mikegr

Members-

Posts

828 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by mikegr

-

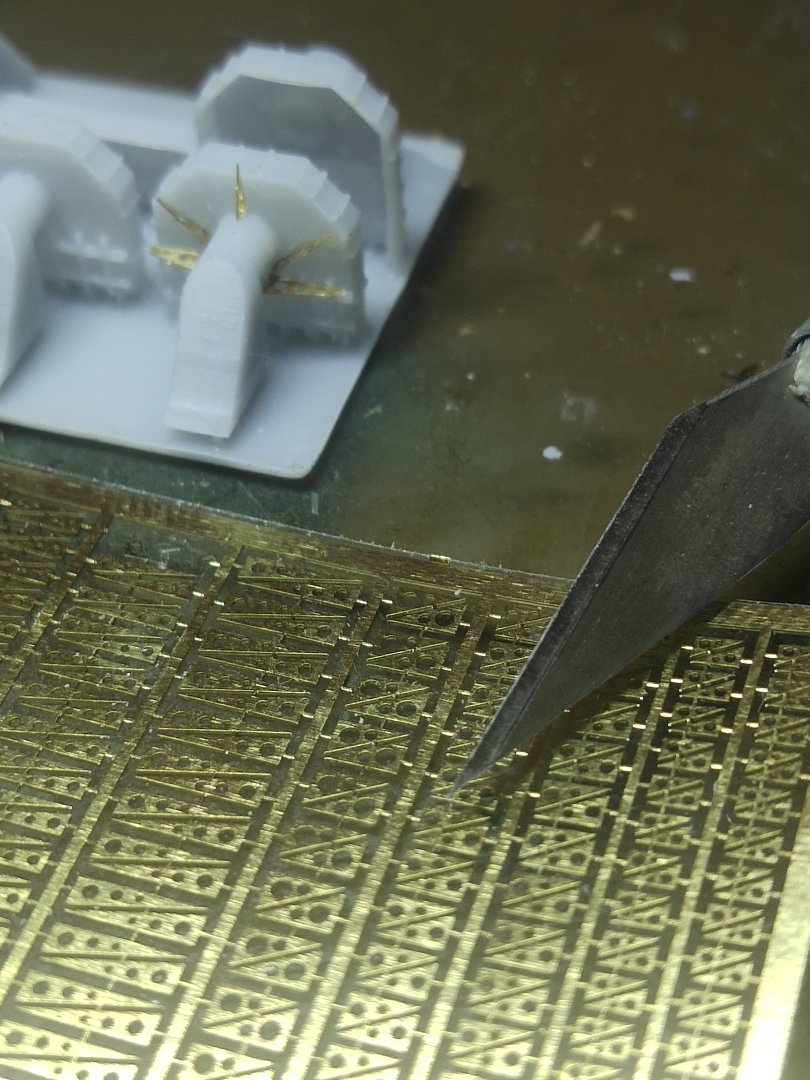

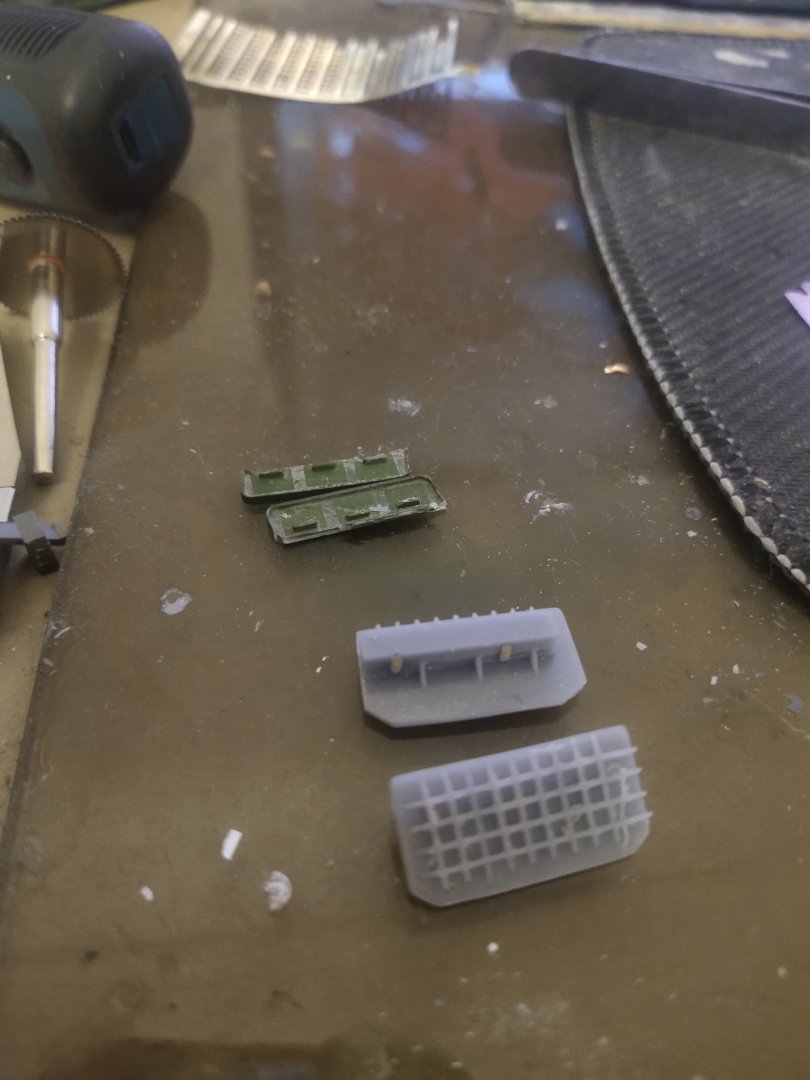

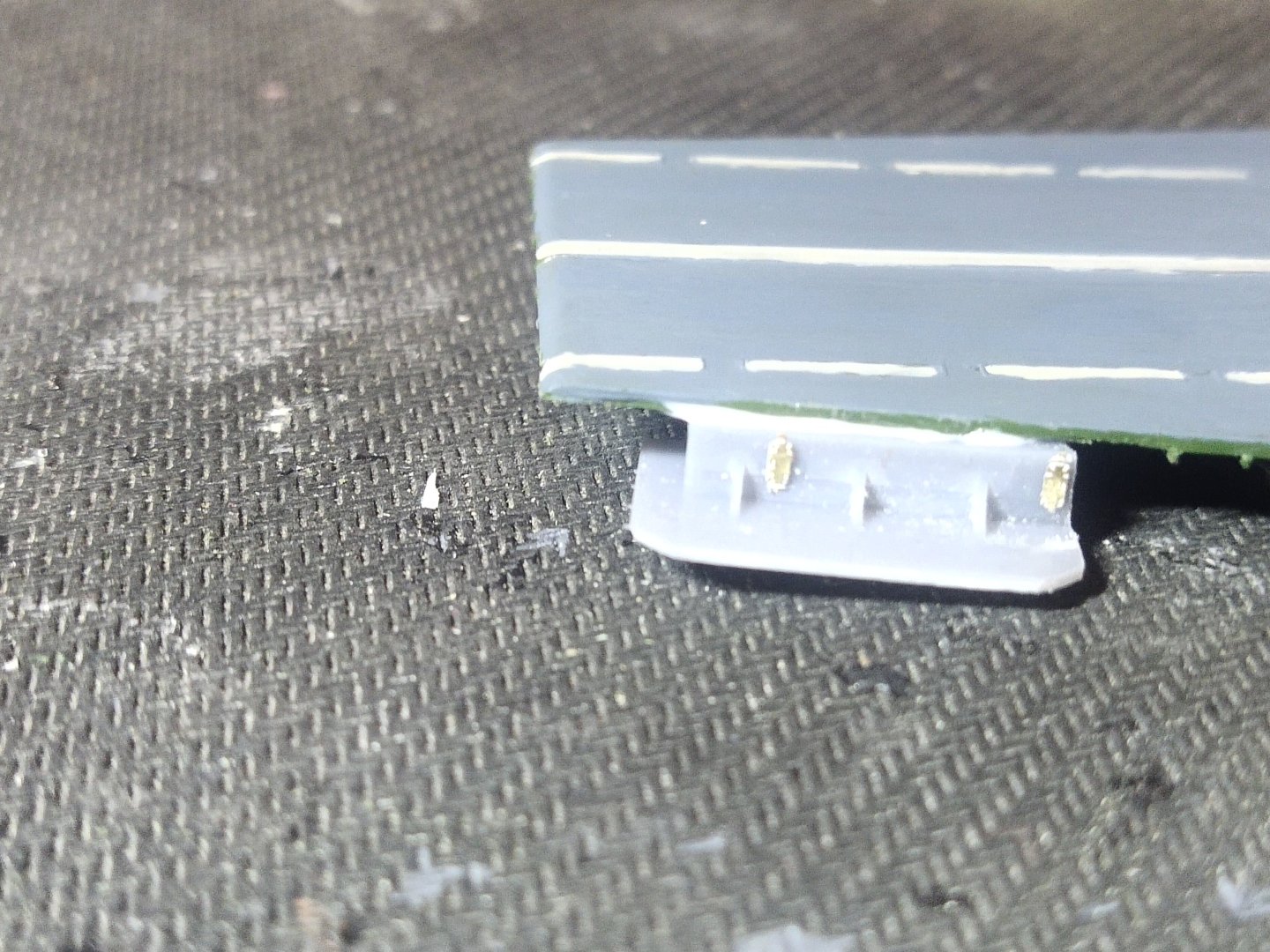

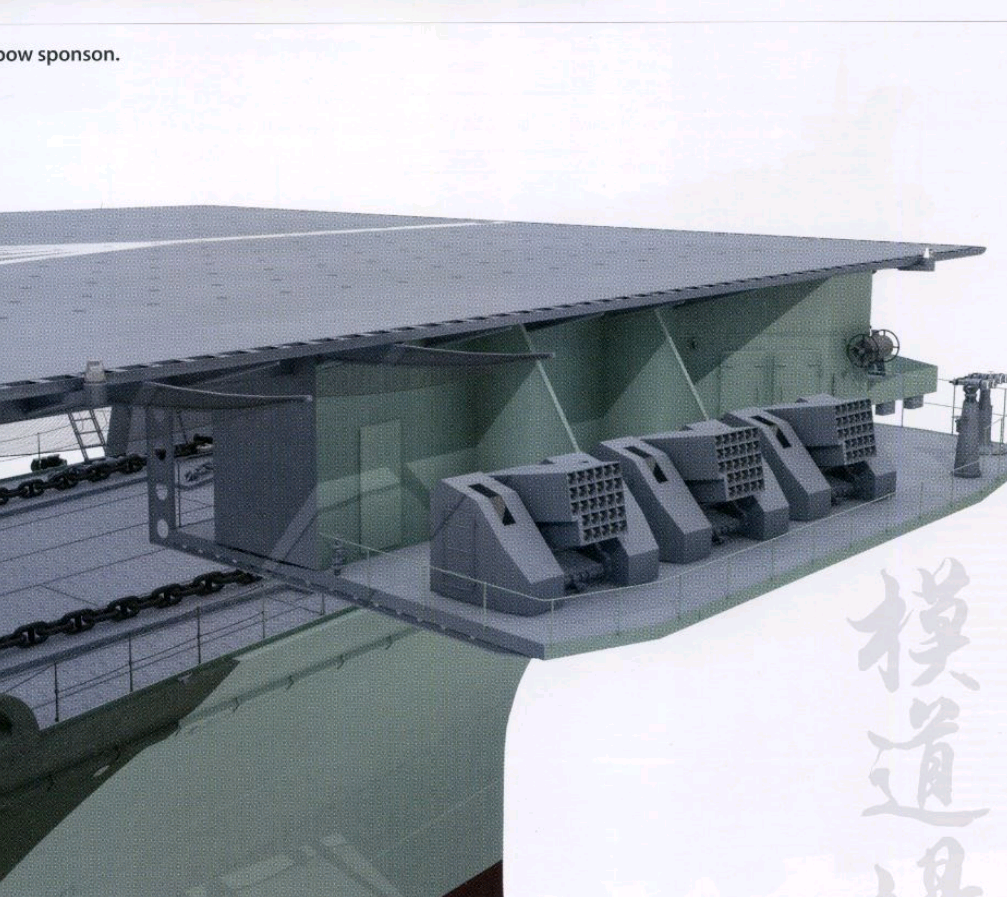

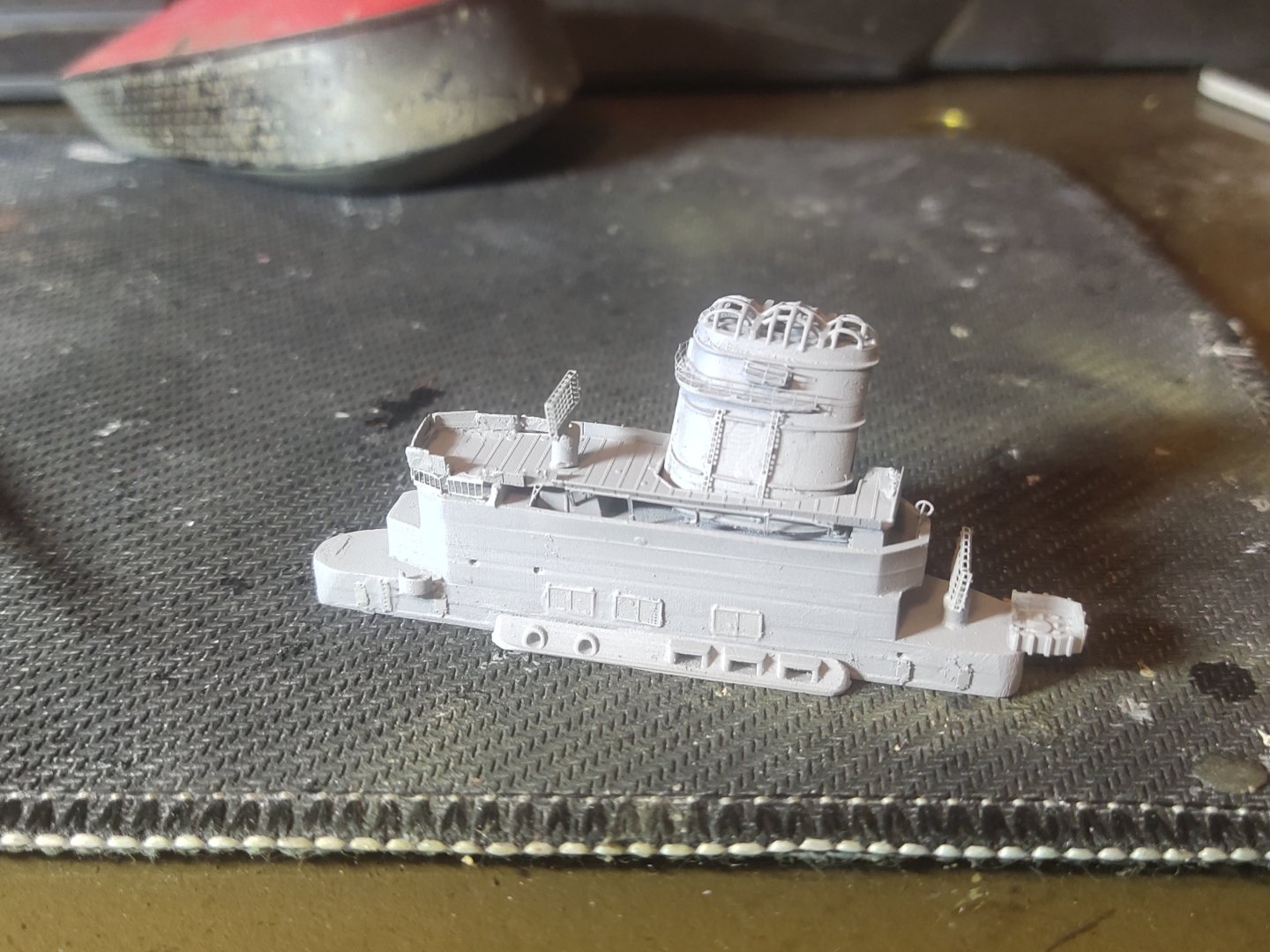

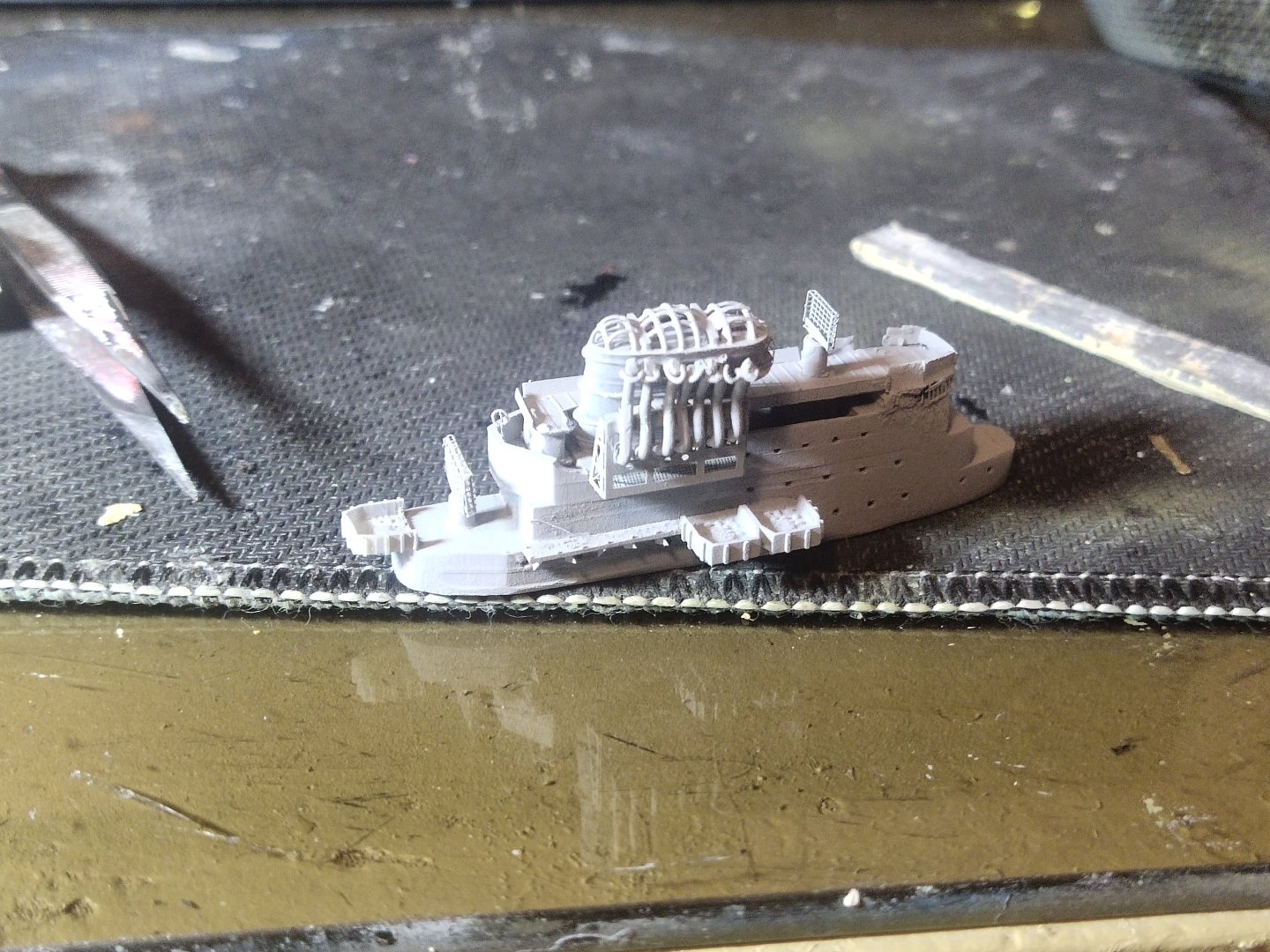

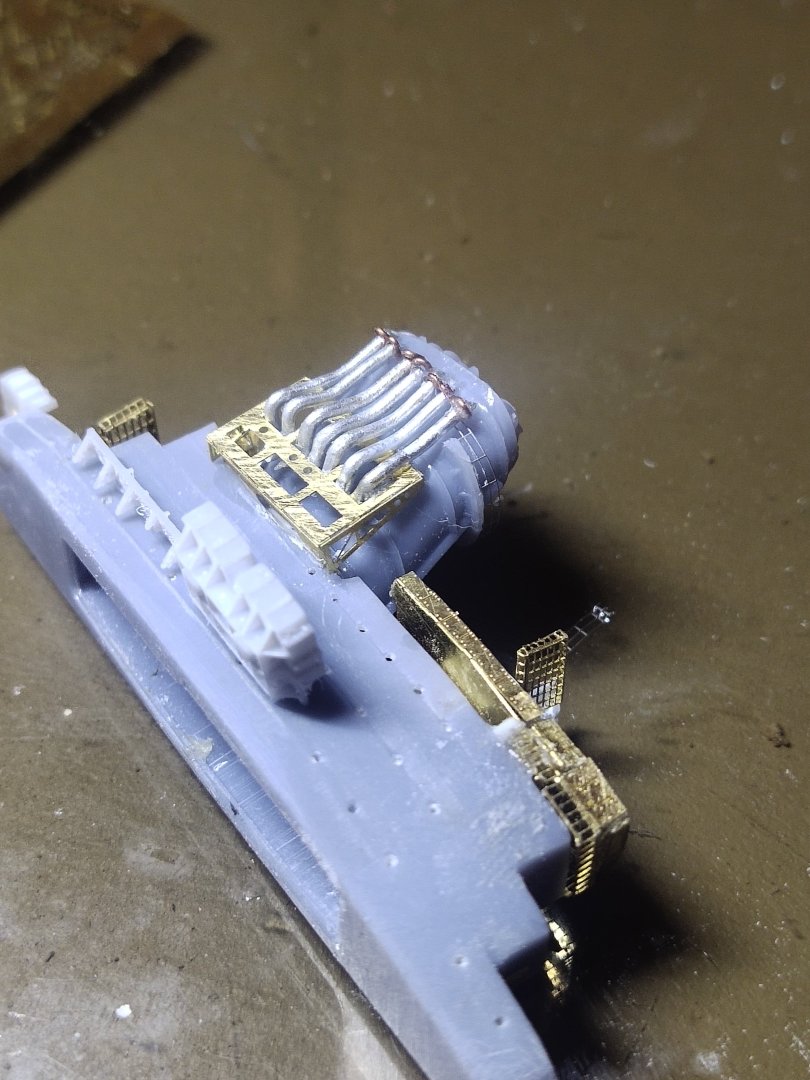

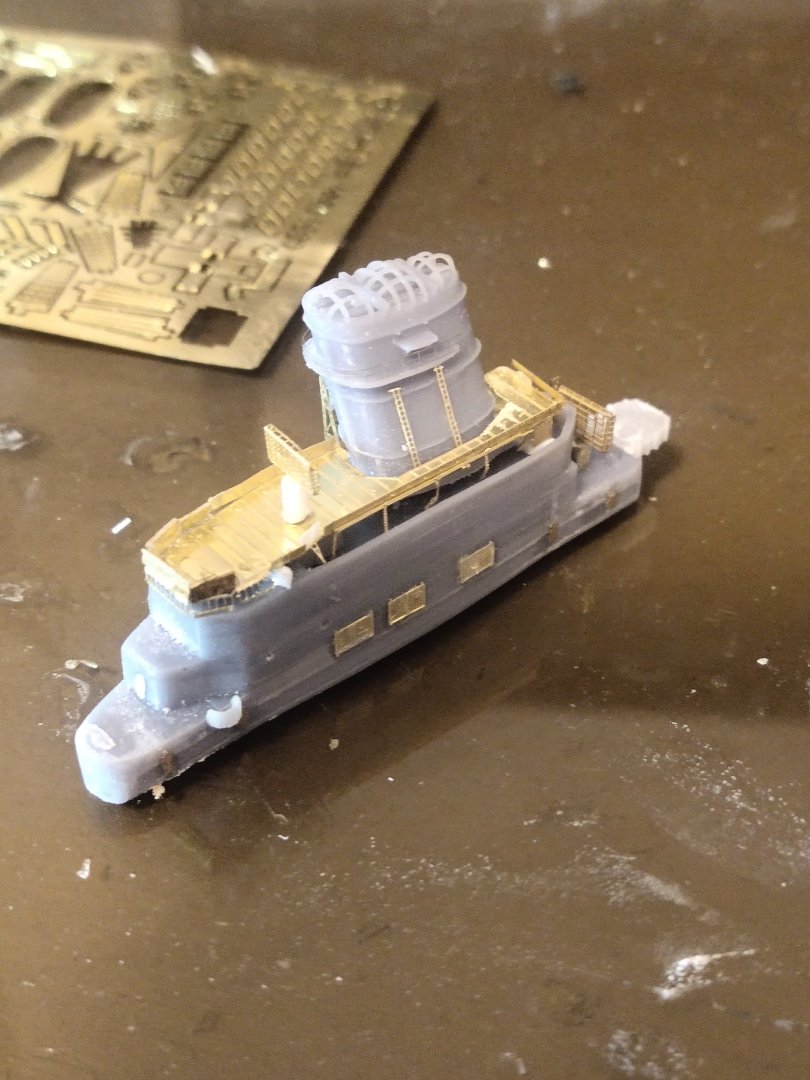

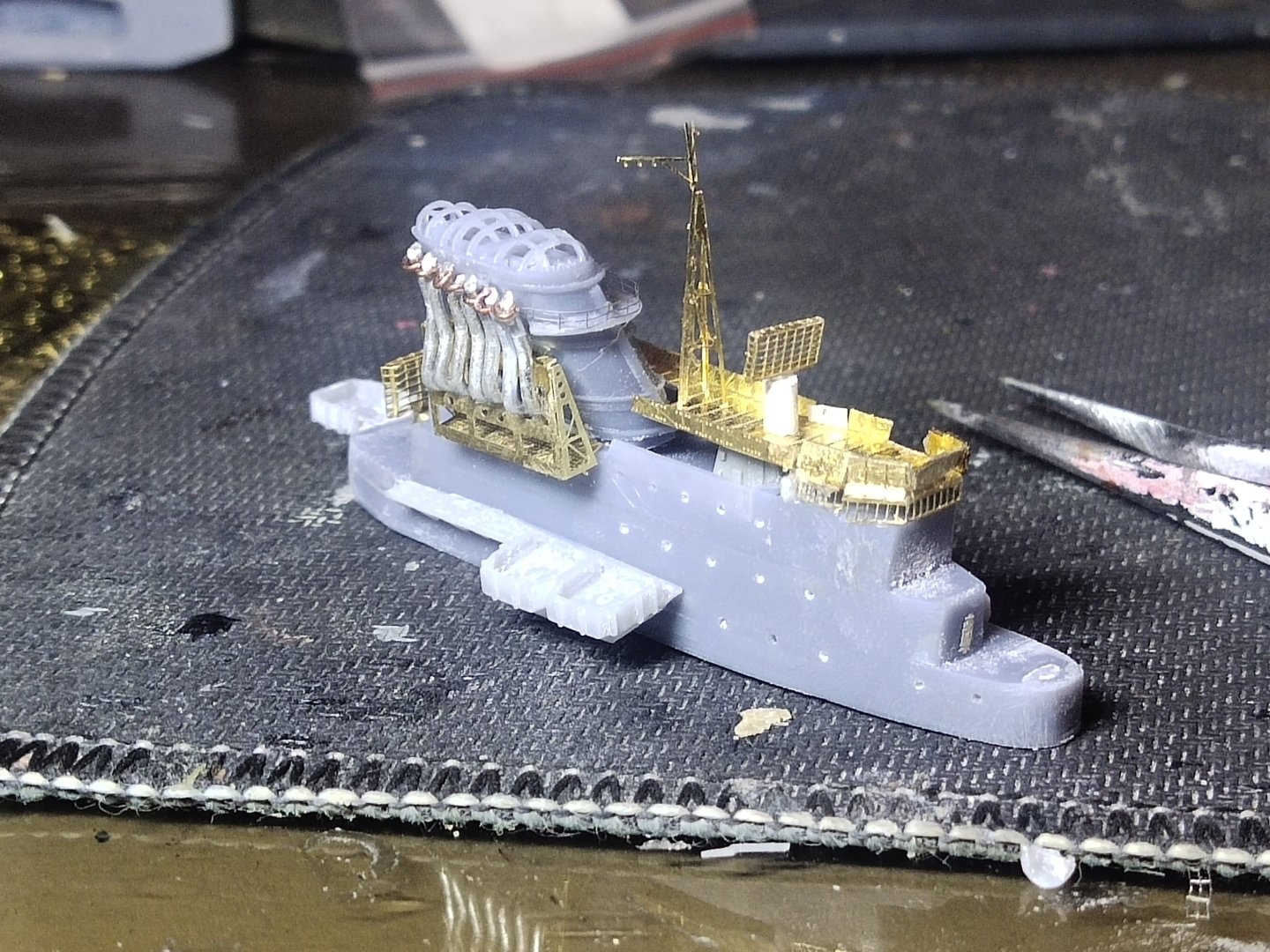

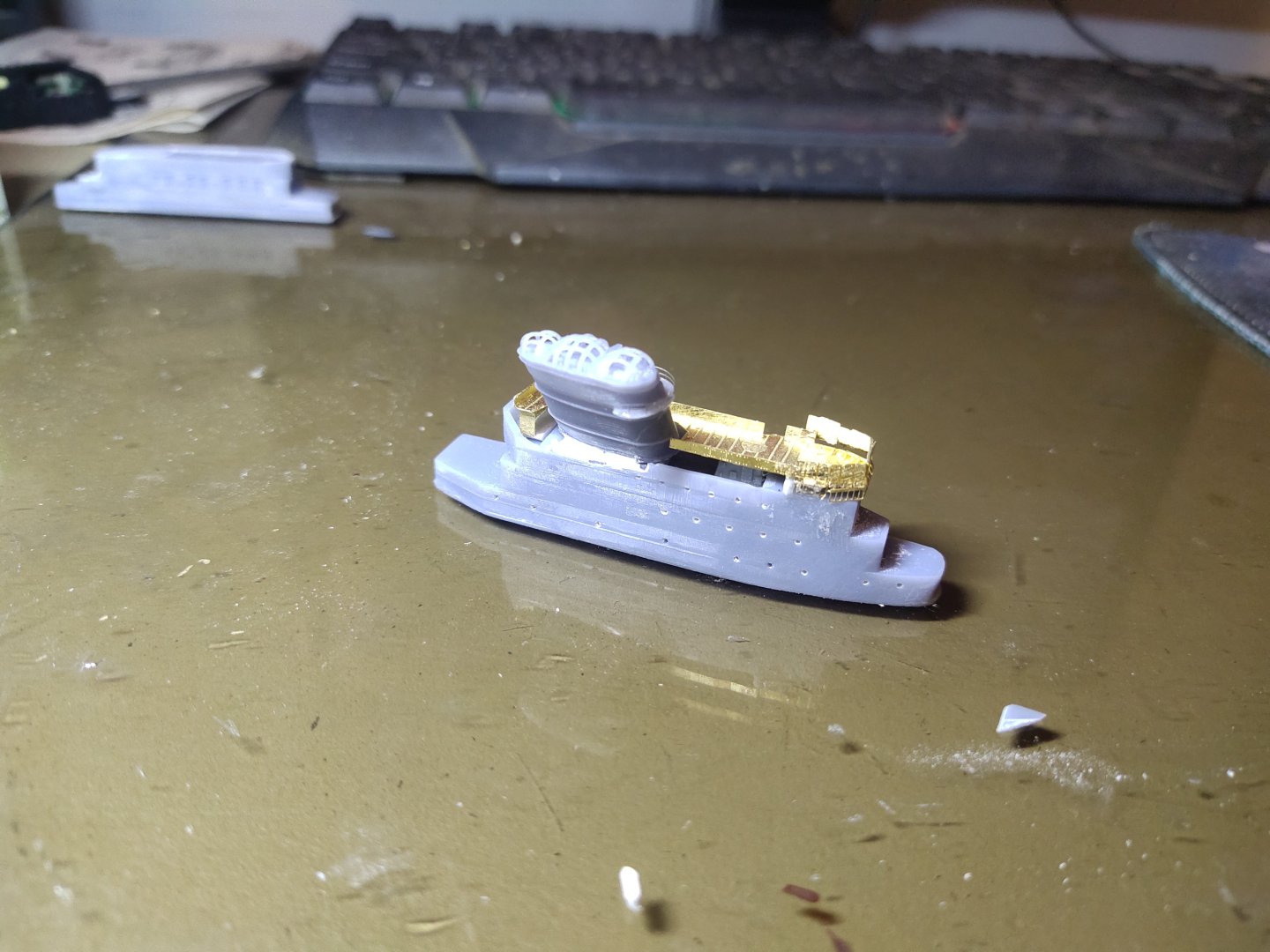

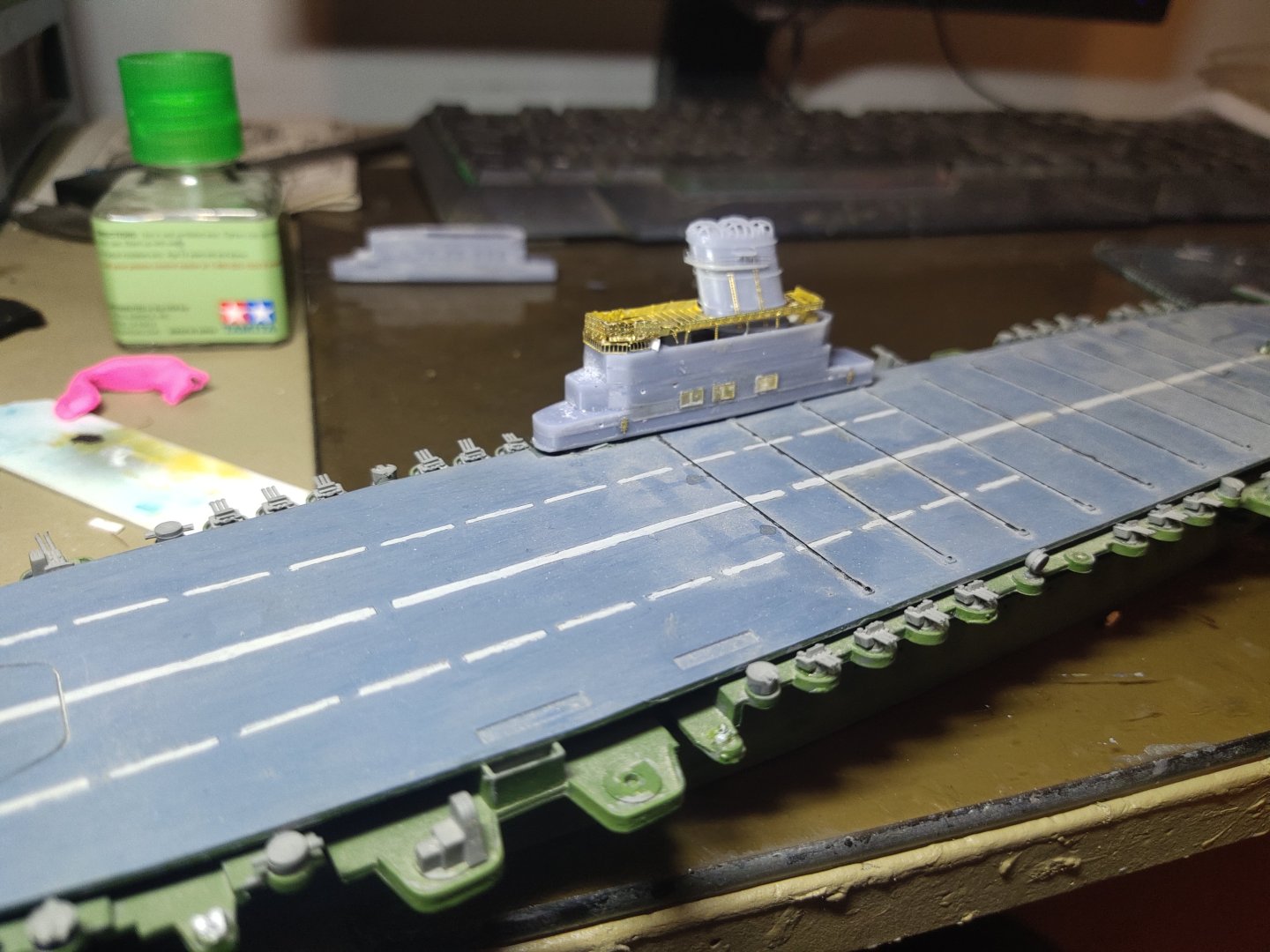

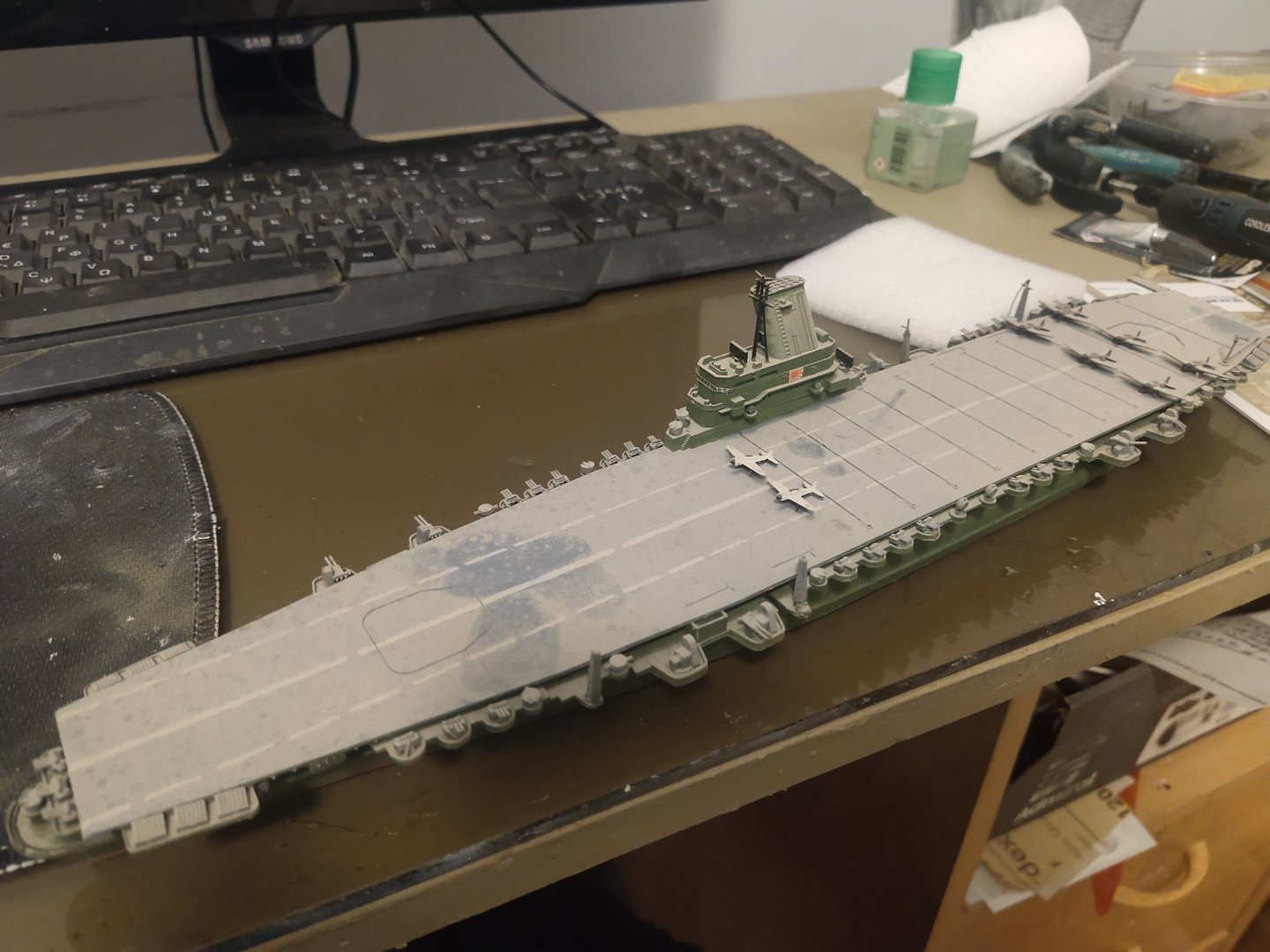

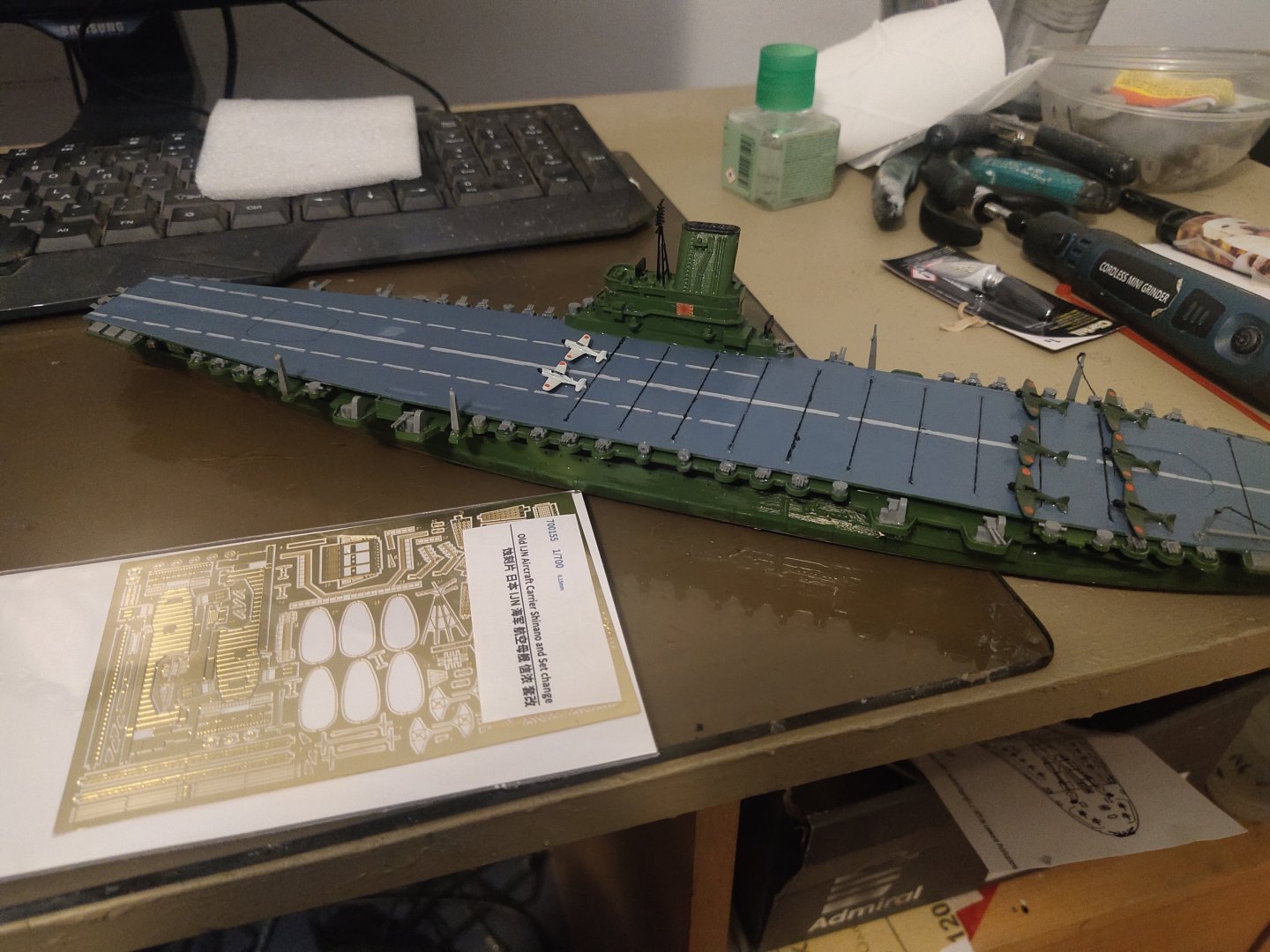

The model is made by 3 main pieces. The flight deck, the hangar area and the lower hull section. I start working on the gun platforms around the main deck. These should be all removed and replaced by correct ones. Unfortunately these are part of the hangar deck, so I had to cut them using a low rpm rotary cutter. Then sand a lot to remove the excess plastic. The fist piece installed was the bow platform set for the rocket launchers Looks like there is a lot of work to be done. I estimate this project to be done before Christmas.

-

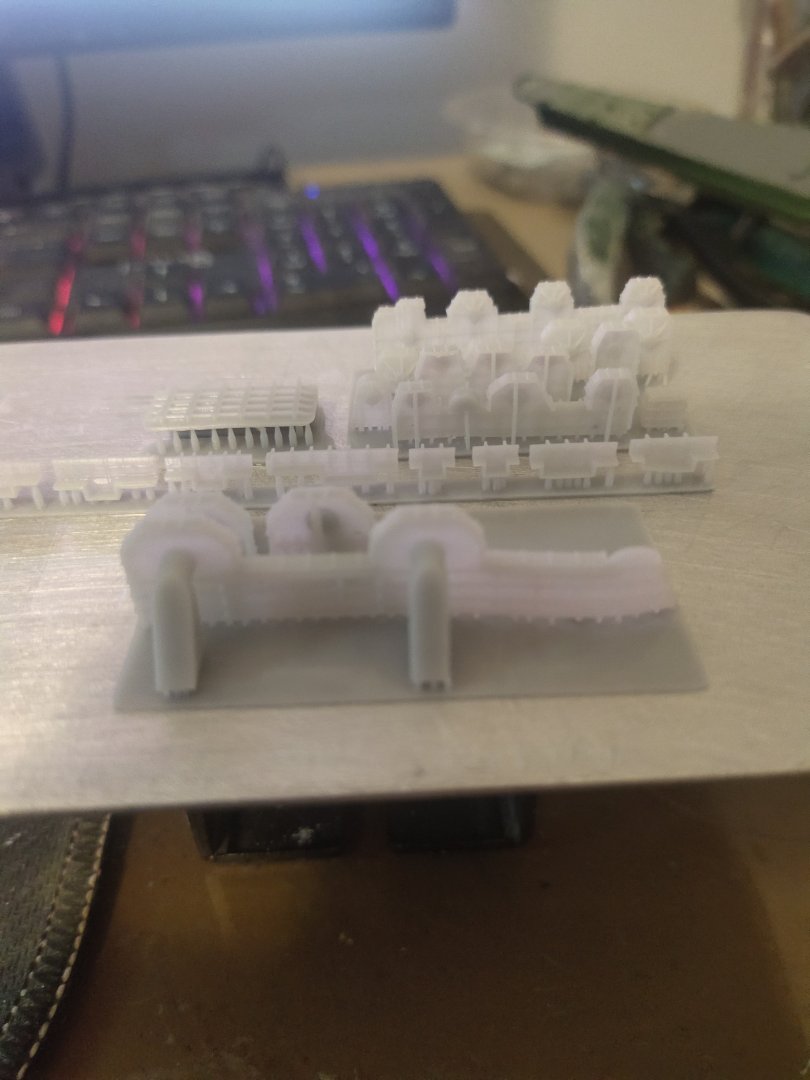

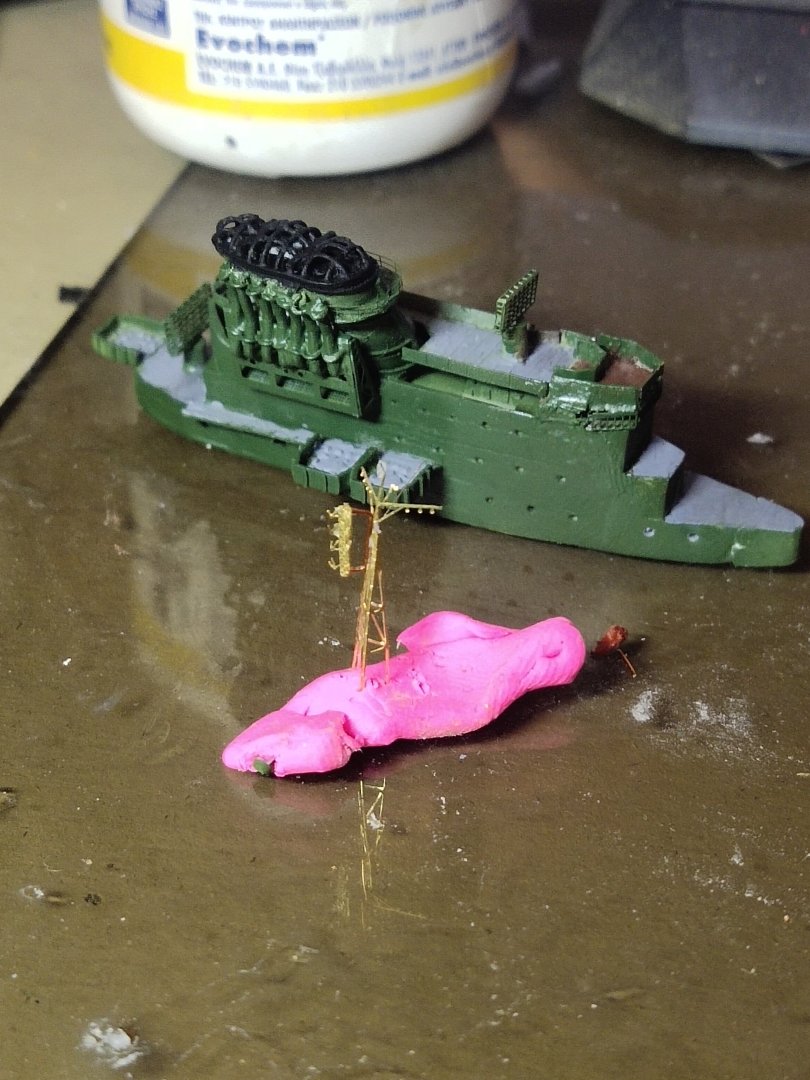

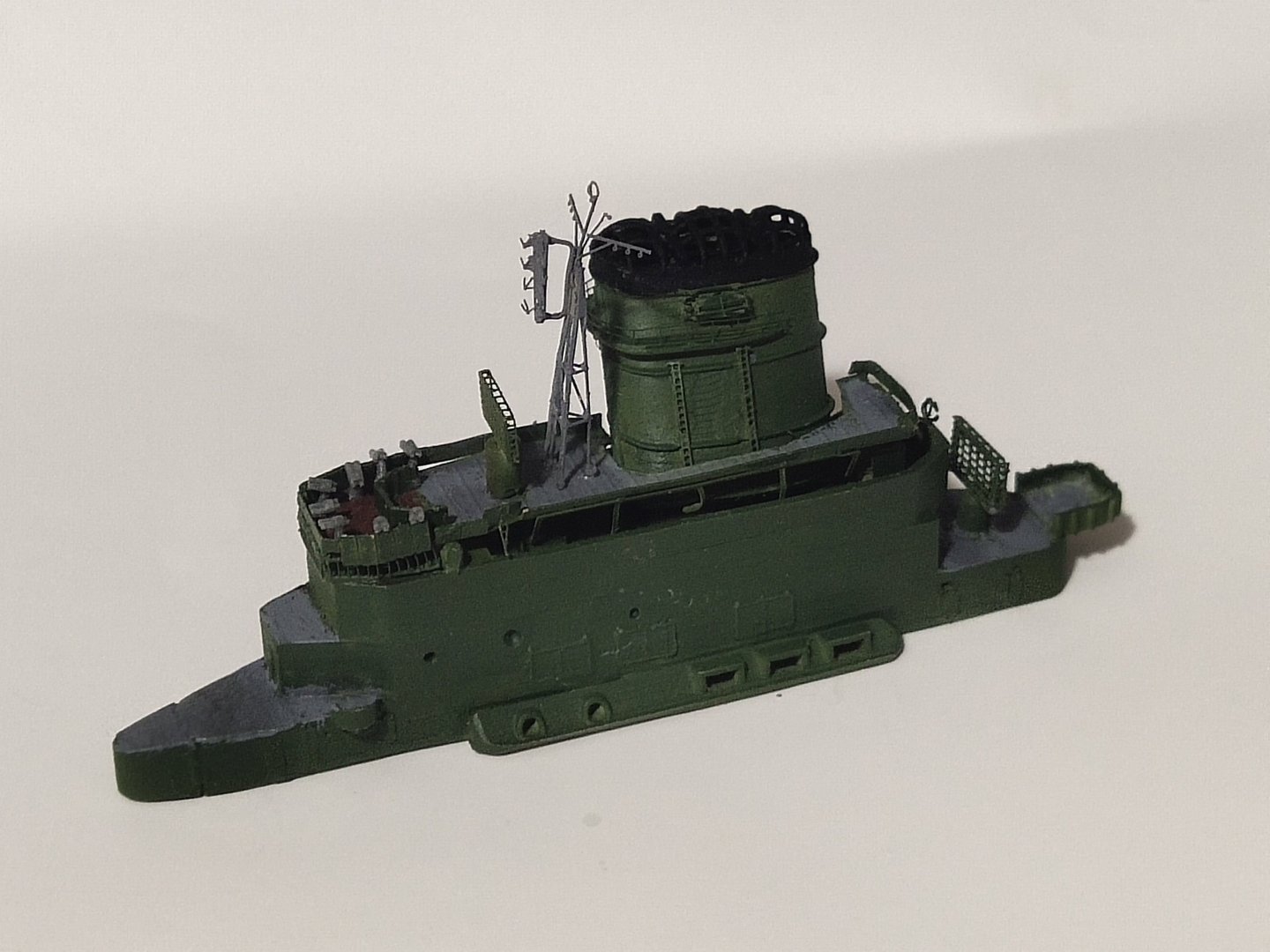

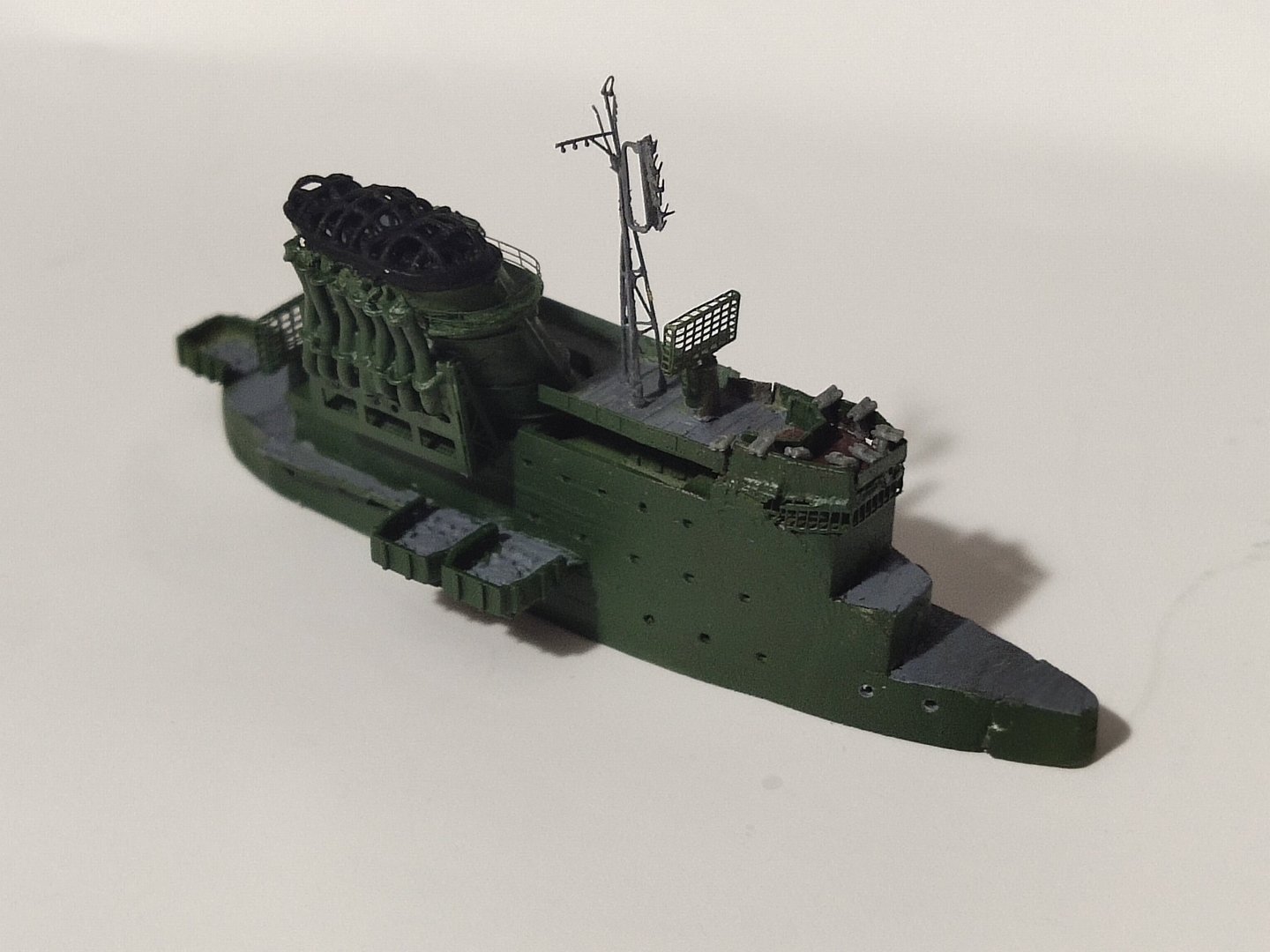

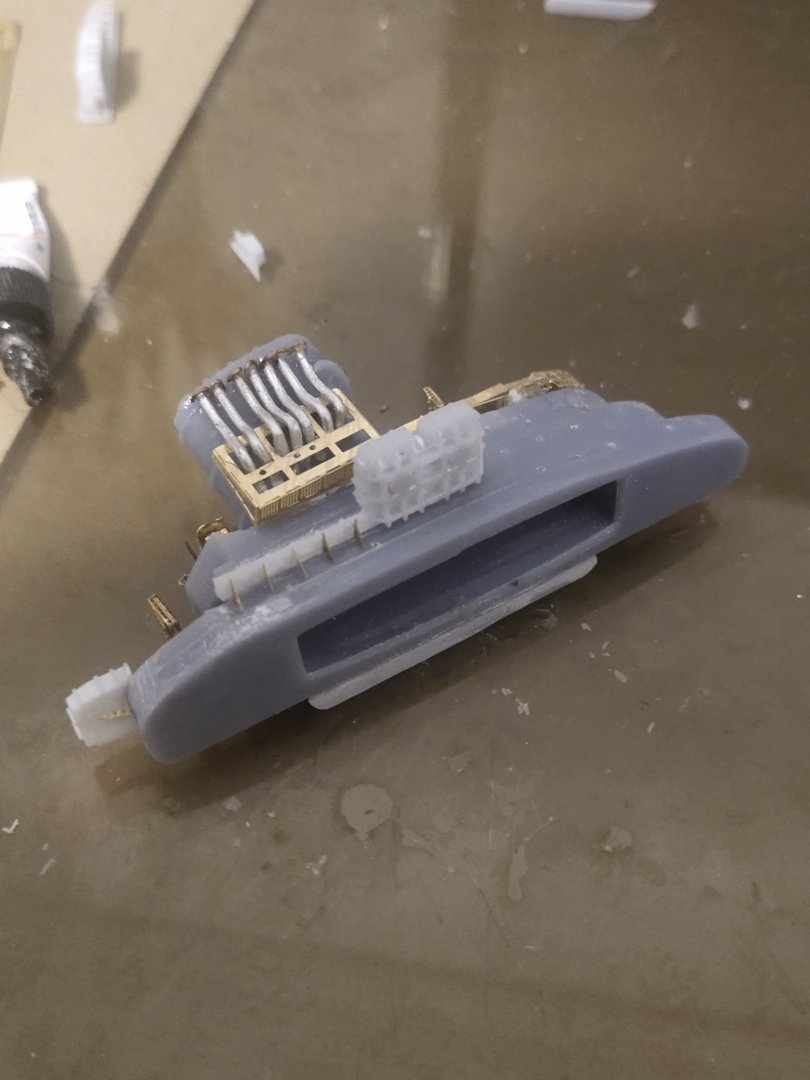

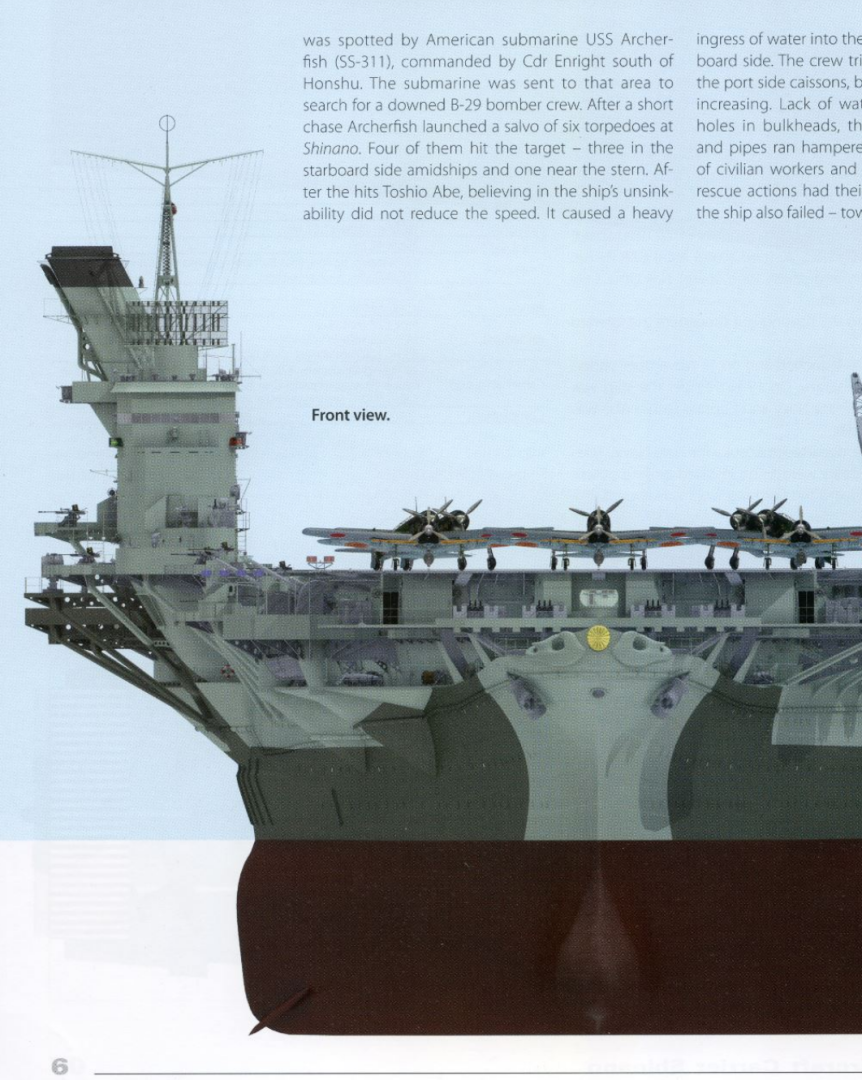

There's only one picture of Shinano available. I have Kagero's 3d book for reference. Starting from the top I realized that the oval shape of the funnel is wrong. So I printed some replacements to experiment with a teardrop shape. The superstructure is also not compatible with the PE parts so I need to work with it also Under the deck there is actually a Yamato class hull which seems that Tamiya used this to the Yamato or Mushasi model

-

Merkava III by mikegr - Revell - 1/72 - PLASTIC

mikegr replied to mikegr's topic in Non-ship/categorised builds

-

Merkava III by mikegr - Revell - 1/72 - PLASTIC

mikegr replied to mikegr's topic in Non-ship/categorised builds

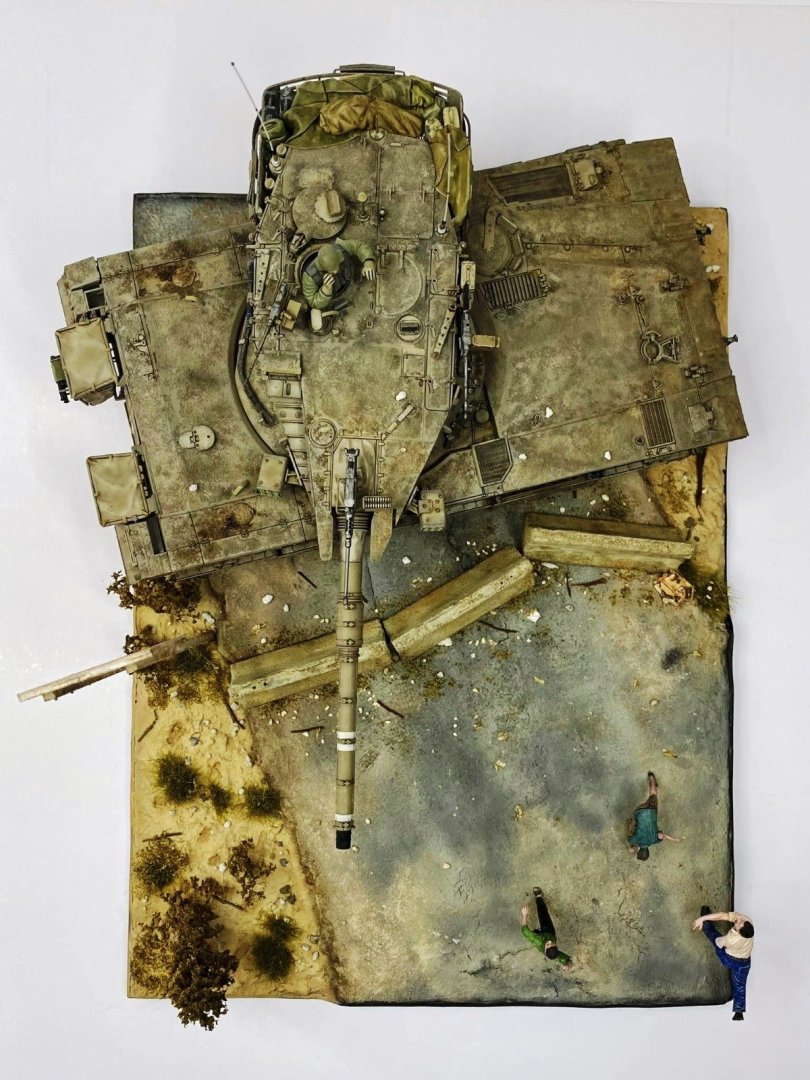

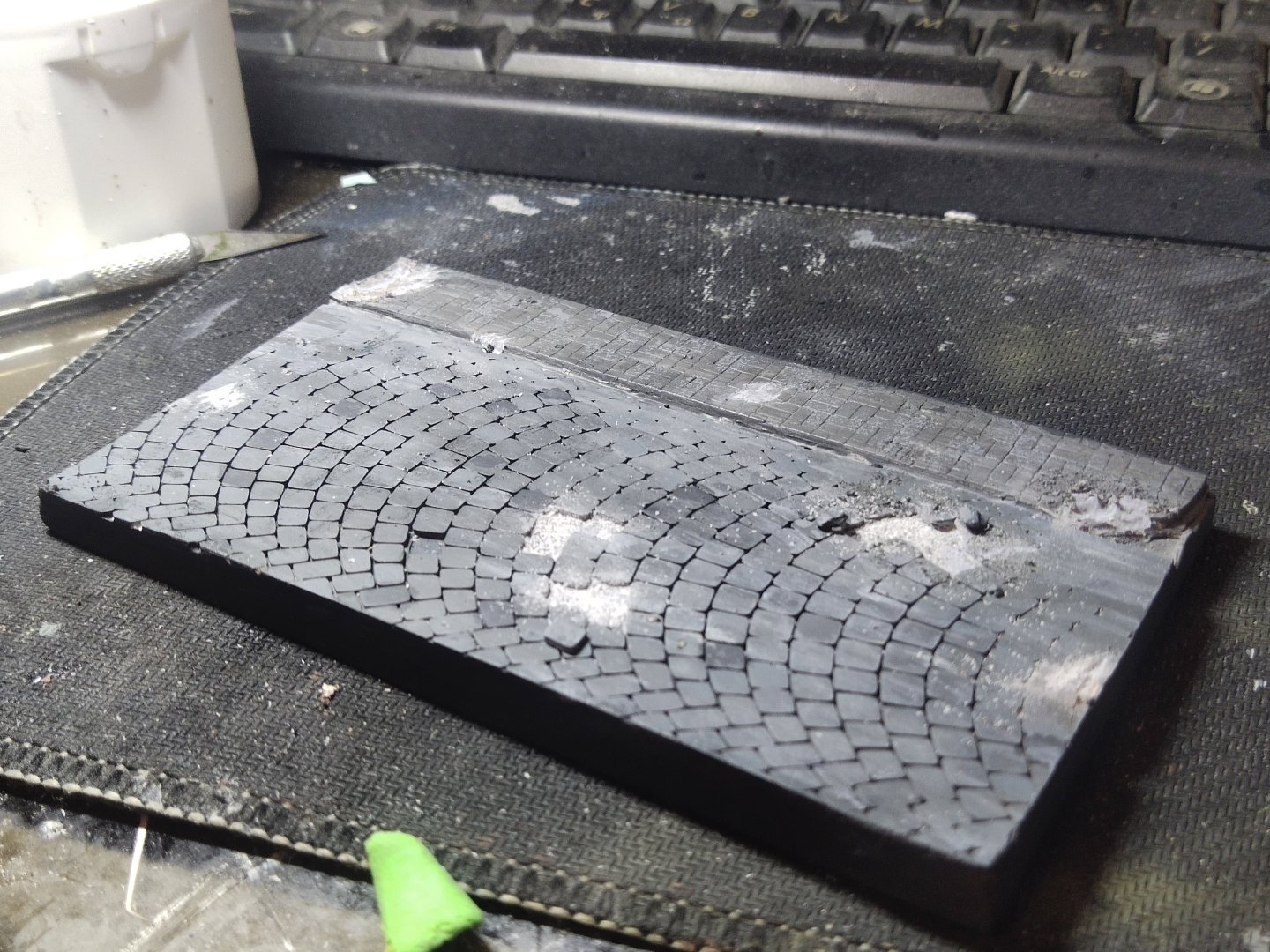

I wanted to build a base, like a small presentation but without spending much time. So I found a some 3d files, however it took me all Sunday to adjusting to my preference and scale. Anyway I turned quite ok. A couple of pics with the other beast. My first base of the M1A1 was big and empty, the T-90 muddy terain was better even simple. The 3rd was nicer I think -

Merkava III by mikegr - Revell - 1/72 - PLASTIC

mikegr replied to mikegr's topic in Non-ship/categorised builds

-

Merkava III by mikegr - Revell - 1/72 - PLASTIC

mikegr replied to mikegr's topic in Non-ship/categorised builds

I added some equipment to fill in the empty space behind the turret. Next was the weathering by painting some areas with light shade. Then applied acrylic black wash all over but i made it thinner over the rougher horizontal surfaces to avoid excess accumulation of dark liquid. Tomorrow more shades will be applied -

Merkava III by mikegr - Revell - 1/72 - PLASTIC

mikegr replied to mikegr's topic in Non-ship/categorised builds

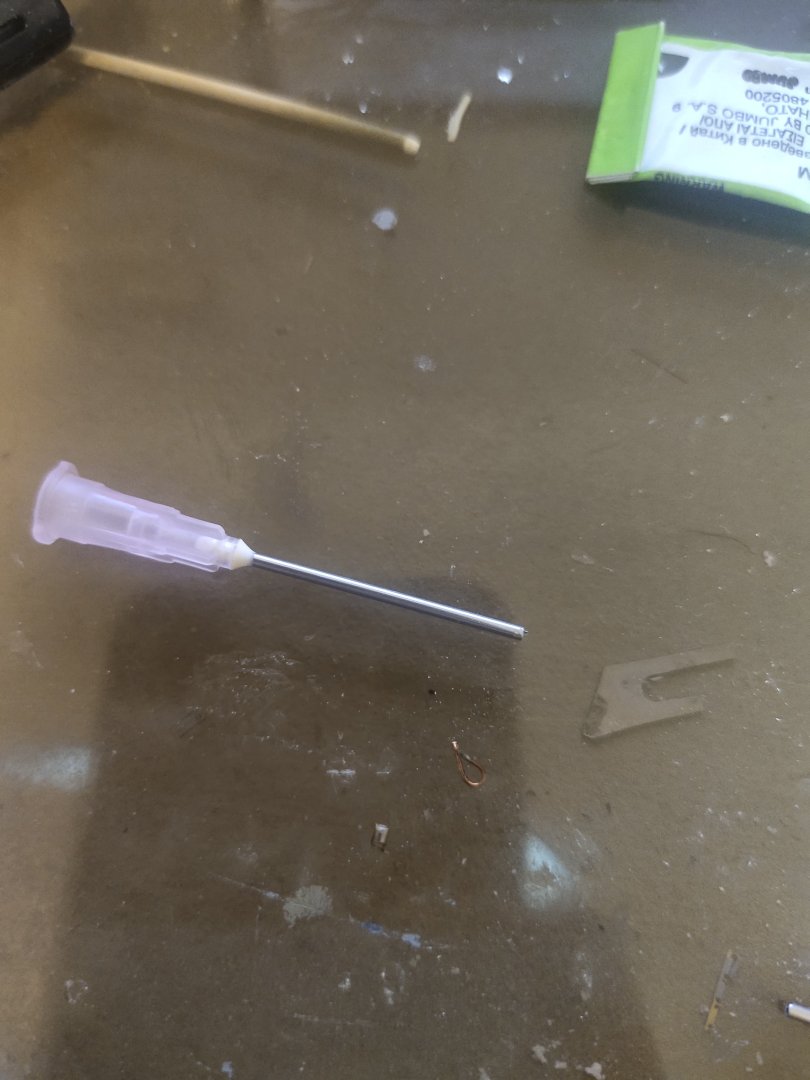

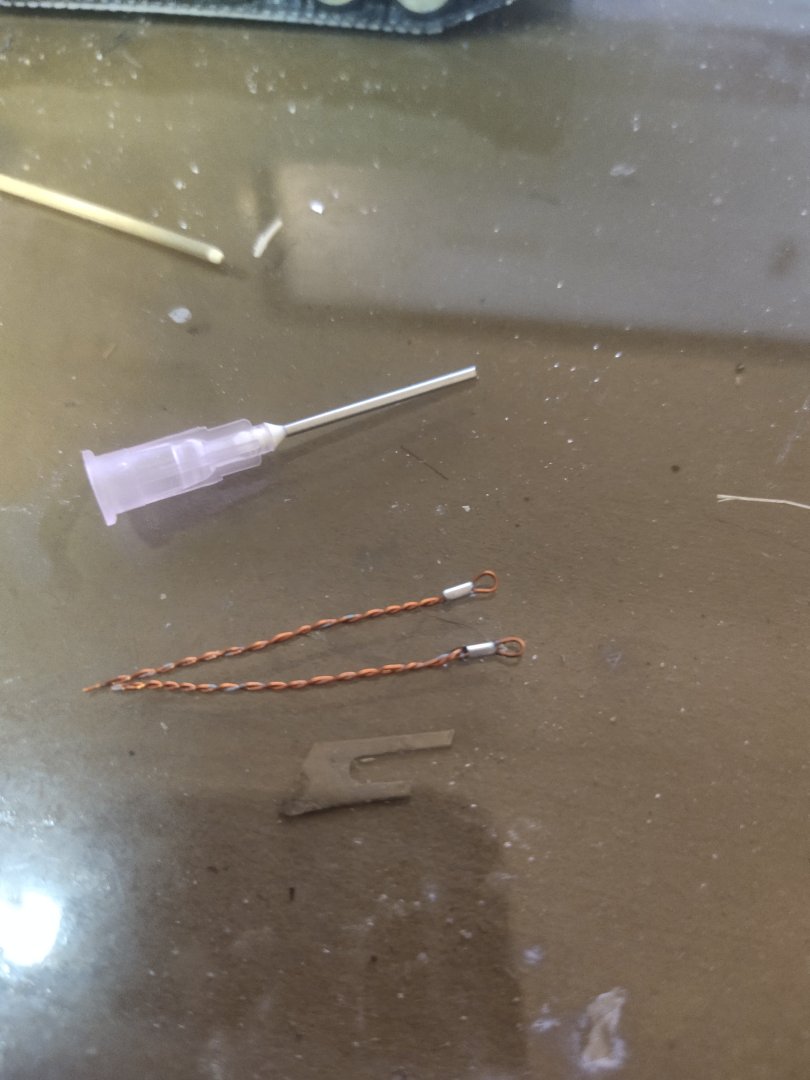

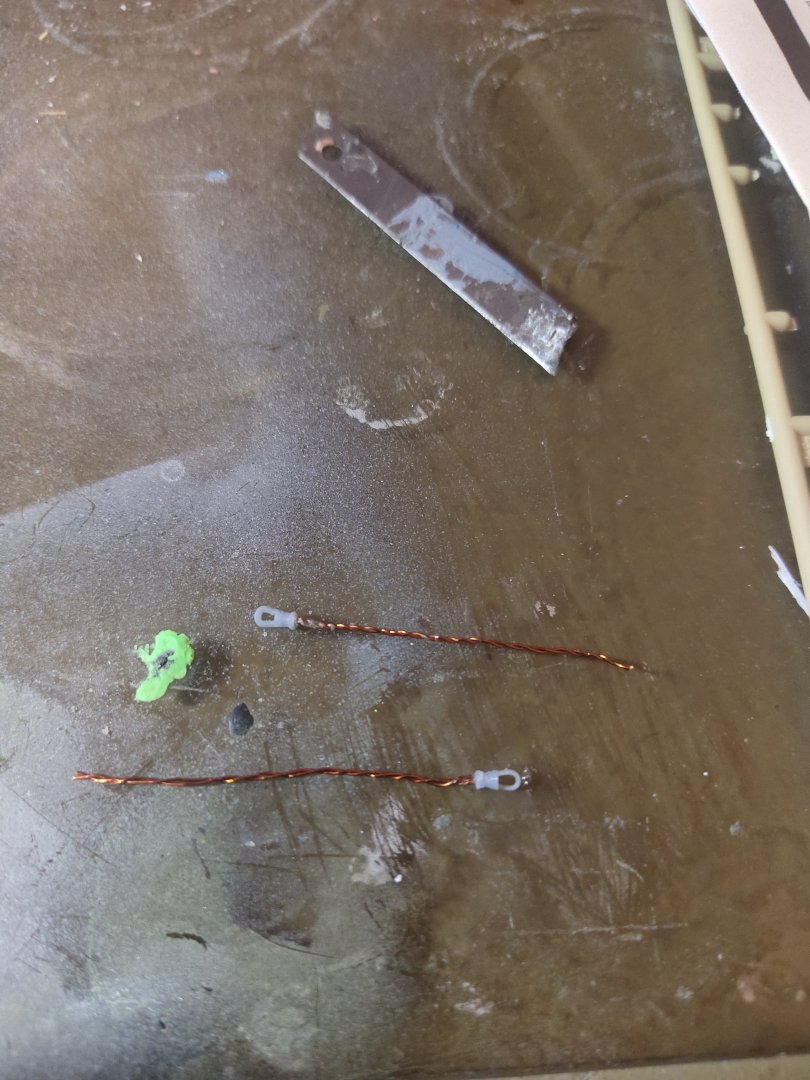

I had to make some loopholes for the wires so I found an affective way I cut a needle in small pieces, made a loop with 0.3mm wire and glued them. Easy. Then I moved on weathering the tracks -

Merkava III by mikegr - Revell - 1/72 - PLASTIC

mikegr replied to mikegr's topic in Non-ship/categorised builds

-

Merkava III by mikegr - Revell - 1/72 - PLASTIC

mikegr replied to mikegr's topic in Non-ship/categorised builds

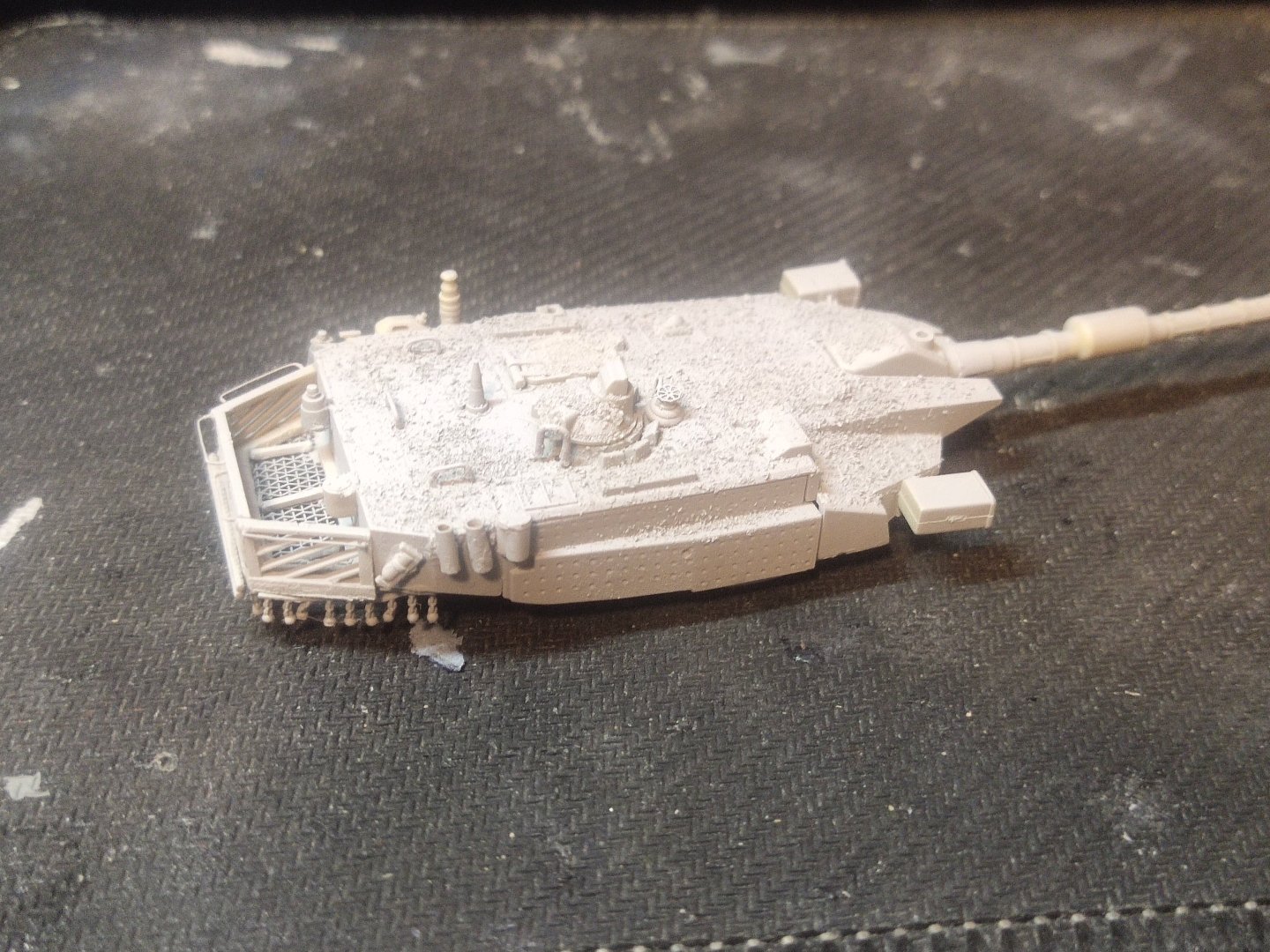

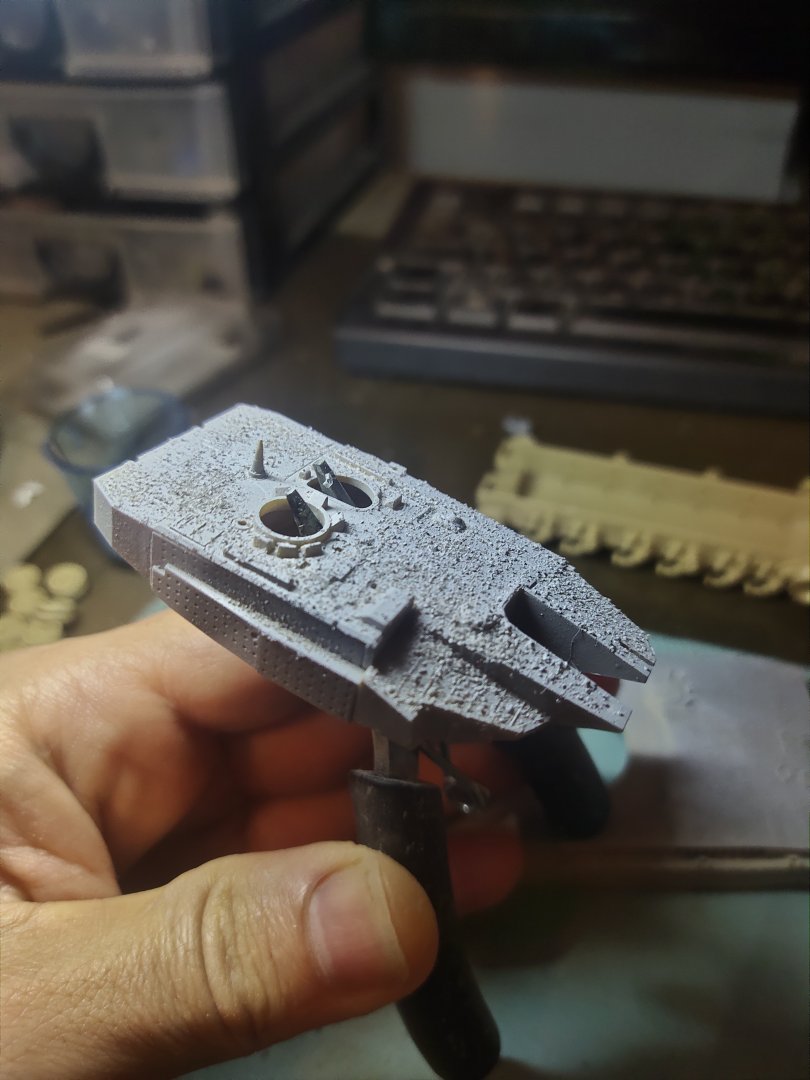

Today I finished the turret. Some details added according to pics. Tomorrow I will deal with the chassis. -

Merkava III by mikegr - Revell - 1/72 - PLASTIC

mikegr replied to mikegr's topic in Non-ship/categorised builds

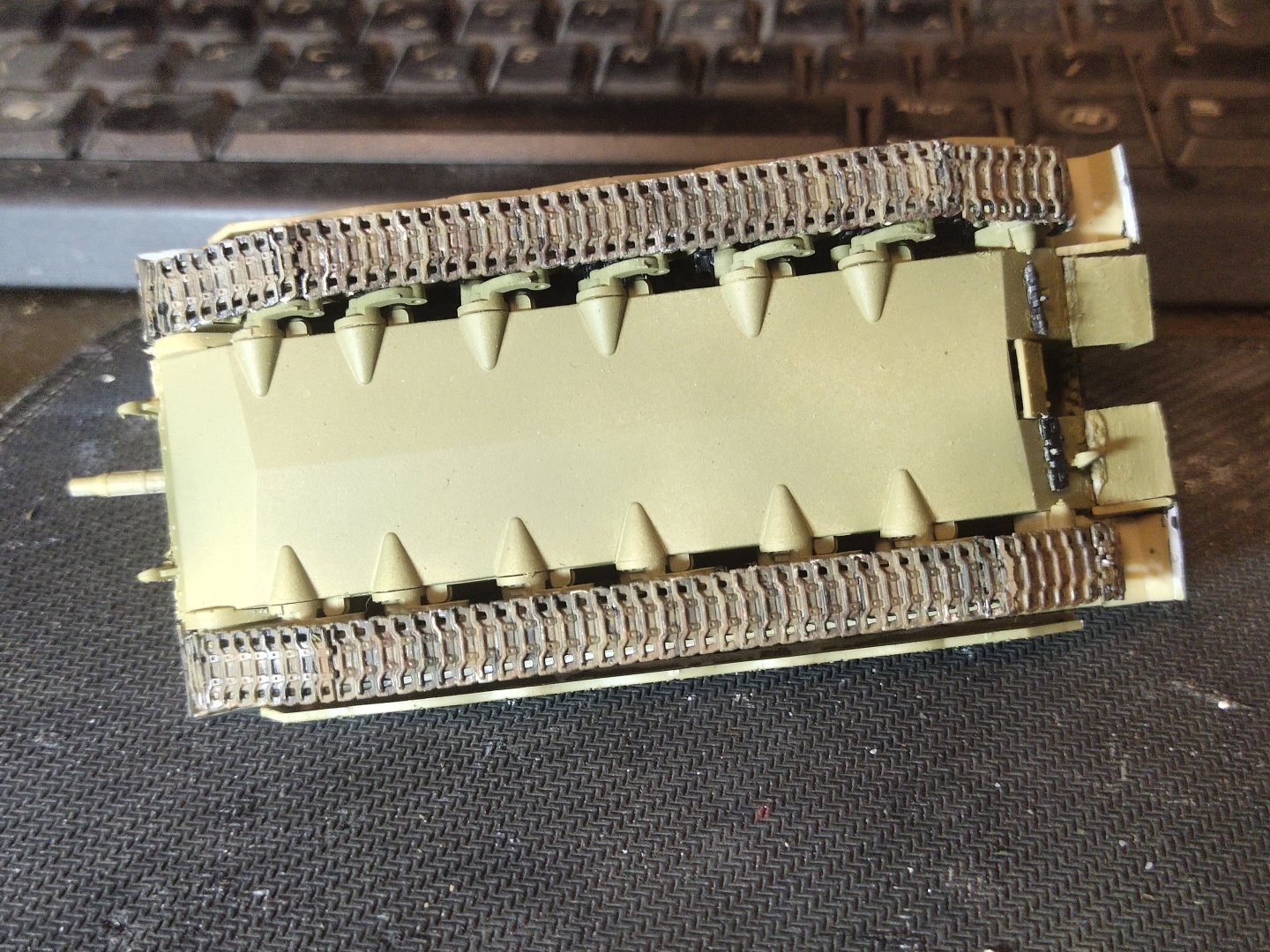

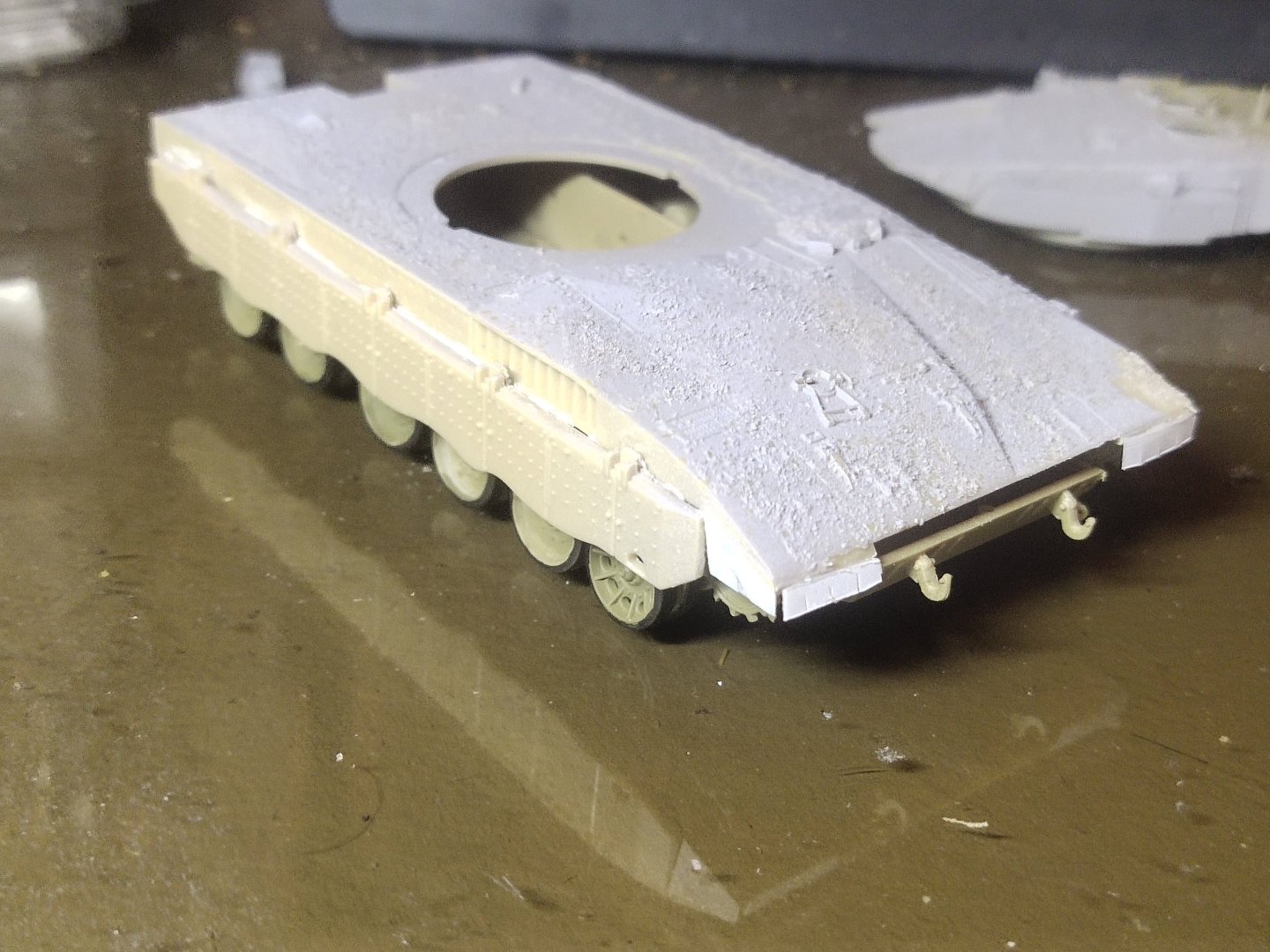

Today I finished the track fitting. Some basic weathering applied although there still more to be done. The fitting was less troublesome however I lost one of two pieces so there were a coyple of gaps under the fenders. I would call the job satisfactory as the result was far from perfect but for the time spended definitely worth it, took me a couple of hours only -

Merkava III by mikegr - Revell - 1/72 - PLASTIC

mikegr replied to mikegr's topic in Non-ship/categorised builds

Thanks Alan actually wheels don't need to be perfect as they are quite weathered and imperfections can be hidden easily. With Tamiya I usually dont get the snowy and watery effect -

Merkava III by mikegr - Revell - 1/72 - PLASTIC

mikegr replied to mikegr's topic in Non-ship/categorised builds

Done painting the wheels. With little brush and micro lenses. Chassis was also painted with airbrush. I really love how easily Tamiya colors are sprayed and thinned. On the upper part I cut the thick plastic at front and rear and replaced it with 0.10mm ABS to create spoilers -

Merkava III by mikegr - Revell - 1/72 - PLASTIC

mikegr replied to mikegr's topic in Non-ship/categorised builds

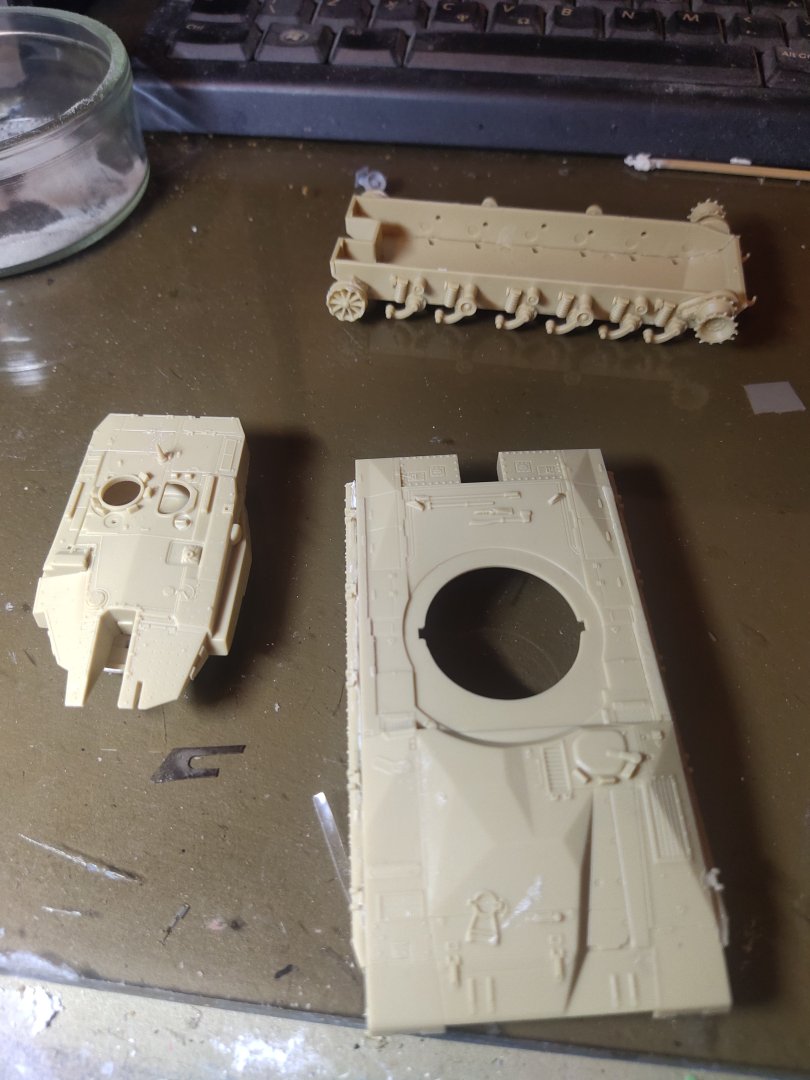

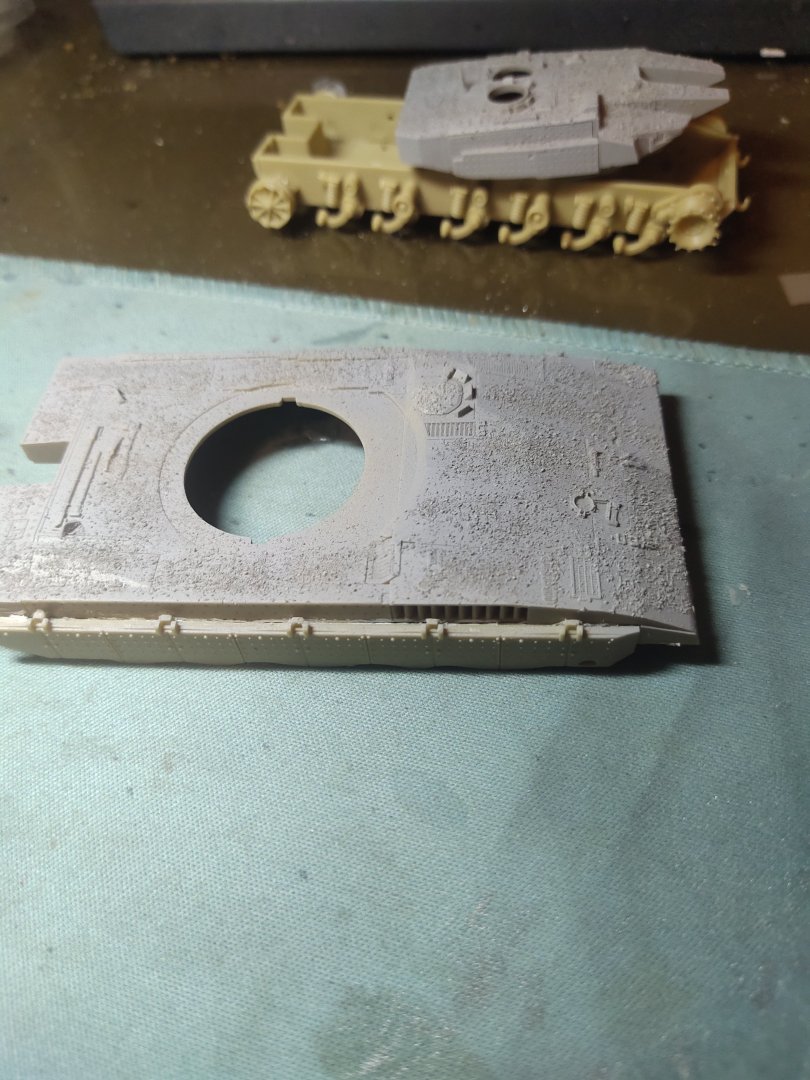

Major parts were assembled I noticed on the above pics that horizontal surfaces are not smooth but have some chipping. Spending some time thinking how to do it I found at the basement some plastic ice crystals that were used on a diorama as ice effect. Put them in a coffee grinding machine, turned them almost in powder form, like salt. Then I brushed the surfaces with PVA + water mix and sprinkle them over. Let them dry for a while then airbrush with primer on low pressure to avoid chipping from blowing away. I have to say the result, after strong initial doubts turned more than satisfying. -

Merkava III by mikegr - Revell - 1/72 - PLASTIC

mikegr posted a topic in Non-ship/categorised builds

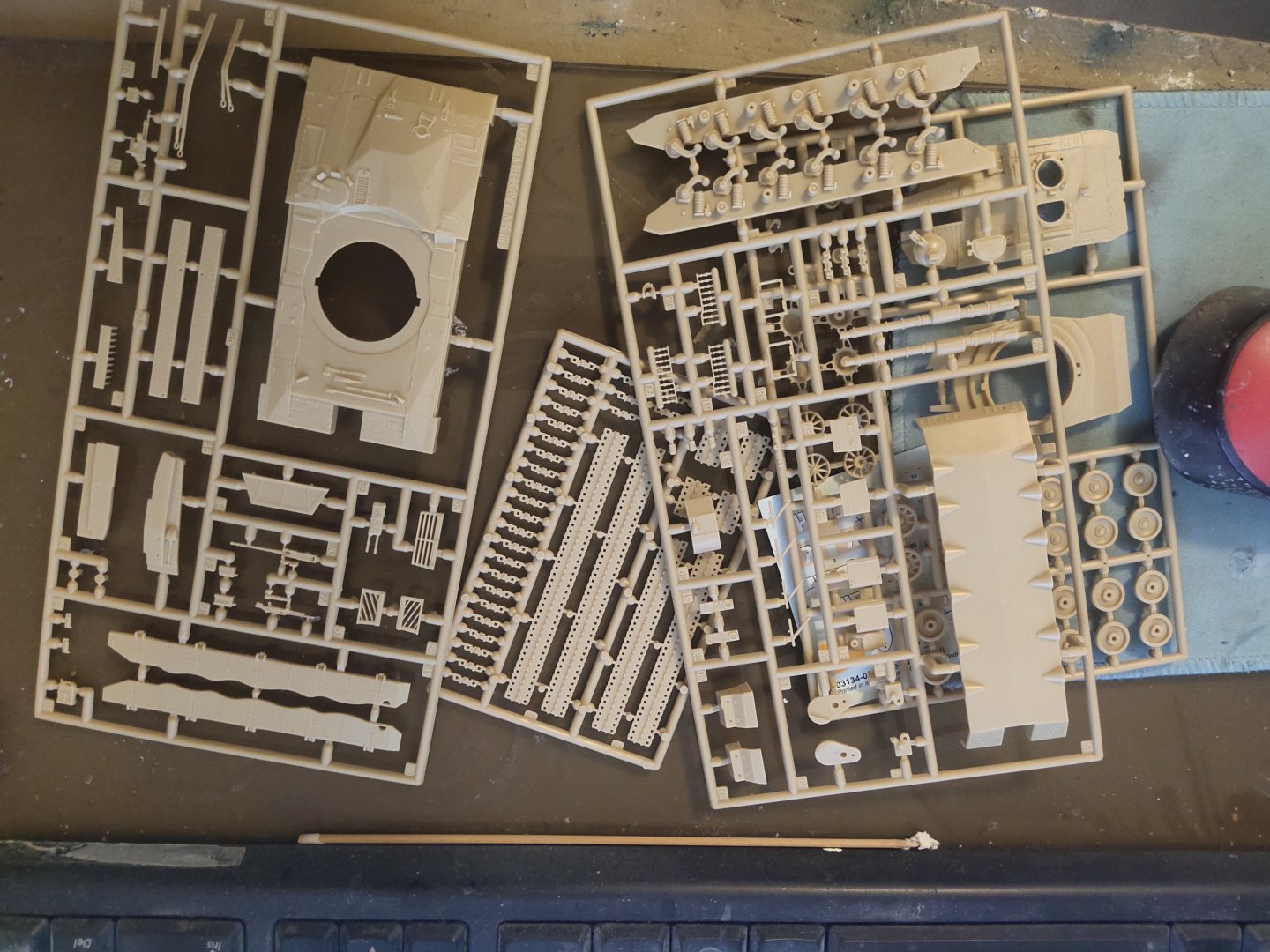

Time for a short getaway from 1/700 scale. Lets built something more relaxed. The kit in details doesn't impress much. The tracks are plastic in many pieces, not the most friendly option to a below average modeler. Somebody on youtube commented that one piece is missing matter how good can be assembled. We will see. The upgrade kit I found for 25€ doesn't sounds tempting although Revell kits do need extra detailing. I have tones of very close pics to get ideas from -

1. Yes you can 2. Yes they do. If you keep it in the garage won't be an issue 3. Yes they do. Below 18°c resin may need warm up. I use a hair dryer. Keep distance to avoid overspill. In hot weather may reduce curing times

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.