marsalv

NRG Member-

Posts

617 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by marsalv

-

- 206 replies

-

- royal caroline

- panart

-

(and 1 more)

Tagged with:

-

- 206 replies

-

- royal caroline

- panart

-

(and 1 more)

Tagged with:

-

- 206 replies

-

- royal caroline

- panart

-

(and 1 more)

Tagged with:

-

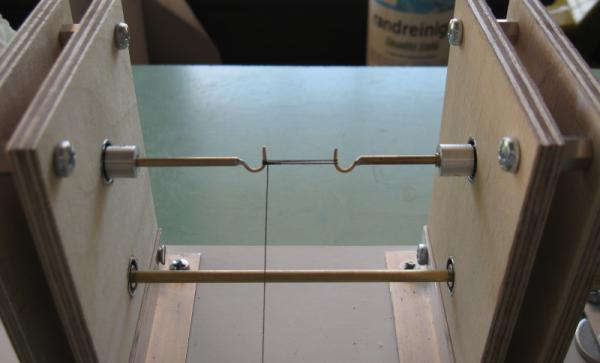

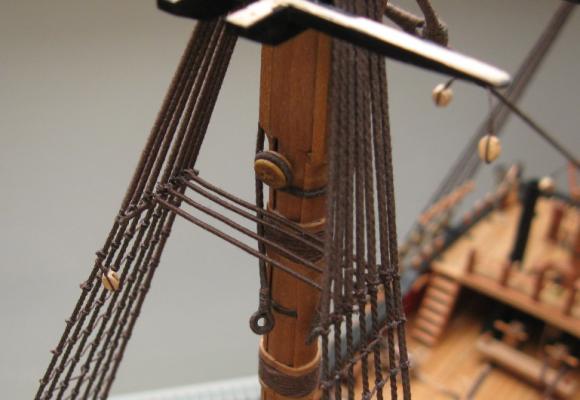

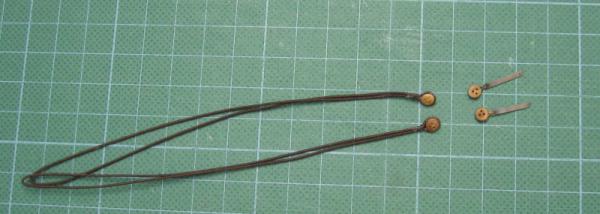

You're partially right. The first two pictures are the futtock staves and third are the catharpins. But the futtock staves don´t run through the end of catharpins. Catharpins are attached to the futtock staves with thread witch is going through loop in the catharpins and about futtock staves.

- 206 replies

-

- royal caroline

- panart

-

(and 1 more)

Tagged with:

-

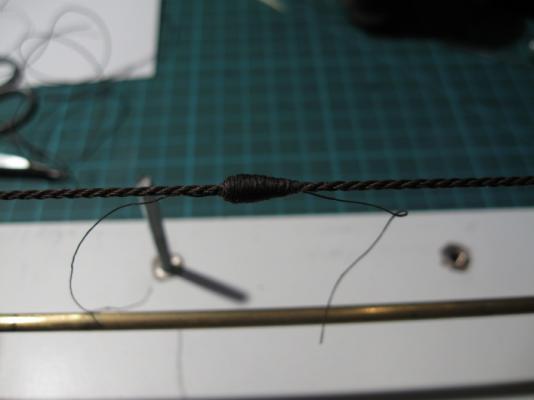

Thanks for nice comments to all . To GuntherMT: The catharpins are made form one thread - see picture tutorial.

- 206 replies

-

- royal caroline

- panart

-

(and 1 more)

Tagged with:

-

- 206 replies

-

- royal caroline

- panart

-

(and 1 more)

Tagged with:

-

- 206 replies

-

- royal caroline

- panart

-

(and 1 more)

Tagged with:

-

Hi to all, the most useful books for me are the following: - Masting and Rigging of english ships of war - James Lees - Rigging a sixth rate sloop of 1767-1780 - David Antscherl Citation from the second one: "In reality there was an eye spilce in each end of line that was then seized to the end shrouds, and the line clove hitched around each intermediate shroud. For model work, unless you are absolute purist, this can be simplified by omitting eye splices and seizing." It is also my case, I used the clove hitch for all shrouds. The knot is finally fixed with small drop of diluted PVA glue.

- 206 replies

-

- royal caroline

- panart

-

(and 1 more)

Tagged with:

-

- 206 replies

-

- royal caroline

- panart

-

(and 1 more)

Tagged with:

-

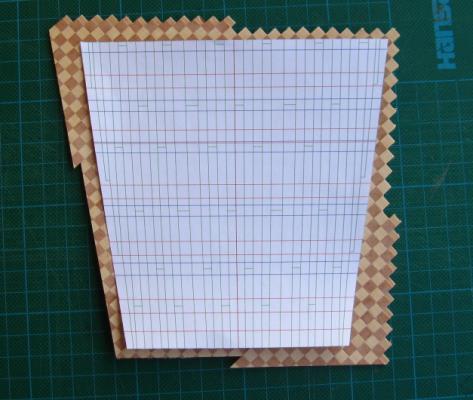

Hi GuntherMT, there is odd number of grooves on the wooden ring, each groove contains one thread. I used a single thread and weaved it around to make a spiral - this is reason why skeleton must contain odd number of thread. If you use even number of thread in skeleton, you can not use a single thread, but you must use a new thread for each row in mouse - this is not good idea.

- 206 replies

-

- royal caroline

- panart

-

(and 1 more)

Tagged with:

-

All the ends are secured with diluted PVA glue to the stay. It is very important that the "skeleton" from thread must contain an odd number. Then just drag out another thread throughout the "skeleton", alternately one under, one above thread. It is little difficult and time-consuming work. The stays (and their accessories) is ready and installed on the model.

- 206 replies

-

- royal caroline

- panart

-

(and 1 more)

Tagged with:

-

- 206 replies

-

- royal caroline

- panart

-

(and 1 more)

Tagged with:

-

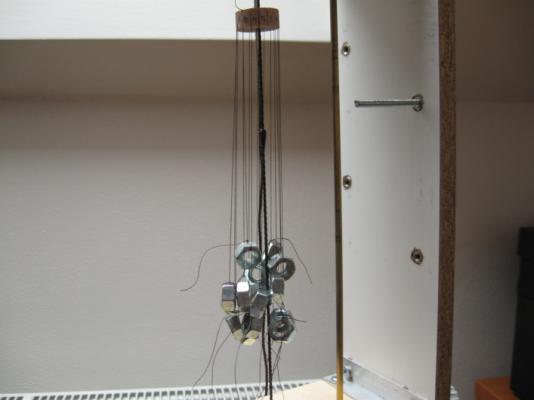

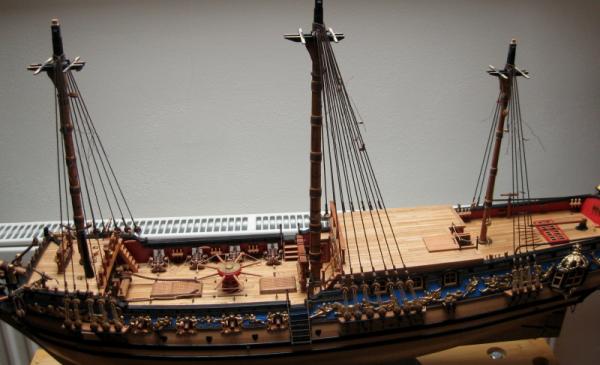

I have finished the shrouds instalation. The used dead eyes are not ideal - groove for the rope is too big and the rope is hidden in the groove. I will try to make my own dead eyes for my next project (Pandora).

- 206 replies

-

- royal caroline

- panart

-

(and 1 more)

Tagged with:

-

- 206 replies

-

- royal caroline

- panart

-

(and 1 more)

Tagged with:

-

Works on bowsprit rigging are cpmpleted now - bobstay shrouds, bowsprit shrouds, boomkin shrouds) and main stay collar.

- 206 replies

-

- royal caroline

- panart

-

(and 1 more)

Tagged with:

-

- 206 replies

-

- royal caroline

- panart

-

(and 1 more)

Tagged with:

-

Hi again, after a short break I would like finally finished my Royal Caroline. Although most of the parts are already done, there is still a lot of work on the sails and rigging. I started slowly preparing blocks and auxiliary cables on the bowsprit. Jib traveller will be mounted later on bowsprit.

- 206 replies

-

- royal caroline

- panart

-

(and 1 more)

Tagged with:

-

Pandora by marsalv - FINISHED - 1:52

marsalv replied to marsalv's topic in - Build logs for subjects built 1751 - 1800

Hallo Alex, thank you for compliment. As you can see I was very inspired by your Sphynx log . -

Pandora by marsalv - FINISHED - 1:52

marsalv replied to marsalv's topic in - Build logs for subjects built 1751 - 1800

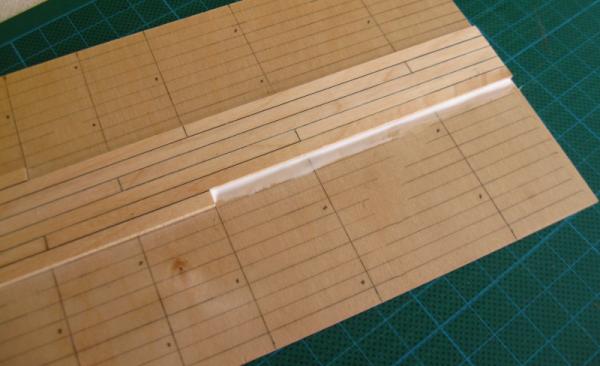

Probably the last work before saving Pandora to hibernate - deck in the officers cabin, gluing the main deck beams. -

Pandora by marsalv - FINISHED - 1:52

marsalv replied to marsalv's topic in - Build logs for subjects built 1751 - 1800

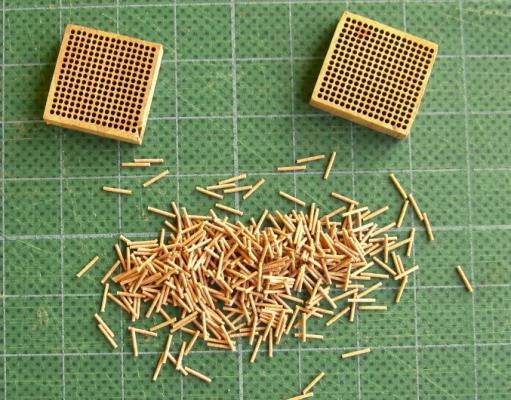

Hi Michael, I will try to answer your qustions (sorry for my bad english). Proxxon drilling maschine has 3 spindle speeds and I use the medium speed. Each treenail is made only with one down/up movement of cutting needle. Sequence is following - down with needle, up with needle, movement wit XY table and again. It´s pretty fast. You must only watch, if you can see treenail in the wood block after drilling. If you see no treenail (black hole), needle is propably blocked with wood and you must clean it. It is also the answer to your third question - treenails MUST stay in wood block. After drilling cover the face side with holes with adhesive tape, carefully cut off the opposite side and then push and remove the treenails from the block. It is easy . -

Pandora by marsalv - FINISHED - 1:52

marsalv replied to marsalv's topic in - Build logs for subjects built 1751 - 1800

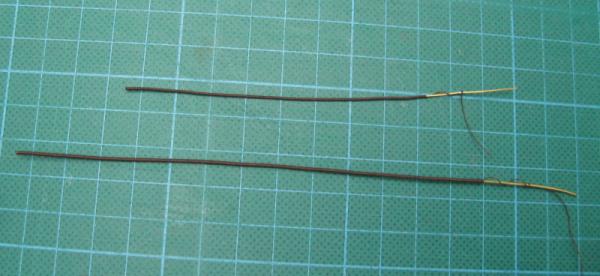

Thank you all for nice comments . I used usual hypodermic needle with diameter 0,8 mm (21G). Needle is carefully ground to the tip - see pictures. As wood is used pear, a necessary condition is that the wood fibers would be parallel to the needle. Is it possible to make treenails with diameter 0,45 mm (needle 0,7 mm 22G). You can see the comparison between 0,55 and 0,45 treenails in the last picture. -

Pandora by marsalv - FINISHED - 1:52

marsalv replied to marsalv's topic in - Build logs for subjects built 1751 - 1800

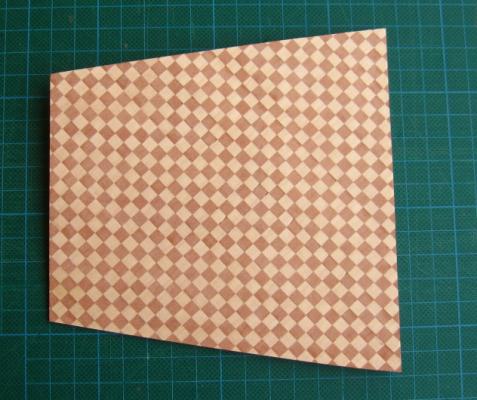

Lower deck - it will not be visible, but I made test how the deck will look with black paper and treenails. I made about 3500 pieces of treenails (diameter 0.55 mm), so I have a sufficient supply for any remaining deck.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.