Wahka_est

Members-

Posts

522 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Wahka_est

-

I did glue that.... was think the same but photos showed to do that. I ordered mini rotary tool-pen size that i plan to use there. 2nd planking done and also 2nd layer of wales installed. Really happy with outcome-cant see it totally caused its taped for overnight but will run to check it in the morning. Size comparison with Cruiser-polotsk should be 2 times bigger QUESTION- what is the best glue for photo etched parts glueing(golden brass on picture). Next is sterns illustratiins and i dont want to mess it up.

-

Thank you JToma! Just looked at topic here "So Where Do You Do Yours Then", showing members workplaces..... It seems im not sick at all or obsessed with model building (at least not yet). Many members have tens and tens (maybe hundred) unstarted kits on selfs.So im good and do not need any medicine for that, atleast not yet .

-

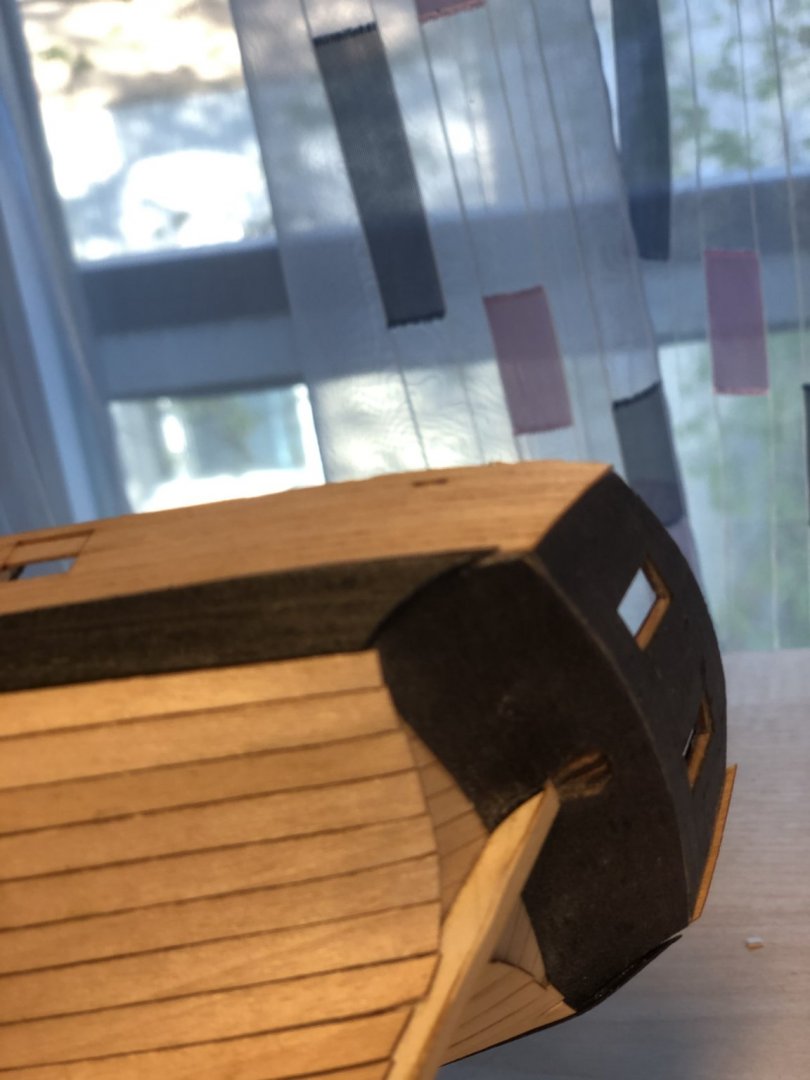

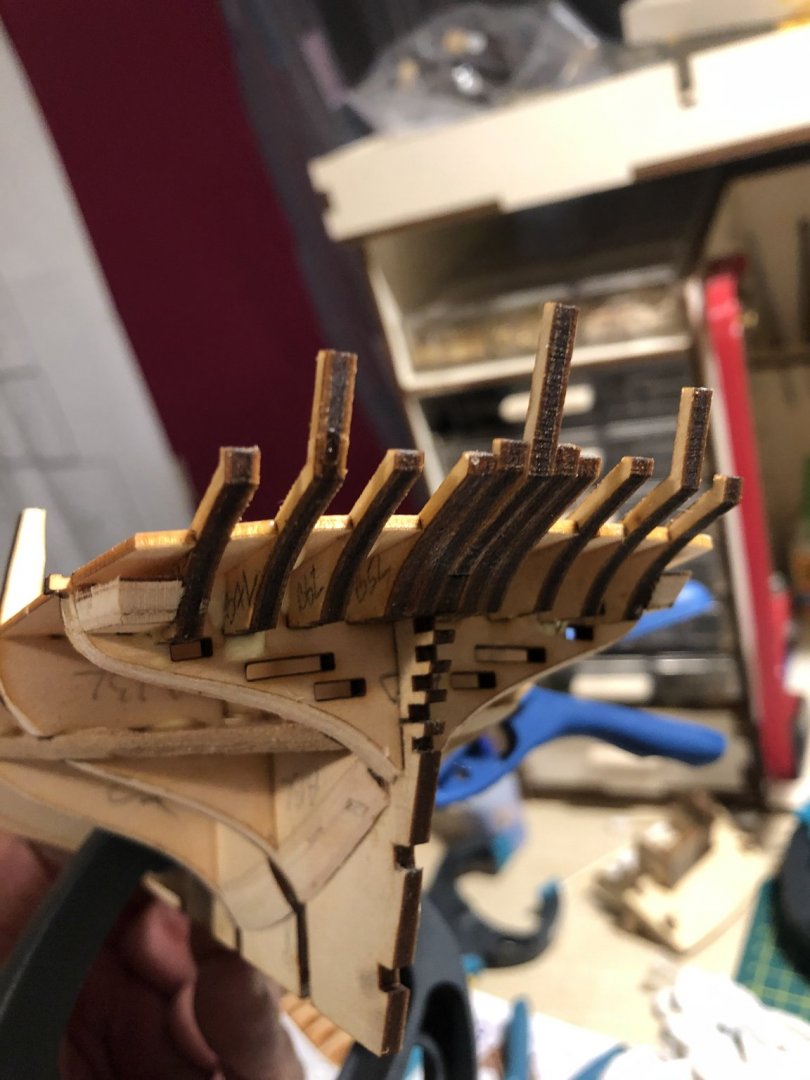

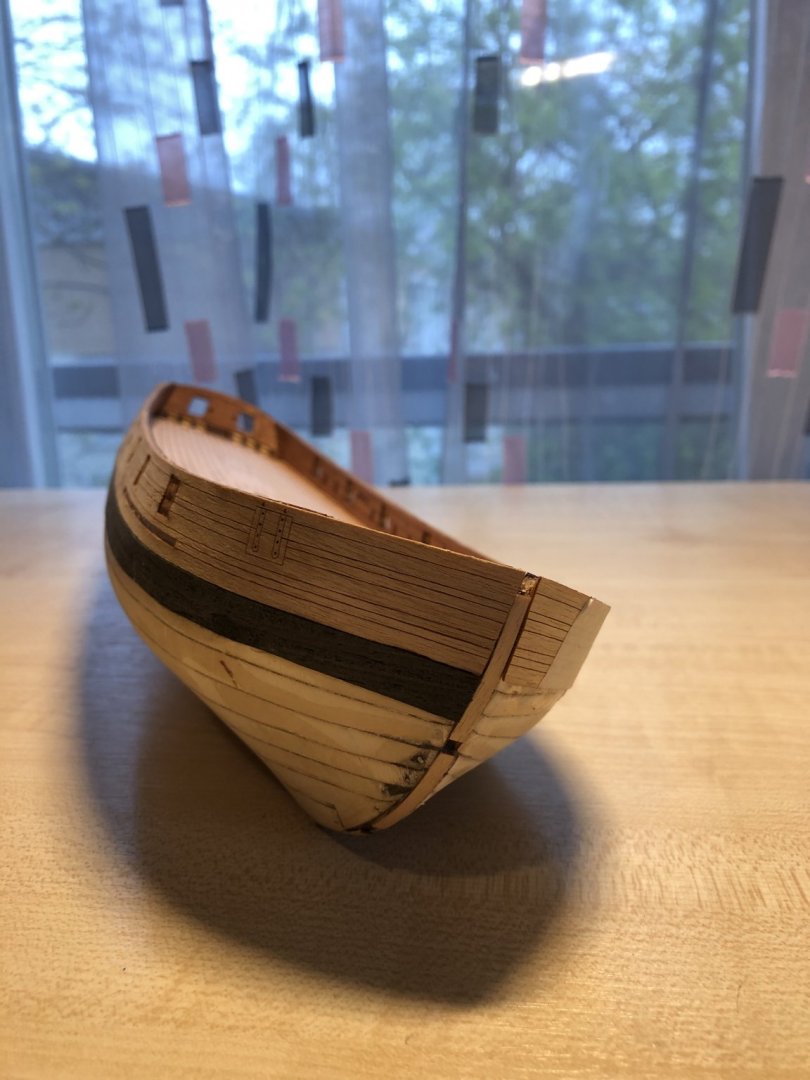

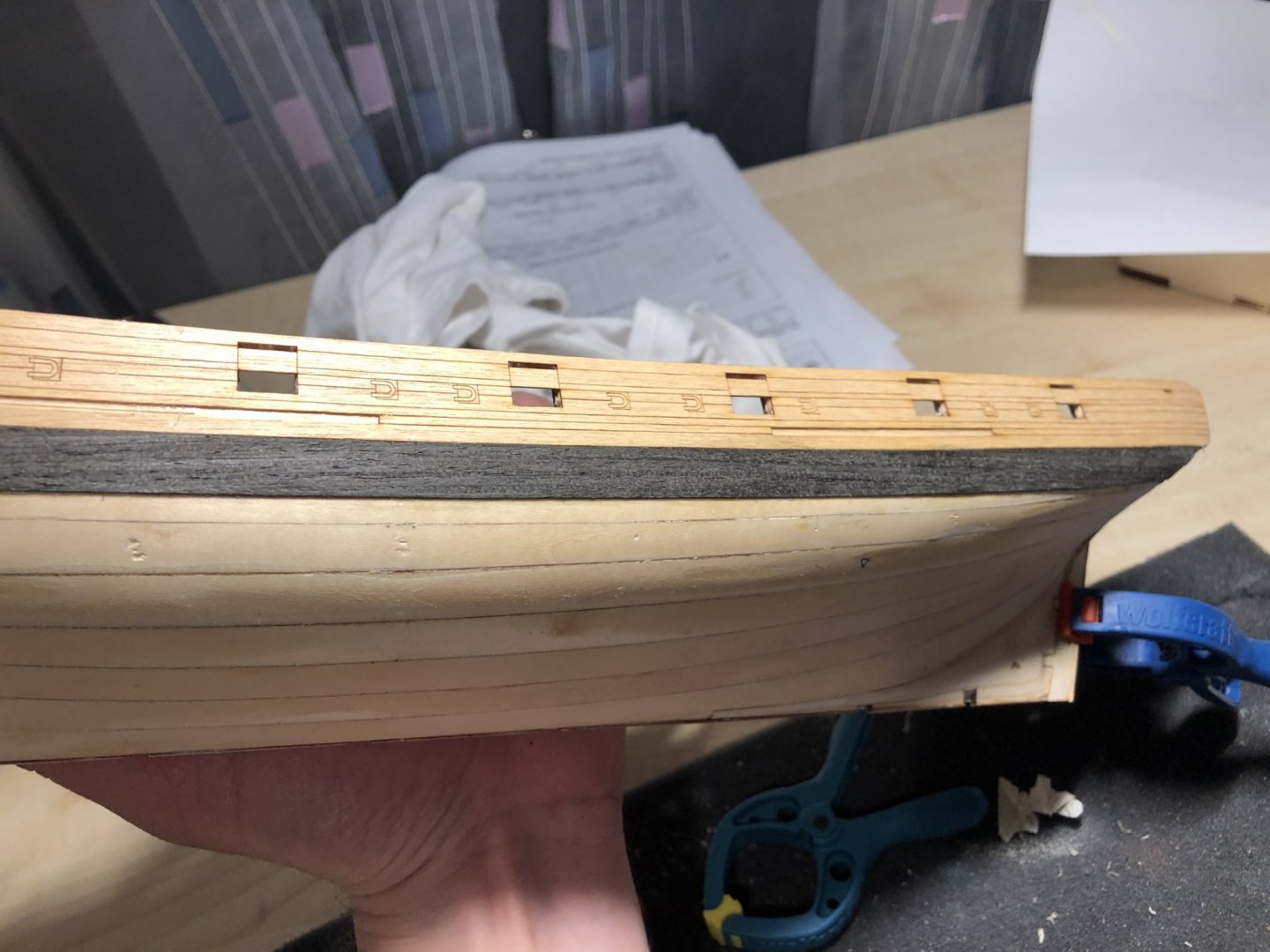

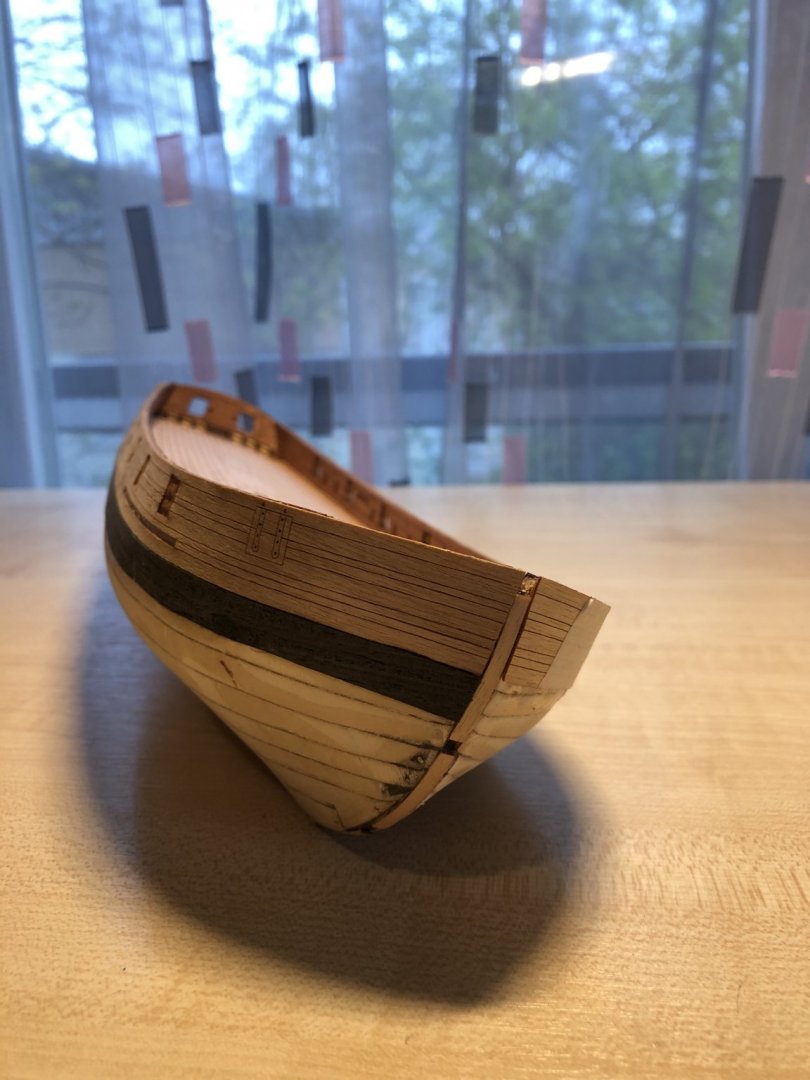

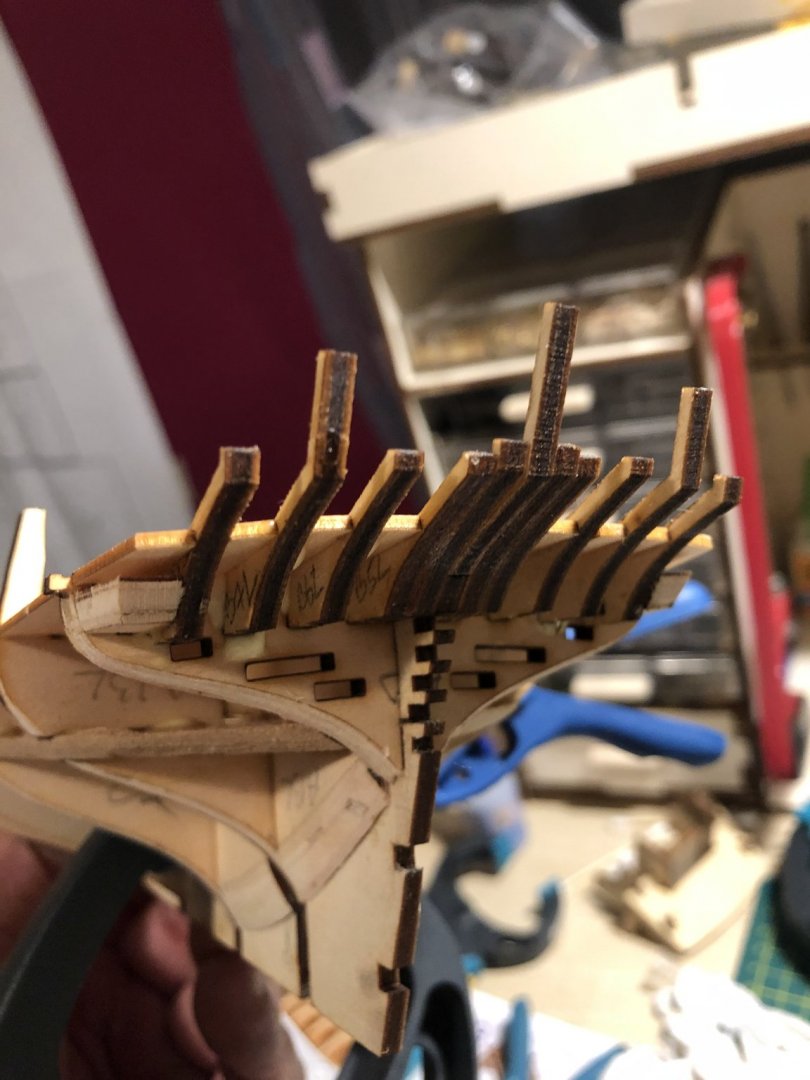

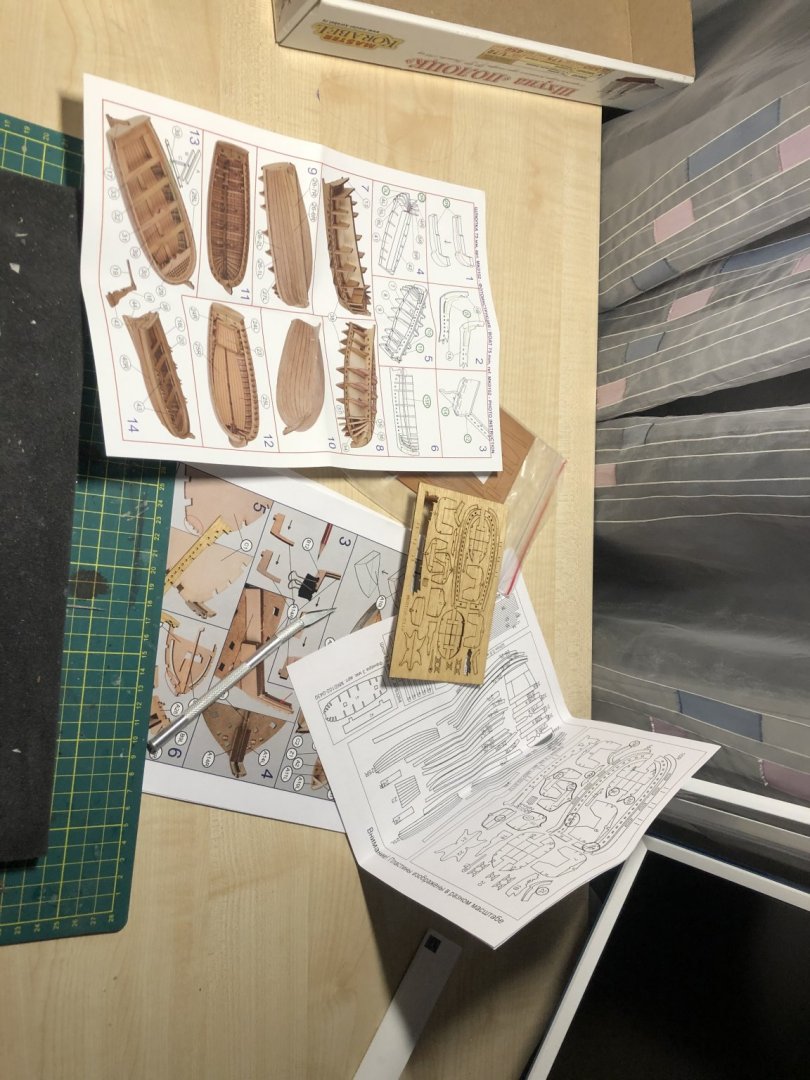

Hi Decided to open a new blog for 3rd ongoing build-i hope no hard feelings from oldtimers as newbie hasnt finished any but allready has 3rd ongoing plus pile waiting to be started. As my Cruiser and Terror are waiting for parts i started MK Polotsk that was waiting for its time, guess that time arrived. My Polotsk is Plus version with pearwood planking. I chose MK Polotsk due to really positive feedback regarding laser cut part and instructions as it goes together like Lego cause allmost everything is laser cut and requires little or no sanding. I have to admit during the build hours i have smile on my face and im truly impressed about the engineering work behind it. Some points; 1) Hull has building template with a lot of holes. Everything fits there nicely. 2) Bulkwark have markings where to sand a after putting it together little extra sanding was needed. 3) All planking os laser cut and fits perfectly. 2nd planking is oearwood and black is ebony. 4) Deck planks (from one piece) and waterways are precut but needed adjustment to fit perfectly. 5) Level of detail is really high but it will also make the parts really fragilr and easy to break. I had an accident also where i dropped the boat during sanding and i lt fell on stern gunport bulkwark corner. A lot of glue and clamps was used to het it into near shape. Therefore i have some deciations with mesaurements in that part. Nothing that eye will really catch if you dont know to look for it. Below you can see progress. I have basicly finished planking on one side-last plank needs to be adjusted according to keel. For 2nd planking i started with pva and ca but wasnt happy with result as edges were rounded up. It came to my mind that i had alplic rapid glue from Cronwall. Didnt use that before vause it had yellow look. This time i took the risk. I have to say best glue so far. Graps quick and you have enough time for adjustments. This means you can plank as much as you want. For last i have to say that detail of the ship is super-laser has done its job! Only real issue is that it ahould be bigger. I will definitely run into problems with smaller details but will try to keep the quality up. Defenitely will order more kits from Master Korabel, probably Phoenix and others that they have on line dor future years.

-

Everything in this kit is basicly lasercut so yes is the answer.

- 106 replies

-

Meanwhile some pictures on MK Polotsk(3rd ongoing as waiting for parts for both) that i havent started blog and probably wont.

- 106 replies

-

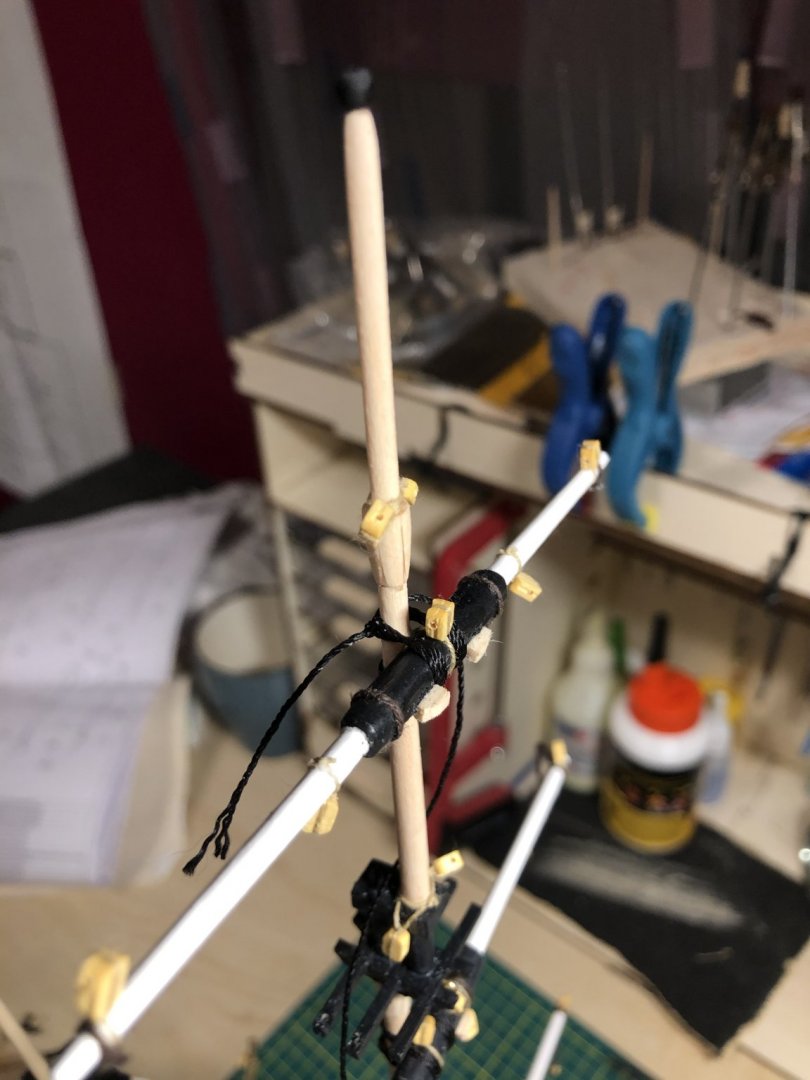

Tnx for info. I allready made the top rings on mast from wood, looks nicer also :D. Regarding chainplates-i tried Occre solution and cane out as a mess. I ordered different oves from Model Dockyard, should receive them soon. Plan is to have oucome on chainplates same as Keith S has. When will you open your blog?

- 106 replies

-

Good job so far! Impressive wuality for first wood build!

- 11 replies

-

- lady nelson

- amati

-

(and 1 more)

Tagged with:

-

My replacement chainplates have been send out, hope to get them soin. And cause i have to move in one moth i dont want to permanitwly fix masts as it will make moving more difficult. So more progress with Terror probably in June. As i have started my second build also (Hms Cruiser) i ran into big problems. All the wood must be replaced besides 1 mast dowel. Replacements have been sent out so hope to get them soon. So basicly i have nothing to do with those 2 kits. Luckily i had MK Polotsk on self so i started that. I really like it-all laser cut and fits together well. Below you can see some pictures. Havent taken many pictures. Didnt dare to start 3rd building log as oldtimer might think the newbie hasnt finished any kits yet but allready has 3 ongoing projects - be must be mad. . But to pure more gasoline to the fire i took use of Model Expo discounts....and got 6 kits, the discount was just to good not to use it. I can aleays sell them atleast for same amount.

- 106 replies

-

Welcome to the club. Most of suggestions are listed here in the blog. But dont rush and read the insteuctions. There is a lot information missing from instructions and aloy info what you will not notice. Just one thing came to mind-keep bowsprit dryfitted when doing the keel.

- 106 replies

-

I would say do a test trial with ebony and paint. Mine is paint but other build here is ebony. I like the stain more now cause it brings out the wood(dissapointed that i disnt choose to stain but also had glue mark problems). Really nice work on deck!

-

I wanted to give my feedback to you. Due to different issues i had to start new build and i had Polotsk on the self waiting for me. The parts fit together perfectly. Little or no sanding is needed. Its magnificent engineering work that you have done there! You can concider me one of your fans - will build allmost every kit you will make. Keep up the super work!

- 216 replies

-

- masterkorabel

- ships

-

(and 3 more)

Tagged with:

-

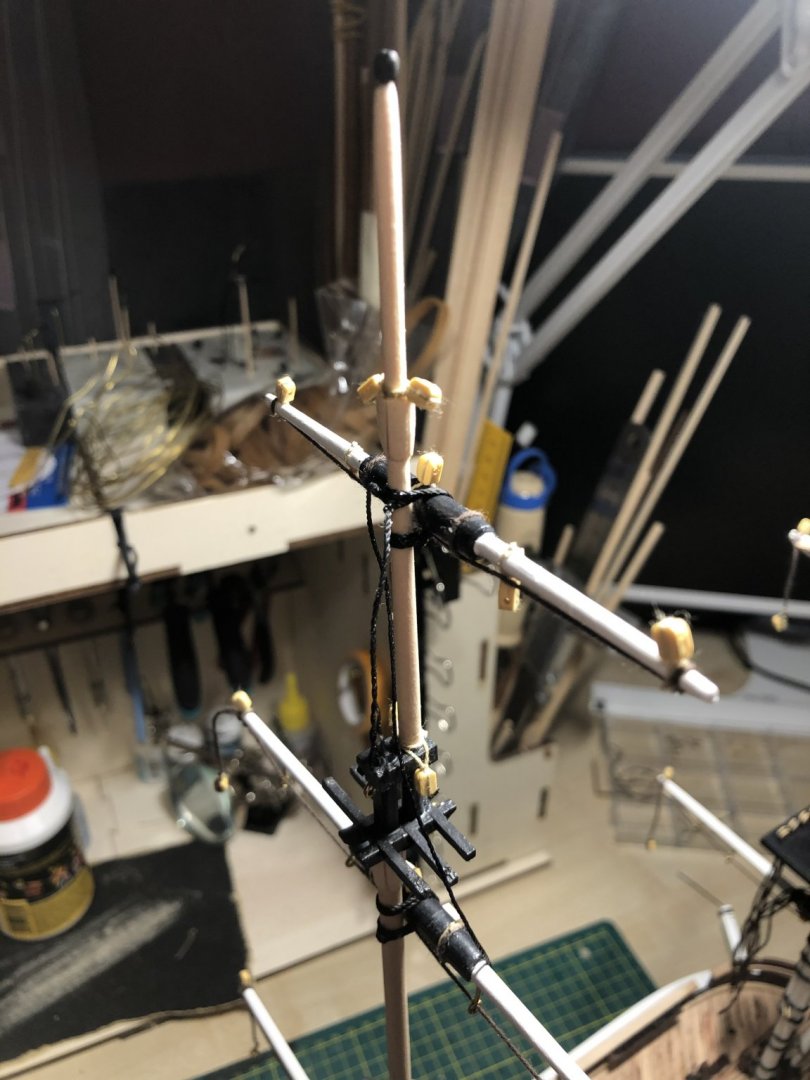

As im waiting for spare parts for Cruiser there has been progress with this build. Main and fore mast - 100% done Mizze mast-all yards done, need to connect to the mast. Repaired the keel under bowsprit-much better than before. Any idea what are those black rings(picture inside plastic box)? Maybe rings for connecting mizze yard to mast? Final picture with all my ongoing projects at the moment(dont dare to take the picture about future ones as intook advantage of model expo sale....).

- 106 replies

-

Your build looks amazing. I really like the look when most of its natural and only some parts painted black. hope to have the same result with mine. Did you change deck planking material or rigging ropes?

- 102 replies

-

- cruiser

- caldercraft

-

(and 1 more)

Tagged with:

-

I have requested new wood. I really like walnut and so far i have managed with 2nd planking. So i hope to get it soon if they approve. I know these requestes put suppliers to tough spot cost wise but i hope they can turn the costs to manufacturer. Honestly - if you pay 250-300eur for box of wood and drawings then the quality should be there.

-

Let me know if you need help with knots. I have collected knots from other kit instructions and books.

- 106 replies

-

Small peogress cause i managed to rigg main mast too deadeyes in wrong direction. 2 holes at lower part not at upper part where it goes to connection deadeye-i guess more focus on details. All wooden parts for masts done. Need details, finishing and attatching to masts. Ordered chain plates. I guess when those arrive i can finish the main parts and move to rigging complitely. I have some bit and pieces around the ship that are uet not done and it would take few nights.

- 106 replies

-

Nice progress. Can you so few close up pictures of deadeyes and chainplates. Im really not happy how mine turned out and i plan to change them.

- 206 replies

-

Hi, Ran into those problems also but also would a solution. 1) regarding pins-i used ebony stain. Check my blog. Worked really well. 2) railing was covering also my pins support. I glued extra strip of 2mm sapelli to support that goes under railing. Joint is barely visible. Width you have to check what you have leftover and fits you the best.

-

Did forst dradeyes with chainplates. Im not happy with the result. As common for Occre the instructions tell to do it one way but photos the other.... I ordered some samples to check and probably will change them. I used brass balck to blacken the wire and it makes wales so messy.... also result ist good enough. Guess i jumped up a level where you invest into better kit fittings to het better results...have to support economy somehow...as bars are closed.

- 106 replies

-

Contacted the supplier and i will het replacement plans. As i want to keep it natural the wuality of wood is really important. As my Cruiser is waiting for replacement parts i got a nice excuse to open Master Korabel Polotsk kit and there is nice little lifeboat as a side project for me. Have to say is a strugge but it fits really good together. Only problem is that its so small and its impossible to use pva. Small details break easily and i repaired them constantly. Other than that a engineering masterpiece-hat off Master Korabel!

-

So thought this walnut problem is acceptable but today i receveived an other kit from Caldercraft and walnut there is superb. Im allready mad that i didnt send in request in to get new planks before. Problem with allready installed planks is that some are glued with CA.... I sent request to Model Dockyard to get new planks - lets see. I guess this is build is off the table until i get new ones. Taken into account i can get those in my country its waiting time about 2 weeks... Guess i need to start a 3rd build. As i cant continiue with Terror also cause i dont really like kits chainplates and havent ordered new ones also yet....

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.