-

Posts

636 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Ilhan Gokcay

-

Janos, thanks. I followed the plans/drawings of the book(Hackney/Hölzel) for the rigging, but crosschecked everything using R.C.Anderson's book (17th c rigging..)and validated. The Anatomy of the ship "Susan Constant" by Brian Lavery was also very helpful.

-

Hi Janos, how are you? Thanks. Ferit, Christian thank you very much for the compliments.

-

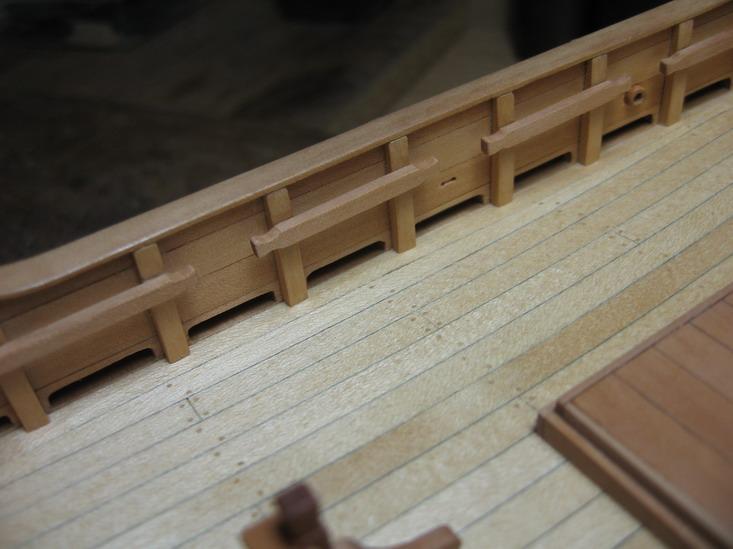

Finished the bulwarks. I’ve painted the remaining planks of the bulwarks seperately. Covered the contact surfaces with masking tape and handpainted with Humbrol enamel matt paint. Again used white glue(PVA) for glueing. Sanded the corners off which needed some touchup afterwards. For large and more detail photos see also: http://www.flickr.com/photos/ilhan_gokcay/sets Best go into the set and choose slideshow or http://www.flickr.com/photos/ilhan_gokcay/sets/72157626433922489/detail/?page=46

-

Hi Keith, Basically Fe(III)Cl is used for dissolving copper to make PCB's(Printed Circuit Board) http://en.wikipedia.org/wiki/Iron%28III%29_chloride#Industrial The reaction should be (FeCl3 + Cu → FeCl2) + CuCl) and (FeCl3 + CuCl → FeCl2 + CuCl2) I works with brass but I don't know the reaction. There is an alternative which is Ammonium persulfate for dissolvig copper (again used to make PCB's) . I did not tried this for brass, I think it should work. While dissolving copper this solution gets blue. Fe(III)Cl stains everything and never comes off. Ammonium persulfate seems to be more safe regarding the stains and also does not need heating.

-

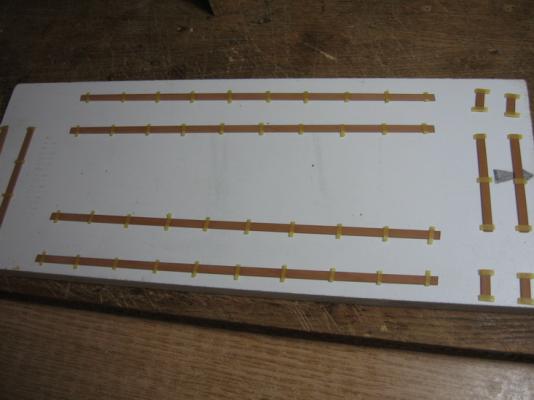

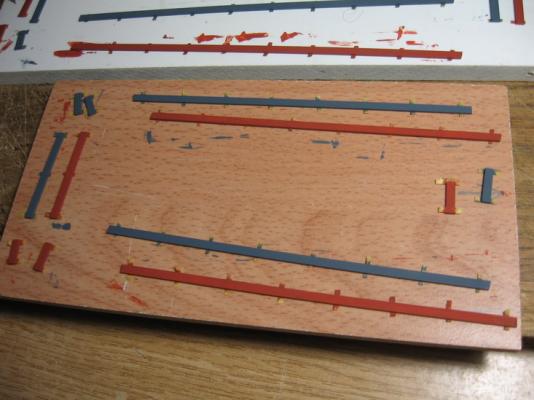

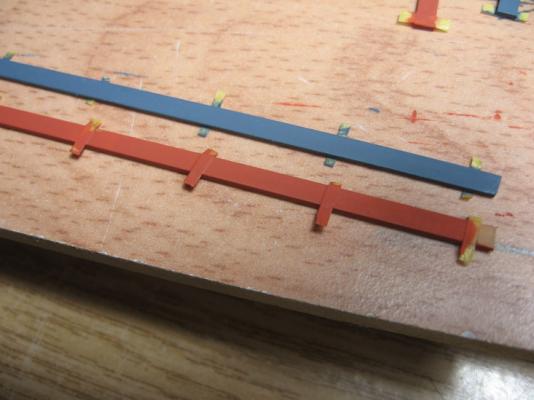

Hi Keith, you're welcome and thank you very much. I used a program called "Adobe Illustrator". I made the drawing by hand, scanned and redrawn(with points) with the program. The program allows me to put points and automayically connects them. It is also possible to move the points afterwards. The drawing as background I made as much points as possible to create the same shape. You described the process exactly as it is. The blue paper is called PNP(Press and peel) paper. The design should be printed on the flat side with a laser printer(ink does not work). Put upside down on brass and heated with iron so that it's transferred to the brass(toner+blue stuff). This print should be as sharp as possible and also dark. Take care while ironing that it does not slip. The solution to etch the unprotected brass is Iron(III)Chloride. Heated in hot water. 40-50'C is ideal but not crucial. For my parts it took 30 minutes to etch. It should be continiously stirred for a good result. Nitro thinner is ideal to clean the nail polish and the PNP. At first it was not that easy, I made several trials to get a good result. And Keith I'm happy to answer any questions, it's never a bother.

-

Hi Don, For the woods pear which I do use and cherry would be ok. Probably oak was used in original and the color of pear and cherry are close enough. For the decks I would suggest lime wood.

-

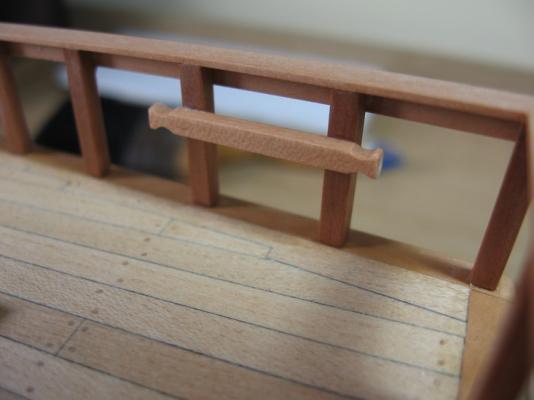

Going on with the bulwarks. I’ve glued the rail and the upper planking using white glue(PVA) and also got rid off the casings. For large and more detail photos see also: http://www.flickr.com/photos/ilhan_gokcay/sets (Best go into the set and choose slideshow)

-

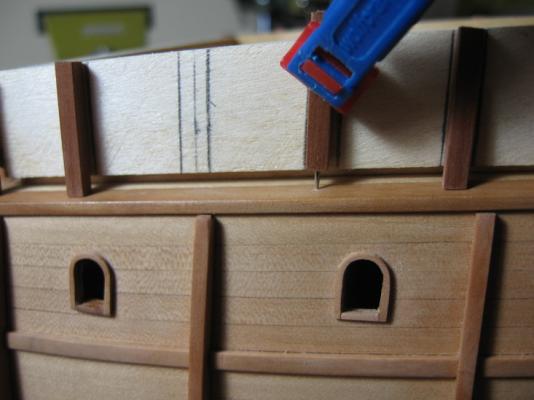

I’ve started to build the bulwarks on the fore- and aftercastle. To fix the stanchions at correct angles I’ve built two casings to guide the structure and fixed these casings temporarily using the holes for the masts. I’ve cut the stanchions from pear strip and drilled the ends 0,7 mm (diameter of an ordinary pin). Using the guide casing I’ve marked the positions, drilled the deck, and glued the stanchions with CA. Ilhan Gokcay ________________________________________ For large and more detail photos see also: http://www.flickr.com/photos/ilhan_gokcay/sets (Best go into the set and choose slideshow)

-

Hey Don, I don't recommend to use the plans form MSB to build a model. There are lots of mistakes which I do not remember all of them right now, but some of them are really serious.

-

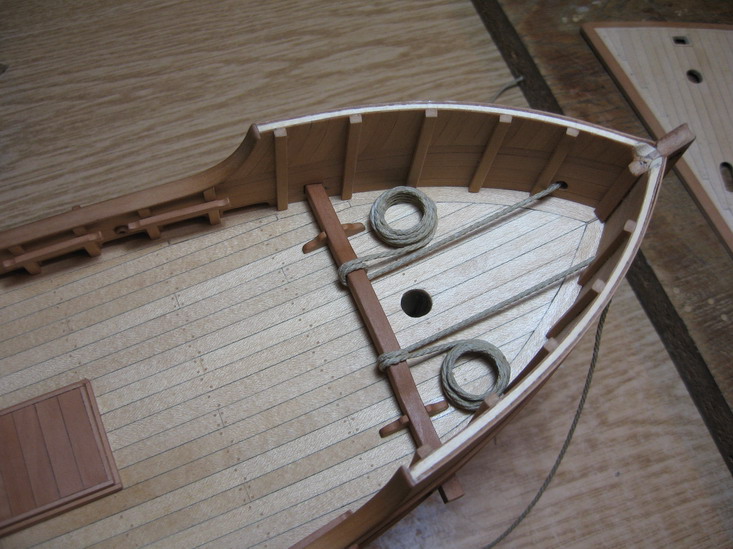

Little progress. Glued the anchor rope and the deck of the forecastle with white glue (PVA). For large and more detail photos see also: http://www.flickr.co...han_gokcay/sets (Best go into the set and choose slideshow)

-

Installed the deadeyes. I’ve used epoxy glue while glueing to the channels. Fixed the deadeyes in correct angle with rubber bands while the glue sets. For large and more detail photos see also: http://www.flickr.com/photos/ilhan_gokcay/sets (Best go into the set and choose slideshow)

-

Glued the cleats at the bulwarks, knight, pin rail and pump at the main deck. I do pay much attention to the sequence of these operations in order that nothing will be obstructed later.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.