-

Posts

4,379 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Egilman

-

Yeah it fits the bill as what it is supposed to represent mechanically, but not visually.... I've done this for the flexible tubing used to connect up intake and exhaust tubing on truck models.... Made my own coils to represent the tube, attached them to the fittings on each end then painted them with micro kristal clear once they are installed in position... When it dries, it shrinks into the gaps between the coils and is completely clear and paintable making it look like a solid tube... Add the clamps on either end and voila! A perfect representation of scale air ducting.... The other option is to fill the insides with something like rice paper dyed black so you can't see through the coils from a distance, but it doesn't come out as good as painting them with Kristal Clear...

-

Gaspatch from Greece has shipping to the world for 13E.... They have several variations of both in 1/32 scale... Vickers US built... https://www.ebay.com/itm/175473761772 Vane Sights... https://www.ebay.com/itm/276443512739 Lewis Gun... https://www.ebay.com/itm/175473752654 All US based evilbay... Victory Models out of Ft Meyers FL. has all three in stock.... https://www.victorymodels.com/search?page=2&q=*Gaspatch*guns*&type=product

-

kit review V8 Engine BUILD REVIEW (TECHING) - EngineDIY

Egilman replied to James H's topic in Non ship-related reviews

The technology of DOHC 4-V (what they call it today) originally came out in 1911 with the 7.7L Peugeot French grand prix racers... Traces it's lineage from there through Miller's engines to Offenhauser's engines to Fords DOHC 427's to Cosworth then the Porshe/BMW engines to finally the Japanese versions they are running today.... Nothing special and nothing secret about it... Smokey Yunick said it best "...the quickest way to get more power, more cubic inches",... But what he was really saying is put more air/fuel mixture into the combustion chamber... Puegeot came to that conclusion 30 years before Smokey was even born.... -

Thanks Craig, and yes he is... He very aptly shows what can be done out of the box with this kit... I think it should be held as the best new race car kit of 2024.... An easy builder of a stunning model from a great company.... Why a great company you ask? I received replacement parts in the mail yesterday, Parts 58 & 59 Brake backing plates.... They were completely unannounced to me so I checked the kits parts... Those two parts in the kit were slightly short shotted, so finely that I didn't even notice in my inspection of the parts for the review... (and to be completely honest it would never be seen when the build was finished) It didn't matter, they replaced them on their own dime without even asking.... That's the kind of customer service you want in a model company.... Top Notch.... I wouldn't hesitate to buy from them again... (in fact I plan on doing just that in the future)

-

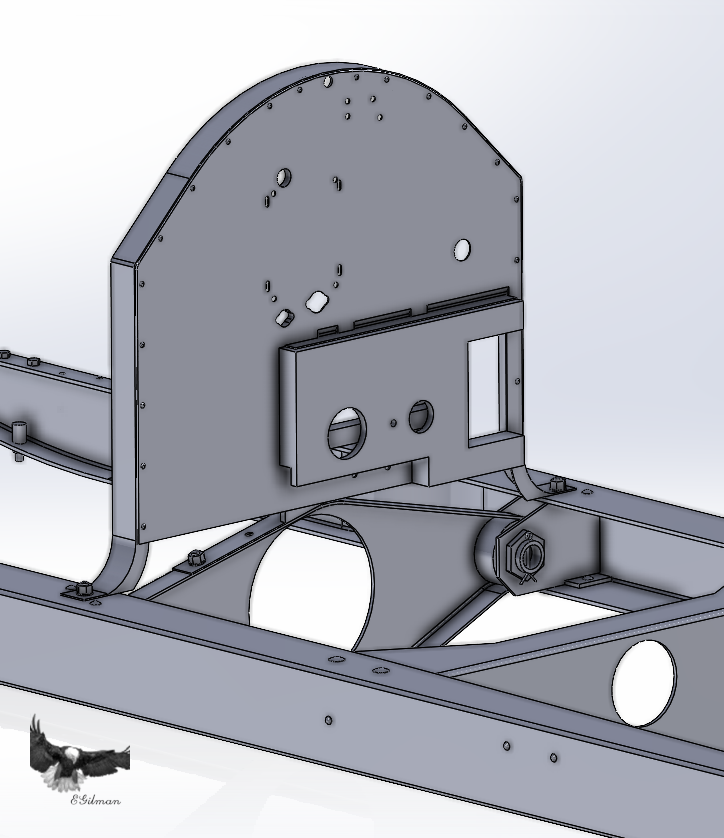

Keeping my head in the game.....

Egilman replied to Egilman's topic in 3D-Printing and Laser-Cutting.

And another short update.... Front firewall, progress report... Front... Only about halfway there on the engine side, I will probably have to wait for the clutch pedal creation to cut the slot for it in the firewall.. Current state of Cockpit side... What your looking at is the wooden foundation of the steering gears, yes, they are built up wood blocks with holes cut thru them to reach the fixture supporting the gears themselves... The wood forms the inner layers between the metal firewall and cast gear fixture... About to start designing the side walls and braces, they need to be done now cause the angle of the steering gears needs to be fixed..... Also, the sidewalls are different from left side to right side... (today, they would be identical mirrors of each other, nothing easy about this thing).... Anyway I haven't left, I'm still here plugging away... Onwards... -

M1A1 ABRAMS by mikegr - FINISHED - Revell - 1:72 - PLASTIC

Egilman replied to mikegr's topic in Non-ship/categorised builds

Yep that is the one weakness all tanks and tracked vehicles have on the battlefield, loss of mobility... The Abrams though is a fast repair, just remove the offending damaged road wheel and repair the track, and she can rejoin the column... This happened several times in Desert Storm.... 45 minutes was the longest loss of mobility.... In Iraqi Freedom this happened to the Abrams several times as well from IED's, once the fires went out, they winch it onto a C-het and send it home where it is rebuilt into a new updated tank... It is the most survivable tank in the world today... The main weapon Insurgents use in an urban setting is knock off a track with an IED or RPG and use Molotov's dropped on it from above to set it on fire... It gets the tank out of the battle line true, but doesn't destroy the tank... But your correct, a tank without the ability to move is a sitting duck.... -

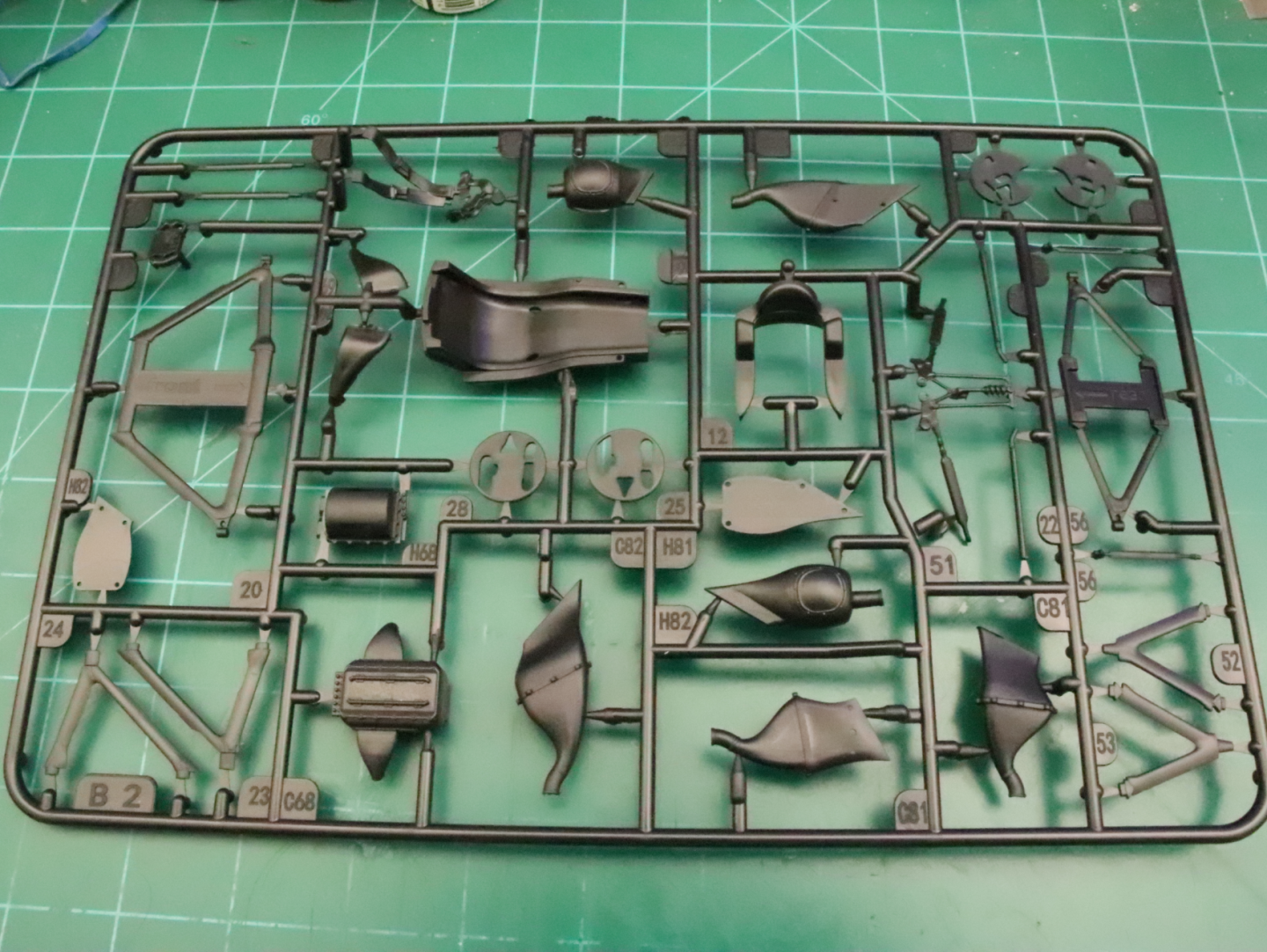

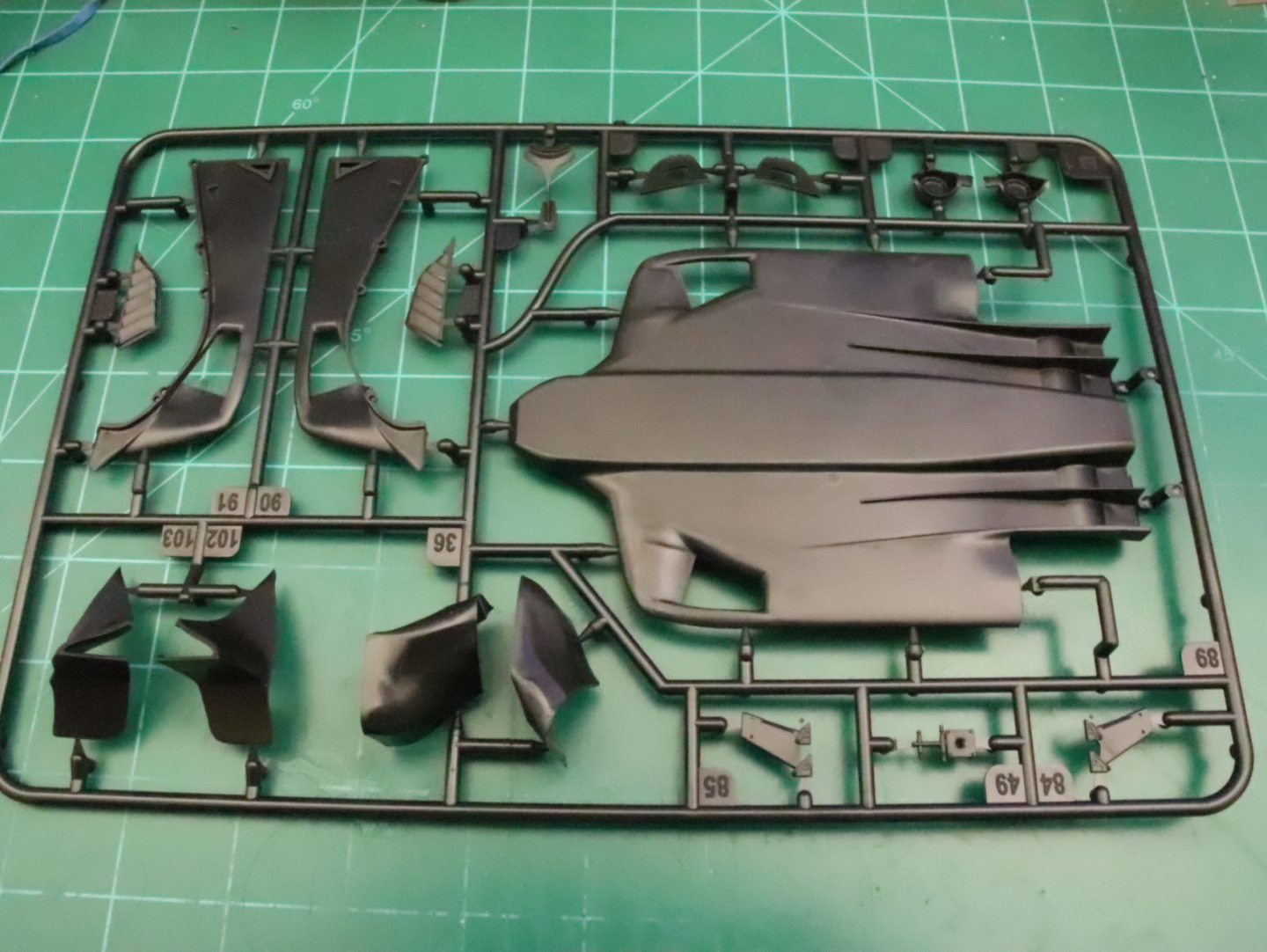

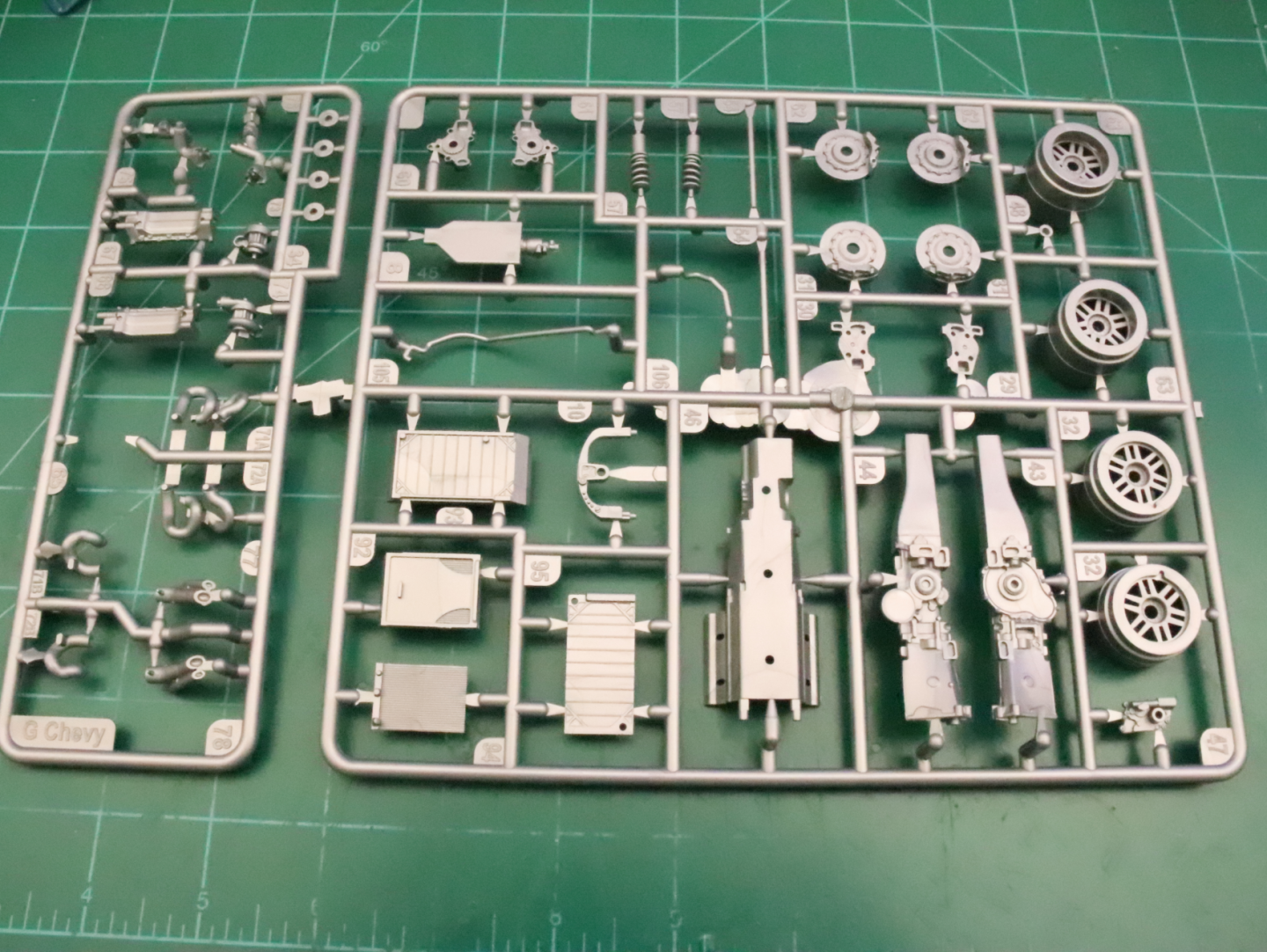

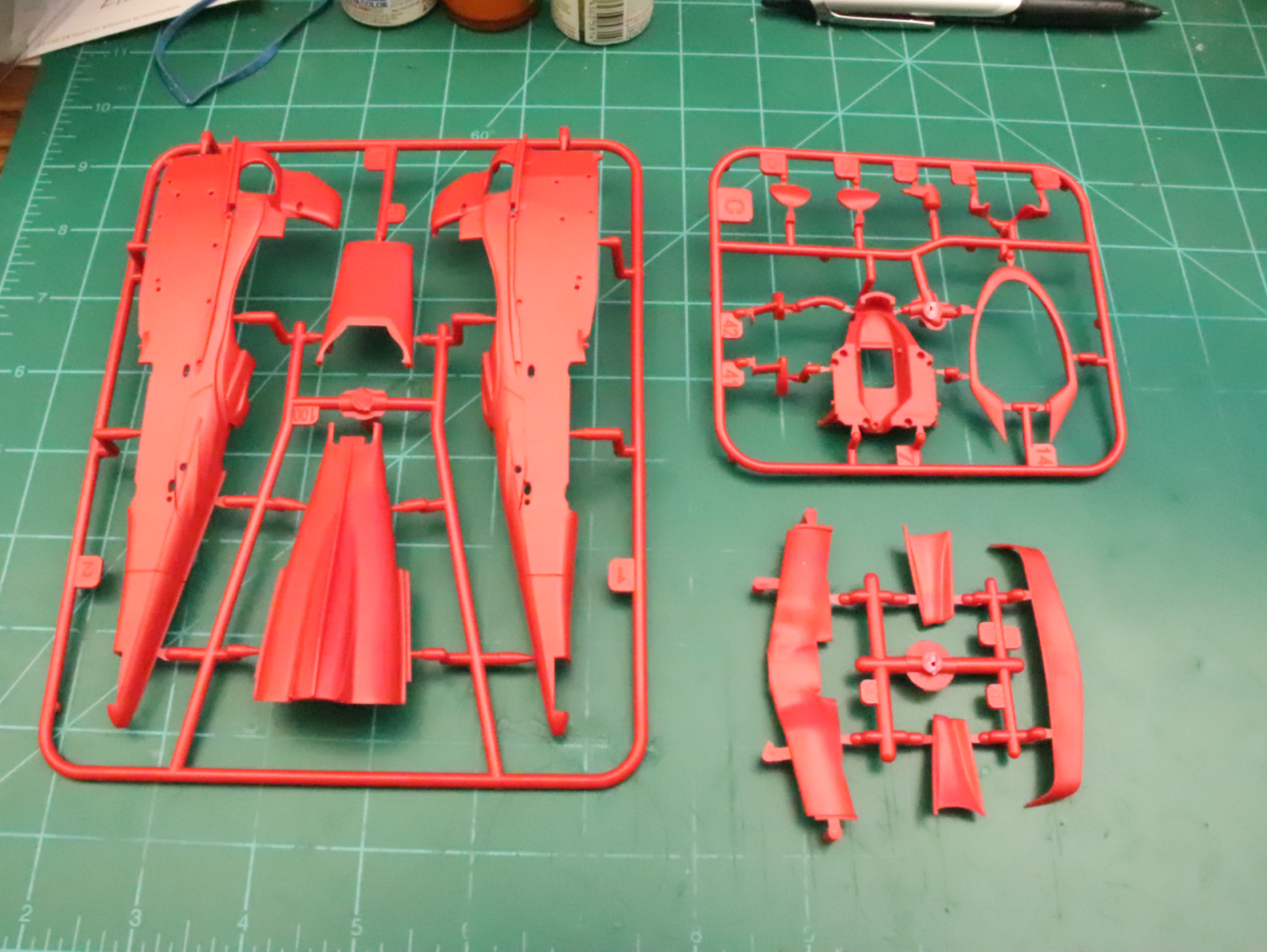

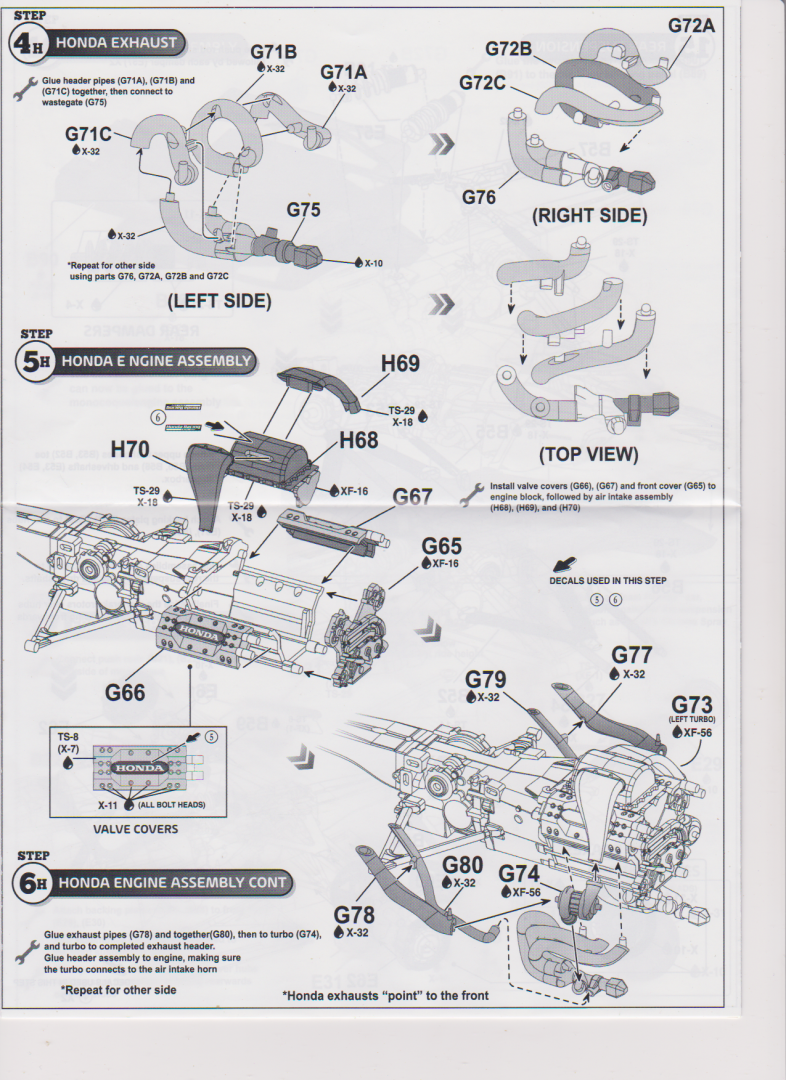

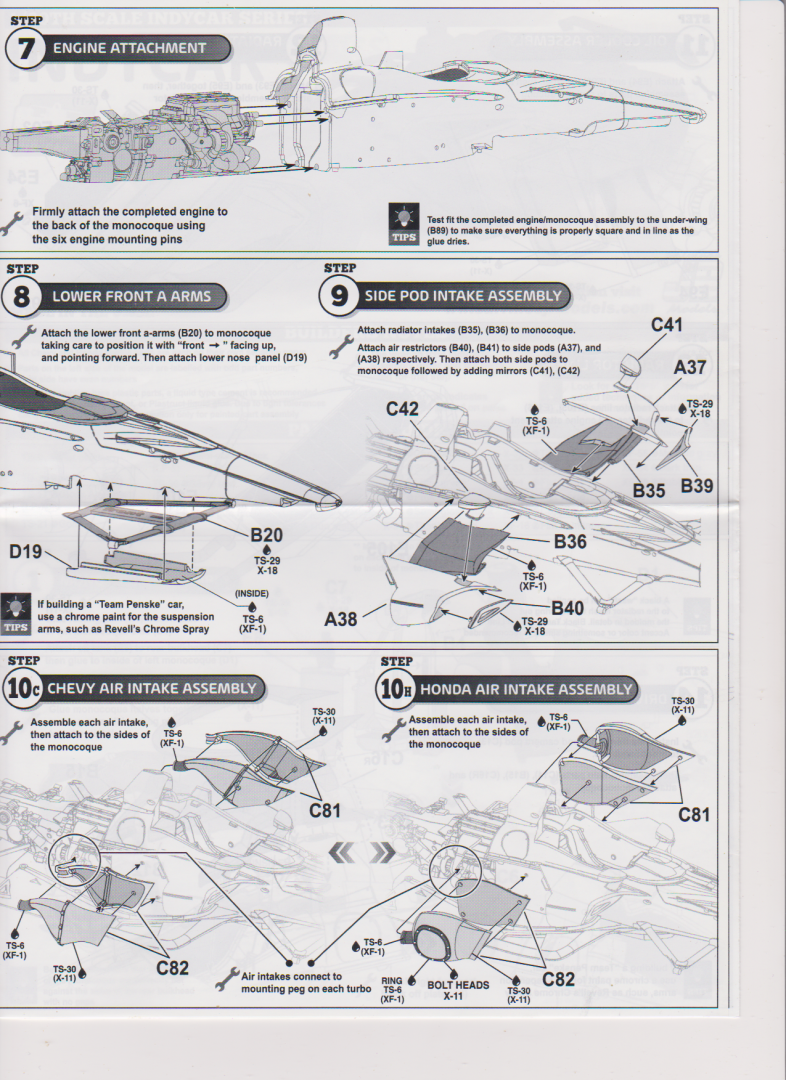

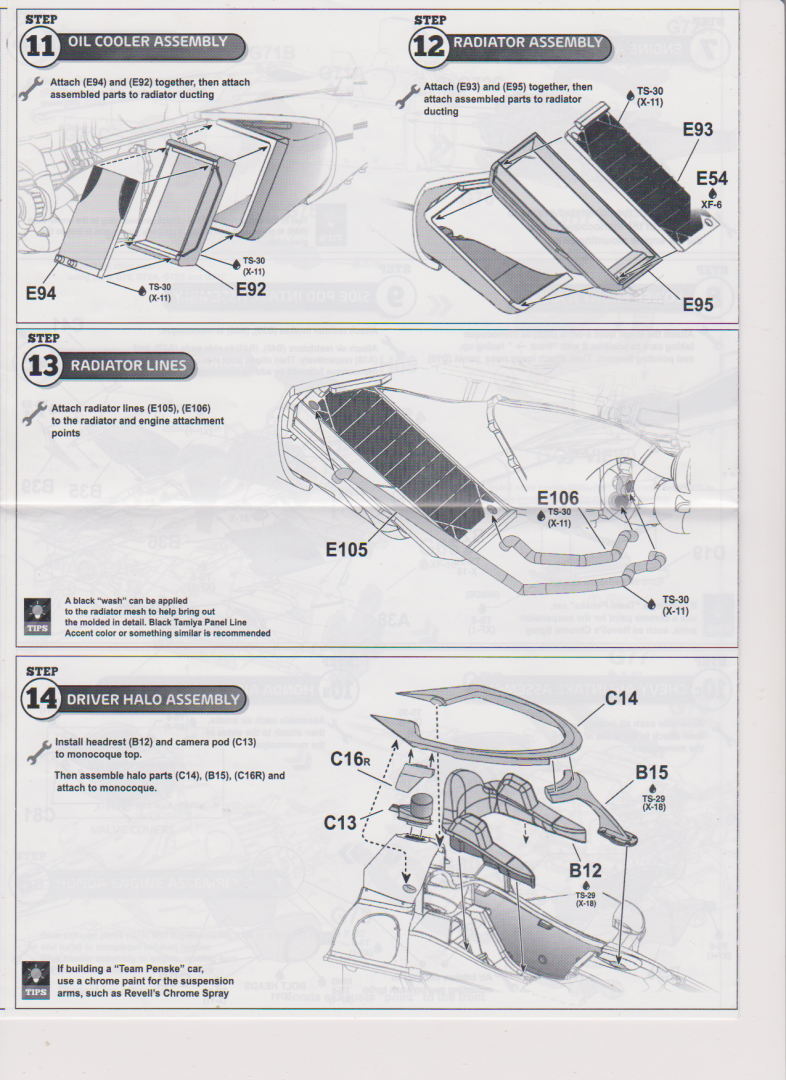

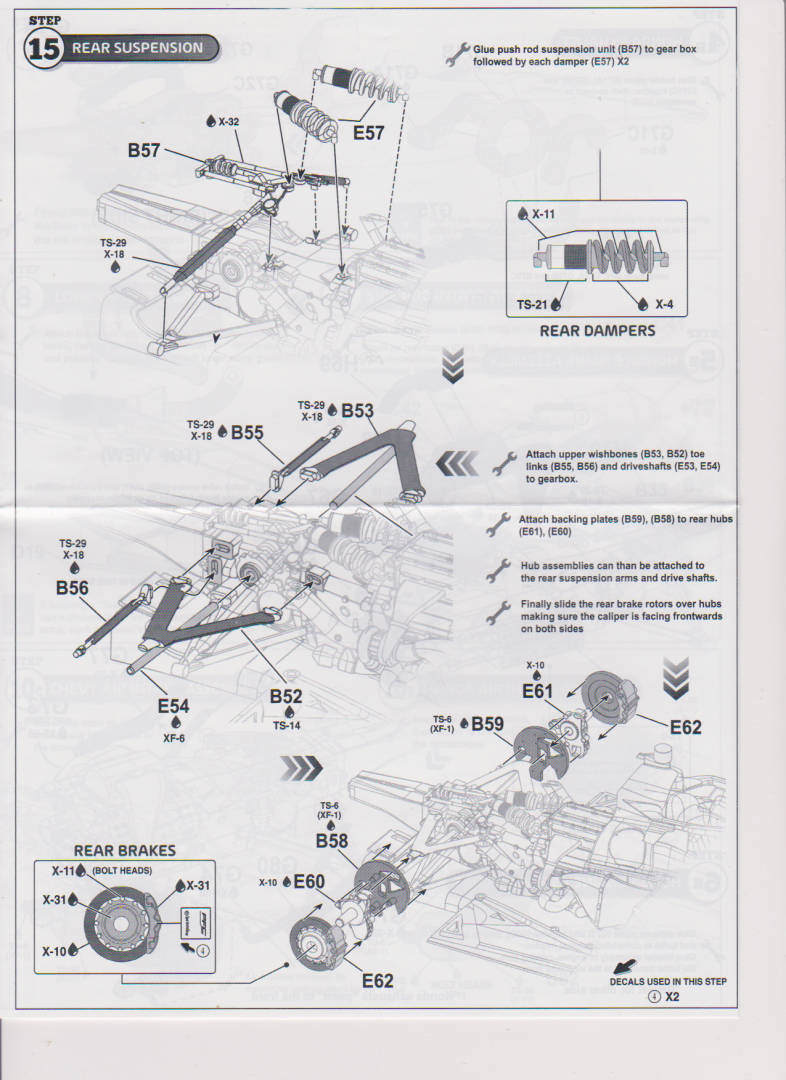

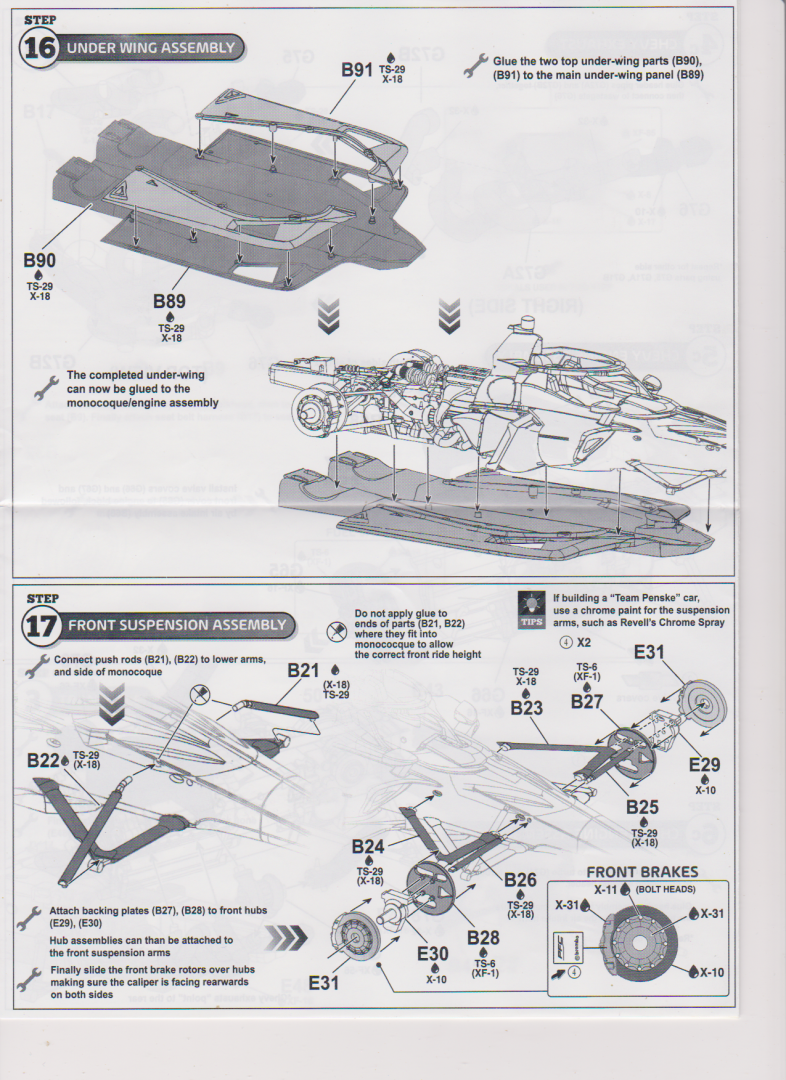

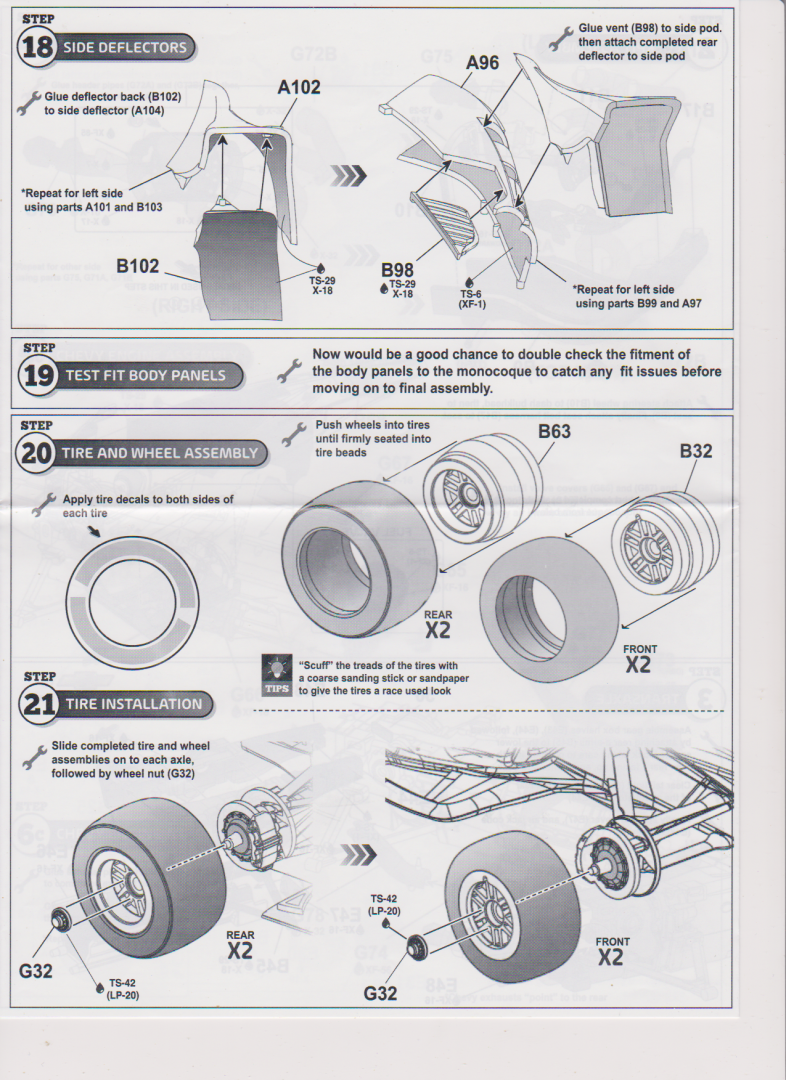

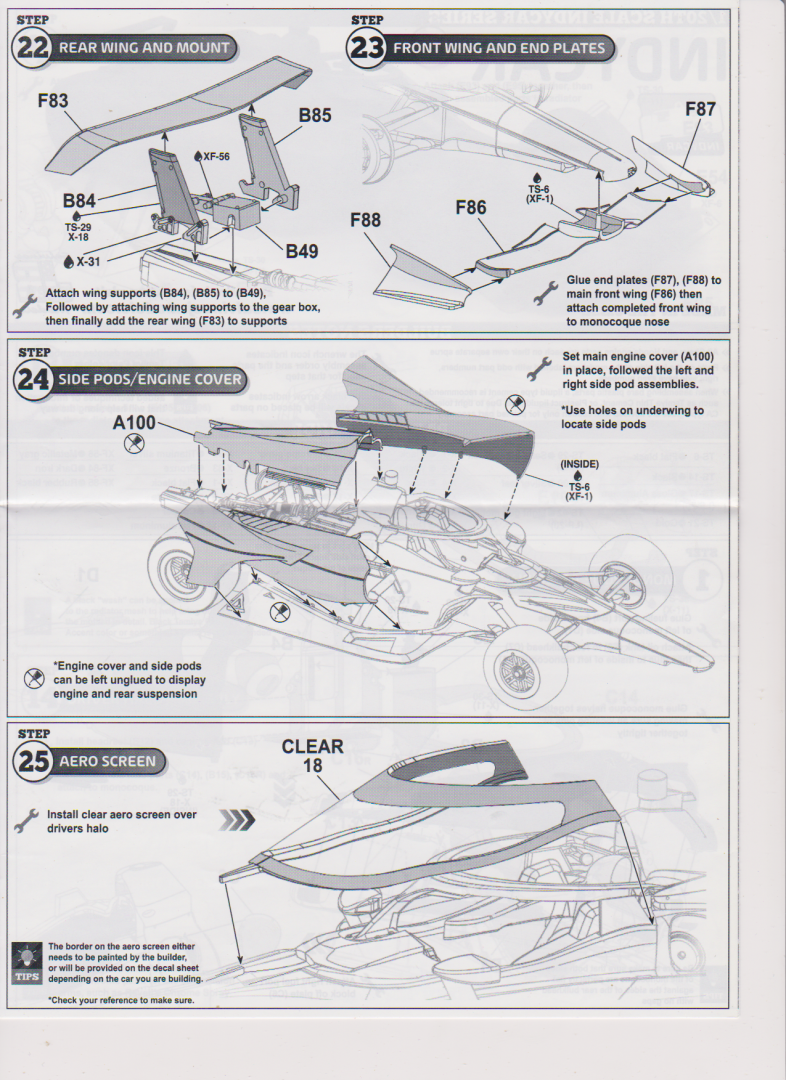

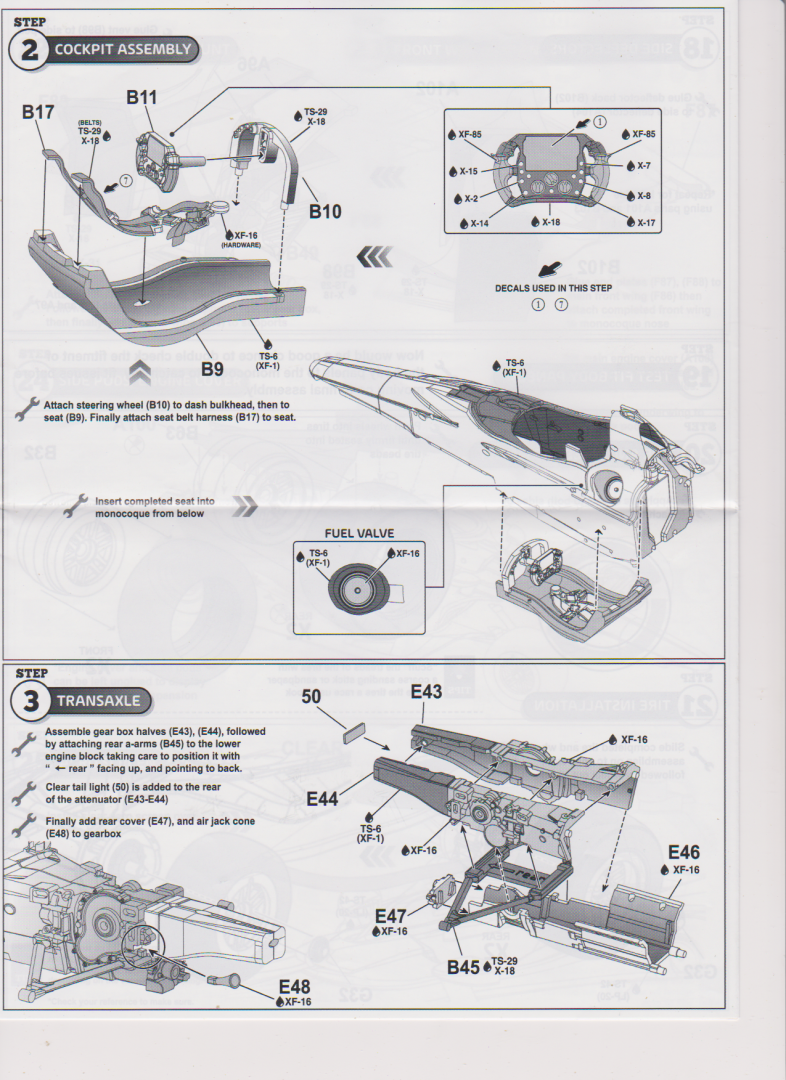

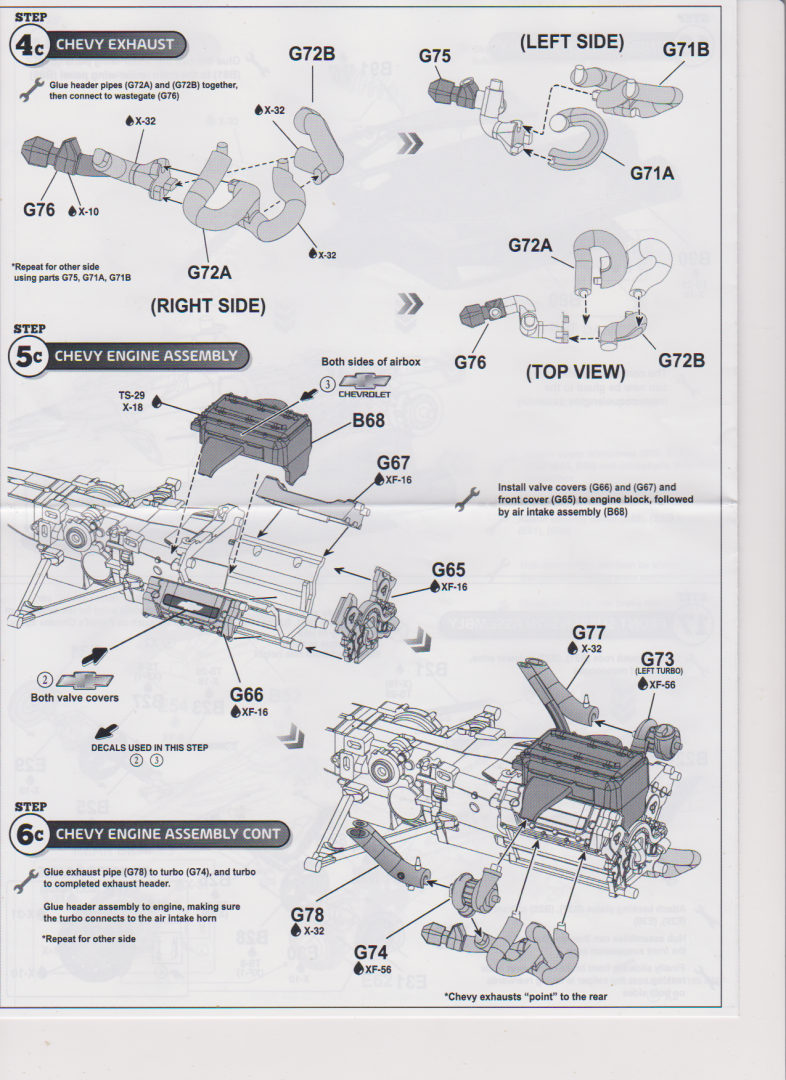

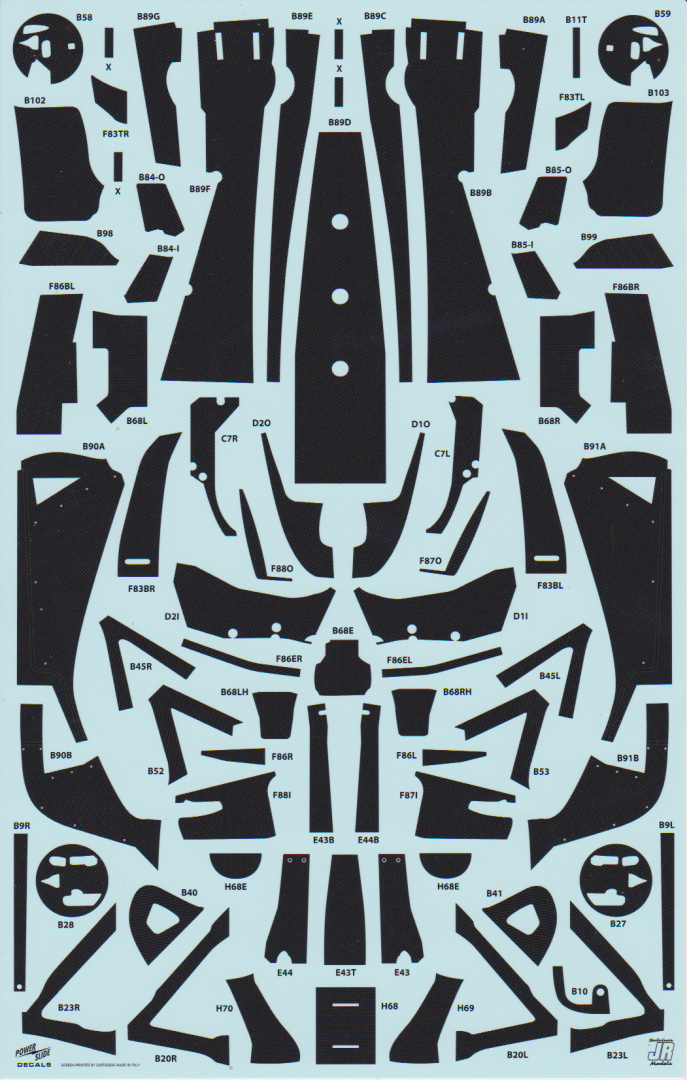

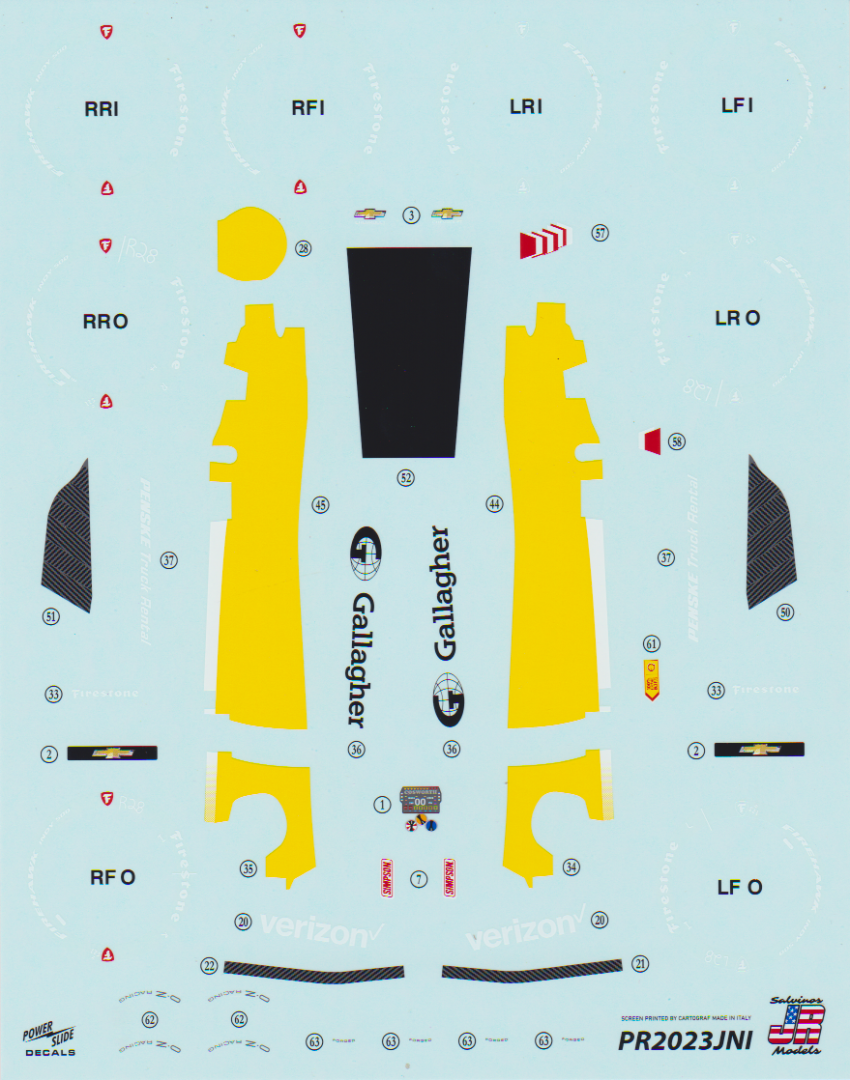

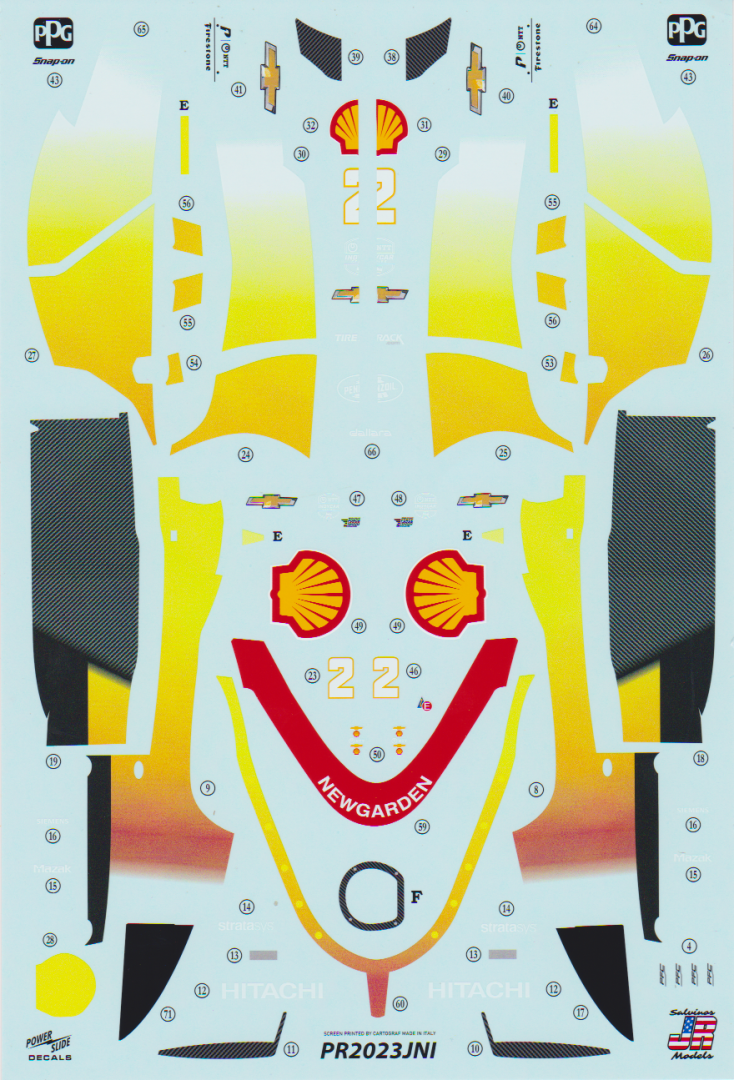

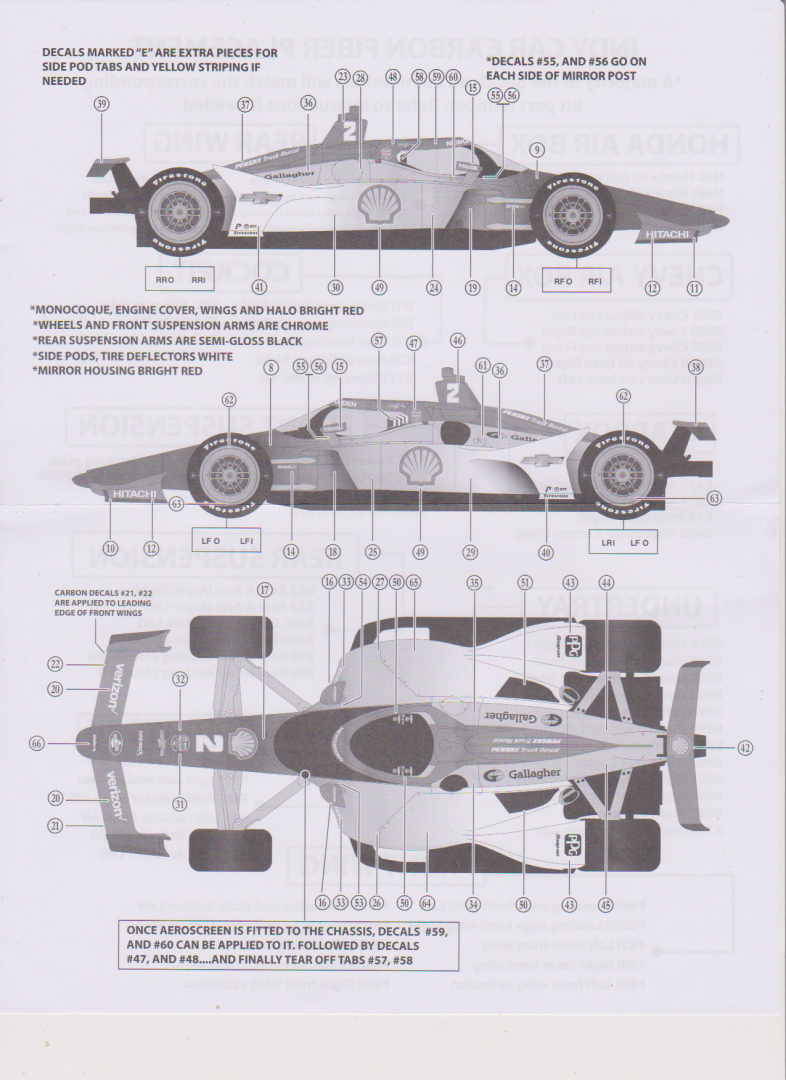

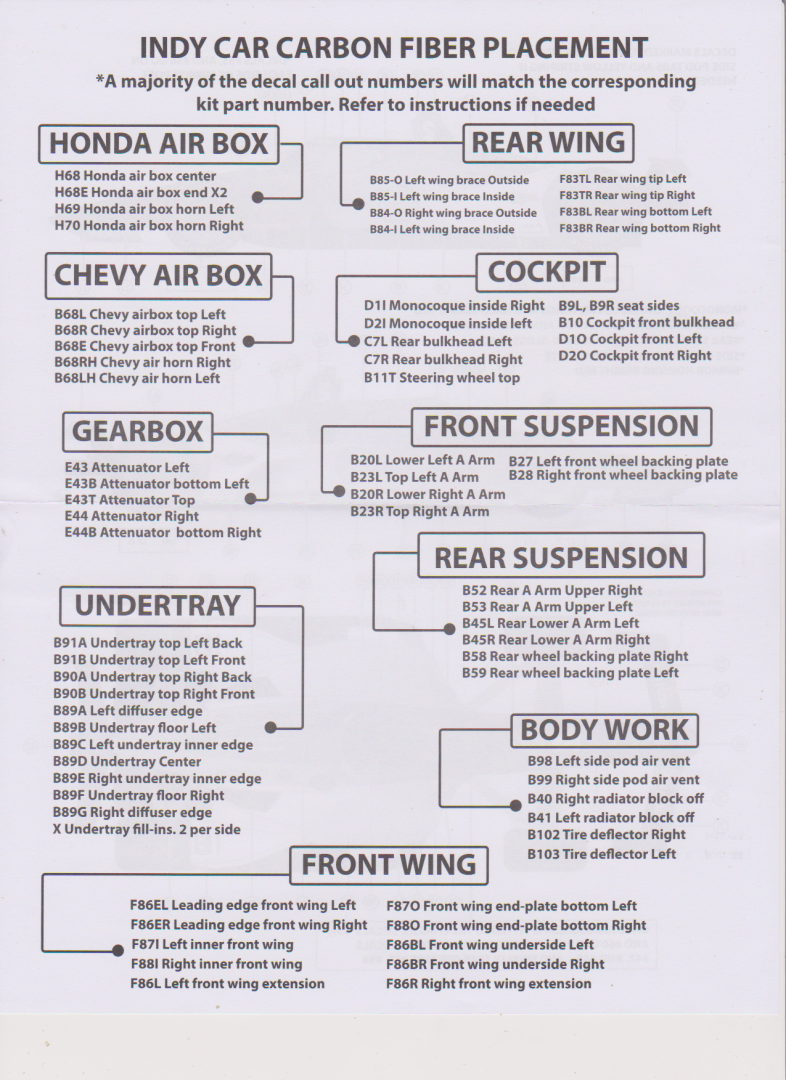

Hello this is my first Kit Review so please bear with me if I don't get it all correct... I recently received in the mail courtesy of my Paypal account and the US Mail one of the brand new Salvino's JR Models 2024 release of Josef Newgarden's 2023 Indianapolis 500 winning car, it is a first edition... I have no connection to JR Salvino except I like the Indy 500 series winners in 1/24th or larger.... And this is an outstanding release... First of all we will cover the subject, The car..... The car is a Dallera DW-12 originally named the IR-12 for Indy Racing 12 (2012 model)... Dan Wheldon was the test driver for the IR-12 and would have been the lead driver for it's introduction to racing for the 2012 season... Except he was killed in the final race of the 2023 season at Las Vegas Speedway in an IR-05 model, the model's last official race... So Dallera decided to honor all of Dan's proving and testing work by naming the chassis after him hence the DW-12 model... Every car raced in Indy has been a DW-12 chassis since 2012 and this will continue through 2026 when it is expected that the new IR-27 chassis will be ready for production... In development the DW-12 was known as the "IndyCar Safety Cell"... It is of Carbon fiber monocoque with honeycomb Kevlar internal structure... Extremely strong and light... The chassis was designed to accept different "Aero Kits" which consist of front and rear wings, sidepods, and engine cowlings.... Development of Aero Kits was open to any manufacturer, with all packages to be made available to all teams... The racing team owners rejected this so for 2012 Dallara was the only producer of the kits.... (the team owners reversed this decision in 2015) with Honda and Chevrolet producing kits as well as Dallera and several teams building their own..... That lasted until 2018 when the league again mandated that Dallera would be the only producer of "Aero Kits" as a result of several flip over crashes in the 2017 season and several serious injuries and one death resulting from body parts separating from the chassis and flying through the air as projectiles... the new rules were that all body kits had to have their parts lanyarded to the chassis so they could not fly around as projectiles and the Aero Screen would be added to the package... (a Formula I improvement for driver safety) So the car we are modeling is a DW-12 UAK18 (UAK for Unified Air Kit of 2018) All Indy cars are required to run this package and only this package from 2018 on... (The Aero Screen was added to the package in 2020) There are two engine suppliers for the 2.2L dual turbocharged package the Ilmor Engineering-Chevrolet Indy V6 (2012-present), Honda HI24TT (2012-present) mated to the same transaxle, the only one allowed, the Xtrac #1011 6-speed AGS (Assisted Gearchange System) sequential semi-automatic paddle-shift + 1 reverse... The idea is to have everyone driving the exact same hardware..... Here is a picture of the car.... In fact change the livery to any indy car raced since 2020 and the kit will still be correct.... Cause they are identical in all respects.... But how can that be? since some of them ran Chevy and others Honda power units? The kit has both engines.... Yes Salvino's thought this one thru thoroughly!!! this kit is COMPLETE!!! It can build any Indy race car from 2020 to the present and on through 2026, just change the livery... Now, on to The Kit... Cover of the box.... Nice very shiny tight top opener in heat sealed shrink wrap.... Upon opening we are presented with 4 sealed bags of sprues in 4 colors Black, Grey, Red & White, one clear sprue and one bag of tires.... 1 assembly/painting Instruction sheet, 1 decal placement instruction sheet and three sheets of Cartograph decals some of the finest decal printing I have ever seen.... Pics below.... Some of the finest injection molding I have ever seen, clean, crisp, sharp details and engraving, rivals anything else out there.... I suspect it will assemble the way it looks... (would be surprised if it didn't) The only thing missing is rain tires, a very nice set of real rubber dry track slicks are provided... Probably very fitting.... I do not know what aftermarket is going to be made available, but this kit shouldn't need it the molding is that good.... The instructions are a five page foldout sheet and are sequential, fold it like an accordian and flip the pages like reading a book... Full color codes for Tamiya paints.... Here are the individual pages.... Very clear on the optional engine, two distinctly different assembly sequences... The instruction seem very clear, concise and complete... On shiny bond grade paper very high quality.... The Decals... First instructions.... Livery Decal sheets.... Carbon Fiber decal sheet... These Cartograph decals seem to be to be a step above what the usual cartograph production quality is, I hope they do this on all their offerings.... Well that's it... All that is in the kit.... My impressions? it should build into a spectacular model, I think the quality is a cut above Tamiya's... Of course this is today production from brand new molds not 20 years ago from half worn molds.... At roughly 80.00 US? worth every penny, this is is much much better than many that sell for 50% or more higher... If you into Indy cars, this Kit will cover all cars for the last four years and two more coming years, I would expect more liveries in the future directed directly at this kit... I bought one simply cause it represented an Indy Winner for my collection I didn't care about the quality, but I'll be buying a few more to cover the Indy winners from 2020 on to 2026... A must buy if your an Indianapolis 500 modeler... EG

-

M1A1 ABRAMS by mikegr - FINISHED - Revell - 1:72 - PLASTIC

Egilman replied to mikegr's topic in Non-ship/categorised builds

Absolutely, this is in the works they already have a contract ready to go for the Israeli system of rocket/drone defense which is reported to work extremely well in the combat examples they have seen... (took their armor losses down by 85%) but they are holding out for a couple of US defense contractors developing their own system right now before they commit... It's supposed to be in the next round of upgrades... They are very optimistic about it... The design thinking right now on the new MBT is for an unmanned turret with autoloading guns reducing the crew to three,... automatic targeting for the light weapons and remote control for the main gun... upgrading the engine to hybrid electric making it more fuel efficient and almost completely silent without losing any of it's speed... and a lower profile to make it more hideable.... If all this works, the next MBT will be an awesome weapon system... These kind of systems are always a balance between firepower, speed/mobility and protection... in '68 protection took a big hit with the tow missile which could turn any tank in existence into a pile of scrap iron, the Israelis learned this the hard way against soviet wire guided tow missiles during the sinai campaign against the Egyptians, but once the missiles ran out, the Israelis kicked A** They developed the reactive armor system to counter hollow charged missiles, then this was countered by first Tow II and then the Hellfire missile... two hollow charge warheads in series, the first takes out the reactive system and the second takes out the tank... then they combine the reactive system with wire cages over them... One day the missile has the upper hand the next day the armor has the upper hand... the Drones are just one of the steps in the constantly evolving process... cause right now the firepower is the dominate thing about tanks there is no defense for that Rhinemetal gun especially firing the US developed DU special shot ammo and the infrared targeting system... A tank appears on the battlefield today it's usually a pile of junk in a matter of a few minutes... Unless it's an Abrams or a Leopard II -

M1A1 ABRAMS by mikegr - FINISHED - Revell - 1:72 - PLASTIC

Egilman replied to mikegr's topic in Non-ship/categorised builds

Yep, they were the first receiving M1A1's in '88 they currently have over 1300 of them in service and a plant that assembles them from local parts and purchased high tech parts.. (mostly M1A2's) Australia was next... Saudi Arabia is 100% Abrams supplied, (over 600 in service) and Iraq also has several hundred as well as Poland has turned in all it's T72's to Ukraine in exchange for M1A2's and Romania is slated to receive them this year.. Understand one thing, NONE of the export versions have any of the special upgraded armor that US issues do, no DU backed composite armor and no DU ammo... It is also reported that a Russian armor display near Moscow has a captured M1A1 on open display... (not something the Russian's destroyed it was something captured in Afghanistan and take to Russia) Right now the only ammo capable of destroying a US operated upgraded M1Abrams consistently is fired by the M1Abrams itself... And of the nine tanks completely destroyed by tank gunfire in Iraq, 8 of them were friendly fire incidents... The earlier models of the M1 are beginning to take casualties in combat, in Syria, (yes Syria) Iraq and Ukraine, mostly to upgraded antitank missiles and improved Russian DU armor piercing rounds, usually in the side and rear armor areas, the front armor has never been penetrated by any weapon known to be used on the battlefields today... It is still, a US operated Abrams, the best most survivable and operable MBT on the planet and is about (2026-8) to undergo another upgrade... Also they are now designing the replacement for the Abrams, seeing as it is now approaching 50 years old as a design and is over 40yrs old as an operational weapons system... -

M1A1 ABRAMS by mikegr - FINISHED - Revell - 1:72 - PLASTIC

Egilman replied to mikegr's topic in Non-ship/categorised builds

Yeah, was very odd to see the US M-48 and M-60 in line with all that Soviet equipment also... (soon to be joined by an export version M-1 Abrams as well) The Egyptian army was the first foreign nation to receive M-1 Abrams tanks... -

Yeah I did, a beautiful job as well... The WnW instruction for this are the best... (glad that Mike got to it before I did) All I can offer is the link to the WnW page for the kit, yes it is still up and functioning, there is even more info on this airplane there... (2 versions) http://www.wingnutwings.com/ww/product?productid=3085 French version http://www.wingnutwings.com/ww/product?productid=3106 (USAS version, take a look at the rigging update page for the US version) She is looking very nice brother...

-

Thanks Rob... I"m a big believer in knowing from whence we came... Understanding these things helps us keep perspectives on life... The internal combustion engine is one of those inventions that was world changing... Prior to that, everything was work for you or your animals... Afterwards all we needed was a tool to do the work for us... Today very few understand that the car or motorcycle is more than a hop in it and turn the key... As a kid we used to walk to the corner store, walk to school, walk to work... Today no one goes anywhere without turning a key, not even to go around the block... And in modeling, we keep the technological history of man alive.... If we are willing to learn the lessons of it.... Give me a lever and I'll move the world, the wheel is a rotational lever, an eccentric wheel combined with a lever gives us back and forth motion as long as the wheel turns.... Everything builds upon that which came before, if we lose sight of that we lose our understanding of what we as a specie went through to get where we are, then we lose ourselves.... Your doing a wonderful job on this kit Brother... And enough of my philosophical ramblings... {chuckle} Model on my friend...

-

Hi brother... I think a bit of explanation is needed here... All ICE's (internal combustion engines) manufactured today use electronic breakerless ignition controlled by the vehicle's CPU... Going back about 50 years the standard was a coil ignition and the Breaker function was provided by solid state components in an electronic module to provide the magnetic field collapse needed to fire the plugs... Prior to that the standard was breaker point ignition which had been around since the early 1900's... The breaker point system consists of a set of Breaker Points, a Condenser, (capacitor) and a Dual Windings coil... (a voltage step up coil) A breaker point ignition system has two circuits a primary (energizing) and secondary (discharging) circuit and how it works is simple.... The primary circuit carries low voltage... (12 volts) This circuit operates only on battery current and is controlled by the breaker points and the ignition switch.... When the ignition key is turned on, a low voltage current from the battery flows through the primary windings of the ignition coil, through the breaker points and back to the battery... (to ground) This current flow causes a magnetic field to form around the primary coil.... The secondary circuit consists of the secondary windings in the coil, the high tension lead between the distributor and the coil (commonly called the coil wire) on external coil distributors, the distributor cap, the distributor rotor, the spark plug leads and the spark plugs.... As the engine rotates, a cam on the distributor shaft turns until the high point on the cam causes the breaker points to separate suddenly.... Instantaneously, when the points open (separate) current stops flowing through the primary windings of the ignition coil.... This causes the magnetic field in the coil to collapse around the coil. The condenser (capacitor) absorbs and stores the energy to prevent arcing between the points each time they open. By sucking up all this energy the condenser speeds up the rapid collapse of the magnetic field..... The line of flux in the magnetic field, (hi magnetic potential to low potential) cuts through the secondary windings of the ignition coil, creating a very high voltage (50 to 75,000 volts for this early engine) - high enough to jump the gaps between the rotor and the distributor cap terminals, and the electrodes at the base of the spark plug..... Assuming that the engine is properly timed, the spark reaches the air-fuel mixture in the cylinder and combustion begins.... As the distributor continues to rotate, electrical contact between the rotor and distributor cap terminal is broken, stopping the secondary high voltage flow.... At the same time, the breaker points will close to re establish the primary low-voltage circuit, allowing primary current (12 volts) to flow. This primary current will again create a magnetic field in the coil primary windings and the cycle is repeated for the next cylinder in the firing order..... This process takes place within a few milliseconds. In fact, it happens approximately 18,000 times per minute at 90 miles per hour. There is no "Condenser Coil", the condenser and coil are two distinct different parts of the system..... The condenser on your bike engine is that little silver cylinder mounted to the side of the distributor.... The condenser is not hidden, the ignition coil is... Not criticizing here, just offering the correct understanding of what the equipment is supposed to be and how it works... EG

-

Keeping my head in the game.....

Egilman replied to Egilman's topic in 3D-Printing and Laser-Cutting.

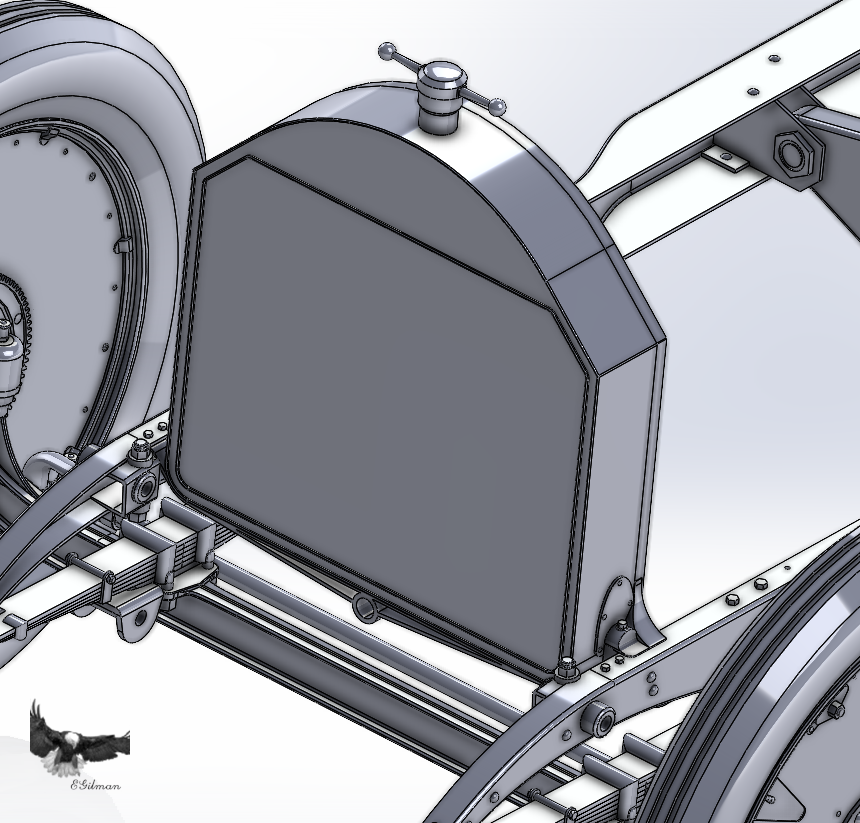

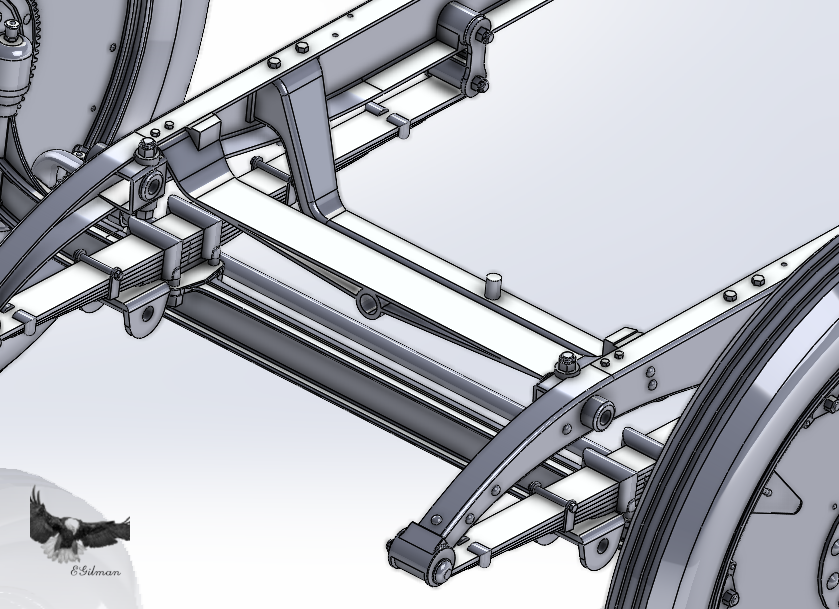

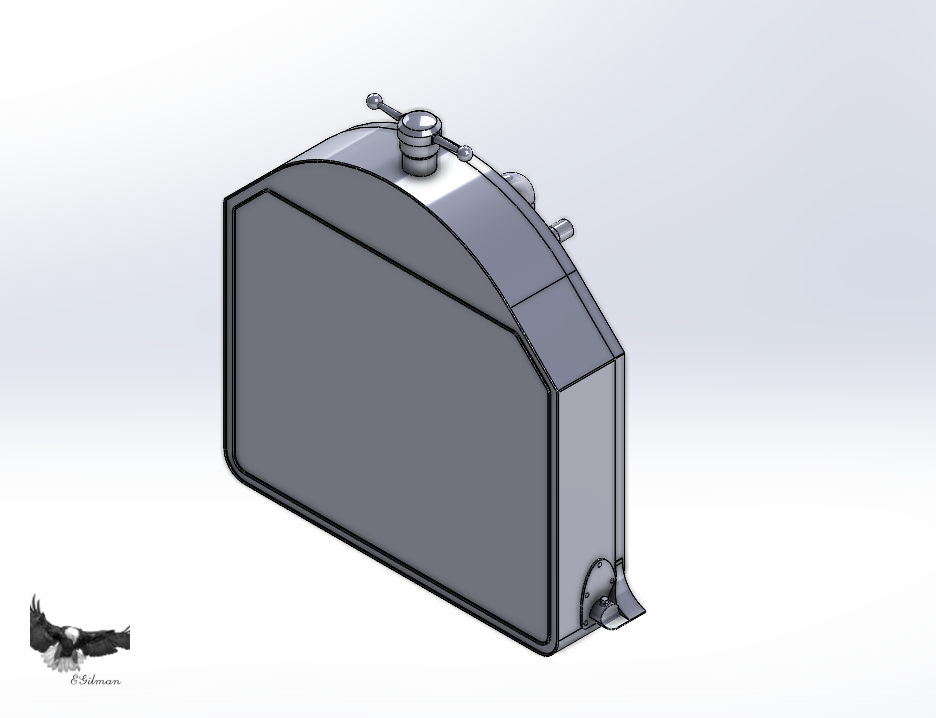

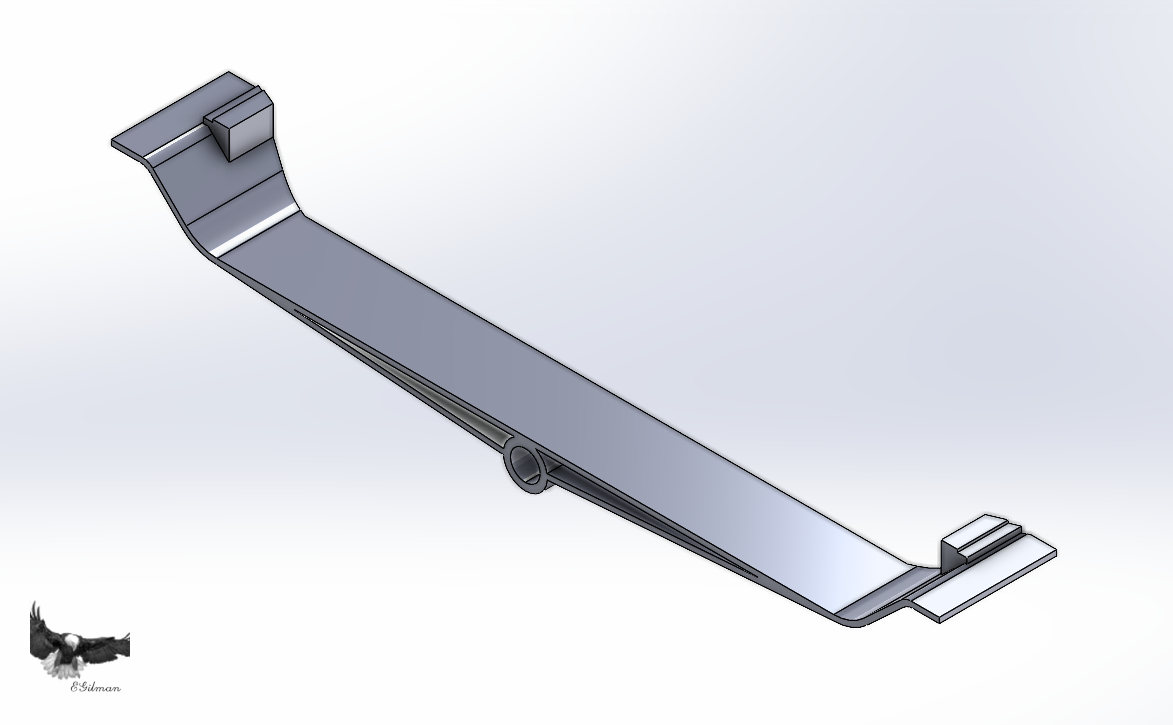

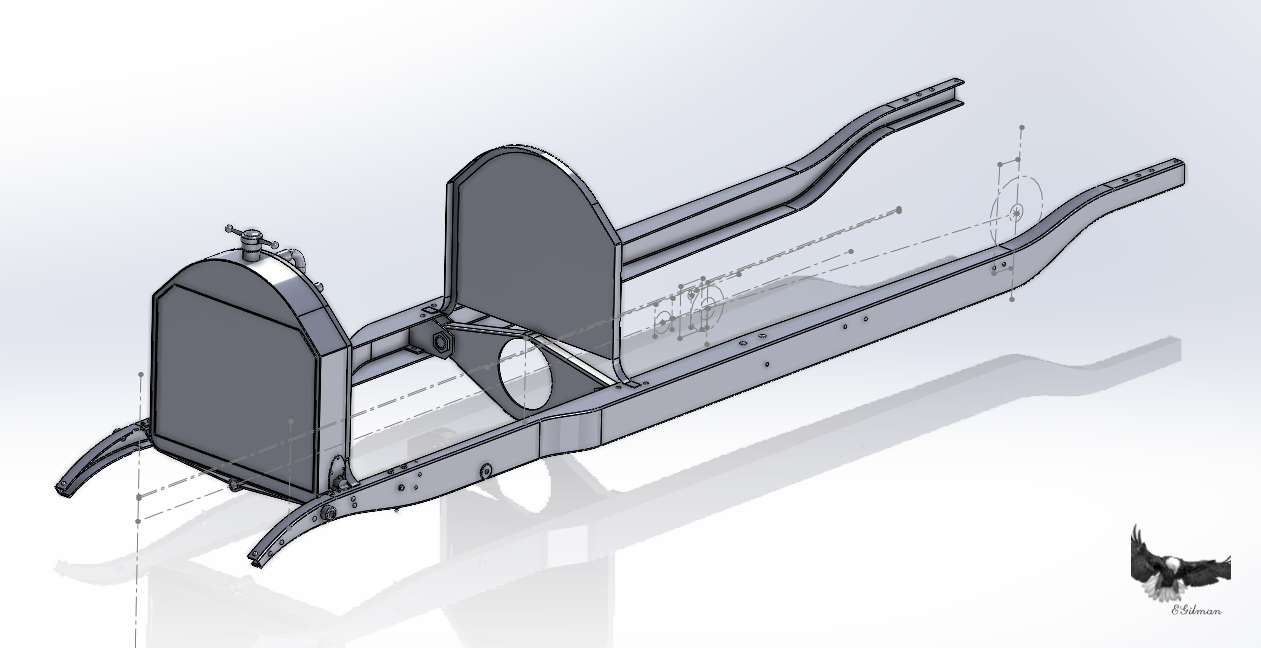

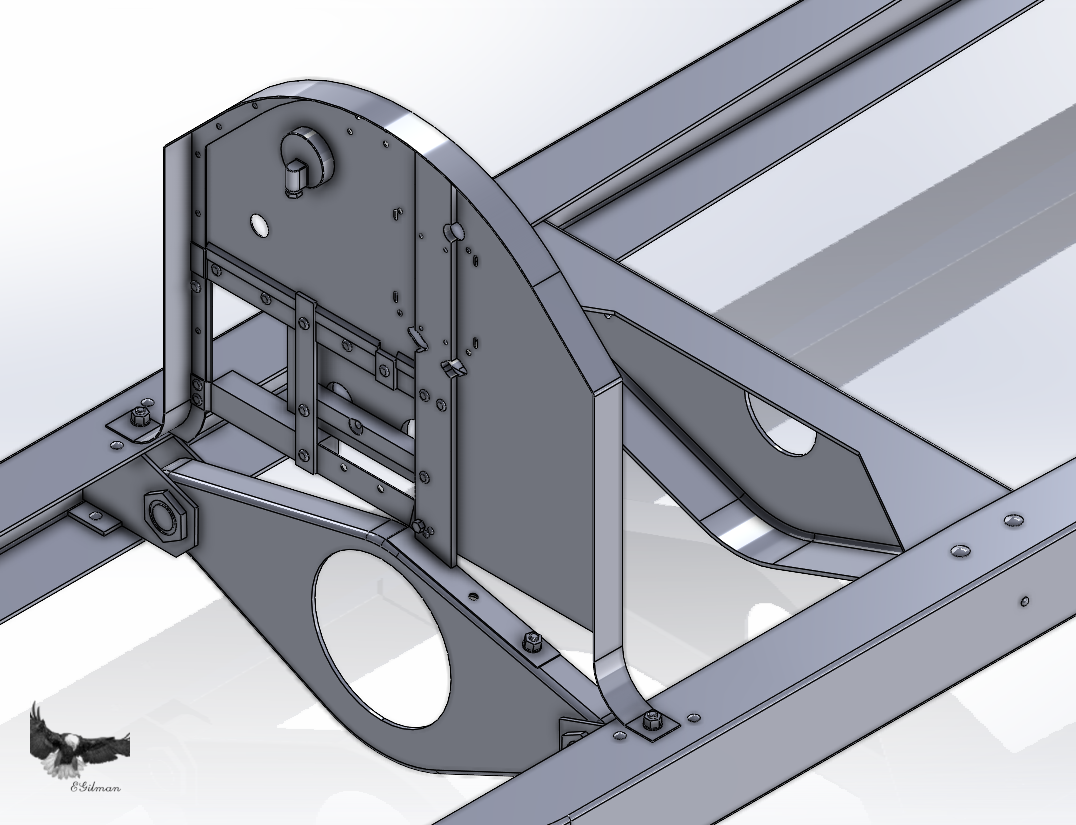

Hey Brothers it's time for another update.... This is prep, setting up the model to build the forward firewall.... We first start with the general shape, this comes from the Radiator, it has the exact same shape as the firewall... And the Radiator sits on the Core Support, all radiators in all cars do... The core support.... Now the core support has two functions, to take the weight of the full Radiator but also to locate it and affix it to the frame so it doesn't move about... It's location in the frame.. Now the design only goes far enough to create it, it will be attached to the Radiator itself when the model is done... The Radiator... And the Radiator's final location.... And here is the results of the prep work... The outer frame is made from hand forged angle iron and the actual sheet is .060 Steel... You can easily see the shapes are identical... And with everything out of the way it's easier to see what is going on.... Anyway this is the state of the model today... Onwards!!! -

“Capt. Eddie” A-7 Corsair II by GrandpaPhil - 1/48

Egilman replied to GrandpaPhil's topic in Non-ship/categorised builds

Ah yes the lost art of printing stenciling... Completely old school I love it!!! The camo look good as well.... (using grey greys instead of grey blues) USAF A-7E Corsair II at the Davis Monthan boneyard....

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.png.5d99135d5dadf195858f81a6419e7e01.png)