-

Posts

1,135 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by CPDDET

-

-

Yes, the NRG Half hull model does a good job of explaining the process.

-

Build logs of the same model are extremely helpful. Different methods to attain the same goal teach us all. Even experienced builders can, with an open mind, learn from beginners.

- RVB and Keith Black

-

2

2

-

It has taken me a bit to research the building of the transom but finally got it done.

Installed the upper, middle and lower transom support pieces. When Mathew built his RC model he double planked the hull and transom. So he first planked the transom vertical, which gave him plenty of surface area for the final horizontal planking. But I’m only using one layer of planking so I decided to add filler blocks to create more surface area.

I used balsa wood for the filler blocks which worked really well. Never used balsa in the shipyard before but I will know keep some on hand. Cuts very easily, sands down very quickly and easy to shape. Only drawback is its softness, so have to go easy on clamping as it dents quite easily. Lucky for me all of this will be covered with cherry planking. I will plank the transom prior to installing it on the build board as the hull planking will overlap the exposed edge of the transom planks. This is easily seen on photos of the original boat in Cuba.

The original boat was built with a forward cockpit as seen here in Mathew’s build.

Sometime in the past it was decked over, leaving just a deck hatch. I understand that Hemingway got tired of the forward cockpit taking on water. In any case the original boat has undergone numerous repairs and modifications over the years due to wood rot, water and hurricane damage. Mathew has done extensive research on the boat and included a lot of documentation in his build log.

When he was building his model he didn’t originally include the forward cockpit and decided to add it later, lucky I caught this while reading through his 32 page build log. It was a tricky thing to do but, as always, he did a beautiful job. I want to build it before planking the hull so I can get my hands in at it. I didn’t have the exact measurements but found them on the line drawing which I noticed while reading his log.

For some reason I didn’t rescale and have printed Mathew’s line drawing of Pilar. So it was back to the printer to have that done. This will be a big help.

Another issue caused by my decision to build this plank on bulkhead instead of plank on frame. Obviously the top of the bulkhead has to be lower in the area of the rear cockpit to accommodate the sole. I forgot to allow for this, but the line drawing will be a big help in making this adjustment on several bulkheads. I haven’t glued any bulkheads onto the build board yet, so that will make this adjustment much easier. As well as building the forward cockpit before hull and deck planking.

-

-

Welcome, you've found a great resource!

- Knocklouder and Keith Black

-

2

2

-

-

Welcome aboard!

- Cast Off and Keith Black

-

2

2

-

-

-

Welcome!

-

It's your model and there are no rules to adhere to on this site. Do what brings you pleasure

-

You can always send yourself an email from your phone, with photos attached and then open the email on your computer and save the images.

- Knocklouder and Keith Black

-

2

2

-

Welcome! Challenges like this are part of the learning process, we all have them.

-

18 minutes ago, mandolinut said:

Looking forward to following your build. Patrick Mathews did a fantastic job on his Pilar which inspired me to also build a scratch Pilar. I was happy with the result but it was not at the level of Patrick's.

Patrick did an expert job. I'm hoping to get close to his level of perfection. Going to be quite a ride!

-

-

Remember, it's the heat thats used to bend wood, not the water.

Steam is used because it can heat wood without burning it. When you touch a hot iron to moist wood it creates steam which heats the wood and allows it to bend.

Some people soak planks but I find that causes the wood to swell too much, at least for me.

Try a few different methods and see what works best for you.

I'll take a temp reading of my iron and let you know what that is. I know it dosent burn the wood and I can hear the hiss of steam when I use it.

-

For me, it's a struggle to keep a balance on how far to go with authenticity. I can tend to overdo.

-

You can either use spiling, as real ships were done, or plank bending.

I tend to use a combination of both.

The NRG Half Hull kit does a decent job of teaching spiling.

When I do bend, I just "paint" the plank with a thin layer of water and then apply heat. Many times I do this on the model.

For example, I will use spiling instead of edge bending to shape the plank. Then glue one end of the plank in place, brush on a bit of water and apply heat while bending the other end of the plank in place.

This process is used almost exclusively at the bow and stern. Just use spiling for the planks in-between.

Be advised, spiling has a definite learning curve.

-

Welcome aboard! Seems you're a skilled modeler and should have few problems building wooden ship models.

-

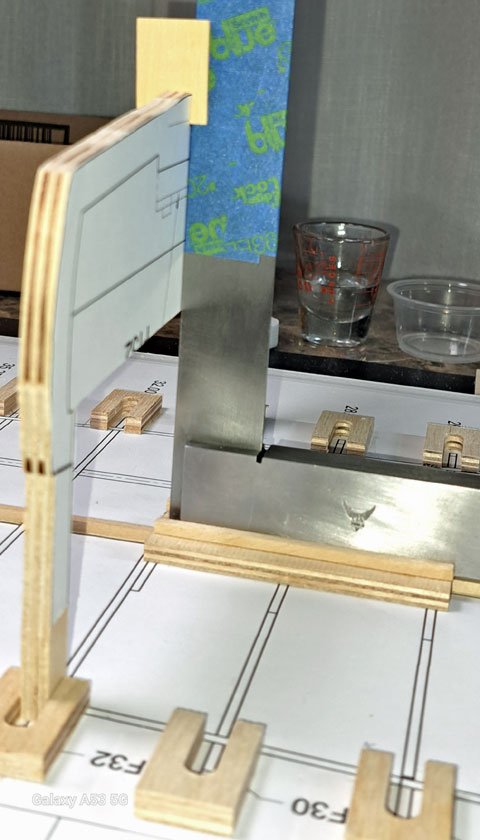

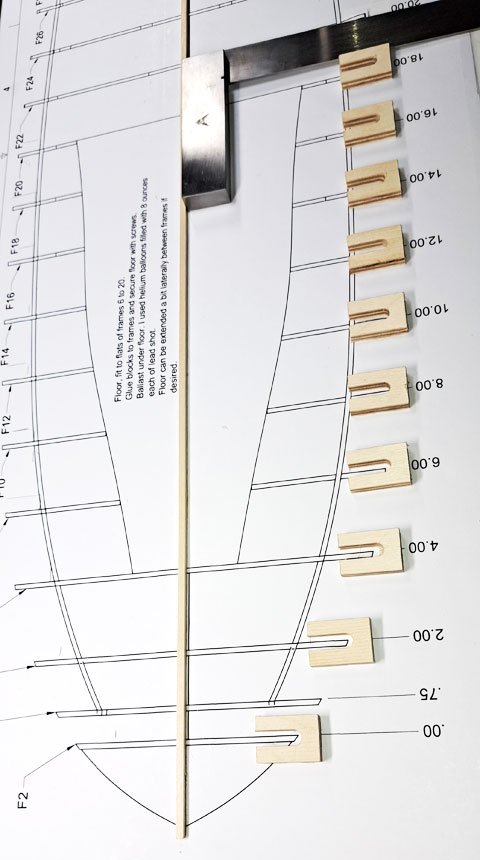

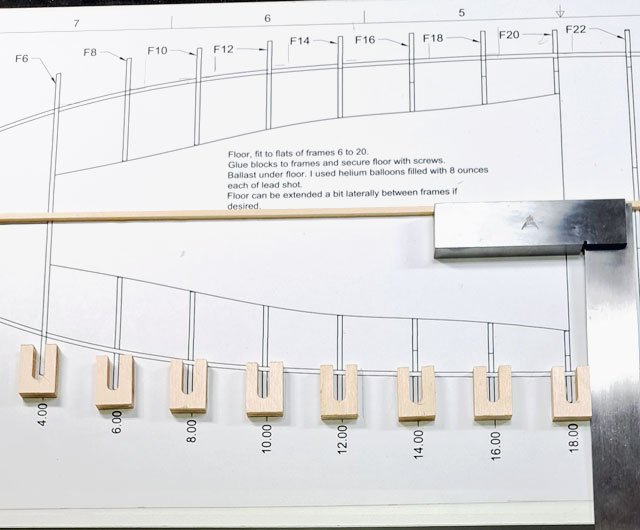

All of the bulkhead supports are now in place.

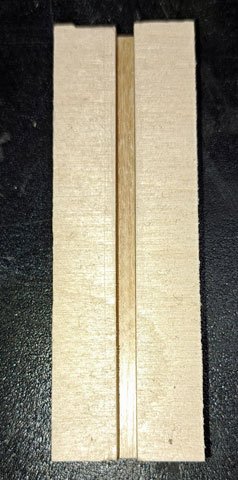

Next up was prepping the bulkheads. I want to tack the bulkheads in place once they are correctly aligned. So I needed to remove some of the paper plans that I glued to them to get wood to wood contact. My thought is to place a small drop of CA to tack them in place and when the time comes I can use acetone to break down the glue or just cut them off, which will have to be done eventually anyway. I had used Elmer’s spray adhesive to stick the plans to the bulkheads and found acetone easily removed the paper and glue.

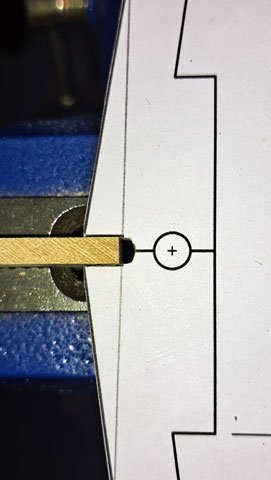

Then I locked a piece of the keel material in a vice and checked to make sure the notch in each bulkhead would accept it. They all needed a slight sanding to widen the slot.

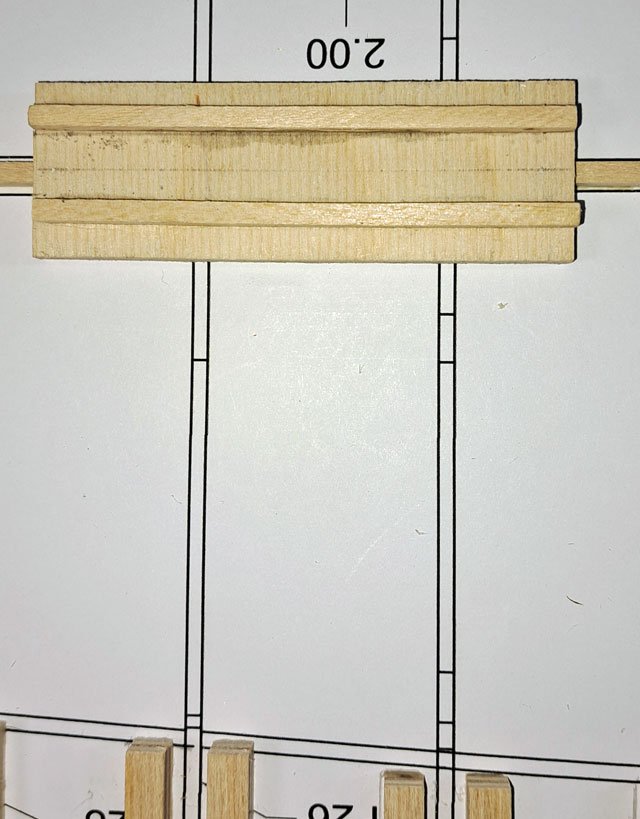

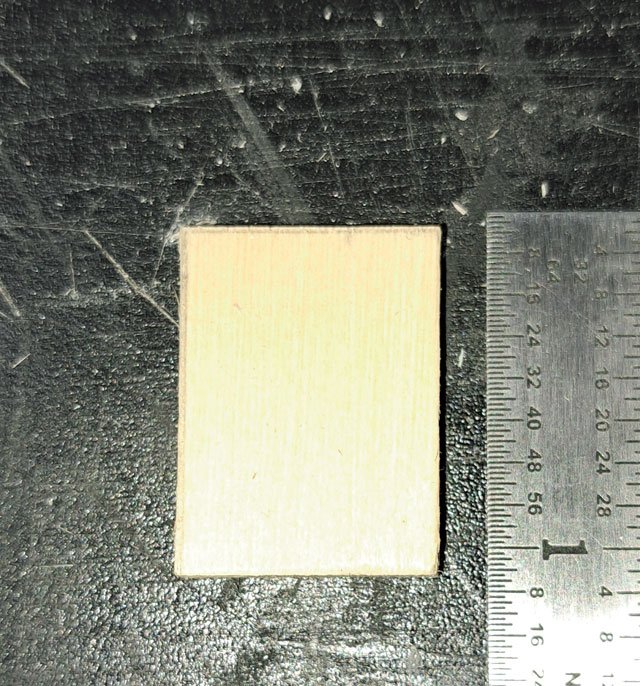

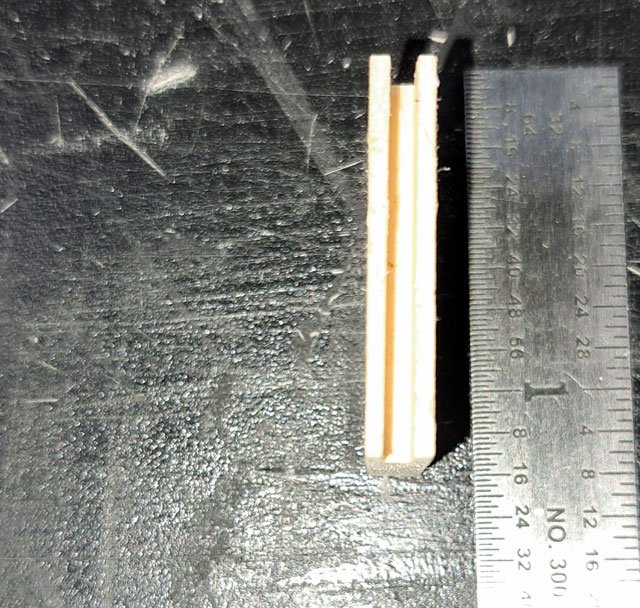

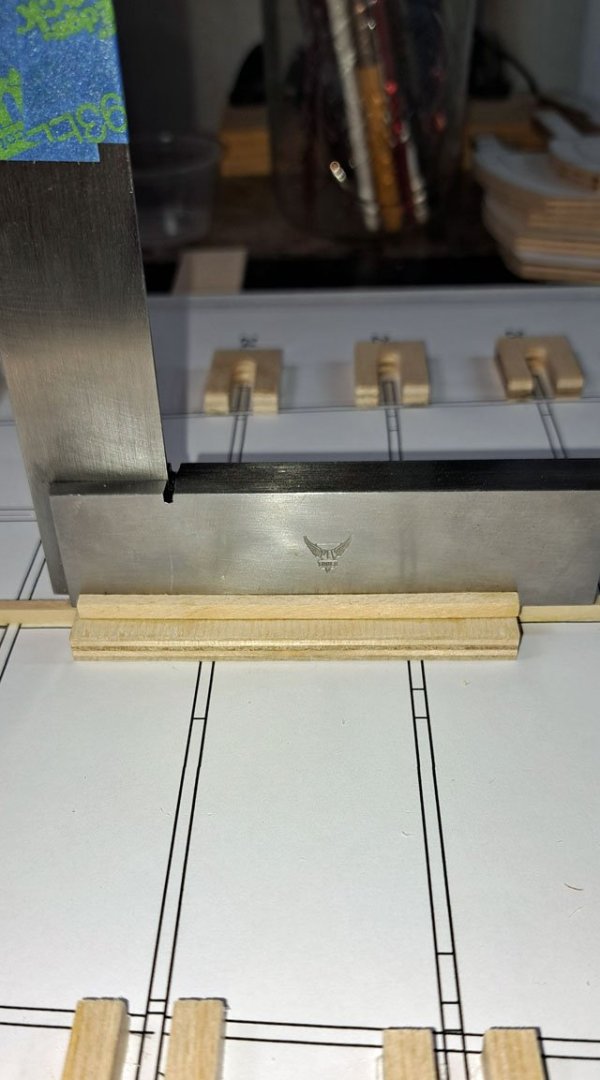

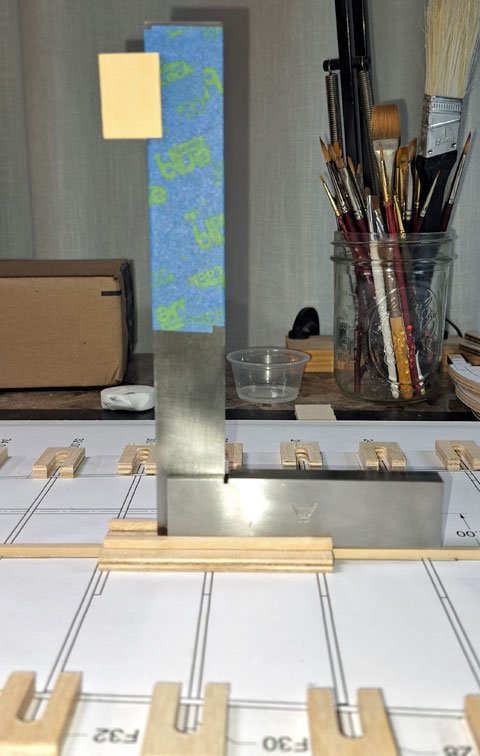

After some thought I came up with an idea that would make it easy to properly align the bulkhead notch over the centerline as well to make sure the bulkheads were perfectly vertical fore to aft. I took a piece of scrap wood and cut a 1/8th grove down the center. This will allow the piece of wood to ride on the 1/8th strip of wood that I glued on the centerline to align the bulkhead supports. Kind of like a sled. On the top side I glued 2 pieces of wood to hold the square centered.

Lastly I took a small piece of the wood that I will be using for the keel and cut a grove that would ride on the upright portion of the square. The thickness of the upright was just under 1/16th (the size of the groove I cut) so I wrapped one layer of painters tape around the upright to make the fit just snug enough. Now the wood piece can be slid down into the bulkhead notch. Now I can easily get the bulkheads aligned correctly.

I’m now contemplating if I should fair the bulkheads before mounting them on the build board. Matthews, the creator of the plans, has dotted lines on the plans showing the amount of fairing needed. I'm not sure of the angle of the fairing so it might mean some trial and error. Of course I could mount the bulkheads first and then fair them as is usually done. Ill have to think about it.

Probably won’t get any more done till next weekend as the coming week is going to be busy for me.

- ccoyle, mandolinut and yvesvidal

-

3

3

-

Welcome aboard! What type of boats have you worked on at the shipyard? Your knowledge and experience may be of big help to us all.

-

Welcome aboard. I really doubt there is any problem posting in 2 groups. I do a build log here and also on a Facebook group.

-

-

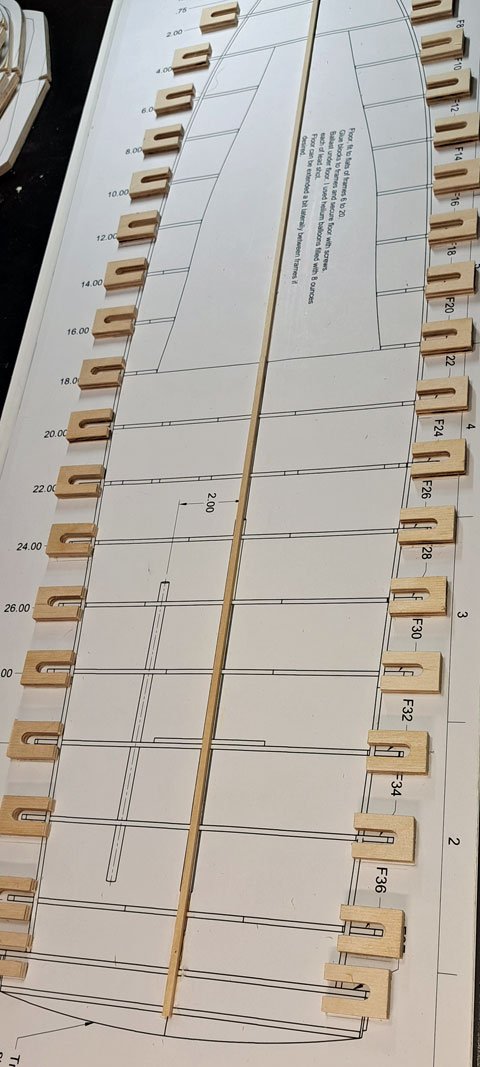

Things are moving along. Picked up a melamine coated shelf (12"X36") and cut what I needed from the build plans. I used 4 rows of double stick tape to mount the build plan to the board. Not the best way to do this as the areas between the tape still lift a bit. It isn't much but spraying the board with an adhesive would have been better. But going forward with what I have.

I decided to glue a 1/8 strip of wood to the centerline to assist in getting the bulkhead supports square to the keel. All the bulkheads are cut and all the bulkhead supports have been made so I began gluing the supports to the plan board. This is a large model, about 30 inches long, and with my small work space I decided to dry fit and align the supports one bulkhead at a time. When all looks right I mark the location of both the port and starboard supports but only glue in the port side. Then I can turn the board around and glue in the starboard supports without trying to reach over and do the side furthest away from me. About halfway done with the port side.

The slotting in the supports allows me to "slide" the bulkhead back and forth across the beam and will allow me, in the next step, to properly align the bulkhead keel notch to the centerline on the plan.

Pilar by CPDDET - 1:18 scale - Hemingway's Fishing Yacht

in - Build logs for subjects built 1901 - Present Day

Posted

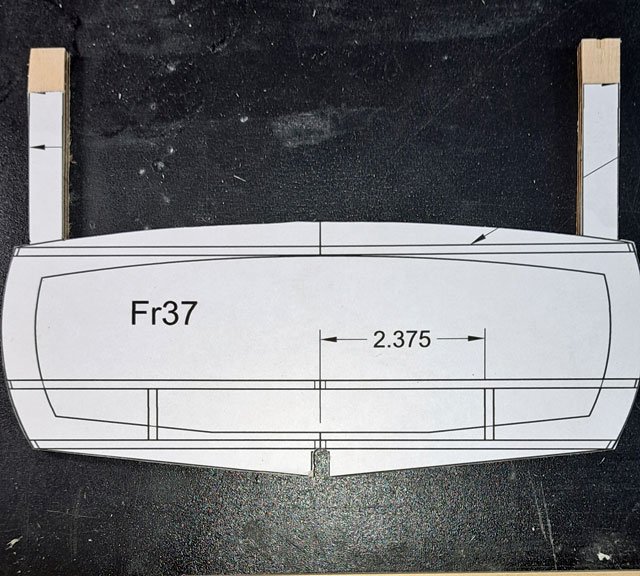

Started off by trimming bulkheads 24 through 36 to allow for the rear cockpit floor. Having the line drawing of the ship made this trimming quite easy, In order to get the undercut, I made several small cuts and then used a chisel to remove the excess material.

Then I cut bulkheads 4 and 6 to accommodate the sole in the forward cockpit. While these bulkheads are right next to each other, the drawing has them numbered this way. Again, the line drawing made this quite easy to do.

I decided to make a shallow cut in the bulkhead extensions where then will eventually be trimmed off. Two reasons for this. For one it will give me a slots for the saw when the time comes. Second, it will mark the trim line if the glued plan comes off or if I wish to take it off. I used a hold down board I made years ago to hold the bulkheads as I cut them with a small pull saw.

Last thing I got done today was to remove the glued plan sheet from each of the bulkhead extensions on all the bulkheads. A touch of acetone made this a breeze.

Next will be cutting out the keel.

I have cherry wood ordered to plank the transom, something I want to do before getting it on the build board. Once I have the wood in hand I’ll do some test strips with a variety of stains and try to get it as close to mahogany as possible. Research show that the boat was built with mahogany from the deck up as well as the transom.