Wahka_est

Members-

Posts

522 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Wahka_est

-

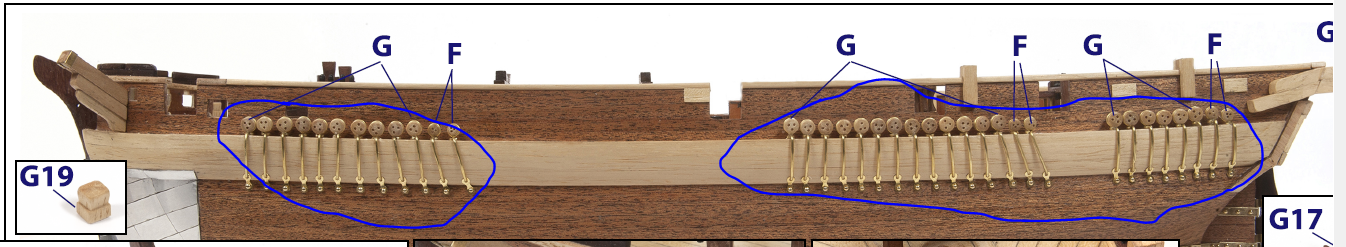

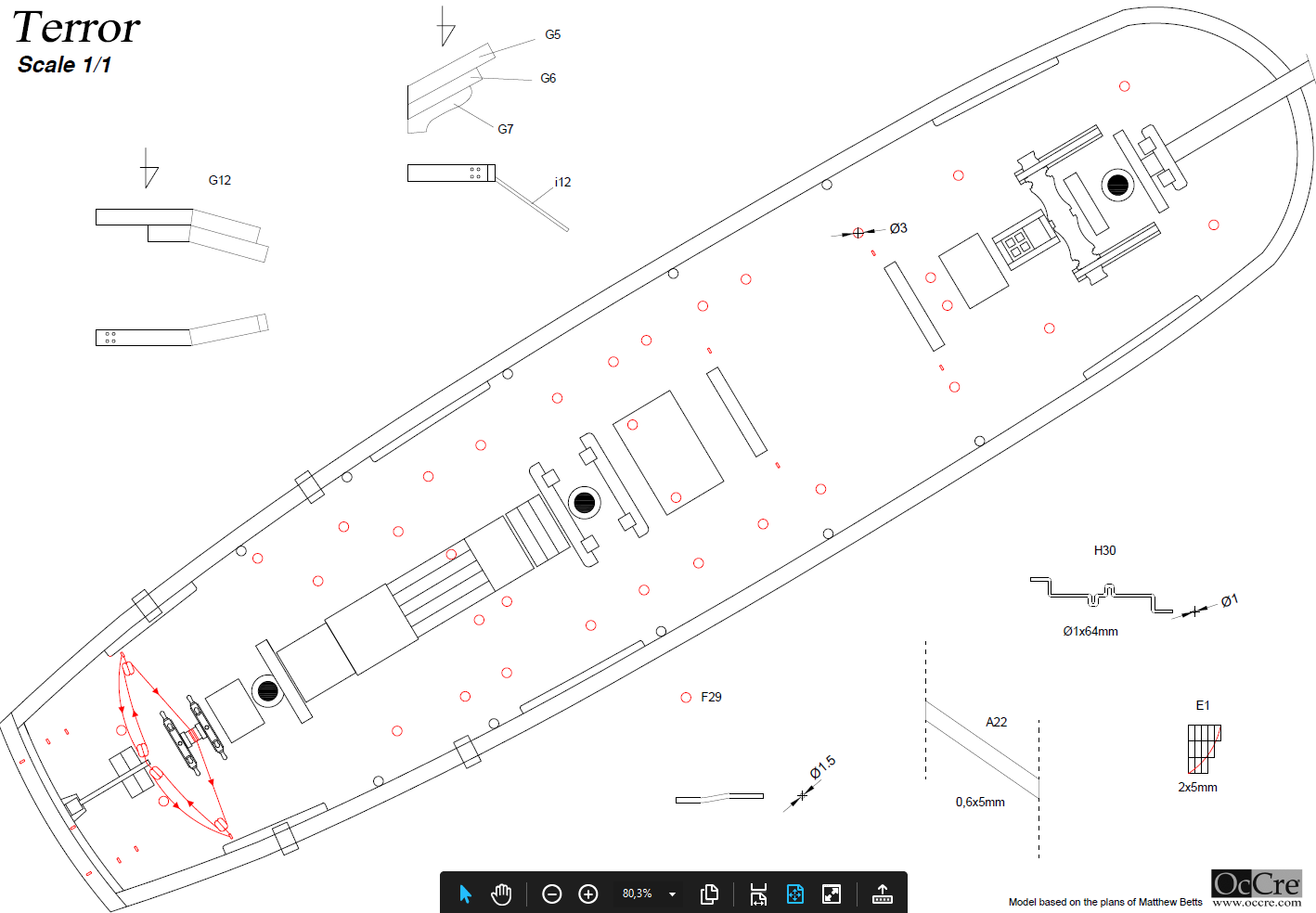

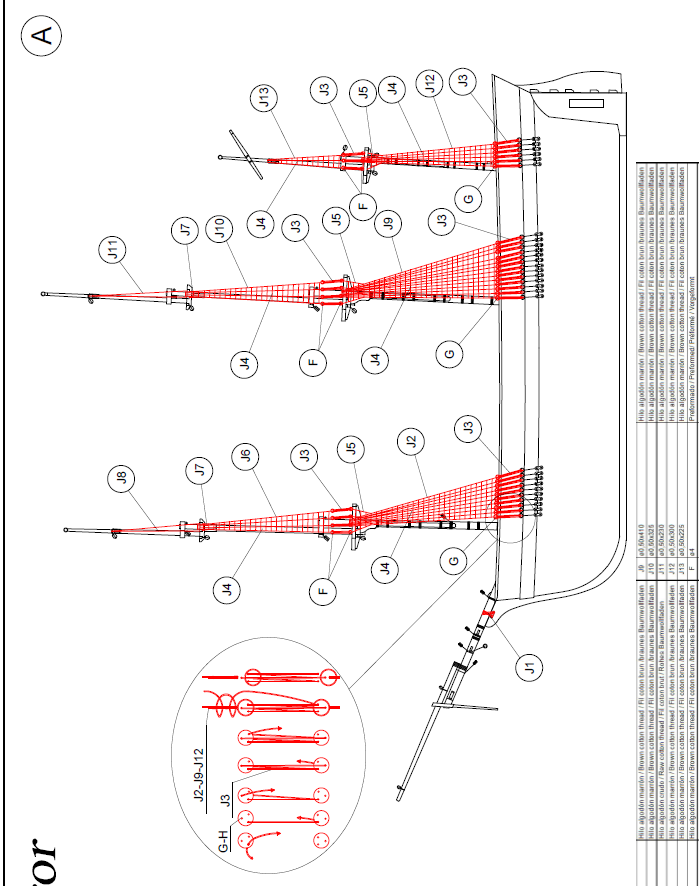

Hi, As im trying to look ahead i got stuck. I cant find any information where those pieces marked with blue should be located. Is there some rule that it should be offset from mast line etc? Cause views are not in any specific scale then you cant take any real dimensions. Or is the only solution to convert it somehow and hope its right?

- 106 replies

-

As i dont have for some reason light blue paint, cant finish the hull-will sort that out tomorrow hopefully. Maskee everything to paint hull comlotely black. Did some research and also fellow MSW members helped so i hope outcome will be good after thinning the paint and multible coats. Question-cant find any instructions how should lines from masts be located on the hull. There isnt any dimensions or locations on ship plans. only way would be do convert from not in scale drawings probably. Any suggestions here?

- 106 replies

-

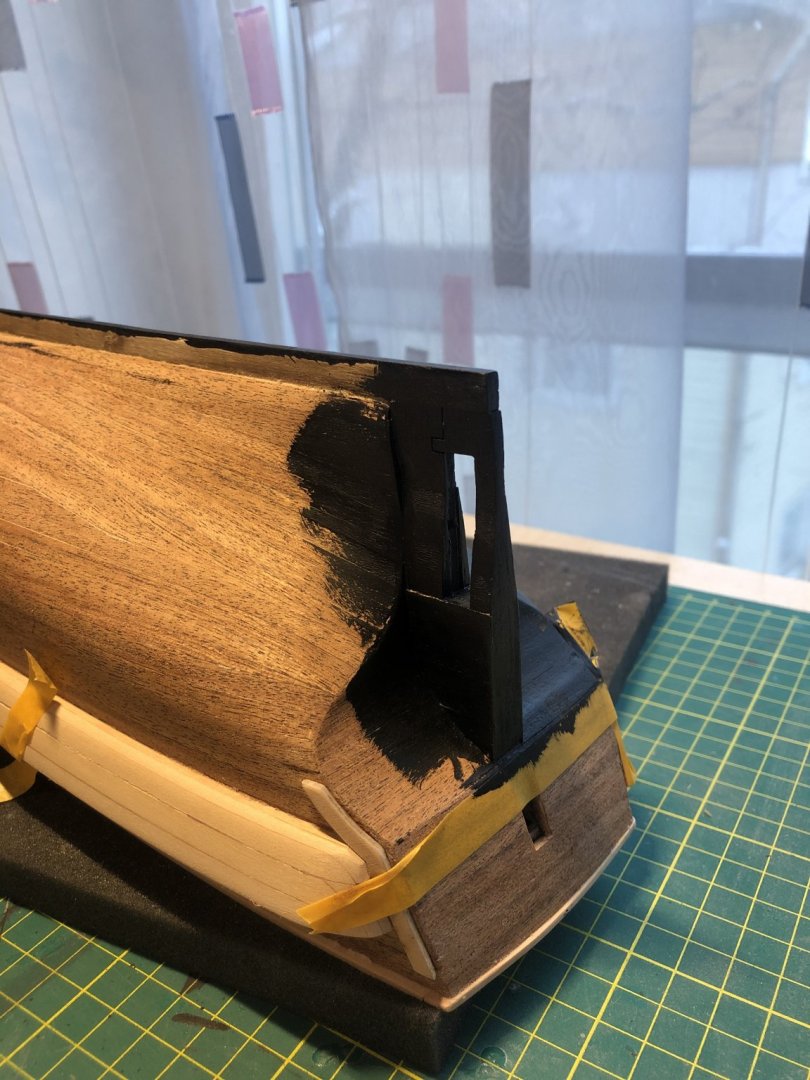

I like it. For a newbie its so called safe way so you know you have right products. There isnt many brush marks also and i didnt thinner it. Color is also interesting black with little shine but then also matt. Also it covers wood well. Some builds i have seen have wood showing but i dint have that at all. My opinion is that when you paint then it should all be covered. Lets see how it looks when its all painted. Wahka

- 106 replies

-

Hi I have planned it to be mu 2nd kit as im building Occre Terror now. Plan would be to leave Hms Cruiser all natural wood and also to change 2nd planking to pear maybe(ordered some pieces to see the apperance of wood). Will definitely open a log when i start. Wahka

-

Hi all Some newbie questions as im doing my Occre Terror(see the log). Cause im not familiar with different paints, varnishes and stains so therefore i ordered Admiralty products as they seemed safe way for me. 1) Can i thinner paint with Tamiya acrylic thinner? Amount is so that its runny but not like water? 2) How many coats of painting i should apply? 3) How to thinner Admiraly varnish? 4) Is it possible to glue for example copper plates on painted hull? Any tips there? 5) How many coats of varnish should i apply? Also i read that you should sand a bit between coats? Thank you for smart answers to newbie questions. Wahka

-

Some progress. Decided that to paint the hull for this build. 1st coat done on one side. Painted earlier than suggested in instructions. I hope i didnt make a mistake and now copper plating will still glue. I thought i need to paint it first and then but copper to have better visual apperance and then pain again. Also wantes to add brass details to the keel after painting so that they would be visible. Paint is Admiralty black dull. Did i make a misktake and now AL plates will not glue?

- 106 replies

-

Thank you all for the input. It seems i still made right decision and will probably start it when im doing riggint for current build so maybe after a month or so. Lack of insteuctions mihht be challenging for me cause it would be mu second build but lets see.

-

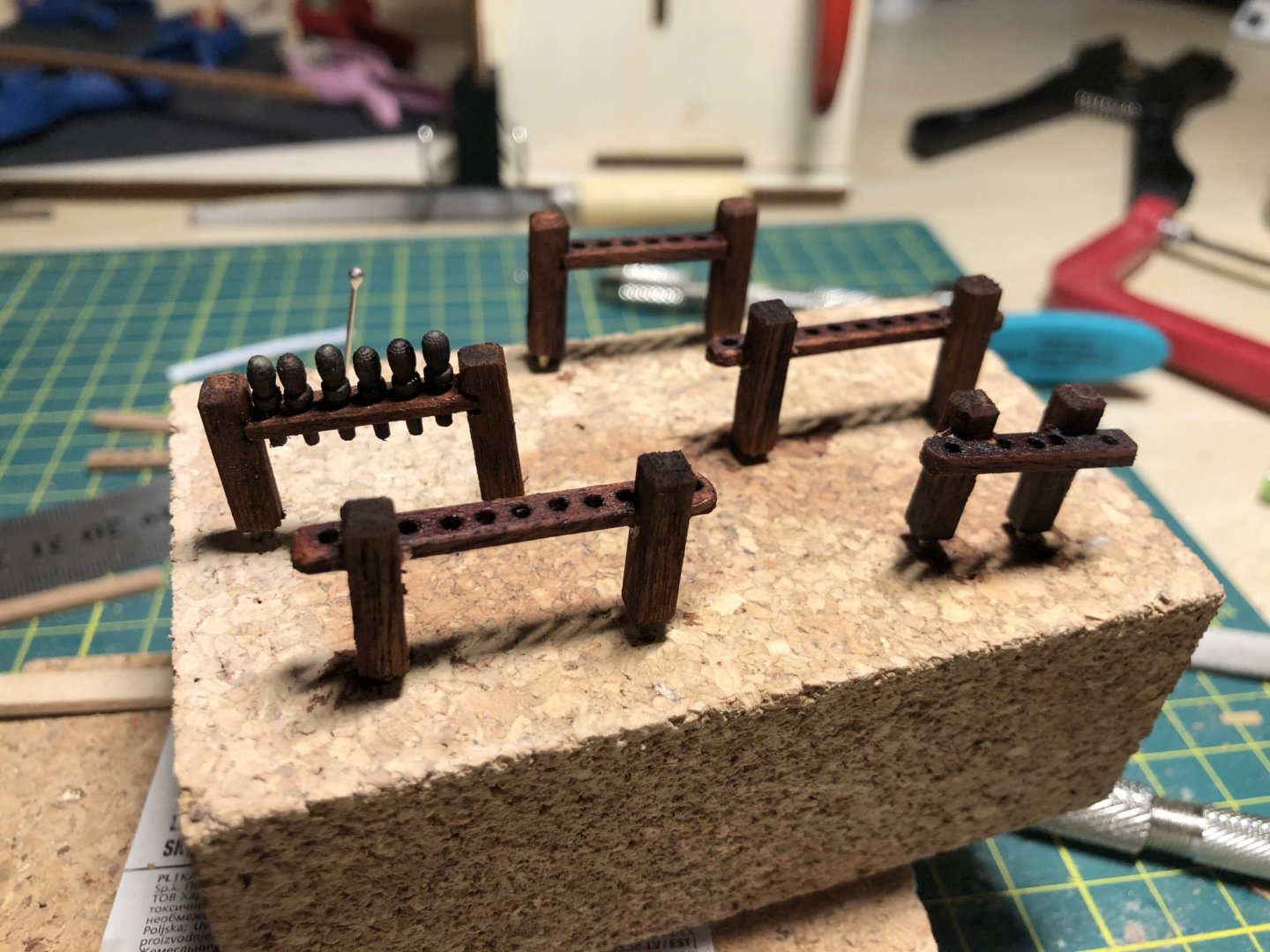

Today worked on small details. Frame - mahagony stain Pins - ebony stain I use Admiralty stains and varnishes cause im not so familiar with hardware stoor products yet and they seems like a safe solution.

- 106 replies

-

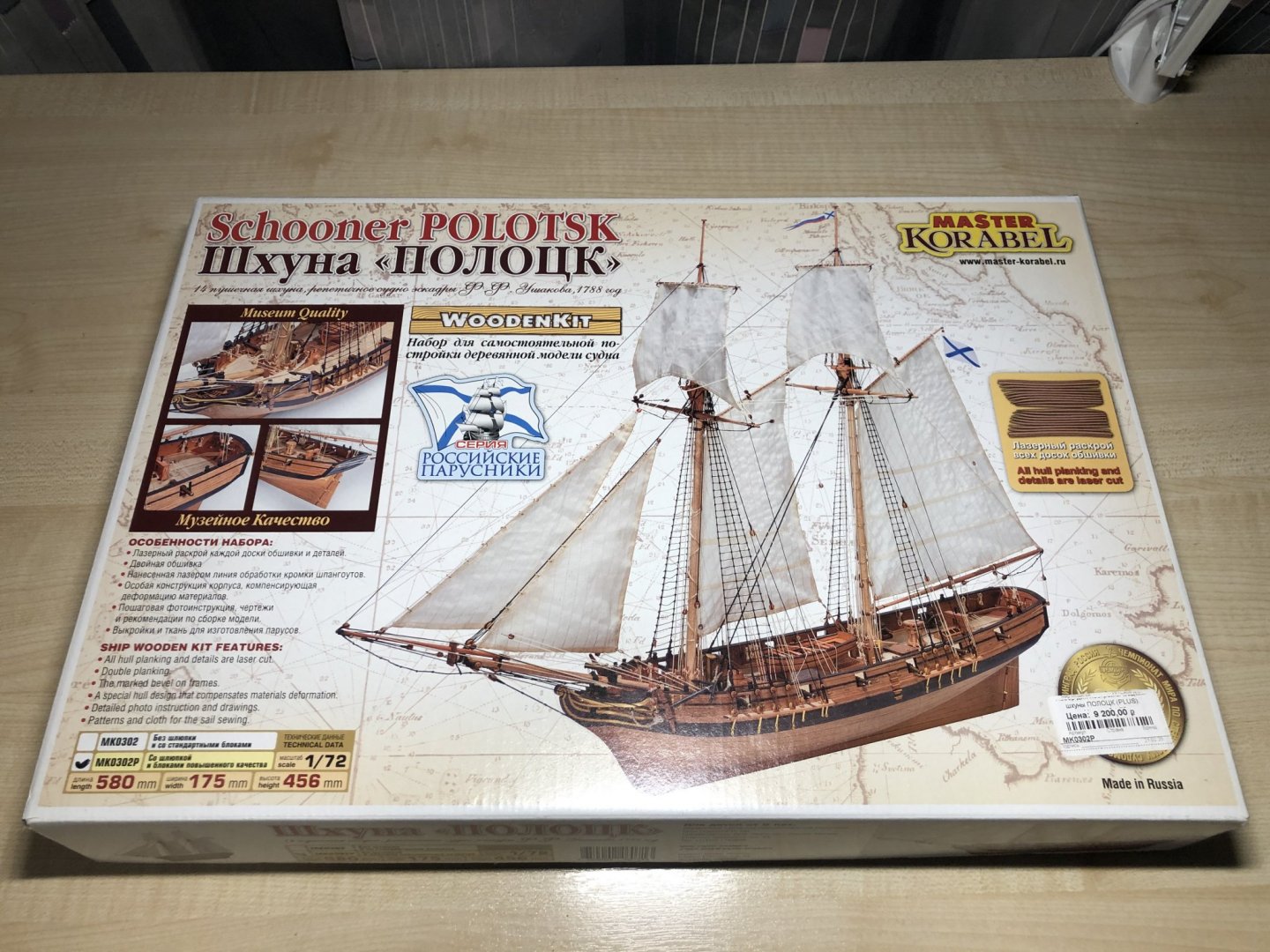

Hi all Have made some progress-installed the keels and railings. Also started with small details-thats a strugle cause my fingers are too big. Need some help-apparently somehow there is hole next to keel on deck olanking. How to fill it so its visually good also? Regarding Occre instructions-they seem many times unclear and there isnt enough pictures about finished ship. Also some drill hole sizes dont match up etc. But i guess every kit has a problem and eventually you will find a way. And offcourse finally its handcrafted by yourself and modifications are allowed. I have had my eye on Caldercraft Cruiser and Master Korabel Polotsk. Found a super deal on Cruiser(stock sale) and ordered it. Also friend visited Russia and got myself Polotsk for almost 50% of the normal retail price. Thought if i dont build them then i can always sell them atleast with same price-so lets call it an investement. Building ships has lead me to think about own house again. Just to have my own room for hobbies soni dont have to collect my stuff every time i finish build for the day. At the moment i share office table with my wife. Cause mu son is only 2 years old i can only build when hes at sleep so progress isnt satisfying for me at the moment:). Butnother than that i keep pushing.

- 106 replies

-

Hi, As a newby i have question regarding changeing 2nd planking material. Is it common for builders to change 2nd planking material example to pear? If you change the material then does it make it "historically uncorrect"? When you change it then why - is it just visual aperance? Thank you for your answers for stupid questions. Wahka

-

Hi all, Somehow Caldercraft HMS Cruiser has catched my eye. I like how it looks like in natural wood finish (may just good photos ). They advertise it as quite simple build with fast completion time. My question here is that there basicly isnt much info about builds etc. Also cant find any good descussions about it. Is there any reason people avoid it? I saw a really good deal for that and allready ordered it (deal was too good to be wasted). All info about the kit and knowhow are welcome. Wahka

-

Tnx. Buffer-a lot of sanding by hand. Tried to achive the exact curve like in insteuctions. First 120 sandpaper followed by 400.

- 106 replies

-

- 106 replies

-

Tnx! No i did it to prevent possible mess with glue. And also To protect deck from stain marks. I needed to stain railing a bit more.

- 106 replies

-

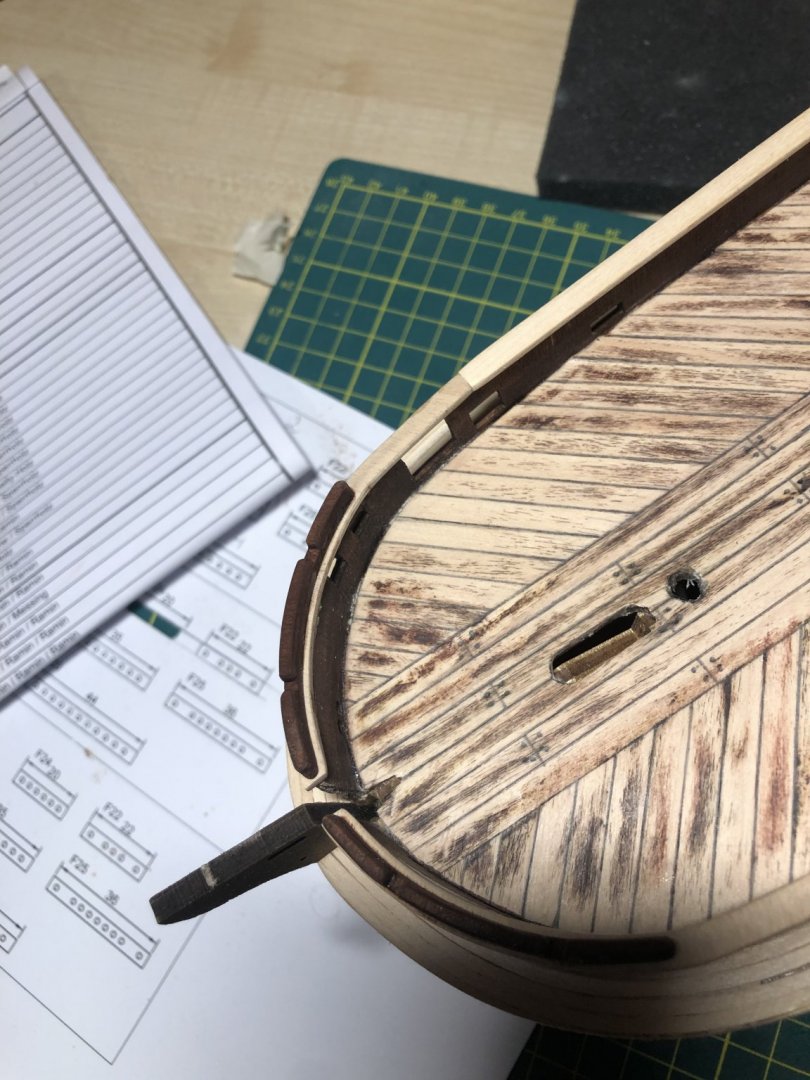

Progress so far. Finished 2nd planking. Needs little sanding. Started with those extensions on side (dont know english word for that). Also started bending rails and deck profiles. Seems i should get myself naval dictionary. Good news is that also recived books about rigging. Have read them and also looked Terror drawings-now feel much more comftrable about that. Good is that i learn so much aling the way so next build will be much better in quality.

- 106 replies

-

Hi That last suggestion is correct. I forgot to mention that. I will definitely also do that for next build.

-

Hi Nice progress! as i understand(correct me if im wrong) tehn varnish if its water based and offcourse for wood then it would fine. Like always make a sample and let it dry overnight. Little suggestion-get good brushes so there wouldnt be brush marks and if needed then make varnish more liquid(dont know the english word for that). Suggestion for next step from experience. Bend the railings first overnight-water and after that to some mold. After drying dry fit it and if its good(maybe hull needs some sanding) paint/stain the railing. so not stain/color it before bending. Also so not use contact glue for that if you are good with it. It might run in deck. Use wood glue + clamps.

-

Hi Welcome to MSW from Estonia.

-

Almost done with one side. today i found sine good local fast drying wood glue so changed superclue to that. Mich better result visually and i have time to adjust the planks. Ends are still fixed with superglue. Almost finished side i also used 400 sandpaper to see if i could get glue marks out. Got a little better but still visible. Any auggestions how to get it better? Also one picture of 2 projects that got me to wooden ships models. Train is finished but ship needs few more days.

- 106 replies

-

Tnx. Lot of effort went into sanding. Even so much that room was apparently covered with wood dust :). Allthough i think i must achive better result next time. You know it really brings a smile on your face when you finish 1st planking and start sanding - you move your sand carefully over the hull and look for any imprefections.

- 106 replies

-

Hi, You are doing a good job! I think you can use those. Just do some testing before as usual. As i unerstand many of builders use different products and due to different locations the products are not the same (for example some are not available here in Estonia).

-

Hi all, Just funny thing - Admiral at home like also look of the boat but was really pissed with all the places covered with wood dust :D.

- 106 replies

-

Started with 2nd planking. Did different test with glues and it seems that contact glue suits best for me. Somehow 1st planking is easier for me-maybe hands are too big for thin wood:). Also tried with pva and heating with plank bender but somehow i cant dose glue just enough that it would mess up everything. Luckily Terror is supposed to be painted. Thought that maybe for next build i get little thicker 2nd planking-anyone done that for same reasons? Pictures of progress:

- 106 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.