-

Posts

190 -

Joined

-

Last visited

Profile Information

-

Location

Stockholm, Sweden

Recent Profile Visitors

-

coxswain reacted to a post in a topic:

HMS Agamemnon by Henke - Caldercraft - 1:64

coxswain reacted to a post in a topic:

HMS Agamemnon by Henke - Caldercraft - 1:64

-

Photoart reacted to a post in a topic:

HMS Agamemnon by Henke - Caldercraft - 1:64

Photoart reacted to a post in a topic:

HMS Agamemnon by Henke - Caldercraft - 1:64

-

TrunkMonkey reacted to a post in a topic:

HMS Agamemnon by Henke - Caldercraft - 1:64

TrunkMonkey reacted to a post in a topic:

HMS Agamemnon by Henke - Caldercraft - 1:64

-

Ronald-V reacted to a post in a topic:

HMS Agamemnon by Henke - Caldercraft - 1:64

Ronald-V reacted to a post in a topic:

HMS Agamemnon by Henke - Caldercraft - 1:64

-

Henke reacted to a post in a topic:

HMS Agamemnon by Henke - Caldercraft - 1:64

Henke reacted to a post in a topic:

HMS Agamemnon by Henke - Caldercraft - 1:64

-

mort stoll reacted to a post in a topic:

HMS Agamemnon by Henke - Caldercraft - 1:64

mort stoll reacted to a post in a topic:

HMS Agamemnon by Henke - Caldercraft - 1:64

-

Nirvana reacted to a post in a topic:

HMS Agamemnon by Henke - Caldercraft - 1:64

Nirvana reacted to a post in a topic:

HMS Agamemnon by Henke - Caldercraft - 1:64

-

Chapman reacted to a post in a topic:

HMS Agamemnon by Henke - Caldercraft - 1:64

Chapman reacted to a post in a topic:

HMS Agamemnon by Henke - Caldercraft - 1:64

-

Greetings friends, Since I am a less knowledgeable modeler I have a question regarding rigging. Instruction calls out to start with the tackle pendants. There is a pair of two (4) on the foremast and I think from looking at one of the rigging drawings there is one pair on the mainmast. Are these pendants the same as burton pendants which are indicated in Lennart Petersson's "Rigging period ship models"? Unfortunately the use of the burton pendants are not very well described in Petersson's book either. Can someone please explain with a picture? Best regards Henrik

-

Wintergreen reacted to a post in a topic:

HMS Agamemnon by Henke - Caldercraft - 1:64

Wintergreen reacted to a post in a topic:

HMS Agamemnon by Henke - Caldercraft - 1:64

-

brunnels reacted to a post in a topic:

HMS Agamemnon by Henke - Caldercraft - 1:64

brunnels reacted to a post in a topic:

HMS Agamemnon by Henke - Caldercraft - 1:64

-

Mr Whippy reacted to a post in a topic:

HMS Agamemnon by Henke - Caldercraft - 1:64

Mr Whippy reacted to a post in a topic:

HMS Agamemnon by Henke - Caldercraft - 1:64

-

Henke reacted to a post in a topic:

Christiania 1774 by TJM – approx. 1:67-1:64 – Danish Light Frigate based on Vanguard Models HMS Sphinx

Henke reacted to a post in a topic:

Christiania 1774 by TJM – approx. 1:67-1:64 – Danish Light Frigate based on Vanguard Models HMS Sphinx

-

Henke reacted to a post in a topic:

Le Superbe by PqLear – Heller – PLASTIC – Built as “HMS Vanguard”

Henke reacted to a post in a topic:

Le Superbe by PqLear – Heller – PLASTIC – Built as “HMS Vanguard”

-

Henke reacted to a post in a topic:

HMS Victory by Rob S - Mamoli - 1/90th scale - first build - Terminated

Henke reacted to a post in a topic:

HMS Victory by Rob S - Mamoli - 1/90th scale - first build - Terminated

-

Dear friends, Decided to follow the instructions building the lower sections of the masts in series instead finalizing the one mast with all building moments. Started with the mizzen mast yesterday. It was some time since a worked on the masts. I cut myself twice before I found the knife skills 🫤. Best regards Henrik

-

Henke reacted to a post in a topic:

HMS Agamemnon by Henke - Caldercraft - 1:64

Henke reacted to a post in a topic:

HMS Agamemnon by Henke - Caldercraft - 1:64

-

Henke reacted to a post in a topic:

HMS Agamemnon by Henke - Caldercraft - 1:64

Henke reacted to a post in a topic:

HMS Agamemnon by Henke - Caldercraft - 1:64

-

Henke reacted to a post in a topic:

HMS Agamemnon by Henke - Caldercraft - 1:64

Henke reacted to a post in a topic:

HMS Agamemnon by Henke - Caldercraft - 1:64

-

Henke reacted to a post in a topic:

USS Constitution by bthoe – Model Shipways – Scale 1:76.8 – 1812 era

Henke reacted to a post in a topic:

USS Constitution by bthoe – Model Shipways – Scale 1:76.8 – 1812 era

-

Henke reacted to a post in a topic:

USS Constitution by bthoe – Model Shipways – Scale 1:76.8 – 1812 era

Henke reacted to a post in a topic:

USS Constitution by bthoe – Model Shipways – Scale 1:76.8 – 1812 era

-

Henke reacted to a post in a topic:

HMS Agamemnon by Henke - Caldercraft - 1:64

Henke reacted to a post in a topic:

HMS Agamemnon by Henke - Caldercraft - 1:64

-

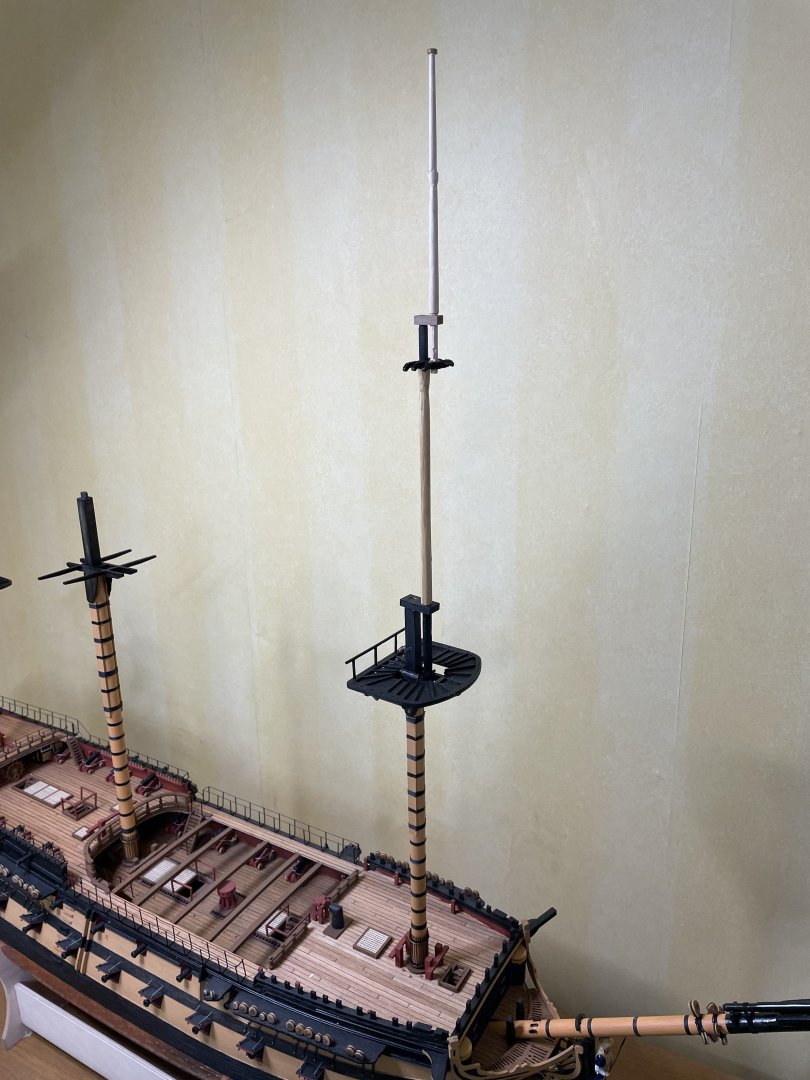

Dear friendly modelers, After a long brake I have now taken up my Agamemnon build again. My last build was a tube phono amplifier but now I am back at the ship yard. Today I did some painting of the main mast mast and the assembly of the boarding pike rack around the main mast. Needs to be repainted but at least the boarding pikes are there. Very fiddly. Best regards Henrik

-

Dear friends, Although there is a sort of hiatus in my Agamemnon build I thought I could show something else. A relative of mine sent me a picture. It depicts my father with one of his model boats. I think the photo is taken around 1947-48. He later became a naval architect but unfortunately passed away many years ago far too early. Later in life he a built a sailing boat in scale 1:1. Is there a particular ship modelling gene which is passed on for generations? Does anyone recognize the model? I hope I am not getting off topic in my build log? Best regards Henrik

-

It looks very nice! Where did you get the blocks and dead-eyes from? The model is 1:150. Mine, in scale 1:64 are tiny for my aging, soon 58 years old eyes 😊. Best regards Henrik

- 27 replies

-

- Le Superbe

- Heller

-

(and 1 more)

Tagged with:

-

Without knowing any details about the Heller kit of yours, I suggest that you fix the masts and do the detailing of the rigging with the level of details according to your ambitions before you do the yards with their blocks but blocks on the masts are probably better to attach to the masts before you glue the masts in place. She looks very nice! Best regards Henrik

- 27 replies

-

- Le Superbe

- Heller

-

(and 1 more)

Tagged with:

-

Hi Piotr, you are a very lucky man to have such a supporting wife. My admiral always asks me in a rather derogatory tone where I am going to do with my models when they finished. "I do not want see them in our living room". Then when it comes to the holes in the deck my suggestion is that you add some kind of circular "seal" with a inner diameter close to the mast diameter and an outer diameter slightly bigger than the hole in the like it is done on my Agamemnon model. Best regards Henrik

- 27 replies

-

- Le Superbe

- Heller

-

(and 1 more)

Tagged with:

-

Hi Piotr, Could you please explain your technique used for the wooden deck. It looks so nice! Best regards Henrik

- 27 replies

-

- Le Superbe

- Heller

-

(and 1 more)

Tagged with:

-

Henke started following Le Superbe by greenskin - Heller - 1/150 - PLASTIC

-

Hi Piotr, Thanks for starting a build log on Heller's Le Superbe. According to Scalemates.com the kit dates back to 1977 so the man who wrote the instructions for Heller in 1977 has probably retired or sailed over to the other side 😌. I have a suggestion for the rigging. Unless you already have a basic understanding of rigging I suggest you get hold of "Rigging Period Ship Models" by Lennarth Petersson. This book gives a basic understanding of rigging of a frigate of the same period as your Le Superbe. I suppose rigging in 1:150 scale has to be simplified a lot but the most prominent details of the rigging can probably be replicated. Anyhow, welcome to MSW and happy modelling Piotr! Best regards Henrik

- 27 replies

-

- Le Superbe

- Heller

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.