-

Posts

1,572 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Garward

-

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

-

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

-

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

-

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

-

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

-

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

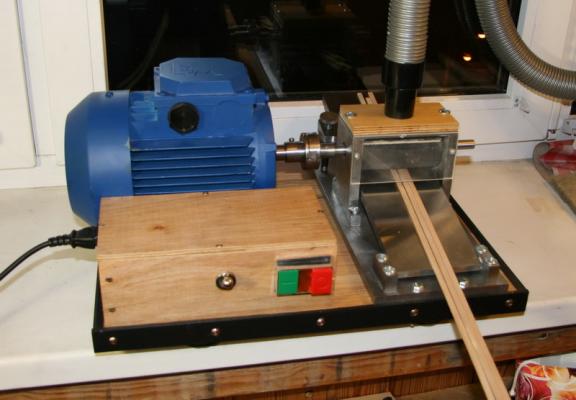

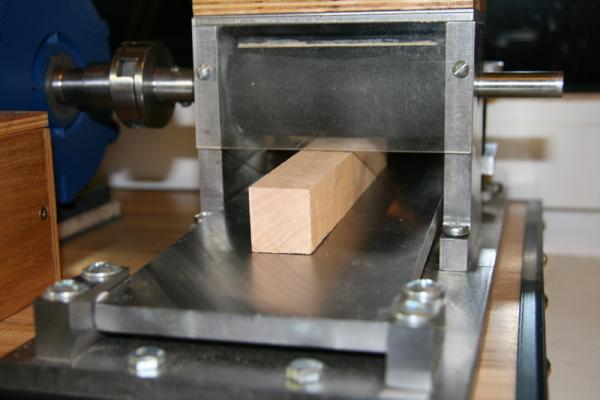

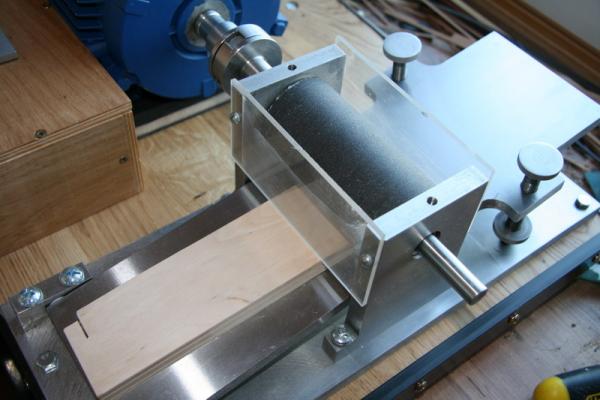

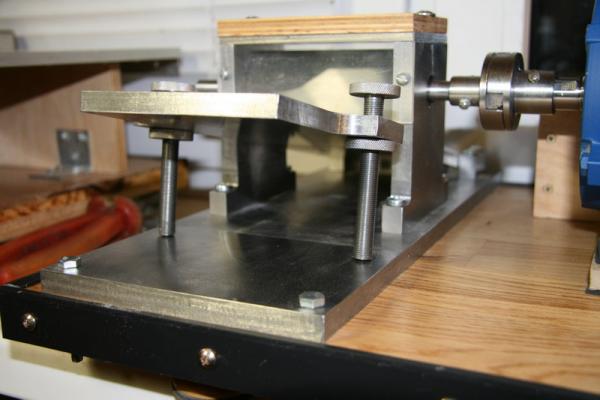

The general configuration Rig details are installed on a wood plate 450х380х24 the mm, the thickness collected from plywood of 10 mm and the laminated parquet board in the thickness of 14 mm. The plate is installed on furniture legs with adjustment possibility on altitude. The motor is installed on an antivibration pad from rubber in the thickness of 10 mm. -

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

-

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

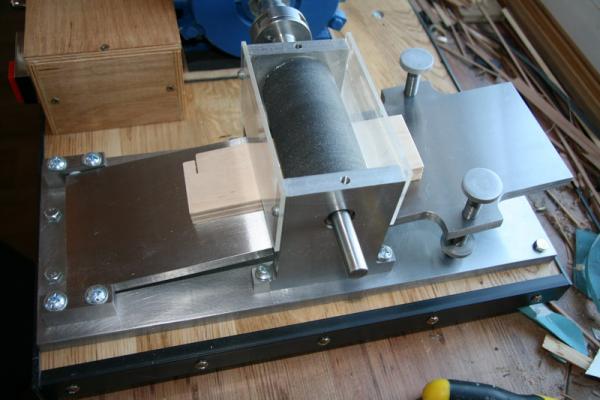

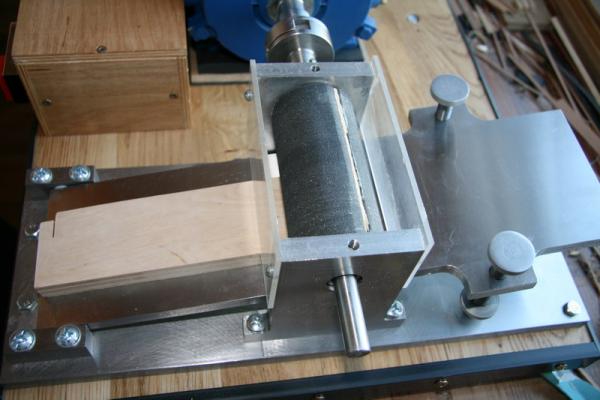

The way of fastening of a skin on a drum also is widely used long ago by jamming by a level in many designs, a difference only in the one who than gets jammed: wooden, plastic or metal level or rubber laying etc. Here to couple of examples of other drums. on which the skin is jammed and keeps very much even decently. -

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

-

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

-

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

-

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

Abrasive Mainly on a fabric basis, the grain size can be any Also it is defined proceeding from polishing problems. -

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

-

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

The electromotor Asynchronous three-phase general purpose of type the AИР power of 0,55 KW on 915 turns in a minute. It is connected to a network 220 in by means of working and starting capacitors and the magnetic starter, provides thus shaft power about 350 W. The given electromotor is chosen first of all because of a corrected speed and desire to use the direct drive. The Polish colleagues on the basis of long application of similar grinding machines experimentally installed that speed of twirl of a drum of 900 rpm in diameter about 50 mm is optimum wood for polishing (in particular, pears). -

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

-

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

-

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

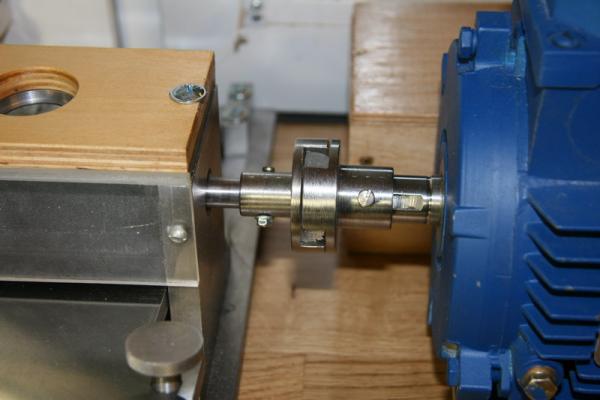

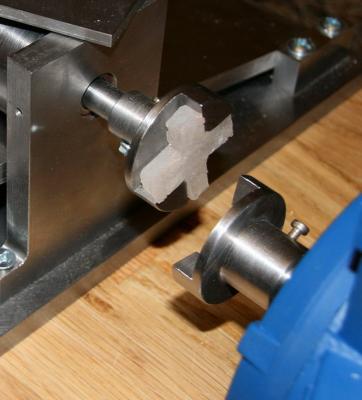

The drive The direct drive through two half-couplings (landing apertures in diameter of 12 and 19 mm) with a silicone crosswise lining (on the basis of successful experience of application of the analogous drive in the circular saw) is used. -

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

-

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

-

MONTANES by Garward - OcCre

Garward replied to Garward's topic in - Kit build logs for subjects built from 1751 - 1800

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.