-

Posts

1,344 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by mtbediz

-

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

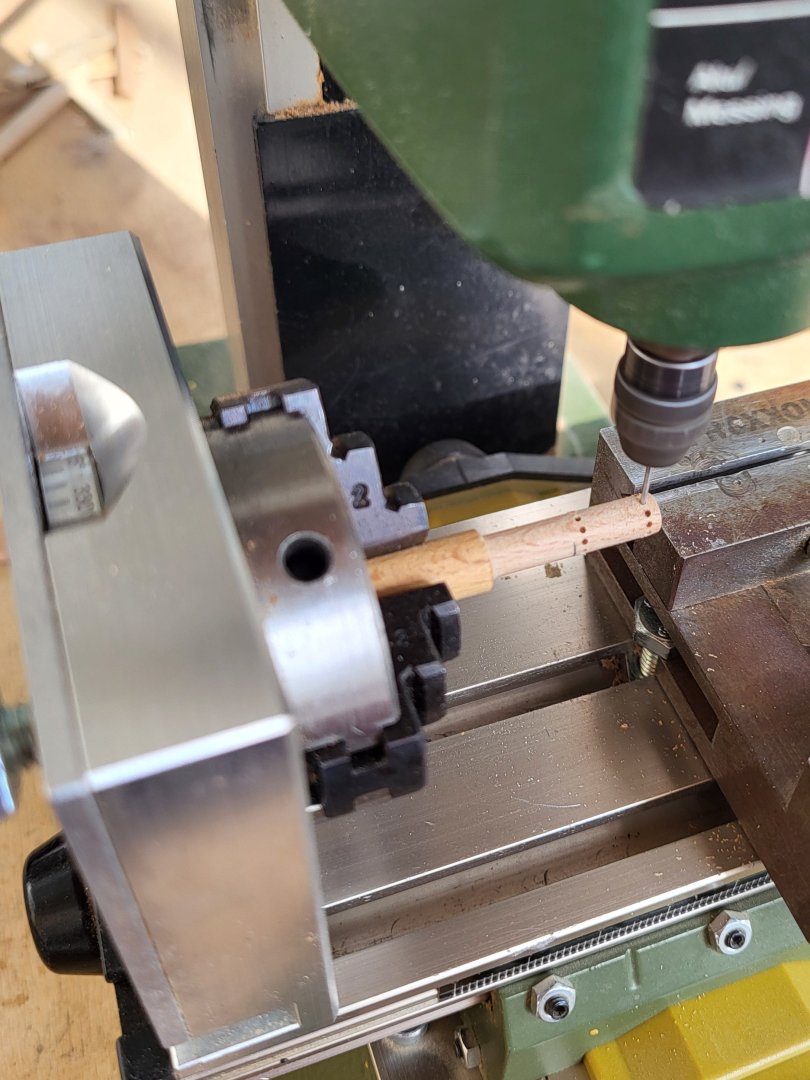

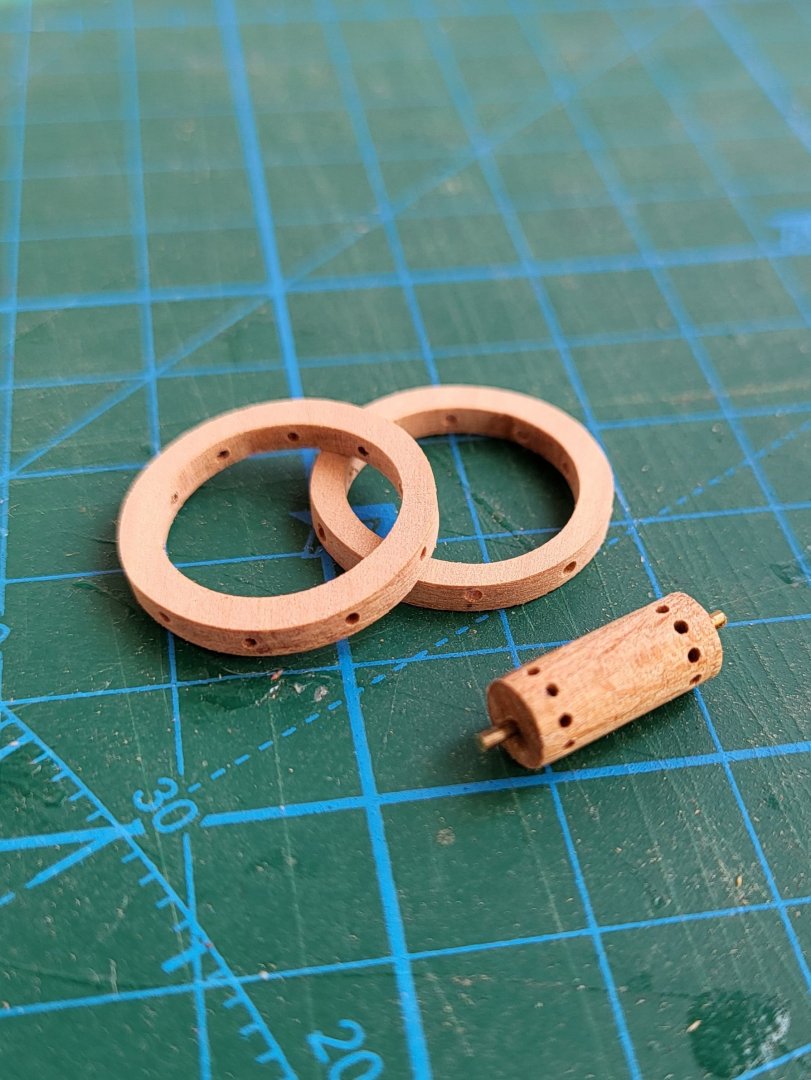

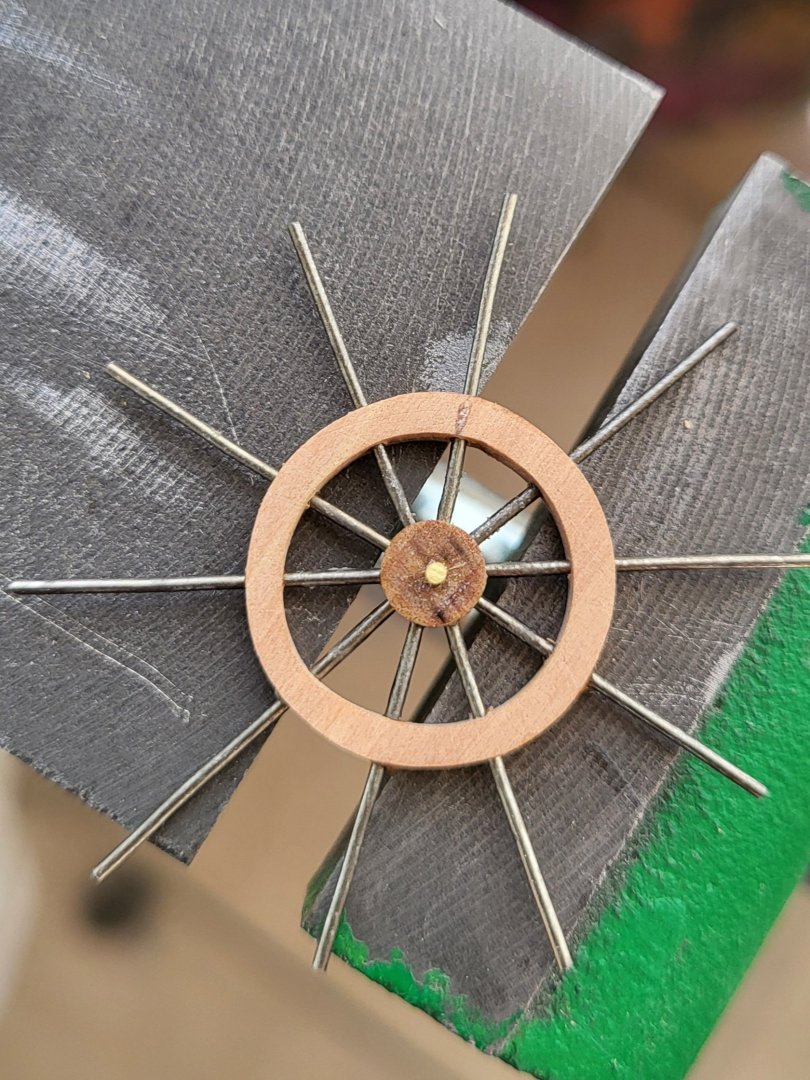

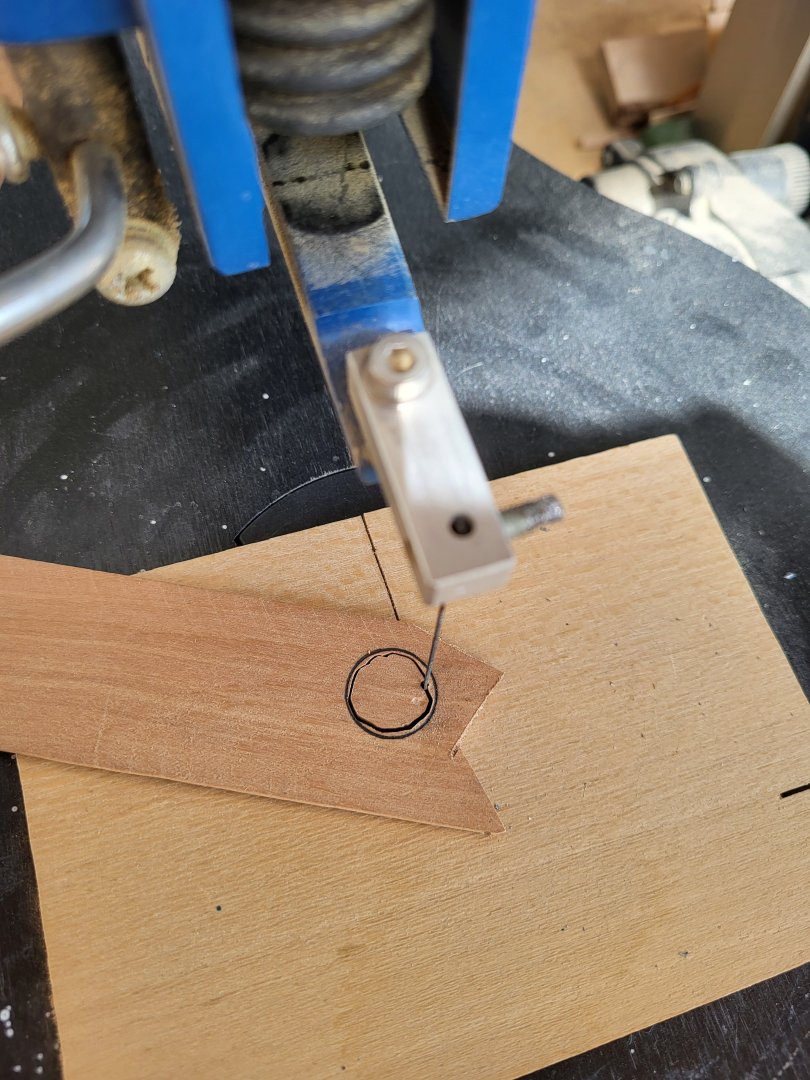

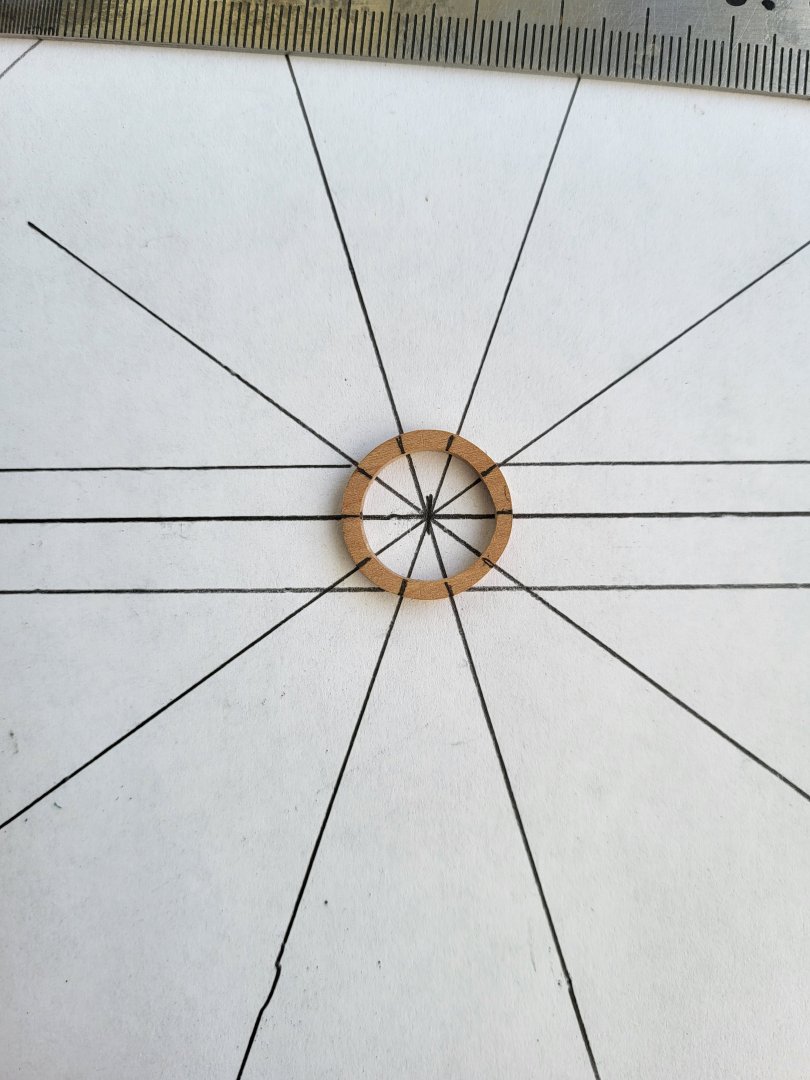

Believe it or not, I bought this dividing attachment two years ago and used it for the first time when I was building this wheel. I don't know when I'll use it again. You'll probably need this tool once or twice during a model ship build, but if you have it, it's a lifesaver and you'll get great results. I agree with Jon, he's in no rush to finish his model, and there's no point in investing in an expensive tool that he might need every 10-15 years! As for milling, a real milling machine is a must, especially if you're building a model from scratch or tackling a kit bashing. Its signature can be found on every square inch of my Constitution. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Thanks Greg. Life is pretty easy with that mill. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

So I made the right decision not to try to make the canopies your way. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

-

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

I just edited my answer, if you read it again it might make sense. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

I didn't use a special jig for this. I just fixed the rail onto a flat surface with tape and soldered the stancions to it while holding them with my hand. By the way, I use soldering paste for soldering, so my hand is free and I can hold the stanchion with my hand. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

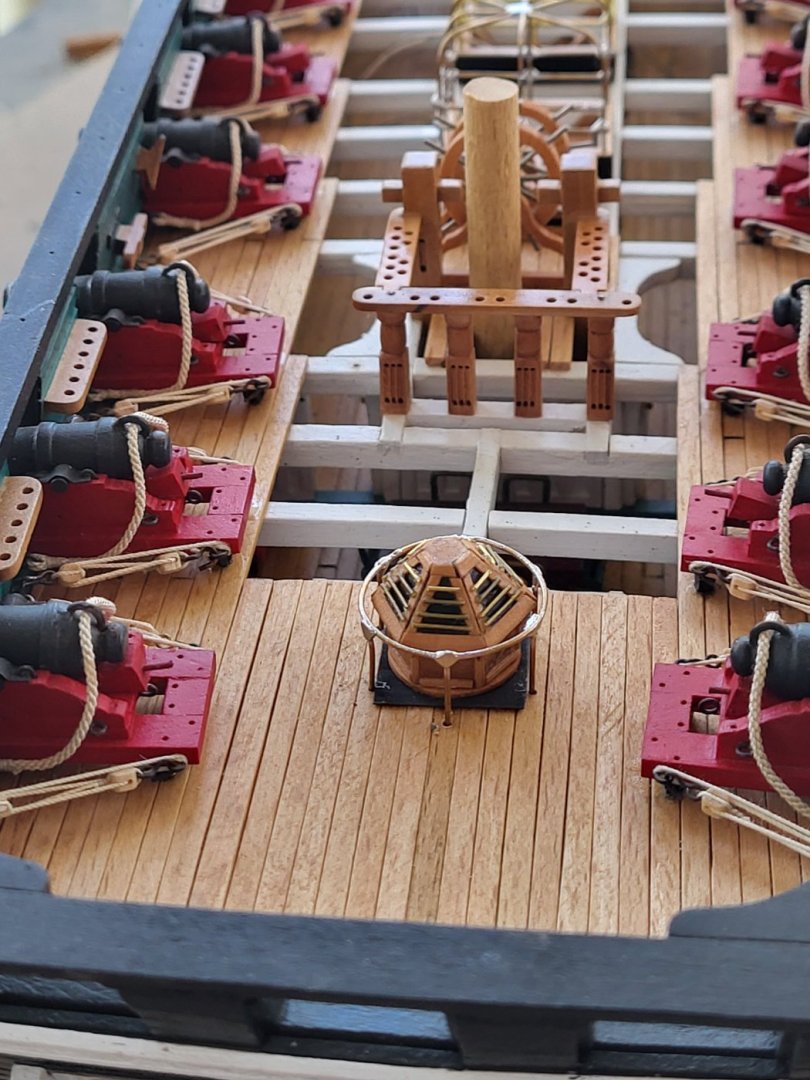

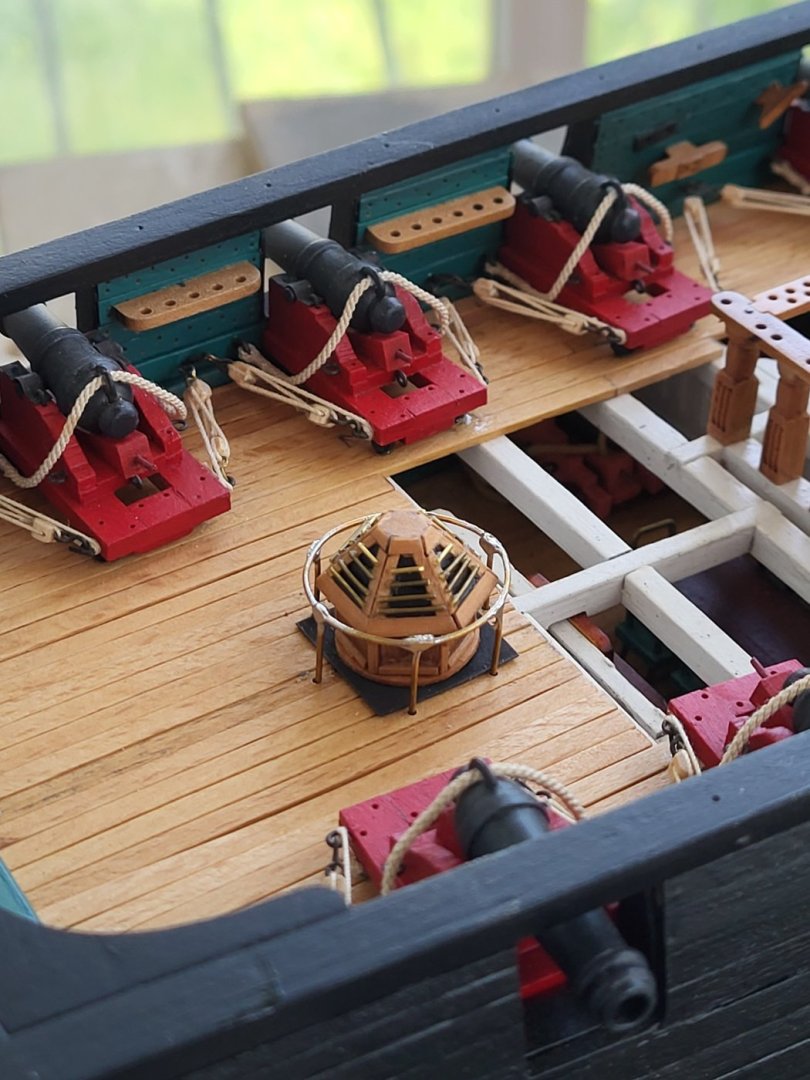

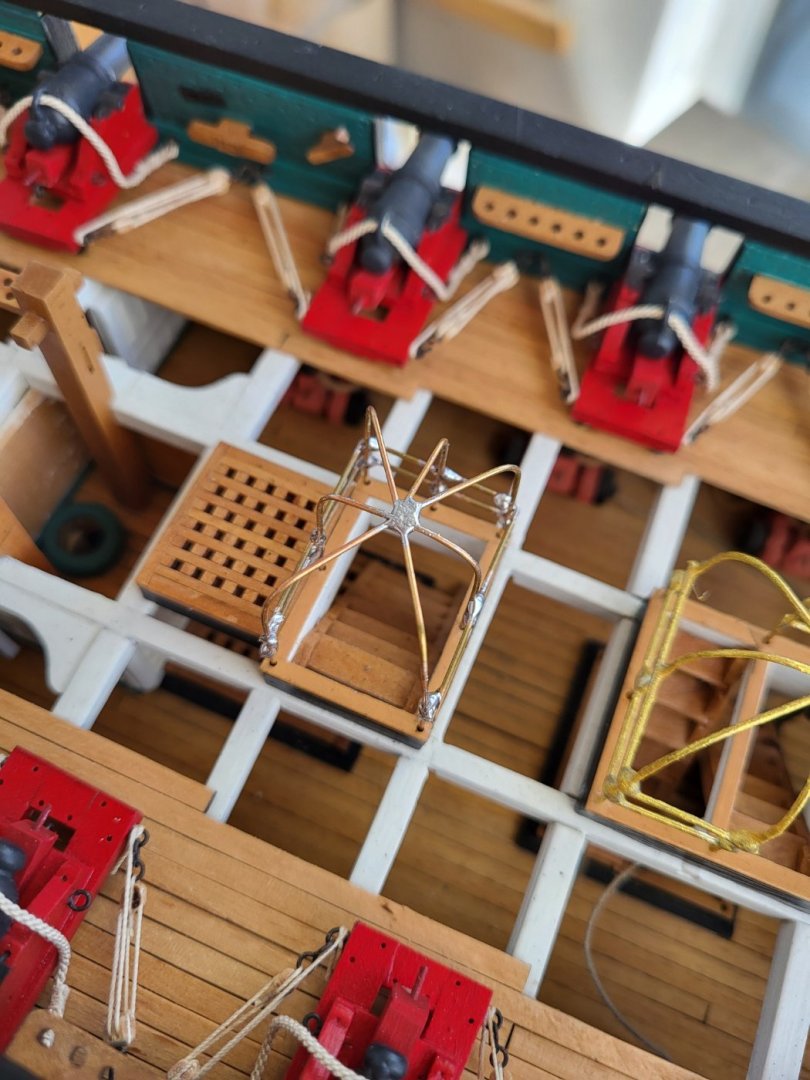

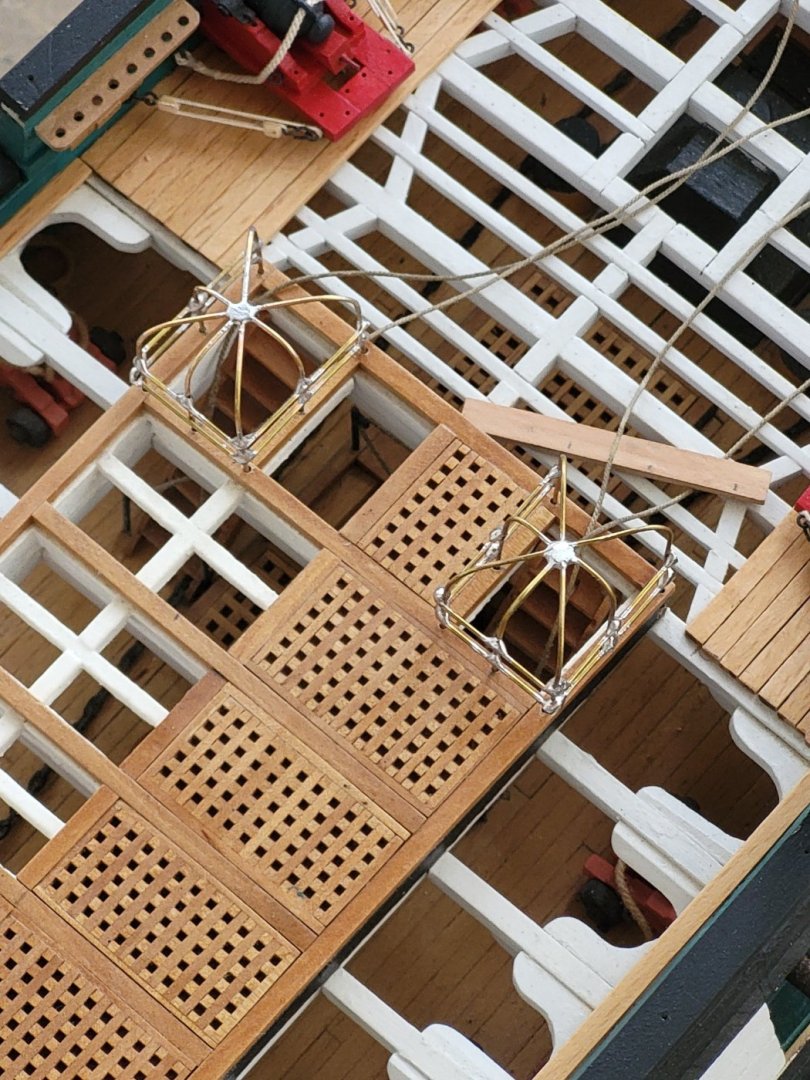

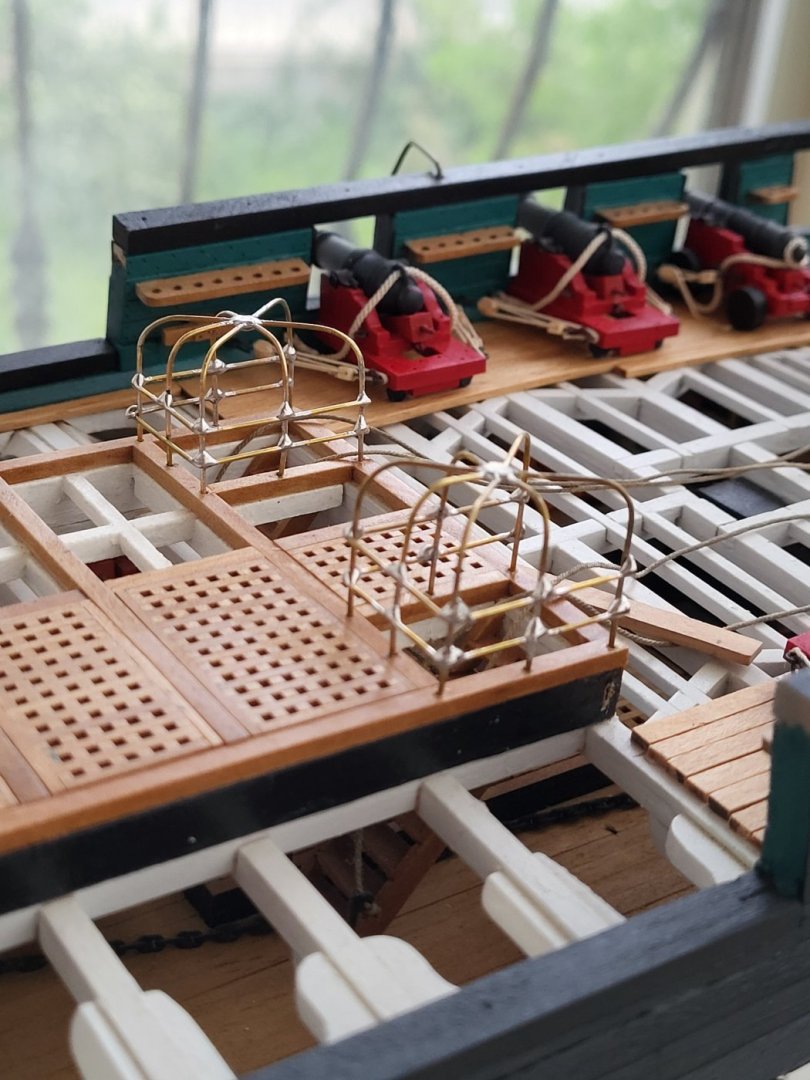

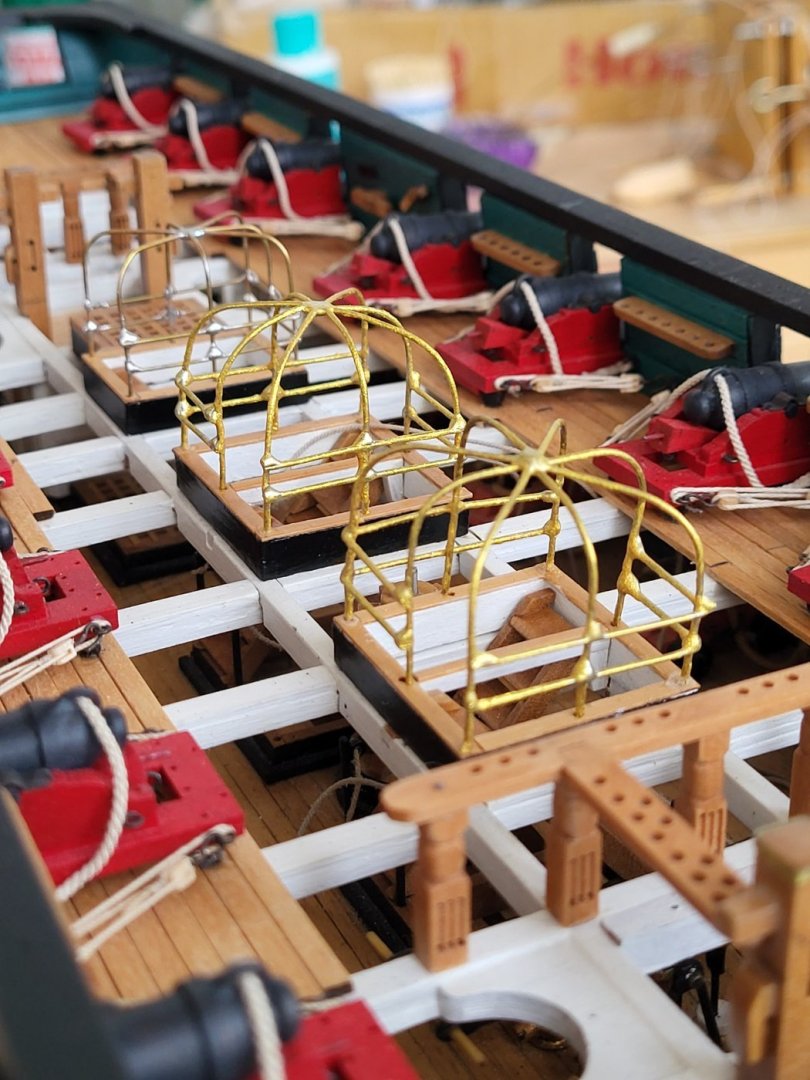

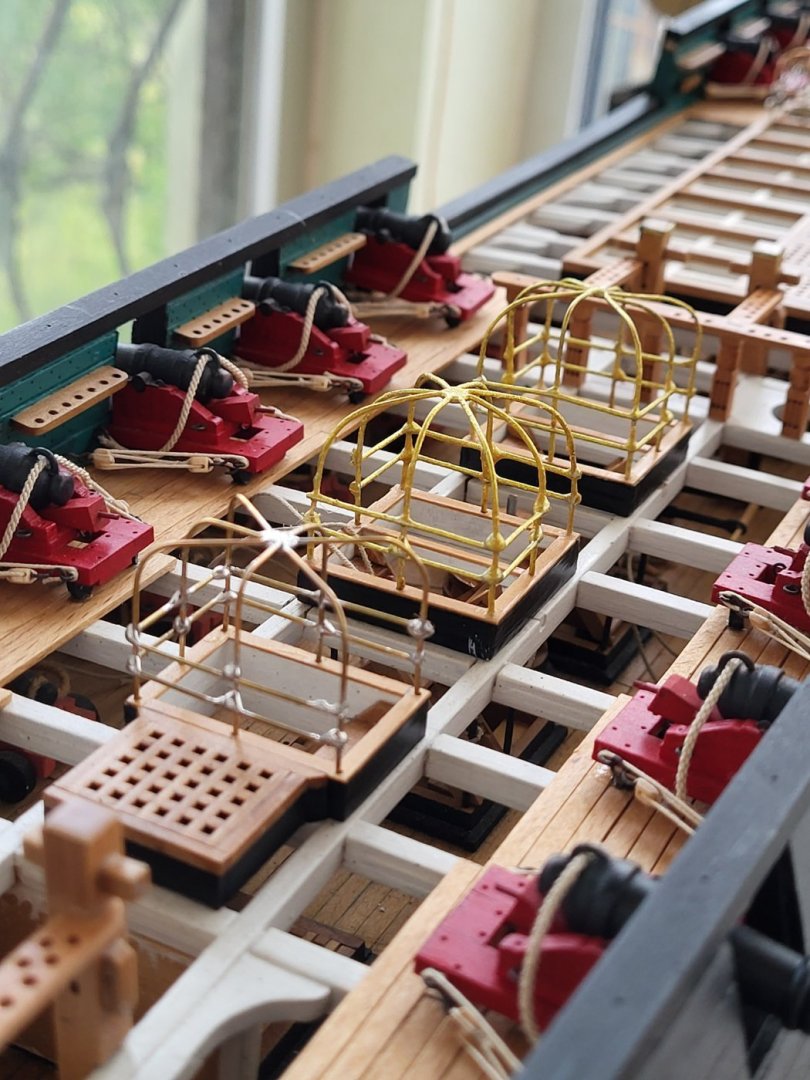

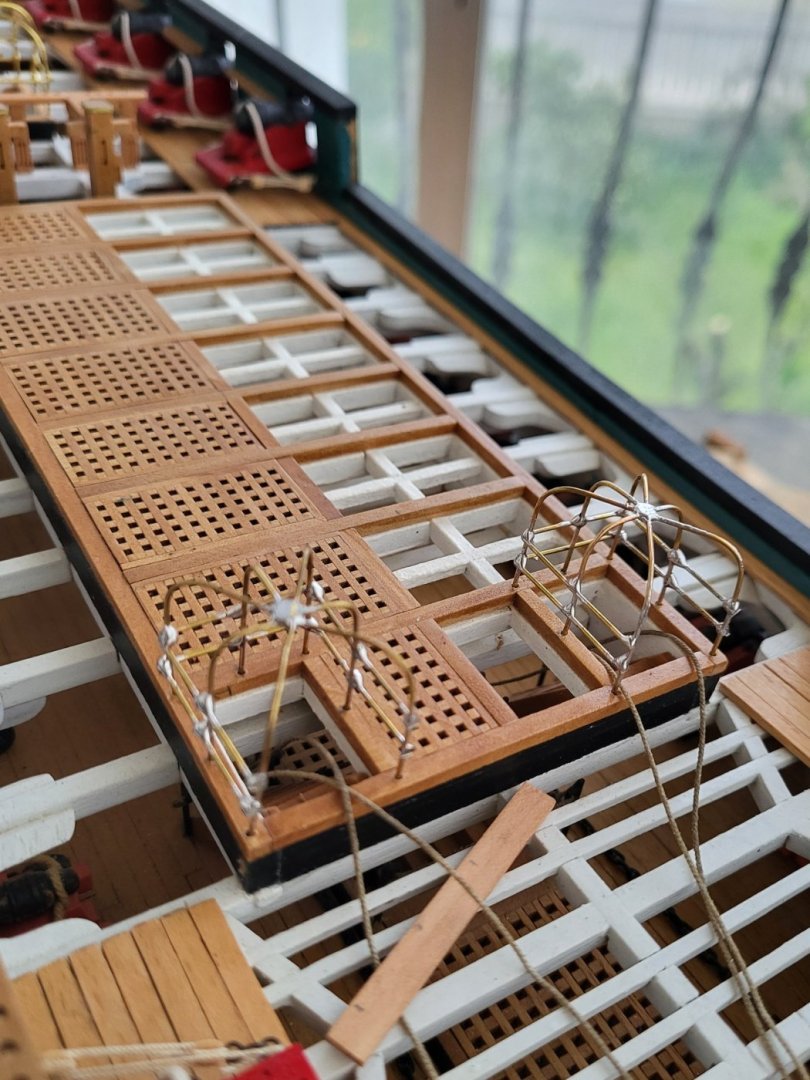

Thank you Jon. For the aft skylight, I cut the base plate from 0.3 mm brass sheet and blackened it. I made the railing of the skylight from 0.7 mm brass wire, but I couldn't clean up the excess solder using my old files. So, I ordered a new set of files. I'll work on that later. Nothing is glued in place yet. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

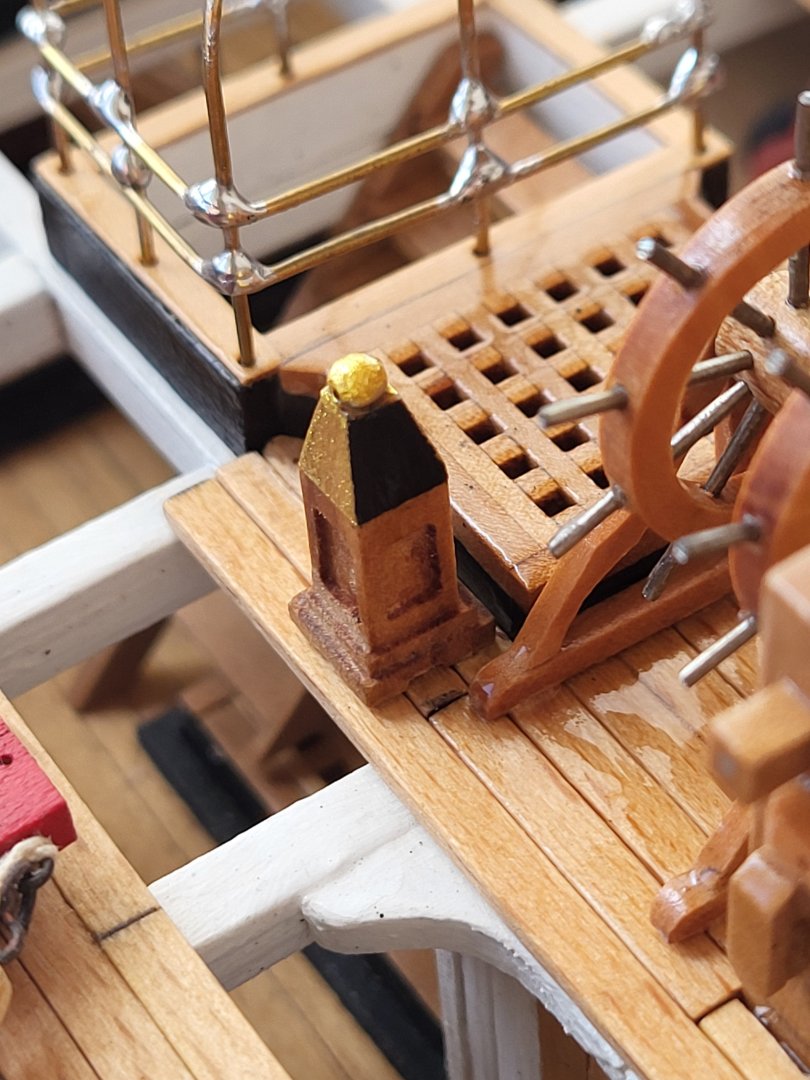

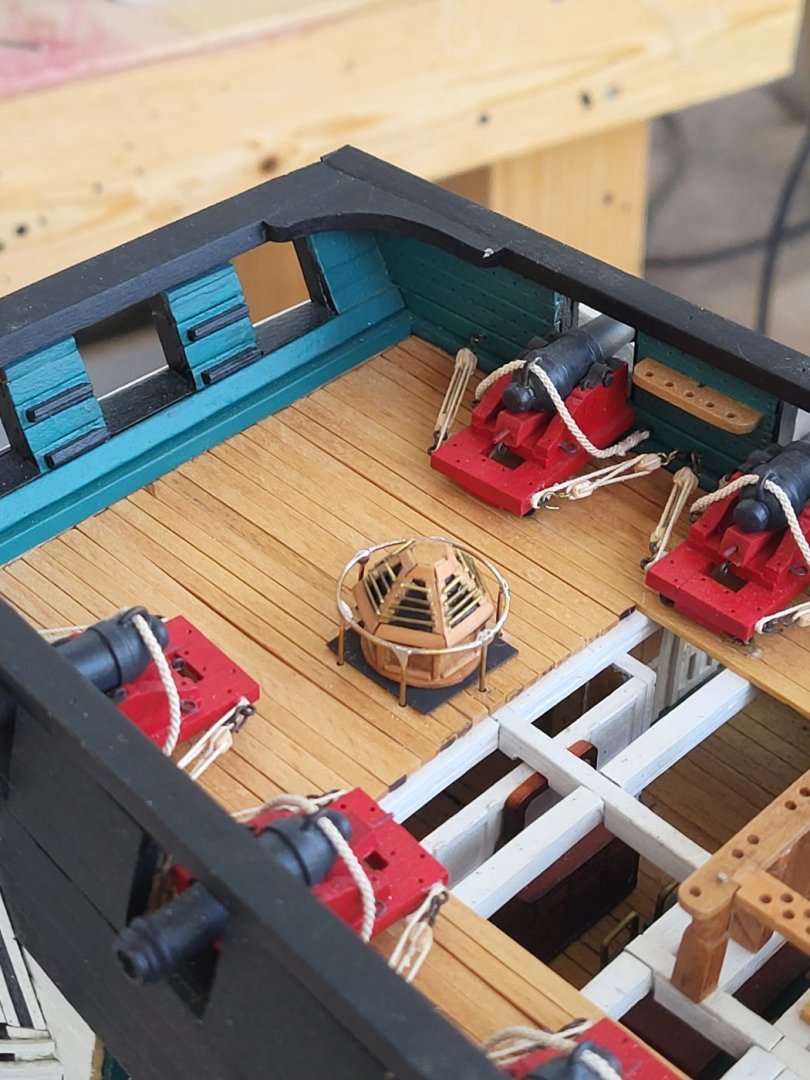

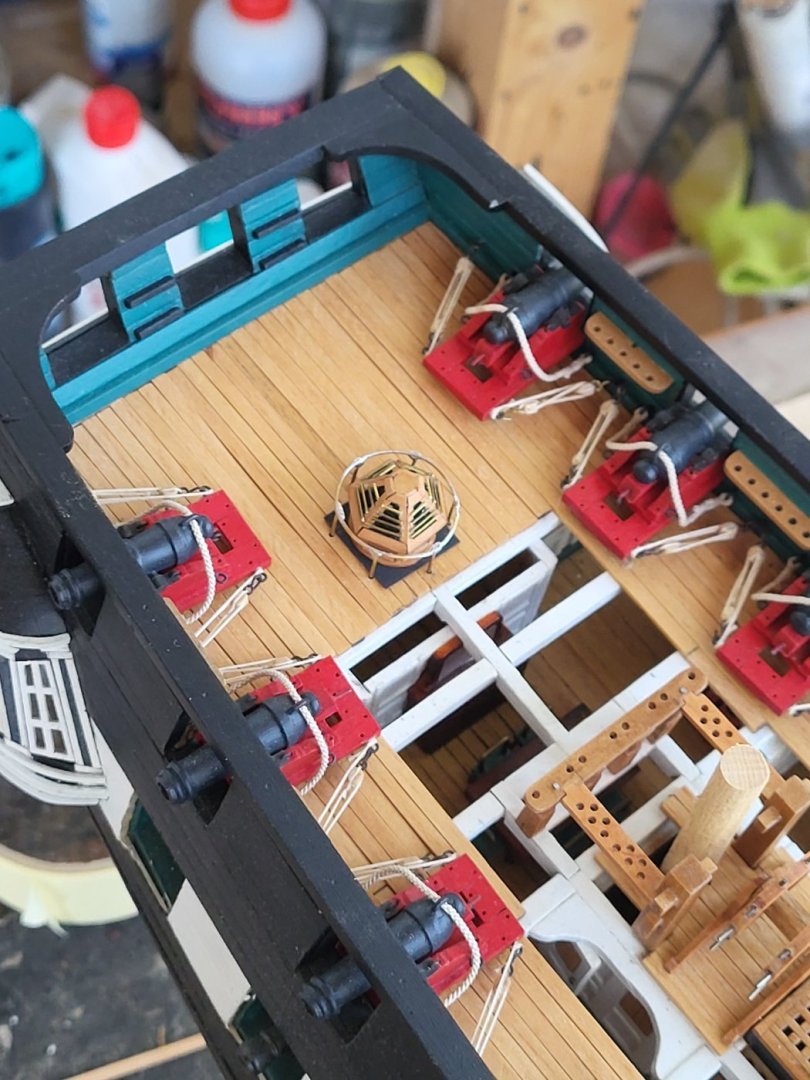

I am working on captain's skylight. I prepared a hexagonal prism and a hexagonal-based conical prism from pear wood, adding details cut from 0.5 mm pear strips. I used black paint to represent the windows and made the window bars out of 0.5 mm brass wire. Finally, I finished it with a matte varnish." -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Never hesitate to ask anything Greg. I'm here to answer questions. Yes, I did exactly as you said and added a beam there. There are a lot of auxiliary beams on the original ship that I didn't add to my model anyway. And yes, I'll plank the aft side of the mizzen mast later. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Thanks Greg. I was wondering where these ropes go and wanted to do a virtual tour to see them, but as you said, they go through the pantry. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Thank you so much for the pictures Jon. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Thank you so much. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

-

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Thank you Jon. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

-

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Thanks Greg. We have a saying; "The tool works but the hand boasts". Proper tools really make my life a lot easier. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

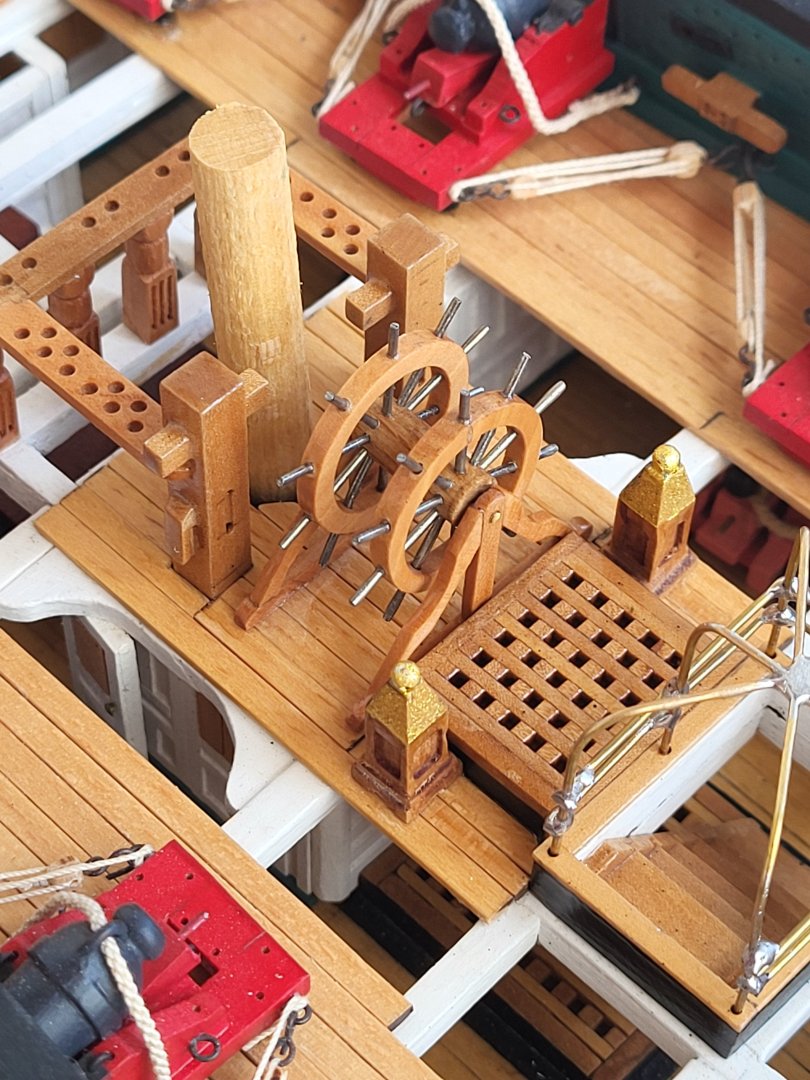

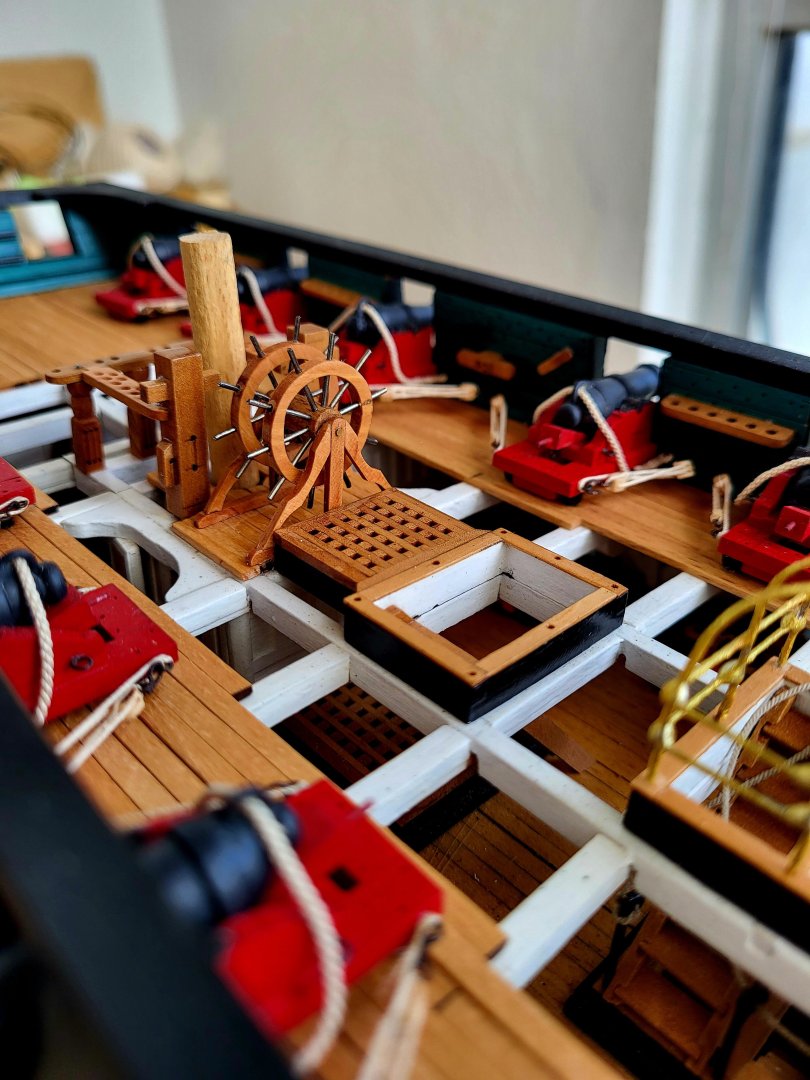

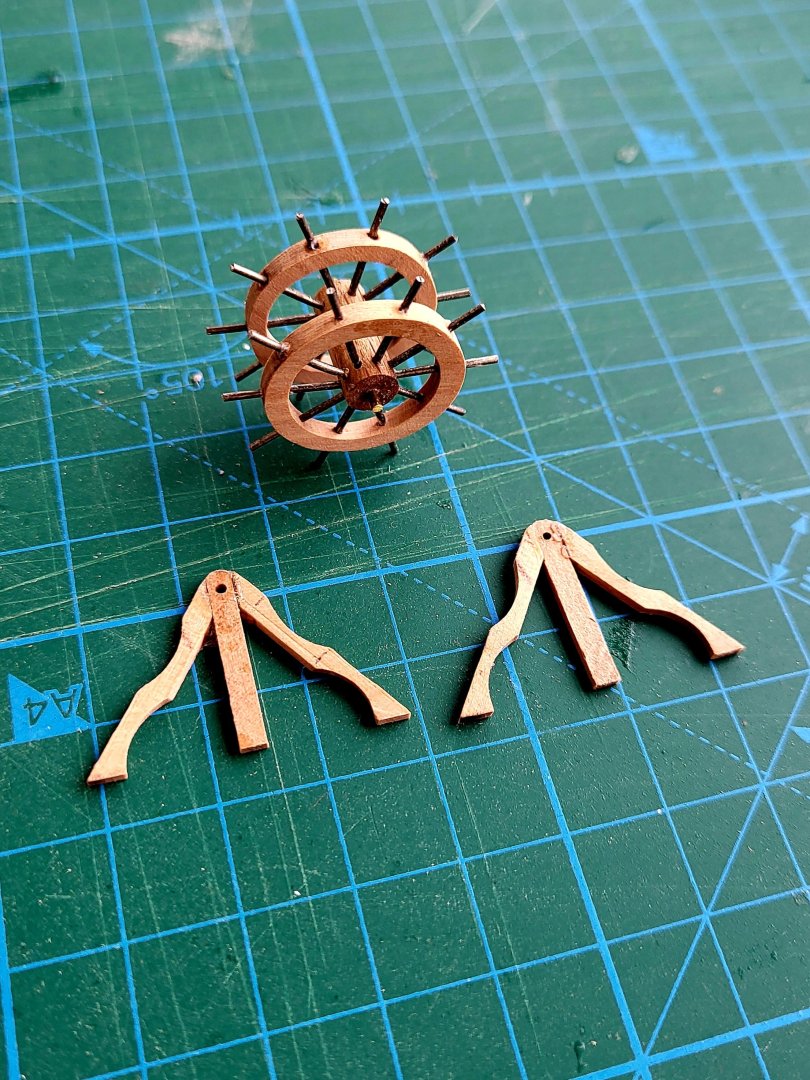

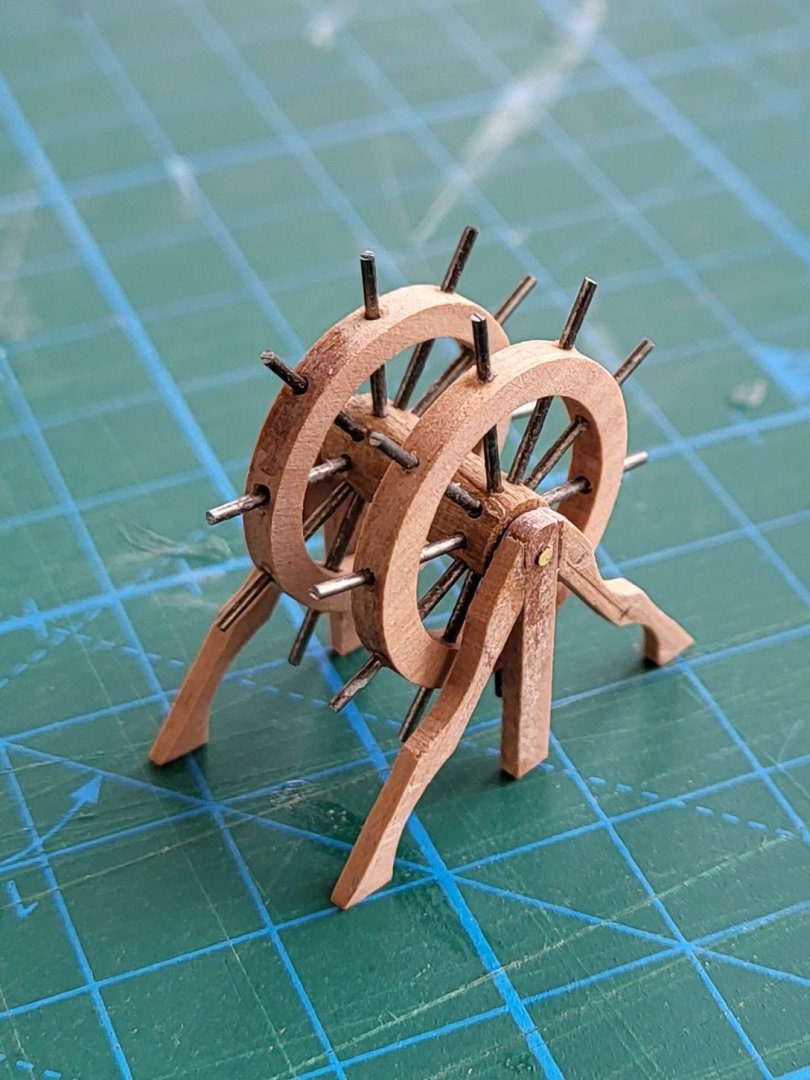

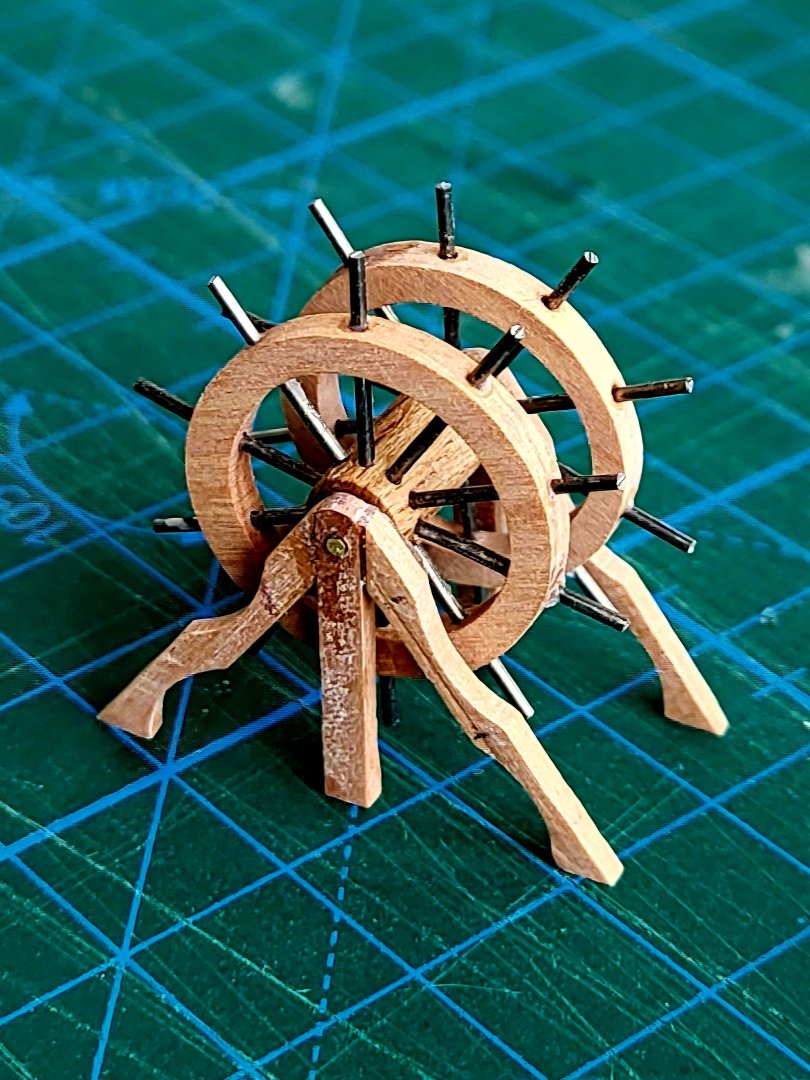

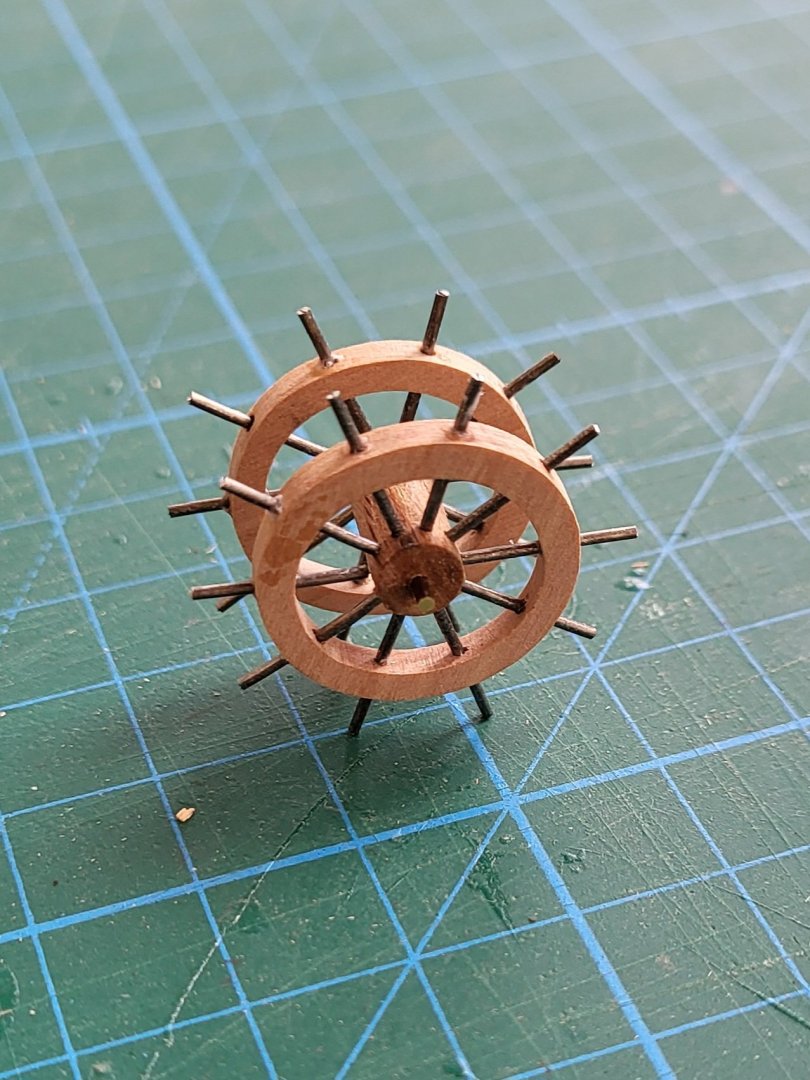

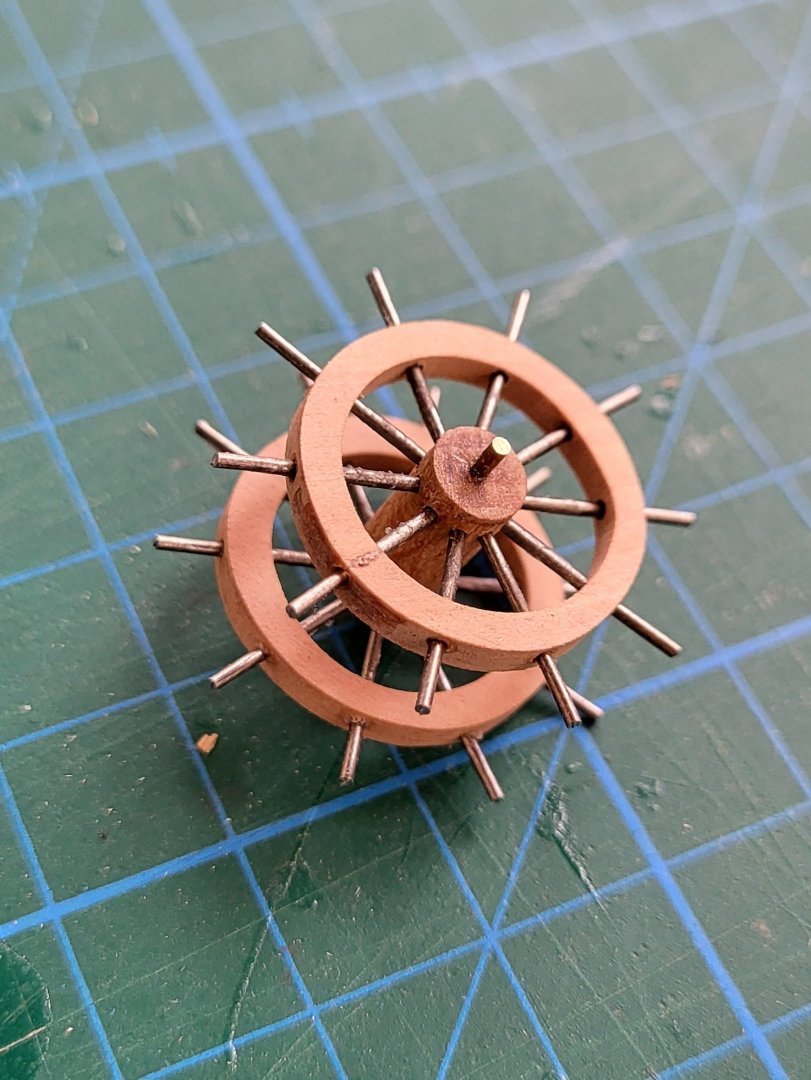

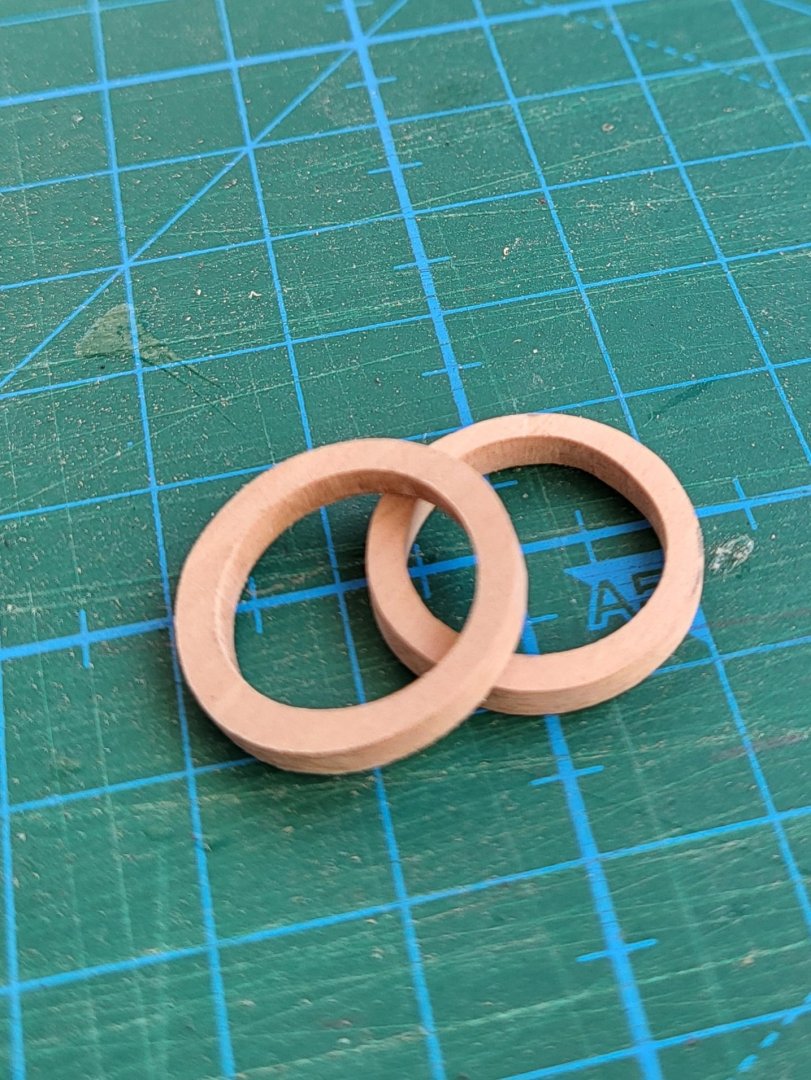

Thanks Jon. I tried to make the spokes out of wood but they were really thin and broke during the turning process. It turned out I needed a drawplate but for now I'll have to make do with metal spokes. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

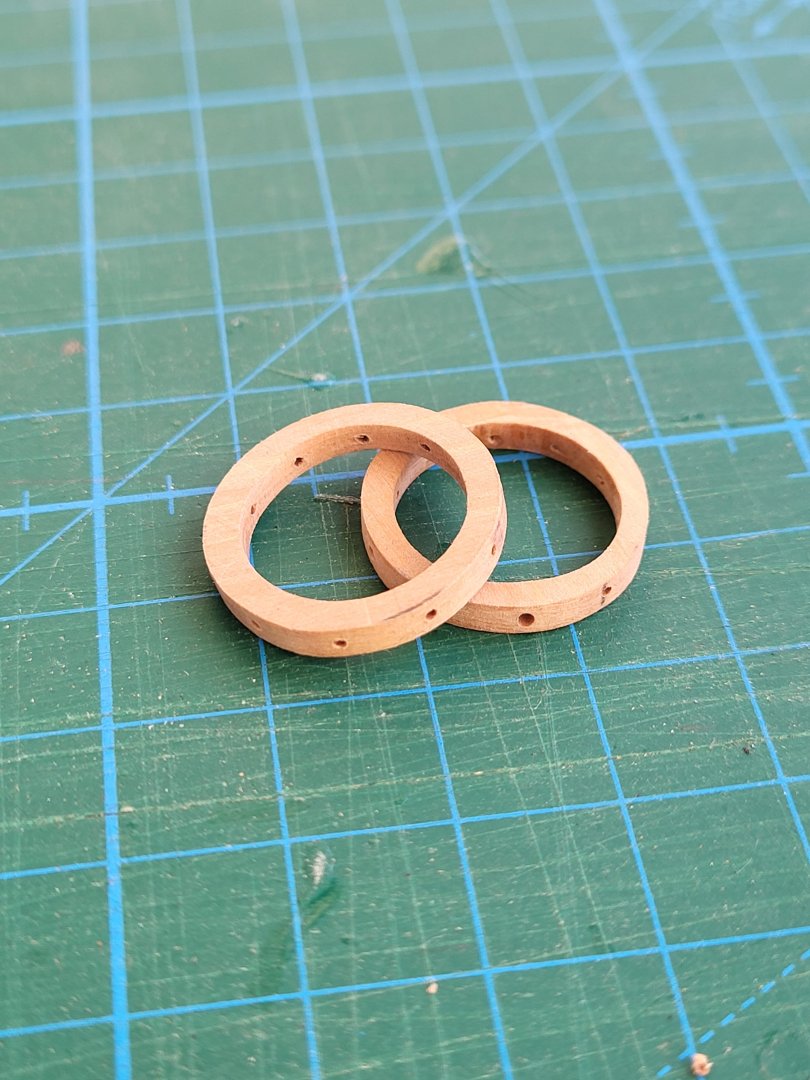

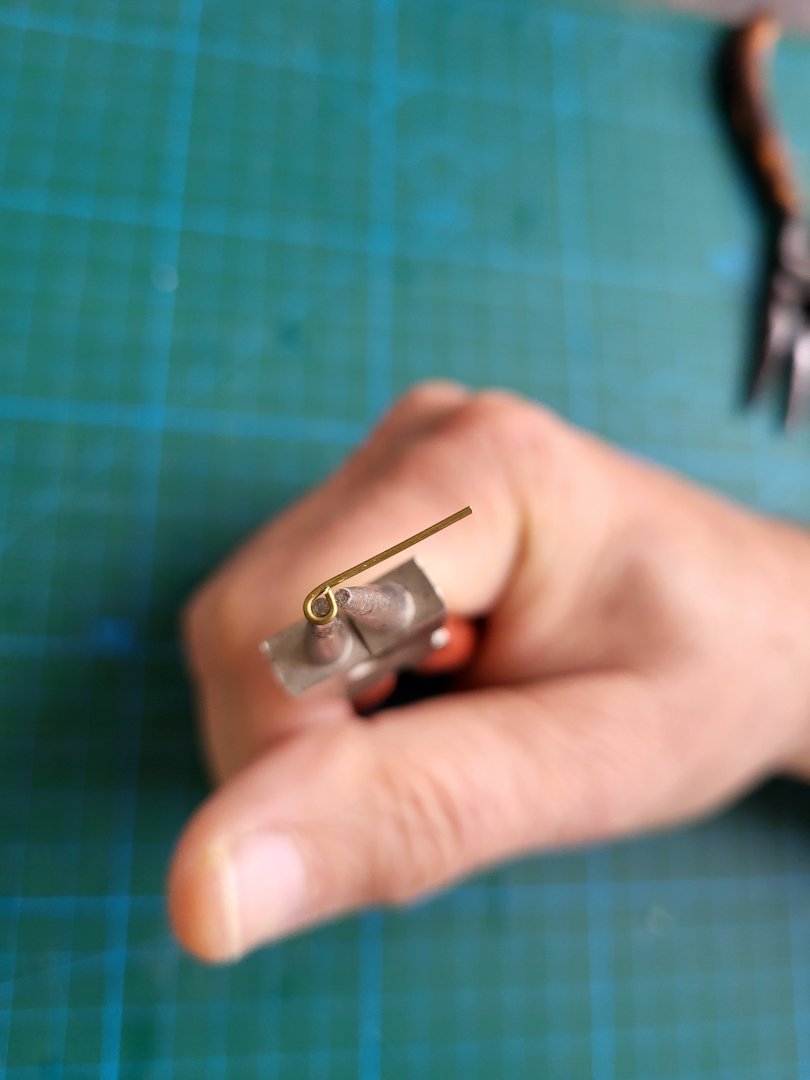

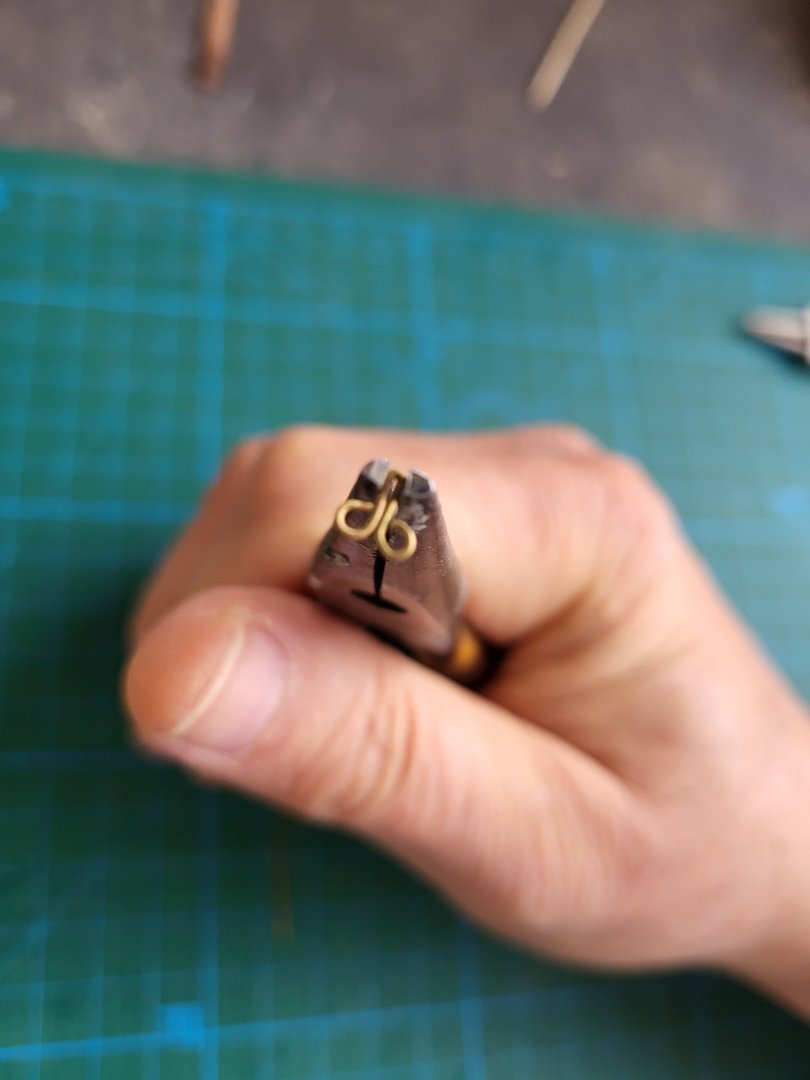

Assembly of the steering wheels done. Since I couldn't find 0.8 mm diameter wooden rod, I made the spokes from metal wire. Later, I will paint them all the same color. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

I didn't want to go down that path because I foresaw that this would happen to me I chose a path that I felt safe in. Also, I wasn't an expert in soldering, but I learned quickly while doing it. Thanks for the steering wheel plans Jon, they will come in handy. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

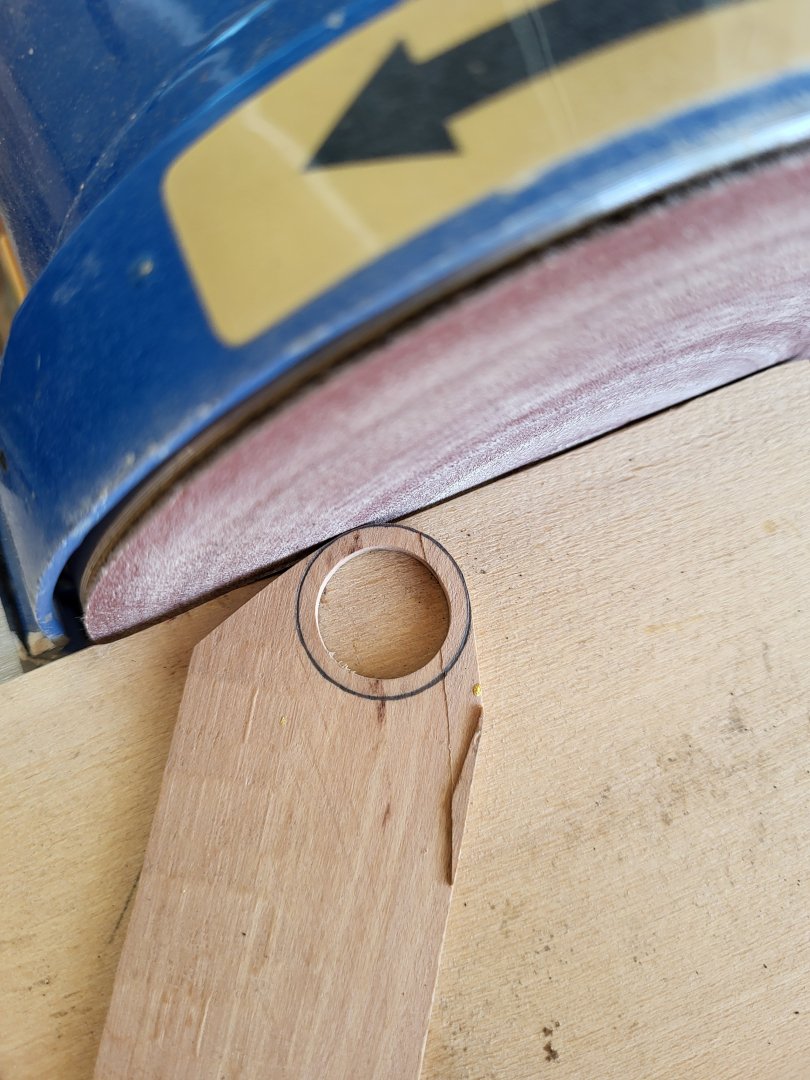

Nope, that's just sandpaper attached to a round stick with double-sided tape. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

-

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Hi Greg, I used 0,7 mm brass wire. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.