GrandpaPhil

NRG Member-

Posts

6,167 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by GrandpaPhil

-

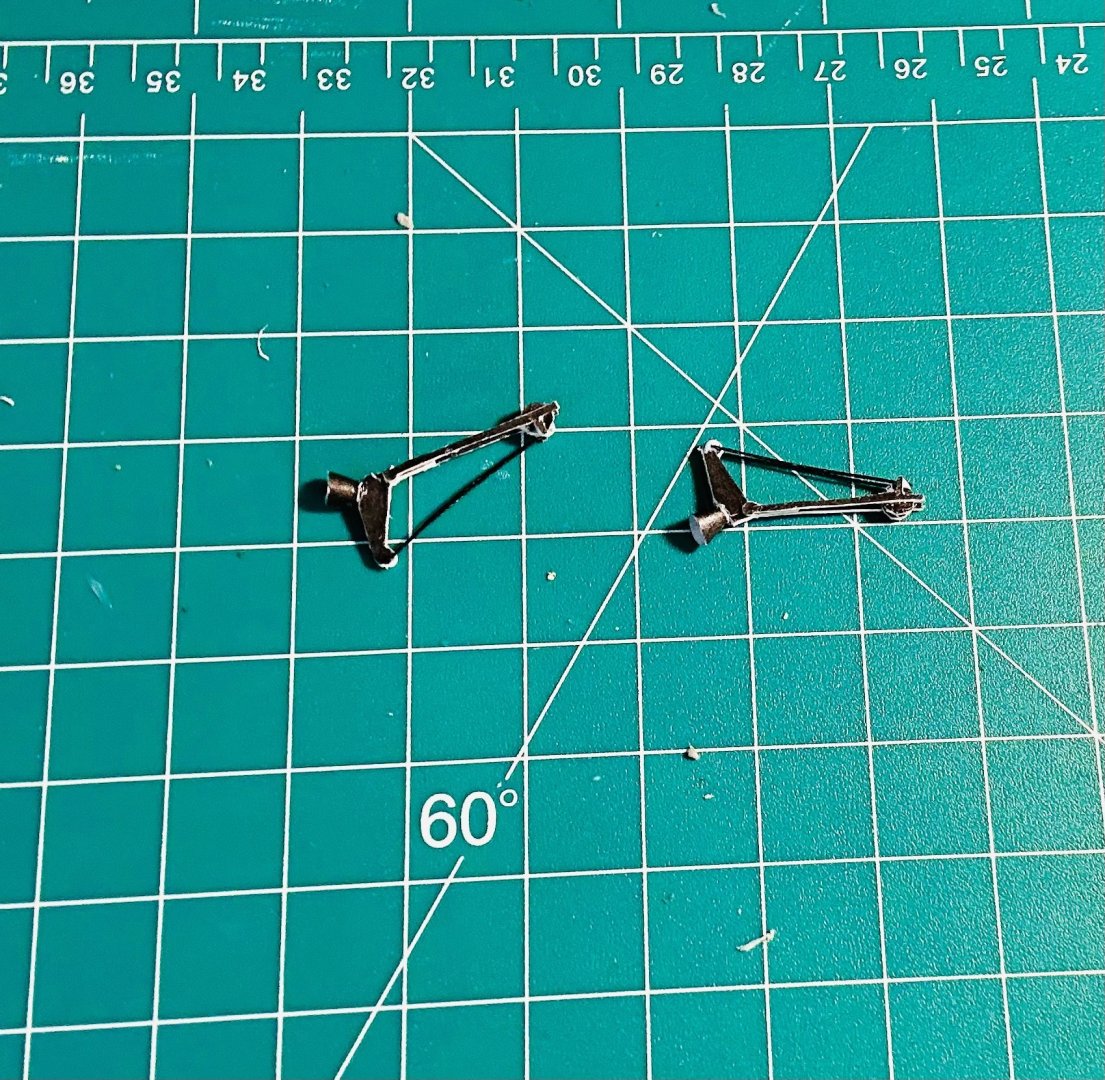

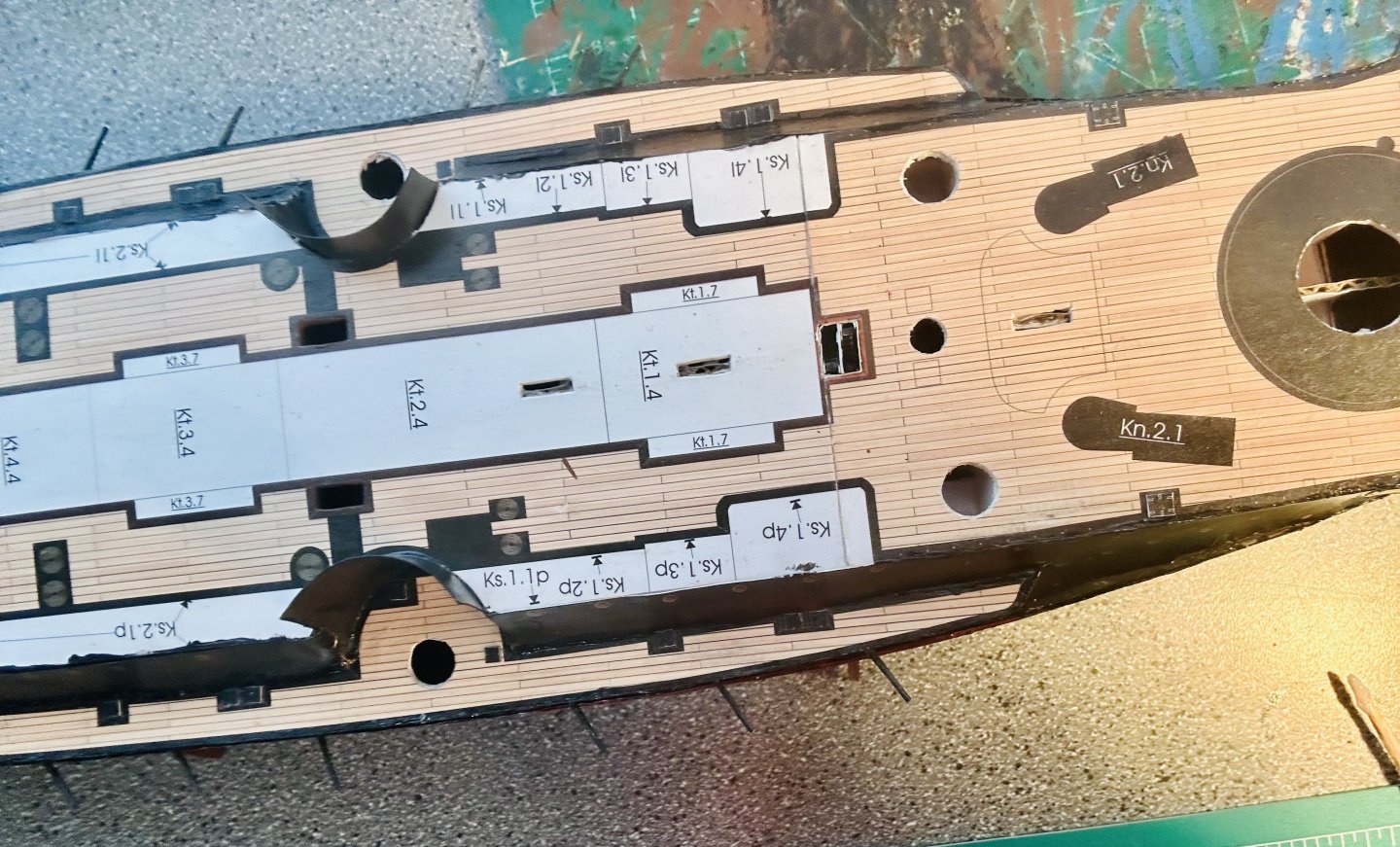

Thank you very much, OC! Thank you very much to all who have hit the “like” button or just stopped by! 2 anchor cranes pending painting and installation:

- 288 replies

-

- Card

- Pre-Dreadnought

-

(and 3 more)

Tagged with:

-

- 288 replies

-

- Card

- Pre-Dreadnought

-

(and 3 more)

Tagged with:

-

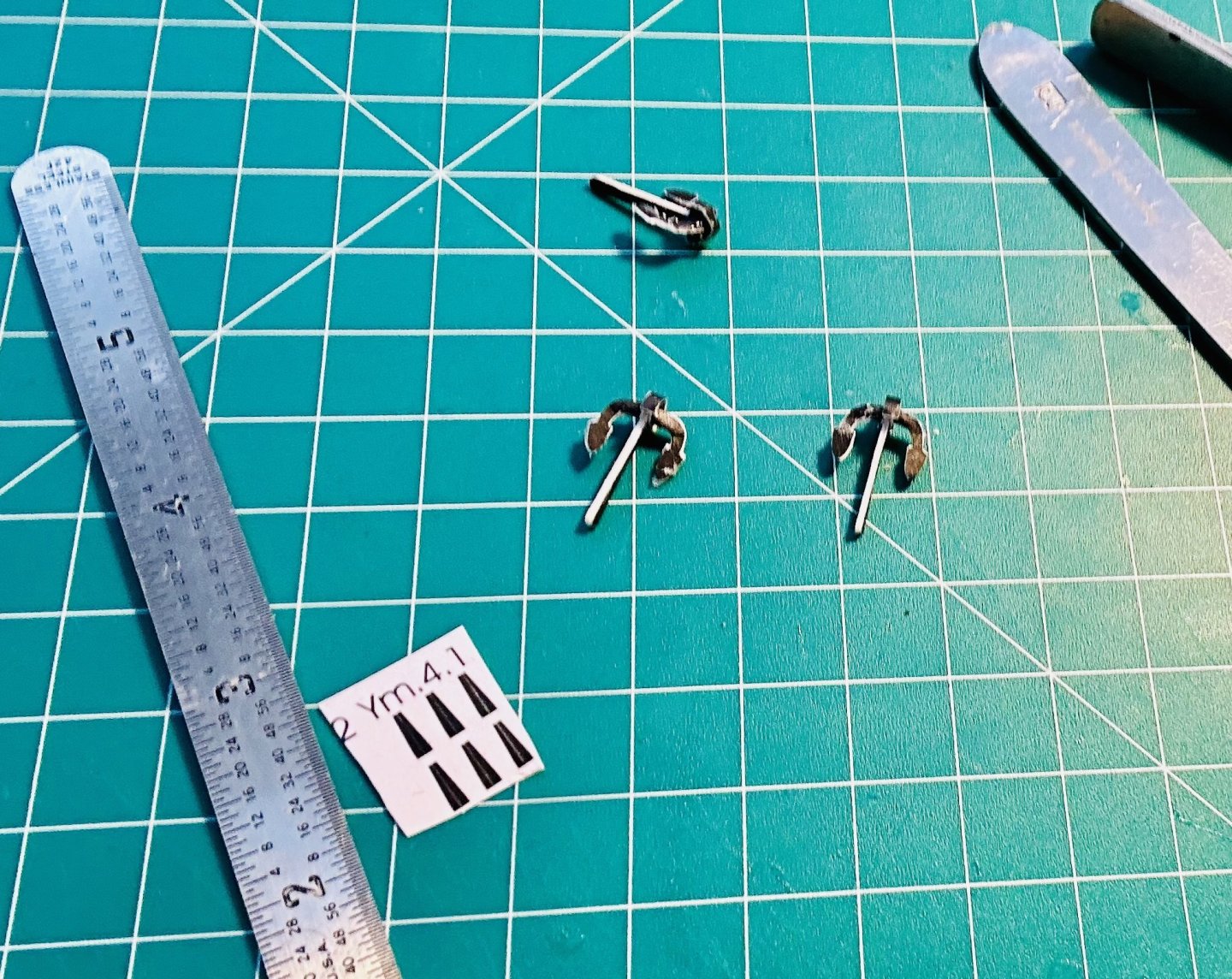

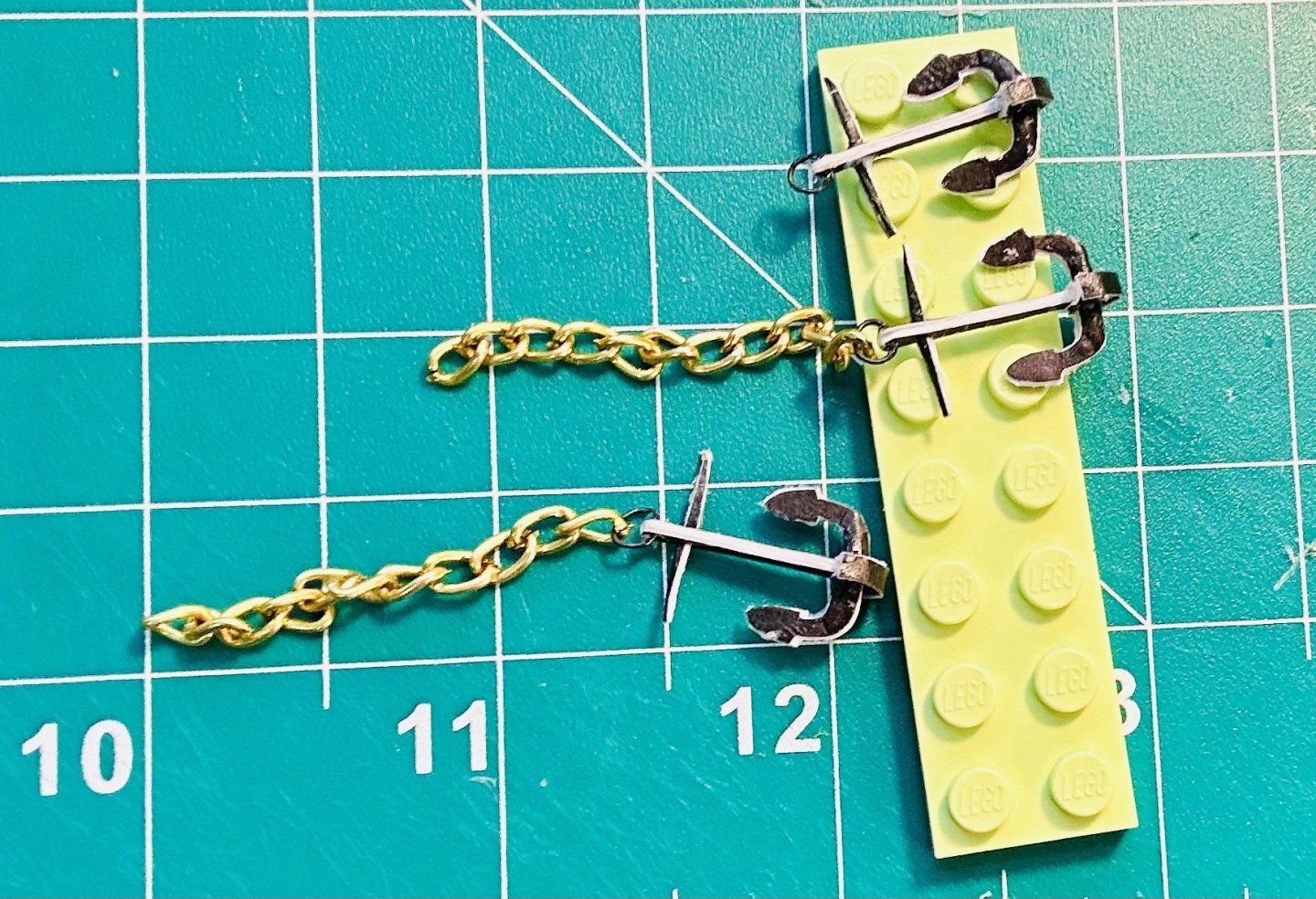

Thank you all for the likes and for stopping by! I started from the bow and am working my way aft like I would on a sailing ship model. So, I am beginning with the anchors! Once I get these done and installed I’ll make the anchor cranes!

- 288 replies

-

- Card

- Pre-Dreadnought

-

(and 3 more)

Tagged with:

-

That is an excellent book!

-

- 288 replies

-

- Card

- Pre-Dreadnought

-

(and 3 more)

Tagged with:

-

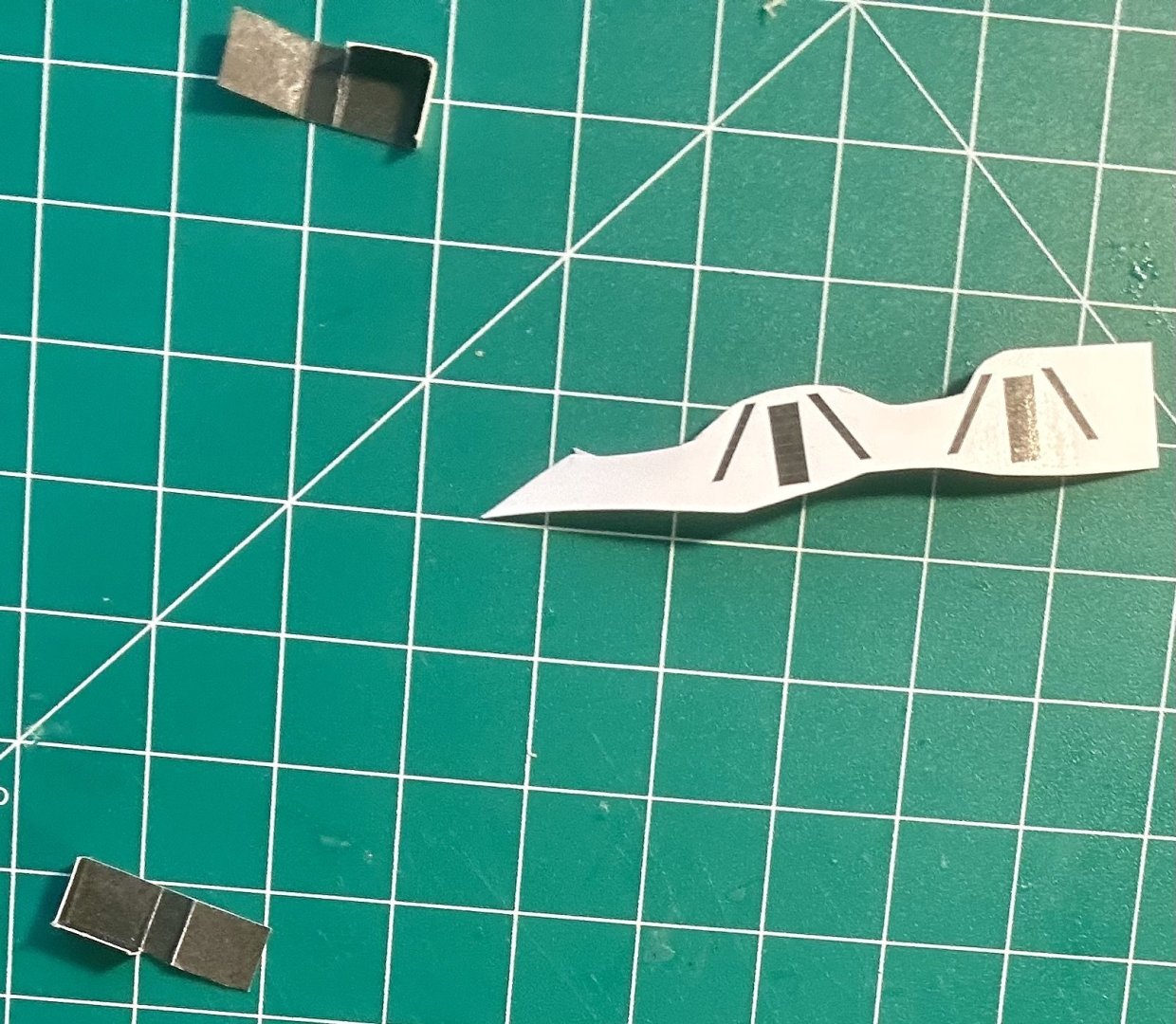

Alan, Thank you very much! Jeff, Lol, I enjoy the hobby quite a lot, and each build I learn something new! The challenge is what makes it fun! I’m having a ladder making party today: Second set for the day: Ladders are one of the hardest parts of a ship for me, especially modernish ships.

- 288 replies

-

- Card

- Pre-Dreadnought

-

(and 3 more)

Tagged with:

-

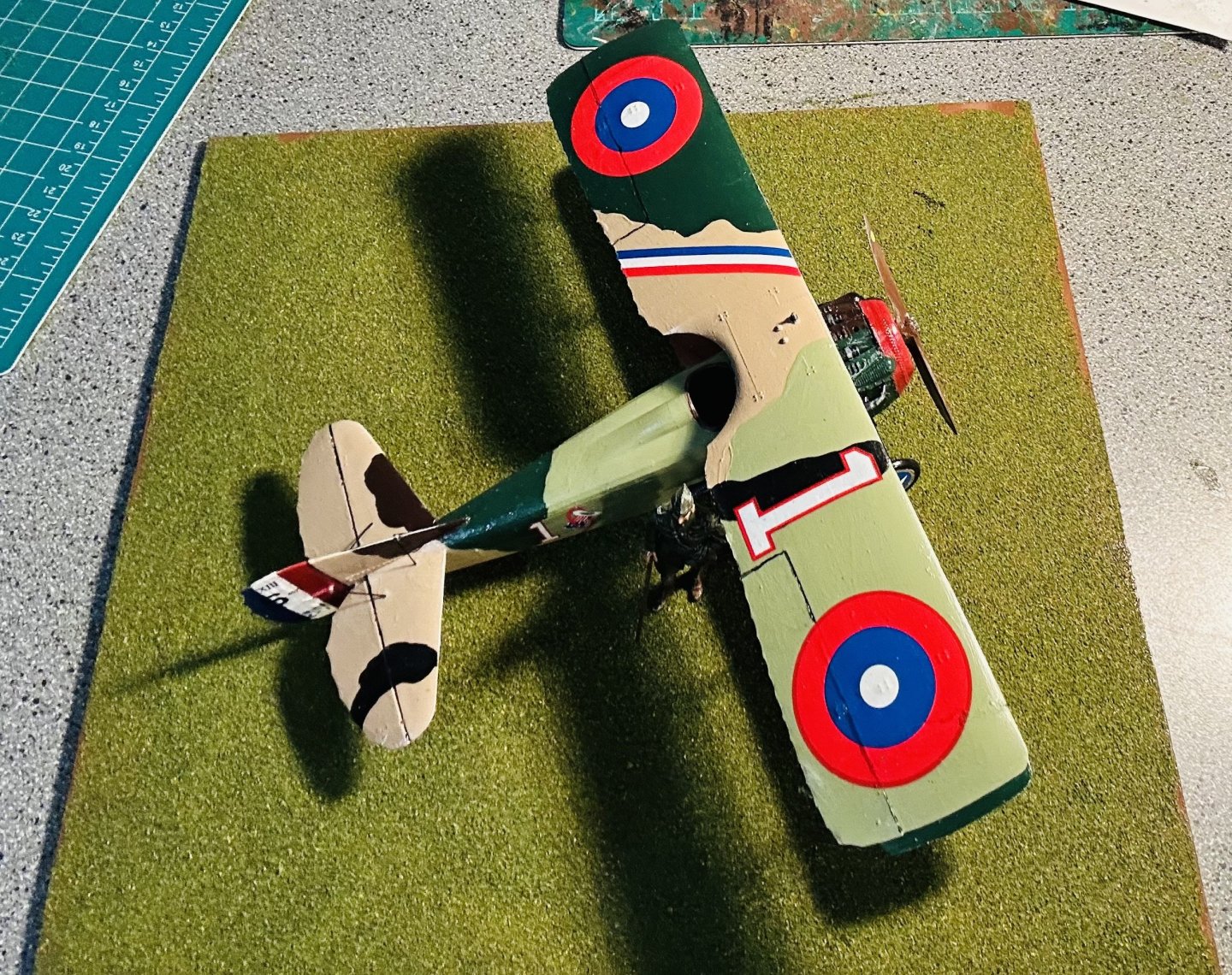

Thank you both very much! Mott’s Military Museum is a very neat place. I like it quite a lot and have been through there a few times. Captain Rickenbacker was a very interesting character. This one took me about 80 hours to build and is now done: I’ll deliver it to its new home this week. Thank you all for watching and following along! Have a very Merry Christmas! And it is now paper ship o’clock!

-

Have you seen the Venetian Galleass in Souvenirs de Marine? That looks awesome and I want to build that one day.

- 176 replies

-

- la reale de france

- heller

-

(and 2 more)

Tagged with:

-

Harold Hahn’s books have his plans of ARW ships too. Some of them are buildable right out of the books with some resizing.

-

The Smithsonian has plans available for most of the US sailing navy.

-

Welcome!

-

Welcome!

-

One very roughed out base coated six color Western Front camouflage scheme: The next time I work on it I’ll touch everything up and do all the detail painting. Then everything’s getting sealed and decals are getting added. Then everything gets sealed again before I add the struts and the windscreen. After that I’ll add that top wing and rig the model!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.