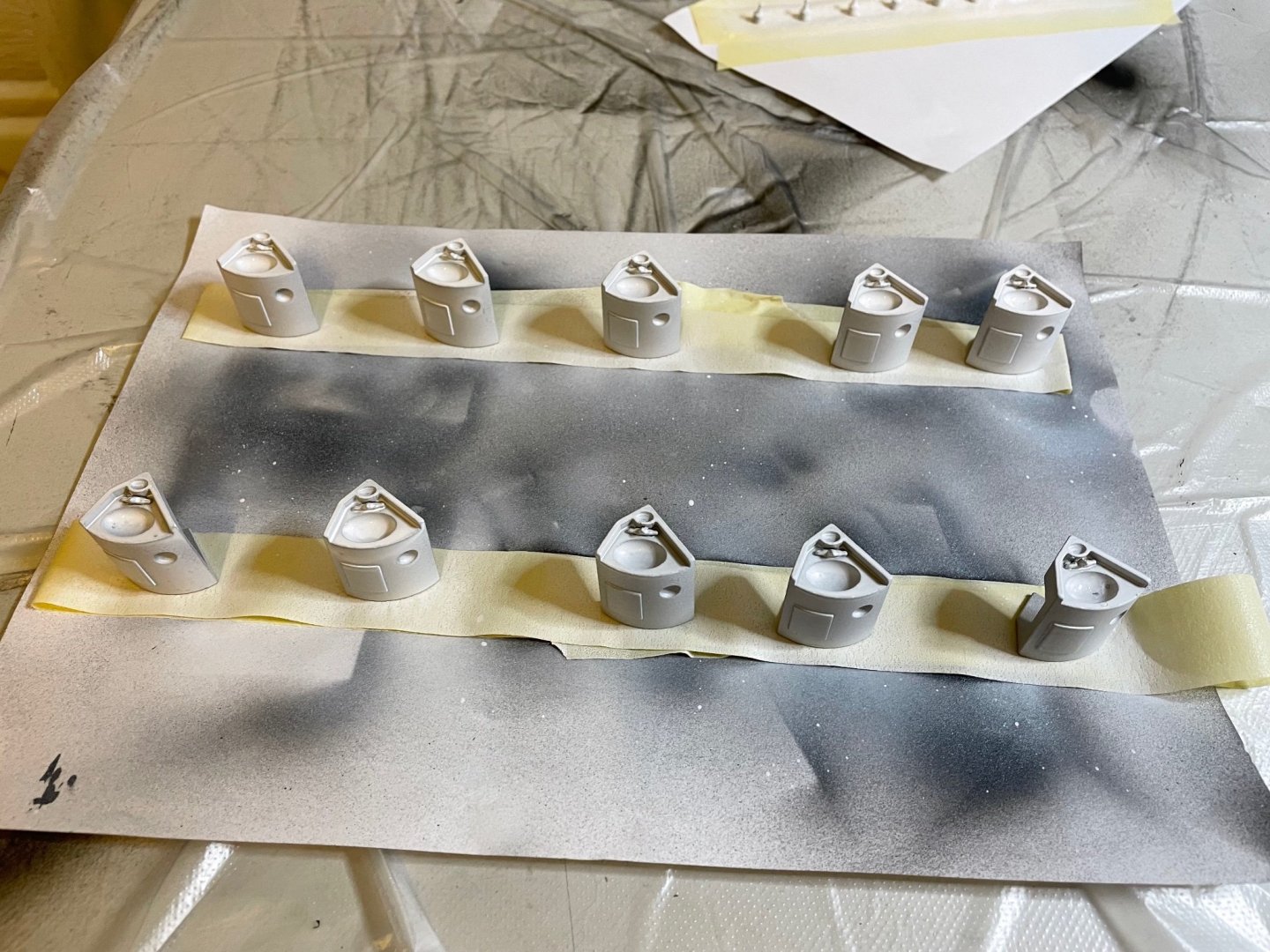

BUILD DAY 17 / 3hrs / (TOTAL: 45 hrs) Headrests. There are altogether 10 pairs of them, one pair for each compartment. I applied white glue using brush until the last step, where I used superglue to fix the loops to the back. Figures 183-193: Below I am adding several photos showing the process. That's all for now! Thanks for watching!

-

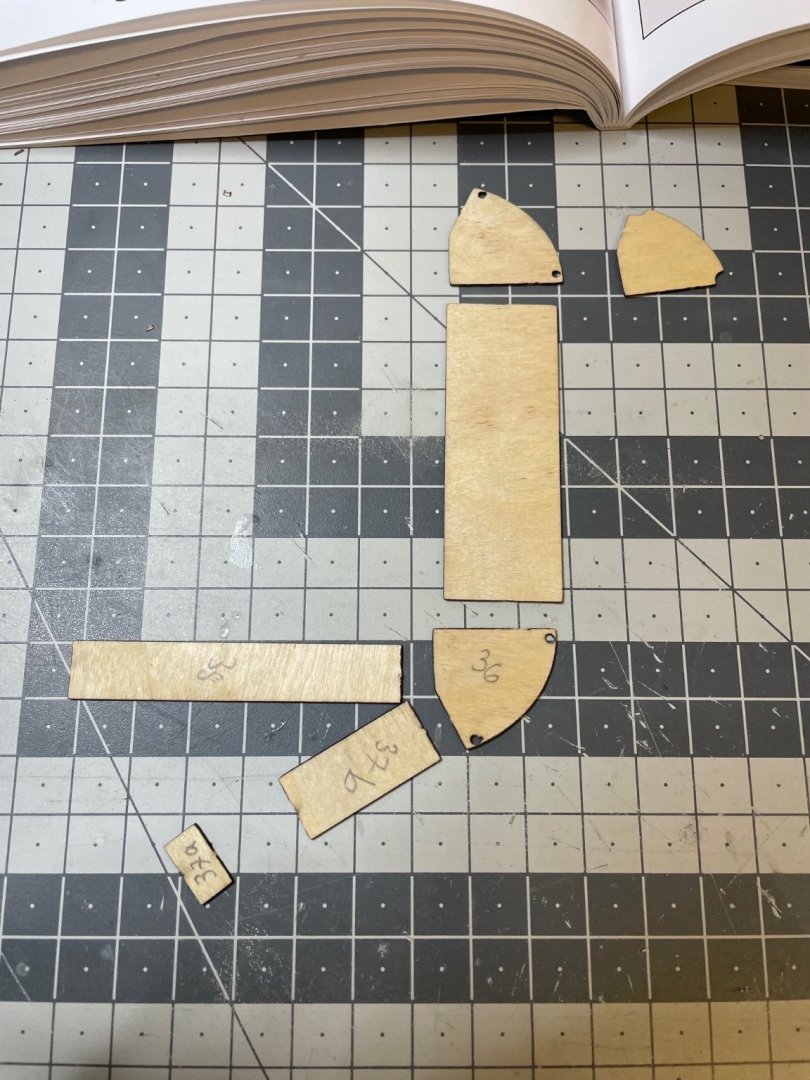

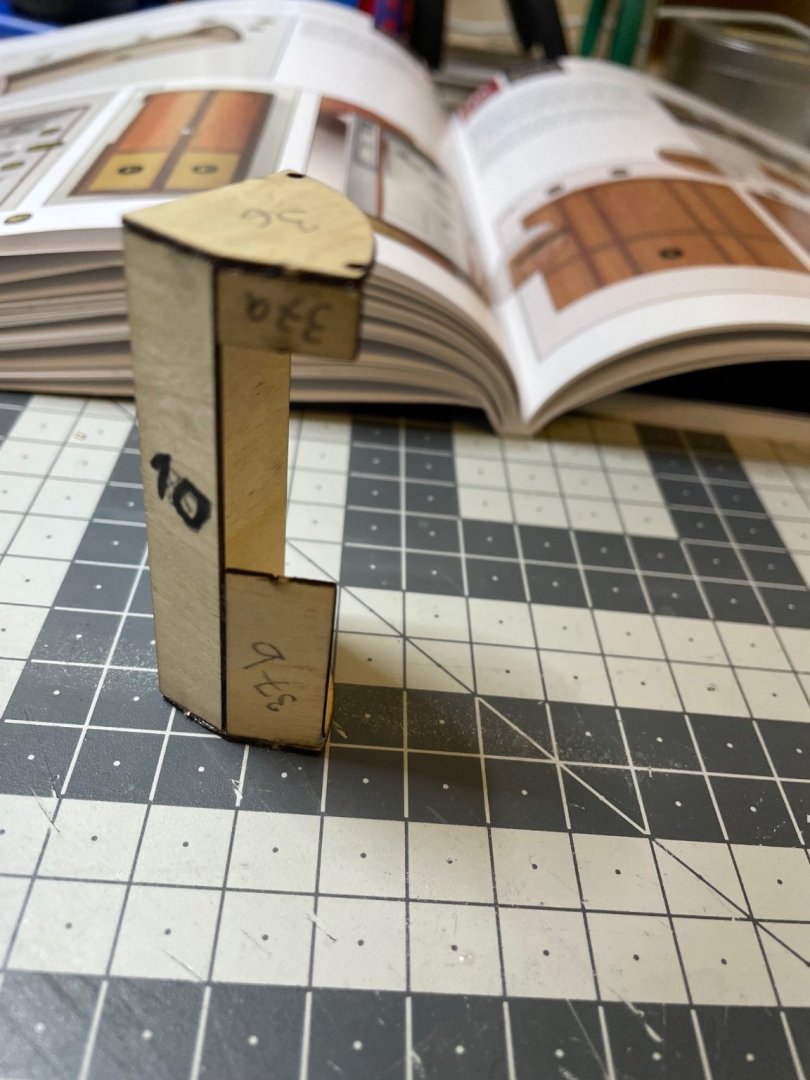

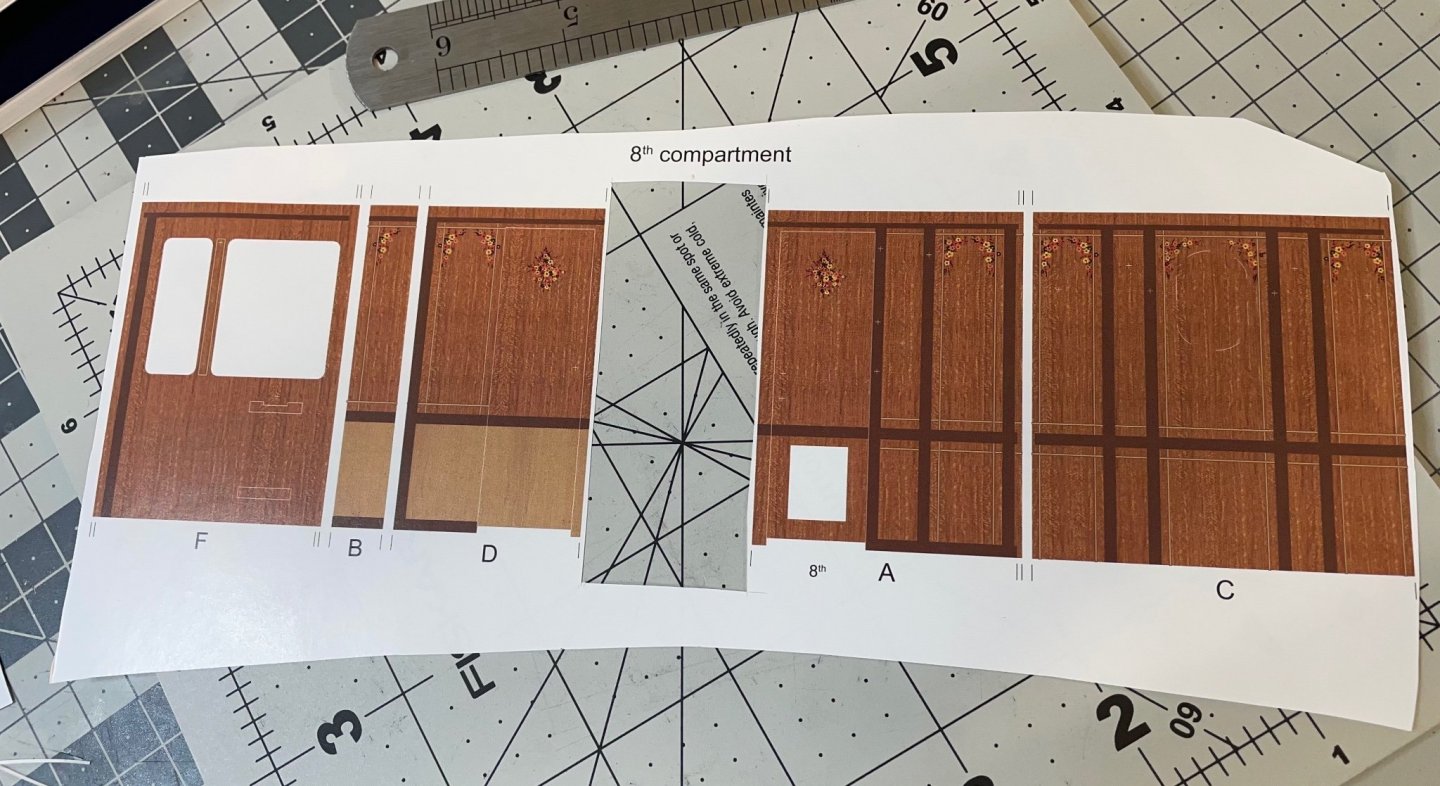

BUILD DAY 16 / 2 hrs / (TOTAL: 42 hrs) Bathroom cabinets have been put side now and it is time to start building the inner walls. Starting with compartment #1. Figure 178: Here again all pieces must be carefully numbered as they are quite similar yet slightly different at each compartment. Top row: plywood sheets. Bottom row: Matching paper prints. Figure 179: Papers glued. I used white glue all the way, applied using a brush. Figure 180: Paper print has several small marks indicating where the accessories will be glued later. Some of these marks remain under the wood lining, therefore you'll need to mark them on the corresponding spot on the wood strip before gluing them, like in this picture. Figure 181: First wood linings glued. NOTE: These are supplied in walnut. According to the instructions they should be stained in mahogany color. I don't know why Amati did not supply them in mahogany at first place. Cost? Most probably. Or maybe they are not available in mahogany in these sizes (1x1 mm and 0.5x2mm). I first thought of leaving them as walnut but then for the sake of precision I ran to the hobby shop and bought mahogany color and also some mahogany strips. The strips are 0.7x2mm and with a little sanding will fit just fine for 0.5x2mm purpose. For these ones in the photo (as well as the walnut strips on the bathroom doors) and 1x1mm strips I will use the mahogany paint. Figure 182: Walls of compartment #1. Note that some of the horizontal wooden strips exceed the edges by around 1mm. They are needed for corner turns. The walls are put aside for now. Some components, such as the headrests, will be installed before the walls are mounted in their places. By the way there are a lot of "build and put aside for now" in building this kit

-

Figures 176, 177: Doors installed and the handles have been glued. They are now to be put aside until later. I have cropped the excess of the hinges (i.e. the copper tube sticks) from the bottom in order to stand straight. I will crop the excess on the upper parts after I have installed them in their place.

-

Figure 174: This is a real annoyance, especially in this kind of a high quality and pricey kit: Bottle holder is too wide for the soap dispenser. 😡 Normally the task is supposed to be as easy as gluing the holder on the wall and then dropping the bottle into it and the bottle should just stay. However now the bottle passes through the ring. This should not happen. Now I have to glue the bottle to the ring from a touch point.

-

Figure 161: Doors ready for painting their inner side. The instructions address to glue the paper decoration outside first and then paint inside, but I see it too risky. Paint will definitely leak on the back surface. There should be no paper decoration at that time. Figure 162: Doors painted matt white.

-

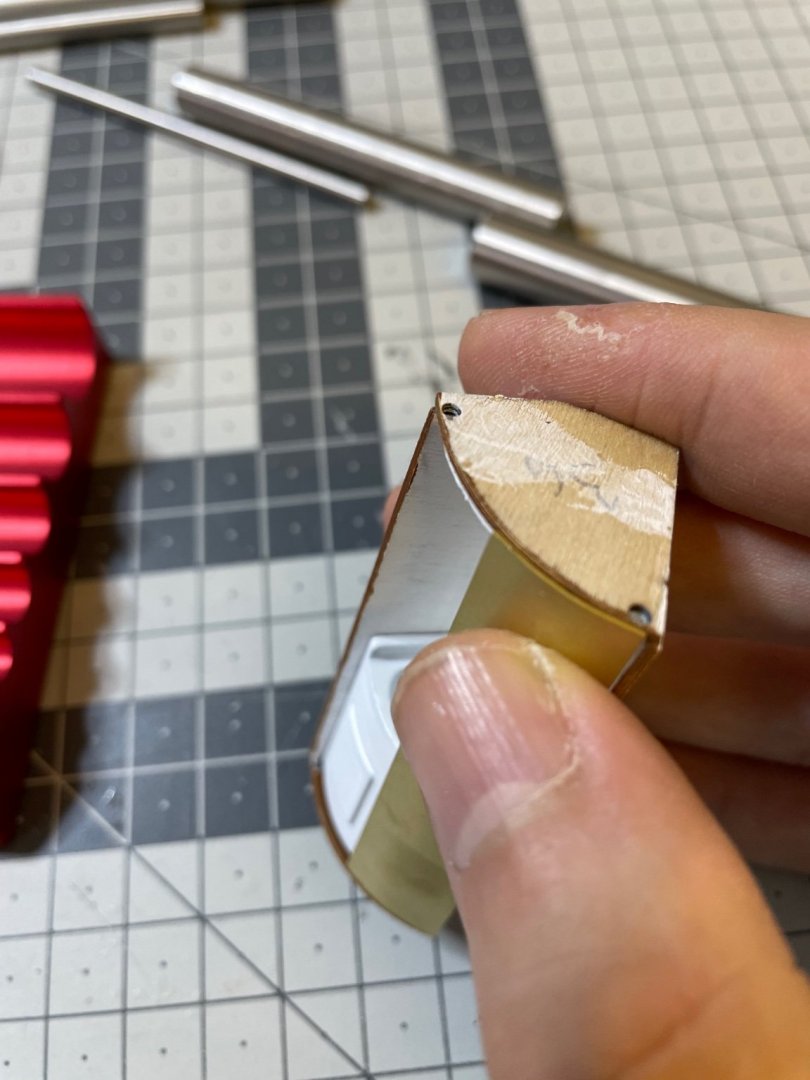

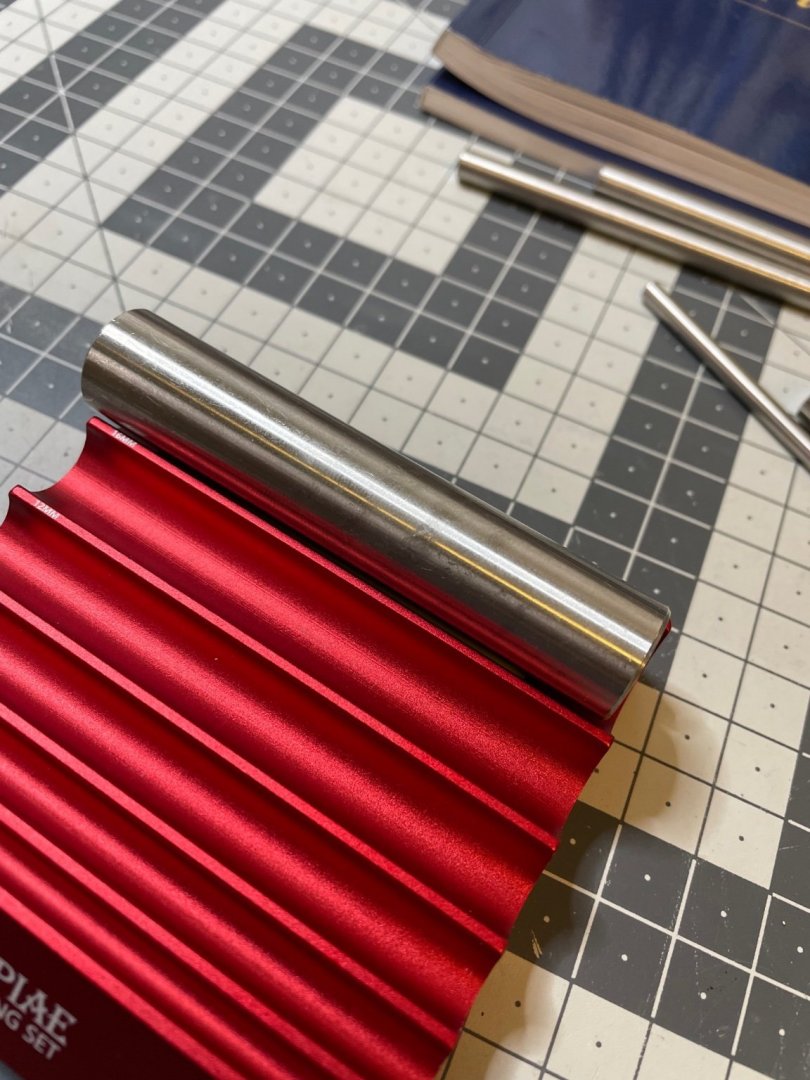

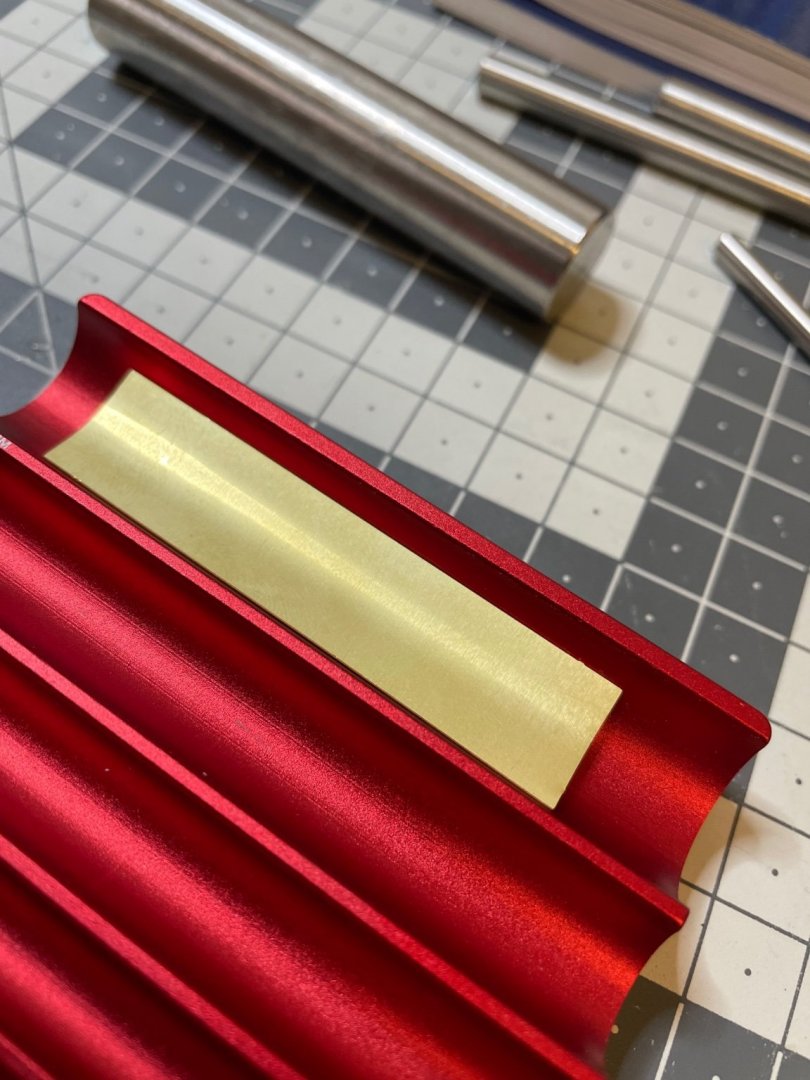

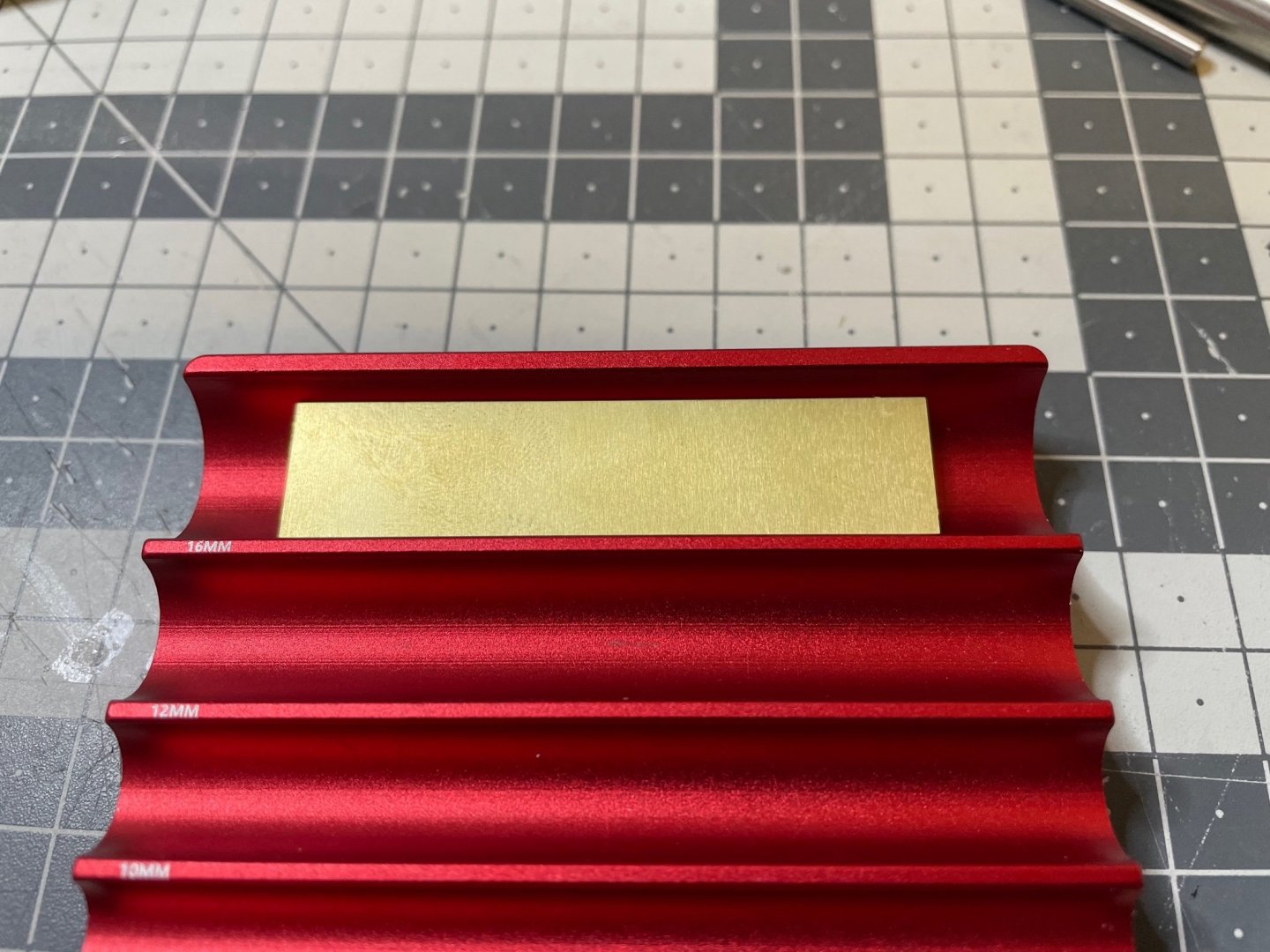

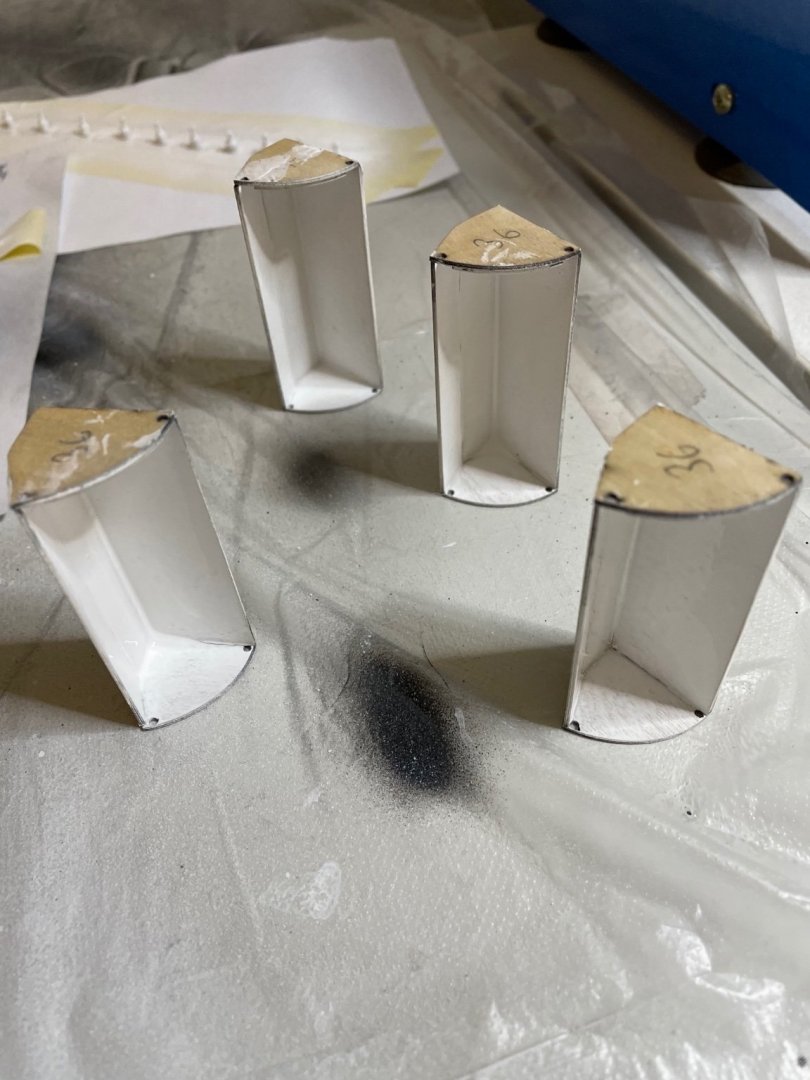

Bathroom doors. One pair per bathroom. They are made of 0.4mm photo etched brass, to be bent to match the curvature of the bathroom cabinet. The bathroom doors are identical regardless of the cabin numbers therefore I build all 10 at once. Figure 155, 156: I use my DSPIAE photo etched roller for this purpose. I tried first with a scrap piece of same thickness and decided to use the 16mm curvature. Figure 157: I press with my both hands on the steel cylinder as hard as I can. Figure 158: I over-bent the parts and then widened the curvature by soft hits with a hammer, until it aligns with the structure.

-

Figure 152: The was basins. They are made of die cast metal. I paint them to white as instructed. I see some videos where the builder has painted the taps to silver color, but I will leave them white just like in the instruction manual. I haven't made a research but I guess they were more likely white porcelain, instead of metal. Look more elegant in white.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.