-

Posts

5,518 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by rwiederrich

-

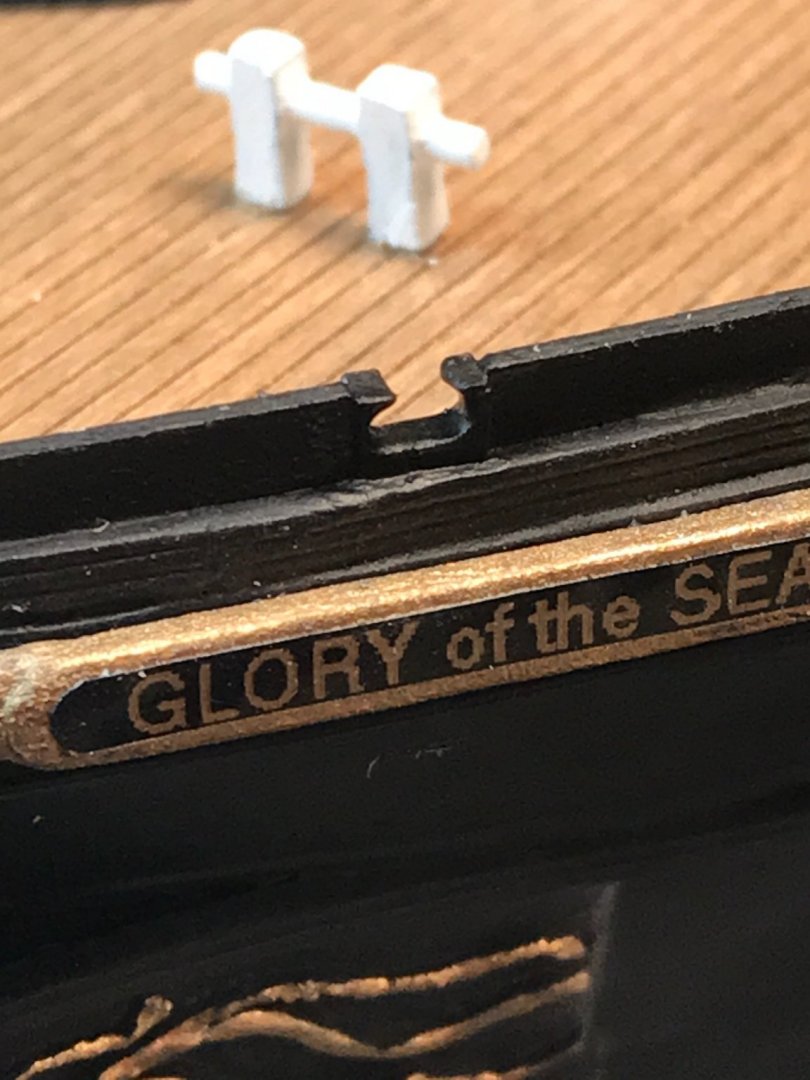

Yeah...but I find great joy in creating my own Glory of the Seas...and it isn't a sad story...it is a satisfying one. Thanks for your fine comments and observations. Rob

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

Doris is a true artisan.......her sculptures are indescribably magnificent. She does use a heat curing clay like material. Truly wonderful. Hey Vlad..one other thing I noticed on your bowsprit. I believe you said you are going to rebuilt it...well, I suggest you correct the sprit CAP. It is not vertical as some caps are. If you look at the pic of Glory at pier side, during her conversion....draw several lines out from the main mast toward the sprit cap. Make those lines the same length...then draw a line vertical down at their edges(Just a grid). You will see that the sprit cap is NOT vertical but leans back and is actually at a right angle to the sprit and jibboom. Some photos give the illusion it is vertical. I noticed this when you made the original bowsprit, but failed to mention it. Sorry. Rob

-

A little money spent now can save a lot of expense later..... However, the Group that owned her wanted FAST money now and foresight was not the attribute they wanted to spend money on. So the scrap man won the argument... Fast money won out again...since they determined she was worth more in pieces then as a whole. Another example that...*The LOVE of money is the root of all evil*. In some small way...if we can build the most accurate model of her...we in essence still have her among us. Now if I can convince Mike to let me make a stand for her from that door he has from her cabins....We will have reached the apex of our intended goal...to reconstruct and display her faithfully. Rob

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

Thanks Rich. I remarked about my speedy pace only derogatorily because it generally means I lack the greater character trait of patience. Sometimes I can’t wait for paint to dry. I do appreciate every fine comment and accolade I receive…….I truly do. I’m hard on myself because I know I could do better, but I’m to lazy to correct it. Im working out the details for making the aft rail and all its complexities. I’ve learned a lot about it’s design in my studies. It’s quite ingenious. McKay was a real thinker Rob

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

Thanks Pat. If anyone knows my building techniques (Great Republic), they will know I’m not slow but work at a rabbits pace. One of my many faults…….. Rob

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

Thanks Michael. She was made from dental light cure acrylic and other dental materials. whatever I have on hand IS the material of choice. Thanks for peeking in Rob

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

Thanks Rich, I plan on keeping this anchor suspended as it is, and have the other hanging from the cat head via it’s internal blocking. Both of these anchors will be removed when I begin work on the channels. Rob

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

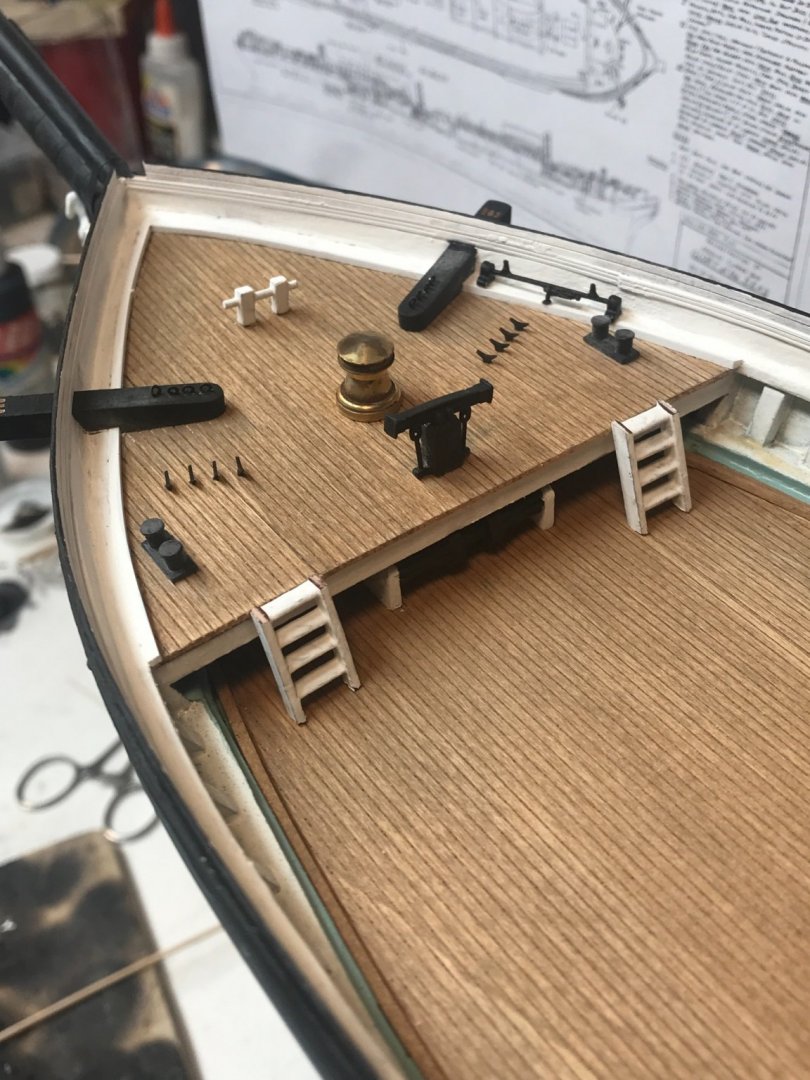

Thanks Vlad, The release mech’s are just under an inch long with their pillow block bearing mounts. Rob

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

Your drawings are amazing Rich. Looking good.

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

I read somewhere that the capstans were a special patented version. A more modern version then what Webb used on his nearly 20 Year older clipper. Rob

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

Worked on the cat release or anchor release mechanism For the starboard side. I also added the cleats for the fairleads for the jib sails and their stays. The ladders are just mocked right now

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

The real capstan didn’t have any brass on it…….it was wood and iron. I’m not sure she didn’t have an all iron one either. Rob

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

I couldn’t make two exactly alike ……so this one is an after market one. Not sure I will use it though. Rob

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.