-

Posts

124 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by AnchorClanker

-

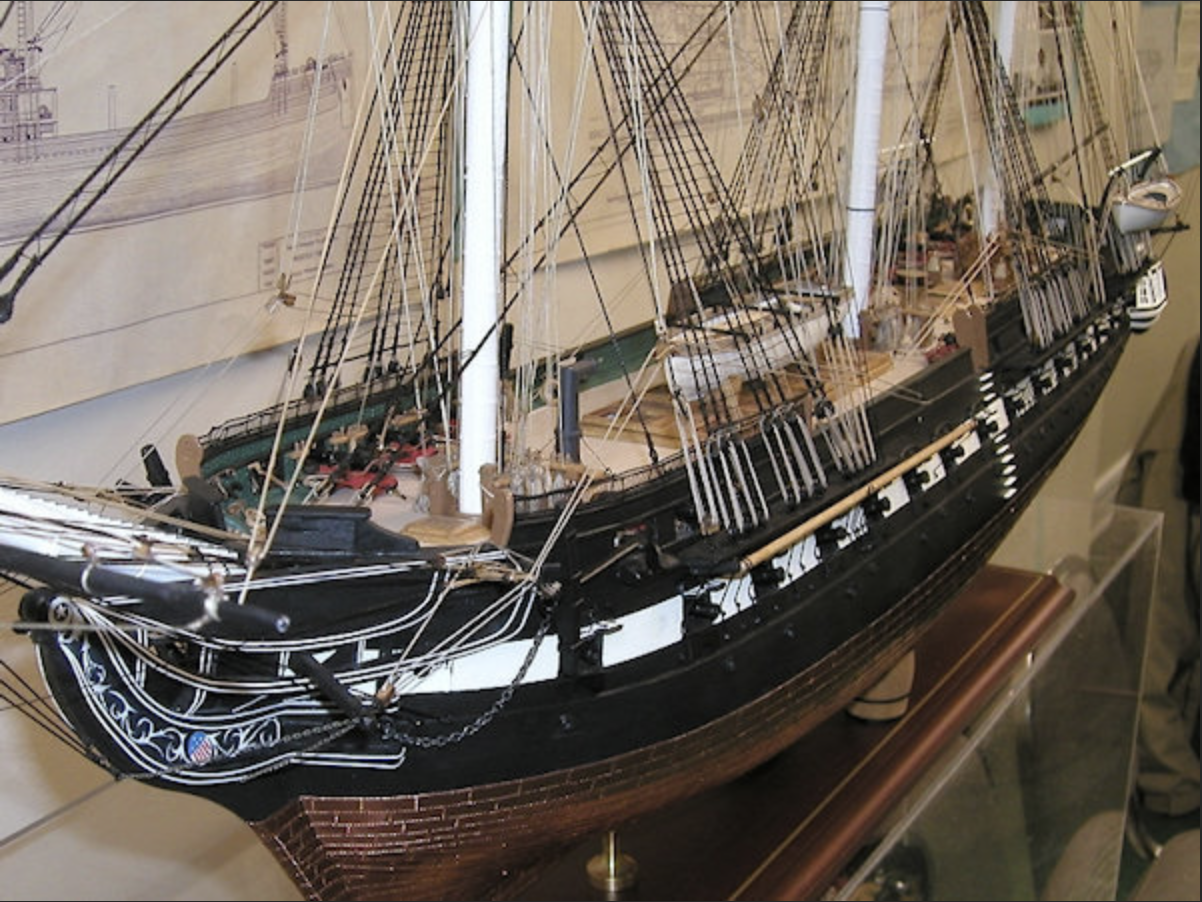

Oh! Heavens, no! I decided to continue building the original ship as a means to learn how to do make and attach the strakes, wales, and bottom planks. At the same time, 'start over' with making the 'plywood' frames, stem post, stern post, and keel. I am also looking more closely at how you built your frames and seeing how I was missing some details. Today I will start to redraw my frame plans. So, all is well and not lost. Fair winds and following seas, Mark

-

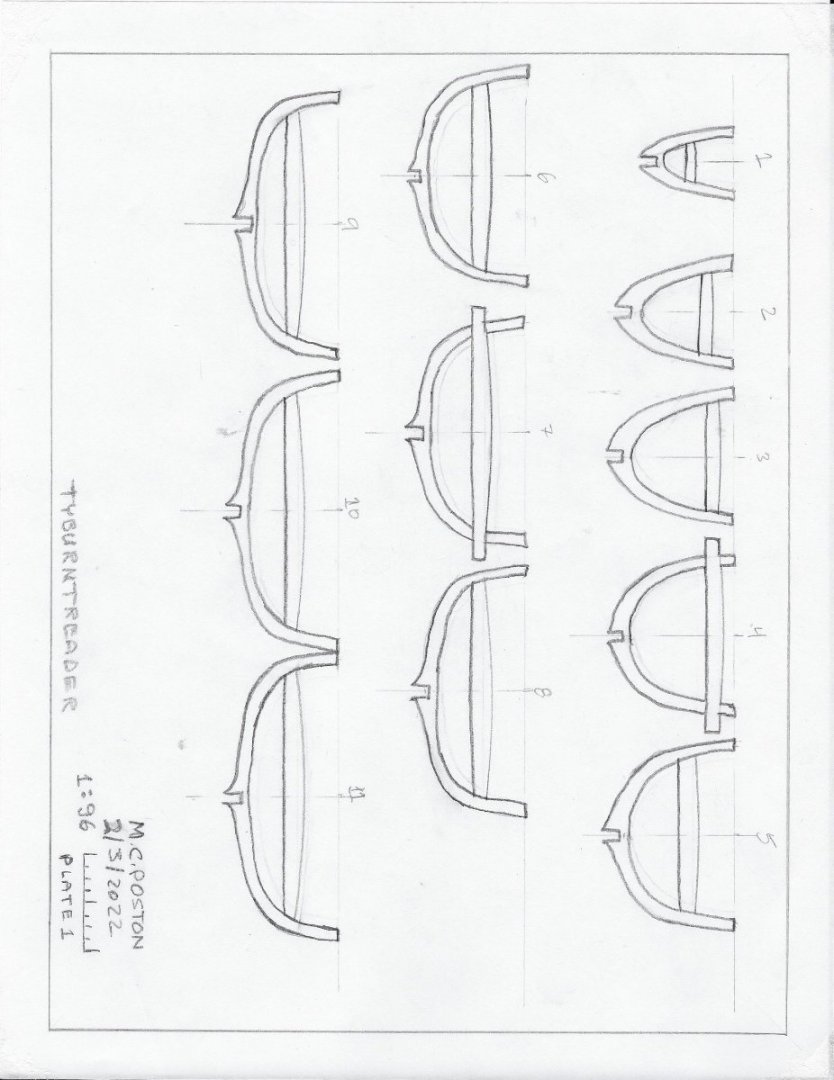

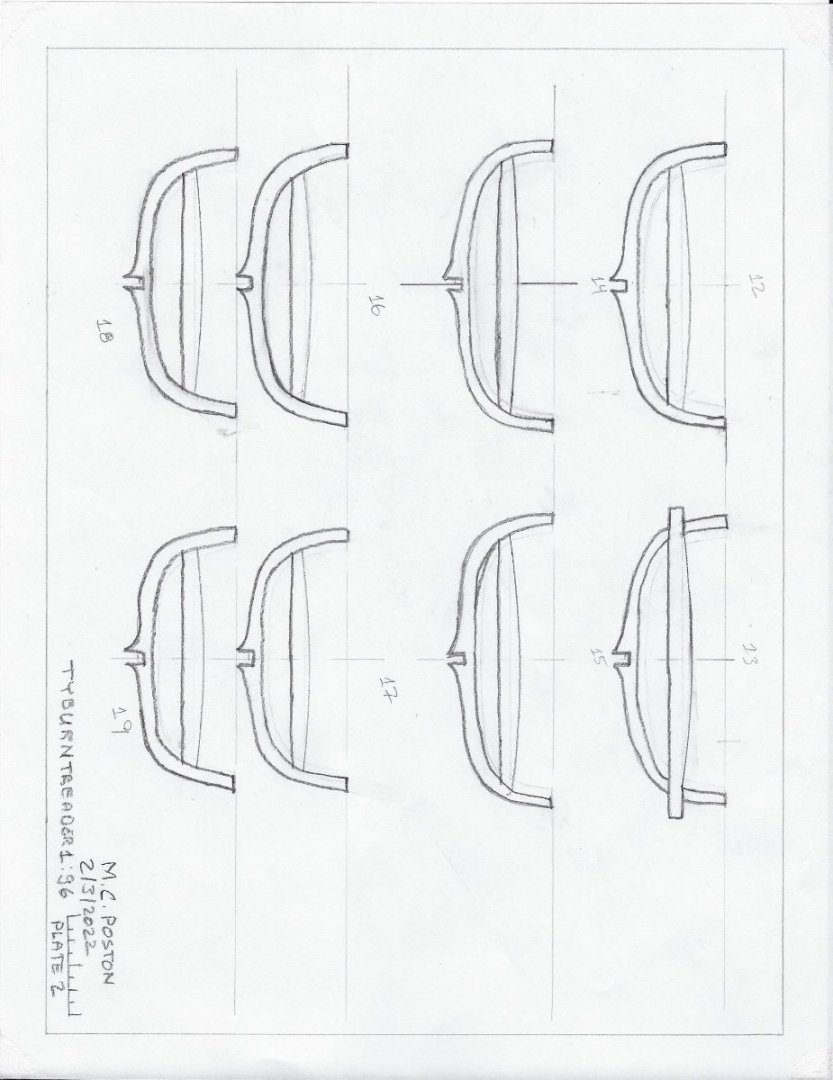

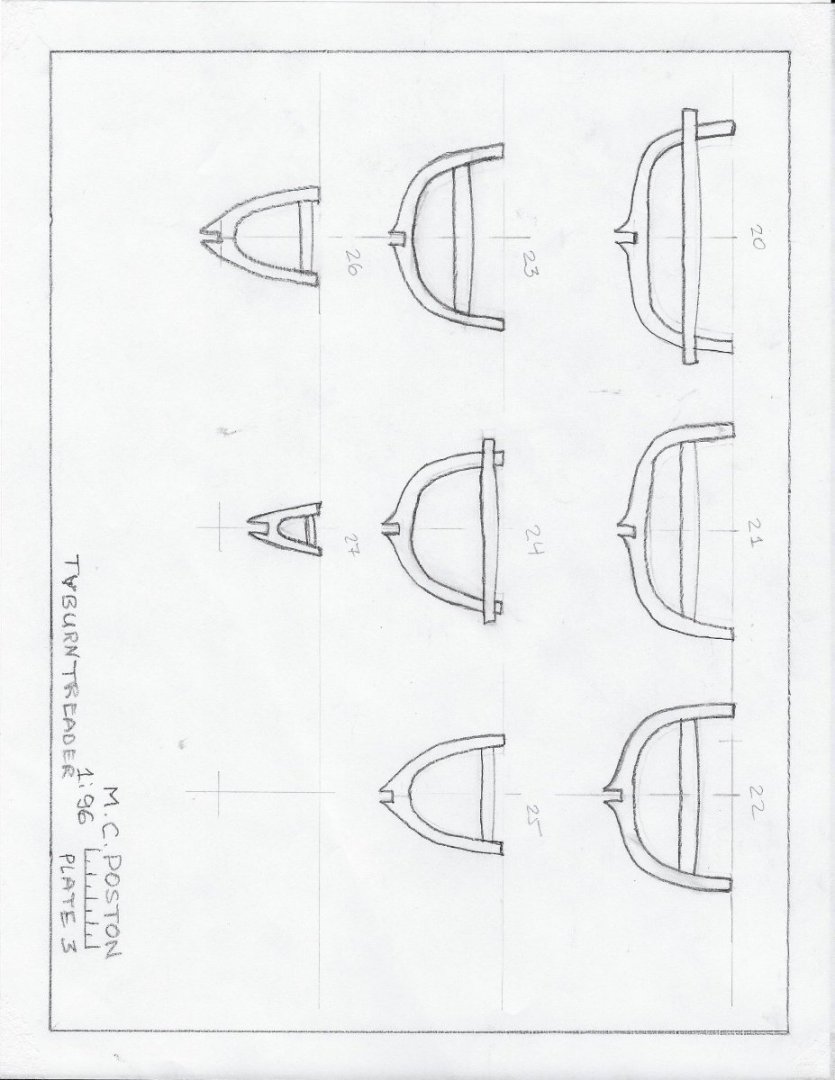

Looking at the drawing of my frames, the grain of the wood is horizontal. The frames are two half frames. The grain of the beams will be oriented longitudinally. Considering the scale, 1:96, I was hoping orienting the grain of the wood in this fashion would eliminate or at least reduce the effects of the grain. It seems to me, I need more advice and to study the frames in the photos and how others have made their frames.

-

It has been a few days since working on my ship. Today I worked on designing thinner frames and have committed to using my scroll saw to do so. Speaking of the scroll saw, I bolted the auxiliary table top to the table top. I am also redrawing the deck beams to show the camber. Tomorrow, if time permits, the frames and deck beams will be either modified or cut out. Then the process of attaching them to the keel will commence. In terms of the hull planks, I will try Louie da Fly's method of using a soldering iron to heat the planks to bend them around the frames. More later.

-

Your model is looking very good! Keep up the good work. Mark

- 739 replies

-

- Tudor

- restoration

-

(and 4 more)

Tagged with:

-

NEW MEMBER and new to model ship building

AnchorClanker replied to Peter6172's topic in New member Introductions

Welcome aboard, shipmate! Glad to have another model railroader in the MSW crew! N-Scale is my scale of choice at this time. I started in HO and may go back to it in a few years. The eyes and fingers are as good as they were in the past. Scale 1:96 and 1:160 are my modeling choices. 1:96 for most ship models. -

Untangling and rerigging or start from scratch?

AnchorClanker replied to Rgpracer's topic in Masting, rigging and sails

One of the correct depictions in this drawing is of the 'king spoke.' It is the top-most handle which is slightly larger and has different shape and feel to it. With the king spoke straight up, the rudder is amidships; the ship sailing straight ahead. In the dark a helmsman can tell in which direction the ship is headed by having his hand one the king spoke. In commencing on being a model shipwright, keep your hand on the king spoke! -

Untangling and rerigging or start from scratch?

AnchorClanker replied to Rgpracer's topic in Masting, rigging and sails

Ray, Looks like you have quite a job ahead of you! Keep it up! -

Keith, Your model is a very impressive model! I love the old photographs and how you solved the problem of the wheels for the guns. What method did you use for your attempt at making the wheels? Mark

-

Right about the sheer. I was examining the plan view again and am taking the sheer into account. At the moment, I decided how to produce the camber on the decks and will give it a try this coming week. After looking at your model, Steve, your point of making the fore deck and after deck with too steep of a slope is clear. In drawing the deck beams and through beams, the importance of correctly making the camber and slope of the two decks correctly is very important. This is where it might take more than one attempt at making these items is in order. As you said, the final result will be worth the effort.

-

Last night I was thinking of making the decks convex upward just for that reason. At 1:96 the rise will be very small and was wondering it is really worth it. The convex does not have to be much, just enough. Also, the keel needs some work. The top and bottom of the keel are not exactly parallel, so the frames and deck beams will not be exactly correct. The keel will have to be modified or remade first. I need to think through how ensure the deck beams are at the exact same height. Doing a dry run is a good way to test this. Redrawing the frames to make each half mirror images of each other came out quite well. Most of the complete frames matched the new drawings. Drawing the deck beams and the through beams is still to be done. About a quarter of the frames need to be separated and re-glued. A Testors Wood Cement was used. I'm not happy with it. For one, it takes 12 hours dry and cure. And it is not very strong. In this case, that is good thing since a quarter of the frames need separating and re-glueing. Going forward I will use a waterproof Titebond II wood glue. As a result, glueing will commence only after a 'dry fit' is 100%. I plan to make my model seaworthy. It's a ship, for heavens sake! For the ballast I will use something called "Critter-clay". After forming it between the frames at on the bottom of the hull and letting it dry, it will be painted with a dull coat lacquer to make it waterproof and glued in place. Thank you for you advice, Steve.

-

Right. It is better to correct sooner than later. It is much less 'expensive'! I copied the plans for the frames and redrew the plans by adding the mirror image. The next step is to add the deck beams to the drawings including the through beams. It seems best to do that now instead of trying to do so after the frames are attached to the keel. After that will be copying the frame and deck beam plans and the use the copies to reconstruct the frames and add the deck beams. When the drawings are complete, they will be added to my build log. Mark

-

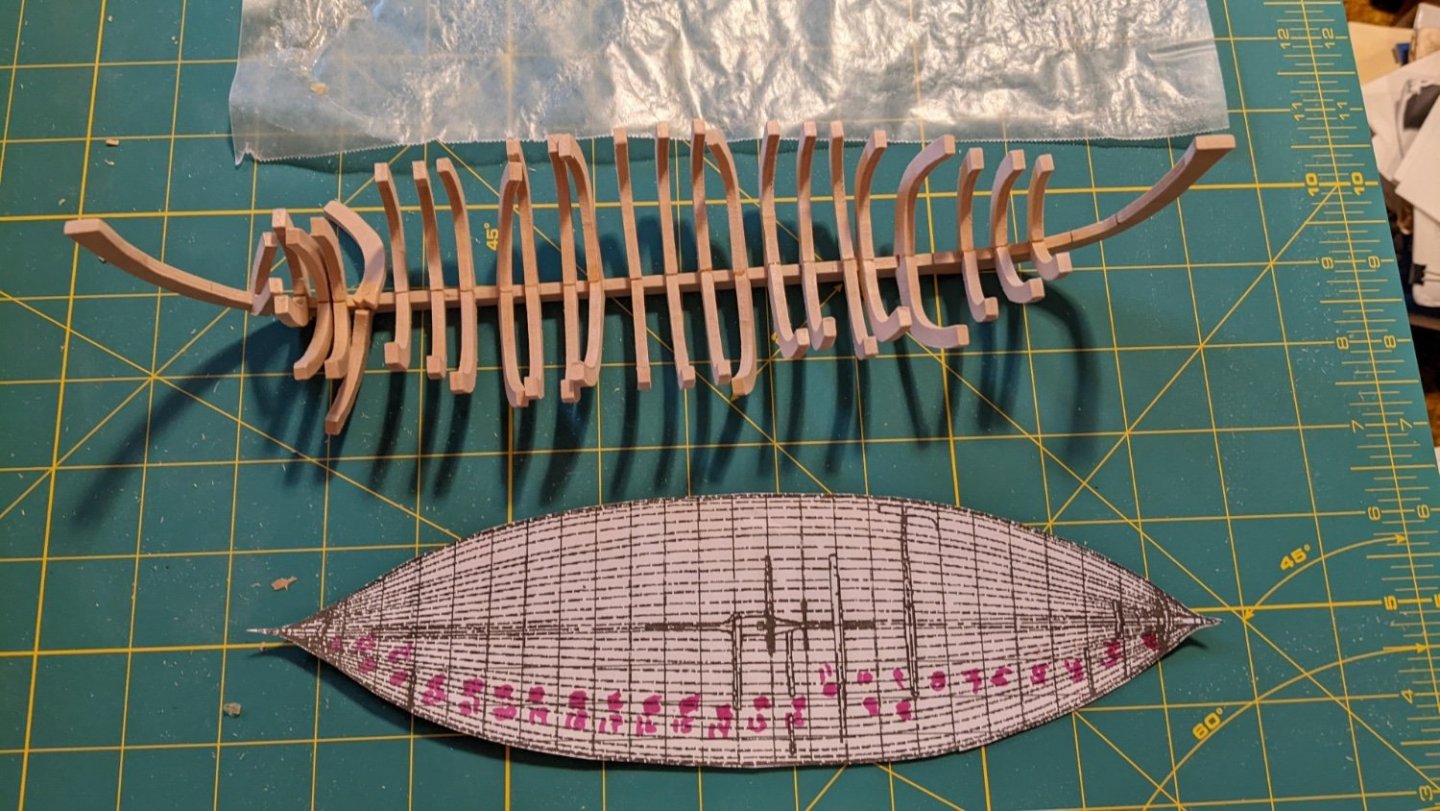

The encouragement to create a jig for attaching the frames to keel is painfully learned. I need to create a jig, or several jigs, for doing so. My first attempt did not turn out as expected. Details, details, details!! I may even remake the keel. The attached photo may show the frames did not line up quite the way they were supposed to. Today I will be making jigs for the frames and a jig for holding the keel and attaching the frames. This process may take longer than anticipated. But, then, maybe not.

-

This afternoon was spent making sure all my frame halves match their mirror pieces. All fit on the keel as they should. Next will be gluing the two halves together. Then it will be tracing the full frames and designing the cross beams. I need to decide on a jig for attaching the frames to the stem post, keel, and stern post.

-

Steve, About a year ago I came across Time Team and Time Line. They are great shows indeed! Mark

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.