src

-

Posts

2,300 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by src

-

-

What kind of hinge would have been used n an 18 century door? I replaced the white metal door on my Enterprise and got to thinking the other night, a door needs a handle and some hinges. I based the door on the kit part and left the "casing" proud like a modern door. Making the knob was easy enough, but I am not sure what the hinges should look like. I have looked through Antscherl's "Fully framed series I and II as well as Lavery's "arming and Fitting" They made no mention of door hinges that I could find. I even looked through the three how too books I have and found nothing. Lots of information on gun port hinges and rudder hinges but nothing about door hinges.

I am tempted to just cut three bits of brass wire and blacken them to represent the hinge barrel. Then I saw on another build a mention of "L" hinges. This sounds correct for what I am trying to do but the only thing I found online was this reproduction hinge :

That hinge is designed to mount to the face of the door and the case, my case is proud by about a 64th". I am thinking of making the "L" portion and soldering it to some wire but I wanted to get some input from some more experienced people. I am not sure if the arm of the hinge should span just the stile or al the way on to the the rails also.

Sam

-

Brain, I am so sorry to hear that. Family first as always, the build will be there waiting for you.

Sam

-

-

Rich, Just getting caught up with your build. Your guns look good. Have you decided, in or out on the install??

Sam

-

Robbyn, nice work!,

Sam

-

Brian, Just getting caught up. Hull looks great. gonna be watching what you do with your blocks.

Sam

PS, Welcome back Alfalfa!

-

Brian, Wayne, Michaelpsutton2,

Thanks for all the info. this weekend I hope to be able to look into this a bit further. Sorry I took so long to respond, life has been.....busy lately.

Sam

-

Russ, Brian, ZyXuz, Thank you!!

Brian, dont sell yourself short, I have seen your work, you may still.

sam

-

Brian,

Thanks for stopping by, I never considered that. I saw another builder, Auger, redo his and thought, "Why not?" Then my nit picky nature kicked in and it had to be "perfect" whatever THAT is. Anyway I am mostly happy with the door, the window frames could be a bit more consistent. I set the door in place a few minutes ago and took an "installed" picture below. Other than my cabin being crooked I may leave it, the window frame is just set in place so I still have the option to push my sanity (and my eye sight) a bit more and re-do it.

May need hinges and a door knob now too. Not sure what the hinges should look like, I havent found anything in any of my books - all 4 of them.....

Ok here are the pics I couldnt post earlier this morning.

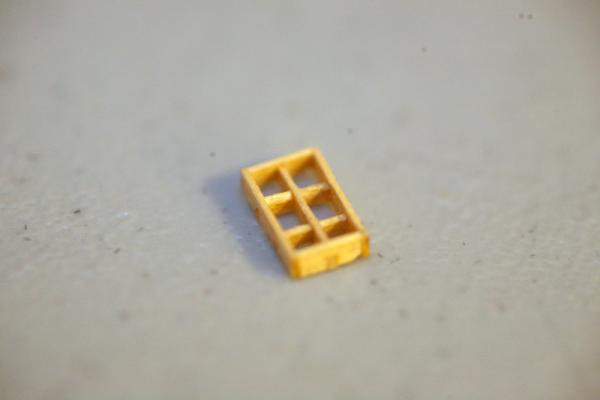

The window frame.

"Installed" in the door

Door progression to date

(edited for typos)

Set in place, Not too bad except the cabin site crooked. Gonna have to rip that off tonight.....

Thats all for now,

Sam

- Matt D, dafi, popeye the sailor and 1 other

-

4

4

-

Not much progress the last few weeks. Between travel, family obligations, etc there has been precious little time to build. I did get a chance to see the log cabin that my grandmother lived in for a few years, it belonged to my great-great-grand parents. That was kinda cool, looks like "Little House on the Prairie" as you drive up to it.

Rebuilt my window frame out of some 0.5mm deck planking, I thought it was bass wood but no. I like the frame work better than the photoetched part, just a bit crooked-y. Its not real noticeable except up close, I may just leave it. The "glass" on the other hand. I used a product called Gallery Glass from an arts and crafts store. I thought it would work well and in the couple of tests I did it appeared to. I didnt take into account shrinkage though. After I took the pictures I applied some more, We'll see how it looks tonight.

Hmmm.... seems I cant get the uploader to work for pictures. It happened once before, I may need to restart safari hat fixed it last time. Its time to go to work now, rather than rewriting this, (I type REALLY slow) I will post and then edit wth pictures tonight.

Sam

-

Robbyn,

Ammonia should blacken brass. try Augies acetone first then perhaps some vinegar to "pickle" it. that might give the paint a bit more bite, we do this a work for galvanized steel. Maybe if you have some scrap to test on first? If none of that works re clean and try the ammonia. I dont know if household ammonia will get it dark enough for you, but it might be worth a try.

Sam

-

Thanks Henry, clearing the gunports makes sense. You probably just saved me from a redo.

I didnt phrase my question correctly. When I look at a shroud I see a triangle formed by the outer two shrouds and the channel as the base. What I am curious about is should the base of that triangle, the channel, be a certain percentage of the mast height or multiple of the diameter?

Wow I just checked Amazon, The Masting and Rigging of English Ships of War 1625-1860 is $228.00 US.

I have blown my building budget clear into September...... The Elements and Practice of Rigging And Seamanship. referenced above is available as an online reference and book copies are more in line with my budget at the moment. Looks like that will be my reference for the time being.

I have blown my building budget clear into September...... The Elements and Practice of Rigging And Seamanship. referenced above is available as an online reference and book copies are more in line with my budget at the moment. Looks like that will be my reference for the time being.Sam

-

JP, Looks great. The only thing I dont like about it is......I didnt do it. It is an inspiration for my next build.

Seriously its your build, but if it was me, like others have said, I would be reconsidering paint.

Sam

- popeye the sailor and augie

-

2

2

-

I have a ways to go before I get back to the channels since it appears I need to set the masts first. In the meantime I have noticed there seem to be a formula for everything shipbuilding. For instance I have seen mention of shroud diameter to be 1/x of the diameter of the mast. Based on the info Allan provided above I would assume that the Fore Mast on an 18 gun ship would have six shrouds; 7 bolts would leave 6 spaces between. But, what about shroud spacing? Is there a formula that says the space between shrouds is to be some fraction of the mast height or maybe of the diameter?

Looks like I need to buy a rigging book, suggestions?

Sam

-

Thanks Russ, the grillwork isnt cleaned up yet. That is resist on the brass, I just laid it up to see more or less what it would look like. If I use it it will be blackened.

I have some 1x1mm bass wood here I may try to make a window out of that and go with whatever looks better.

Sam

-

Brian, the planking looks great! .5mm strips with nothing behind them? I am afraid I would sand through. Like your new avatar, kinda miss Alfalfa though, the look on his face is similar to how I feel when building; "Yikes! How did I manage THAT!" Looking forward to seeing where you go with the finish.

Sam

-

No worries Brian, I kind of look at my build log as a back and forth conversation. If it is reasonably close to being related to our builds, most anything that is not malicious ok with me.

Build time has been limited the last few weeks, between work, summer traveling and "Domestic Bliss" (chores) I have not been able to build much.

I have several mini projects going at once, stern gun ports, rails, cabin, door the stem.

I decided to redo my gun port hinges, after some more reserch I noticed they were short and the barrels/knuckles of the hinge were incorrect. That required more solder of different melting temps to redo, still need to do that.

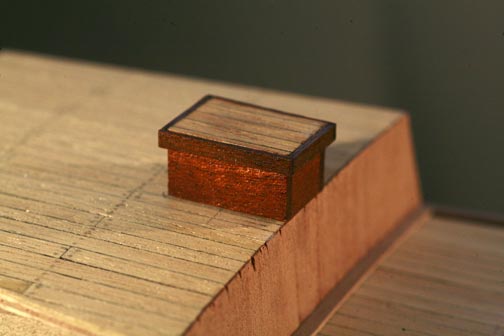

I was looking at the captains cabin or the hood as the instructions call it. I had originally stained then shellacked it, It came out too glossy and with my decision to go with a rubbed oil finish I had to strip the finish off. then decided it should have been planked so I dug up a couple of my last bits of planking and planked it. Turns out I have a few more small bits left, my redo my gun ports too.

My early attempts

this weeks version

Hmmmm... a bit like a jail cell.

Sometime back I decided to scrap the door that came with the kit and go with a wooden one. I made and finished one but was never really happy with it so made plans to re-re-do it.(or is it re-re-re-do it? I can remember) I made some photo etched frames for the new one, not sure yet if I like it, looks too much like jail cell bars. I need to refigure the jambs around the door, that is going to require a bit of surgery on the upper waterways.

Original stain

replanked and restained

That is about it for now, maybe the goddess of chores will be busy elsewhere and I can get some building done this weekend........Who am I kidding?

Sam

-

Brian,

That looks really REALLy clean! Nice work.

Hmmmm lacy curtains huh?

sam

-

Russ, just caught up with your build, as always, great work. Looking forward to seeing your rails. I dont know about you but there is something about looking at a well done scarf joint that makes me say "oh yeah!"

Sam

-

Thanks for the info Brian, it will help when the time comes. FYI the enterprise is double planked, I tried to single plank and failed miserably. I do appreciate the compliment though, thanks.

Gonna plop myself back down in my seat and take notes now.

Sam

-

Brian,

Been following along quietly here for a while. Coming along nicely, I like your moldings, I know what you mean about a camera YOU can control. When I first started my log I was using my little nikon point and shoot cause I didnt want to mess with getting the big guns out. Gave it up quick for the 5d and a tripod.

The rattlesnake is the ship I would like to make my 2nd build, if you had to do it all over again would you choose this kit or the other offering - Model Shipway(?) Just curious.

sam

-

Brian,

Two humans and sheep for neighbors, how come that doesnt sound bad at all?

Ya gotta love the internet, I try to buy from local hobby stores as much as is practical but even being blessed with multiple sources I have found that I still get most of my ship building supplies online.

How is your bulkhead and deck fit up coming along?

sam

-

Richard,

I think it depends on what your goal is. Can you give us a picture of what you are working with and trying to accomplish?

Do you want a smooth surface to do your second planking? Based on your response of being interested in sawdust filler and your question of staining patch and paint it sounds to me like you finished planking and are searching for a stainable filler? The wood dust is most likely your best bet if all you want is to fill minor gaps in the planking, if you need to "float" it over the hull and then stain, my opinion is your asking for trouble. Rockler, Woodcraft and Homesteadfinishing.com(S) all have sandable fillers as well as the local hardware stores. You will need to experiment with the right combination of filler and stain though. In my experience they dont always take the stain the same as the wood.

If you re going to paint like Bob did (nice finish Bob) then a light weight filler may be the way to go. I have seen drywallers use a light water based topcoat for patching and touchups, they will smooth it on and use a wet sponge with most of the water wrung out and smooth the surface with that. Might be something to experiment with.

Good luck, hope this helps.

Sam

-

I've not actually seen a model showing the air spaces - yet!

Me-thinks I am being challenged!

Sam

Door hinges

in Discussion for a Ship's Deck Furniture, Guns, boats and other Fittings

Posted

Hadnt thought about opening inwards.

"T" hinges then. Something like this I suppose:

http://dckitchensjoinery.bttradespace.com/our-galleries/jobs-portfolio/gallery-item?mediaId=942C8F8A2EA31FB4E040BB0A462B3FBC