-

Posts

205 -

Joined

-

Last visited

Reputation Activity

-

liteflight got a reaction from EJ_L in 10th-11th century Byzantine dromon by Louie da fly - FINISHED - 1:50

liteflight got a reaction from EJ_L in 10th-11th century Byzantine dromon by Louie da fly - FINISHED - 1:50

What a relief! Now I understand all the baffled looks when I sang.

If the sails would only be used for running with the wind astern or very close to that; there would be little need for tacking, or handing the sail round the mast. So the running rigging would be simpler as the decision would be “sail or not sail”. So I’m not sure about the rope you label as “vang” and it’s usefulness. I have sailed Thames Barges with a big sprit rig, and the vangs would only be used for close-hauled work. ( I have still not become quite reconciled to transatlantic use of the word to mean a kicking-strap, nor it’s pronunciation as spelled).

But, especially in the Med, brailing would be important to kill the sail if the wind got into a sub-optimal direction. Dropping the halliard would be faster? But more messy and hazardous to keep the sail under control with the wind, say, on the beam.

Do sail handlers really shin up lateen rigs to furl the sail (or release jammed brails ). Must do I suppose, and it would be a colourful addition to your dromon.

Thinking a bit further, It would be a good place for a lookout, if not very comfortable, but it would not be impossible to have a semi-permanent canvas sling seat for a lookout. Kinder anyway than a bight of rope on bare feet.

but this would only work if the yard was raised in the sailing position. And even a fully braided sail would present a severe windage to an unkind wind.

-

liteflight got a reaction from Keith Black in 10th-11th century Byzantine dromon by Louie da fly - FINISHED - 1:50

liteflight got a reaction from Keith Black in 10th-11th century Byzantine dromon by Louie da fly - FINISHED - 1:50

For my 2 denarii worth, she would look awesome with a pair of goose winged lateens. ( and no glue globs)

Who knows if sail was used at the same time as oars (sweeps), but I would take a fair bet that it was done, because it could be done.

So when you have completed the research and rig- could you fancy a quinquireme (port of registry Nineveh, last port of call: Ophir) with full and weary crew and peacock sound effects?

I see you have a neat French bon mot as your signature. I am always puzzled by the French canadien song about “ Alumette, gentil Alumette , je te plumerai.....”.

Or do I have something grabled?

-

liteflight reacted to Louie da fly in 10th-11th century Byzantine dromon by Louie da fly - FINISHED - 1:50

liteflight reacted to Louie da fly in 10th-11th century Byzantine dromon by Louie da fly - FINISHED - 1:50

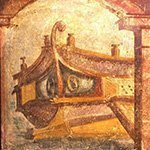

Well, I'm afraid I'm waffling a bit whether to have the sails set. Bigpetr's question got me thinking - do I know they used the sails while they were rowing, did I read that somewhere, or is it just an assumption on my part? If I can't remember where I got the idea, maybe I'll never be sure I have it right. So I did a bit of investigating; unless I read all the way through Pryor's book Age of the Dromon I'm not likely to find the reference (if there is one). I'm prepared to do that, but it's going to take a while. In the meantime the pictorial record does provide some evidence. Here are some Byzantine representations of dromons with both oars and sails in use: from the 9th century Sacra Parallela BNF Gr. 923 f. 207r and the 12th century illustrated copy of the Synopsis Historion of Ioannis Skylitzes held in the Biblioteca Nacional in Madrid (yes, I do believe that's a sail).

And one from the fifth century AD Roman Aenid of Vergil in the Vatican Library (Cod. Lat. Vat. 3867, fol. 77r) which is a little early, but a galley is a galley . . . the 12th century Spanish Cantigas de Santa Maria, and the late 12th century Italian Liber ad honorem Augusti (f. 131)

However, there are also plenty of contemporary pictures of galleys, and not only in combat, without sails set, and in most cases without the masts either. The first two from the Synopsis Historion, the third from the Cantigas de Santa Maria and the fourth from the 12th century Byzantine Sermons of Gregory of Nazianzus, (Pantaleimon Cod. 6 f. 183r.)

So, where does this leave me? There seems to be enough evidence to justify having the sails hoisted while the oars are in use - unless the artists just decided "Hey, we've got oars and sails - let's show everything!"

However, I'm also up against the problem that when I laid the whole thing out - hull, superstructure etc - belaying points were the furthest thing from my mind. So one pair of shrouds fouls the midship castles, and I'm really not sure if the same thing won't happen with the running rigging. Perhaps I'll just have the thing under oars alone, with the masts and yards stored on their stands above the deck - it's still an option. I need to do some serious thinking about all this.

In the meantime, today I've been cleaning up remnants of white glue. I'm a bit over-enthusiastic about slathering it all over the place (still better than when I was 17 - parts of the Great Harry are not a pretty sight). I've previously used rubbing alcohol (otherwise known as isopropyl alcohol or isopropanol) to dissolve glue to remove things I'd glued down, but Liteflight put me onto using it to remove gobs of glue. So this afternoon I got a bit of cloth, a toothpick and some isopropanol and started rubbing the messy bits of glue that detracted from the look of the model, particularly on the gunwale where the oars and pavesades were glued on. And it worked! Looks much better. A fair bit of elbow grease involved, but well worth it. So thank you, Liteflight.

-

liteflight reacted to Louie da fly in 10th-11th century Byzantine dromon by Louie da fly - FINISHED - 1:50

liteflight reacted to Louie da fly in 10th-11th century Byzantine dromon by Louie da fly - FINISHED - 1:50

And now it can be told.

I was planning to change the final configuration of the ship - rather than have her under full sail I decided that it would look really cool to do a bit of "living history" - to leave maybe four pairs of oarbenches empty and carve new figures to take the place of those oarsmen I'd already done, but assign them to "other duties". I'd have the foresail hoisted but still furled, with two or three guys up on the yard unfurling it:

and a bunch of others in the process of hoisting the after sail like this:

or perhaps this:

I even carved four guys based on the picture above:

Then I changed my mind. Good though this might be, I really think it wouldn't look as good as an overall display as my original idea, to have both sails fully set and drawing (the wind directly aft - the only circumstancs the sails would be set in a dromon because of its low freeboard) and "goosewinged" as in the pictures below.

So there you go. I'm happier with this idea - I think it will look a lot better.

Perhaps I could feel that my making these new guys had gone to waste, but in fact it was fun - a welcome relief from doing so many figures all the same. I don't really care if they never get used. If I'm not stuck on a "sausage machine" production line, I really do enjoy carving.

-

liteflight reacted to Cathead in Viking longship by Cathead - Dusek - 1:35 - FINISHED

liteflight reacted to Cathead in Viking longship by Cathead - Dusek - 1:35 - FINISHED

More problem-solving and warnings for future builders.

First, the planks are fitting less and less well as I progress up the hull. It's possible, even likely, that I'm not laying them out exactly as the kit designer intended, which is a problem with pre-spiled planks. But I think it's more than that. For example, on the fourth strake, if you line up the stern plank thus:

the bow plank ends up sticking out this far past the previous plank:

I think that's way beyond an error I could have made, and I'm sure I'm using the right planks. Though one improvement the kit could make is to lasercut or otherwise label the actual wood sheets with the plank numbers. You have to consult the plans to match the wood sheets, and it's pretty confusing when there are lots of very similar planks right next to each other.

In the last strake, I ended up needing to nibble a bit off the plank ends to keep the end correct, but this time it's ridiculous. So something needs to be cut. Oddly, if you match the actual end of the plank with the stem (so you'd be cutting off extra from the middle portion where it butts against the stern plank), the curve doesn't fit at all. But if you butt the orginal end (as shown in the photo), the curve fits nicely, just with a lot of extra. So I cut it off at the bow end. Strange but effective.

Next problem: The deck insert does not match the shape of the planking; it sticks out rather badly into the run of the planking and needs to be carved back quite a bit. For example, look closely at where the deck interacts with the frames in the photo below (especially between the two foreground frames), and envision how a plank set into the notch in the frame would interact with the deck:

It can't be done. Rather a lot of material needs to be taken off the edge of the deck to allow the planks to flow naturally within their precut notches in the frame. This is true at both ends. I initially tried to do this with a sharp knife, but the geometry is really difficult and tight and I came very close to either nicking the planks in place or christening the vessel with blood. The deck wood is pretty hard and the knife doesn't want to carve in that semi-cross-grain direction, plus the assembly is somewhat fragile. Then I hit on using a pair of nippers instead, which worked far better.

These take out nice chunks of wood at at time, are easy to align with the flow of the hull, and it doesn't matter that their cut is rough because this is a false deck that will be hidden by the planking and the real deck above it. So I just hacked away until I got close, then finished the edge with knife and file. I had to remove a LOT of material at bow and stern to get the planks to run cleanly. But it worked great.

Another problem this deck is about to cause, is that it interferes with using frame-based clamps to hold the planks on. The next few strakes are going to be especially tricky. This deck has been a problem from the beginning and I'm wishing I'd just never installed it at all. The frames are held solid by the braces on top, and I could have filled in a supporting deck later on once the hull was complete.

Anyway, here's what the deck edge looks like in the same view as above after it was carved back; can you see how the edge now allows the planks to lie in their notches?

One final note on laying planks, for future builders. At both stem and stern, the planks transition from clinker (overlapped) to carvel (edge to edge) as they flow into the stem/stern keel piece. There's an awkward short zone where each plank dips beneath the next and is following elements of both styles. In the photo below, it's between the two frames; left of that it's full carvel, right of that it's full clinker:

I've found the best way to do this is to sand/file a bevel onto the edge of the plank in just that area, like this:

It lets the plank start sliding under its neighbor without looking any different from the outside. Maybe this is obvious to others, but it took some careful testing for me to figure out just how I wanted to do this for each plank.

Thanks for reading along as I keep wrestling with this "relaxing" project.

-

liteflight got a reaction from Binho in Oseberg Viking Ship by liteflight - Billing Boats - 1/25 Scale - 9th Century

liteflight got a reaction from Binho in Oseberg Viking Ship by liteflight - Billing Boats - 1/25 Scale - 9th Century

A little progress!

Slow but deliberate, I like to think.

I have also decided that The Oseberg ship (needs a name) IS the personal ceremonial conveyance of Queen Asa and that the aforesaid lady is a Good Thing, and appreciates her Ship.

I am aware about the debates, and I have decided that academics are doing what they do - arguing: and I will do what I do - imagining, building and learning!

And one step backwards! The prow bend has returned! It will not be tolerated and will be heated/counterbent out of existence. In normal circumstance I would proceed smartly to Float-a-Boat (this is a wonderful name, especially when pronounced if rich Geordie - the dialect of Newcastle-upon-Tyne) and buy some 4mm birch ply and remake the offending part.

After a lot of thought I am fairly certain that the distortion of this bit of ply is the cause of the "non-laser-cutting " of the end of the sheet where it resided. Probably this end of the sheet was jacked away from the platen by the bend.

I will sort the bend, and NOW is the best time to do so, as the ply is now stripped of doublers and available for massage.

Staining

A bottle of stain in the hand is worth 64 theoretical stains on a shade chart, so I have proceeded to stain the faces of the frames. I have also covered the exposed ply edges of the end frames with pine veneer using my hot-melt technique.

because some of the radii are small - in both directions - I have wetted the veneer, draped it into place and tacked it down with the "barrel" of the soldering iron - set to 200 degC.

Then the veneer was applied over the whole area by mostly rolling the iron along so that the veneer followed the curves

In the photo the rear frame was veneered with unstained veneer, and the front frame with pre-stained veneer. This may account for the colour difference where the veneer is fixed to the cedar insert. I have not tried to even the colour out yet, but I would not be too upset if it remained like that.

Frame stringers

I have decided to follow (faint but pursuing) the examples of Jack P and Von Kossa. They insinuated a frame between each of the kit frames and thus made the hull structure above the floor look a lot more scale.

This is also essential if the floor is to look anything like the actual ship.

The kit provides long Obechi planks 1.8mm x 12 for decking, and they are supposed to run the full length of the deck. They are supposed to rest on the tops of the frames, and be cut out to fit around the frames.

Easy decision - NO!

How would we bale when the Queen's picnic party was hit by a squall and shipped a lot of 'oggin which is then sloshing round in the bilges and making the ship terribly mushy?

Have YOU ever carried a full baby bath after bathing your little darling on the floor in front of the fire?

You have?

Then you know EXACTLY how the ship feels when she needs baling, and your feet were warmer and better-smelling than the crew's!

So we will have scale (ish) floorboards fitted between the frames.

SO

Floorboards level with the top of the frames means that the floorboard thwartships bearers have to be 1.8mm below the frame horizontal parts

So

The longitudinal 4 x 8 battens which stiffen the frame assembly before planking will have to be lowered by 1.8mm. I considered deepening the cutouts in each frame - but instead have marked and cut out the battens. I am now searching for my diamond needle files to tidy up the cutouts.

Tonight I will read my Guru's build logs (again) to find out what they did to sort the floor levels. I suspect that JackP used thick enough oak veneer on the ply frame to raise the frame level, and I KNOW that he made the floor from thin white oak planks.

During the "notching" process (razor saw and no 11 scalpel ) I discovered again why Obechi is off my Christmas list

Huge and wavy grain - nearly impossible to make any sort of exact shape

However these obechi parts are used in compression , and only functional in the early parts of planking to stiffen the backbone.

Apologies for the messy picture. This is where and how they go. You can almost see (if you stand on tiptoe and squint) that the stringers are recessed below the horizontal parts of the frames.

Nothing is fitted yet or glued, so the stringers are being retained in the frames by faith and friction.

Scrollworks!

I have commenced thinning the supplied 3-ply laser etched scrollworks. As supplied (3-ply) is 2.1mm thick.

I have winkled chibbled gnawed delicately chiseled the rear ply off and sanded the back. Fairly successful once I discovered that

A) the best weapon is a narrow chisel

and b) sometimes I can find the joint line of weakness, and a lot of the ply comes off with zero force

C) Not easy to hold the increasingly weak part while keeping all the fingers behind the chisel

This is the favourite tool for this process

I broke off one head by being hamfisted, and have therefore glued it back on - hence the greaseproof paper and weight!

Australia and solvents, eh?

Louie da Fly has a LOT to answer for! He sent me hi-res images of the actual scrollwork - which is actually beautiful intertwined supporting beasts and a dragon's head - and now I NEED to do something about this!

The carvings are now a goal. Maybe not for this build, but perhaps the next!

-

liteflight got a reaction from Cathead in Oseberg Viking Ship by liteflight - Billing Boats - 1/25 Scale - 9th Century

liteflight got a reaction from Cathead in Oseberg Viking Ship by liteflight - Billing Boats - 1/25 Scale - 9th Century

A little progress!

Slow but deliberate, I like to think.

I have also decided that The Oseberg ship (needs a name) IS the personal ceremonial conveyance of Queen Asa and that the aforesaid lady is a Good Thing, and appreciates her Ship.

I am aware about the debates, and I have decided that academics are doing what they do - arguing: and I will do what I do - imagining, building and learning!

And one step backwards! The prow bend has returned! It will not be tolerated and will be heated/counterbent out of existence. In normal circumstance I would proceed smartly to Float-a-Boat (this is a wonderful name, especially when pronounced if rich Geordie - the dialect of Newcastle-upon-Tyne) and buy some 4mm birch ply and remake the offending part.

After a lot of thought I am fairly certain that the distortion of this bit of ply is the cause of the "non-laser-cutting " of the end of the sheet where it resided. Probably this end of the sheet was jacked away from the platen by the bend.

I will sort the bend, and NOW is the best time to do so, as the ply is now stripped of doublers and available for massage.

Staining

A bottle of stain in the hand is worth 64 theoretical stains on a shade chart, so I have proceeded to stain the faces of the frames. I have also covered the exposed ply edges of the end frames with pine veneer using my hot-melt technique.

because some of the radii are small - in both directions - I have wetted the veneer, draped it into place and tacked it down with the "barrel" of the soldering iron - set to 200 degC.

Then the veneer was applied over the whole area by mostly rolling the iron along so that the veneer followed the curves

In the photo the rear frame was veneered with unstained veneer, and the front frame with pre-stained veneer. This may account for the colour difference where the veneer is fixed to the cedar insert. I have not tried to even the colour out yet, but I would not be too upset if it remained like that.

Frame stringers

I have decided to follow (faint but pursuing) the examples of Jack P and Von Kossa. They insinuated a frame between each of the kit frames and thus made the hull structure above the floor look a lot more scale.

This is also essential if the floor is to look anything like the actual ship.

The kit provides long Obechi planks 1.8mm x 12 for decking, and they are supposed to run the full length of the deck. They are supposed to rest on the tops of the frames, and be cut out to fit around the frames.

Easy decision - NO!

How would we bale when the Queen's picnic party was hit by a squall and shipped a lot of 'oggin which is then sloshing round in the bilges and making the ship terribly mushy?

Have YOU ever carried a full baby bath after bathing your little darling on the floor in front of the fire?

You have?

Then you know EXACTLY how the ship feels when she needs baling, and your feet were warmer and better-smelling than the crew's!

So we will have scale (ish) floorboards fitted between the frames.

SO

Floorboards level with the top of the frames means that the floorboard thwartships bearers have to be 1.8mm below the frame horizontal parts

So

The longitudinal 4 x 8 battens which stiffen the frame assembly before planking will have to be lowered by 1.8mm. I considered deepening the cutouts in each frame - but instead have marked and cut out the battens. I am now searching for my diamond needle files to tidy up the cutouts.

Tonight I will read my Guru's build logs (again) to find out what they did to sort the floor levels. I suspect that JackP used thick enough oak veneer on the ply frame to raise the frame level, and I KNOW that he made the floor from thin white oak planks.

During the "notching" process (razor saw and no 11 scalpel ) I discovered again why Obechi is off my Christmas list

Huge and wavy grain - nearly impossible to make any sort of exact shape

However these obechi parts are used in compression , and only functional in the early parts of planking to stiffen the backbone.

Apologies for the messy picture. This is where and how they go. You can almost see (if you stand on tiptoe and squint) that the stringers are recessed below the horizontal parts of the frames.

Nothing is fitted yet or glued, so the stringers are being retained in the frames by faith and friction.

Scrollworks!

I have commenced thinning the supplied 3-ply laser etched scrollworks. As supplied (3-ply) is 2.1mm thick.

I have winkled chibbled gnawed delicately chiseled the rear ply off and sanded the back. Fairly successful once I discovered that

A) the best weapon is a narrow chisel

and b) sometimes I can find the joint line of weakness, and a lot of the ply comes off with zero force

C) Not easy to hold the increasingly weak part while keeping all the fingers behind the chisel

This is the favourite tool for this process

I broke off one head by being hamfisted, and have therefore glued it back on - hence the greaseproof paper and weight!

Australia and solvents, eh?

Louie da Fly has a LOT to answer for! He sent me hi-res images of the actual scrollwork - which is actually beautiful intertwined supporting beasts and a dragon's head - and now I NEED to do something about this!

The carvings are now a goal. Maybe not for this build, but perhaps the next!

-

liteflight got a reaction from EricWilliamMarshall in Oseberg Viking Ship by liteflight - Billing Boats - 1/25 Scale - 9th Century

liteflight got a reaction from EricWilliamMarshall in Oseberg Viking Ship by liteflight - Billing Boats - 1/25 Scale - 9th Century

I know the definition of an expert, so look you no!

Indeed and to goodness

But I do speak French like a native*

* of Scotland

-

liteflight got a reaction from Louie da fly in Oseberg Viking Ship by liteflight - Billing Boats - 1/25 Scale - 9th Century

liteflight got a reaction from Louie da fly in Oseberg Viking Ship by liteflight - Billing Boats - 1/25 Scale - 9th Century

Ironic, I was raised metric and had to learn a lot when I got into industry

Why not?? What is wrong with having peas?

My bugbear (well one of my bugbears) is US and Imperial liquid measure. In a discussion several years ago about an absolute weight to calibrate a scale an American vouchsafed "A pint's a pound the world around" Full marks for rhyming, 7/10 for scansion. Nul Points for not being aware that a "pint of pure water weighs a pound and a quarter" and there are two pints, quarts floz. etc

Mixing 2-stroke for my racing bike using American oil was pretty interesting, because the bottle gave dilutions in ounces per gallon, and my petrol came in Gallons Imperial. 50/1 isn't difficult in metric.

Agreed, I'm sure there would be limber holes (or Nordic equivalent) to allow the water to reach a place where bailing was possible/easy. I have thought a bit about that, and looked at the bailers found at Oseberg. They are quite small, perhaps half a pint🤣 but not shaped particularly to access water in triangular spaces, or a lot of it.

I assume that the crew would raise a section of boards around midships to aft on the lee side and propel the bilge water over the lee rail.

Also the replica sailors would face similar issues, cos the replicas would ship water and leak rather like the originals, so Somebody knows and has lost knuckles in the process of learning.

-

liteflight got a reaction from FriedClams in Viking longship by Cathead - Dusek - 1:35 - FINISHED

liteflight got a reaction from FriedClams in Viking longship by Cathead - Dusek - 1:35 - FINISHED

Eric

Excellent thinking with both the soaking/bending container and the binder clips

Do you mind if I use the idea in future?

My Oseberg actually has doubler pieces which effectively make the planking "end-stops" and should produce a sweet and smooth curve

(It says here in the small print)

-

liteflight reacted to KrisWood in Oseberg Viking Ship by liteflight - Billing Boats - 1/25 Scale - 9th Century

liteflight reacted to KrisWood in Oseberg Viking Ship by liteflight - Billing Boats - 1/25 Scale - 9th Century

Yes, bailers were found on the ship. 🙂

-

liteflight reacted to Antti in Oseberg by Antti - Billing Boats - Scale 1:25

liteflight reacted to Antti in Oseberg by Antti - Billing Boats - Scale 1:25

I felt like fiddling with the mast fish and the surrounding deck area for a change.

The kit supplied parts for the mast fish would produce an abomination of stacked plywood so I made a new one from apple wood.

(I cut down one a year ago and stored it for modelling purposes)

All though I'm not 100% satisfied with the result, I'm reluctant on making another one as this one took me a full day.

So I'll probably use this one.

Having read the other build logs here I learned that apparently, on the real Oseberg the deck formed a "hump" around the mast fish, deck planks rising against an elevated umm... stringer? running accros the deck.

The kit instructions don't mention of this, instead a normal straight deck is suggested with plywood stringer floating above the deck.

So I'll need a new stringer part too, I made one out of goat willow (hah, I'm not sure about that word either but that's what the dictionary gave me ).

Rather than trying to twist deck planks to match the curves of the stringer I eventually ended up making square blocks of wood and sanded the required shape on them.

I think this is the way to go...

-

liteflight got a reaction from mbp521 in Viking longship by Cathead - Dusek - 1:35 - FINISHED

liteflight got a reaction from mbp521 in Viking longship by Cathead - Dusek - 1:35 - FINISHED

Eric

Excellent thinking with both the soaking/bending container and the binder clips

Do you mind if I use the idea in future?

My Oseberg actually has doubler pieces which effectively make the planking "end-stops" and should produce a sweet and smooth curve

(It says here in the small print)

-

liteflight got a reaction from Cathead in Viking longship by Cathead - Dusek - 1:35 - FINISHED

liteflight got a reaction from Cathead in Viking longship by Cathead - Dusek - 1:35 - FINISHED

Eric

Excellent thinking with both the soaking/bending container and the binder clips

Do you mind if I use the idea in future?

My Oseberg actually has doubler pieces which effectively make the planking "end-stops" and should produce a sweet and smooth curve

(It says here in the small print)

-

liteflight got a reaction from Cathead in Oseberg Viking Ship by liteflight - Billing Boats - 1/25 Scale - 9th Century

liteflight got a reaction from Cathead in Oseberg Viking Ship by liteflight - Billing Boats - 1/25 Scale - 9th Century

In preparation for fitting the frames to the keel, I have been carrying out the preliminary work which I vowed I would do before the ship was too far assembled.

One area to prepare for is the Access holes , both bow and stern in the final frames, which are 4mm plywood

So that all the cut edges would have to be veneered

THINKS I have a thermostatic soldering iron which would be promising to veneer with in small spaces!

Here are the two frames in question, pierced and with a piece of venetian blind let in because

A) the ply was getting too thin at the top of the frame

b) I needed a deck support for the small decks in the prow and stern

Good News, the venetian blind material turns out to be close grained, pale wood, and with the distinctive aroma of a cedarwood!

Veneering of the exposed ply edges is now happening.

I have reverted to PVA diluted 30% with water for veneer adhesive. It is reluctant to "wet" freshly sanded ply so a couple of drops of washing liquid will be added to help this.

The Left Hand frame in the picture above has a continuous bit of veneer applied, and clearly it will follow all the contours, both positive and negative. This is glueing, but I intended to use the soldering iron to attach the veneer (having applied PVA and allowed it to dry.

Needle top PVA bottle just visible at the top of the picture

This was originally a bottle of low-temperature gun oil that I used to lubricate my CO2 engines for model flying. I believe that such oil is now available for paintball guns, which have the same problem of low temperature lubricity.

I will not be veneering the rest of the frames because they have cutouts in them for longditudinal stiffeners, and I would like the veneer to be continuous

-

liteflight got a reaction from Cathead in Oseberg Viking Ship by liteflight - Billing Boats - 1/25 Scale - 9th Century

liteflight got a reaction from Cathead in Oseberg Viking Ship by liteflight - Billing Boats - 1/25 Scale - 9th Century

This is my euphorian day,

I will ring welkins and before anybody answers I will run away

Ogden Nash, "No doctors today - thank you"

Seems appropriate, as I have just made useful progress with Oseberg.

All the woodworking glues are dissolved by Isocol (iso-Propanol) I read on MSW.

So, having decided to remove the ply doublers round the prow and stern I had a bash at softening the (weldbond) glue with Isocol.

Since the doublers form a gutter I ran Isocol into it and left the joint with a reservoir of Isocol for an hour.

No noticeable softening or loosening of the joint

Now I had read somewhere recent (and Authoritative!) that all the woodglues are softened by heat so I lit up the Iron and had all 8 doubling pieces removed in about 10 minutes

Maximum heat setting, max steam

The paper that everything is sitting on is Baking paper, which I folded over and ironed through to prevent the sole of the Iron from getting clarted up with Weldbond (even though I KNOW now how the remove it)

One lesson from this exercise is that a tool more heat resistant than my thumb is a good plan to winkle to parts apart. Guess how I discovered that one!

So - while feeling successful and Euphoric ; I heated and manipulated the bent prow piece till the ply was straight !

So the whole keel has gone back into the jig to cool and settle

Obvious thought

The parts could have been added just as easily by coating with glue, allowing to dry then ironing them in place! might be useful where a dry process is preferred - perhaps to avoid globs of glue!

Might be a good way to go clinker planking on Osebergs!

-

liteflight got a reaction from Cathead in Oseberg Viking Ship by liteflight - Billing Boats - 1/25 Scale - 9th Century

liteflight got a reaction from Cathead in Oseberg Viking Ship by liteflight - Billing Boats - 1/25 Scale - 9th Century

Steven.

Warm thanks for your time and good sense in making this helpful response

The kit really doesn't have conflicting instructions, really none at all relating to the ply scrollwork apart from the wee sketchie I reproduced

This is the two pieces of the 3-ply scrollwork (2.1 mm thick) laid roughly in place over the ply doublers already fitted in accordance with the build book.

When I am finished with this build the "book" will be filed in our extensive library next to the Greek Ferry Timetables* in the Fiction section

*borrowed from Douglas Adams, author of the (increasingly inaccurately named) Hitch Hikers Guide to the Galaxy Trilogy

Howsomever, I have decided what I am doing!

I will remove the prow and stern doublers Fit the Scrollwork - possibly having reduced them to 2-ply (1.4 mm thick) Vertically extend the turnover jig to allow for the additional height (to avoid wiping off the delicate scrollheads) Stain keel , frames Fit frames Plank

-

liteflight got a reaction from Louie da fly in Oseberg Viking Ship by liteflight - Billing Boats - 1/25 Scale - 9th Century

liteflight got a reaction from Louie da fly in Oseberg Viking Ship by liteflight - Billing Boats - 1/25 Scale - 9th Century

In preparation for fitting the frames to the keel, I have been carrying out the preliminary work which I vowed I would do before the ship was too far assembled.

One area to prepare for is the Access holes , both bow and stern in the final frames, which are 4mm plywood

So that all the cut edges would have to be veneered

THINKS I have a thermostatic soldering iron which would be promising to veneer with in small spaces!

Here are the two frames in question, pierced and with a piece of venetian blind let in because

A) the ply was getting too thin at the top of the frame

b) I needed a deck support for the small decks in the prow and stern

Good News, the venetian blind material turns out to be close grained, pale wood, and with the distinctive aroma of a cedarwood!

Veneering of the exposed ply edges is now happening.

I have reverted to PVA diluted 30% with water for veneer adhesive. It is reluctant to "wet" freshly sanded ply so a couple of drops of washing liquid will be added to help this.

The Left Hand frame in the picture above has a continuous bit of veneer applied, and clearly it will follow all the contours, both positive and negative. This is glueing, but I intended to use the soldering iron to attach the veneer (having applied PVA and allowed it to dry.

Needle top PVA bottle just visible at the top of the picture

This was originally a bottle of low-temperature gun oil that I used to lubricate my CO2 engines for model flying. I believe that such oil is now available for paintball guns, which have the same problem of low temperature lubricity.

I will not be veneering the rest of the frames because they have cutouts in them for longditudinal stiffeners, and I would like the veneer to be continuous

-

liteflight got a reaction from Cathead in Viking longship by Cathead - Dusek - 1:35 - FINISHED

liteflight got a reaction from Cathead in Viking longship by Cathead - Dusek - 1:35 - FINISHED

Good thinking, Eric

Correct appearance with no loss of integrity. Win-Win!

I have been looking at the scarph joints shown here. If I were a Viking shipwright, I would arrange the scarph joints so that they were "trailing" ie the raised edge on the outside facing the stern (rather similar to coppering on a ship, and any joint on a plane.

If this is so, then this view is towards the stern

I will go and check on those sites. Perhaps as I grow up I will check before posting

But it doesn't affect this build

-

liteflight got a reaction from Cathead in Oseberg Viking Ship by liteflight - Billing Boats - 1/25 Scale - 9th Century

liteflight got a reaction from Cathead in Oseberg Viking Ship by liteflight - Billing Boats - 1/25 Scale - 9th Century

“Everything in moderation; including moderation” is my watchword.

Thank you Stephen. I have taken note of your excellent and assiduous rowers and their different, but muted garments. Yes, I know that dyes and pigments are different in type, but I expect to be aiming for a range of cheerful, artistic and potentially authentic colours on the shields, and possibly as accents elsewhere.

Currently I have no plans to carve a crew of rowers, but I would love to learn a new skill.

Speaking of rowers and seating; when I commenced Osberging I had believed that Viking crews sat on their sea chests (probably, I thought, on a sheepskin to minimise chafing and saltwater sores). I did not even know that there was a debate about it!

“If you can’t measure it, it’s an opinion”. Probably Lord Kelvin. It sounds like his delicate, diplomatic tones.

Today I have been trying to measure how much of a problem to expect with rogue glue. I put large globs, smears, Fingerprints, dots, etc on an edge of the Ply sheet where the strakes are nested. I also tried my usual cleanup of a wet cloth to remove recent glue. Glue is Titebond original

Bother, the iPad operates completely differently and rotates the iphone pictures. I post more explicable pictures when I get to my laptop

I also made a blended-wing aircraft for indoor flying when my copy of Aeromodeller arrived and inspired me

Well, who knew? The resident format of two of the pics has led to them being rotated 90 degrees, but not the one with the plane in it. I will rectify ASAP

Tentative conclusion on glue. It will be a problem, but not insoluble, if I stain after assembly. Staining before assembly is the better plan, but demands that I plan ahead enormously.

So I aim to stain everything, and let it dry completely before assembling. I will still remove as much glue as possible while it’s wet, but not fash mysel’ too much if some glue has to be removed

Rubbing alcohol Works as well on globs of glue as it does on mistakes!

-

liteflight got a reaction from Louie da fly in Oseberg Viking Ship by liteflight - Billing Boats - 1/25 Scale - 9th Century

liteflight got a reaction from Louie da fly in Oseberg Viking Ship by liteflight - Billing Boats - 1/25 Scale - 9th Century

Thanks, Binho

That's very interesting and blows into the weeds at least one thing I was taught as a nipper. I am reading the Woodland treatise with interest - thanks for posting it.

I have also been reading material about the Skuldelev ships (and other finds from this era) and would not have asked about where the oaks grew if I had done my homework.

I can see that I will finish up with a splendid static Ship and a store of knowledge.

Shield colours: Yet to be faced!

My top-of-the-head feeling about 11thC paint is that it would have been prone to being scuffed, fading in sunlight (remember sunlight, anyone in the southern continents?) and would have started out matt (because the pigment particles would probably have been in a range of sizes) and become more matt with time.

So the array of shields would have been faded, muted, matted and non-bright

I still have to read and digest the colour information the Binho posted in his build log (sorry, havn't succeeded in "quoting " this here, but I will)

Found a useful resource from the Danish National Museum. The actual scientific article is only in Danish, but there is a good article on Science Nordic about it in English, including a color palette with a description of each pigment and the presumed relative cost.

https://sciencenordic.com/denmark-history-society--culture/how-to-decorate-like-a-viking/1455997

-

liteflight got a reaction from Louie da fly in Oseberg Viking Ship by liteflight - Billing Boats - 1/25 Scale - 9th Century

liteflight got a reaction from Louie da fly in Oseberg Viking Ship by liteflight - Billing Boats - 1/25 Scale - 9th Century

“Everything in moderation; including moderation” is my watchword.

Thank you Stephen. I have taken note of your excellent and assiduous rowers and their different, but muted garments. Yes, I know that dyes and pigments are different in type, but I expect to be aiming for a range of cheerful, artistic and potentially authentic colours on the shields, and possibly as accents elsewhere.

Currently I have no plans to carve a crew of rowers, but I would love to learn a new skill.

Speaking of rowers and seating; when I commenced Osberging I had believed that Viking crews sat on their sea chests (probably, I thought, on a sheepskin to minimise chafing and saltwater sores). I did not even know that there was a debate about it!

“If you can’t measure it, it’s an opinion”. Probably Lord Kelvin. It sounds like his delicate, diplomatic tones.

Today I have been trying to measure how much of a problem to expect with rogue glue. I put large globs, smears, Fingerprints, dots, etc on an edge of the Ply sheet where the strakes are nested. I also tried my usual cleanup of a wet cloth to remove recent glue. Glue is Titebond original

Bother, the iPad operates completely differently and rotates the iphone pictures. I post more explicable pictures when I get to my laptop

I also made a blended-wing aircraft for indoor flying when my copy of Aeromodeller arrived and inspired me

Well, who knew? The resident format of two of the pics has led to them being rotated 90 degrees, but not the one with the plane in it. I will rectify ASAP

Tentative conclusion on glue. It will be a problem, but not insoluble, if I stain after assembly. Staining before assembly is the better plan, but demands that I plan ahead enormously.

So I aim to stain everything, and let it dry completely before assembling. I will still remove as much glue as possible while it’s wet, but not fash mysel’ too much if some glue has to be removed

Rubbing alcohol Works as well on globs of glue as it does on mistakes!

-

liteflight got a reaction from mtaylor in Viking longship by Cathead - Dusek - 1:35 - FINISHED

liteflight got a reaction from mtaylor in Viking longship by Cathead - Dusek - 1:35 - FINISHED

Good thinking, Eric

Correct appearance with no loss of integrity. Win-Win!

I have been looking at the scarph joints shown here. If I were a Viking shipwright, I would arrange the scarph joints so that they were "trailing" ie the raised edge on the outside facing the stern (rather similar to coppering on a ship, and any joint on a plane.

If this is so, then this view is towards the stern

I will go and check on those sites. Perhaps as I grow up I will check before posting

But it doesn't affect this build

-

liteflight reacted to Binho in Oseberg Viking Ship by liteflight - Billing Boats - 1/25 Scale - 9th Century

liteflight reacted to Binho in Oseberg Viking Ship by liteflight - Billing Boats - 1/25 Scale - 9th Century

bigpetr is right on the provenance for the Skuldelev ships. For the Oseberg ship, the oak appears to be from western Norway, and not local to the immediate area the ship was buried. The presence of beech in the ship might narrow it's construction location in western Norway even more, to just north of Bergen, where there is the only beech wood in that area. This is roughly the same area the two later Skuldelev ships from Norway were built. You can read more here, pg. 6 talks about the Oseberg ship building location.

That's interesting! I don't believe this view is true anymore. From pollen samples in British bog sites it seems most of Northern England, Wales, and Southern Scotland was Oak-Hazel woodland. Woodland clearance rates seem to have peaked in the Early Iron Age, well before the Romans arrived. By the Roman period, only about 50% of the woodlands survived (in fact, Caesar mentions how intensively farmed southern England was in his writings). It doesn't seem the Roman occupation caused any more extensive deforestation than before. By the Norman arrival woodland cover was only 15%, and by the Black Death it was 10%. Good summary here. It's actually increased since then! But a lot of that is managed woodland, especially fast growing pines.

-

liteflight got a reaction from FriedClams in Viking longship by Cathead - Dusek - 1:35 - FINISHED

liteflight got a reaction from FriedClams in Viking longship by Cathead - Dusek - 1:35 - FINISHED

Don’t know if it helps with the scarphing question, but I recall seeing a video of a full size ship of this type being planked. The planks were bent and held by wooden clamps until rivets had been fixed. The planks were joined with a short scarph (not much longer than the thickness of the plank). The joint was sealed with something fibrous (?horsehair ) and something goopy (a blackish tar-based mastic?)

I don’t recall any rivets or reinforcement on the back of the joint

By the time the next strake is fitted and rivetted the joint will be well supported on a clinker hull

My big Oseberg shows a short 45 degree scarph in each strake, and I never thought to look on other people’s build logs to see if they lay on a frame. There has been comment on the fact that all the joints land in a small area roughly amidships.

Perhaps it’s a non-event, and that is why it’s not mentioned in the logs?

.thumb.jpeg.fc5d633a7b34428fcf19419a73d56d55.jpeg)