-

Posts

1,490 -

Joined

-

Last visited

About Maury S

Profile Information

-

Gender

Male

-

Location

Fort Worth, TX, USA

-

Interests

Member: Nautical Research Guild

Current Build: Emma C Berry as a Schooner

Recent Builds: C. Chase, Centerboard Schooner, Anchor Hoy, c. 1825

Echo Cross Section from Admiralty Models

http://modelshipworld.com/index.php?/topic/513-echo-cross-section-by-maury/

Long Boat from MS http://modelshipworld.com/index.php?/topic/2284-longboat-18th-c-by-maury-modelshipways-by-Chuck/

Fair American (POF) from Laukstreet.

http://modelshipworld.com/index.php?/gallery/album/203-emma-c-berry-132-pof-by-maury/

Contact Methods

-

Yahoo

mstuffmann@yahoo.com

Recent Profile Visitors

-

WestPort reacted to a post in a topic:

Using a serving Machine. ( Syren Serv o matic)

WestPort reacted to a post in a topic:

Using a serving Machine. ( Syren Serv o matic)

-

DARIVS ARCHITECTVS reacted to a post in a topic:

Topping lift (Main and fore booms on schooner)

DARIVS ARCHITECTVS reacted to a post in a topic:

Topping lift (Main and fore booms on schooner)

-

CiscoH reacted to a post in a topic:

Anchor Hoy by Maurys - POF Harbor craft c. 1825 -- 1:48 - Finished

CiscoH reacted to a post in a topic:

Anchor Hoy by Maurys - POF Harbor craft c. 1825 -- 1:48 - Finished

-

Nirvana reacted to a post in a topic:

Modifying Harbor Freight Workbench for Full Drawer Access

Nirvana reacted to a post in a topic:

Modifying Harbor Freight Workbench for Full Drawer Access

-

Archi reacted to a post in a topic:

Thickness sanders.....Byrnes vs Micro Mart

Archi reacted to a post in a topic:

Thickness sanders.....Byrnes vs Micro Mart

-

thibaultron reacted to a post in a topic:

Wood Storage Idea

thibaultron reacted to a post in a topic:

Wood Storage Idea

-

Maury S reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

Maury S reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

-

MAGIC's Craig reacted to a post in a topic:

Emma C Berry by Maury S - 1:48 scale - POF rigged as schooner

MAGIC's Craig reacted to a post in a topic:

Emma C Berry by Maury S - 1:48 scale - POF rigged as schooner

-

MAGIC's Craig reacted to a post in a topic:

Emma C Berry by Maury S - 1:48 scale - POF rigged as schooner

MAGIC's Craig reacted to a post in a topic:

Emma C Berry by Maury S - 1:48 scale - POF rigged as schooner

-

MAGIC's Craig reacted to a post in a topic:

Emma C Berry by Maury S - 1:48 scale - POF rigged as schooner

MAGIC's Craig reacted to a post in a topic:

Emma C Berry by Maury S - 1:48 scale - POF rigged as schooner

-

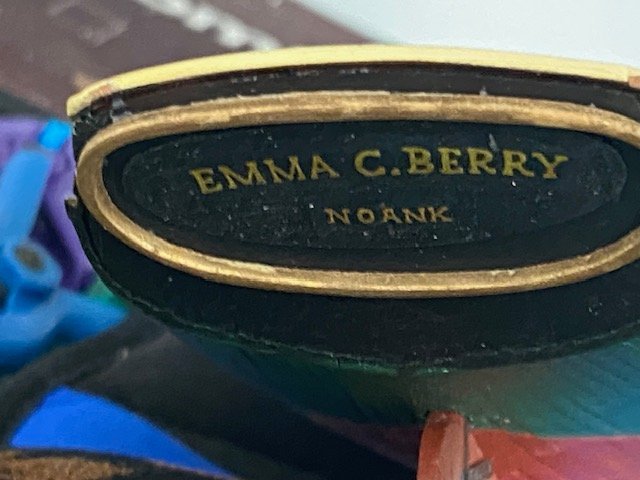

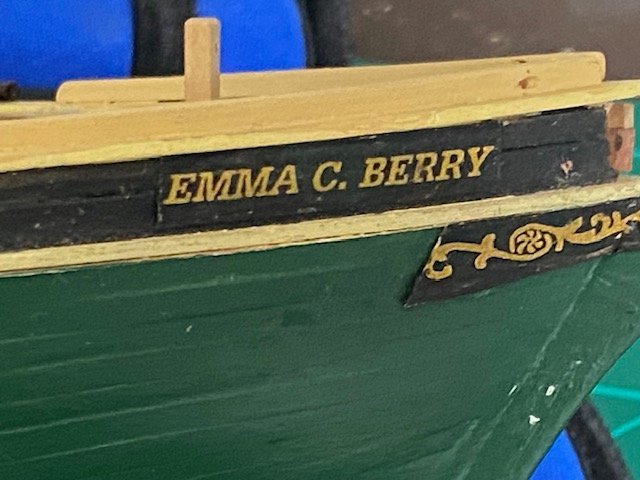

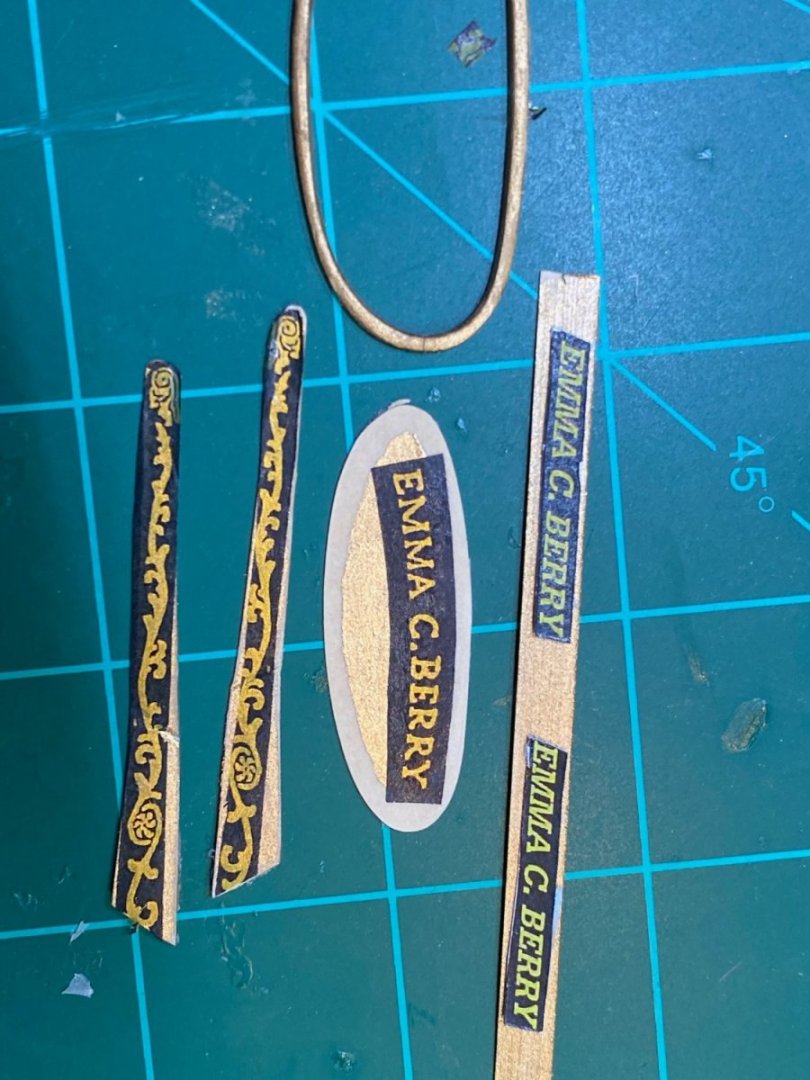

Back in the shipyard for a while. Working on lettering and scroll work for the trail boards. The name boards and trail boards are cut from .015" laser board. They are painted gold so the color shows through the decal. The surrounding areas will be painted flat black. The two names on the right are still on the decal backing and have not yet been attached. Maury

-

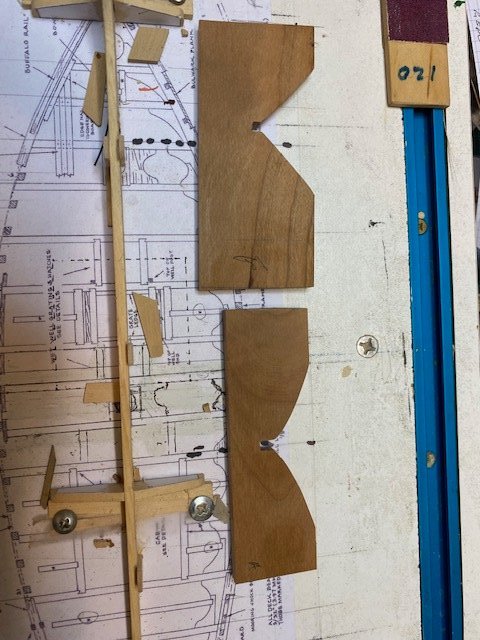

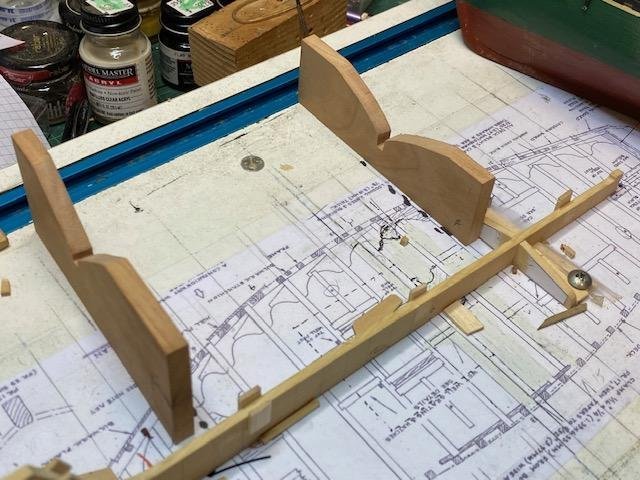

It's time to take her off the building board. The support system is a pair of cradles similar to the cradles for my Centerboard Schooner Post 302 March 21, 2021. I start by tracing the #4 and #17 frames from the plan sheet and transferring that pattern to card stock for rough fitting. The lower part of the frame is close to the shape of the hull at the points where the embedded nuts are located. After that, I copy the shape to some 1/32" box for final shaping. Since the ECB is built on a sloped jig, I measured the distance from the top of the jig and the building board at the two mounting points and transferred that measurement from the keel slot to the bottom of the rough cradle. The scroll work will be done later. Maury

-

Maury S reacted to a post in a topic:

Sloop Speedwell 1752 by Chuck - Ketch Rigged Sloop - POF - prototype build

Maury S reacted to a post in a topic:

Sloop Speedwell 1752 by Chuck - Ketch Rigged Sloop - POF - prototype build

-

Maury S started following SMALL nuts and bolts , Anchor replacement source? and Using a serving Machine. ( Syren Serv o matic)

-

Scotty, ...and of course you're going to serve the ring, right? Maury

-

Maury S reacted to a post in a topic:

Sloop Speedwell 1752 by Chuck - Ketch Rigged Sloop - POF - prototype build

Maury S reacted to a post in a topic:

Sloop Speedwell 1752 by Chuck - Ketch Rigged Sloop - POF - prototype build

-

I too am waiting for my recollection to improve. Maury😊

- 3,596 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Using a serving Machine. ( Syren Serv o matic)

Maury S replied to DaveBaxt's topic in Masting, rigging and sails

see post#244 for use of Serv-o-Matic: https://modelshipworld.com/topic/28039-emma-c-berry-by-maury-s-148-scale-pof-rigged-as-schooner/page/9/#comment-974182 -

Serving the shrouds: I have been using Syren's Serv-o-Matic for years now. The only modification I've done is to put a key into every place where the brass tube goes into the gear to prevent slipping. Easy to use, and I can only do about an hour at a time due to eye focus strain. I run the serving thread through the rope (with a needle) near the left side, tie a couple of overhand knots, then serve to the right. The rope is held in the tube with alligator clips (with heat-shrink tubes over the teeth). I make sure the serving is going the opposite lay of the rope threads and maintain a mild tension on the serving thread. Maury

-

Allan, I don't know. I have a Nickel blackener that I'll try, then it's paint. Maury

-

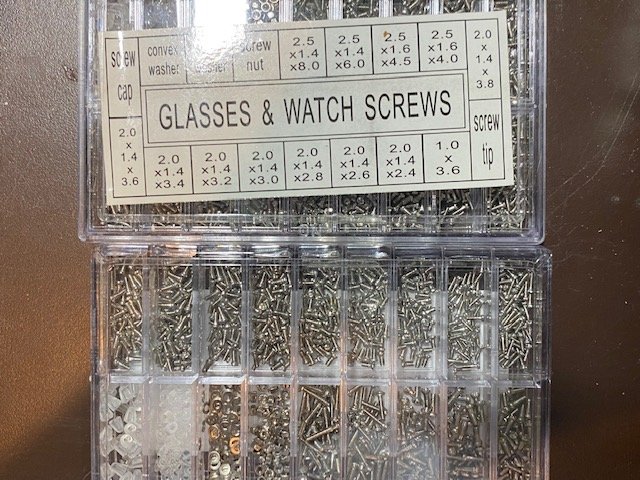

My partner gave me a kit of small nuts and bolts (washers, etc.) for watch and glasses repair. It comes with 6 drivers that is all he wanted. I haven't tried to blacken anything yet, but for about $20, there must be hundreds of these things that might be useful. Label reads "King'sdun" Maury

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.