-

Posts

346 -

Joined

-

Last visited

About Tomculb

Profile Information

-

Gender

Male

-

Location

Spokane, Washington

-

Interests

In addition to model ship building . . . bicycling, kayaking, hiking, pickleball, sailing, travel, reading

Recent Profile Visitors

-

Tomculb reacted to a post in a topic:

Lynx by Gaffrig - Panart - Scale 1:62

Tomculb reacted to a post in a topic:

Lynx by Gaffrig - Panart - Scale 1:62

-

Tomculb reacted to a post in a topic:

HMS Beagle by usedtosail - OcCre - 1:60

Tomculb reacted to a post in a topic:

HMS Beagle by usedtosail - OcCre - 1:60

-

Tomculb reacted to a post in a topic:

HMS Beagle by usedtosail - OcCre - 1:60

Tomculb reacted to a post in a topic:

HMS Beagle by usedtosail - OcCre - 1:60

-

Tomculb reacted to a post in a topic:

Endurance by Pierre Greborio - OcCre - 1:70

Tomculb reacted to a post in a topic:

Endurance by Pierre Greborio - OcCre - 1:70

-

Tomculb reacted to a post in a topic:

HMS Beagle by usedtosail - OcCre - 1:60

Tomculb reacted to a post in a topic:

HMS Beagle by usedtosail - OcCre - 1:60

-

Tomculb reacted to a post in a topic:

Endurance by GeneralNuisance - OcCre - 1:70

Tomculb reacted to a post in a topic:

Endurance by GeneralNuisance - OcCre - 1:70

-

GeneralNuisance reacted to a post in a topic:

Endurance by GeneralNuisance - OcCre - 1:70

GeneralNuisance reacted to a post in a topic:

Endurance by GeneralNuisance - OcCre - 1:70

-

Knocklouder reacted to a post in a topic:

Endurance by GeneralNuisance - OcCre - 1:70

Knocklouder reacted to a post in a topic:

Endurance by GeneralNuisance - OcCre - 1:70

-

The way I look at it, if it looks good to you, then do it! Even with the large number of Frank Hurley photos out there, there is no right way to do this model (or any other one), because ships like this are not static; they change almost day to day. I had a lot of fun making my Endurance unique; not better, just unique. You have the opportunity to do the same. I've seen this photo many times, but I have yet to see a model with a dinghy lashed to the ratlines. Looks like a great addition.

-

Tomculb reacted to a post in a topic:

Endurance by GeneralNuisance - OcCre - 1:70

Tomculb reacted to a post in a topic:

Endurance by GeneralNuisance - OcCre - 1:70

-

Tomculb reacted to a post in a topic:

Endurance by Pierre Greborio - OcCre - 1:70

Tomculb reacted to a post in a topic:

Endurance by Pierre Greborio - OcCre - 1:70

-

Tomculb reacted to a post in a topic:

Endurance by Pierre Greborio - OcCre - 1:70

Tomculb reacted to a post in a topic:

Endurance by Pierre Greborio - OcCre - 1:70

-

Tomculb reacted to a post in a topic:

Endurance by GeneralNuisance - OcCre - 1:70

Tomculb reacted to a post in a topic:

Endurance by GeneralNuisance - OcCre - 1:70

-

clearway reacted to a post in a topic:

Endurance by Tomculb - FINISHED - OcCre - 1:70

clearway reacted to a post in a topic:

Endurance by Tomculb - FINISHED - OcCre - 1:70

-

Jared reacted to a post in a topic:

Endurance by Tomculb - FINISHED - OcCre - 1:70

Jared reacted to a post in a topic:

Endurance by Tomculb - FINISHED - OcCre - 1:70

-

TerryPat reacted to a post in a topic:

Endurance by Tomculb - FINISHED - OcCre - 1:70

TerryPat reacted to a post in a topic:

Endurance by Tomculb - FINISHED - OcCre - 1:70

-

Dr PR reacted to a post in a topic:

Endurance by Tomculb - FINISHED - OcCre - 1:70

Dr PR reacted to a post in a topic:

Endurance by Tomculb - FINISHED - OcCre - 1:70

-

Years ago I used Bondo, but it's fumes are terrible and I don't use it (or recommend it) anymore. I think it was Nic at BlueJacket that suggested spackle, which in my experience is used mostly for small holes and cracks in drywall. It's most commonly found in powder form, which needs to be mixed with water, but I found some spackle paste lying around the house, which is pre-mixed. I usually find myself "digging" a shallow hole in what's in the container and mix in a few drops of water to get the consistency I want. I find it works really well and is very easily sanded. Only drawback is that it's white, so it's only appropriate for wood that's going to be painted.

-

Canute reacted to a post in a topic:

Chris Watton interview

Canute reacted to a post in a topic:

Chris Watton interview

-

thibaultron reacted to a post in a topic:

Chris Watton interview

thibaultron reacted to a post in a topic:

Chris Watton interview

-

Ryland Craze reacted to a post in a topic:

Chris Watton interview

Ryland Craze reacted to a post in a topic:

Chris Watton interview

-

chris watton reacted to a post in a topic:

Chris Watton interview

chris watton reacted to a post in a topic:

Chris Watton interview

-

Nice work Chris as an interviewee, although I suspect all of us at MSW would appreciate your holding on to your day job as a model ship kit manufacturer, saving your stage and screen career for the occasional cameo appearance. 😀 Since the subject of future projects has come up on this post, I thought I would throw in my two cents. How about a model of the HMS Beagle? Although initially launched as a brig sloop (perhaps a successor to Harpy?), she was converted to a bark before she went anywhere, and she came along several years after that ship. And although launched as a man-of-war, she was used almost exclusively for surveying. Most obviously, what made her famous was the renowned scientist on her second voyage, Charles Darwin. Given her design, era, and history, I think she would be a unique addition to your collection of kits. And after my recent experience with OcCre’s Endurance, I know you would produce a far better kit. Personally, I am itching to get started on Grecian (which I bought several months ago), but given the holidays, it may be a while. I may do a build log, but only if I feel I can add something to the excellent logs of those who have preceded me. This looks like a magnificent kit. This is the first time I first chose a kit based on the manufacturer, then only with that decision made, chose the ship I would model.

-

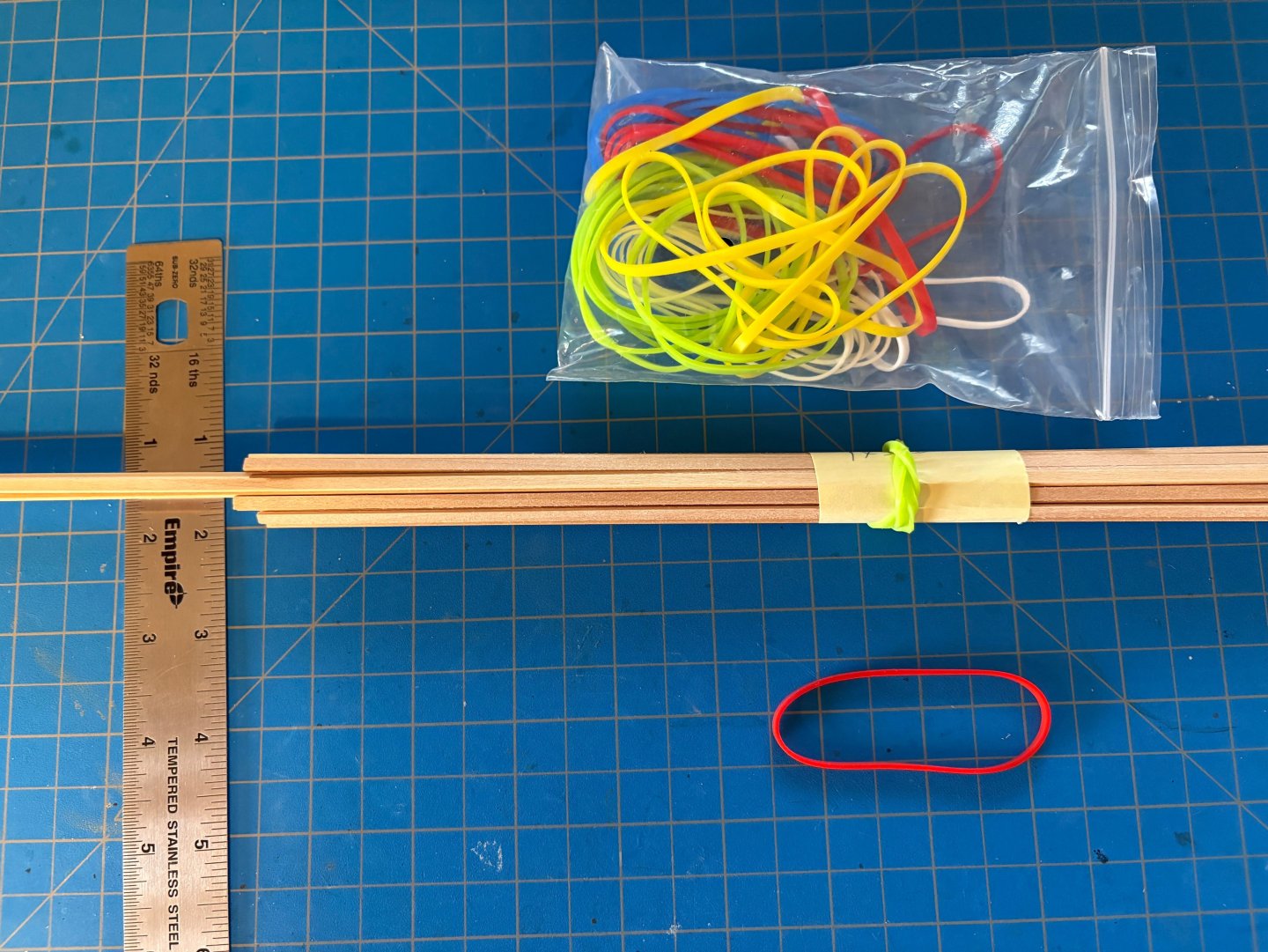

I suspect what you really meant was bicycle tubes, not tires, as you really can't stretch bike tires. Tubes are much more stretchy, so if you cut a few 1/8" bands from a tube, you might have something like a rubber band. I usually have reasons to visit bike shops with some frequency, so I'll give that a try. My only concern is their durability, if they are in fact made of rubber like rubber bands are. A bike tube lives a very long time (assuming you don't get a flat), but it lives in a sealed environment, unlike rubber bands. Let us know if you've used your bike tube bands long enough to know whether they won't deteriorate after a couple of years or so. Doing some Google sleuthing, I learned that the best bands for durability are silicone bands. They are widely available on Amazon. They are used for a variety of purposes, including cooking, since they do not melt at temperatures used in cooking. Their downside is that they don't stretch very well. I bought some 3" long ones, seen in the picture below. Triple banding one so as to hold the roughly 3/4" diameter bundle of strips in the picture below took enough force that I was afraid I might crush some of the wood. Double banding was too loose to hold the wood together. Bottom line is that they don't work very well for my purposes.

-

A bit belated on my part, but . .. congratulations on a great build, Chimp. Beagle is on my "someday" list, so it's nice to know there's another log for me to follow when I get around to doing my build. In addition to being a pretty ship, I like the idea that Beagle is best known not for its prowess as a ship of war, but for its most famous passenger, Charles Darwin. If you ever get to Ushuaia (assuming you haven't been there already), you'll find that it sits on the Beagle Channel, and its museum has a nice model of the Beagle. Again, congratulations on your beautiful build, and for the great work you're doing on Granado.

-

I haven't been to the post office yet, but the USPS website shows maybe 2 dozen boxes they have available, and none of them are what I want. Thanks for your suggestion Dziadeczek, but the space I have available is horizontal, not vertical. Also, many of my wood strips are considerably shorter than others. My plan would be to cut off the lids, thereby opening up the entire length of the top of each box to facilitate finding what I want.

-

Of the various methods of storing and organizing wood strips described in this forum, the one that would probably work best for me are the 2x2x24 inch mailing boxes. Going online, I see that they are readily available, but only if you want to buy 50 of them for about $50. Far more than I need. Also looked at the UPS Store and similar outlets, without any luck. Has anyone found a source for maybe 10 of them, at a reasonable price?

-

Thanks for the likes and all the kind words. I do hope others will find some usefulness reading my log, since I have been inspired by the logs and comments of many many others on these boards. I hope to see some other Endurance builds; it's definitely a fun project.

- 206 replies

-

- Endurance

- Shackleton

-

(and 2 more)

Tagged with:

-

Several posts on this board reveal some great ideas for storing and especially organizing quantities of wood strips. Often I find it useful to put say all 2mm thick strips in one tube or bag, then separate in that tube or bag the 4mm and 5mm wide strips using rubber bands. But a year later when I need a 2 x 4 strip, the rubber bands have disintegrated into hard brittle pieces. Does anyone know if there is such a thing as a durable rubber band, that will serve its purpose more or less indefinitely? I haven't found one.

-

I can now say that after more than 2½ years, my Endurance build is finished. And it has been a wonderful journey. This is my first build with considerable kit-bashing. Doing a lot of research, especially Frank Hurley photos of the ship posted various places online, and then incorporating what I found into the build, was fun and rewarding. I also enjoyed and benefited from others' build logs, but at the same time I was a bit disappointed that so many that were underway when I started (at least a dozen or so) had disappeared unfinished by the time I finished. I think Chris Coyle’s @ccoyle review of the kit matches my sentiments pretty precisely, when he says “The new OcCre Endurance is not what one would call a great kit, but it is by no means a bad kit either. OcCre has economized here and there . . .”. The many modifications I made along the way are described in my log, and there are many more things I could have done but didn’t. Among the latter would be planking the insides of the bulwarks, using better blocks and line from the likes of Vanguard and Syren, and building ships boats that looked more like Endurance’s boats and not so much like OcCre’s. The one thing I did do for which there is no historical justification was to break up the two rows of dog kennels. I’m a little doubtful as to whether that was the right decision, but I’m not losing any sleep over it. I have two kits awaiting my attention: the NRG’s half hull project, and Vanguard’s Grecian. I would like to develop the skills which the NRG kit would hopefully provide me, but Grecian would be a lot more interesting and fun, so I’m almost certain that will be next. It is the first time I have selected a kit manufacturer, then decided on the specific model I wanted to build. I’m thinking it unlikely that I will be doing a build log since there are already quite a few excellent complete ones for both kits. I don’t know that I’d have anything to add to what is already out there. On the other hand, I had that concern about doing a log for Endurance, and now I’m glad I did it. Finally, here are some photos (some better focused than others) . . .

- 206 replies

-

- Endurance

- Shackleton

-

(and 2 more)

Tagged with:

-

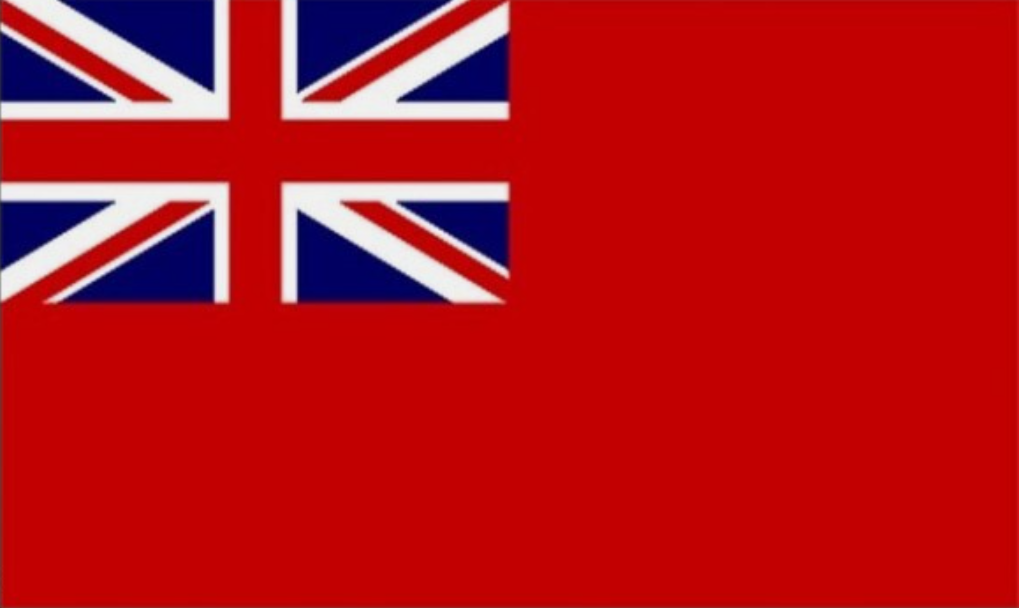

The final task I have been working on is installing the OcCre supplied flag onto my ship. That flag comes as one piece, to be folded in half so that you end up with a flag showing on both sides. After reading a few posts on these forums about making flat flags look much more realistic, I experimented with a flag (cut into two flags) I had left over from a prior build, also intended to be folded in half. I coated the back side of the experimental flags with diluted white school glue (what I use on knotted rigging), lay a piece of thread down the middle as its halyard, and folded the flag in half and let it dry overnight. Once dry, I found I could bend it around a small dowel and I could unbend it and try again if I didn’t quite get the look I was hoping for. So I got up the courage to try this with the Endurance flag. The halyard stayed loose despite the glue, but with the help of some of my tiny clothespins, I hung the flag from the block I had tied to the end of the mizzen gaff months ago. Even before trying to give it some curls and furls, I wasn’t too happy with the result. To my eye, it looked too big and too bright. I calculated that the real thing would be 12' by 5.5’. On the model, it would be the first thing an observer’s eyes would be attracted to. Also, the flags I experimented with were made of somewhat different material from the OcCre/Endurance flag. Unlike the first material I worked with, when I tried to fold and curl the Endurance flag, it didn’t want to stay that way, and the two sides of the flag began to separate. After digging through lots of photos of the real thing, I found one showing Endurance leaving Buenos Aires with a flag which looks noticeably smaller. It was also dark, not mostly white. That led me to inquire of Professor Google, who informed me as follows. The white ensign supplied by OcCre was/is for British naval vessels. British commercial ships display the red ensign, three quarters of which is red, not white. Endurance wasn’t a naval vessel, so its flag should be the red ensign. If any of our knowledgeable British friends (or others) on these boards know otherwise, please let me know. Bottom line, I decided to abandon the flag. My final, finished post will come along shortly.

- 206 replies

-

- Endurance

- Shackleton

-

(and 2 more)

Tagged with:

-

One thing I forgot to mention. The most recent issue (Autumn ‘25) of the Nautical Research Journal has an article by Dick Ritchie entitled “The Twelve Rules of Successful Model Building”. While I think most of the article would be a must-read for beginners (and many of the rest of us), I take issue with his Rule 6, when he says “Identify and fix mistakes before moving forward.” Sometimes subsequent building will render a later fix too difficult or impossible, but if that is not the case, I usually wait for another day to fix mistakes. The reason is that if I do the fix right away, my mind is at least half occupied wondering why I was so stupid as to make the mistake. If I wait a while (sometimes a long while), my mind is completely dedicated to the fix. I mention this because at least a year ago I snagged one of my anchors on something, dislodging the cathead from the deck and pulling out one of the eye rings used to lash the anchor to it. A few days ago I finally got around to doing the fix. It was difficult given all the rigging and fixtures which surround it, but it was doable since my mind was in the right place. I didn’t take a before picture . . . only after. One more task and I'll be finished! 😄

- 206 replies

-

- Endurance

- Shackleton

-

(and 2 more)

Tagged with:

-

A few small things since my last post . . . Finished the mizzen ratlines, including those on the futtock shrouds . . . Added aft two pair of mizzen shrouds . . . Did a do-over of the port aft ship’s boat aft lanyard coil. Decided to leave well enough with the forward one of those coils. Some time ago I glued a couple of OcCre supplied bollards to the aft deck (in addition to the two already on the anchor deck). OcCre would also have you place bollards at the fore and aft corners on either side of the lower deck, which raised an issue in my mind. Bollards like that are usually used for docking and perhaps towing lines only, not standing or running rigging. But such docking lines would be led directly from the bollard to the dock, not up and over the bulwarks as would be necessary as placed by OcCre. Which made me realize that dock lines would best run through scuppers, whose main purpose was to drain water off that lower deck. But neither OcCre, nor any of the plans I have seen for Endurance, show such scuppers. Were there some sort of internal drain pipes to drain water? Scuppers would be more efficient and more common, in my view, but what do I know? Had I thought about it at the time I probably would have drilled or carved some scuppers along the bottom of the bulwarks, but it’s too late now. In any event, I chose not to install bollards on that lower deck.

- 206 replies

-

- Endurance

- Shackleton

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.