-

Posts

5,539 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by RGL

-

- 200 replies

-

- Transport No. 103

- Hasegawa

-

(and 4 more)

Tagged with:

-

- 200 replies

-

- Transport No. 103

- Hasegawa

-

(and 4 more)

Tagged with:

-

- 200 replies

-

- Transport No. 103

- Hasegawa

-

(and 4 more)

Tagged with:

-

Bugger!!!! I finished mine some time ago, I once sneezed a mouthful of black coffee over a battle ship

-

- 200 replies

-

- Transport No. 103

- Hasegawa

-

(and 4 more)

Tagged with:

-

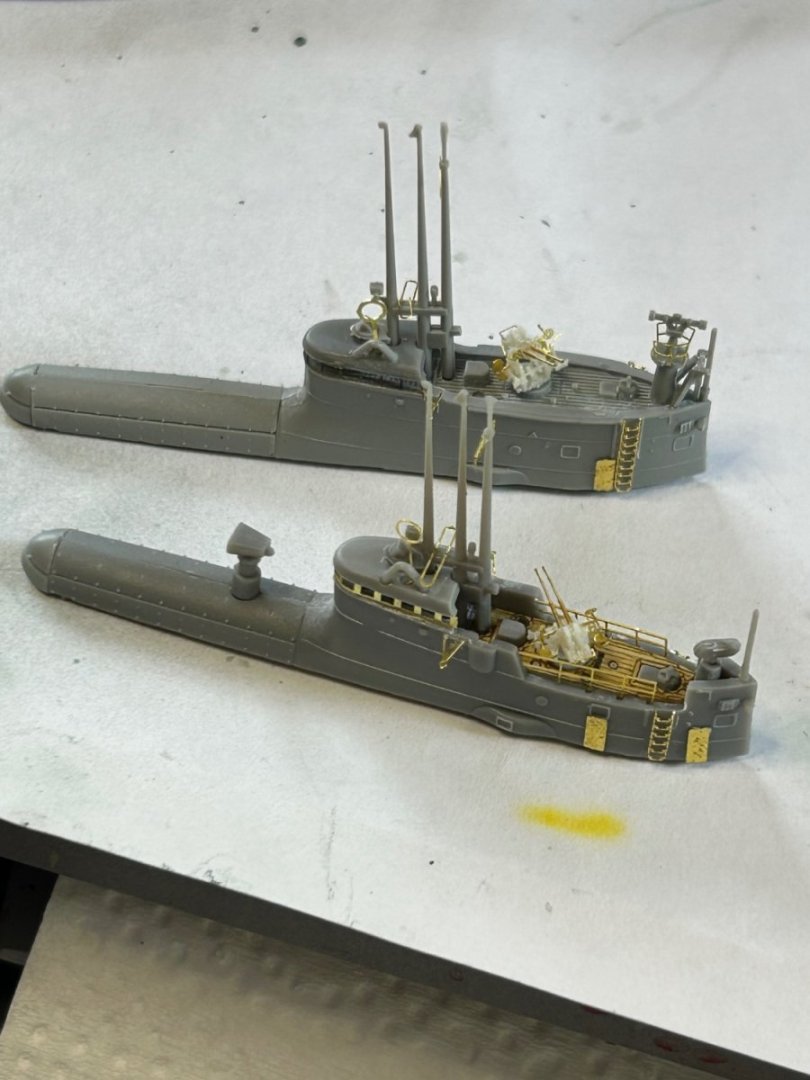

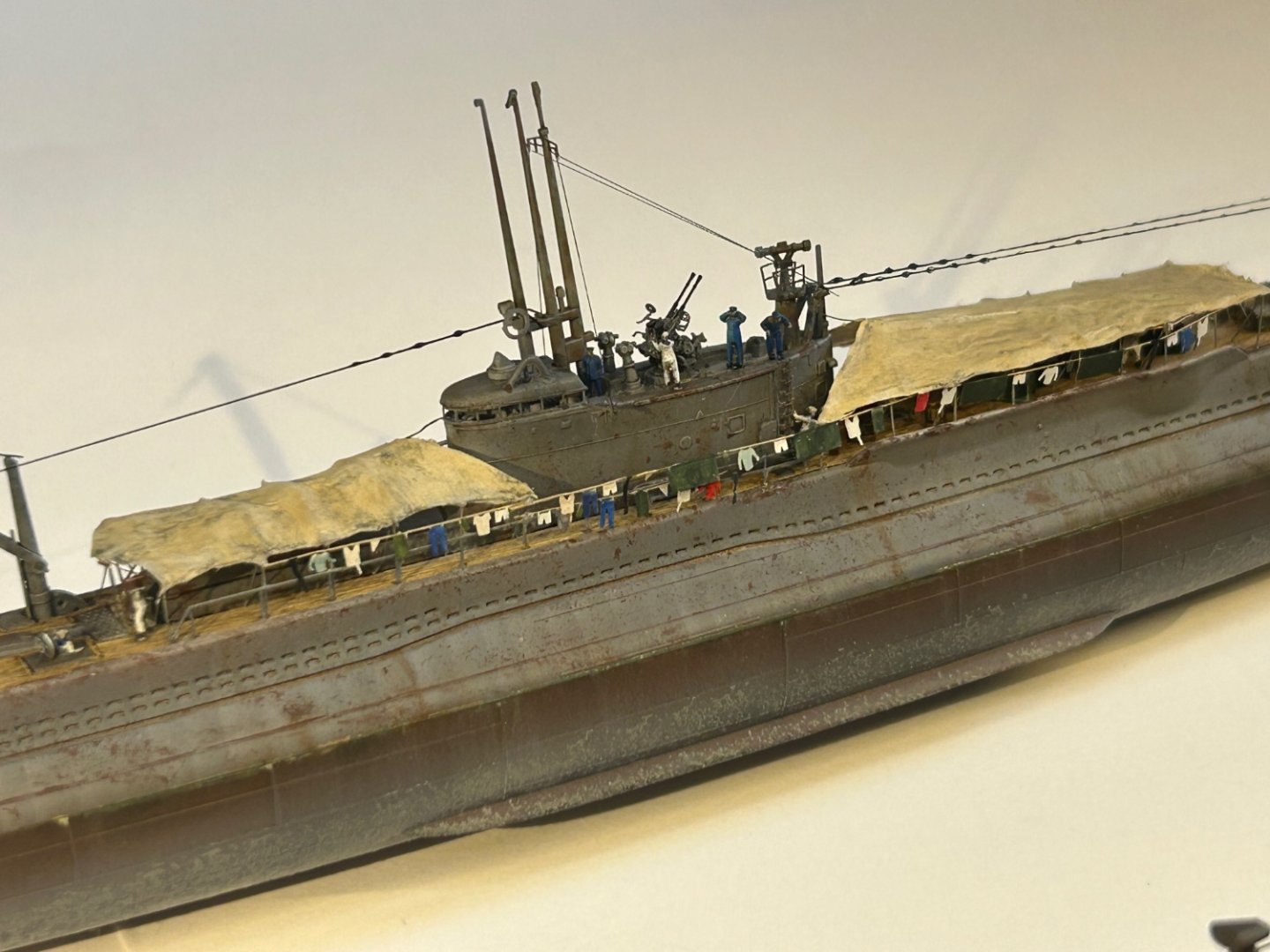

So I’ve finally got a bit of time to finish the framing, I’ll do a smaller one on the other sub then use cigarette paper like in the Zara

- 200 replies

-

- Transport No. 103

- Hasegawa

-

(and 4 more)

Tagged with:

-

- 200 replies

-

- Transport No. 103

- Hasegawa

-

(and 4 more)

Tagged with:

-

- 200 replies

-

- Transport No. 103

- Hasegawa

-

(and 4 more)

Tagged with:

-

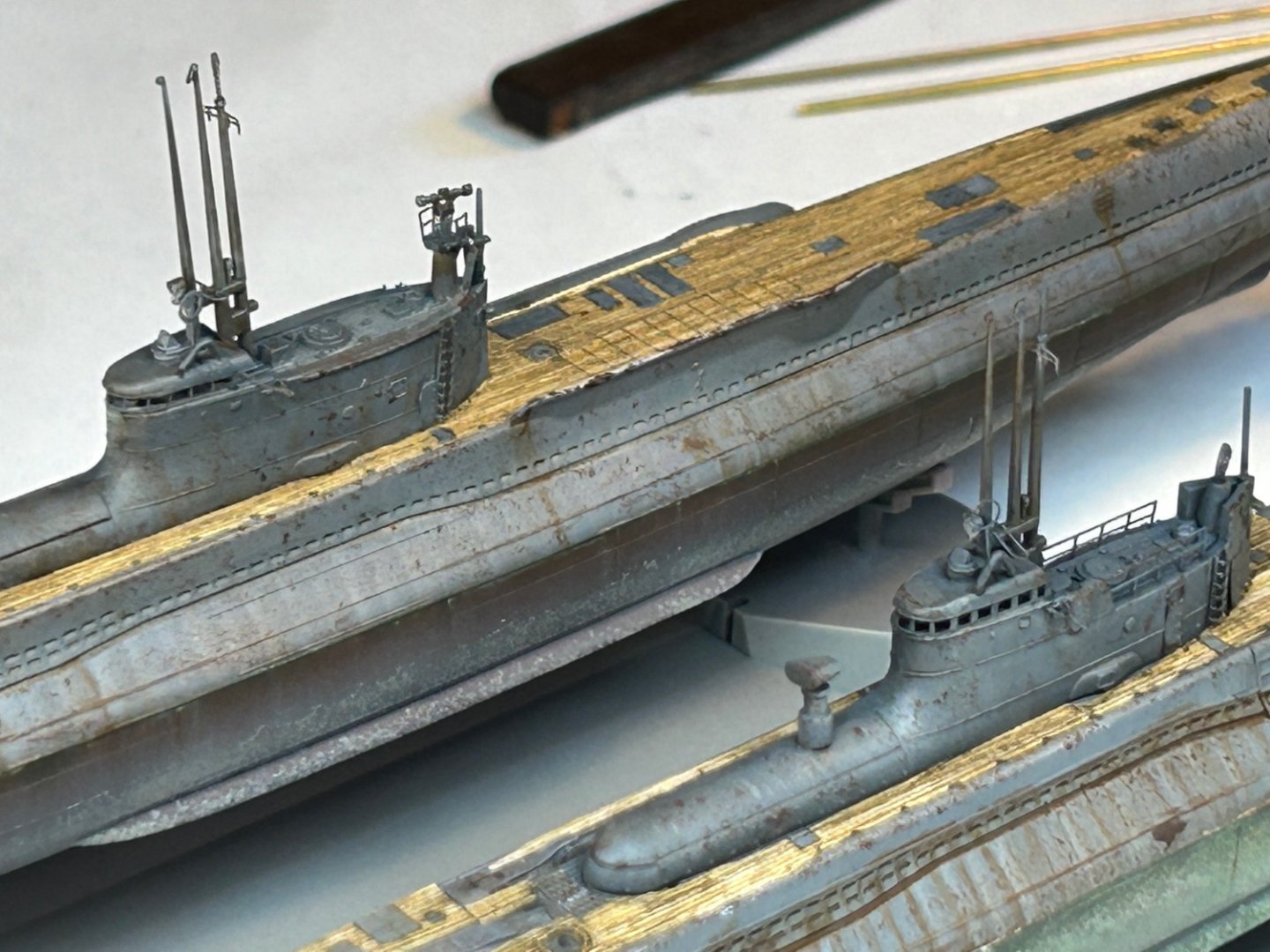

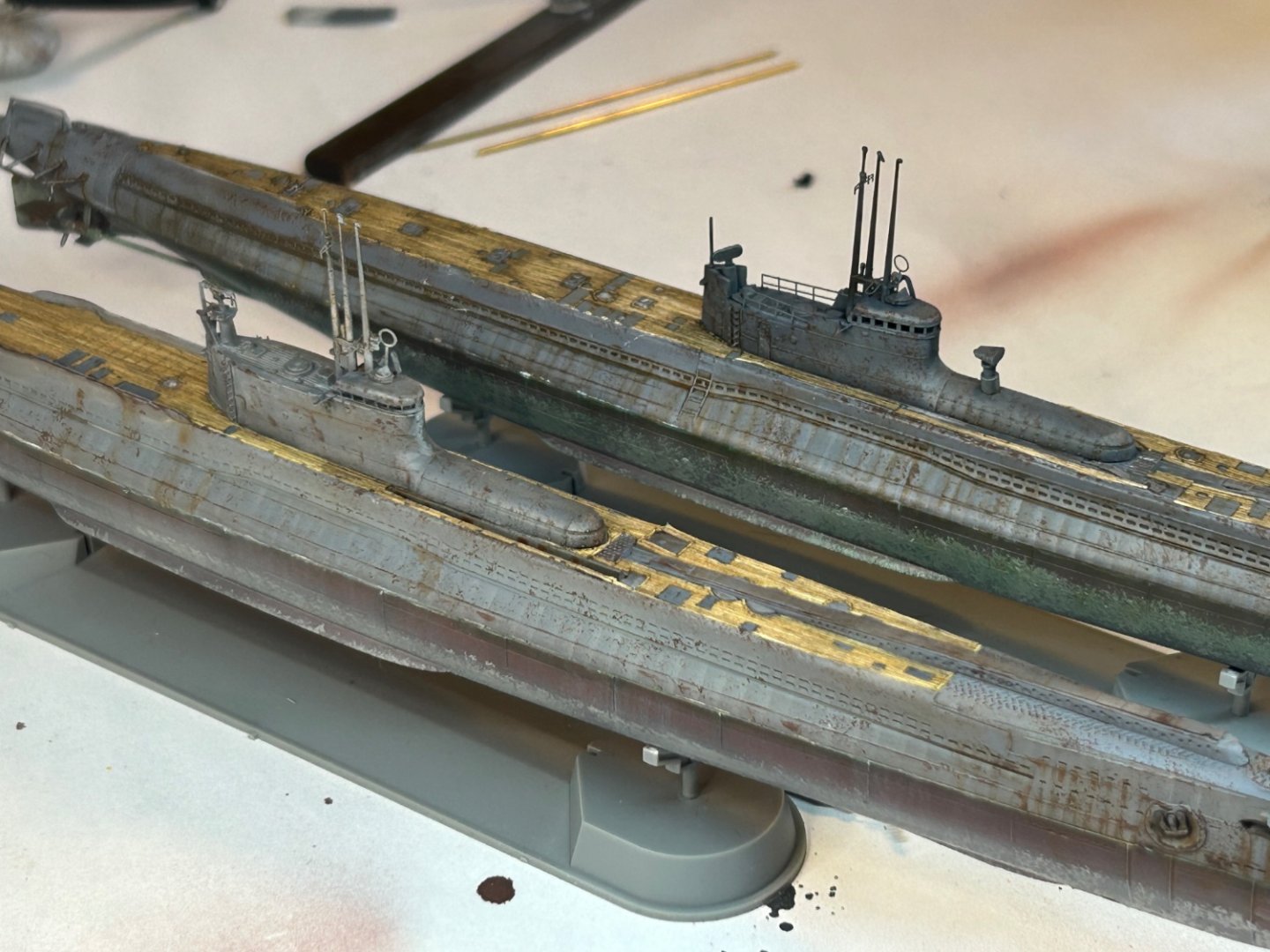

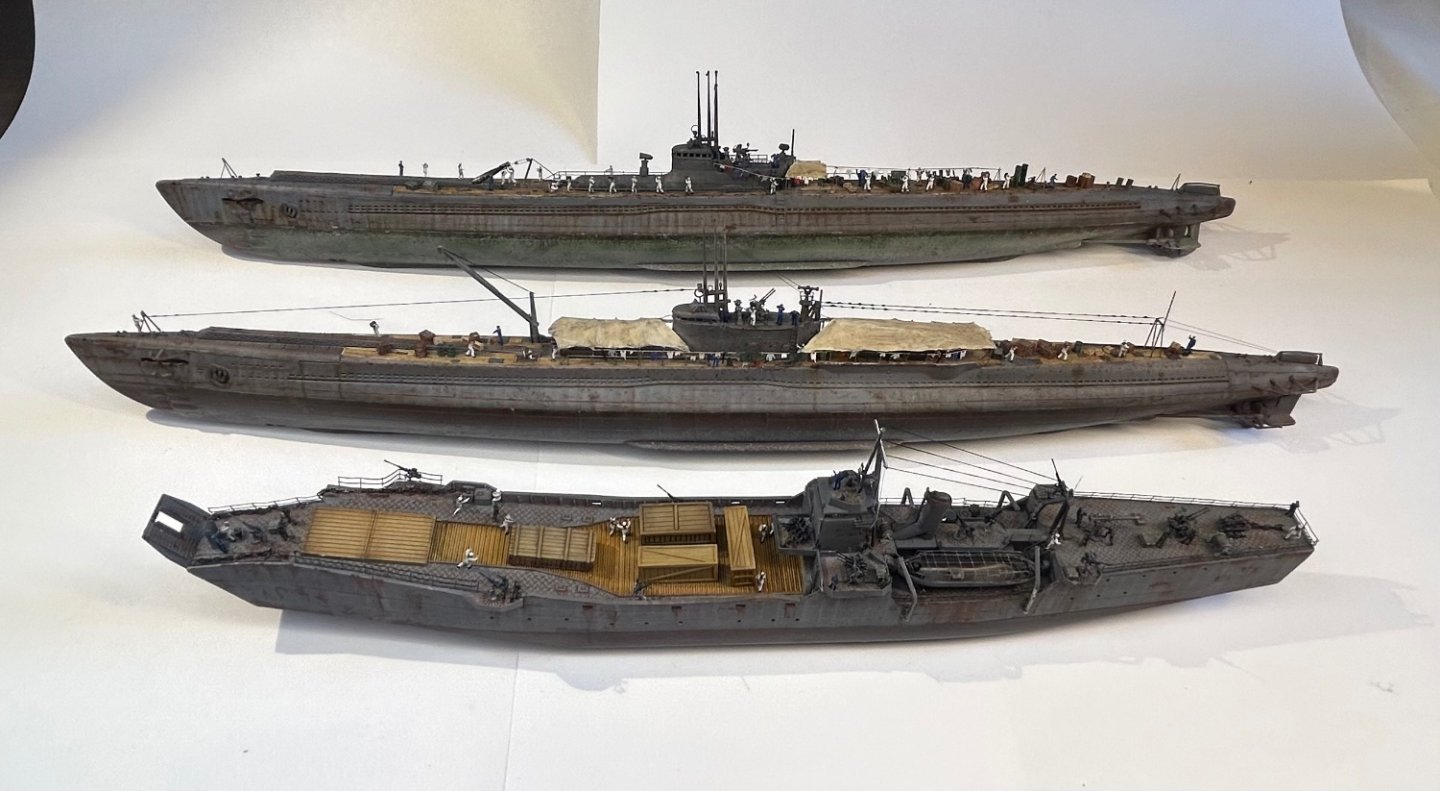

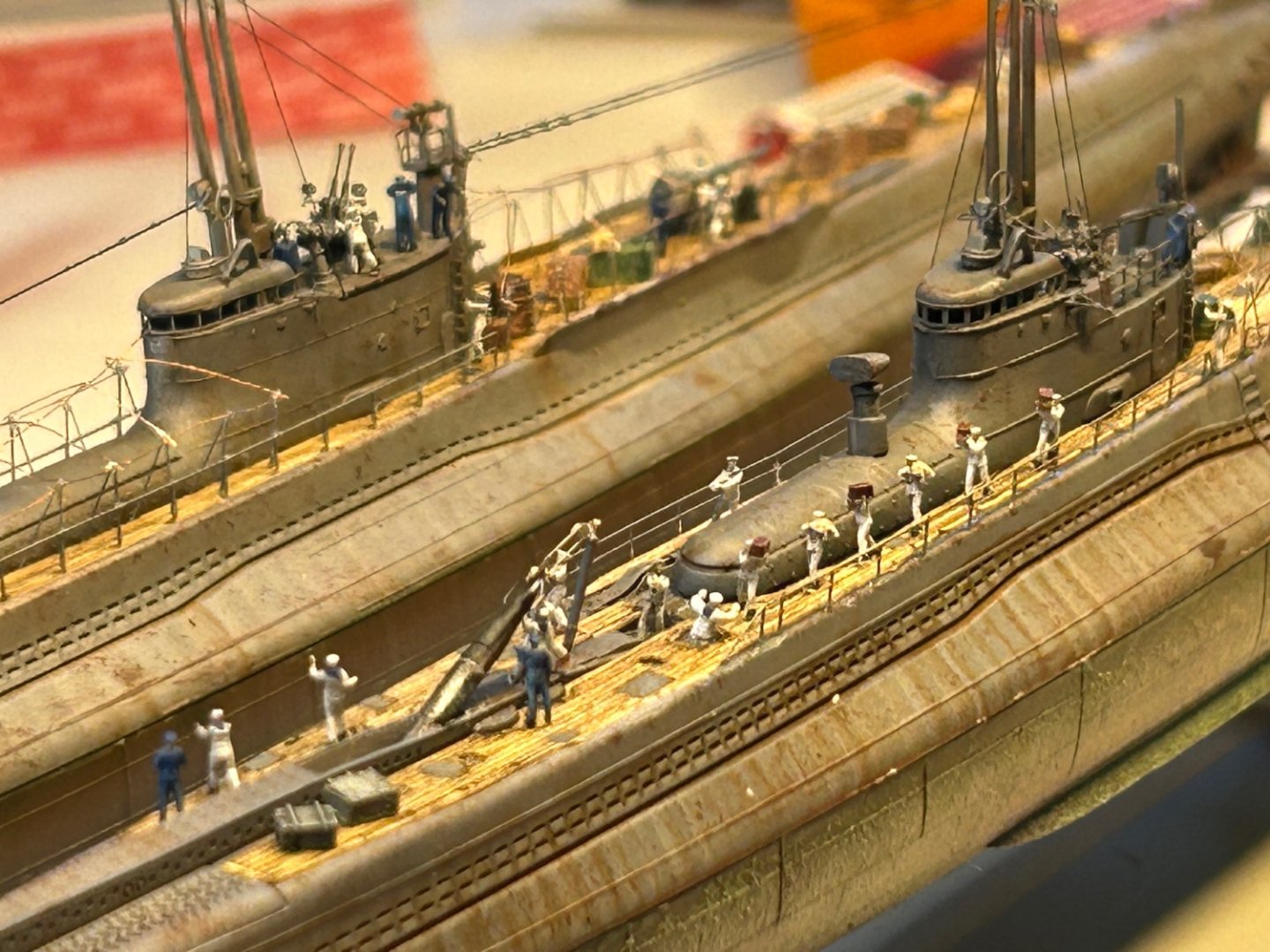

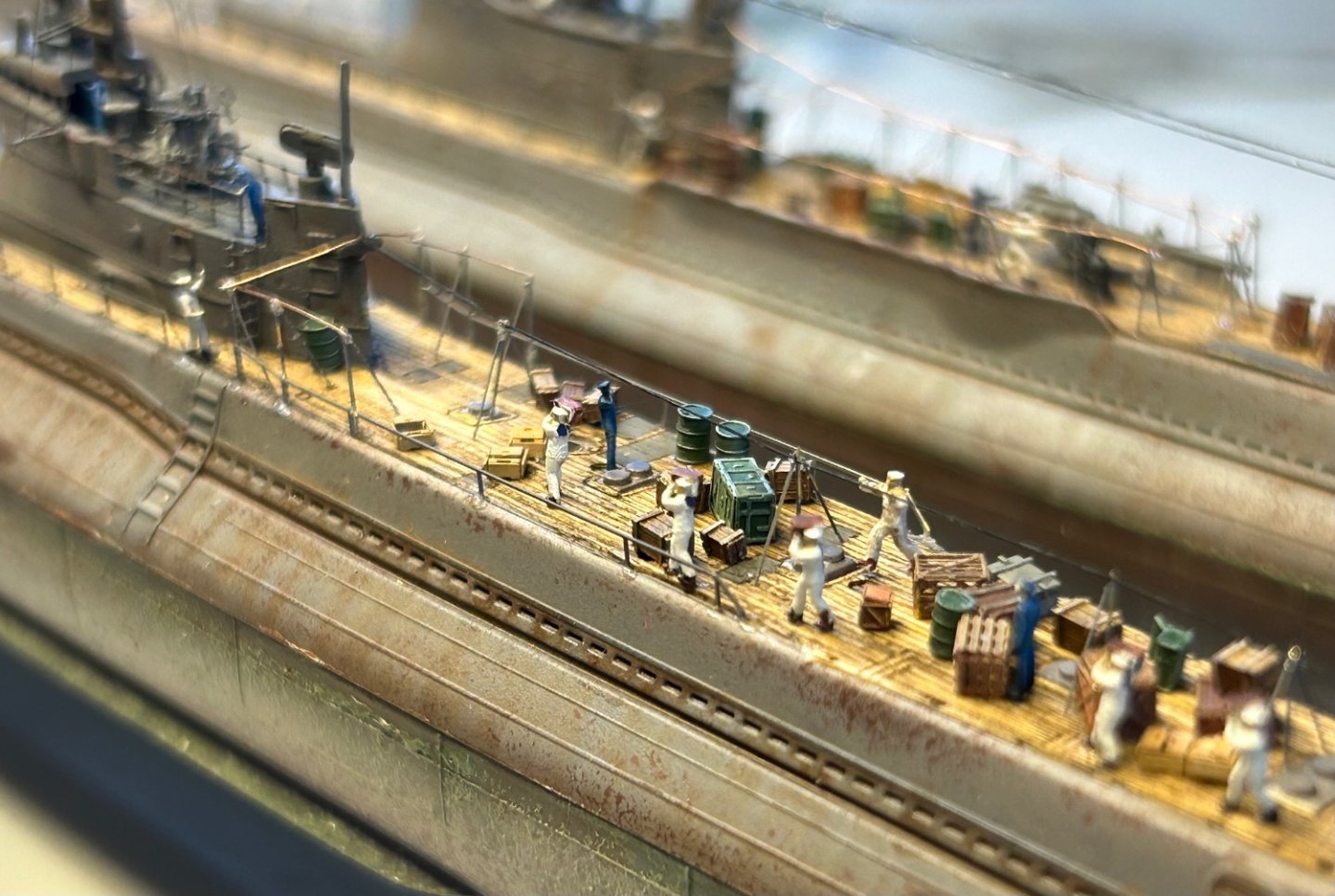

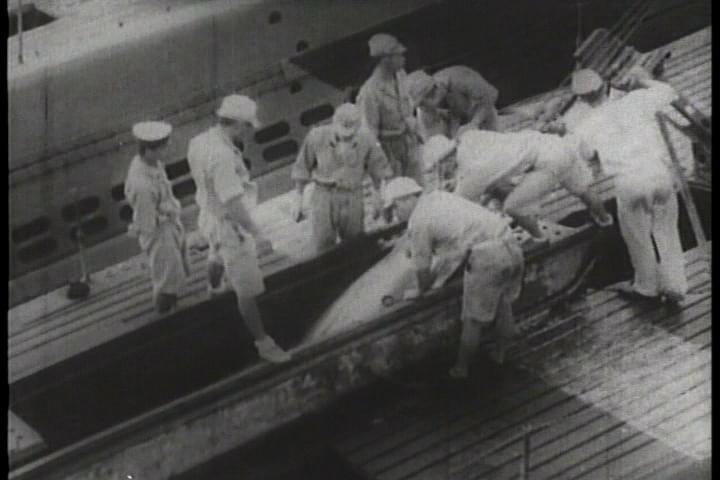

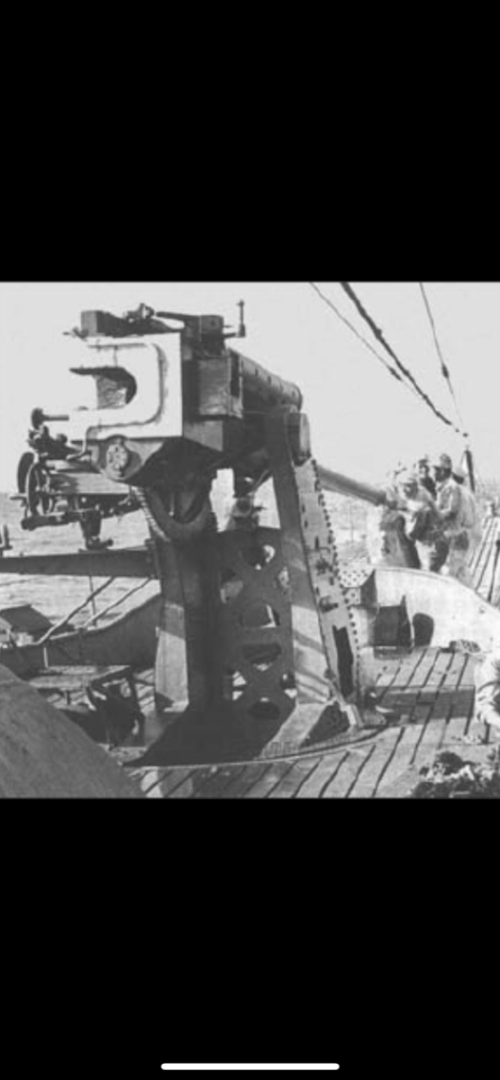

So looking at the old B&W images of IJN Subs, they were filthy things. So many images cover the big I400 class, and the older subs in 1/350 are not available anywhere in the world at a sensible price. My intention is to have one loading a torpedo, and lots of activity on the deck that one would expect for a replenishment operation.

- 200 replies

-

- Transport No. 103

- Hasegawa

-

(and 4 more)

Tagged with:

-

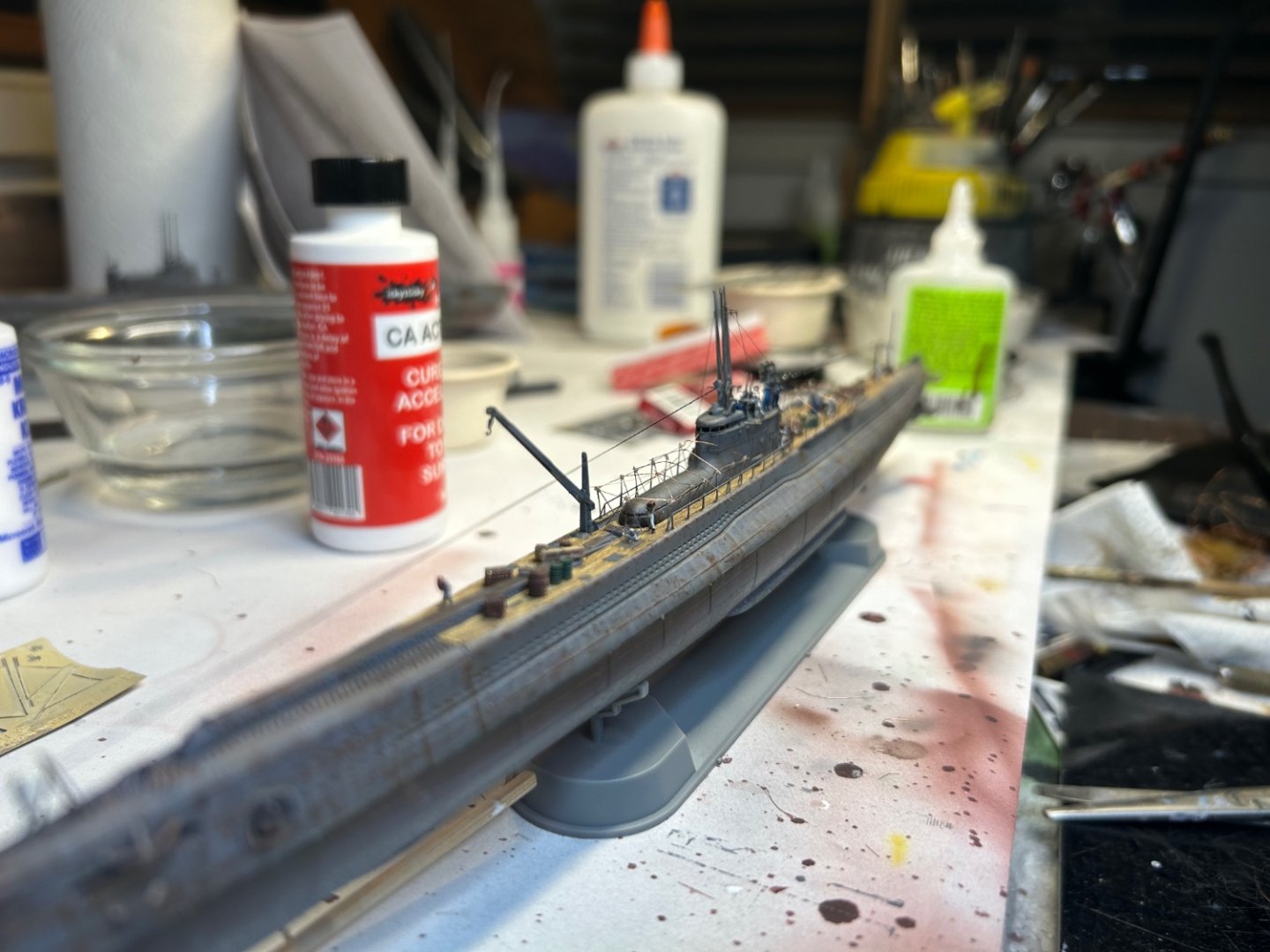

Bridges added, so I reckon I’m about 70% done now, I need to add guns, cranes, railings, tarps and figures

- 200 replies

-

- Transport No. 103

- Hasegawa

-

(and 4 more)

Tagged with:

-

- 200 replies

-

- Transport No. 103

- Hasegawa

-

(and 4 more)

Tagged with:

-

- 200 replies

-

- Transport No. 103

- Hasegawa

-

(and 4 more)

Tagged with:

-

- 200 replies

-

- Transport No. 103

- Hasegawa

-

(and 4 more)

Tagged with:

-

- 200 replies

-

- Transport No. 103

- Hasegawa

-

(and 4 more)

Tagged with:

-

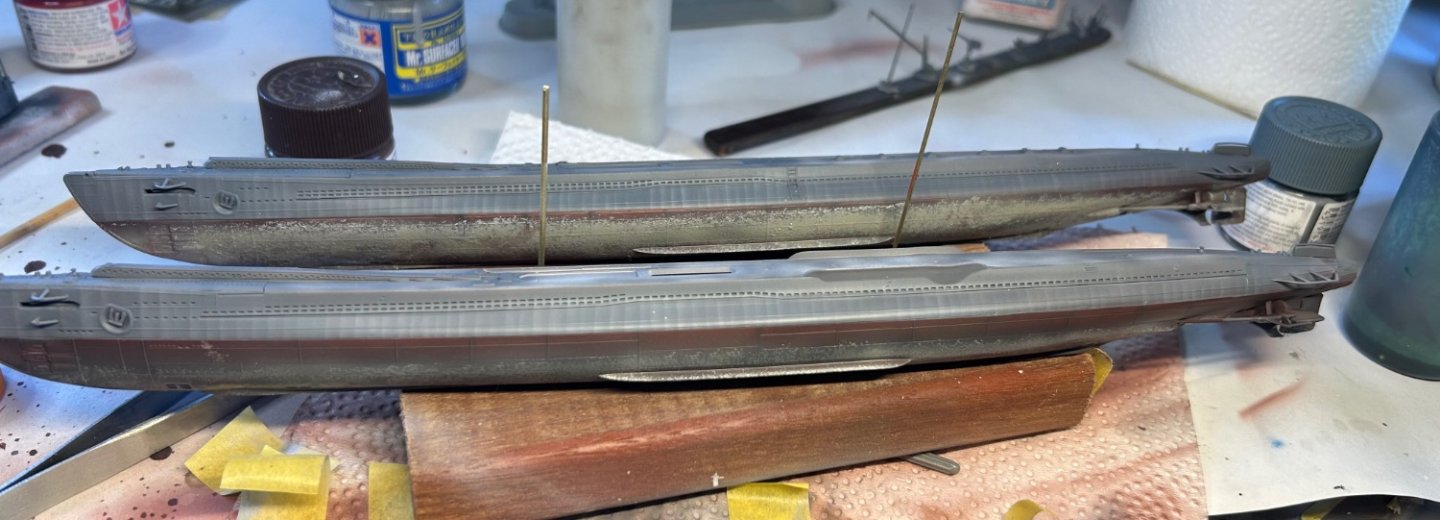

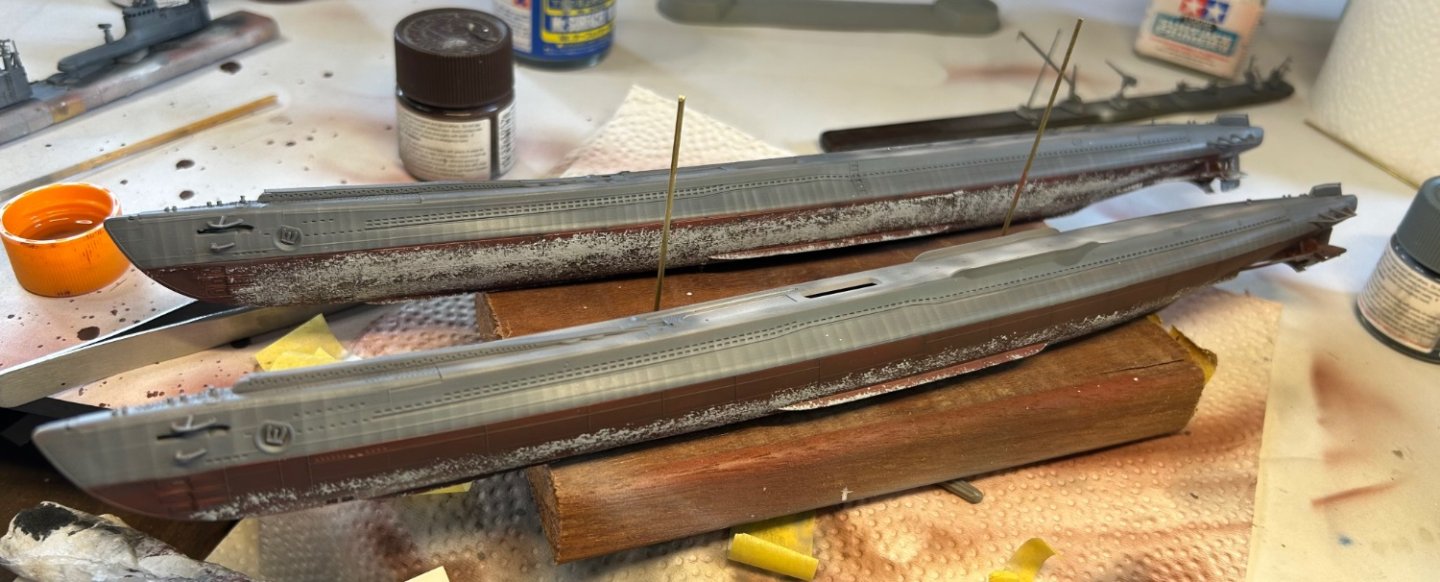

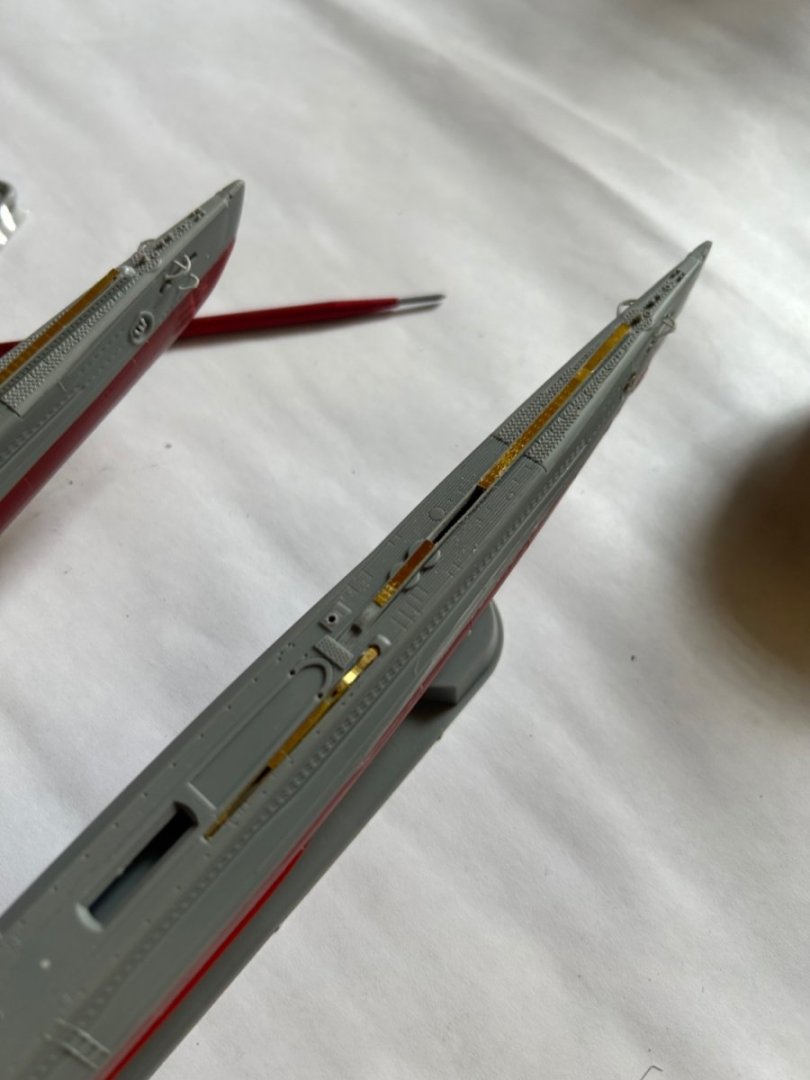

Grunging the lower hulls, first sponge on some old Mr Surfacer 1000 then a grey coat overspray followed by a black then a tan I wanted to make them a bit different to show different times out on mission. I will not add numbers to the hull as they were temporary anyways

- 200 replies

-

- Transport No. 103

- Hasegawa

-

(and 4 more)

Tagged with:

-

- 200 replies

-

- Transport No. 103

- Hasegawa

-

(and 4 more)

Tagged with:

-

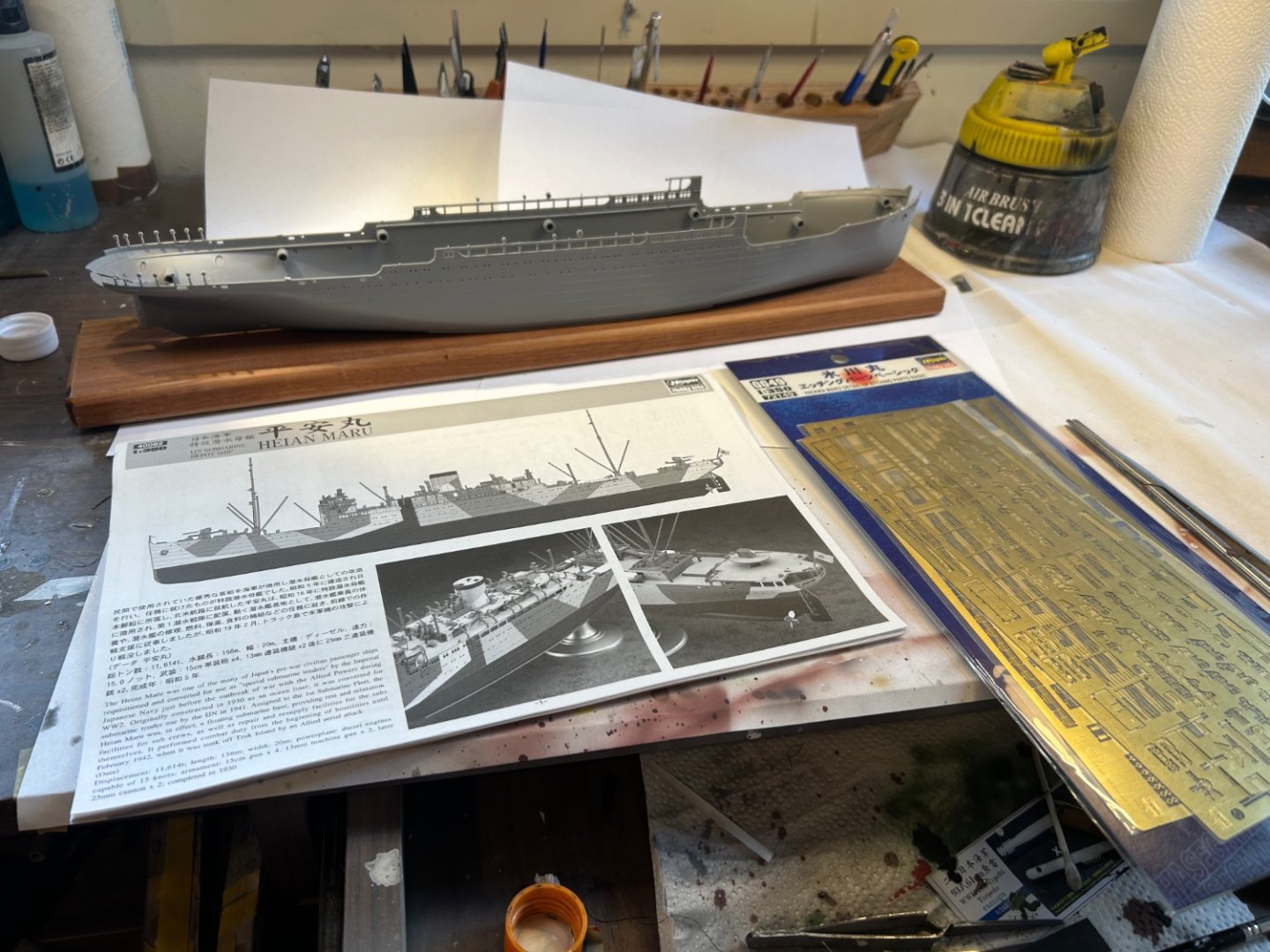

Ready for a base coat to look for errors. I have cut a hole in the float plane ramp so I can model a torpedo being loaded

- 200 replies

-

- Transport No. 103

- Hasegawa

-

(and 4 more)

Tagged with:

-

And a final and new photo is not seen of the deck of a landing craft which I wish I had of seen before

- 200 replies

-

- Transport No. 103

- Hasegawa

-

(and 4 more)

Tagged with:

-

The pressure hulls, the forward housing is the torpedo loading hatch which I intend to do on these ones loading torpedoes.

- 200 replies

-

- Transport No. 103

- Hasegawa

-

(and 4 more)

Tagged with:

-

- 200 replies

-

- Transport No. 103

- Hasegawa

-

(and 4 more)

Tagged with:

-

- 200 replies

-

- Transport No. 103

- Hasegawa

-

(and 4 more)

Tagged with:

-

Camel by RGL - FINISHED - Machinen Krieger - 1/20

RGL replied to RGL's topic in Non-ship/categorised builds

I watched a Video on U-tube. -

Camel by RGL - FINISHED - Machinen Krieger - 1/20

RGL replied to RGL's topic in Non-ship/categorised builds

I did some 1/35 in the 1980’s really badly, airbrushes make a big difference -

Camel by RGL - FINISHED - Machinen Krieger - 1/20

RGL replied to RGL's topic in Non-ship/categorised builds

-

Camel by RGL - FINISHED - Machinen Krieger - 1/20

RGL replied to RGL's topic in Non-ship/categorised builds

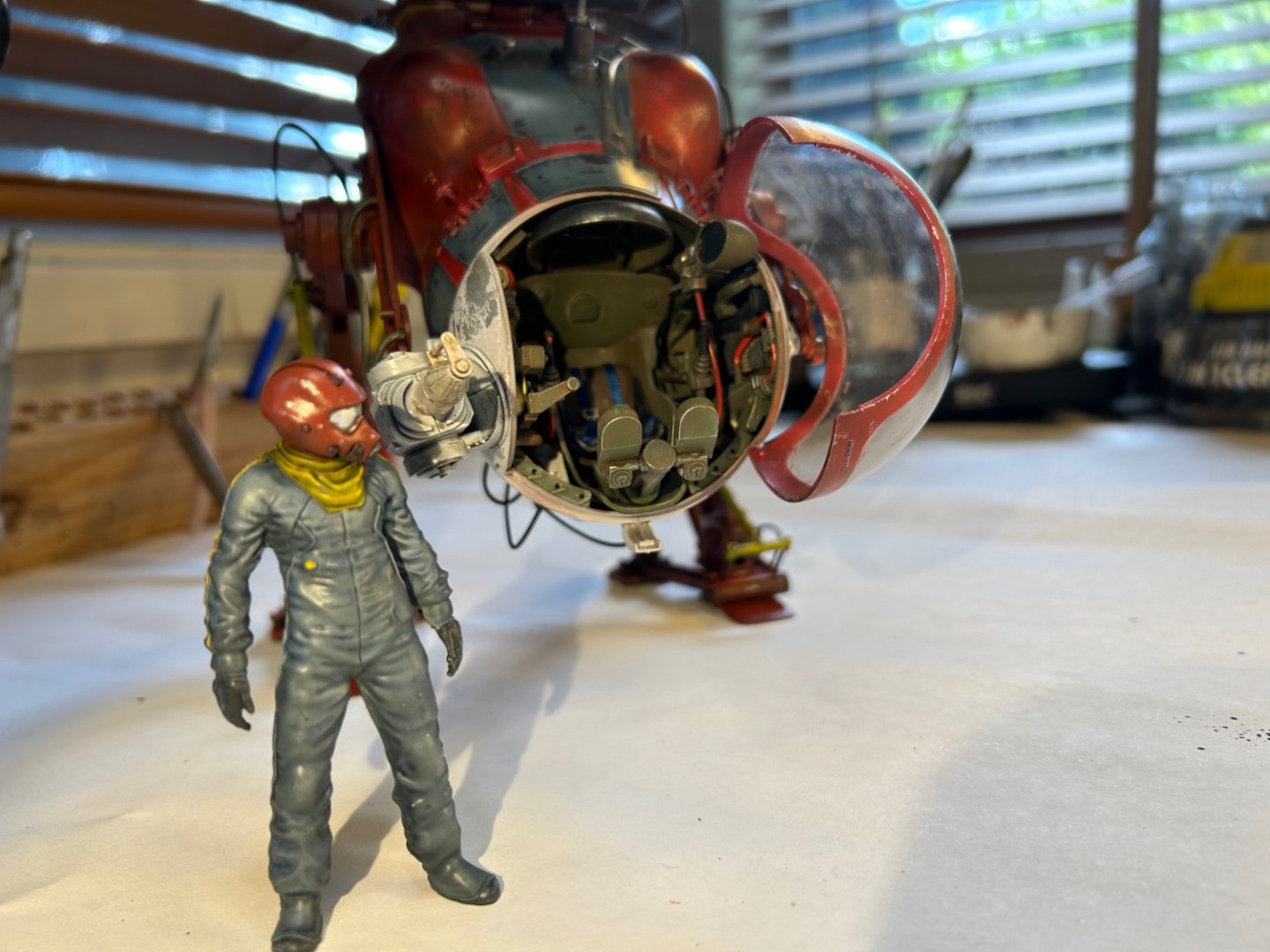

So my first attempt at a figure this century. I’ll come back to it tomorrow to do some touch ups then a matte coat.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

surrenderedatMaizuru1945NihonnoGunkanv12.jpg.dc4872cd114368d0e6705e06cd50b528.jpg)