-

Posts

314 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by KrisWood

-

Ok I took the MDF back to Home Depot and got 1/4" plywood instead. Hopefully I'll have time to make sawdust soon. I'll add some new photos when I do.

-

Does plywood work better than MDF? I was afraid the ply would be harder to cut because of the crossed grains. I was also thinking I'd need to stick pins in the bulkheads to hold the planks in place and thought the pins would split the layers in the ply.

-

I may have found a solution. The hardware store may not have wood suitable for modeling, but it does have sheets of 1/4" x 2'x2' MDF that might work for the planking bulkheads. I'm going to give it a try. 🙂

-

Ok I've got a problem. I've drawn all my planking bulkheads and they need to be approximately 9"x7". As I've said earlier in this thread, I'm having a hard time finding sheets of wood wider than 4" locally, which would mean the bow and stern would need to hang over the ends of the work surface if I want to do the planking upside down as shown on this site: https://www.arbeitskreis-historischer-schiffbau.de/mitglieder/modelle/oseberg/ Does anyone have any suggestions of how to either build upright, or to work with smaller wooden bulkheads or other materials for larger ones upside down?

-

I took a break from painstakingly copying lines onto my keel/stem/stern parts to work on drawing bulkhead templates for planking the first 9 strakes (10-12 go on after the frames are in place). Does anyone have tips for building a jig for planking a lapstrake ship? I've never built one before and am at a bit of a loss as to how it's done. Ideally I'd like to be able to re-use the parts that keep the keel in place when I switch from bulkheads to frames. Thanks!

-

Yeah, that's what most of the reviews say, too. Don't expect it to be as accurate as the machines that just do one thing, and let the saw do the work.

-

https://www.amazon.com/Rockwell-BladeRunner-Portable-Tabletop-Accessories/dp/B00L47FZ8A It's basically an upside down jigsaw mounted on a small table. I like that it does multiple types of cutting without needing to buy multiple tools I can't afford. I also like that it's portable since I work on my front porch. I worry a little that it may not be up to accurately cutting out the curvy parts, but it can't do any worse than I'm doing by hand. The only things I'll need are the right T-shank jigsaw blades.

-

Minor updates and a question. I'm still in the process of remaking the keel, stem, and stern parts. It's a slow going process with the tools I have available. I've decided to make all the scarfs before gluing and before shaping the cross sections of the parts this time, so that if any specific part gets ruined I only have to remake that part instead of all of them. Meanwhile I've decided to get a scroll saw or equivalent. Currently I'm leaning toward the Rockwell Bladerunner X2 because it also includes a fence to function as a mini table saw. I know it's not the best tool for the job, but it's inexpensive and versatile and even if it's terrible it can't be any worse than my skill level with the coping saw. Has anyone used this saw? Is it worth getting? What blades would you use for cutting basswood? Most reviews say to use Bosch jigsaw blades, but I don't know which ones to get. I already have some laying around so I'm hoping those will work, but at least they're not expensive if I need to get more.

-

Ok, since no one has warned me away since yesterday, I'm going ahead and ordering it. What jigsaw blades would you use for 1/16" to 3/8" basswood?

-

Sorry for reviving an ancient thread, but I’m thinking about buying this model because it’s inexpensive and also works as a mini table saw. It looks like it takes any standard jigsaw blade so I don’t think the tooth count of the blades that come with it should be an issue. I figure it’s got to be better than the coping saw I suck at using. Has anyone used this saw and if so would you recommend it for someone on a modest budget who doesn’t already have a scroll saw?

-

Hi @Louie da fly I saw this paper today and thought you might find it interesting: https://www.academia.edu/9689593/Pulak_C._R._Ingram_and_M._Jones._2015._Eight_Byzantine_Shipwrecks_from_the_Theodosian_Harbour_Excavations_at_Yenikapı_in_Istanbul_Turkey_an_introduction._International_Journal_of_Nautical_Archaeology_vol._44.1_39-73?email_work_card=view-paper

-

I did some more work on the keel parts last night and figured out this is more a problem of skill with the tools I have than a problem with the tools I have available. When I first cut out the pieces yesterday with the coping saw (and chisels when I got frustrated with how slow the coping saw was at cutting out the long part of the keel) I ended up with a ragged, lumpy chunk of wood. A couple hours of careful work with an x-acto knife, a plane, a sanding block, and a file cleaned them right up. While doing so I realized several mistakes I'd made on my last attempt, the foremost being, how do you tell if both sides of the keel are the same? This morning I realized all I need is a right angle to compare it against. I think I'll be ok. I'm still going to try to get a scroll saw though.

-

How do you know if your coping saw is straight up and down / cutting at the right angle? I don't really have a good strong light other than my phone's flash, and that's hard to hold steady while cutting. I've been working on the front porch so I don't get sawdust all over the house. This also means I don't have a stable work surface.

-

I'm in the process of cutting out my keel, stem, and stern parts again, and doing it by hand with a coping saw / chisels takes FOREVER and I can't get a straight line for the life od me. I tried using a rotary tool but that thing has a mind of its own and the cutting discs only like to go in a straight line. What tools do you use for cutting out parts? Do you have any links handy for how to cut out parts that are not videos? (I learn best by reading)

-

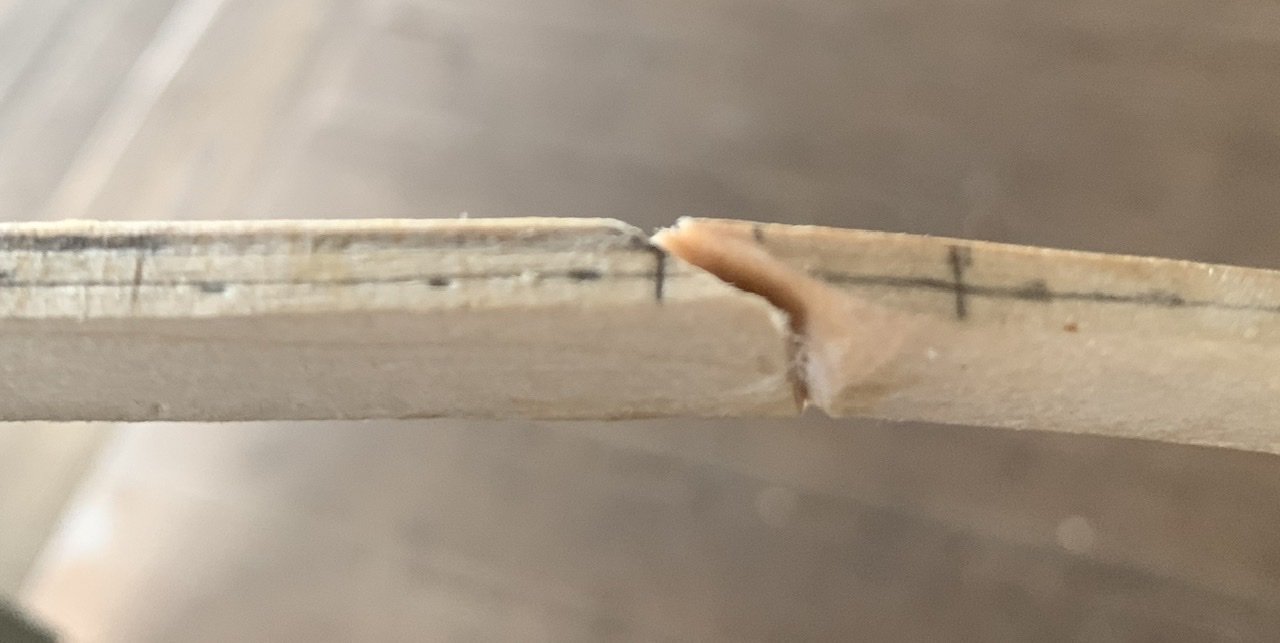

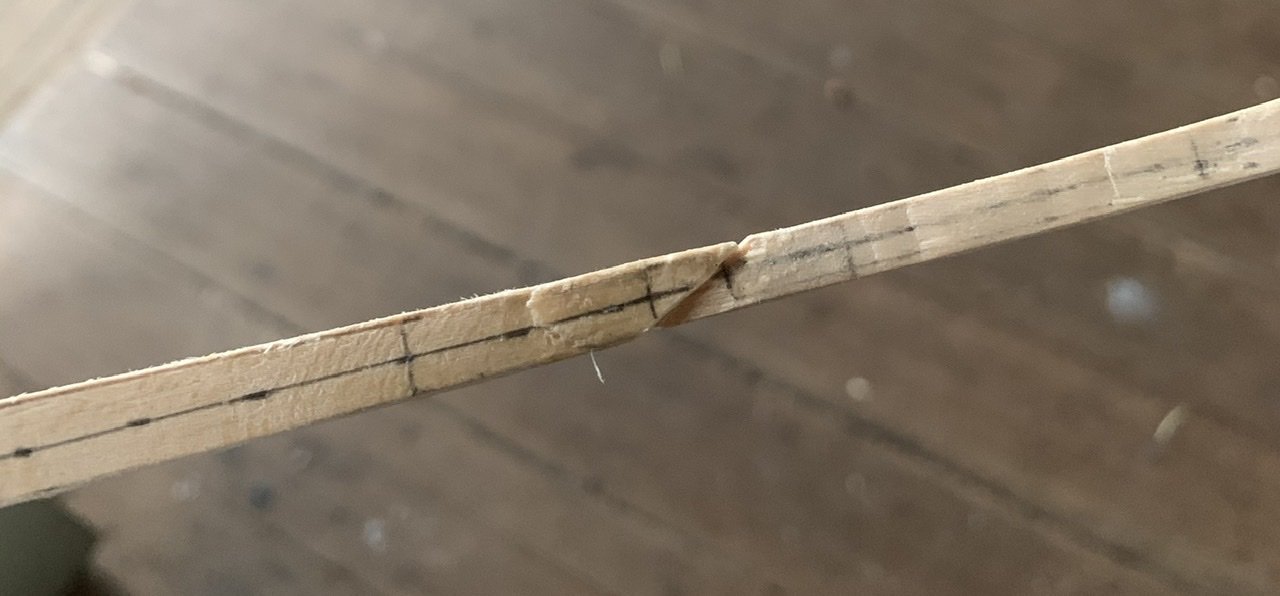

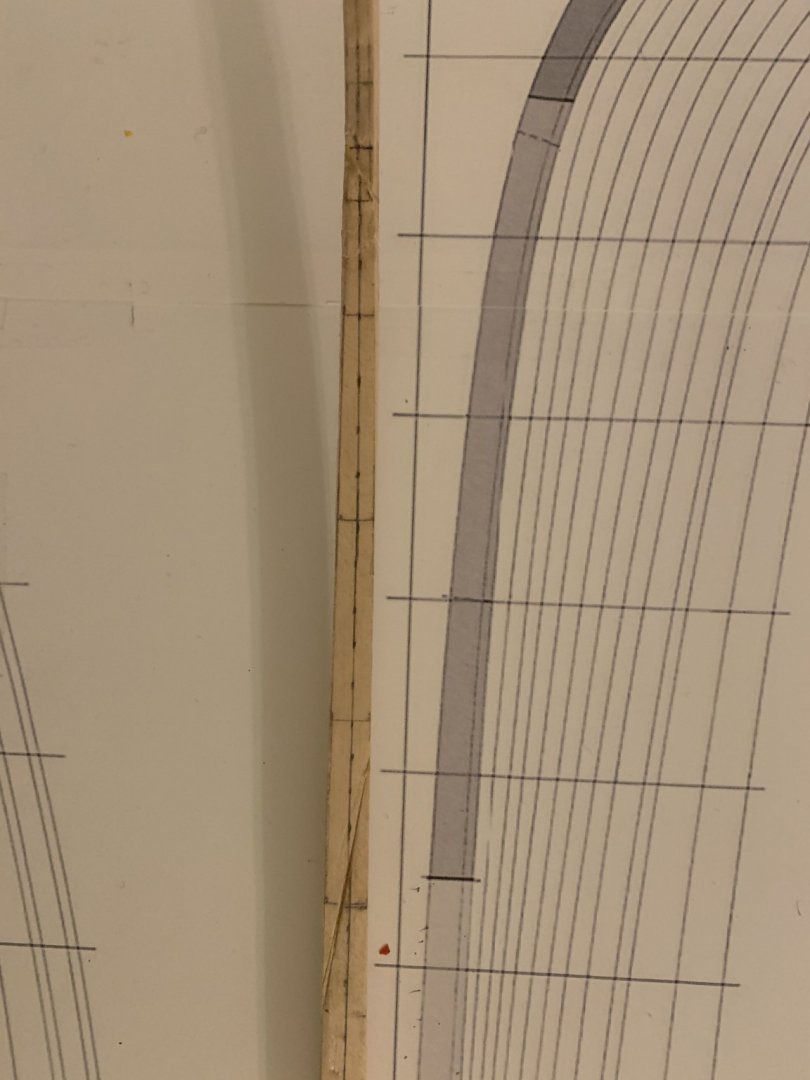

The good news is, it's straight as an arrow now. The bad news is, in all the fixing of the scarf, first from bad cuts and then having to take apart the joint, I lost about 2mm from each side of the joint. This puts it well into the curve of the stern. If I'd glued it at the angle that the scarf lined up, my sternpost would have leaned several degrees aft. I decided last night to put it at the correct angle and hope. The attached photos show the result. I also discovered, now that my stern is straight, that the stem leans much farther to starboard than I'd thought so that needs to be taken apart as well. At this point I've decided to call it a learning experience and start over. I've got much better plans to work with now and have a much better understanding of how to cut scarfs. Now to run to the hobby store for more 3/8" basswood.

-

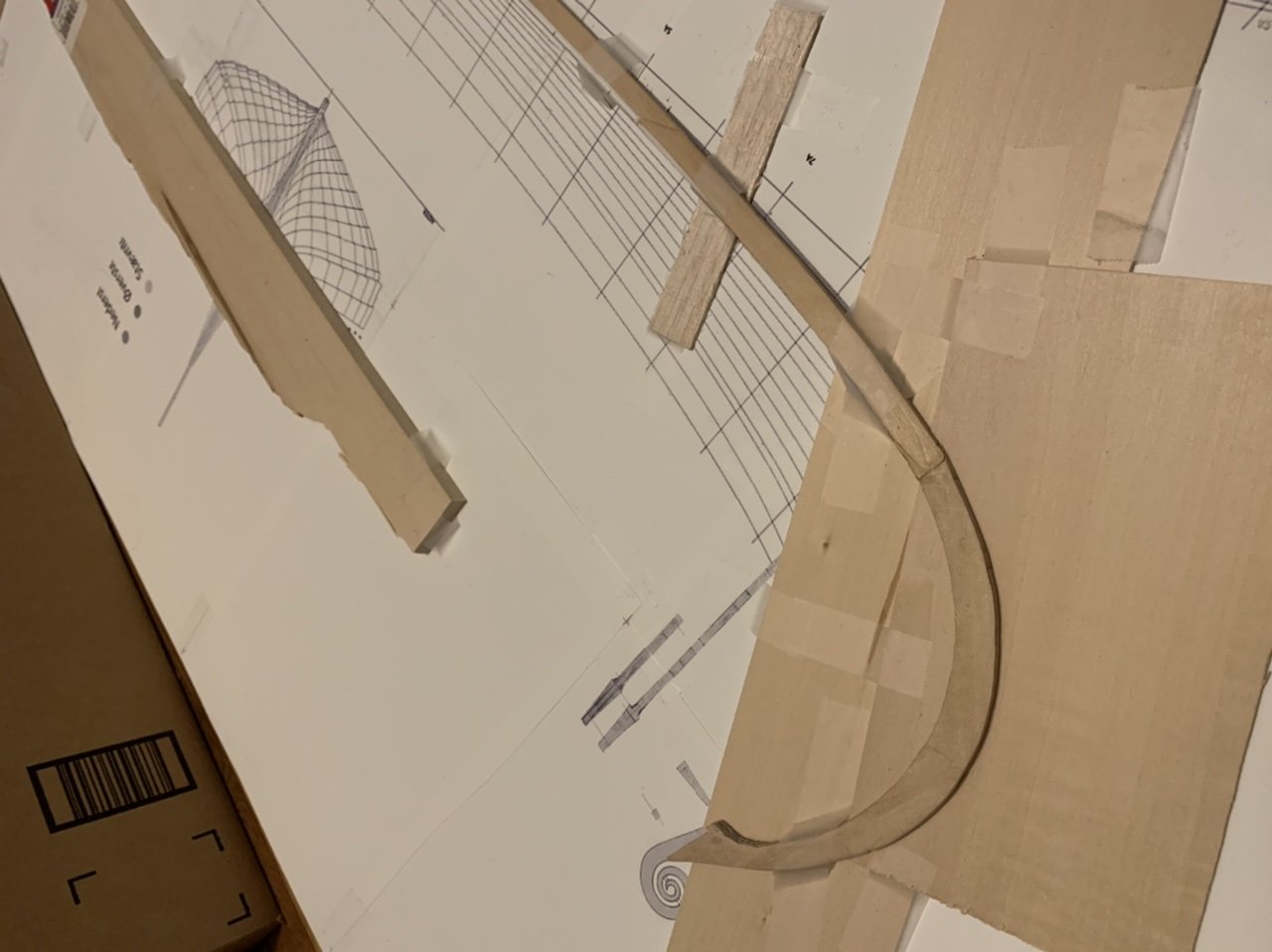

Then I put plywood on top and covered it with books. Not sure why the forum doesn't pick up the orientation of these photos. Moment of truth to come when I open this up later. 🙂

-

Shims in place. I taped down the keel and stern too, just in case, then put the appropriate thickness of shims on top the thinner parts.

-

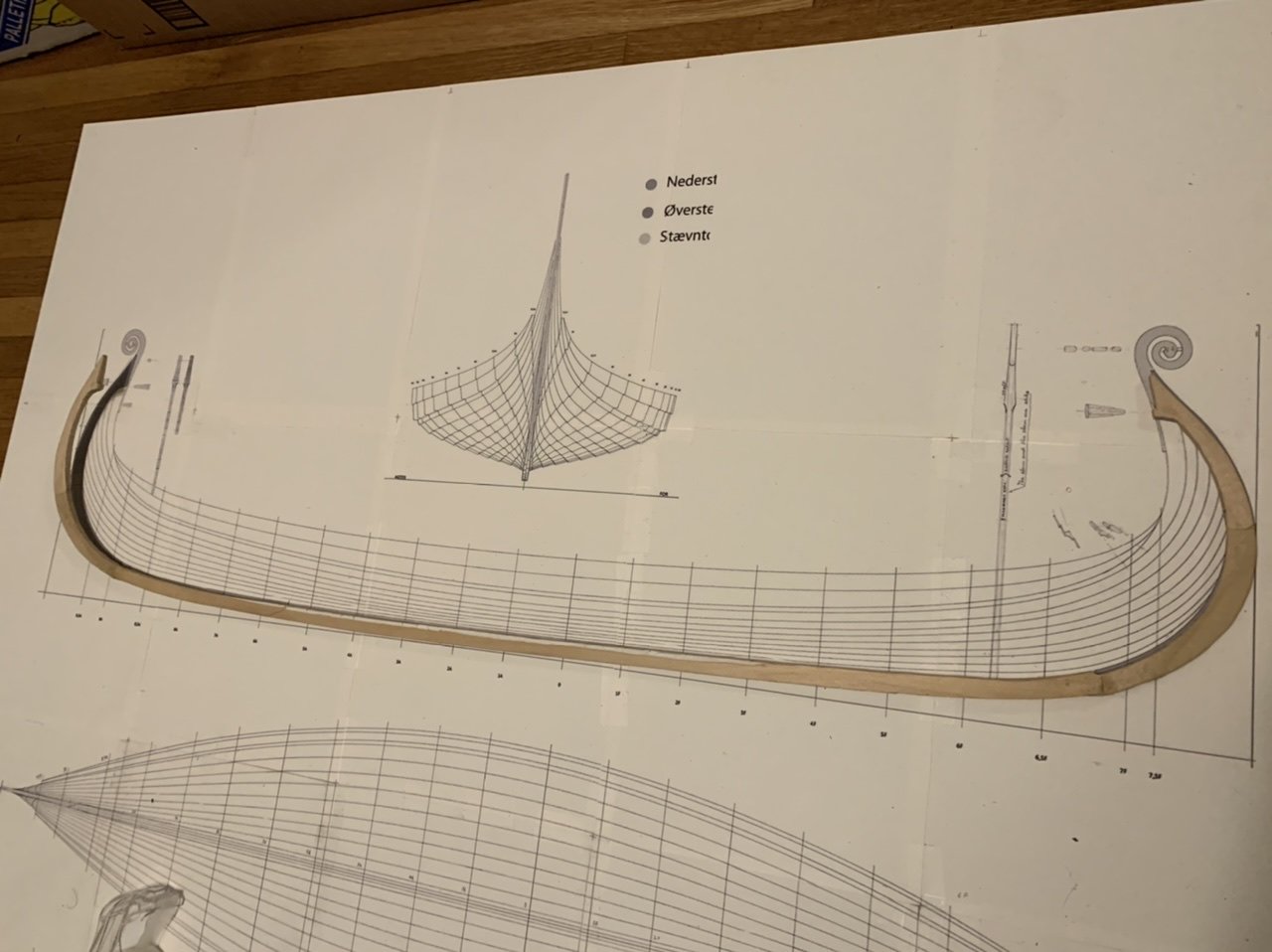

When I glued them the joints were too small for the clamps to hold them straight so I placed thin flat shims of wood on Either side and used multiple clamps to make the shims into a sort of splint holding the joint in place. I suspect the problem on this part is that I didn't cut straight on the base of the stern. Meanwhile, my copy of "Saga Oseberg: rekonstruktion af et vikingeskib" arrived today! It took about a month to get here from Denmark, and it's written entirely in Danish, which I don't speak, but it's got tons of photos, plans, and information on both the original Oseberg ship and the Saga Oseberg reconstruction. This will take me a while to digest, but I think it's the single most valuable resource I've found yet for this project. 🙂

-

Looks like it’s at the two joints connecting the aft piece of the keel to the fore piece and the stern. Each joint tilts a little to the left when viewed from the front. I forget if that's port or starboard.

-

I got the stem and stern scarfed to the keel now, but there's a definite twist in it somewhere. The stem leans sightly to the right and the stern leans slightly to the left. Is this a problem? How do I fix it?

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.