-

Posts

4,377 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Egilman

-

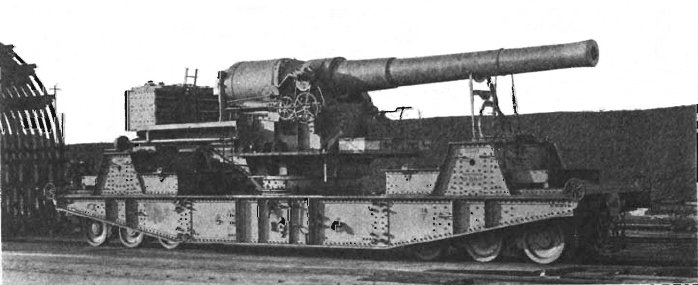

Hi guys... This was coast defense railroad artillery.... And the D-Model designation is Mk I which is the designation of the carriage not the gun itself... The Gun itself is a Mk III to a Mk VI adapted to the Mk I deep well railroad carriage... Here is a picture of one in operation in France.... from "THE FIELD ARTILLERY JOURNAL". VOLUME VII NUMBER 2. April-June 1917. THE UNITED STATES FIELD ARTILLERY ASSOCIATION WASHINGTON, D. C. Downloaded from http://sill-www.army.mil/FAMAG/1917/APR_JUN_1917/APR_JUN_1917_FULL_EDITION.pdf This photograph Q 4280 comes from the collections of the Imperial War Museums. Photograph of British BL 9.2 inch gun, Mk III* or Mk VI HMS Iron Duke, mounted on Mk I railway truck, in action at Maricourt, France, during the Battle of the Somme Sep. 1916. There were no Mk I guns produced in 1896 as they were deemed deficient.... Most of these guns were reclamations from the Royal Navy as they replaced them on their capital ships... The Guns had a 10 deg traverse left to right on the mounting any further traverse was accomplished by moving the gun on it's curved track to change it's bearing on target... It's elevation was 28 degrees which was improved to 35 degrees sometime in 1916... All of these guns were scrapped after WWI... The only ones that were saved were the Mk XIII model and those are the ones that served into WWII... They were mounted on a straight back carriage..... Interesting gun.... Beautiful model Brother....

-

Looks beautiful Brother, absolutely authentic except for the unattended Chauchat sitting there on the sidewalk, (never happen in real life) probably should be near the gunner with it's bi-pod legs folded leaning up against something.... A more casual setting given the casual setting of the scene itself... It would never be set up in firing trim in that situation...

-

Nice rendition of the discolored stainless steel aft fuselage... That is about the color of overheated SS... When hot, it would exhibit all the colors of the rainbow, reds, purples and blues in bands between the bulkhead stiffeners... Very pretty... when they first sent them to SEA, they painted them in camo, but that quickly burned off after a few missions... It makes for one of the most difficult planes to paint... You have a great start on a early war bird.... Very nice...

-

No doubt Brother, once the war was over, the debate on the proper usage of the new weapon ran for years... Even though the tech hadn't quite kept up with the thinking... And figuring out the logistics of moving tank columns were still being worked out... And then, expanding the ideals to Combined Arms in actual combat.... The development of the armored forces concept is a broad and very deep subject.... And we can't forget Dwight Eisenhower in the mix, he was the other genius behind what the US Army Armored force became...

-

Andy not going to argue here but armored vehicles were a concept recognized as advantageous for centuries... Just about every nation on the planet has someone that can claim to be first... Hussite forces in Bohemia developed war wagons – medieval horse-drawn wagons that doubled as wagon forts – around 1420 during the Hussite Wars. These heavy wagons were given protective sides with firing slits; their heavy firepower came from either a cannon or from a force of hand-gunners and crossbowmen, supported by light cavalry and infantry using pikes and flails. Heavy arquebuses mounted on wagons were called arquebus à croc. These carried a ball of about 3.5 ounces (100 g) Armored wagons and locomotives were used during the Civil War... The concept is as old as the hills... But the melding of it all together into a cohesive plan of usage was Patton's idea... The FT-17 is recognized as the first modern pattern tank and set the pattern that has been used ever since... The pierce and encircle calvary tactics was perfect for the equipment of the day... Everything else since is simple refinement of the successful concepts that he first employed in France....

-

Tanks are what they are today due to the forward thinking of one man... And one man only.... George S Patton.... He was the first to apply calvary tactics to light tanks on the battlefield... During WWI he commanded the AEF's tank battalions to great effectiveness... Post war he served under Eisenhower who commanded the US Army's tank school until they disbanded the Tank Corp.... Take a look at the US army's combat cars... 40mph in the '20's but the depression prevented the army from filling their ranks with them... Patton worked closely with Christie to develop the T3 combat car, of which the army had 7... He eventually went back to the calvary when the Tank Corp was disbanded due to inter-army political influence/warfare... but during his time after he was sent to Namur, the French military school where he expounded his ideals with people like Liddle Hart, who wrote books about good armor tactics and was considered the world wide authority on Armor usage on the battlefield... His writings were studied by Heinz Guderian, who developed combined arms blitzkrieg tactics based upon Liddle Hart's books and Patton's writings.... (and developed the methods of supporting them on the battlefield, the infrastructure, the chain of supply for moving armor columns) The rest of them, including Rommel, all learned from the masters... Patton, Liddle Hart & Guderian.... George Patton is the godfather of tank tactics, he wrote the ideals of and demonstrated the proper usage of tanks on the battlefield, during WWI...

-

It's lineage runs to the Holt Tractors... the ideal was the holt artillery tractor, (which worked well in that capacity) would work a lot better with a light gun mounted directly to it, then the usual line of modifications chain took over, Armor, Revolving turrets, Machine gun mounts more than one gun mount, etc etc... What eventually happens in these situations is they overload the load carrying capacity of the chassis itself... Or the power of the engine to actually move it... That is what eventually happened to all the Holt/Catepillar line of armored vehicles, they couldn't get past ordinance testing under real life battlefield conditions... (mostly underpowered and very poor battlefield mobility) But they did learn a lot from them...

-

M3A1 Scout Car by brunnels - Tamiya - 1/35 - PLASTIC

Egilman replied to brunnels's topic in Non-ship/categorised builds

Well, check these out brother.... https://www.ebay.com/itm/172103212015?_skw=tudibaker+US+6+wheels&itmmeta=01K5A51C2WE4H5GSF9K47AF4VB&hash=item2812269bef:g:hZYAAOSwezVWwkdT&itmprp=enc%3AAQAKAAAA0FkggFvd1GGDu0w3yXCmi1dPAcq5kxXbKIx%2BI9M%2BSgx%2BdadejbVBD8ltaeZCluDQSCsCtuoebQZFFECwZuD1l0vid4IWEhNr08kPkVQZLyGBdjAmXSHLlP1WDcJ65T5A7RUrJwu1sTugKEdJuRxmdu7vz64GobWGkg2eSWDMgpdbB0HJvJ%2FxiGcZcU0UkM4mgB6SOFrmA%2BGop8%2FxbCp0UeyAglzUFZeASptfYGum0OXhwcGqwBPMiUez3yAiEQYCCHEEFU3fXVgmbYQPnCqHbio%3D|tkp%3ABk9SR77ChcWqZg Studebaker 6 ton wheels and tires... Same size as the M3 Scout car with the same non-beadlocked rim, and it has the proper split lug traction tire tread... Out of Virginia in the US... I can't tell if they are the Goodyear or Firestone tires, but in their e-Bay store they have both versions... The tire size is a 7.5X20, the standard US truck tire of WWII... I think they will ship anywhere... EG -

Actually, there is only one SB2U left in existence... It was recovered from Lake Michigan in 1990, needless to say it was a wreck after 5 decades underwater... After 20 years of restoration it now resides at the National Naval Aviation Museum I believe... They restored what they could, replaced the fabric covering but left the instruments and parts in the condition they were recovered in, after stabilizing them of course... A very interesting airplane....

-

One of the most famous products to come out of this process was Kingsford Charcoal Briquets... The waste product of Henry Ford's woodworking plant... The white oak and hickory char from burning the shavings from the spoke lathes was found to be great firestarters and when compressed into lumps made excellent cook fire fuel.... It all started in 1919 when Edward G. Kingsford helped Henry Ford procure a stretch of timberland to supply wood for his auto plants. Mr. Ford wondered if all the wood waste generated by his sawmill and plants could be put to better use, and found his answer in a new process for pressing blocks of reconstituted char... While the innovative charcoal briquet was initially marketed under Ford’s own brand, it was eventually renamed Kingsford Charcoal in Edward’s honor..... Very profitable product once it became known... The process was split off into it's own company after Henry passed and still operates today...

-

M3A1 Scout Car by brunnels - Tamiya - 1/35 - PLASTIC

Egilman replied to brunnels's topic in Non-ship/categorised builds

Nice! Especially with a family reference... I would also get a set of these.... M3A1 Scout Car - early 6 holes rim wheels If you really want to match the vehicle in the pic... An early US issued M3A1 I will be following along..... EG -

They also created the L76 engine in 1912.... A 7.6 litre, 4 valves per cylinder, dual overhead cams... The first 4V-DOHC IC engine ever made.... It proved itself in the French Grand Prix, and the Indy 500 and became the racing engine of choice from those days forward... Harry Miller took it and designed his V4 DOHC engine based upon it and made himself a legend at Indy, only to be followed by a guy named Offenhauser.... Peugeot was one of the technical engineering leaders of their day... Right up there with Ford and Krupp and all the rest...

-

Hey Brother, Tank Tracks? Painting.... A long sinuous discussion track... First off, what you paint them depends... Yes it depends on when in the tanks life you want to represent... A new on the ramp tank, a recently issued tank, (Baker gave you a GREAT shot of a recently issued tank, which means original manufacturers tracks) or an old road or battle worn veteran tank... They all look different.. A new tank on the delivery ramp? Same color as the tank with bare metal cleat bottoms.... A new issued tank just out on manuevers? As I said, Baker gave you an exemplar photo... Perfect, the sprocket ends show the same color as the tank, the track bodies have picked up a coating of dust and the Cleats have almost worn off the initial paint coat on their bottoms showing plain steel.... Perfect for a well maintained or newly issued tank... A note: Tank tracks wear out quickly... One of the major supply issues with tanks is not only fuel and ammo, but replacement tracks... Especially in WWII, all metal tracks were painted in their tanks base color... For a British tank would be British Army Green... A battle worn tank? I would start by black basing the track overall then using dry brushing and washes bring out the rust browns and dirt browns remembering to leave patches of the green showing, for a tank that has really seen the muck then you can go the mucky dirty look with hard basing some kind of medium on the track to show the lumps then the browns and greys to represent the colors of muck... the world of track painting is just as varied as WWII camuflage, get a few decent color pics and experiment until you gat the look you like... Backer's pic of the late war newly deployed Comet is priceless in this regard... Personally I would go with it.... EG

-

Gloster Meteor F8 by AJohnson - Airfix -1/48- PLASTIC

Egilman replied to AJohnson's topic in Completed non-ship models

Well they tested them in an F8, that's why I said generally... which is true.. But as always, there are exceptions to general rules... Elmer -

Gloster Meteor F8 by AJohnson - Airfix -1/48- PLASTIC

Egilman replied to AJohnson's topic in Completed non-ship models

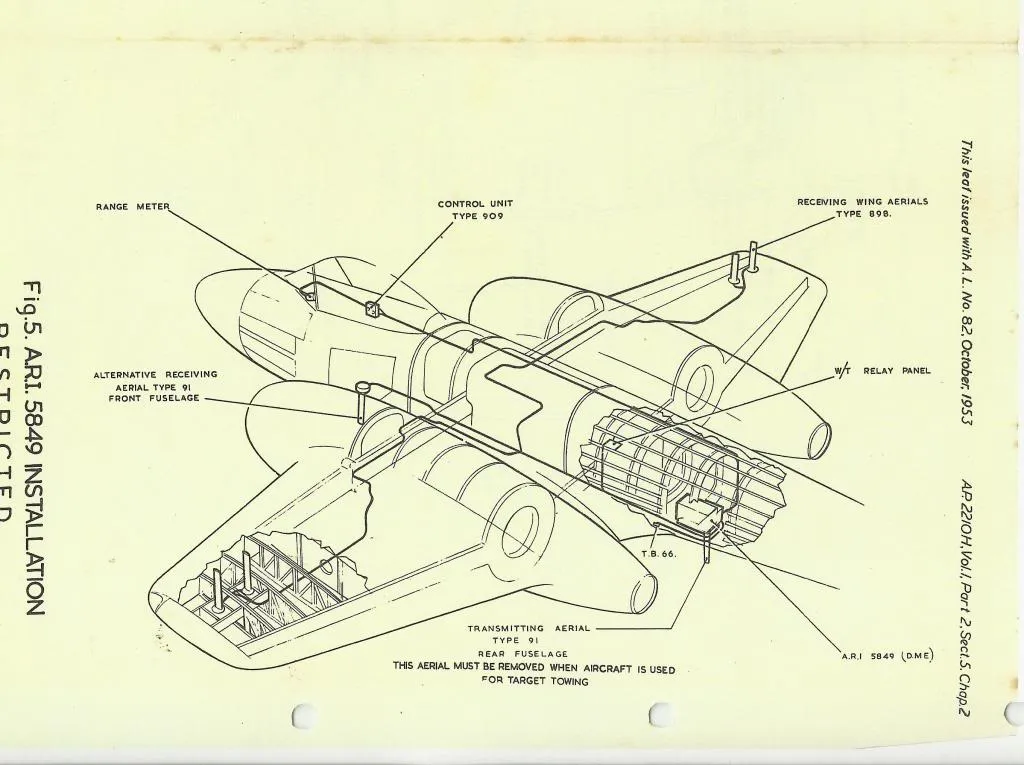

ARI 5849 or Rebecca Mk.7. (also known as TANCAN) you will find them on Meteors F13 & 14's late in their lives... I believe it was a radar homing device of some type.... They were tested in a Meteor Mk.8 in 1953.... https://apps.dtic.mil/sti/tr/pdf/AD0020257.pdf Note the transmitting antenna on the bottom of the fuselage as well.. You will also see these on Vampire T11's as well... EG Also note: F8's generally didn't carry them.... -

F-84G by Javlin -Tamiya - 1/48 - PLASTIC

Egilman replied to Javlin's topic in Completed non-ship models

Future/Pledge also needs a wet coat brother, on everything/place your going to put it... So plan on complete coverage and do your setup accordingly... It dries very thin so the only real complication is handling run off... (thinned wet coats tend to run) What I do is keep a pile of absorbent material next to where I'm clear coating and when the future runs enough to start collecting on the low spot, touch it to the absorbent material to wick off the excess... You only want the droplet that forms to touch the wick, do not allow the surface to touch otherwise you will have a touch up to do... Definitely needs a wet coat to work properly... EG -

Modular layouts have been around for about 70 years, and yes it is the way to go when building larger layouts... And OSB, (oriented strand board) makes a great foundation for a layout... Doesn't have to be perfect and is almost as strong as plywood... (besides being about a third the cost of good plywood) Nice progress, watching with interest... EG

-

Usually they have a platform that allow the grain to be shoveled off the wagons into a hopper that gravity feeds the elevator... The elevator, (think bucket chain hoist) lifts the grain into the top of the silo which is gravity fed into the hopper cars when loading the train... The doors, (usually two) were there for elevator chain replacement, these elevators were used continuously during harvest season 24/7... The chain lifts would wear out in a single season in an area of large farms... There was equipment in the machinery room to effect the swapping of the lift chains, and it could be done in two days... They would actually use grain loaded in the buckets to balance the weight so it was a simple low tech hand operation to change them... Otherwise, the doors remained closed at all times.... This is why you don't see them open in period pics... (usually taken during harvest season when the elevator is in operation) EG

-

BR-18 Locomotive by Greg Davis - OcCre - 1/32

Egilman replied to Greg Davis's topic in Non-ship/categorised builds

They were flush riveted on the boiler plates, the bands reinforced & covered the riveting.... They were also built during the end of WWI thru approximately 1928 in several variations.... There is one still in operation today... Plate arc-welding as a manufacturing process didn't come into use until 1932, and even at that time was limited to the shipyards building warships... It's became widespread during WWII... -

You know, they lived with it on the real car... The door windows were plexi on the real car and the parts for the slider were as well just glued together... The rivets were for reinforcement... A few minor scratches adds to the authenticity... This is my opinion of course, but they are there on the real thing... Absolute fact... So, nothing to be sad about, an inadvertent detail added by accident, but very very realistic... (especially since you have to be on top of it to see them) Perfection I say... EG

-

You know, I've been debating whether I should mention this or not... The idea is to scale down the car, NOT scale up the lumber it's sitting on... Where on god's green earth you obtained in scale metal flake blue paint? They don't make such an animal... So you see my point.... So please stop scaling up the wood... {chuckle} It confuses us.... EG PS: very nicely done Brother... VERY VERY NICELY DONE...

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.