-

Posts

389 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Richvee

-

Looks great! Smart move not rigging the cutting tackle at this point. It would be a nightmare rigging that around all the running rigging.

- 38 replies

-

Looks fantastic. Are you planning on rigging the cutting in tackle? If yes, get that in before you get too deep into the braces and running rigging. It's a tough enough rig with nothing in the way. Hope you have fairleads drilled in the fore top if you're going to run bunt and leech lines. It's going to get crowded up there. Don't forget the fairleads on the front shrouds as well. I used bulls eyes

- 38 replies

-

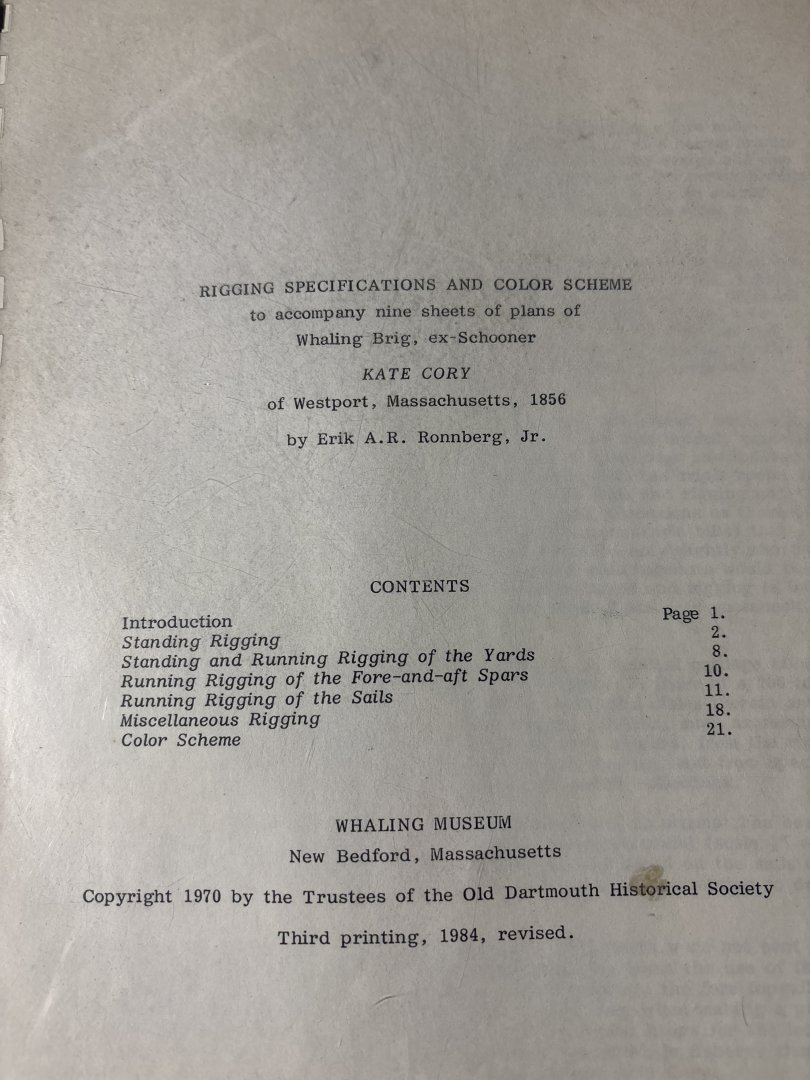

Tom was an asset to me as well. Being my first serious model, the booklet came in handy because it not only told you colors and diameters of ropes, it gave block sizes, where and how lines and blocks weee sized, or belayed, and the path of the running rigging. Wish I found your build sooner. I’ve been more focused on model railroading the past year and a half and haven’t spent much time here. Again - outstanding work!

- 38 replies

-

Great work. Impressive build. When you got the plans from New Bedford, did you get the rigging specs and color scheme booklet by A. R. Ronnberg Jr? There’s a lot of great info in it.

- 38 replies

-

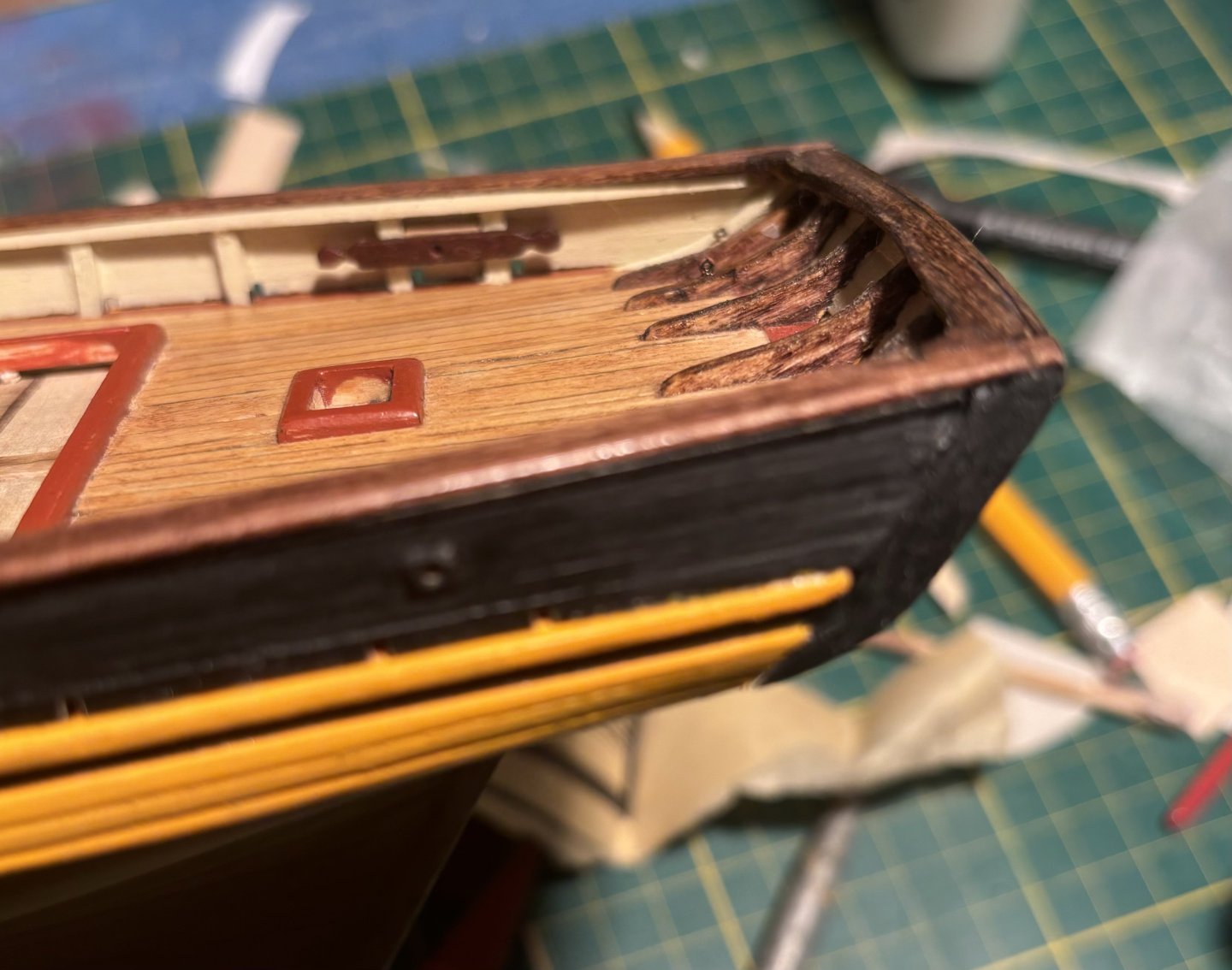

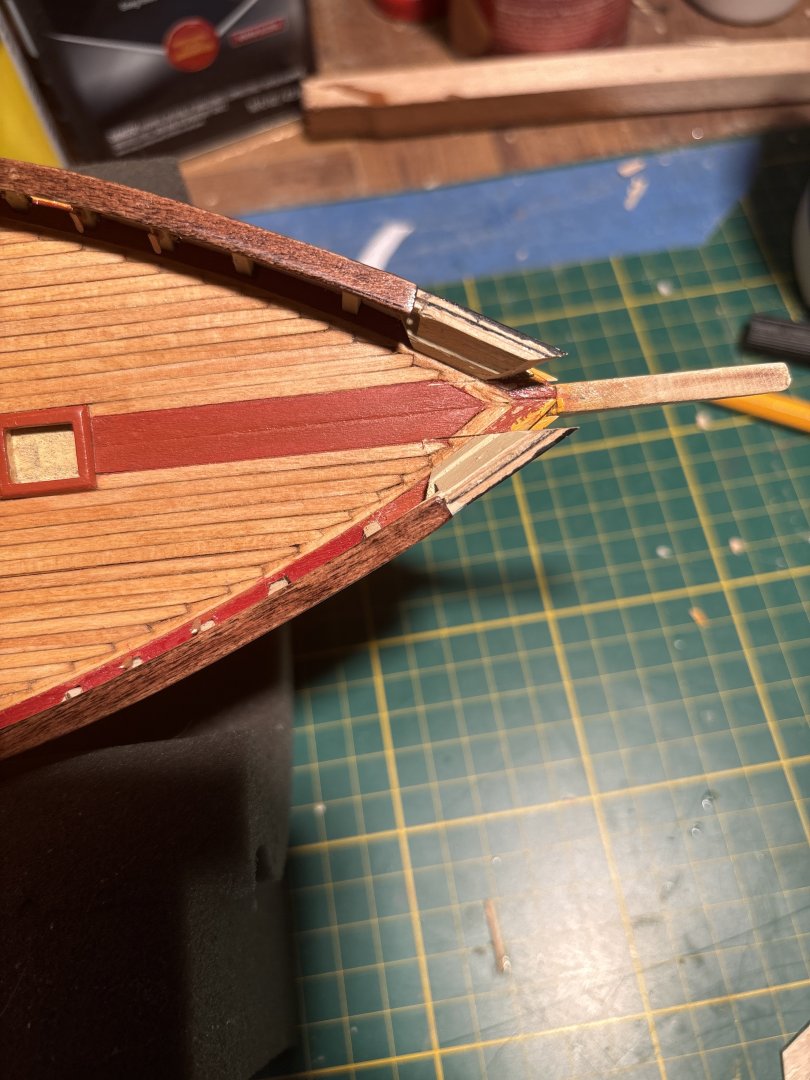

I printed out a tiny Maryland flag and made the shield for the middle of the transom. Can’t add that stuff until I get the letters on there. Some fresh paint in the fashion pieces and transom trim. While I wait for the letters to arrive, I guess I’ll turn to finishing the rail at the bow I also need to drill the howse pipe holes.

- 51 replies

-

- Model Shipways

- Baltimore Clipper

-

(and 1 more)

Tagged with:

-

Work has been progressing at a decent pace. (Well, a decent pace for me😁) I stained the rails, and added quite a few coats of glossy wipe on poly, then I went about securing the rail. I then turned to the sternposts, stained and added the wipe on poly. I then cut and fit the stern rail in place. Again staining and finishing prior to attaching it to the model. Next up was the trim, and side fashion pieces for the transom. I knew this was going to be challenging, because somewhere along the line, the taper of the wales on the sides, and the edges of the stern were not exactly symmetrical-to say the least. So I knew I’d have to do some fudging to make it look at least passable. First I cut the stern trim from cardstock, transferred it to a 3/32” thick sheet, cut and worked it to fit, trying to make the inner curve mask the fact that the sides were slightly different lengths. It ended up looking like this. The fashion pieces were next. These took several attempts, and a lot of fudging from the actual plans to get an acceptable look. Some sanding and painting is next up. In the meantime, I’ve been thinking about the lettering for the transom. I ordered some dry transfer letters. We’ll see if I can apply them and get a decent result.

- 51 replies

-

- Model Shipways

- Baltimore Clipper

-

(and 1 more)

Tagged with:

-

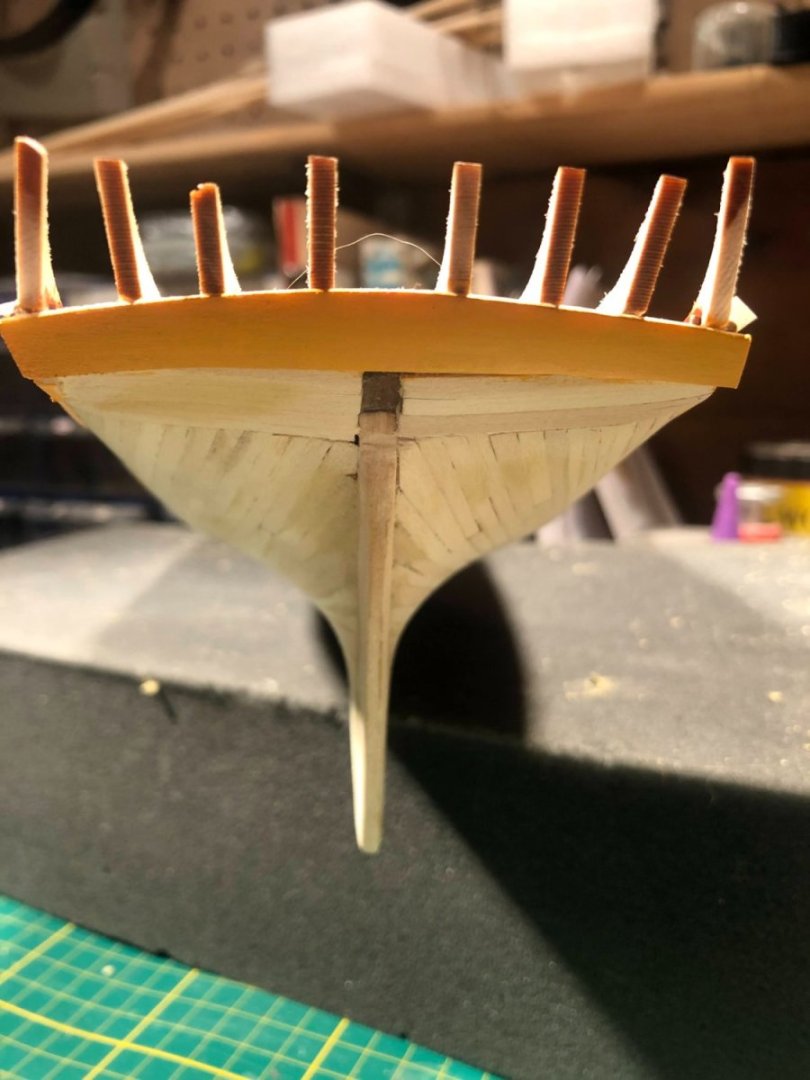

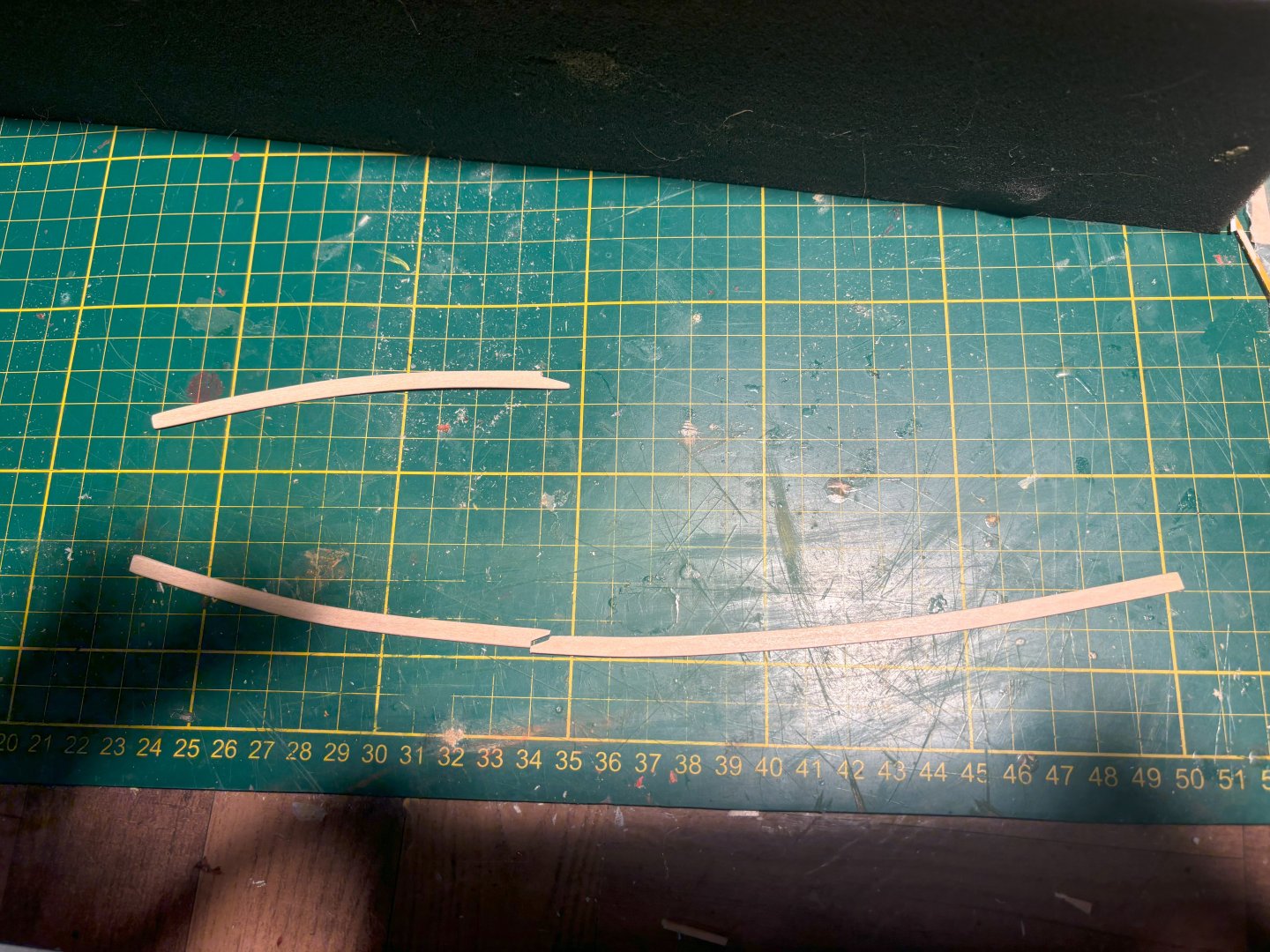

Thanks for looking in and liking! Finished cutting and sanding the top rails today. Here they are just loosely placed in approximate position. The starboard rail is NOT wider than the Port side. I guess camera angle is causing that. I don't think I can hold off dealing with that pesky transom any longer. I reordered some new stern knees because I broke one, and didn't set the angle of the two outside ones correctly. Now it's just a matter of getting a smooth arc across the knees and a rail secured over them. I think I'll smooth out the arc of the posts, cut the stern top rail, test fit, but not glue the stern rail in place until the side rails are mounted.

- 51 replies

-

- Model Shipways

- Baltimore Clipper

-

(and 1 more)

Tagged with:

-

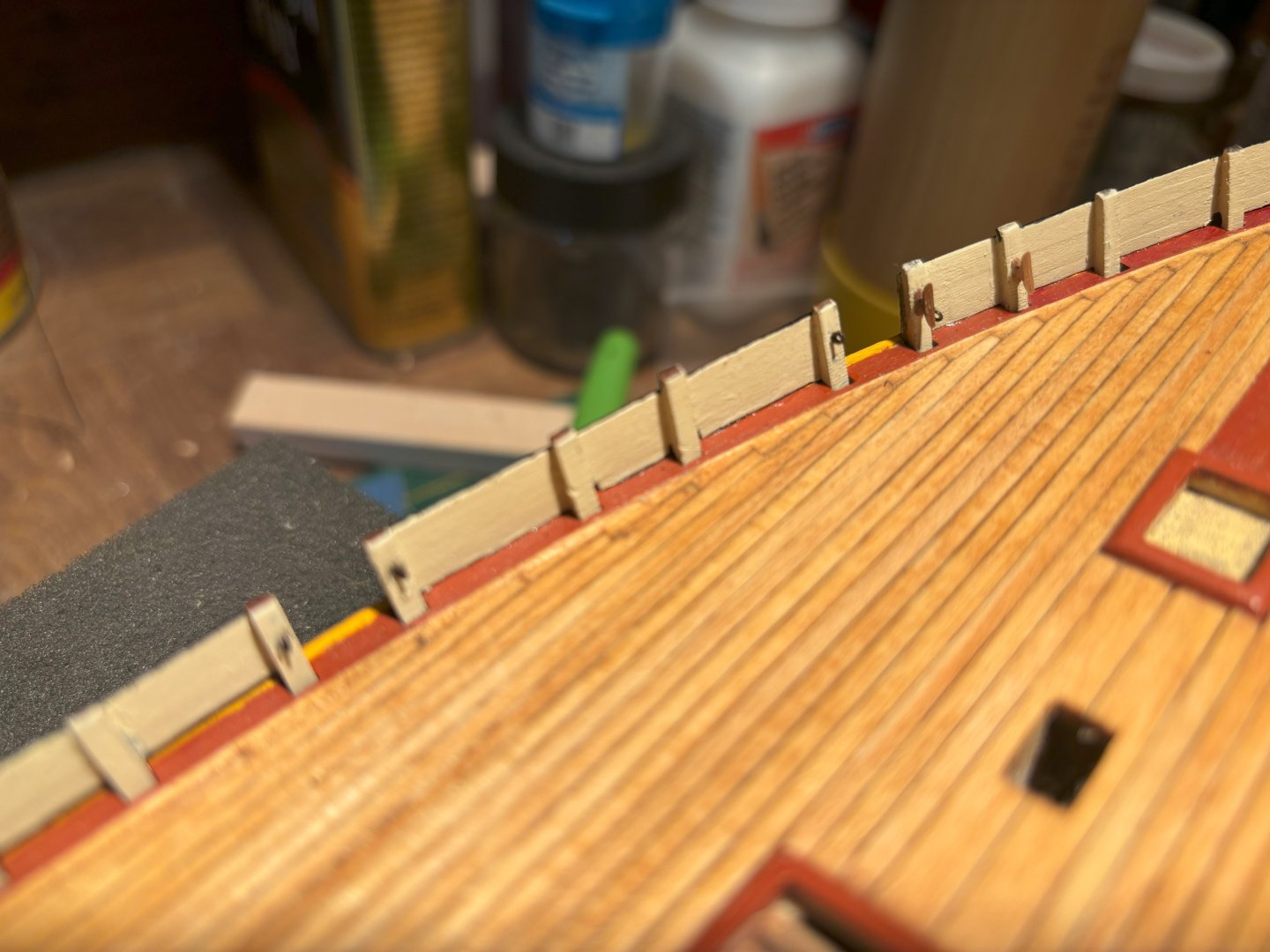

With baseball season over there's some more time to modeling again. Next up was adding cleats, eyebolts, calvils and mooring ports to the bulwarks. Painting and installing. Now that the bulwarks were in place, I added the stringers along the inside and outside that will sit under the top rail. I figured this would give me more area for the top rail to adhere to. Outboard stringer Once they were installed, I sanded the top to make the stringers and stanchions level to accommodate the top rail. Outboard stringer is painted. looks like I may have made those scuppers a bit large. 😔 Haven't painted the inboard stringer yet, but that will be done before the top rail is installed. I started making sections of the top rail. Cutting the right curve to follow the bulwark, a smooth edge, and a uniform width is proving to be quite challenging. I've been cutting the curve of the rail by taping a 1/2" wide, 3/64" thick strip to the workbench. flipping the hull upside down, and tracing along the outboard stringer with a sharp pencil, then cutting that curve about 1/16" past there, giving me the 1/32 overhang and an extra 1/32 to sand the side to round. Then with a divider, measure 7/32" in and scribe a line and cut the inside of the rail, that leaves me the extra 1.32" to smooth and round off the rail. I think I'll stain these pieces before installing. They are to be stained a mahogany color, and pictures of the real ship show they are varnished with a gloss. Here's the start of the rails And placed to test curve and width. So far, so good..Only took about 5 tries to get these three decent pieces done! You'll notice inboard stringer missing at the top of last picture..That's to accommodate the pin rails, which will adhere to the bulwark and the underside of the top rail.

- 51 replies

-

- Model Shipways

- Baltimore Clipper

-

(and 1 more)

Tagged with:

-

Ratlines look great. Glad you liked the sewing method. It ends up with a clean look, and so easy to adjust before gluing and cutting. I came across this technique back when I was a kid building the 1/8" scale Model Shipways Benjamin W Latham in the instruction book. Eric Ronnberg Jr knows a thing or two about modeling. 🙂

- 431 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

Use a needle. Obviously thinner than the shrouds, “sew” the ratlines through the shroud. You can cut each rung long, adjust the curve and tension, then when satisfied dab some diluted white glue to hold the ratline to the shroud. Let it dry, shave off the excess on the outsides of the shrouds.

- 431 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

Don't drive from Mystic to Boston without a stop in New Bedford. The Whaling museum is also a treat.

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Hi Jared. I've been following along silently. Great worK! I agree with Rick. The thinner line looks better. At this scale, I don't think you would lose much detail if you threaded the ratlines rather than tied them off. That might make working with the thinner thread easier. The naked eye can barely pick out the hitches anyway.

- 431 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

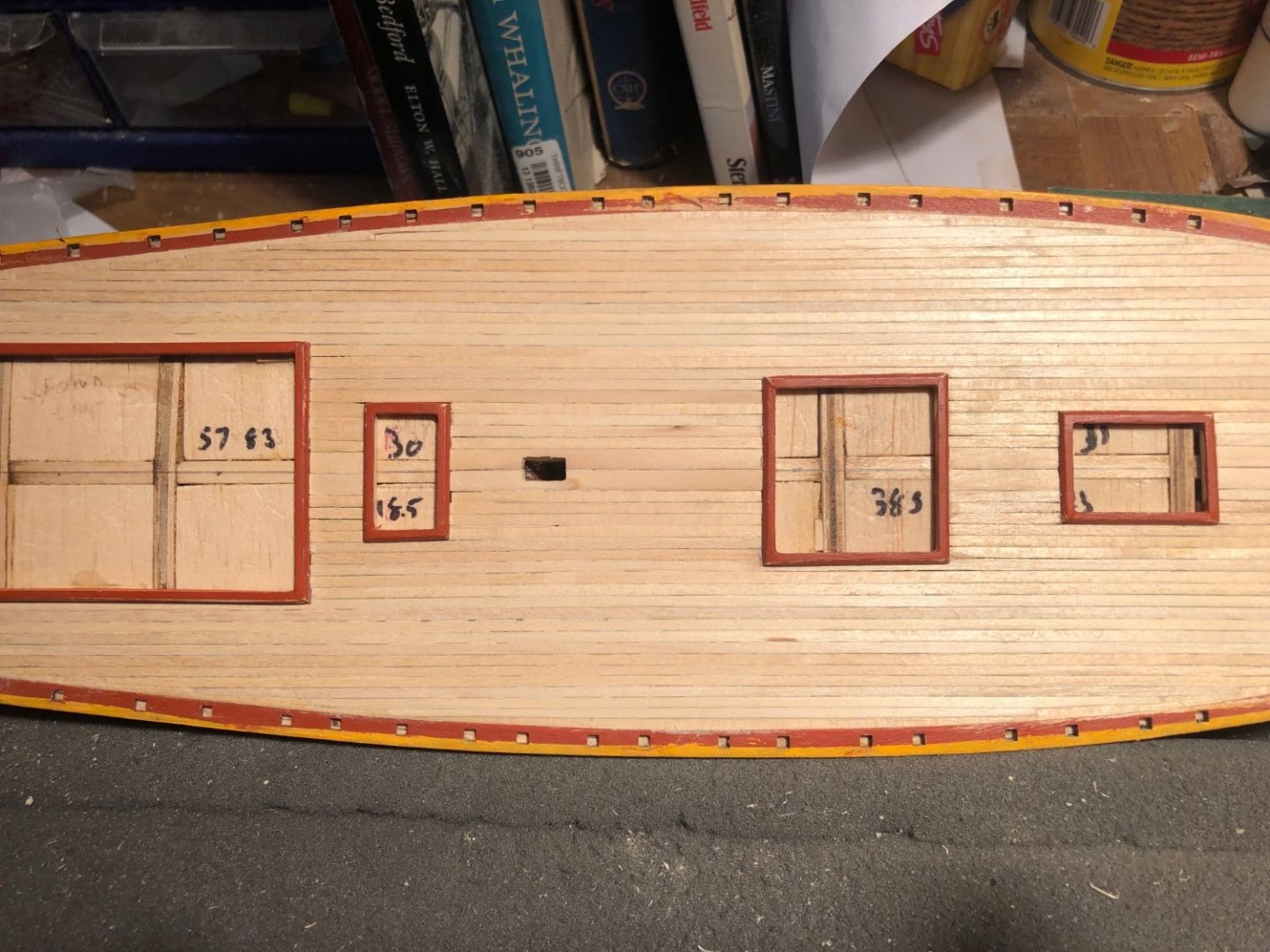

Ten months later, Finally some progress. I didn't realize I never added photos of the stained and poly coated deck. I have also completed the upper bulwark sections. I assembled them off the model. I will paint them and then instal them after adding some inboard details like cleats, rings, etc. The stringers are continuous pieces over the gunport openings, so I'll add them once the bulwarks are installed. Here's a few shots of the bulwarks. Nothing installed ..Just placed for a quick picture or two. Inboard details and paint next up. Hopefully it will be less than ten months before the next update!

- 51 replies

-

- Model Shipways

- Baltimore Clipper

-

(and 1 more)

Tagged with:

-

Deck planking completed. Next I’ll cut in the wide support planks for the fife rail and windlass. Then sanding and staining.

- 51 replies

-

- Model Shipways

- Baltimore Clipper

-

(and 1 more)

Tagged with:

-

Deck planking had been moving at a decent pace. I’ve been sanding a little with 220 grit as I go. Nibbing isn’t as difficult as I thought it would be. I think it’s coming out pretty good. I switched from CA to a wood glue for the deck planking. Gives me a lot more control, and easier to pull up some planks where I wasn’t happy with how they originally looked. A few more planks to finish off, then sanding, and touching up the red combings and planksheer. I also need to cut in the wider boards that sit under the fife rails and windlass. Starboard side completed Soon I’ll need to start considering stain color for the deck. Question—— Do I apply a poly coat on the deck prior to staining? Or stain first, then poly coat?

- 51 replies

-

- Model Shipways

- Baltimore Clipper

-

(and 1 more)

Tagged with:

-

Planking continues at a snail's pace, and my first attempts at nibbing are complete. You can practice, but once you start making cuts into that planksheer, there's really no turning back. So far so good...No major issues. Far from perfect, but I can live with it.

- 51 replies

-

- Model Shipways

- Baltimore Clipper

-

(and 1 more)

Tagged with:

-

Thanks for the likes, all. Some progress. I've cut, sanded, painted, and installed the coamings. I'm sure the paint will need touching up before all is said and done, but this seemed to the best way for me to get a nice clean line of red coaming against the deck. Installing the coamings first also seemed to be the best way for me to get the coamings to look flush to the deck given the deck's curvature, I guess we'll see if how it works out as the deck planking procedes. I have started by installing the nibbing planks to the bulkheads and edged glued to the planksheer. This will be my first attempt at Nibbing plaks so I'm hoping to get the hang of it quickly and not butcher this task. But first, the two wider thicker planks down the center. These are simply one on each side of the centerline, straight down the ship. Can't forget to cut out the decking for the mast holes. Looks like I need to manipulate the fore side of the large cabin coaming. I'll unglue, and add some some wood shims on the port side. That should even out the coaming height side to side.

- 51 replies

-

- Model Shipways

- Baltimore Clipper

-

(and 1 more)

Tagged with:

-

Thanks Eric. I’ve actually just finished the coamings and I have a few coats of paint on them. They’ll be on the deck soon, and the deck planking will begin. I’ll add a few pics when the coamings are installed.

- 51 replies

-

- Model Shipways

- Baltimore Clipper

-

(and 1 more)

Tagged with:

-

The hull has been sanded, I've added the counter planking and the lower half of the transom, and the stern knees. Not sure if adding the stern knees at this point was a good idea, as I've already broke a small piece off one. I'll deal with that when I plank the upper half of the transom. That's not going to be until I have the bulwarks in place because looks like that whole Counter/transom, transom trim, rail, bulwarks is going to take a lot of tinkering to line up and look at least halfway decent. I figured I should get the stern knees in so I can add the planksheer in between them, get them painted before I start planking the deck. I've started a few coats of inboard planksheer paint, and measured out the areas for the deck coamings. That will be the next step. Building, paintig, and adding the coamings and stern planksheer. Then it will be on to planking the deck. The sanded hull The counter and stern knees And the layout of the coamings for the deck fixtures with painted and masked planksheer

- 51 replies

-

- Model Shipways

- Baltimore Clipper

-

(and 1 more)

Tagged with:

-

While planking the counter, and filling and sanding, I’m contemplating the next steps . Looks like there’s several directions I can take and see several different methods to accomplish these things. Once the hull is fully sanded and I’ve added some polyurethane, I think I’m going to add the inboard transom pieces, paint the inboard planksheer and pre paint and install the combings prior to laying the deck. Looking past there, I like the idea of building and painting the bulwarks off the model and then install. Seems that’s the best way to get sharp, clean paint on inside of the bulwarks being that the planksheer, stanchions and rails are different colors. . I’ve got time to figure that out. Sanding, filling, coating, transom, combings, and finally deck planking all before the upper bulwarks. That may take me into 2024 and beyond 😂

- 51 replies

-

- Model Shipways

- Baltimore Clipper

-

(and 1 more)

Tagged with:

-

Well, I've finally managed to finish planking the hull. I think it's OK. Learned a lot along the way, including the fact that cutting, fitting, and installing planks is not my favorite part of this hobby. I have to finish up the counter, and then on to filling some low spots and sanding. Maybe in another year or so I'll have that done 😁

- 51 replies

-

- Model Shipways

- Baltimore Clipper

-

(and 1 more)

Tagged with:

-

Wow. Two years into this build already. It's been sitting quite a while. I've gotten back into the shipyard a bit, and the planking continues. Nothing worth showing, as it's coming along the same as the first side. 🙂. Recently I've been looking over the plans a bit getting ready for the deck planking, stern and bulwarks. Hopefully there's more progress soon.

- 51 replies

-

- Model Shipways

- Baltimore Clipper

-

(and 1 more)

Tagged with:

-

It sure had been a while. I still need to finish planking the other side. It’s been a busy baseball season and that combined with work and house upkeep has kept me out of the shipyard. I’ll get back at it soon.

- 51 replies

-

- Model Shipways

- Baltimore Clipper

-

(and 1 more)

Tagged with:

-

Thanks Bob. Slow and steady. I’ll get there eventually.

- 51 replies

-

- Model Shipways

- Baltimore Clipper

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpg.8dec573b1e998c40e08bfd61857232a7.jpg)

.thumb.jpg.a10aac990d367b0c203a78e8a81eeb86.jpg)