-

Posts

311 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Tomculb

-

-

Hi Mark. No, I haven't thought of anything I want to do with those kennels, even though I agree with your characterization of them. Maybe I should put some thought into that. Probably wouldn't add dogs, because then I'd think I need to add people, and I don't really want to do that.

Different subject . . . I took a look at your Lynx log, which is coming along really nicely. I'm about 80% sure that my next build will be Vanguard Model's Baltimore Clipper Grecian. Despite the fact that Vanguard models are highly detailed and result in beautiful models, I may do some modifications (mostly cosmetic) to make my model more of a generic Baltimore Clipper instead of the specific one Vanguard chose to model. To get ideas, I've been looking at other Baltimore Clipper build logs, along with pictures of and articles about other Baltimore Clippers. So far, this is only fun window shopping.

-

Before rigging the mizzen mast, I needed to finish rigging the main mast; that is, I needed to rig the gaff sheets that have been hanging from the main gaff for a few months now. OcCre has you simply secure them to eye bolts installed in the outer edge of the deck, but as I have said before, securing running rigging that way just doesn’t seem right to me. I decided on a double block (secured to an eye bolt at the edge) and a cleat (glued to the deck). OcCre doesn't supply cleats, but I had ordered some online knowing that I would need them.

Rigging the sheets that way meant I had to make a decision about the dog kennels. As the kit is designed, they get in the way of any rigging of those gaff sheets. Personally, I don’t like the look of those kennels anyway, but they were certainly part of Endurance once she headed south from Buenos Aires. What to do about the kennels has rattled around in my brain for a long time now, and I couldn’t put off the decision any longer.

What I decided to do was break each of the two strings of kennels into three parts, leaving some space for rigging and for access to the two aft ships boats (yet to be built and installed). Not historically accurate, as reflected in Frank Hurley’s photographs, but then the two uniform rows of kennels as contemplated by OcCre isn’t very accurate either. The kennels reflected in those photos are pretty ramshackle and haphazard in appearance.

Once the kennels could be placed I was able to secure the gaff sheets as described above. I also installed stays for the funnel. And I secured the lowest stay between the main mast and the mizzen to an eye bolt just behind the funnel.

Now I can start to work on running rigging for the mizzen mast.

-

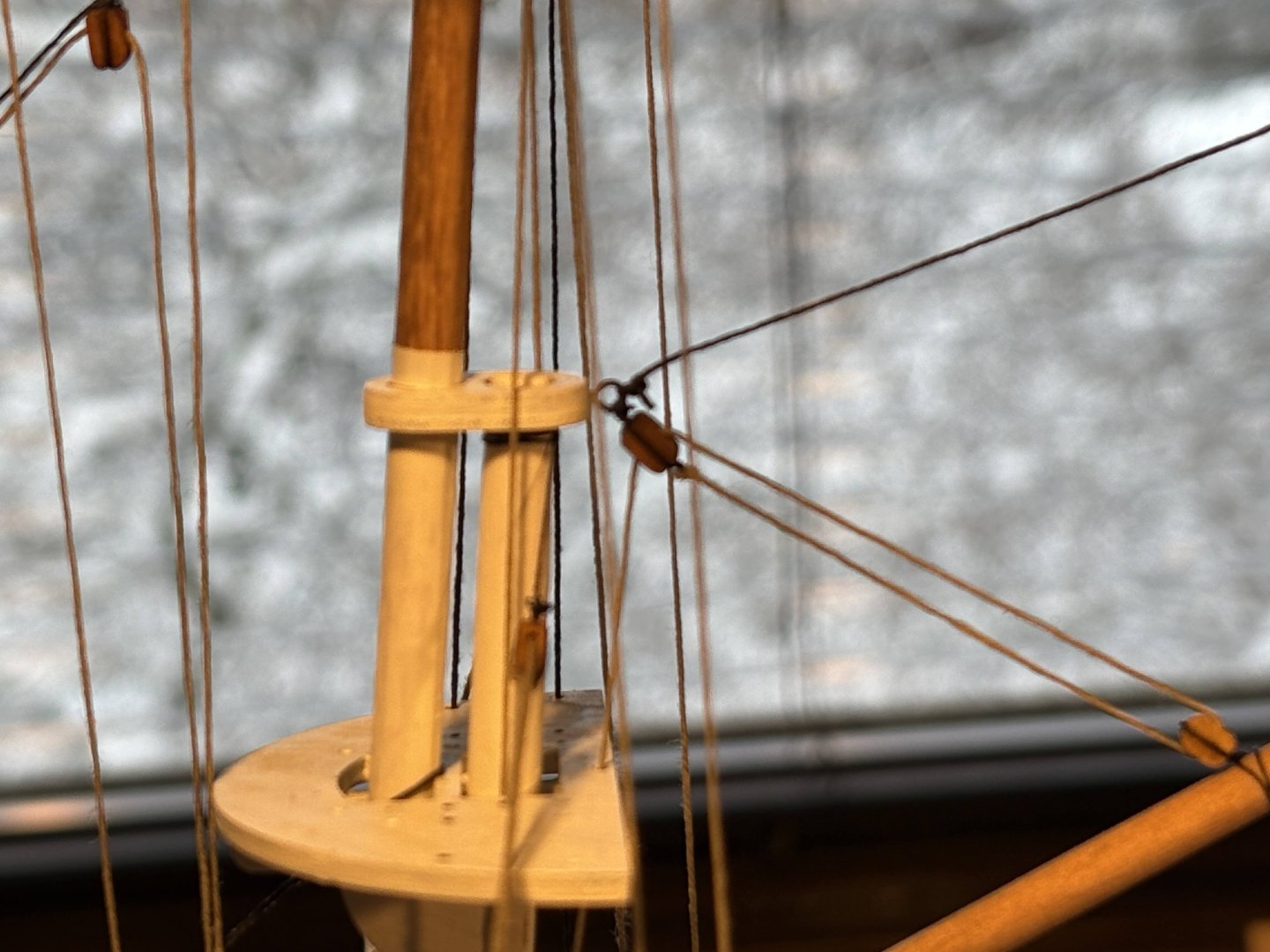

Quick update; the mizzen mast has now been assembled. The base of the mast has a slot that it fits into, deep inside the hull. That slot leaves a little wiggle room, and the eraser you see in the photo leans against the mast pushing it forward enough to have its rake conform to the other two masts. Obviously not glued in place yet, and it won't be until I have blocks and any other fittings tied to it. I may also rig the gaff and boom before gluing the mast in.

Every spring for a week or so I am treated to our magnolia tree in full bloom, out the window behind my shipyard. The picture doesn't do it justice . . .

- king derelict, ccoyle, gak1965 and 1 other

-

4

4

-

Your model is progressing really nicely. Planking the inside of the bulwarks looks really nice. As I mentioned in my log, I wish I had thought of doing that. I admire your willingness to try many varieties of things (ladders and doors most recently) to get just what you want; I don't have that patience. From the look of things, you trashed some ladders I would have found quite acceptable. Keep up the good work.

-

- The Gimps Chimp, ccoyle, SaltyScot and 3 others

-

6

6

-

After an unfortunate mistake and some travel interruptions, I have now finished one of the two forward ships boats. As I mentioned in an earlier post, I chose to stow the forward boats inboard rather than hanging outboard from the davits as OcRre does, and chose to stow the smaller pair of boats forward, since the larger boats barely fit forward and inboard.

I used some 1/32” strips for planking, since they are slightly thinner and bend more easily than the OcCre supplied 1 mm planks. As usual for me, the planking job looked abysmal and required much sanding and filling to hide my lack of skill when it comes to hull planking.

The ugly . . .

Now for my big mistake. The laser cut stem pieces have a longer end and a shorter one, and without noticing that difference, I glued them in place with the longer ones running along the bottom of the hull, which wasn’t correct. I found nothing in the instructions alerting the builder to this important distinction. In the following two pictures I have added tiny 2mm x2mm pieces to bring the stems above the laser cut rail cap piece as intended, but I still have some sanding and filling to do to make things look acceptable.

The bad . . .

And finally, after installing flooring planks, seats and the rail cap, the good . . .

Some months ago I built the structures to stow these boats inboard, and I have now glued them in place, after adding eyebolts for the lashing that will hold the boats in place. The planks that run between the two decks are dry fit in place for now, as is the one boat I have completed. Now on to that second boat, with the hope that I have learned some things that will make things go more smoothly.

- clearway, Giddy Gibberish, gak1965 and 1 other

-

4

4

-

Great work Giddy, and glad you have found my build log to be helpful. A few comments . . .

I like the color of stain you chose for the deck planking; it looks really authentic and certainly better than what I chose.

Based on several recommendations on these boards, I use Birchwood Casey's Brass Black to blacken virtually all the brass on my models. Search the name on the MSW website and you'll find a number of tips on how best to use it. It's a pretty easy process and the results are good.

Endurance had a wooden railing on top of the stanchions at the stern, which I overlooked when I installed those stanchions. I keep telling myself that I should go back and clip the tops off the stanchions (eliminating the upper cable), cut out a wooden railing using my jewelers saw, somehow drill holes in the right places to accept the tops of the stanchions, and glue the wooden railing in place. I haven't yet built up the courage to do that. If you choose to do so, it looks like you still have the opportunity to use the laser cut railing that OcCre supplies and has you install at deck level, and install it on the tops of the the stanchions instead. Or copy the supplied railing to make a second one for the top.

I look forward to following your build.

Tom

-

The foremast standing rigging is now complete, with the addition of three more shrouds on each side of the mast.

With my attention focused on securing these shrouds to their deadeyes, and then lashing the pairs of deadeyes together, I wasn’t paying much attention to where I had wrapped each port and starboard pair around the mast. The lower pair was run through the top, no problem there (and no picture). The middle pair was secured to the mast just below the mast cap, and somehow the lashing slipped and it got twisted off center a bit. At this point I don’t think there is any way to remedy the problem. Fortunately it is not as evident to the naked eye at a viewing distance as it is in a close up photo. The pair secured at the top of the mast is much better, although the several lines secured there are a bit messy (again, worse in the photo).

I also finished installing the braces; that is, the running rigging attached to the ends of the foremast yards and running back to double blocks on the mainmast, from which they run down to the spider band at the base of that mast. As I have mentioned previously, I have chosen not to put sails on my Endurance, and I am not installing running rigging that would be attached to those sails, which leads to a cleaner look (but not as accurate).

You can also see the standing rigging described above in first picture below.

OcCre has you secure the end of the lower braces, and the double block they pass through, to the stay running from the mainmast top to the deckhouse roof just aft of the foremast. When I rigged the jib halyard/downhaul lines with blocks attached to the forestays (again, as OcCre directs), I was unable to do it without distorting the run of the stays, as can be seen in the first photo immediately above. To avoid that, instead of attaching the lower braces to the stay, I looped them around the mainmast and through the top, and I attached the double block directly to the mast at the height of the gaff gooseneck. I have no idea which is more historically accurate, but I like the look of how I did it better.

Taking a needed break from rigging awhile, I’ll next start working on the forward pair of ship's boats.

- RossR and The Gimps Chimp

-

2

2

-

The foremast ratlines are finished! Slow patience was the trick, never doing more than three on each side at one sitting. As I expected, the most difficult ratlines were nearing the top of the lower shrouds, finishing at the futtock shrouds. Tying knots with tweezers has never been my strong point.

As you can see, I have also completed the pair of lower shrouds (on each side) which parallel the ratline shrouds.

-

Thanks for the kind words Mike and Jeff. I hope you find my log to be helpful when you get around to your Endurance builds. I have gained immensely from what I’ve learned from the logs of others, so it’s nice to hear every so often that there’s something to be learned from mine.

-

Random progress report . . .

I don't know why I didn't think of this before, but to help with visibility in doing all of this rigging, I created a screen behind the model, by opening a manila folder, taping some of the same material to the back for stiffness, and taping it all to a 2 x 4. That has helped immeasurably. I love the view out my window, but it can be a major hindrance when it comes to seeing what I'm doing with my Endurance.

The ratlines on the upper foremast are nearing completion.

I have installed the lower shrouds which will support the lower ratlines, and I'm off to a good start on those. The ends of those shrouds will be clipped off only once I have finished all the ratlines. Tying the ratlines sometimes results in unintentional and careless jerking of one of the shrouds, which last fall resulted in a main mast shroud coming apart at the deadeye. Hopefully this will reduce the risk of that happening again.

Finally, I have installed the ratlines on the futtock shrouds. That proved to be a major test of my patience and my clumsy arthritic fingers, and somewhat to my surprise I did it without any major mishaps.

-

Fun to discover another Spray build Jeff. What you have done in about six weeks probably took me at least that many months. I like your weathering of the hull.

Happy to see your Nantucket log, as that model is rising to the top of my list of next builds.

-

Slow progress, and only one picture of that progress. The mainmast standing rigging is now complete, including ratlines and all shrouds. I also drilled holes for the remaining stanchions, but I have not glued them in place yet. I have also started on the foremast standing rigging, wondering again why I didn't do this before rigging the yard lifts.

In addition to the usual distractions this time of year slowing things down, for the first time I can remember I've found myself frustrated that it's taking as long as it is to finish this model. A year ago I thought I would be finishing about now. That's led to some rushed work, a few mistakes* and do-overs, and the occasional sense that I needed (not wanted) to get back to work on my model. So I'm now intentionally slowing things down (somewhat counter-intuitively), getting my mind back to recognizing again that it's all about the journey, not the destination. And it's working; the last couple of sessions in the shipyard were shorter and more enjoyable. So if a month or more passes before my next post, you'll know why.

*The most obvious (but not the only) big mistake was running the middle stay from the main mast to the foremast top rather than to the mast cap. What should have been incredibly obvious is that running that stay to the top meant it interfered with the main mast gaff's peak halyard. Live and learn 😵💫, and correction made.

-

-

I have now glued the mainmast in place and rigged the three stays running from that mast forward to the foremast.

I have also rigged the pairs of lower shrouds, port and starboard, that will be home to the ratlines. While securing the lanyard above the upper deadeye on the final one, I managed to pull that deadeye away from the shroud to which it had been secured. That meant I had to do that pair of shrouds all over again. To reduce the risk of bringing on that calamity again, I left the bitter ends of the shrouds untrimmed, until after I have rigged the ratlines.

As can be seen in the first photo below, the upper part of the lower shrouds don’t align with the futtock shrouds very closely, and I was concerned how I was going to tie them together as they should be. But when I tied the lowest ratline onto the futtock and the lower shrouds together, they came together quite well, distorting the straight run of the shrouds only slightly.

Up next . . . too many more ratlines.

- The Gimps Chimp and clearway

-

2

2

-

Amazing work on the 3D printer! It's going to be really great seeing these features when they become an integral part of your build.

As you may have seen, I've been working on my Endurance for about 20 months so far and estimate I have 3 to 6 more months to go. I'm finding there is a lot to like about OcCre's kit, but also lot's of potential to make corrections and to add details that are not part of the kit, planking the sides of the deck house (as you have done) and the bulkheads being prime examples. I'm looking forward to following your build.

-

On 11/19/2024 at 6:22 PM, Carkinjim3 said:

I didn't know the forecastle was indented like that.

Jim, here's one of several Frank Hurley photos showing the opening in that bulkhead. The anchor windless was in there (as you probably saw in my log), probably linked to the captain above, with the chain locker immediately below.

-

Next project was upper shrouds and ratlines on the main mast.

As @theoracle09 pointed out on his log, and as can be seen immediately below, the upper shroud ratlines go only a little more than half way up. Aft, between the shrouds, is a ladder, the ratlines on which overlap the other ratlines part way and continue on up to an opening in the bottom of the crow’s nest.

I attached the ladder to two eyebolts extending out from the back of the maintop, visible in the closeup photo of the bottom of the ladder and the futtock shrouds. The top of the ladder is attached to two eyebolts extending out from the mast at 45° from astern, not really visible in the attempted closeup of the top of the ladder.

Ratlines are seldom easy, but I found these to be more than a bit of a challenge. I think the thread I used was too stiff, making it definitely uncooperative. But I got it done. What has me concerned though is the shrouds and ratlines on the foremast. I have no idea why I installed that mast's running rigging first, rather than doing its shrouds and ratlines first. To give me a little practice I’ll do the main mast standing rigging first (with little running rigging in the way), then tackle the counterparts on the fore mast.

- gak1965 and The Gimps Chimp

-

2

2

-

Hi Jim, welcome to the group of Endurance builders. While your approach is different from mine, I think yours is a beautiful build. Both Keith and Josh @theoracle09 stopped posting quite some time ago, which as far as I can tell, leaves me as the only Endurance builder still posting. A year or two ago there were quite a few. I would love to have some company if you want to start posting. Or add whatever comments you want to mine. The link is in my signature block below.

Tom

- Keith Black, clearway and Carkinjim3

-

3

3

-

I have built the mainmast and installed the gaff, crane and crow’s nest barrel. One of the pictures below shows the mast installed on the ship, but it hasn’t been glued there yet. Among other things, I will probably rig the upper shrouds, futtock shrouds and ratlines with the mast temporarily installed in a 2x4, which makes it more accessible.

The only thing deserving comment at this point is the crane/boom, which I thought seriously about not installing. I think I’ve only seen one or two photos in which it appears, and I’m guessing it would be used only when loading things on and off the ship. It might even have been removed except when needed. The lower stay between the foremast and the main mast would have to be unrigged for the crane to be useful. As you can see below, I chose to rig it pulled up tight against the mast.

I have two sizes of photo etched hooks left over from prior builds, I feared the larger ones were too big, and I used one of the smaller ones. Now I think that was a mistake as it can hardly be seen, but not important enough to redo.

OcCre has the loose end of the hook’s tackle tied to an eyebolt at the boom’s inner end, a place which probably couldn’t be reached by anyone. I ran it through a block on the inner end of the boom, then down to the forward cleat on the spider band at the bottom of the mast. That’s also where the working end of the boom’s peak halyard is secured. There’s really no other good place to secure it. There are 8 cleats on that spider band-- one for the gaff peak halyard, six (three on each side) for the foremast braces, and one for the crane rigging.

-

Unrelated, but my wife and I just returned from a trip, and I posted here about the amazing ship model collection at Amsterdam’s Rijksmuseum.

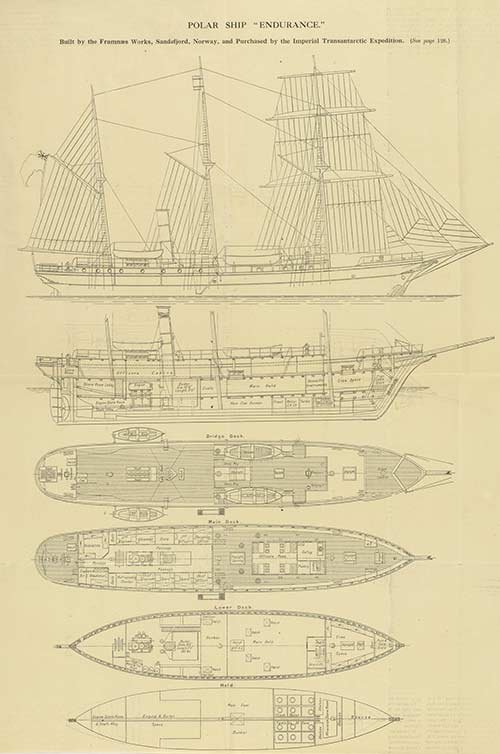

I mentioned previously that I intend to place the forward ship’s boats on racks inboard from the bulwarks, instead of outboard hanging from davits as OcCre intends. The ship’s plans I refer to and a number of the Frank Hurley photos show the forward boats stowed that way. Before leaving on our trip, I built the basic frames for this stowage, and I partially assembled one of the boats to see how everything would fit. I had already determined that the smaller boats fit better forward, with the larger boats aft, the opposite of the way OcCre places them.

Neither these racks nor the deck gangways are glued in place yet. I will assemble, rig and install the mainmast before these things are glued in place.

- gak1965, clearway and The Gimps Chimp

-

3

3

-

Thanks SHJ. I wish I was smart enough to deserve the credit you gave me. Actually I didn't paint those lines at all. What I did is find some grey thread which I used untreated, then mixed some white and grey paint to give the brass stanchions a color that is at least close in color to the lines. The goal was to have the lines look like wire cable.

- Snug Harbor Johnny and gak1965

-

1

1

-

1

1

-

At long last the time has come to glue the deckhouse in place.

As I mentioned in an earlier post, OcCre shows a stay running from half way up the main mast down to an eyebolt at the front of the deckhouse roof/deck. Stays are frequently rigged with a lot of tension, they should be fixed to something having plenty of strength, and what could be stronger than the base of Endurance’s foremast? I stared at it for some time, trying to figure out how I was going to get my big clumsy fingers in there to wrap the thread around the mast a couple of times and then using thin thread, tie half a dozen or so half hitches around the two parts of the stay, all without disturbing the lines tightly secured to the mast’s spider band and the bulwark pinrails. Eventually I decided that it can’t be done (only barely acknowledging that it can’t be done by me). So I installed an eyebolt to the deck of the deckhouse as instructed and secured one end of the stay to it.

I then loosened the gaff sheets to make room, applied glue to the bottom of the deckhouse, gently slid it in between all the running rigging, and glued it in place. I was then able to tighten and secure the gaff sheets to the pin rails and glue the remaining ladders in place.

- Ronald-V, iMustBeCrazy and clearway

-

3

3

-

After some delays, I have now finished rigging the headsail halyards and the downhauls.

There are four headstays. OcCre has you install running rigging and sails on the inner three, consistent with plans and some photos I have. Other photos show running rigging on the outer three. For no particular reason, I chose to do the latter.

In each case, OcCre's instructions show a halyard and two downhauls on each designated stay. One downhaul is attached to the head of the sail and one attached to the tack. I have been on many sailboats but never one with a downhaul attached to the head of the sail; the weight of the sail was always sufficient to bring it down when the halyard was released. Also, the tack was secured to a fitting on the bow (on the bowsprit here), and the purpose of the downhaul was to adjust the tightness of the luff (leading edge of the sail). As such, the bitter end was attached to the bow, and the line ran up through a grommet a short distance up the sail and then back down to a block and then aft. But then the largest sailboat I’ve been on was about half the size (by length) of Endurance and about half a century newer, so what do I know? In any event, I opted for one downhaul and linked it to the halyard. Keep in mind that I decided not to install any sails.

The loose ends of the downhauls and halyards were then secured to the forward pinrail and the foremast’s spider band respectively.

- ccoyle, iMustBeCrazy, RossR and 1 other

-

4

4

Endurance by Tomculb - OcCre - 1:70

in - Kit build logs for subjects built from 1901 - Present Day

Posted

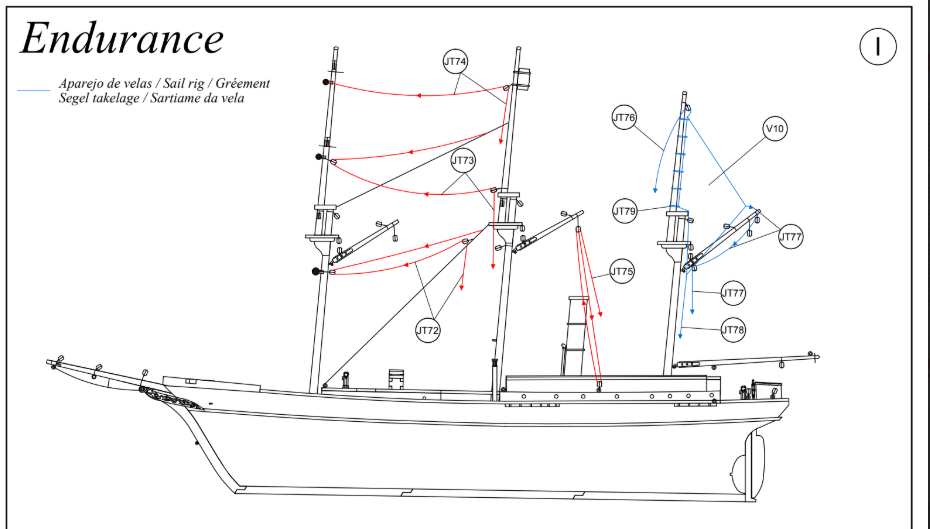

Mizzen mast running rigging . . .

Last summer (post #126 above) I said that I didn’t understand why OcCre included gaff throat halyards when the gaffs were attached to the mast with fixed goosenecks. What I failed to recognize at the time was that gaffs generally are attached to the mast with jaws and parrals, and gaff sails are usually brought down by lowering the gaff (to the boom if there is one), which requires both throat and peak halyards. Maybe I should have attached the gaffs on Endurance with jaws and parrals, but it’s a little late to do anything about that now. After a somewhat cursory search, I haven’t found any Frank Hurley photos to confirm whether I’m right about any of that. But if I’m correct, then it appears that OcCre (and I) erred in placing the foremast gaff above the lowest yard, where it can’t be lowered to bring the sail down, or it can’t be done without lowering the yard as well, which seems unlikely. Maybe that gaff should be attached to the mast below that yard, not above it.

The first running rigging I installed on the mizzen is a topping lift, running from the outer end of the boom to a block just below the gaff gooseneck, then down to a cleat at the foot of the mast. If I had been thinking about what I described above, I would have placed the block on the mast above the gaff, not below it. I did this and what follows with the mast off the ship, slipped into a hole in a 2 by 4, as I did with a lot of the running rigging on the other two masts. All but the final photo in this post are with the mast only dry fit on the ship.

I am not installing sails on my Endurance, and as I mentioned in a prior post, I am keeping the rigging simpler by not installing most rigging that attaches directly to a sail. However, I decided to make an exception for the topsail that is above the gaff on this ship. For whatever reason (or perhaps no logical reason), I liked the idea of suggesting a sail up there, even though I wasn’t installing one. So I ran a halyard through a block at the top of the mast and an outhaul through a block at the outer end of the gaff, and attached the ends of each such line to the other. Assuming there would be something like a snap shackle at the end of each line to attach it to the sail, I simulated a pair of such fittings with a pair of linked tiny rings.

So that the gaff will be firmly secured in place, I won’t secure that halyard and outhaul to the cleats on the mast until I have secured the gaff sheets to blocks and cleats on the deck. The base of the mizzen mast fits into the slot built for it long ago with some wiggle room, which sure is better than no wiggle room and misalignment. As can be seen below, to get the mast rake right, I pulled it forward with some thread at the top of the mast, gently weighted with some mini clothespins (they’re only about an inch long; somehow they look a lot longer in the photo). And I leaned an eraser against the foot of the mast to get it aligned with the other masts. All that after fitting the mast into its hole and slot with a gob of wood glue at the bottom.