-

Posts

916 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by aydingocer

-

Thanks Grant! It is always a motivation when you know somebody is watching

- 62 replies

-

- bosphorus

- tersane model

-

(and 1 more)

Tagged with:

-

FINAL PHOTOS - 21 build days and 49 hours! Here is a bunch of photos from the finished model. Thank you very much for watching and let's see when I will be off to the next building adventure (hopefully soon) Regards, Aydin

- 62 replies

-

- bosphorus

- tersane model

-

(and 1 more)

Tagged with:

-

TURKISH FLAG It comes as a paper. I used aluminium kitchen foil to give a wrinkled look. You can see it better in the final photos. I think it looks much better than a starched rigid piece of plate

- 62 replies

-

- bosphorus

- tersane model

-

(and 1 more)

Tagged with:

-

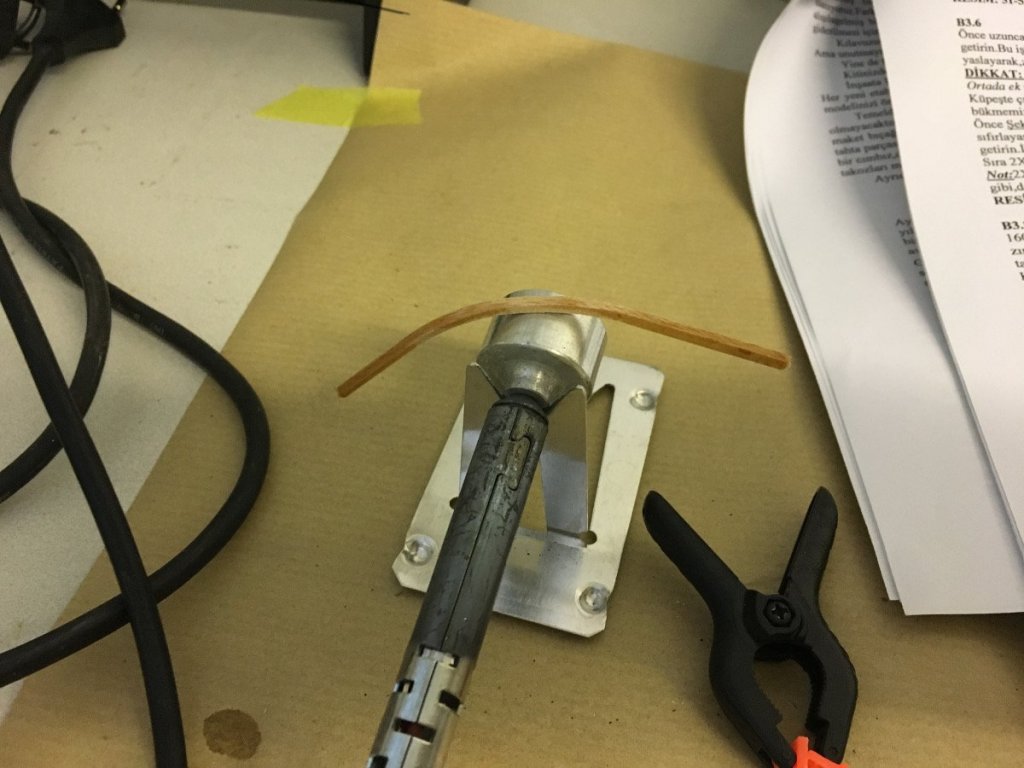

This is a rubber belt which lies on top of the end of the rudder handle. I think it helps control the rudder, or just keeps it in place. The belt is fixed as a loop from its ends using metal braces, then attached with hooks to the hull:

- 62 replies

-

- bosphorus

- tersane model

-

(and 1 more)

Tagged with:

-

- 62 replies

-

- bosphorus

- tersane model

-

(and 1 more)

Tagged with:

-

- 62 replies

-

- bosphorus

- tersane model

-

(and 1 more)

Tagged with:

-

- 62 replies

-

- bosphorus

- tersane model

-

(and 1 more)

Tagged with:

-

- 62 replies

-

- bosphorus

- tersane model

-

(and 1 more)

Tagged with:

-

ENGINE, EXHAUST PIPE AND GAS TANK Exhaust pipe is fixed to handrails using a metal plate. Gas tank is in fact a canister hanging on the side (Note the copper wire resembling the gas input pipe from the canister to the engine)

- 62 replies

-

- bosphorus

- tersane model

-

(and 1 more)

Tagged with:

-

- 62 replies

-

- bosphorus

- tersane model

-

(and 1 more)

Tagged with:

-

Build days: 20-21 Finished building. 5.5 hours in three days, 49 hours in total. I am glad to announce that my Bosphorus Fishing Boat is finally complete. Here is a log of final steps: ANCHOR Anchor consists of 3 hooks to be glued to the main rod, which is attached to a chain and finally to a thread. I had to drill the hole which the chain is hooked using a 0,5mm drill bit. And in place:

- 62 replies

-

- bosphorus

- tersane model

-

(and 1 more)

Tagged with:

-

Build day: 17-18-19 3 hours in three days, 43.5 hours in total. It is about time to start painting the hull, i.e. before installing the ornaments and other accessories. Overall total work did not take too long after all, only waiting in between the drying time of the paint and varnish. Below are some photos. Photo from the package. I like the choice of colors therefore I intend to make similar (remember this is a serial production boat which can come in any color so it is up to you to paint it how you like it or where you want to display it): White stripe at waterline: Varnish inside This is the status at the moment. Rudder and oars will be painted separately. Thanks for watching.

- 62 replies

-

- bosphorus

- tersane model

-

(and 1 more)

Tagged with:

-

Thanks Eddie! I am almost gettin' there! Cheers, Aydin

- 62 replies

-

- bosphorus

- tersane model

-

(and 1 more)

Tagged with:

-

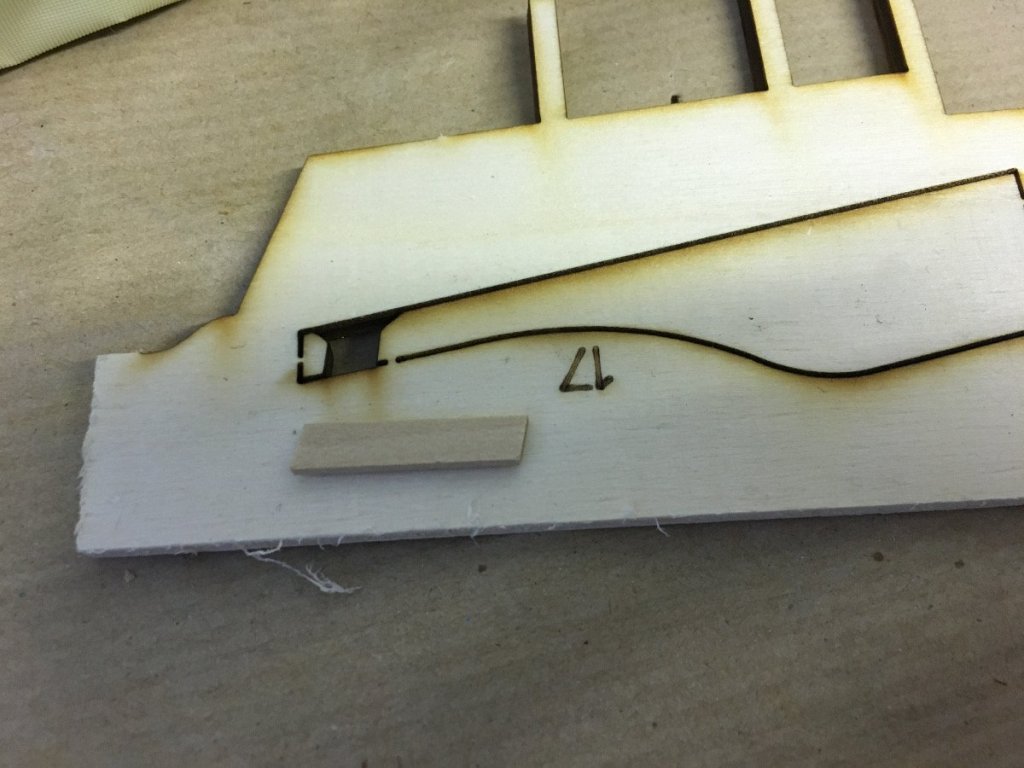

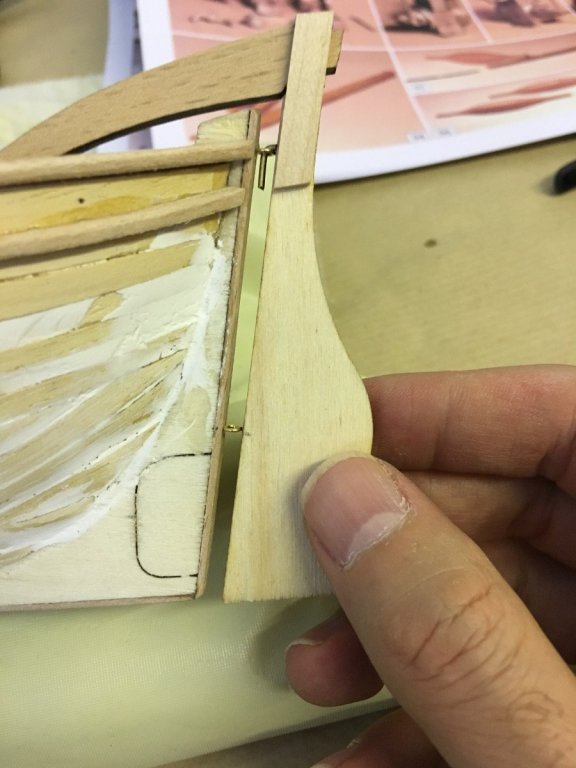

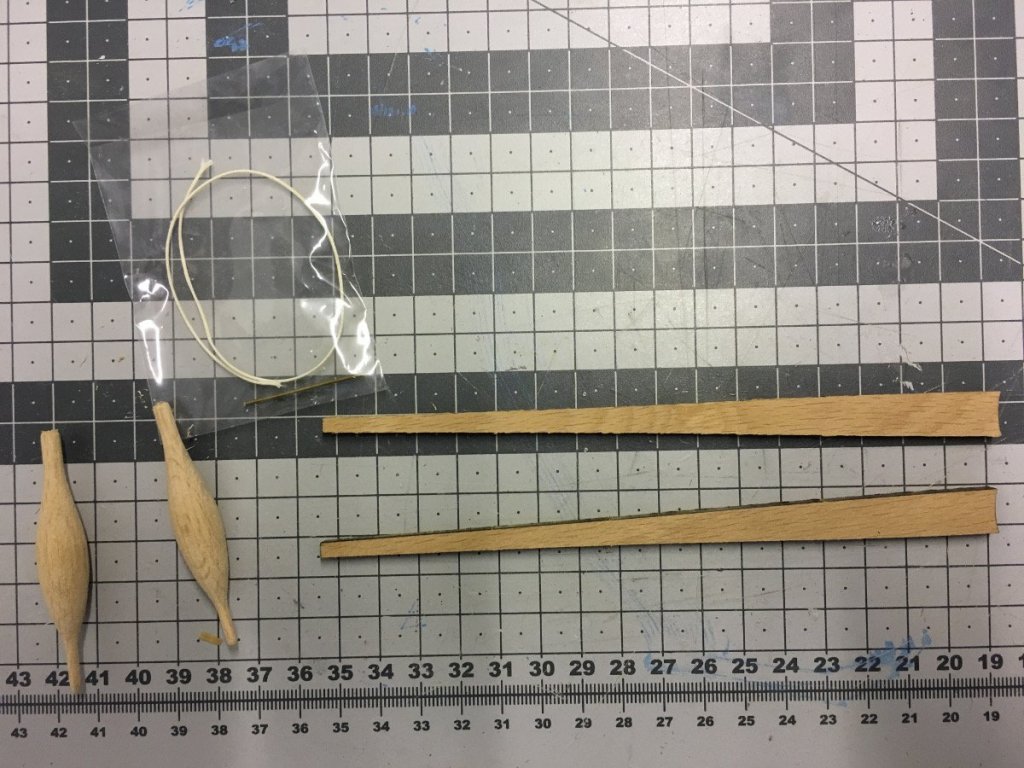

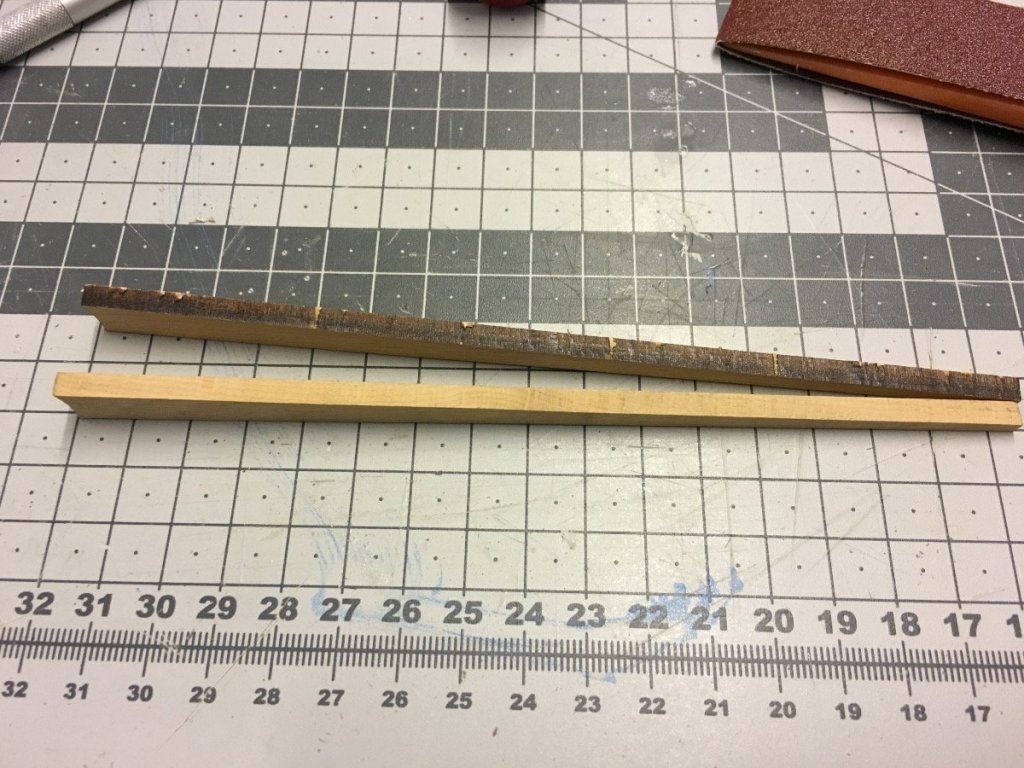

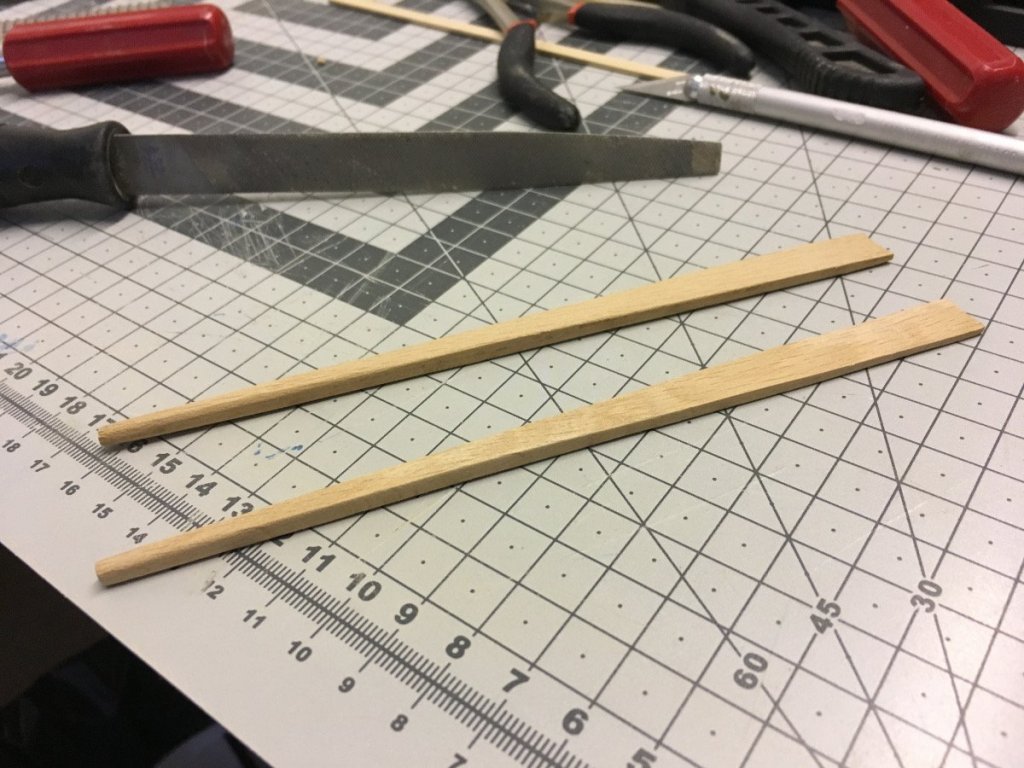

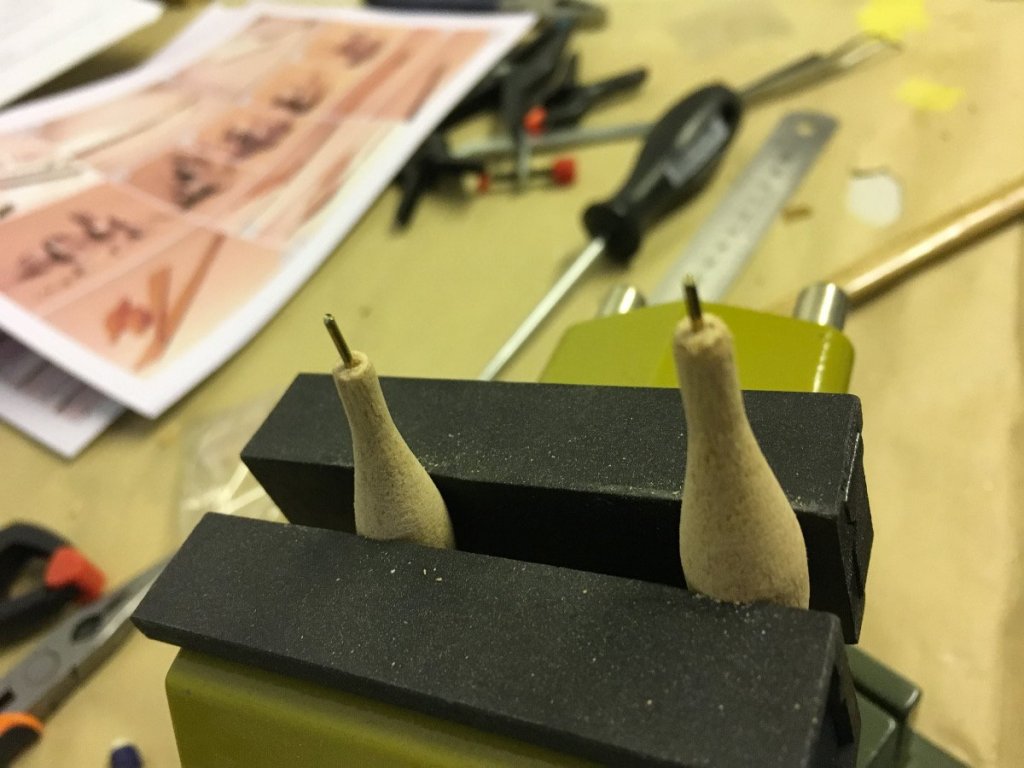

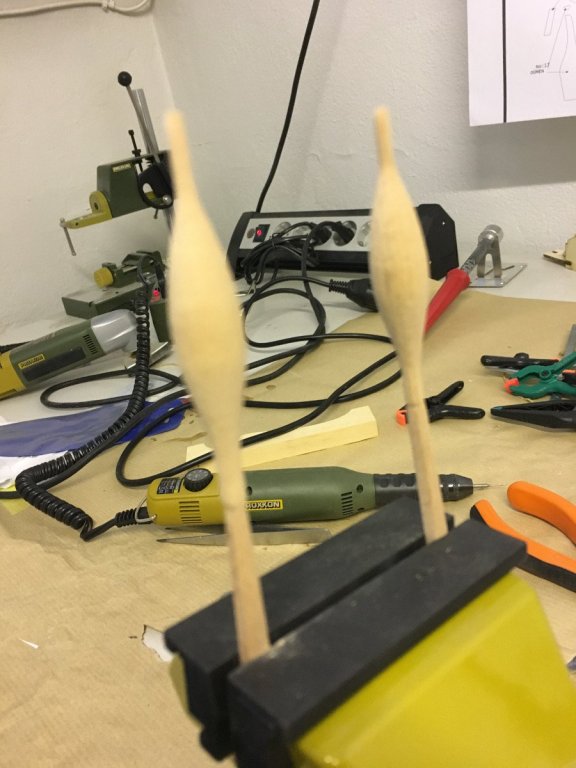

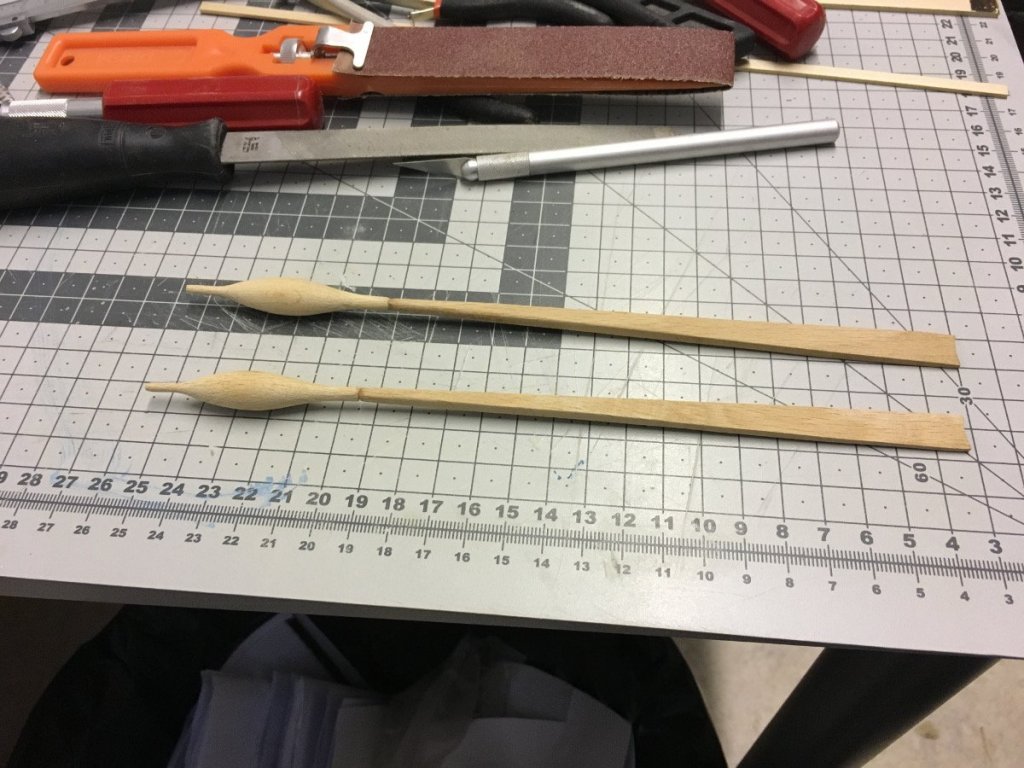

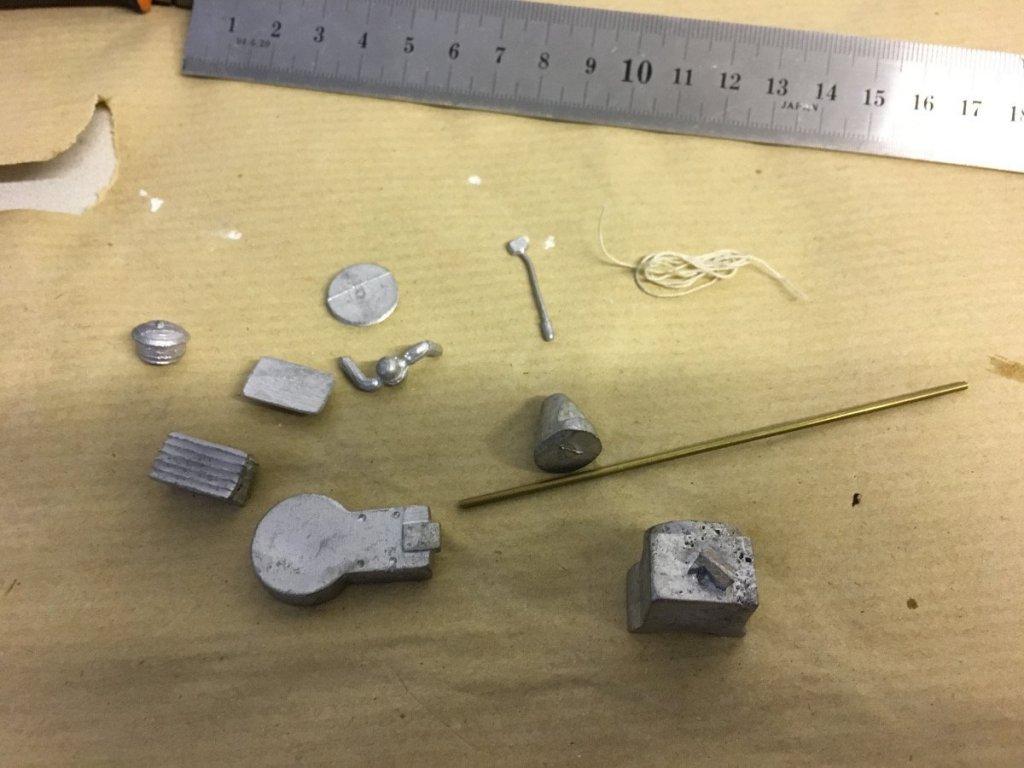

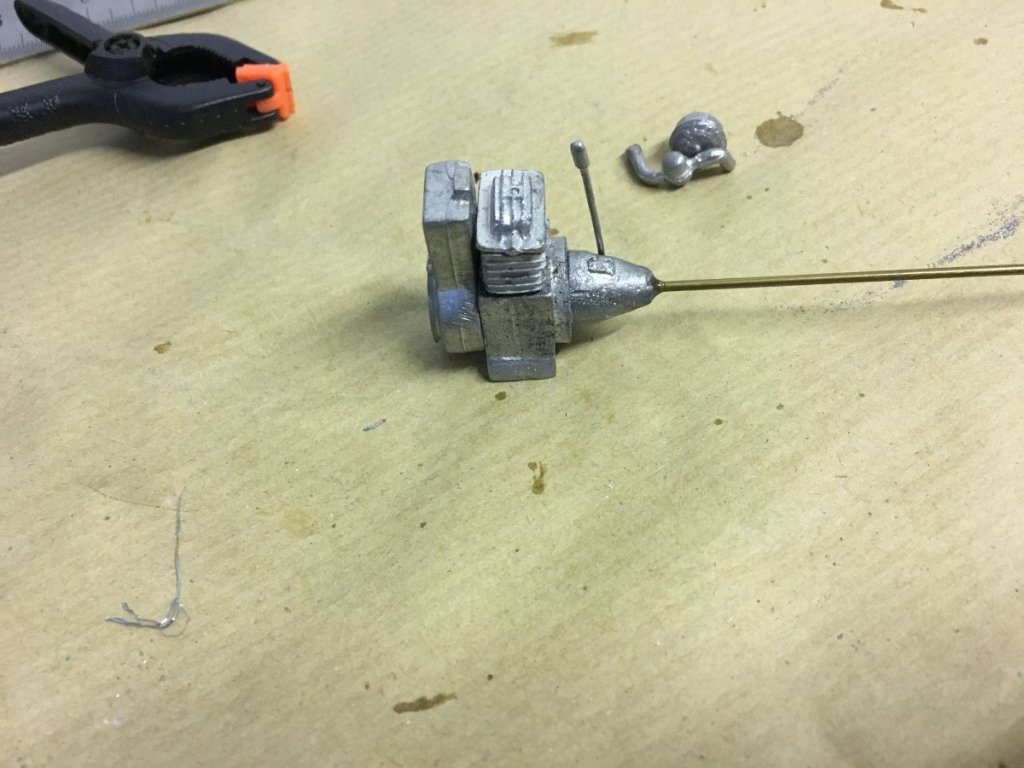

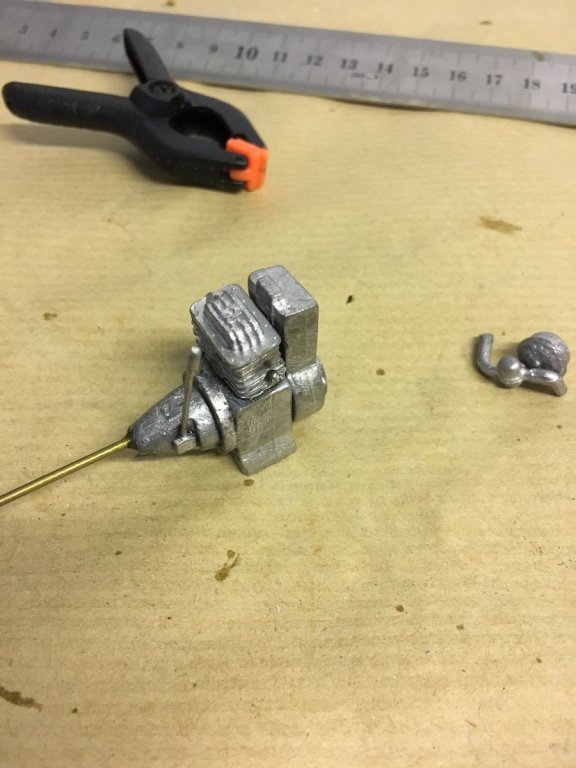

Build day: 15-16 6 hours in two days, 41,5 hours in total. In these two days I worked on - the handrails, - engine ramp, - rudder, - oars - engine After these steps now the boat is ready for painting. Once the essential parts have been painted/varnished, it will be about installing the other accessories like hooks, anchor, spear etc. I am posting quite many photos below, with some explanations where I feel helps understand what's going on. Below I installed the posts for the oars (you'll notice them in both port and starboard, a bit offset the seat): Engine ramps: Floor boards getting frames: D shaped strips following the handrail on the hull: THE RUDDER Construction of rudder follows and interesting and smart way: In order to maintain correct size of the slot where the handle will be inserted, one of the support strips is glued before removing the rudder pieces from the plywood. One of the support pieces glued: The parts have now been removed from the plywood: Rudder "handle" is inserted (dry fitted at the moment since it will be on the way while drilling as well as painting): These small parts are used for attaching the rudder to the hull: OARS: Each one of the oars are made of two pieces. The longer piece which is removed from plywood needs to be tapered on the water end and and rounded on the other end, to fit the second piece. Below is a series of pics to show the progress: Sanding away the laser cut burns from the sides (photo shows the sanded piece vs not sanded): ENGINE: Engine comes in cast metal. I have to say I was quite disappointed with the quality. Inaccurate parts with lots of burrs here and there. Besides, some parts (you will see in the later photos) were impossible to glue. The rod is supposed to go through all the way through the components but there was no hole in them and there was no way I would waste my drill bits trying to drill hole through the metal. So I just glued them using CA and only drilled a 2-3mm hole to stick the rod, which will go to the propeller. The two pieces you will see in the second last photo will not fit therefore I will just leave them out... This is the status after these two days. Thank you for watching. /Aydin

- 62 replies

-

- bosphorus

- tersane model

-

(and 1 more)

Tagged with:

-

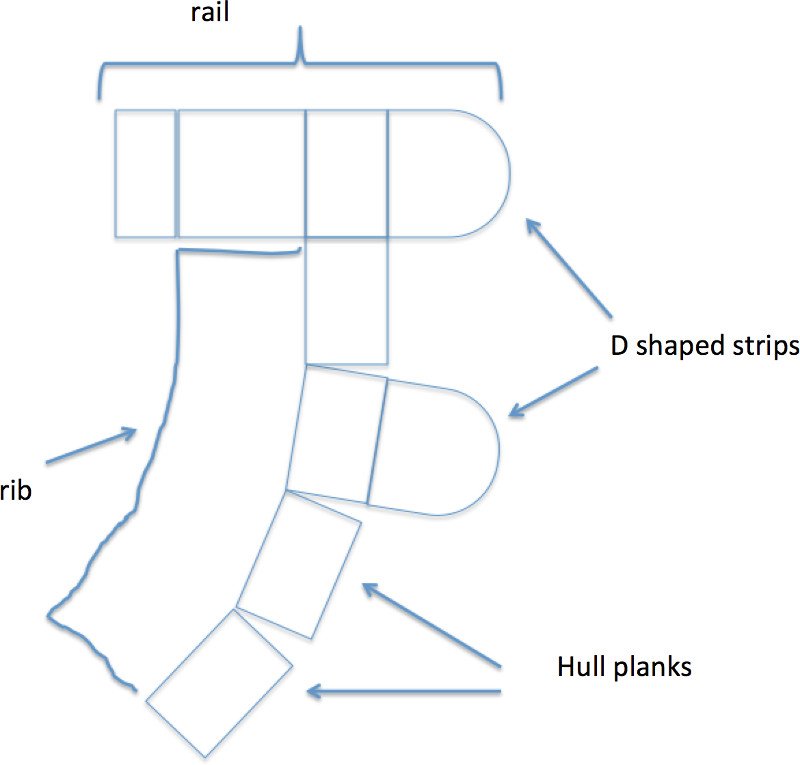

Build day: 14 1,5 hours today, 35,5 hours in total. Continuing with the handrails. 4 of the 2x2mm strips need to be rounded to a D shape. Two of them will be used on the outmost rails, 2 of them will be aligned approximately 1cm below the handrails, outside the, parallel to rails. Below is a rough cross-section illustration of how the rails are formed: Strips filed and sanded to D shape: Gluing the two inner rail strips: This is all for today. Next, I will glue the D shaped strips and sand all of them to level. Thanks for watching.

- 62 replies

-

- bosphorus

- tersane model

-

(and 1 more)

Tagged with:

-

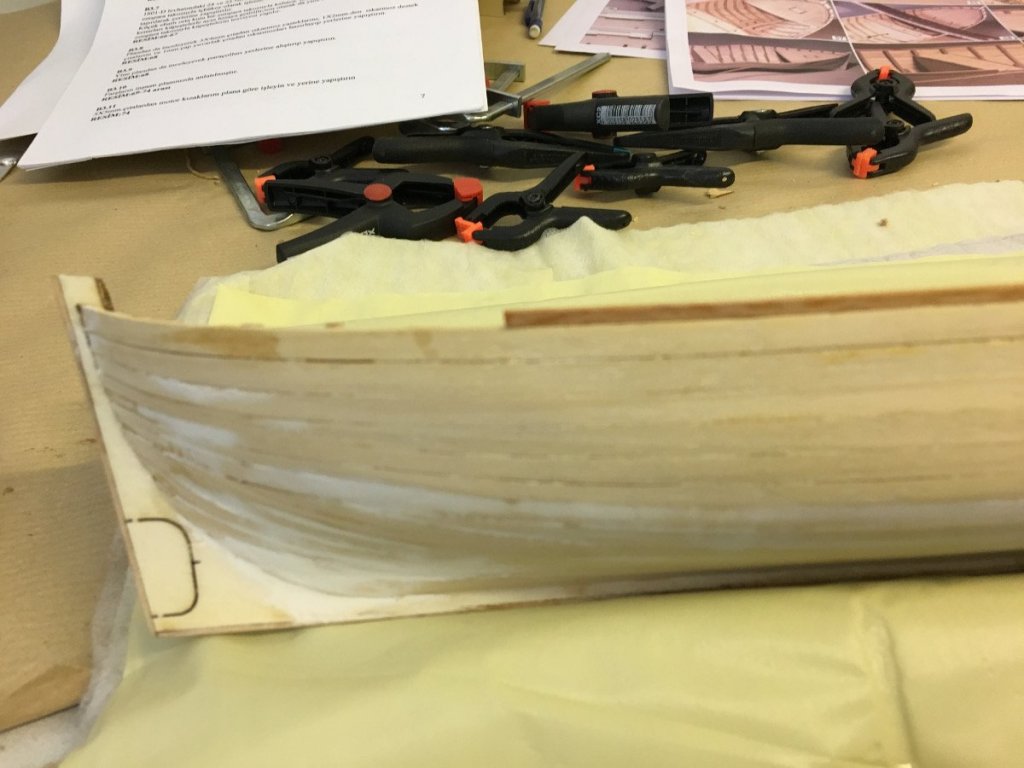

Next in line is adding the handrails. Instead of struggling with bending a single wide strip, they will be constructed by gluing thinner strips together. It starts with 1x2mm walnut strips glued right over the topmost hull plank, following it flush. (This is the part I finished today) Next, more walnut strips (2x2mm) will be added both inside and outside of this strip. First strip being glued: First line of strips completed. This is the status after today. Thanks for watching! /Aydin

- 62 replies

-

- bosphorus

- tersane model

-

(and 1 more)

Tagged with:

-

- 62 replies

-

- bosphorus

- tersane model

-

(and 1 more)

Tagged with:

-

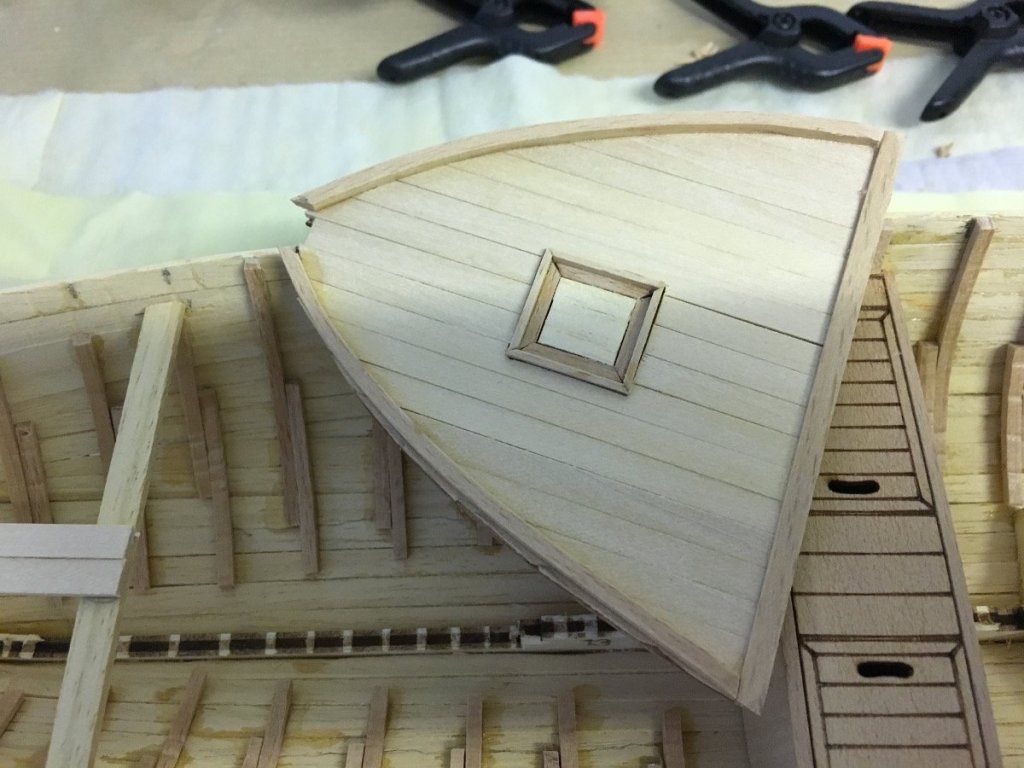

Added the deck lid and the 1x5mm strip across the ends of the planks (on the right side, you see the 1mm edge)

- 62 replies

-

- bosphorus

- tersane model

-

(and 1 more)

Tagged with:

-

Started my own version of stern deck, planking directly on the hull. If you check my earlier posts, I had prepared the deck independently off the hull as instructed, planking on the false deck supplied. However the false deck had been warped so badly in the package that it kept warping back no matter how many times I soaked it and clamped flat until dry. With a last hope I completed the planking but still it wasn't acceptable to my expectations. So now I first glued the 1x5mm strip across the 3rd rib and proceed with planking: This is the structure which I discarded: Stern deck planked:

- 62 replies

-

- bosphorus

- tersane model

-

(and 1 more)

Tagged with:

-

- 62 replies

-

- bosphorus

- tersane model

-

(and 1 more)

Tagged with:

-

Build day: 13 4 hours today, 34 hours in total. Continuing with the "ribs" and proceeding on the stern deck. Bending the 2x2mm strips using the electric bender:

- 62 replies

-

- bosphorus

- tersane model

-

(and 1 more)

Tagged with:

-

Thank you very much for your reply, Robert and it is never too late for answer :). I think the waterway had been already glued in your case. How hard was it to remove the the waterway piece properly clean after you have used the blade on the marked lines? Did you use a weaker glue when you fixed it on the false deck in order to make it easy to rip off pieces afterwards? Or was it just easy to do it? /Aydin

- 66 replies

-

- bluenose ii

- artesania latina

-

(and 1 more)

Tagged with:

-

Well, I searched around and found this topic in this forum about my question above. I will check it out but any first hand experience tips are still appreciated (I tried to edit my post but Forum did not let me, therefore I had to post a new reply about it).

- 66 replies

-

- bluenose ii

- artesania latina

-

(and 1 more)

Tagged with:

-

Hi Bertu, Excellent job indeed. Congratulations. I have this kit as my next project and I was wondering how did you manage to get those plank nibs so smoothly into the waterways (see picture below for what I mean)? Did you first install the waterways and cut off parts as the planks come by, or did you use some other way? Can you share your method? BR; Aydin

- 66 replies

-

- bluenose ii

- artesania latina

-

(and 1 more)

Tagged with:

-

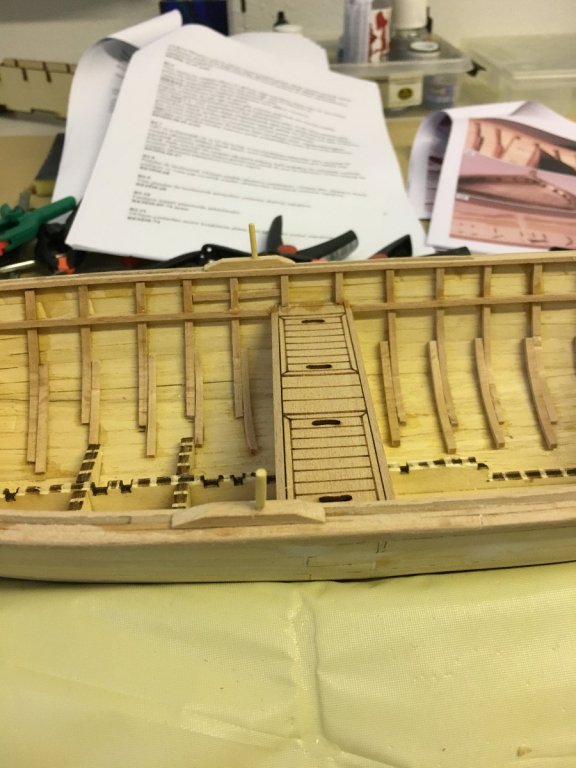

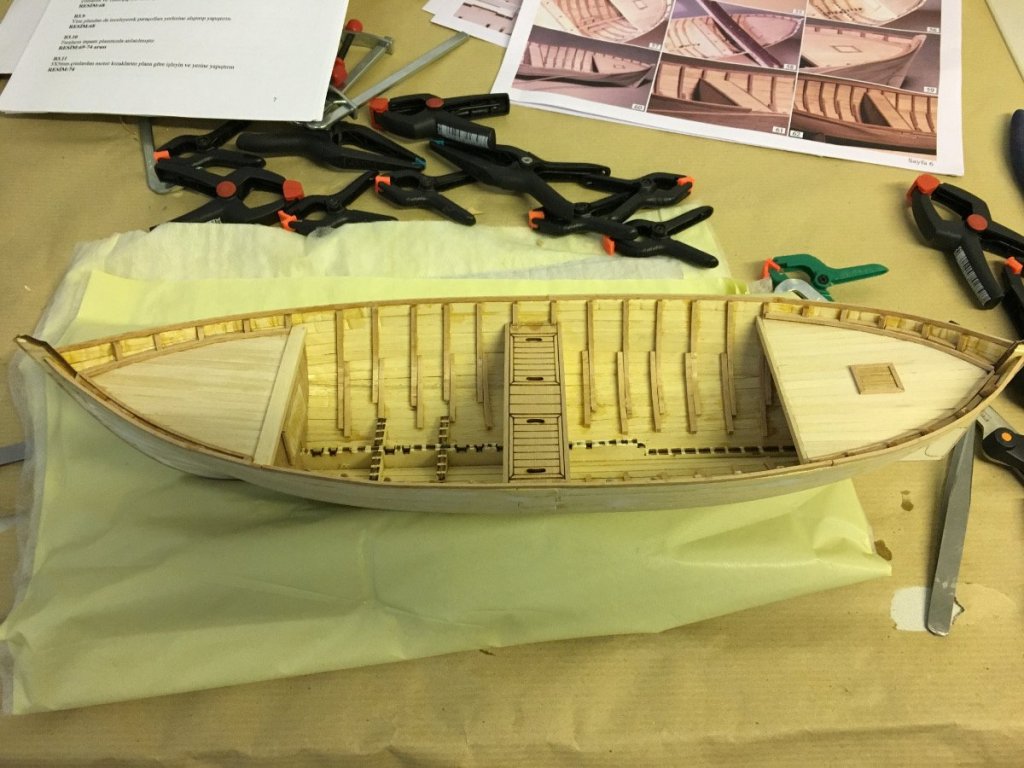

Build day: 12 2 hours today, 30 hours in total. Today I spent some time for installing the support bars (or ribs or whatever they are called). I used the electric hot plank bender most of the way instead of the Amati clamping plank bender in order not to make any dents, since in this case the inner side of the strips are visible (as opposed to hull planking where the outer side is visible). This process slowed down the work significantly. Here is the work so far. The boards on the floor are still dry-fitted. Thanks for watching.

- 62 replies

-

- bosphorus

- tersane model

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.