Jeff59

NRG Member-

Posts

593 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Jeff59

-

Thanks for liking it, it’s not till you go back to the start of the log that you are reminded how much work and time is taken to get were you are😳 worse thing is that I have hundreds of models up the loft to build. I do realise that this is just not going to happen, considering this shall be the first model I’ve completed in decades, How did you like building your Arizona ?

-

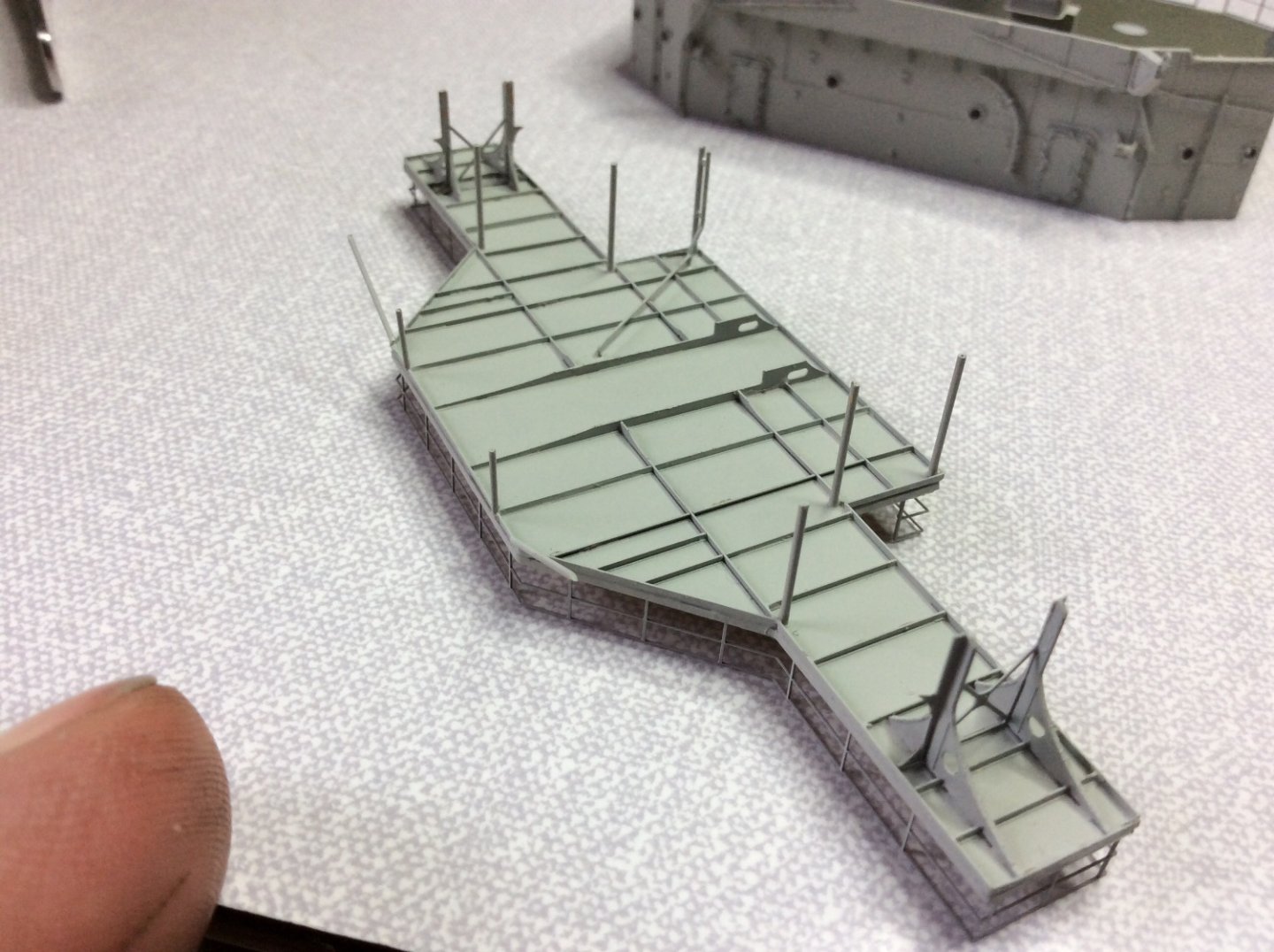

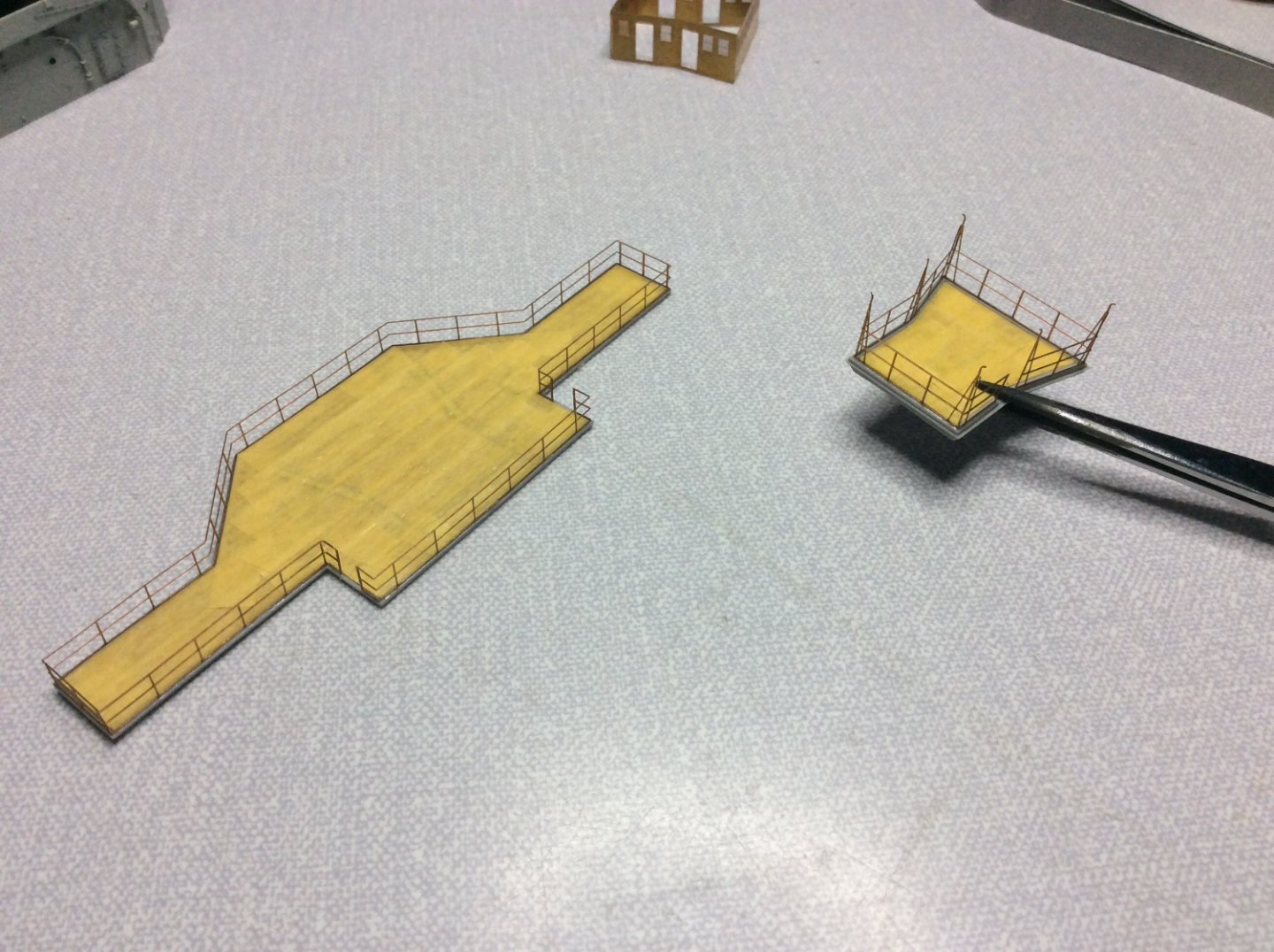

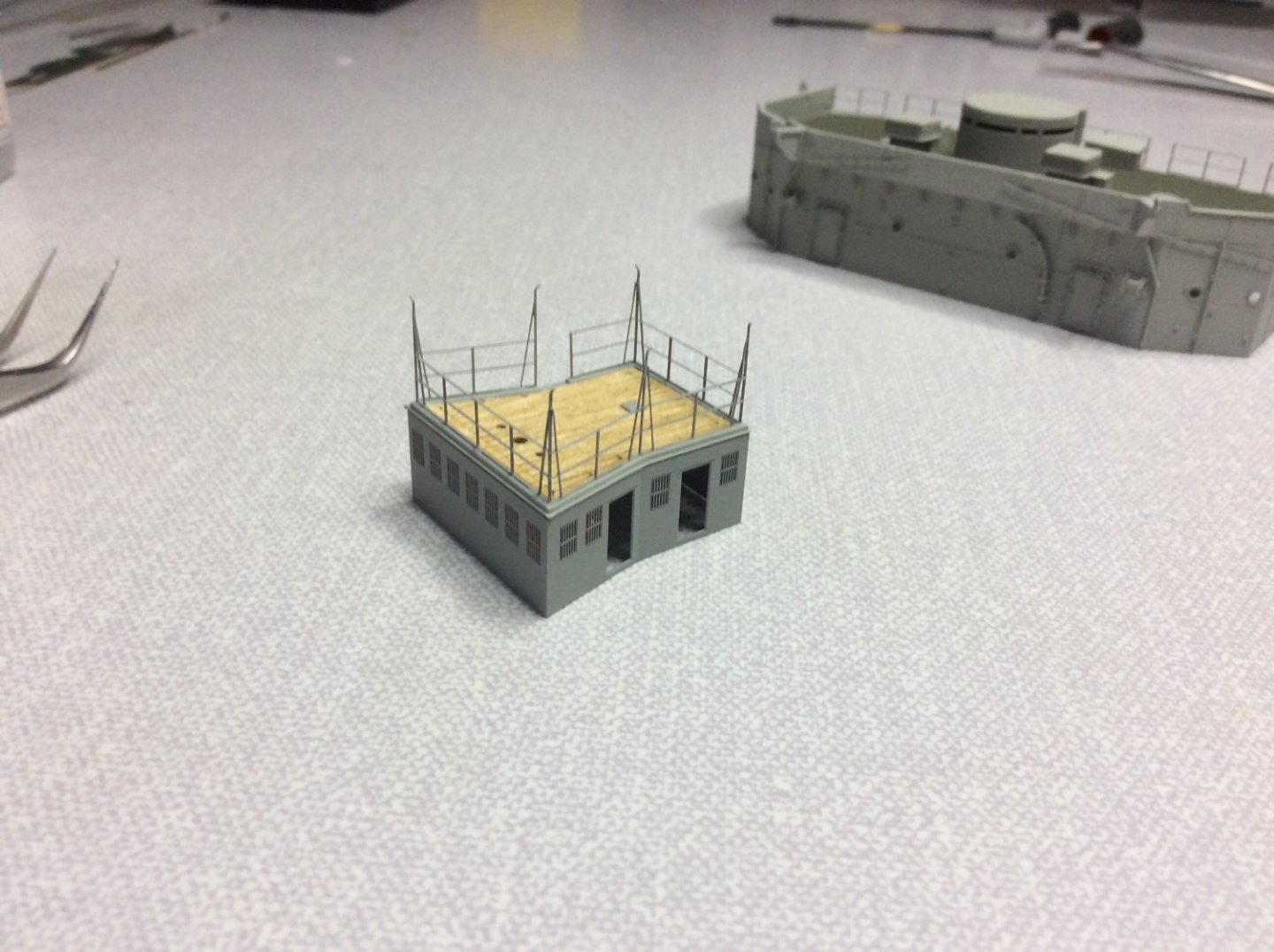

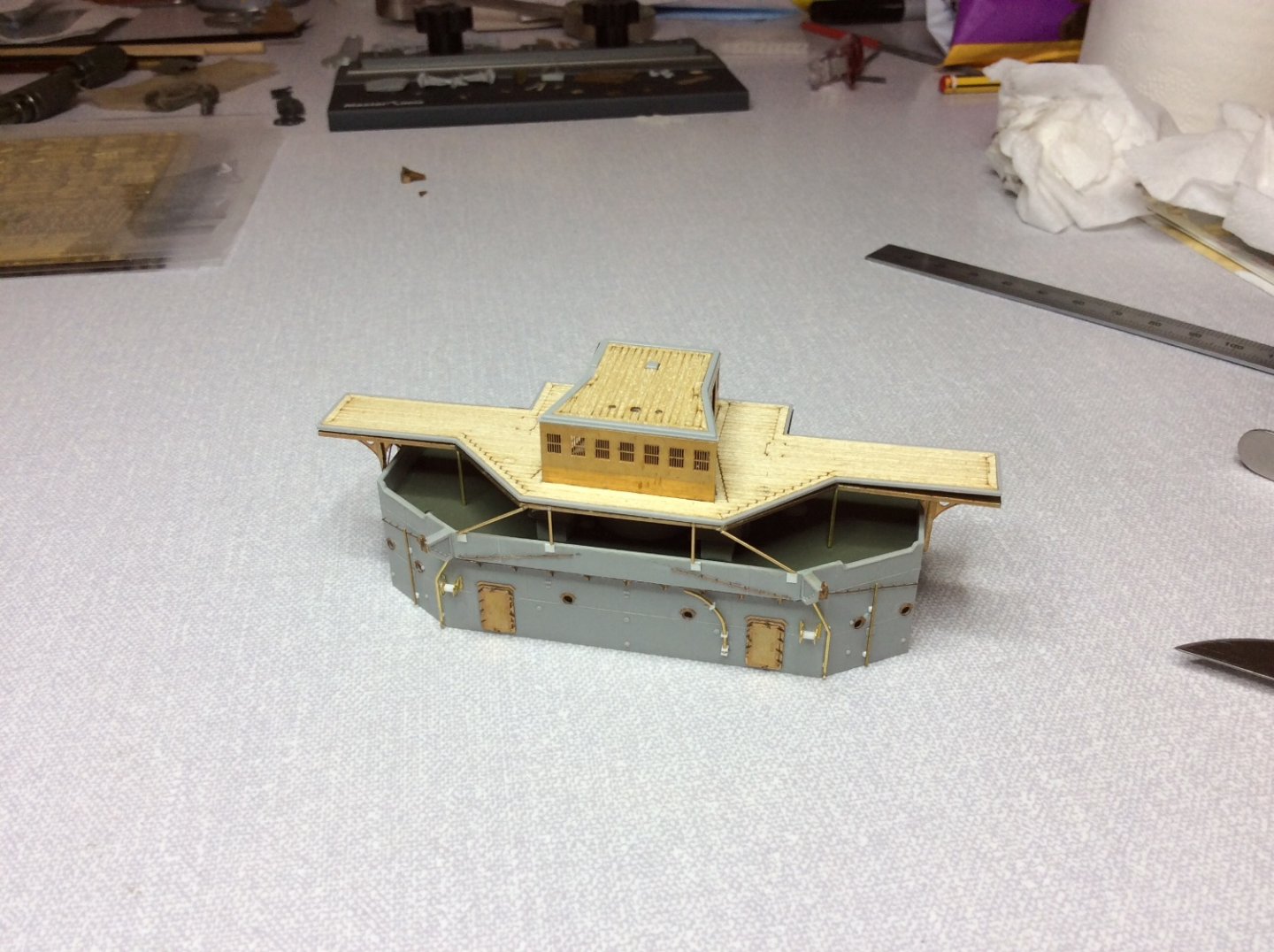

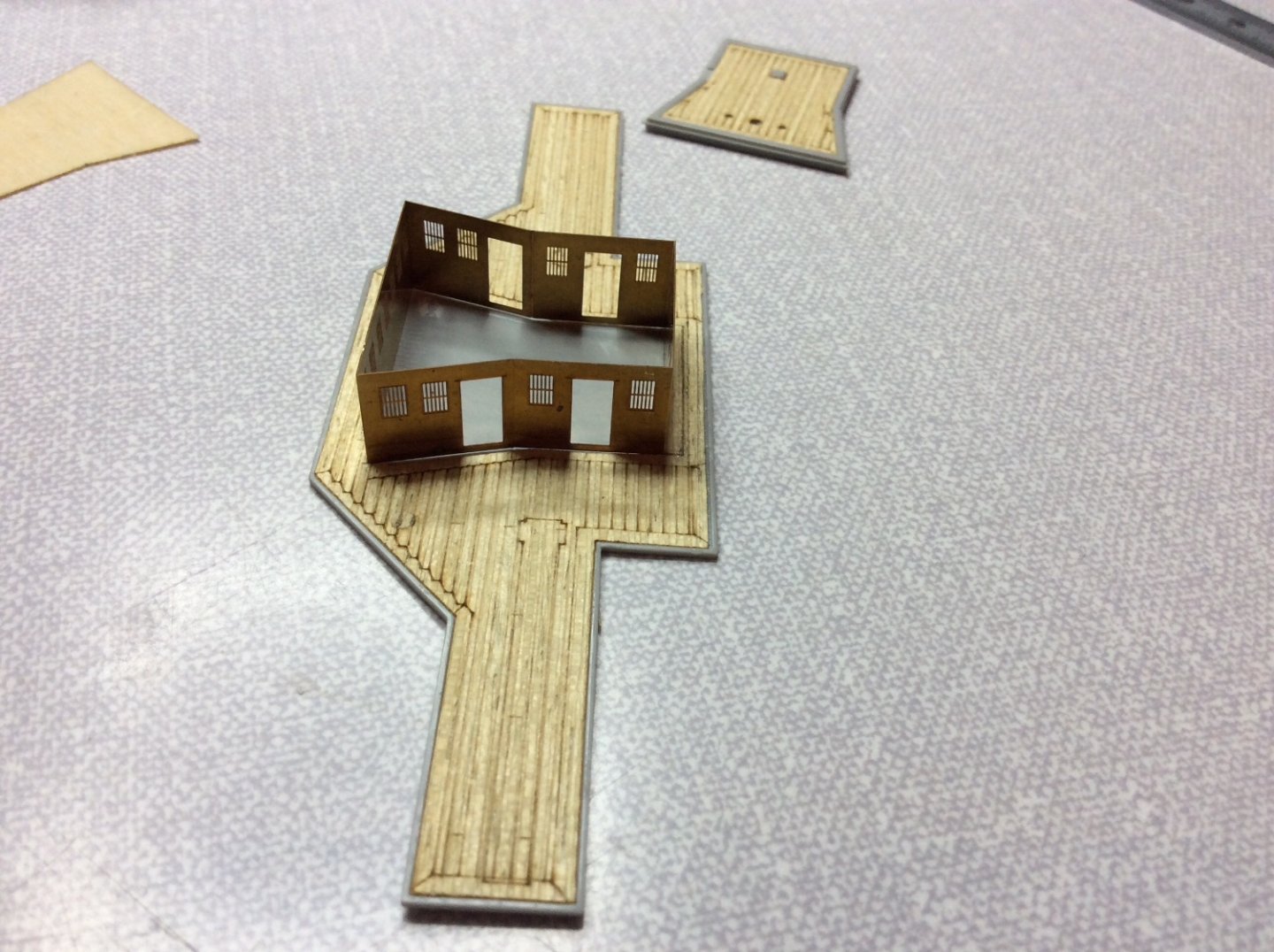

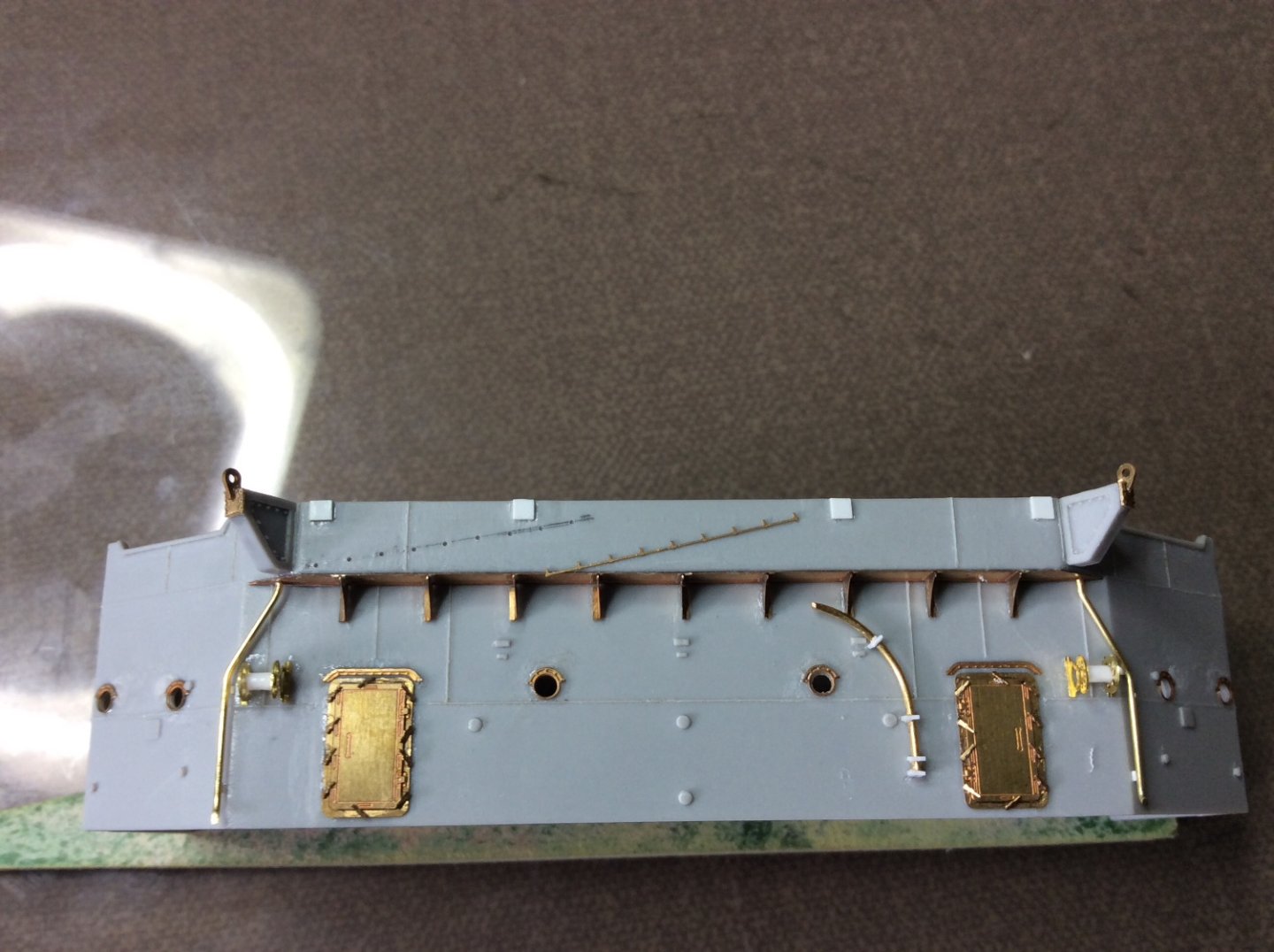

Also try to show how I glued the plastic part of bridge wing to the metal etch part which is all very fragile. After both parts painted separately the handrails were turned upside down to sit on flat surface, then lined up the etched bridge wing on top of this and glued together applying light pressure were necessary, take plenty of time here. You may prefer another method, not saying this is suitable for anyone, just my own solution. 👍

-

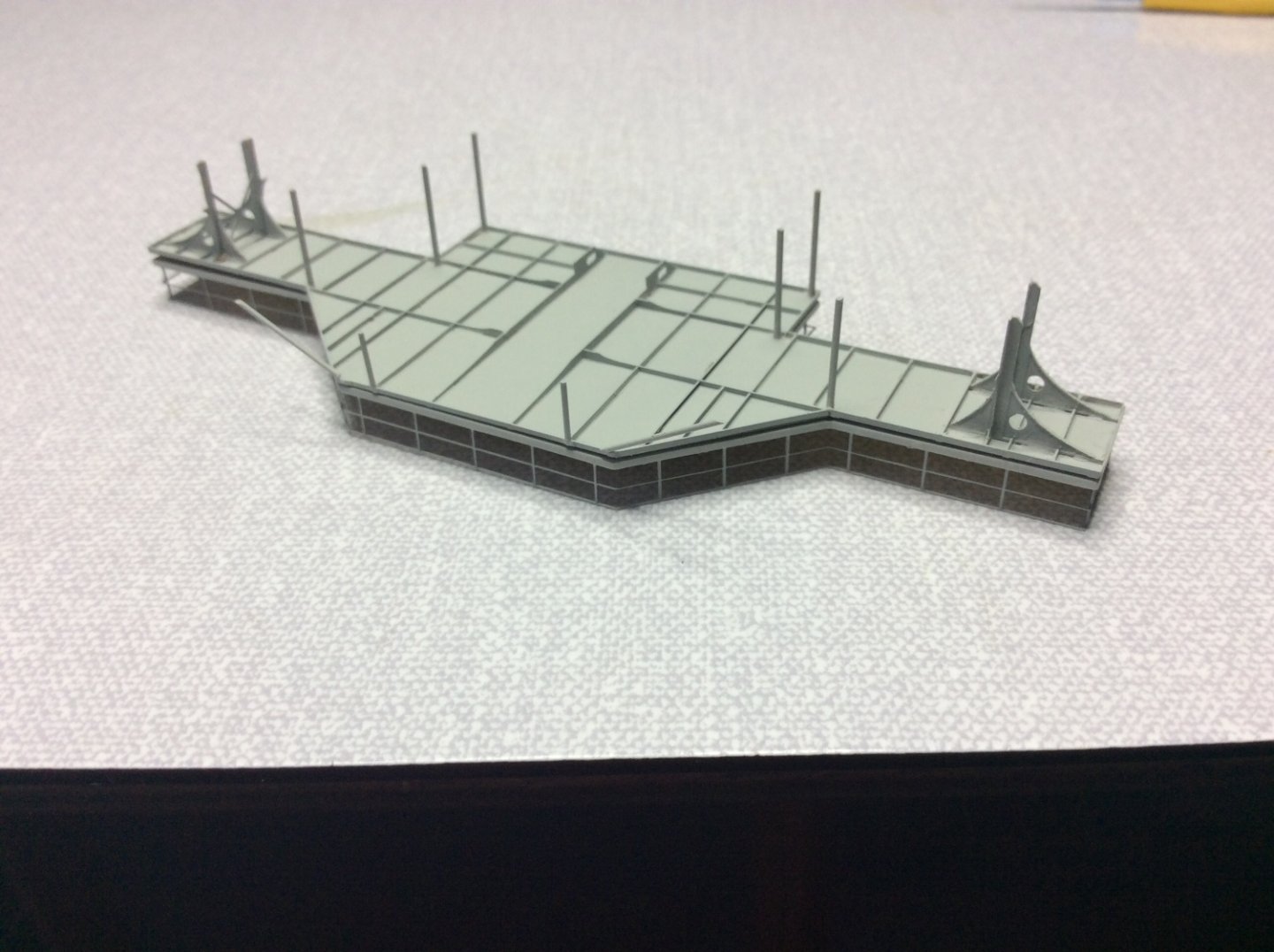

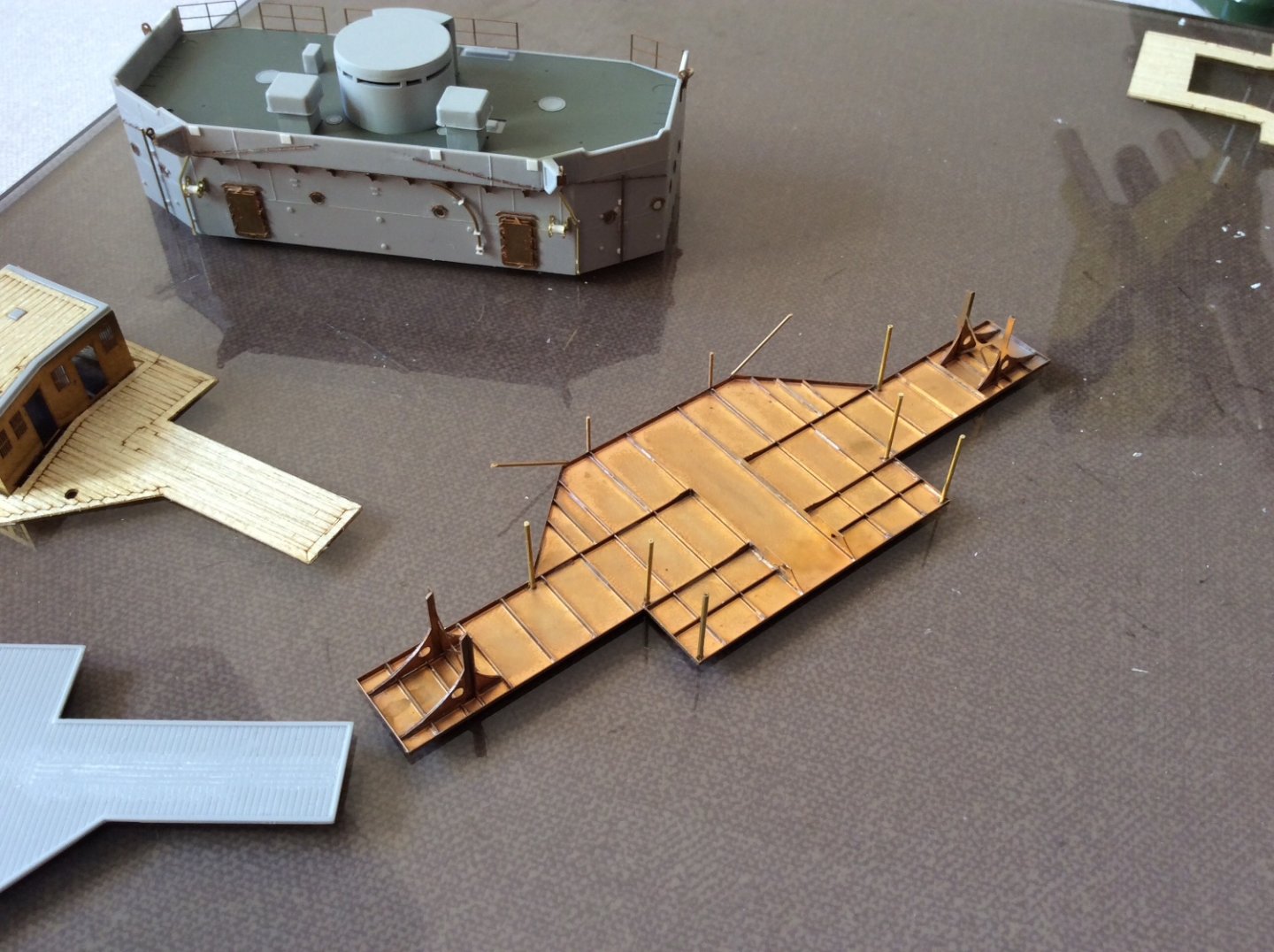

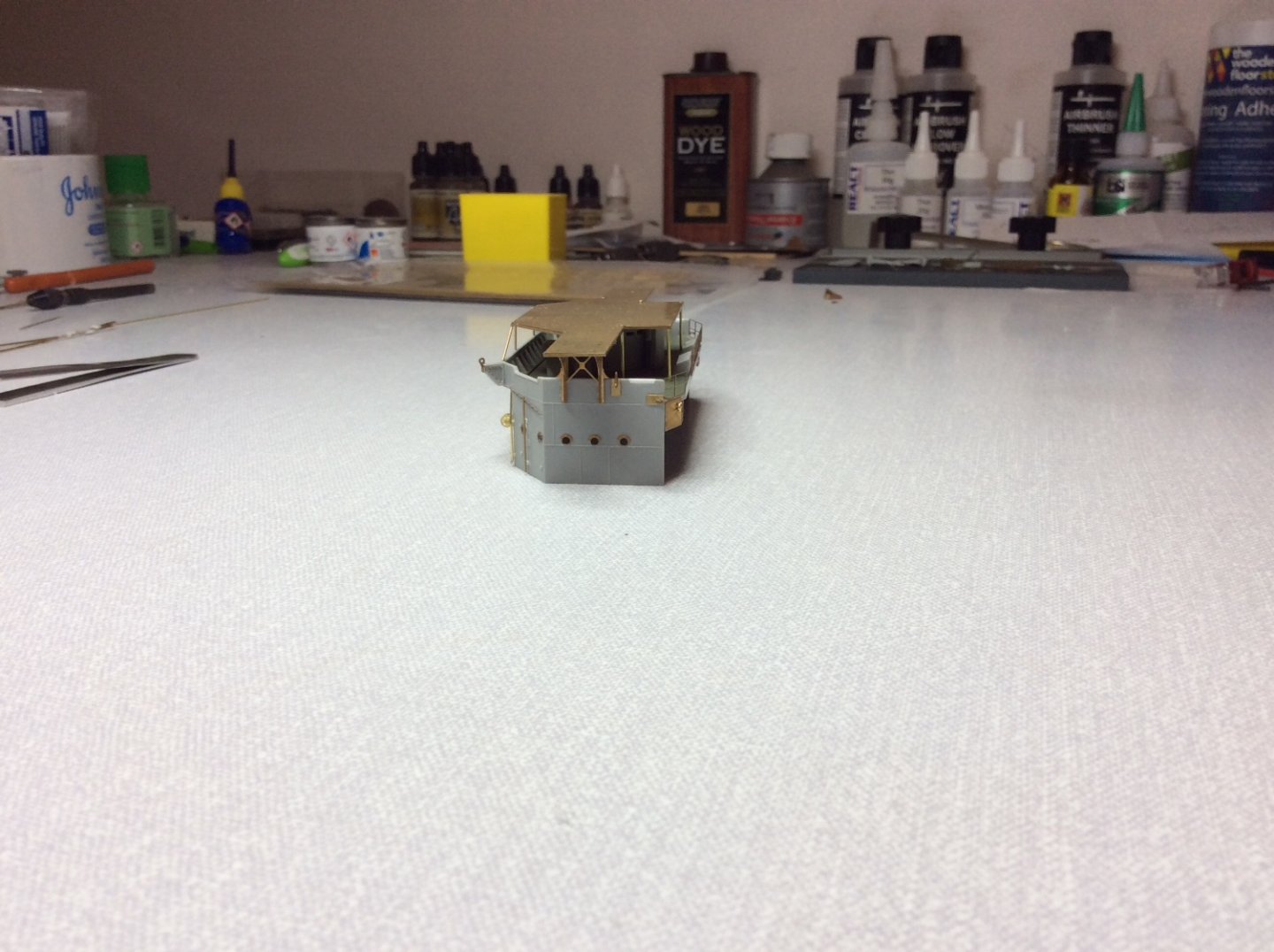

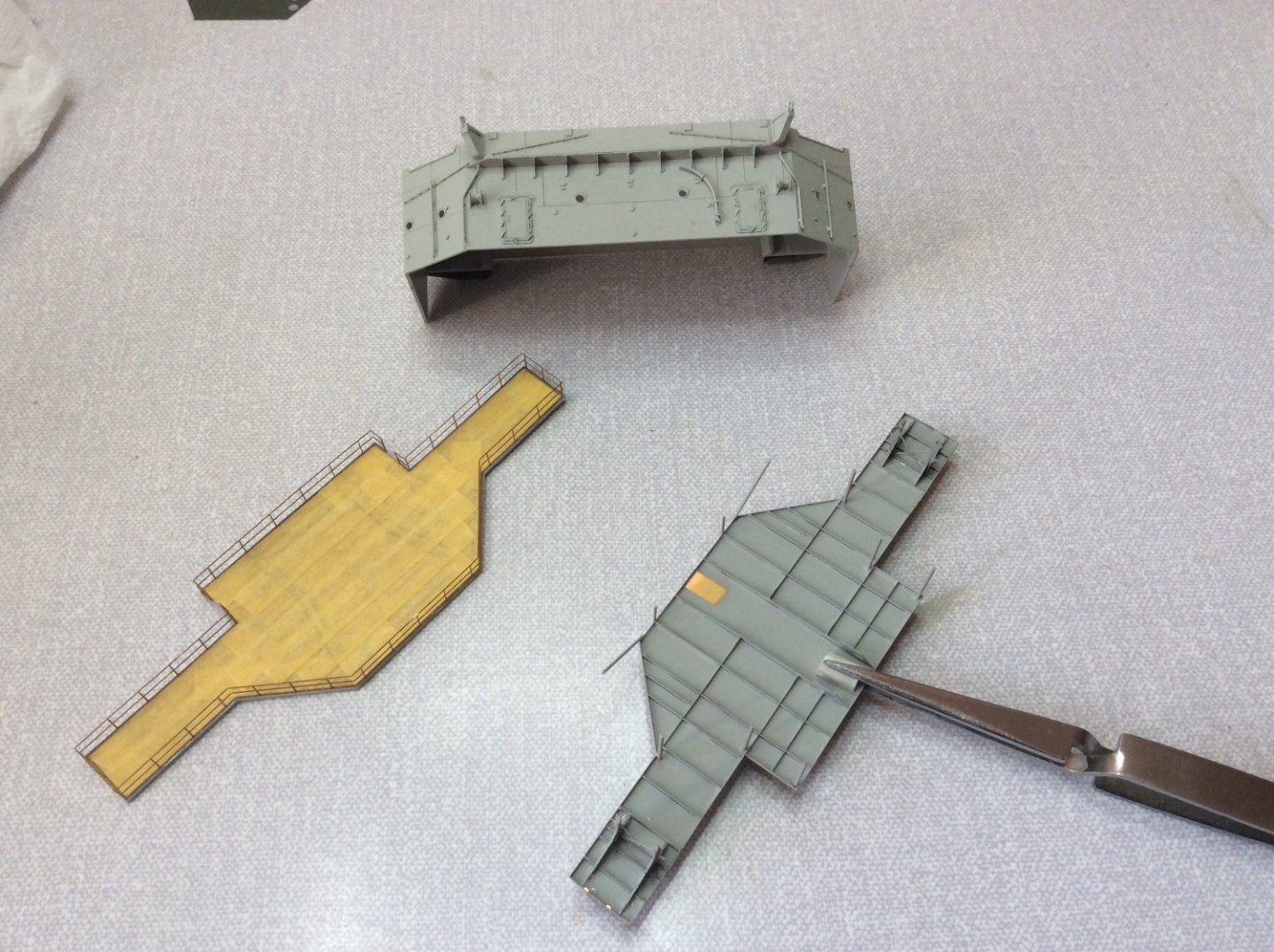

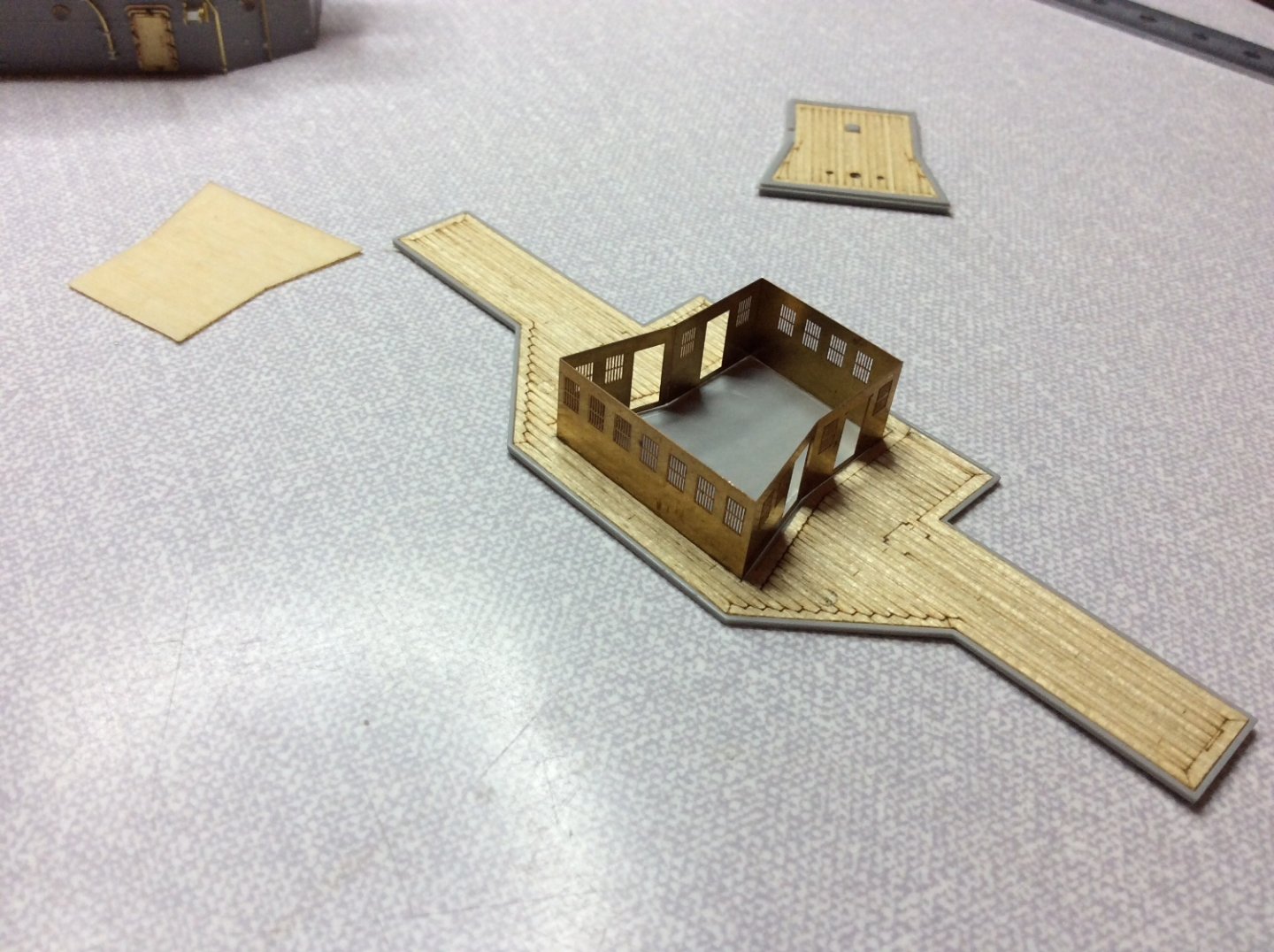

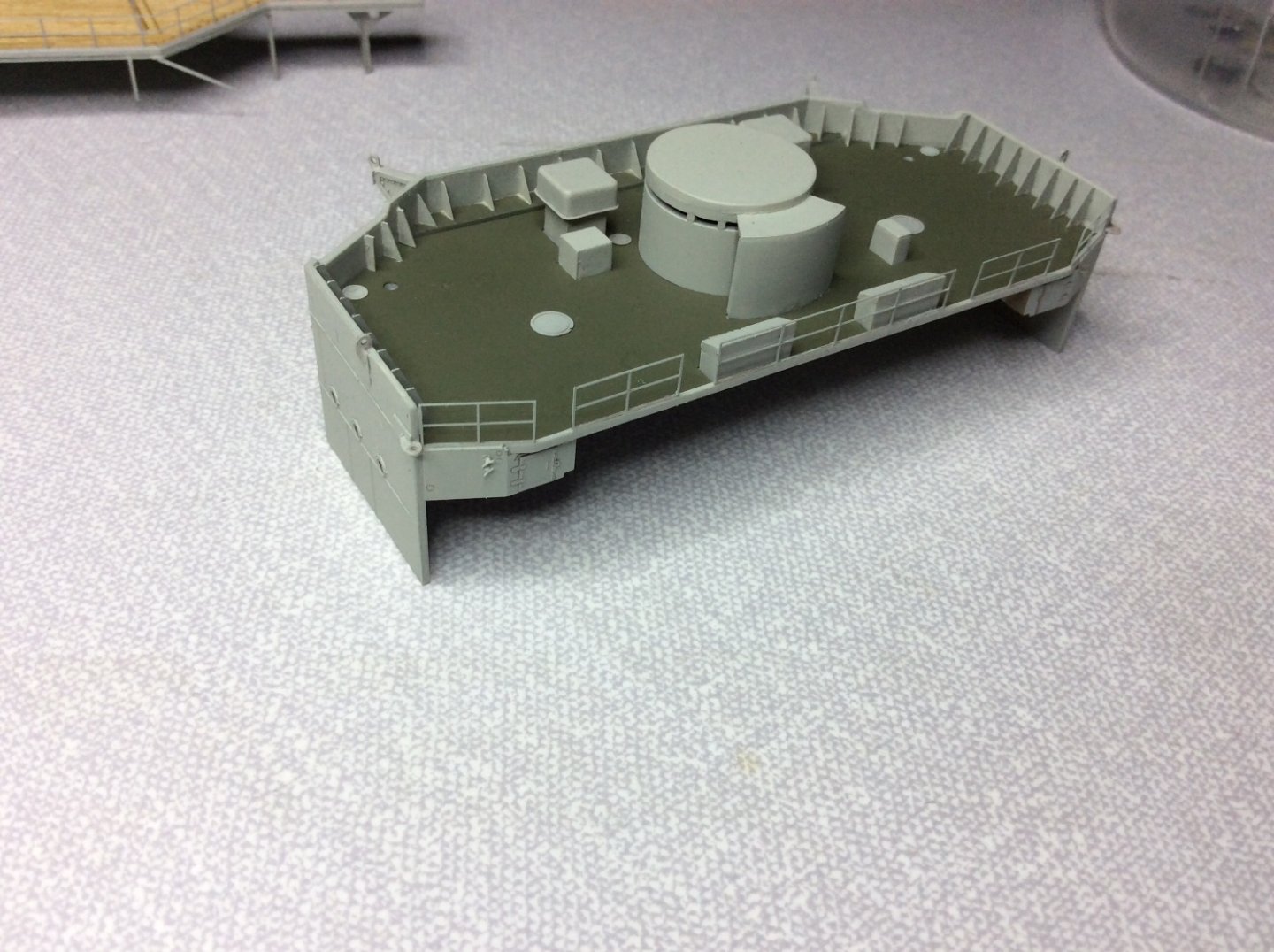

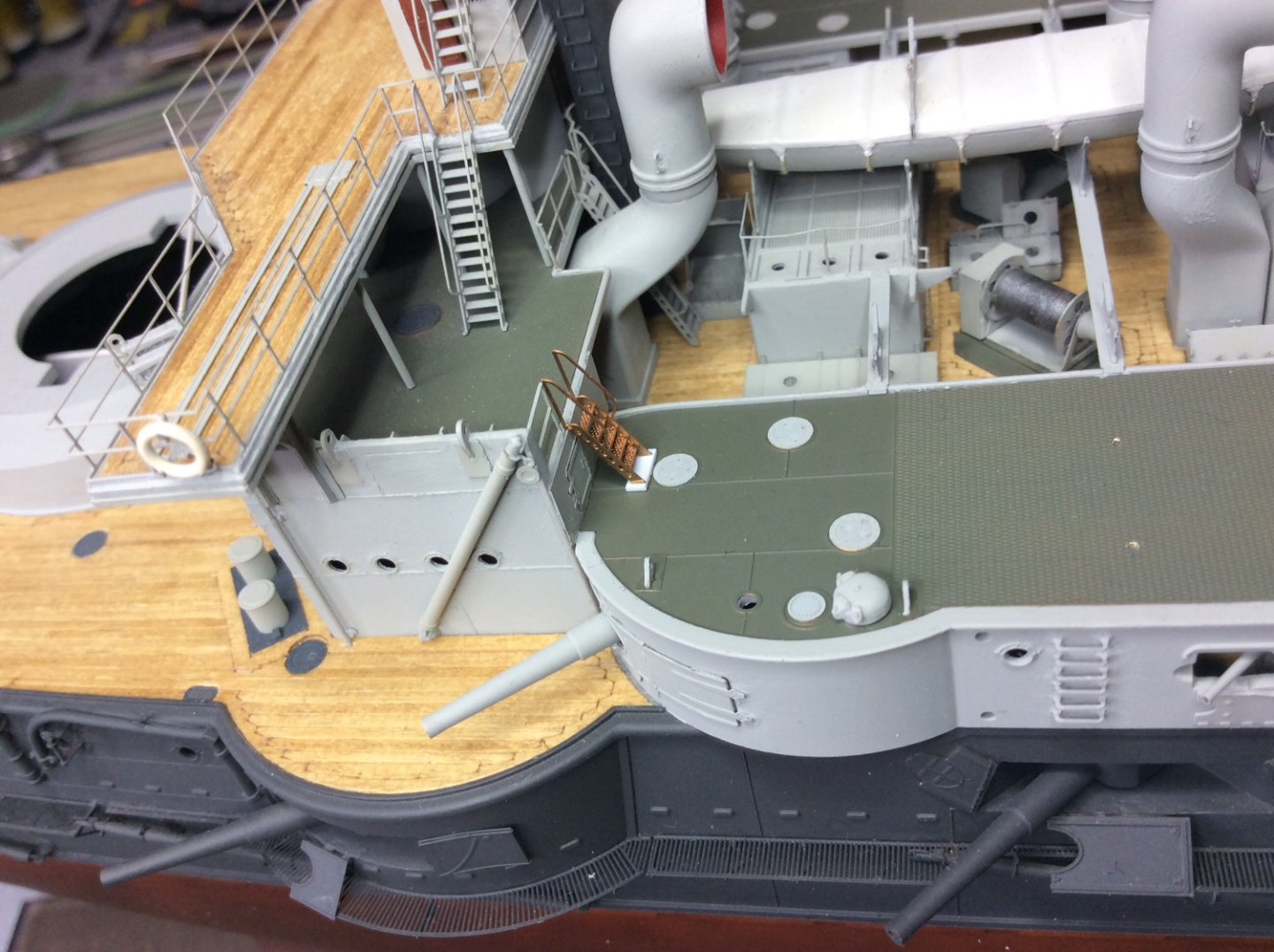

Time to try to progress with another update. The metal etch details for the underside of the bridge wing is a little gem but a lot of work, same as after bridge really, the steelwork framework at each end is quite tricky. Shall put some photos up to show how I tried to set them, still not easy though.

-

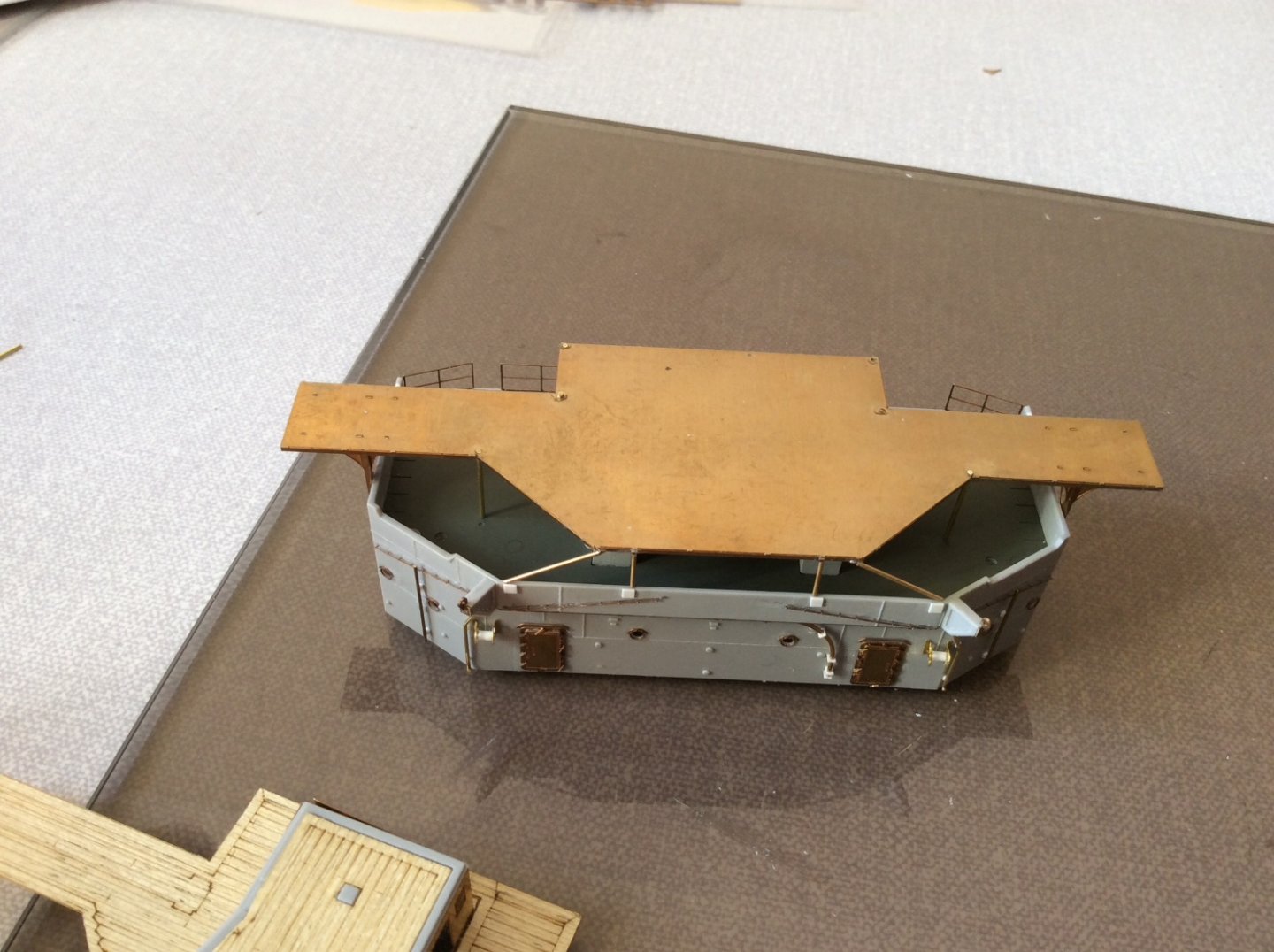

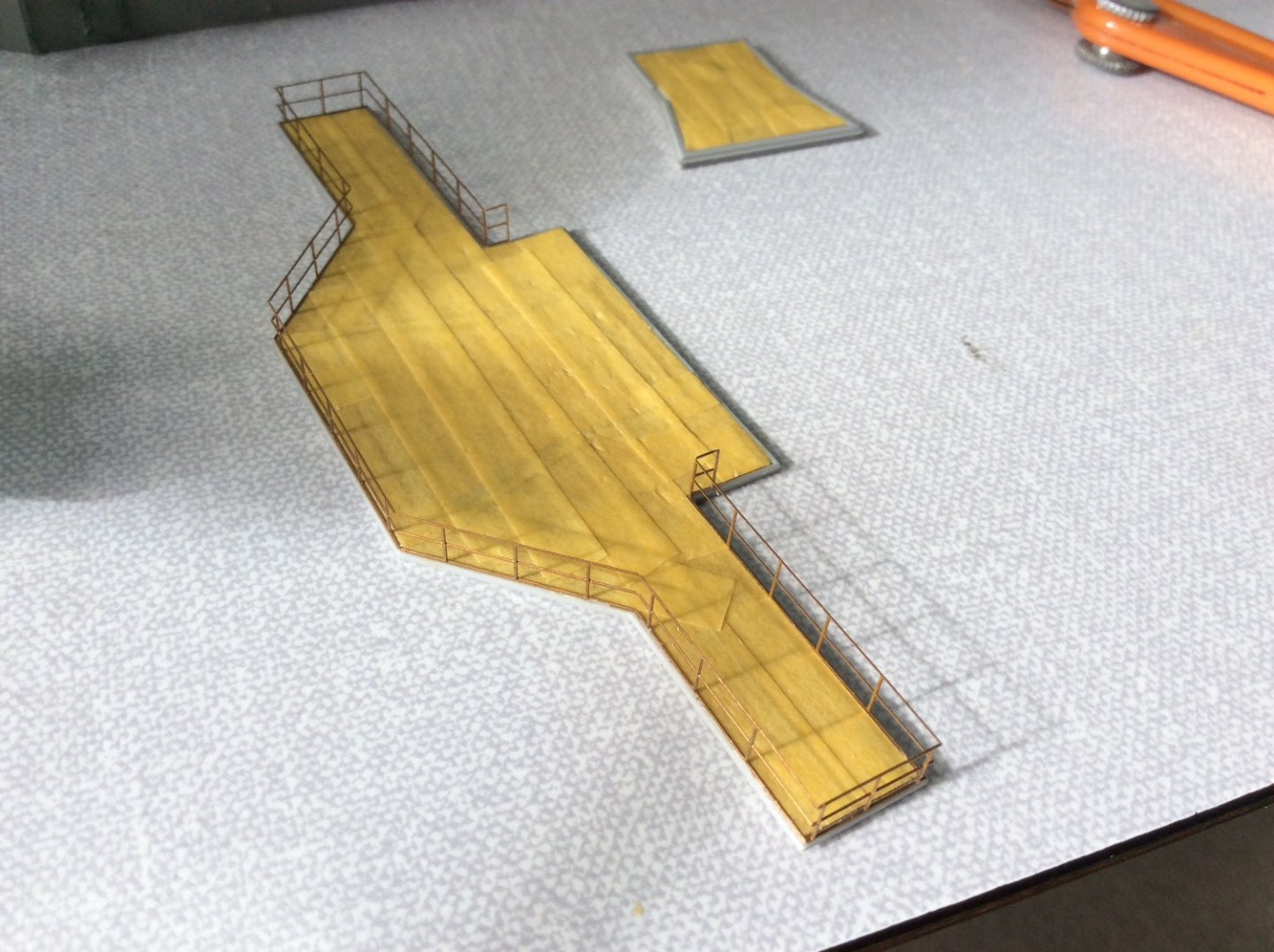

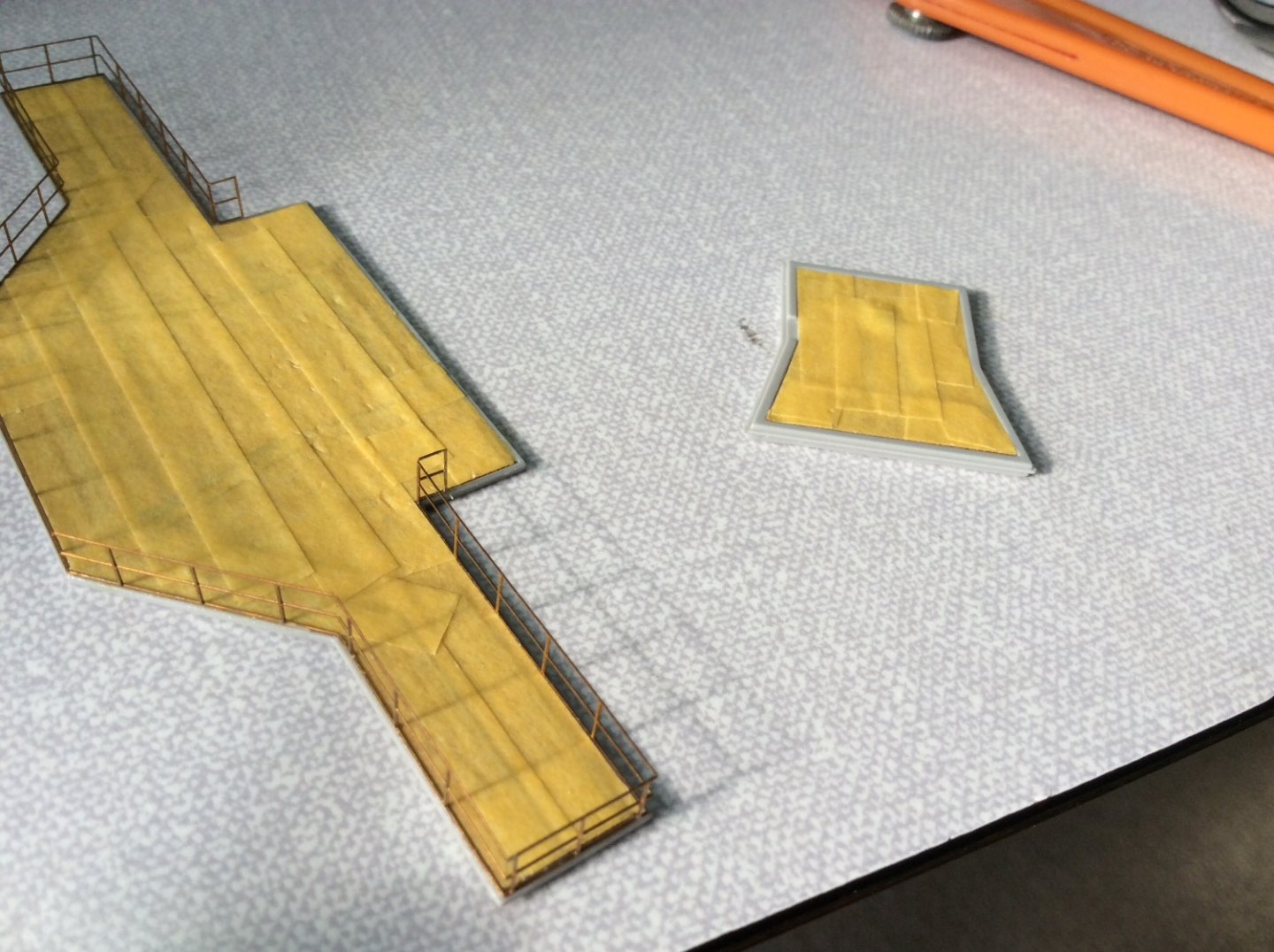

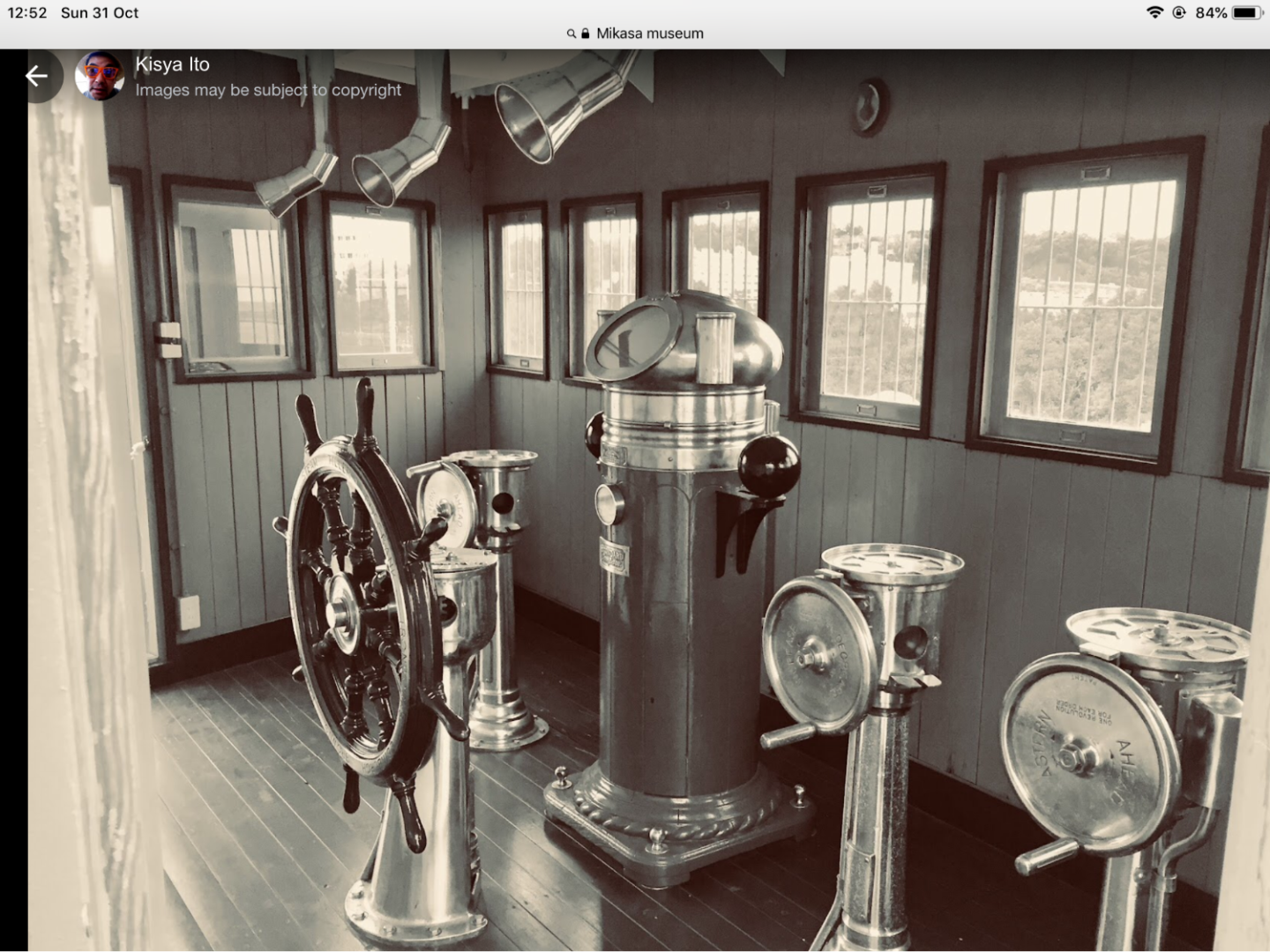

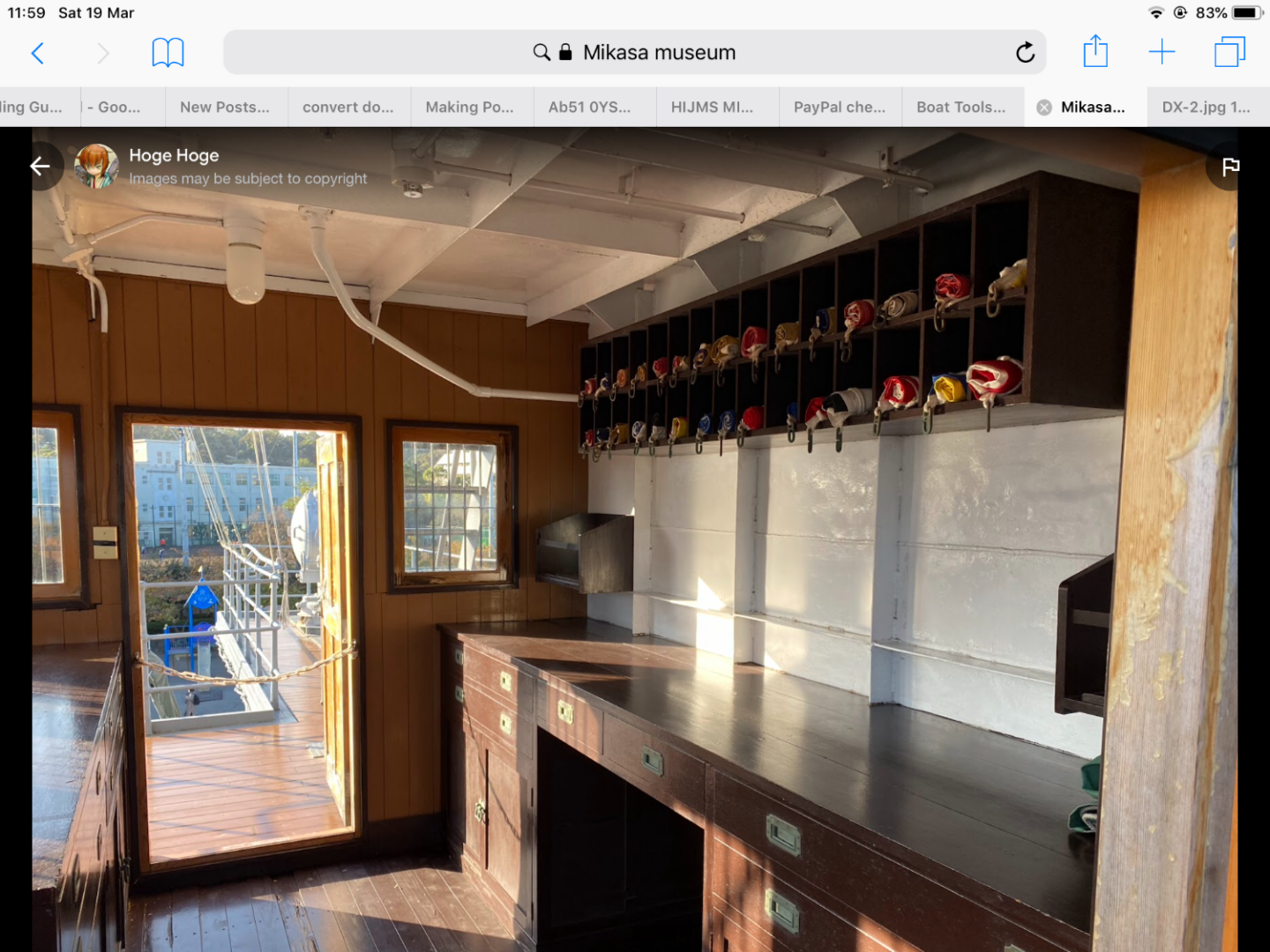

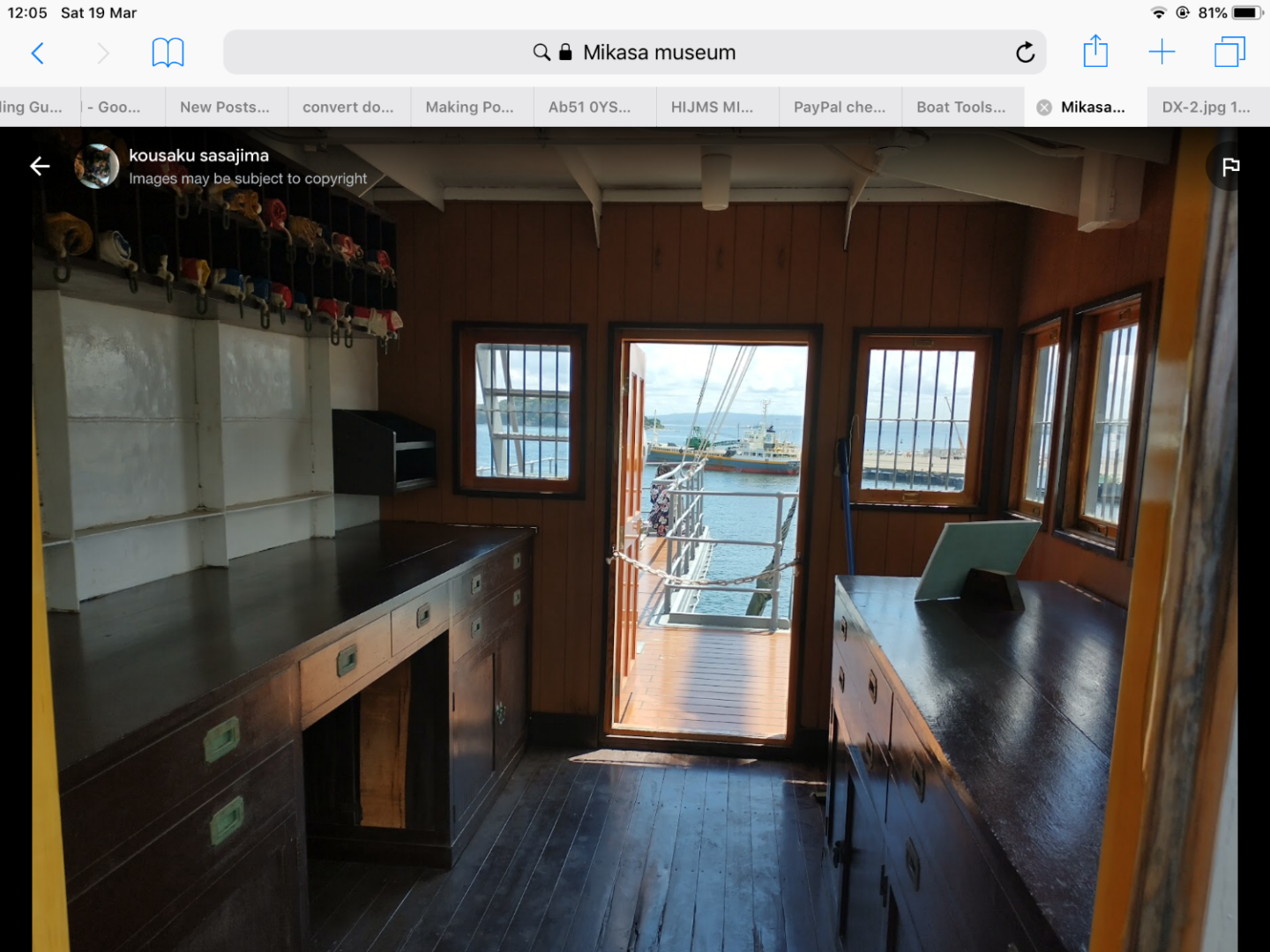

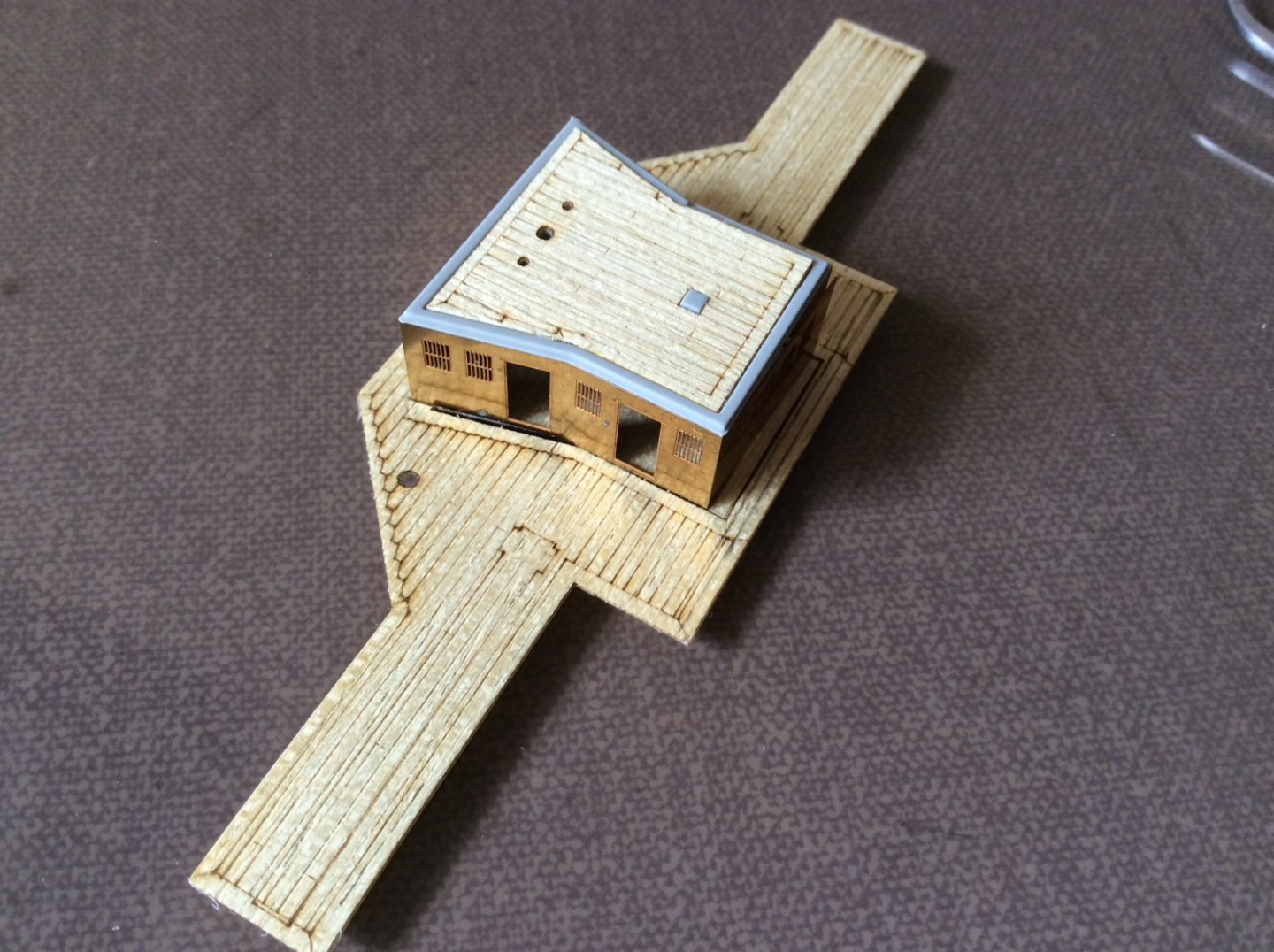

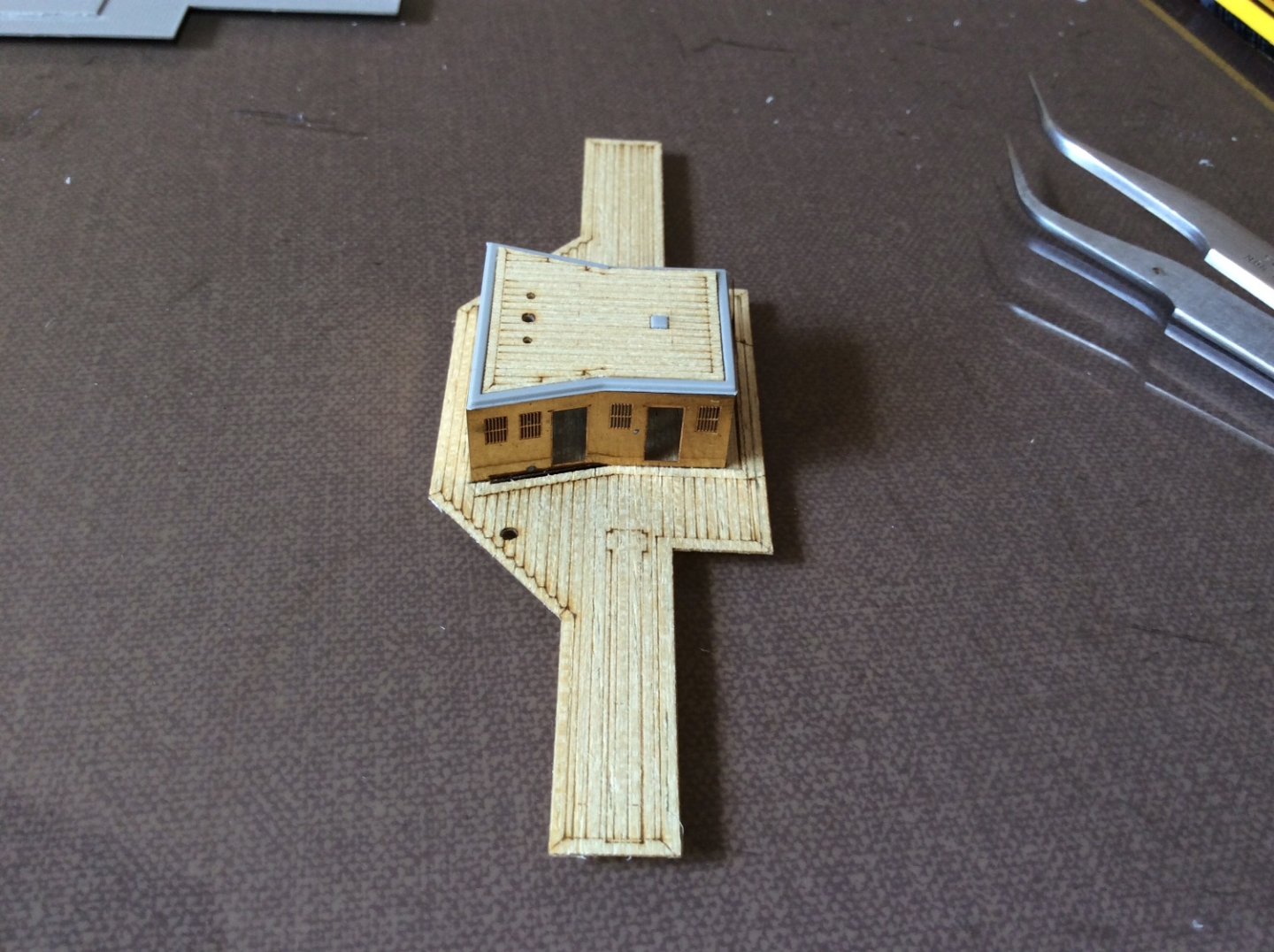

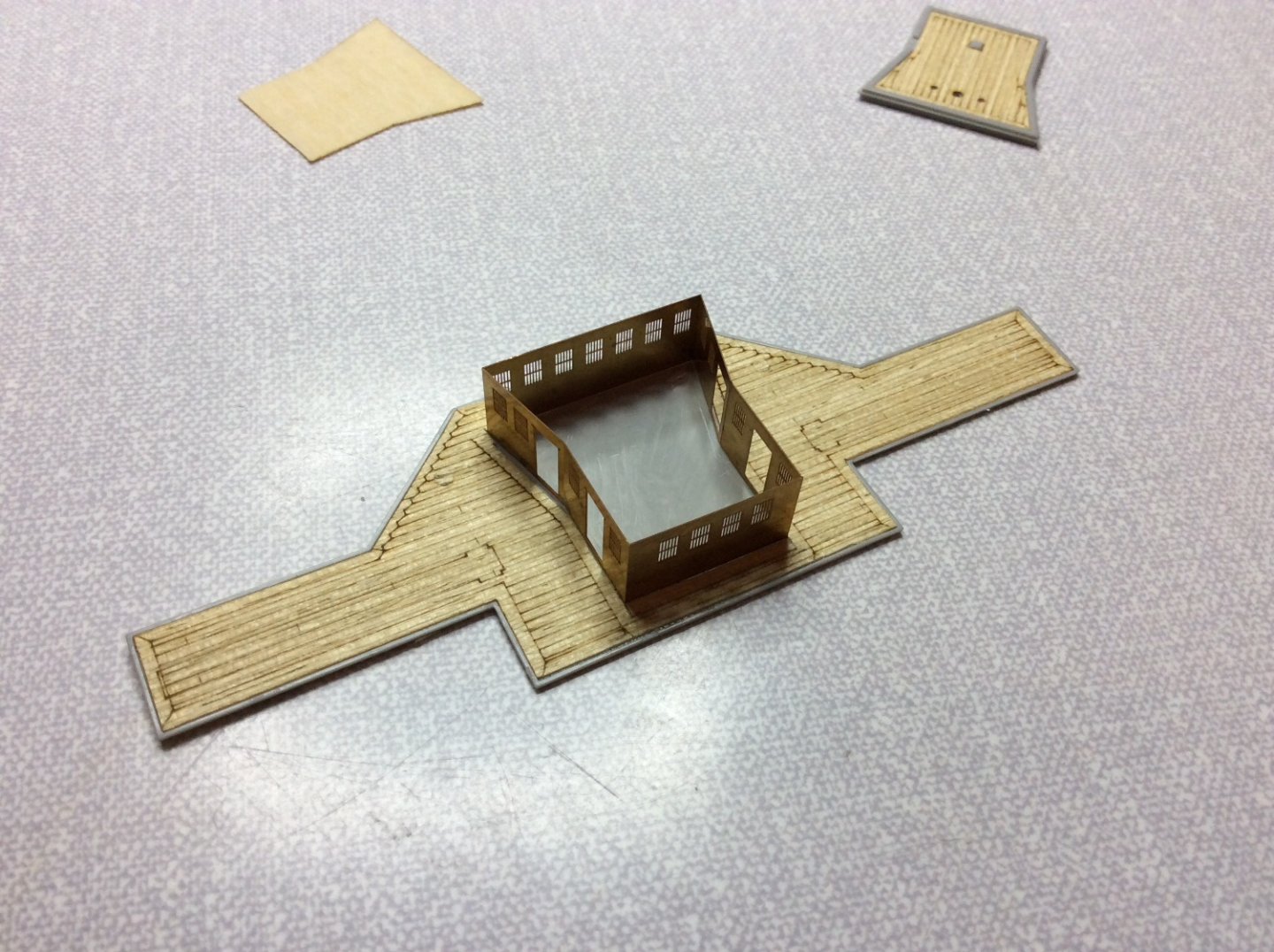

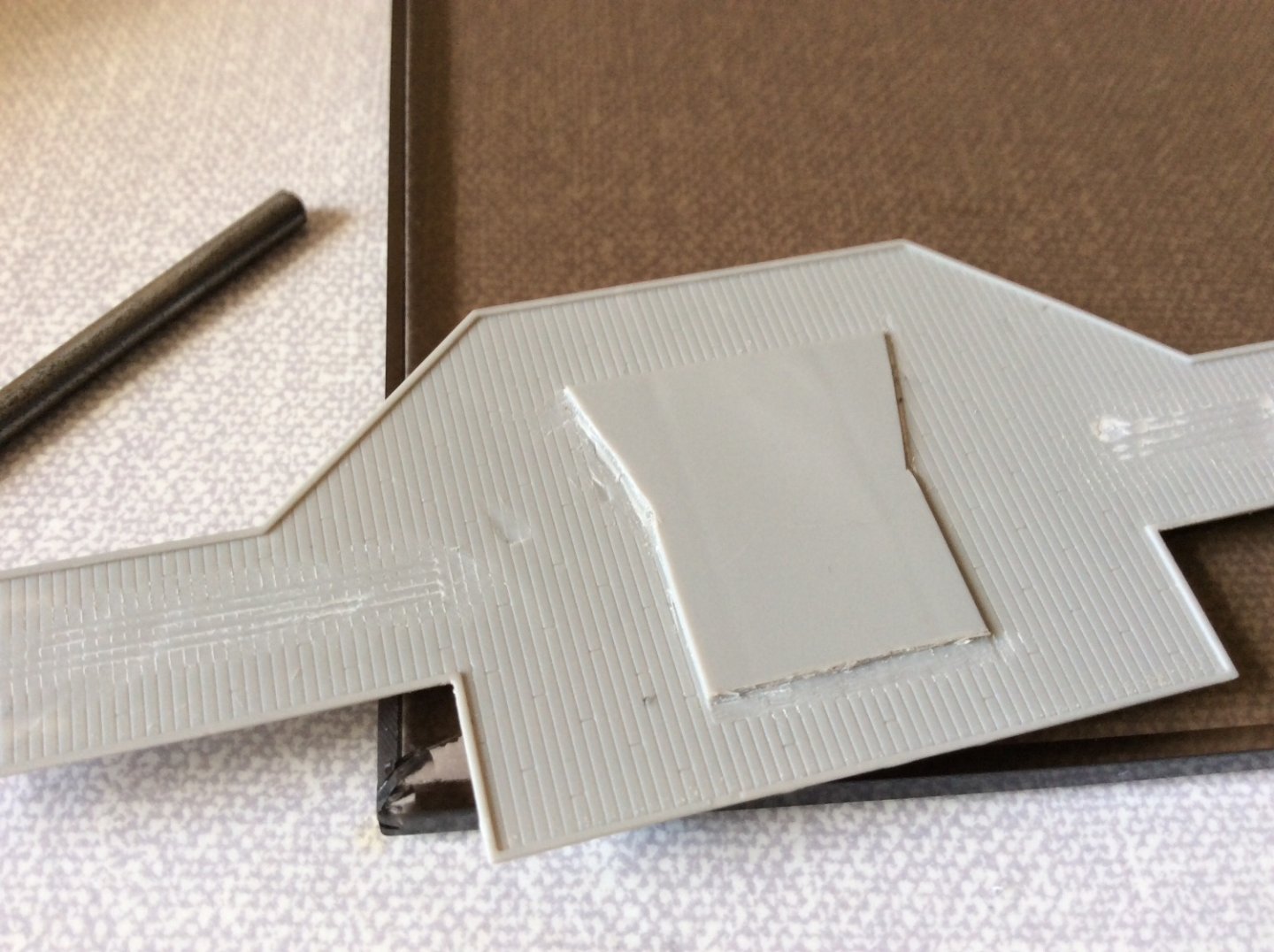

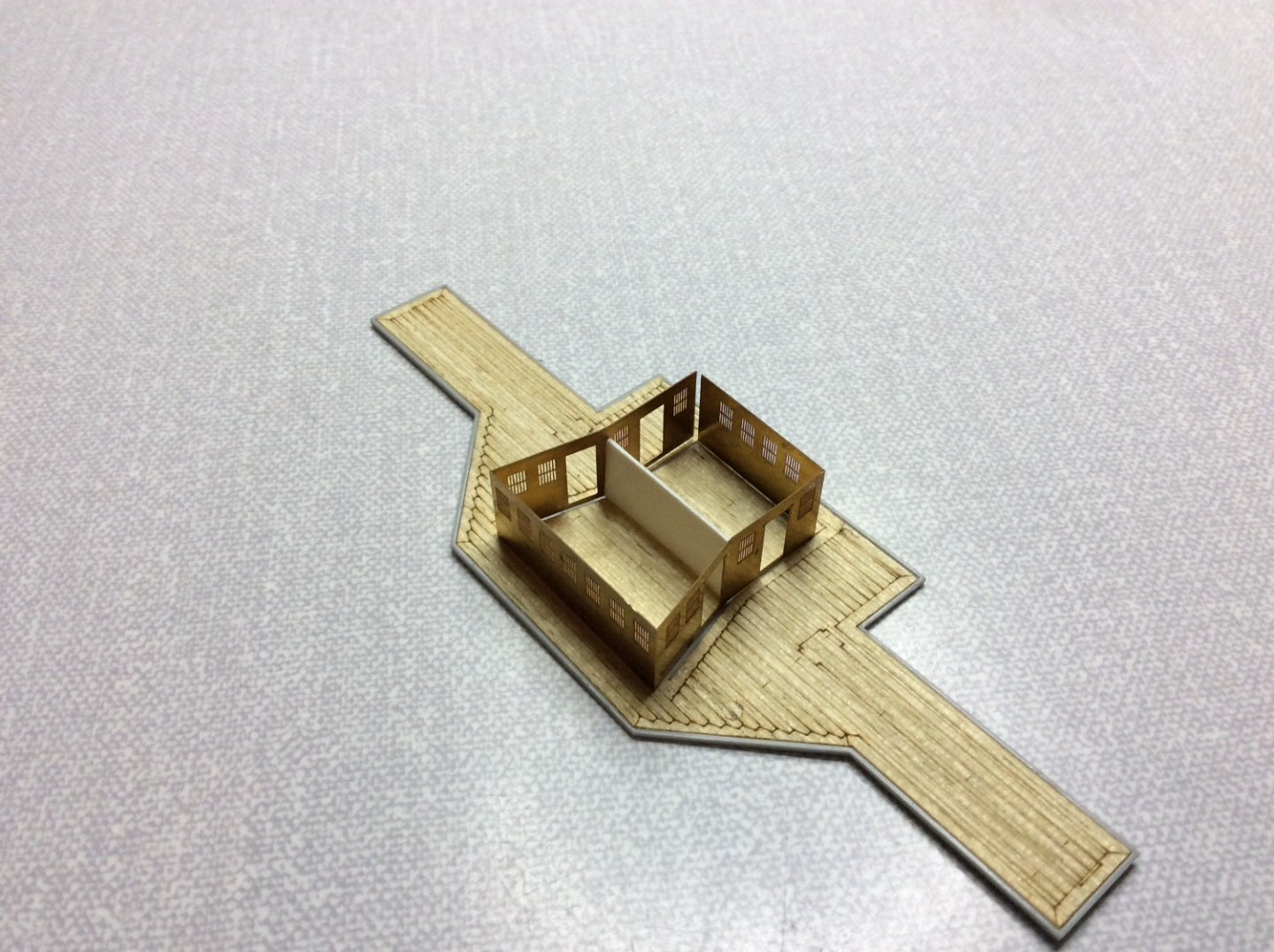

The bridge wing deck requires plastic details removed top and bottom. My sequence was to stain the wooden decking for this and the bridge roof, then clue to plastic parts using white glue. Followed by masking of the decking, I then fitted the handrails then painted them, carefully removing masking once paint was dry. Incidentally I did alter the position of the upper bridge forward by about 2mm, seems to be this way on actual ship at mueseum. My best guess anyway.

-

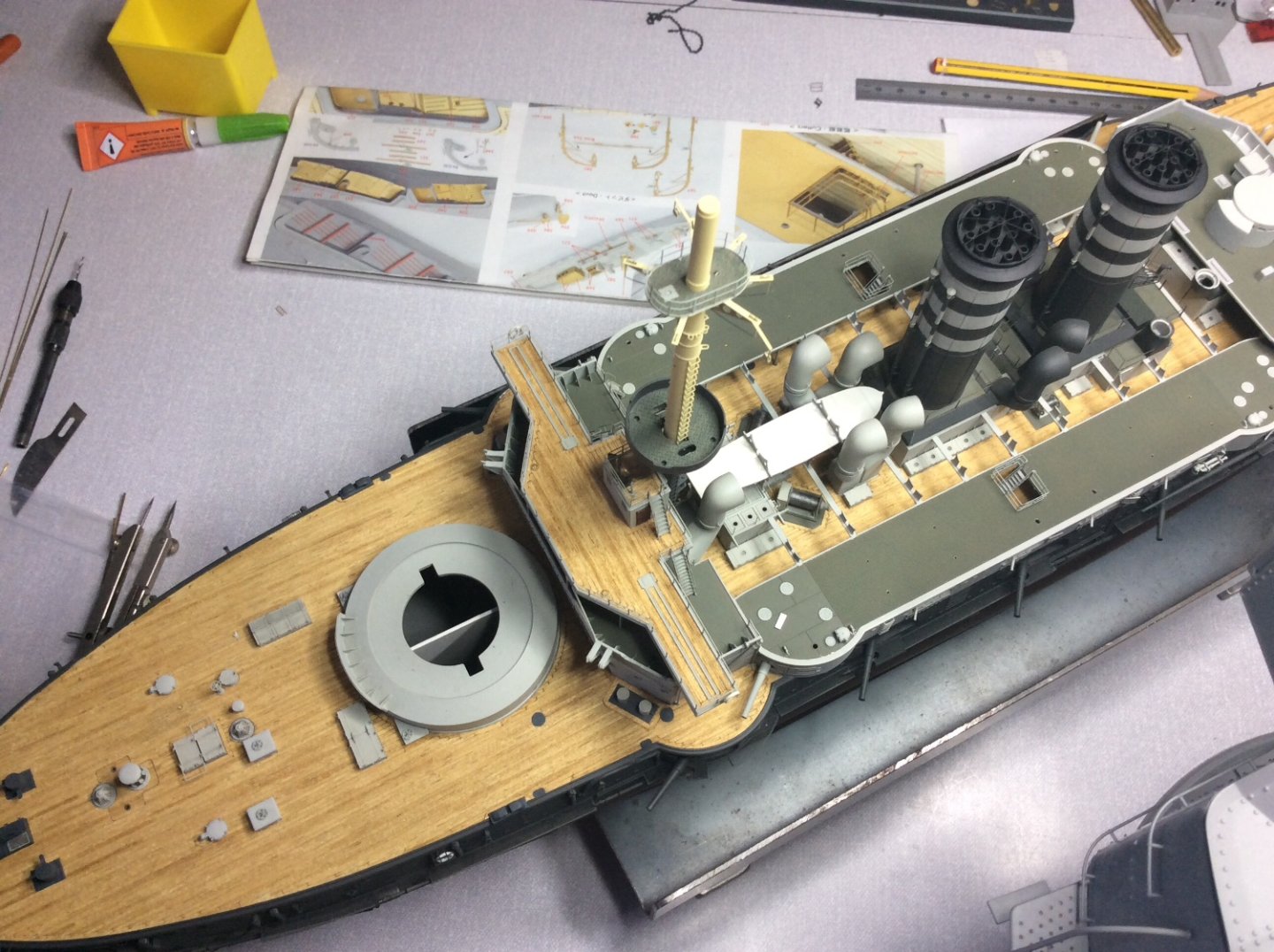

It takes a while to get round all the detailing and painting them separately before fitting, I did purchase a second Pontos set to get the necessary parts I wanted, I know this is over the top but there’s no way of producing the 1902 version without the necessary parts, it would be great if Pontos could do an additional set to help if the markets out there. 👍

-

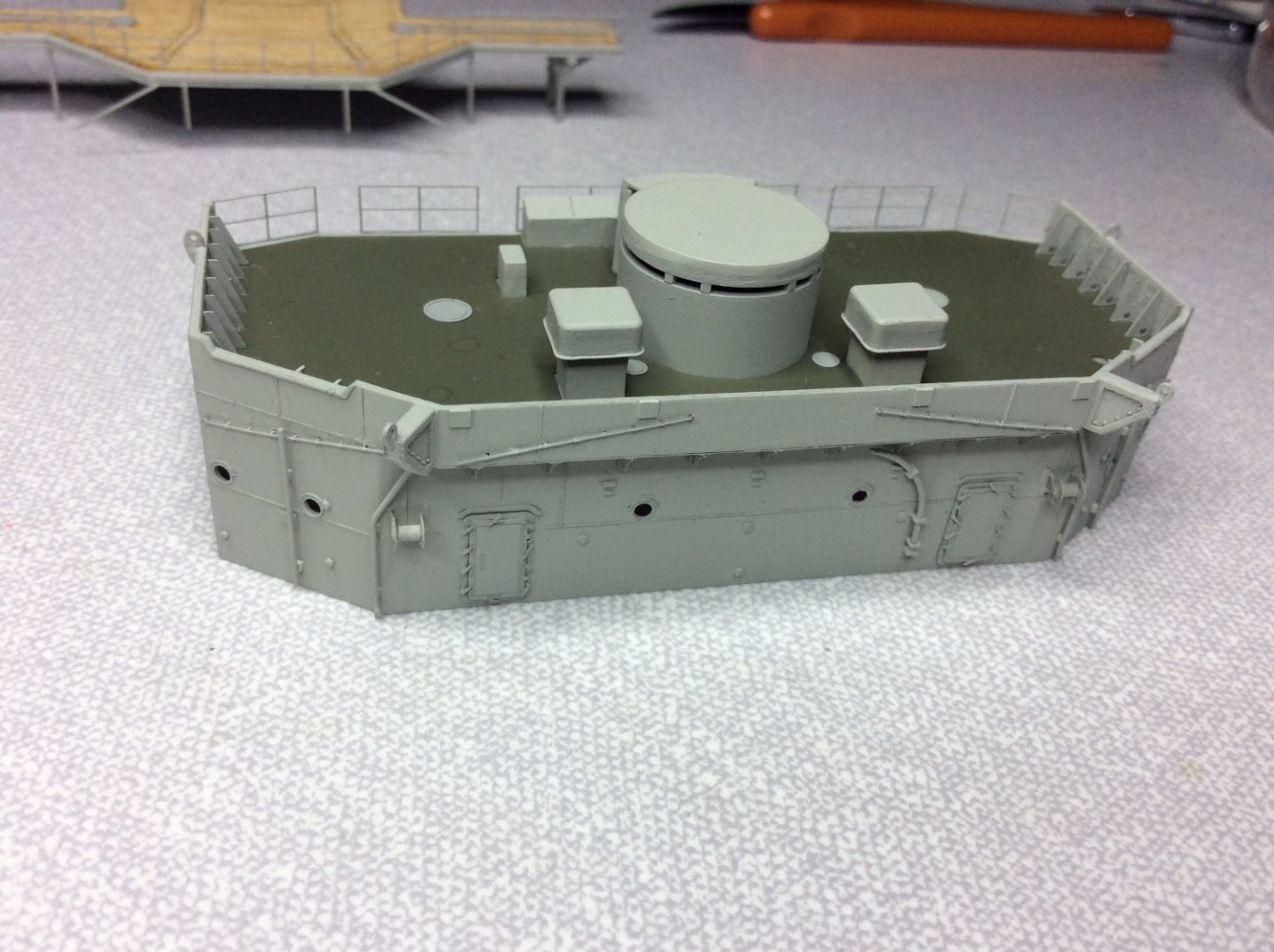

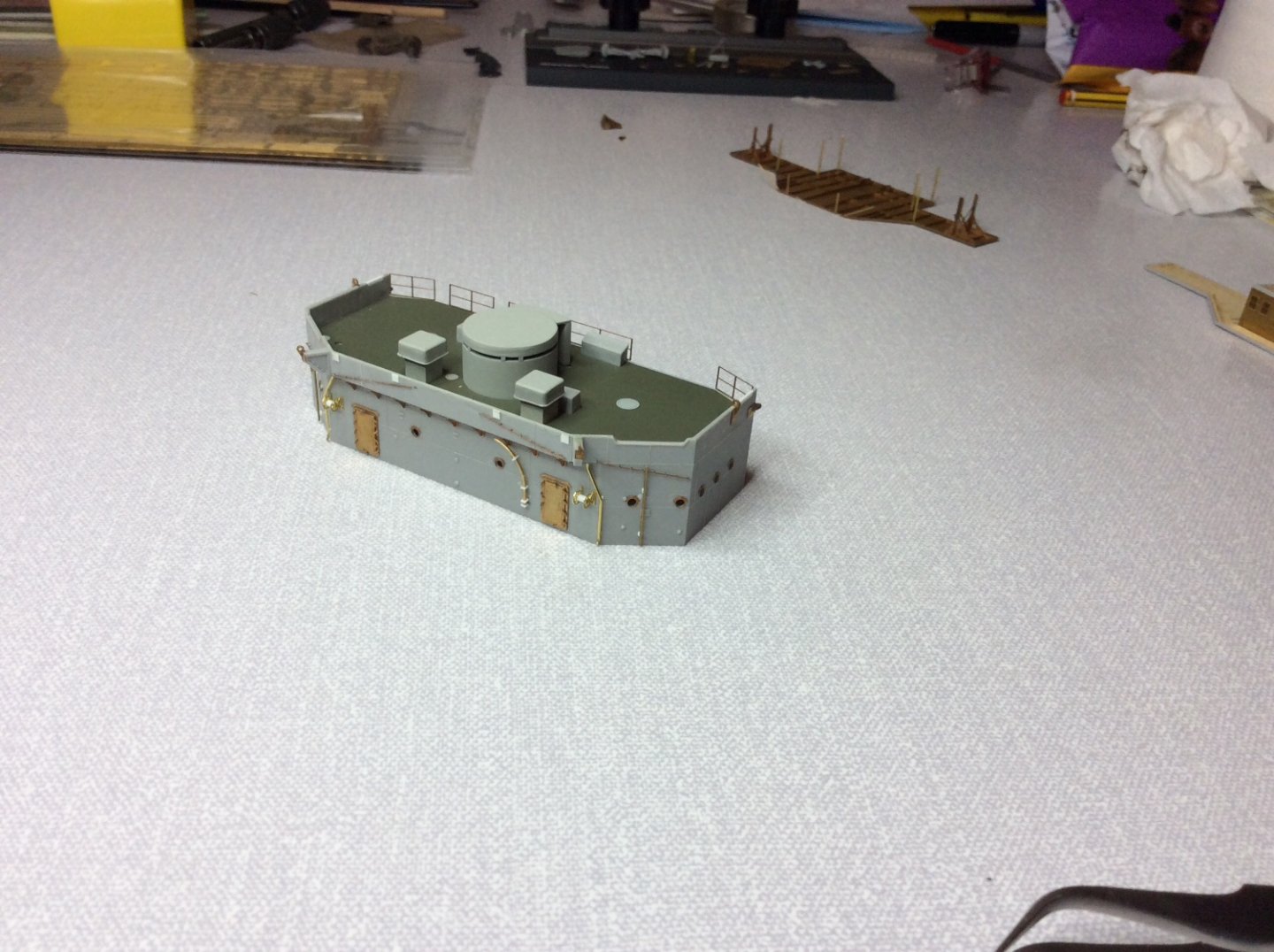

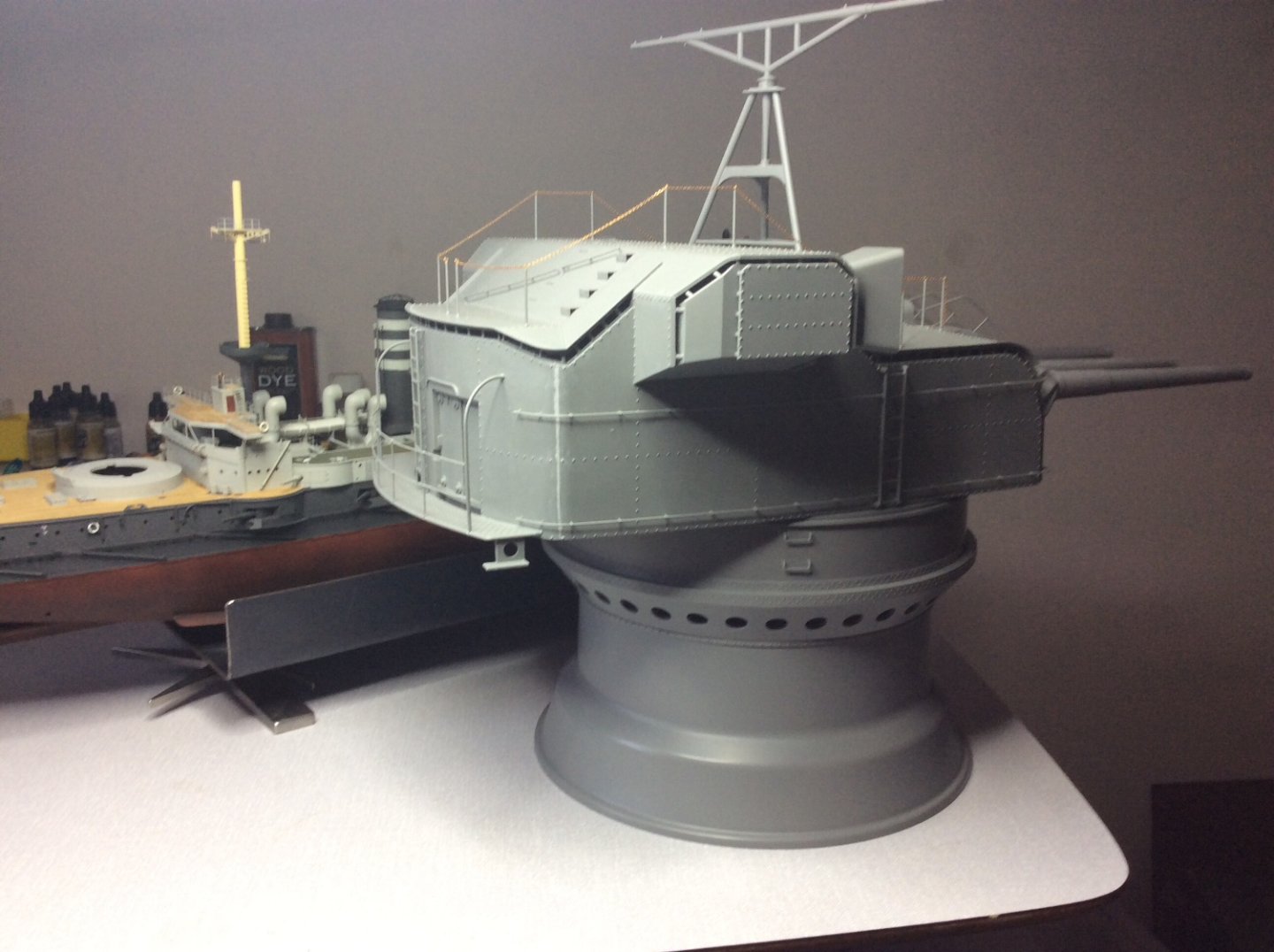

Hello again, Yip it’s that time of life, time for an update. I remember this part of build being quite busy to say the least and knew it would take a while. Starting with the lower bridge super structure following Pontos instructions removed unwanted surface details using electric chisel and my craft knife with curved blade, then start fitting the etch details, following the sequence in instructions works easy enough. Just added some extra details, pipes and jibes, cable drums, it all helps to bring the model to life.

-

Thanks Tim, seems we are always trying to get better. As usual the photos show up the imperfections that makes you strive to doing them better, guess that’s what modelling is about. 👍 Hope your build coming on well. ?

-

You can see more clearly in these photos the point I’m trying to show. Think all these sort of steps would be generically set at the same angle, shows up this way as you can see it lining up with the handrails which is always more pleasing to the eye. Hope you agree.

-

Greg it is quite big, a lot of wow factor for £70 kit. Seriously I would buy the whole Battleship in this scale if they were mad enough to go for it. Building it in sections would be quite manageable. Would be good for the likes of a modelling club to tackle. Just living the dream. 😂

-

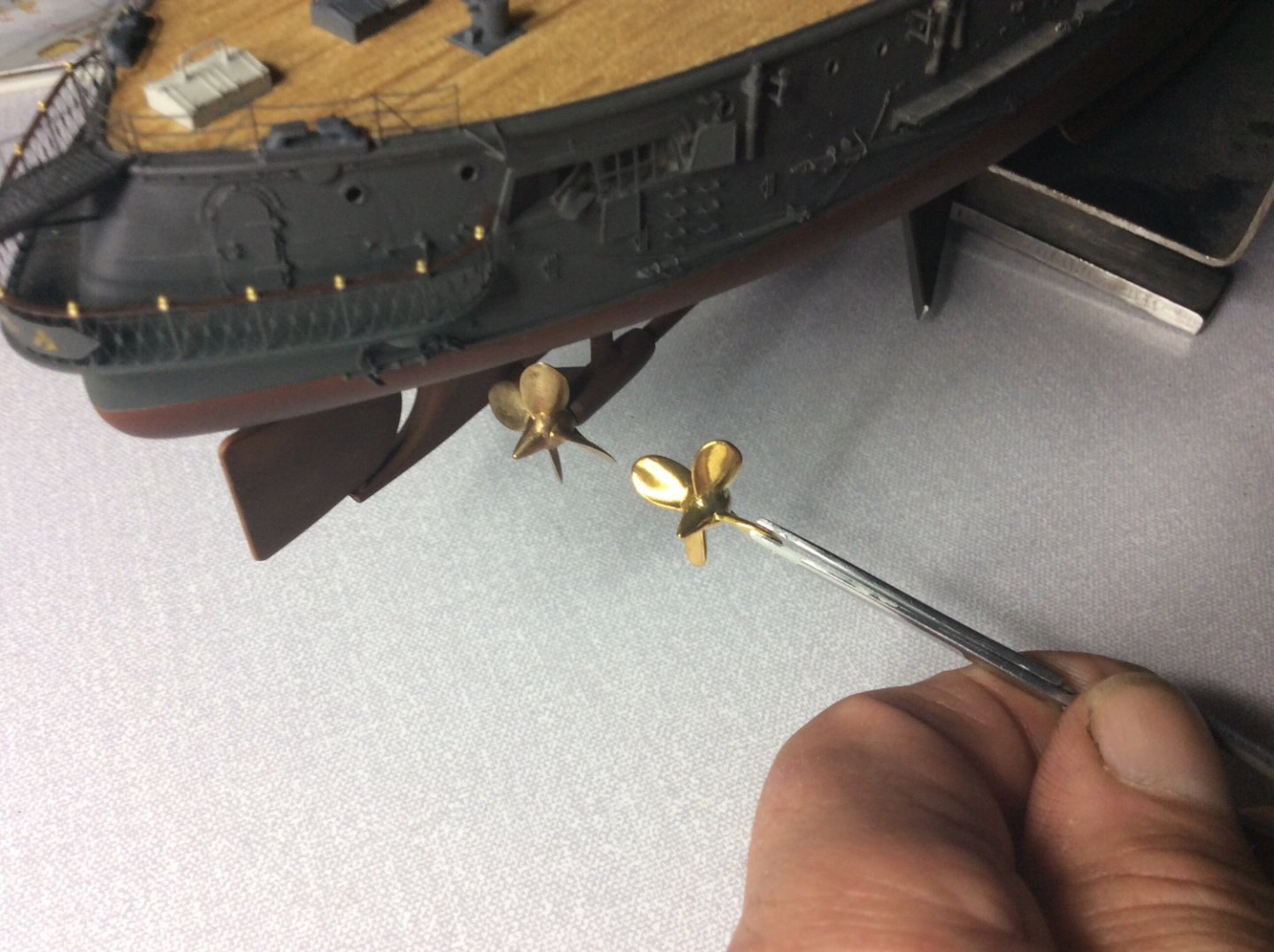

Well that’s it for now, shall need to start work on forward bridge structure and mast, a lot of work in this area so don’t hold your breath. 🤪 Jacqueline also bought me a second Pontos set so l have the parts I need to go forward. Who said us modellers are sane. Here’s a photo of the propeller before I dressed it up.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.