hopeful

-

Posts

278 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by hopeful

-

-

Hey Jason,

Don't know where you buy Silver soldering stuff in your part of the world but here is a photo of what I use to silver solder.

The tube contains both flux and silver solder. Purchased everything you see in the photo for under $100.00USD. Black block is made of charcoal.

BFK

Hopeful aka David

-

You may be aware of the battery powered dremel. If not, here is some info and a few pics of the one I purchased a few days ago.

Model 7300 (Newest)

Two speds Low 6,500 RPM High 13,000 PM

Comes with one 1/8" collet, Set available with 4 collets 1/32, 3/32, 1/16, and 1/8 as an accessory

Charger (3 hour charge time)

9.2 ounces

6 1/2 long without drill bit or other accessory

Cost $45 at Home Depot (Canada....less everywhere else in the world I'm sure.)

Accessory |Collets $13

Runs true and smooth with 0.60mm drill bit at both speeds chucked into 1/32 collet. Fits

hand well and is used as a pencil. Unit is well balanced. Most inportant.....unit is high tourque. Drills and sands without bogging down. Purchaced because I wanted a small but powerful unit without a cord. Don't know the run time.

Rests on flat bottom..Watch your eyes!

BFN,

Hopeful aka David

-

Hi,

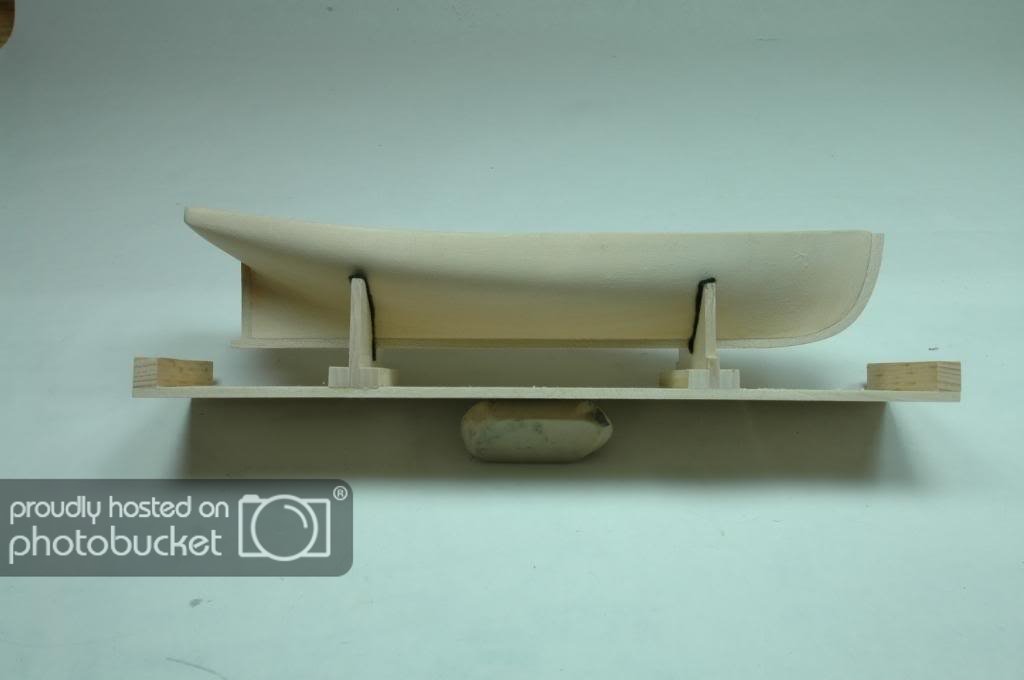

Post 5 of my Phantom build.

At this point I added the waterline to determine if my starboard and port hull sides matched after fairing the hull. If good to go, I can continue on with the build If not I need to spend more time faring the hull.

The traditional method to add the waterline is to have the model deck up as in this photo.

Photo 21

Photo 22

Because the Phantom hull is small (1:96) I decided to pencil the waterline keel up. This allowed me to carefully add the waterline to the rear quater of the vessel with care because I was able to see the hull in that area clearly.

After looking at the waterline I noted that I need to do a bit more sanding on the starboard rear quarter where the hull and the sternpost meet , about three minutes work. Now on to the rudder.

Thanks for looking in on the build. All questions, comments, and constructive criticism is always appreciated.

BFN

Cheers,

Hopeful aka David

“there is wisdom in many voices”

-

Hi Bob,

Thanks for the Photos of the Pantom. Wonderful build. I am going to add scuppers the way they were were done on your vessel. Looks like you planked the deck, nice. All the details are very well done. Nice paint, not easy at any scale!!!

Thanks again for taking the time to post the build, appreciated.

BFN

Hopeful aka David

-

-

-

Hey Pete,

Tell your daughter she is doing a fine job making a photo record of your work. Tell her we like lots and lots of pictures of Daddy working. HAhaha!

Am learning much from your build. Love the way you turned down the diameter of the drum sander spindle, gonna remember that one and, the noodle ofcourse.

The hard maple is gonna test your patience when sanding. I have had good success using a scraper on the hard maple. The Brynes saw and hard maple, fantastic.

Wish you well as you move along.

Hopeful aka David

-

To add to what Andy and others have said which I agree with. I have also used gesso as a primer and arylic paints on white metal. The best bet is to spray but I don't know how to use an air brush...one day!

Wish you well!

Hopeful aka David

-

Hi

Druxey, Mahuna, and Pete38..... Thanks for your input will check out the units mentioned. What do think is a resonable price to pay for a scroll saw?

Thanks for the input.

Hopeful aka David

-

Time for me to purchase a good scroll saw. Have no idea what to buy. What make model do you recommend?

Thanks for your input.

BFN,

Hopeful aka David

-

Hi Andre,

Wonderful restoration. Wish you well as you continue along.BFN,

Hopeful aka David

-

Thanks for posting idea, Tarjack.

Hopeful aka David

-

Hi Garwood,

Yes, you are correct.

Thanks for looking in on Martin's thread. I enjoy your build logs very much. Have learned much from you regarding machine work. You and Danny have a great influence on me. Am just a humble newby to this fine craft.

Wish you well,

Hopeful aka David

-

-

JP.

The two (2) most common methods are a vise and step clamps. Vises and steps are made to fit the ross slides one purchases, e.g. Proxxon vise and step clamps are made specifically for the Proxxon cross slides. Both should be available from the eplace you got your other Proxxon items.

Hopeful aka David

-

J.P.

Wish you well with your new toys. Good Choices and great prices for the Proxxon equipment. Are you interested in the vise and step clamps?

Looking forward to your review.

BFN,

Hopeful aka David

-

Martin,

Am encouraging Wacko to stop hyjacking your thread. Hahahahaha!

Yes, Wacko. Start a new thread on the Sherline CNC stuff and stop hyjacking Martin's thread. I guess that goes for me too, yikes! Sorry Martin.

BFN, Mates.

Hopeful aka David

-

Hey,

B.E. (Blue Ensign), Hakan (Wintergreen) and, Pete 38: You guys are great builders. Thanks for the encouragement!!!

Ok, here is where I am with the build....pushing to finish the work on the hull. If I had a magic wand it would finito!

Thanks for looking in on the build. All questions, comments, and constructive criticism is always appreciated.

BFN

Cheers,

Hopeful aka David

“there is wisdom in many voices”

- Chuck, Blue Ensign and Gentlegiant

-

3

3

-

Wacko,

Like the 4th axis (rotating column) with the Sherline 2000 series. I can retro a 4th axis plate to my Sherline 5410DRO. For now I am usin the angled table. That is one thing I love about Sherline......more accessories than any other machine on earth, big or, small. CNC...you are breaking my heart. Would love to do CNC but I am computer illiterate. If I were your next door neighbor I'd go for CNC as you could help me learn How!!! Whenever I want to have some fun I go to youtube and search Sherline CNC and the vids are incredible.

Re the Proxxon Mill. the front-back y axis at 1 13/16th is entirely adequate if working 1/64 scale vessels. One needs the vise and hold down blocks for the Proxxon just like any other mill.

I have wasted more money trying to make things work that never do. My motto is buy the best once and move on even though it hurts the pocket book from time to time.

I am still a Proxxon and Sherline guy. Think they are the best options.

JP is right that mills are slow to drill as one needs to crank the up-down z axis. So what's the hurry.

Wacko.......the Proxxon comes with a measurement guide on the table to tack movements of the cross slides, is it accurate?

Martin, If you want the Shereline mill save hyour pennies and go for it. Any questions re Sherline ask away! Save 15% if retired, priceless!

Hopeful aka David

-

Good luck Martin.

So many choices....always a problem. Great comments by everyone on this thread. Boils down to what do you want to do and, how much do you want to pay to do it!

BTW, the blocks made by Chuck can be made using the Proxxon mill, no problem. Think he uses a MicroMark mill.

BFN,

Hopeful aka David

-

Martin,

I'm not trying to hijack your thread but since we are all taking about various makes of mills, lathes, drill presses, etc., I'll go ahead and answer J.P.'s question directed to me.

"Can I ask what Lathe and mill you purchased, whether they were just for model ship building and how you like them?" JP

Bought a Sherline long bed lathe and, a mill with digital readouts on the x,y,and z axsis. I bought them specifically for Shipbuilding. My motivation was to tool up for two reasons. First to make components out of any material, metal or wood. The second reason is to become a better builder by making my own compoments be they dead eyes, blocks, masting parts, etc. I bought both machines as part of a package, e.g. the unit plus must have acessories. If I could only buy one tool at a time I would buy the mill first as it is far more useful. To each his own.

The Sherline lathe and mill are both available with digital readouts which are essential to machine to insane dimensions. Chuck just posted a thread about how he made 2.0mm blocks on his mill...very small stuff. Digital readouts enable the user to dimension parts to remarkable tolerances. When one starts milling micro stuff it is very difficult to detect the movement of tools or materials easily. That is why I bought Sherline. I paid more but I got what I paid for, precision and quality. Sherline tools are used by NASA, and Colleges and University in their Engineering departments as well as in mico. industries

I was very familar with full size equipment but was not knowledgeable regarding micro tools. So like everyone else on this thread I did research into what tools are available from who and at what cost. I narrowed my search to Sherline and Proxxon. I like tools made in Germany and the USA. I eliminated any machine tool made in China because in micro tools one needs extreme precision and the absence of vibration. For the price, Proxxon represents good value with a sufficient number of accessories. Their lathe is good as well but with only a short bed. As mentioned by others, the travel distance of the x and y axis cross slides is limited with the Proxxon compared to that of the Sherline mill. Builders on the forum use Proxxon equipment with great results. Others use Sherline, MicroMart or, other Chinese brands like those available at Harbor freight. Everyone choses their stuff based on price, availablitiy, afordability, quality, and service.

I remember when I started out with amature photography. I bought good stuff. I had a firend that had lesser stuff and his photos were always better than mine. He understood how to take a good photo and I did not. Its the same way with equipment. It takes time and knowledge to learn to use the stuff to advantage. I've got a long way to go but am not in a hurry.

I must confess I love tools. I think we all do. Shipbuilding is very important to me so I spoil myself with tools when I have some extra money. We all do, right? I have lots of tools that I do not use often but they are there when I need them, that is if I remember where they are.

My two cents.

BFN.

Hopeful aka David

-

Martin,

To help us assist you better, please let us know what you intend to make using a mill and at what scale, generally speaking. In terms of investment, ask yourself this question, what percent of a vessel is made using a mill?

I had all the same questions you have before I made the plunge and purchased a lathe and mill. Can one build a fine looking vessel with out those tools, absolutely positively yes and, builders have done so for ions.

I live in Canada. We import everything. When I order from outside Canada I have to pay money exchange, shipment, duty, freight, and taxes. My tools help me be self sufficient. That is the real reason I have tools. I can't go to the store here and get what I need, so more and more I make what I need. If I buy $20 worth of stuff from Model expo I pay $50 in shipping, lol!

If you want stuff you can't afford at this time wait until you can and just keep building. The truth is, you get what you pay for when it comes to tools.

My two cents.

Hopeful aka David

-

Masterful in every detail. Thanks for reposting the build, your effort on our behalf is very much appreciated. I am especially pleased you added the tutorial on sail making (inspirational) and a photo of the completed model encased (lovely).

Thank you B.E.

Hopeful aka David

-

Hi Tony,

Your build log is rich with tutorials, thanks! I know they take time but, they are appreciated. Nothing like bashing a kit!

A scratch built ship's boat, wow! Thanks for sticking with the challenging project. You allow us all to know just what is envolved in making a ship's boat from drawings. Not a big gal either. Buy the time you are finished you will be able to move from kit to scratch builds.

Continue to follow as your Shelbourne is very close to the Lady Nelson.

Agree with you that learning all the skills of a shipwright if fun and challenging.......and the weeks and months go by! Wish you well as you move along.

BFN

Cheers,

Hopeful aka David

“there is wisdom in many voices”

Completed: Sharpie Schooner (Midwest) Posted to the Gallery

Current: Sultana (MSW)

Current: Phantom (MSW)

Next: Lady Nelson (Amati Victory)

Phantom by hopeful - Model Shipways - Scale 1:96

in - Kit build logs for subjects built from 1851 - 1900

Posted

Answers to the forum,

JP: "I am curious, the sanding in the stern, you could see at what point on the hull the line curved that the two sides were not the same. Is this correct?"

I took measurements with my pointers at each section line. Generally when the waterlines of both sides of the vessel meet perfectly at the center of the stem and sternpost your good to go. If not, something is wrong. I could see my problem because the smooth graceful pencil line hit, on further inspection, 120 grit sandpaper scratches which thew the waterline slightly off. I gently sanded out the scratches and the line smoothed out and met at the center of the sternpost with the other side. It amazes me how the eye detects anomalies.

Wayne: Everyone needs to make a living.

BFN

Hopeful aka David