DaveBaxt

-

Posts

1,301 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by DaveBaxt

-

-

11 hours ago, Jerry said:

I did the wales after sealing and sanding. There's too much chance of nipping the wales while sanding if they are in place. Don't worry about the rigging and I believe you'll eventually find that to be the most enjoyable part of building the ship. Just make sure you install your masts and booms soundly as they are the foundation for your rigging. As for the deck planking, I have attached a picture of how I do my decks. Notice that the planks repeat position every four planks. I hope you understand what I mean.

Best,

Jerry

Looks like really nice deck planking. I know what you mean about every 4 planks.there is a really good artical on deck planking on this website and shows each step including how to mark it off and the sequence for laying the planks. and for different patterns, so thanks for that.

Regarding the wales, what did you use for the 4th & 5th wales down? The instructions say 2x2mm however on the scale drawing they are clearly much wider. The guy on the Amati video uses 2 pieces of the first planking which as you know is 1.5 x 6 mm.

Thanks again for your input it is very much appreciated and I am really looking forward to the challenge of the rigging.Best regards Dave

-

2 hours ago, Jerry said:

Wow, Dave! The planking looks terrific. You don't need any advice any longer. You've got the job down pat. Your work on this phase is as good as any I've seen. I know that about this time you're probably thinking how nice it'll be to do some other kind of operation on the ship than planking. You're well on your way now and i compliment you on a job well done.

Best,

Jerry

Thanks for you very kind words Jerry. However I still feel I have lots to learn especially when it comes to the rigging. It is a bit monotonous doing the second planking straight after the first planking and sometimes think I would like to do something else on the model. However I think I will stick with it while I have the hang of it and I have a bit of a routine going . Hopefully I can continue with the same progress and hopefully I don,t make too many mistakes. Shortly after the Wales followed by the deck planking.More planking to do. A question regarding the wales. Do fit the wales before or after applying the sand and sealer.? Thank you again for you input Jerry,best regards Dave

-

50% of second planking completed. Changed tack after struggling using CA glue as I used this on the first layer of planking the two pieces at the bow where the planks raise above the deck at the cut water or stem post came away. Probably my fault and should be more careful. As I say it wasn,t going as well as I would have liked so I then tried using Speed Bond which is what I used on the first layer of planking but I needed something to secure the planks while the glue was setting . This worked with using large elastic bands the elastic wrapped around the hull but ihought they were getting in the way a bit when wiping off the access glue.Eventually I ended up not using them but I started shaping the planks on the model itself and after soaking overnight I used my electric plank bender to shape the planks on the model. This seems for me to be the easiest way. Once I put the glue on the model and wait a few minutes before placing the planks in position it does not take very long for the glue to hold the plank. Here is a couple of photos of my first attempt at second planking,although far from perfect, I feel with a bit of light sanding will remove any lips that have appeared at one or two edges. There are also one or to cracks which hopefully I will be able to fill with sanding dust and glue.Let me know what you think

-

2 hours ago, bruce d said:

Dave, I have a stack of the stuff you are welcome to if you are still stuck. Let me know.

Otherwise, I suppose SpyGlass and I can start a shipyard? We'll be rich!

Thanks for the kind offer,however I think I am sorted. There are only a couple of planks ,where they show so might get away without, Once they are on the model it doesn't show so much so perhaps they are drying out a bit.Best regards Dave

-

16 minutes ago, SpyGlass said:

Have a look a Cornwall Model Boats they stock walnut strip and its not tooo expensive so maybe just replace ?

How much do you need I have some Amati 1x4 in my wood box with no plans for it!

SpyGlass thanks for that very kind offer. I ordered some from Cornwall Model Boats which is where I got the model from as I thought I better get some for the deck, although I could possibly get a way with using one end. I only ordered it a few days ago and it has just come in the post. Great service. Thanks again for the offer. Best regards Dave

-

1 hour ago, Gregory said:

It looks like they were exposed to sunlight, near a window that created a sharp demarcation..

What is the kit, and where didi it come from..

Chances are you could get the supplier or manufacturer to replace them for you.

Amati. I agree it looks that way. I will probably complain, although I don,t think they are too expensive for say another 10 or so. Maybe it will fade with time. I have tried staining a few of the planks but they are way too dark. I might have to live with it as I don,t want to be held up, especially as we are in lock down due to covid and I have so much time on my hands.

-

-

After opening up my bundle of second layer of Walnut planking the difference in the shade is quite extreme. I understand that difference in the planks is normal, however the difference is in every one of the planks and is 50% of each plank. Fortunately I have a few spare and managed to use these for most of what planking is not painted unfortunately I few will be seen.. I have an idea of perhaps staining the hull of the ship that is not painted but will try a few planks first. The other thing so I carry out the staining before using the sand and sealer? Any thoughts would be much appreciated. Here is a photp of the planks in question.

-

On 11/9/2020 at 5:56 PM, Roger Pellett said:

My favorite wood filler is Durham’s Rock Hard Water Putty. I keep a large can in my shop and use it for all sorts of things. It comes as a powder. You mix it with water to your desired consistency. Exact mixing proportions don’t seem to matter. It is odorless and sands well. Being a powder, shelf life or hardening in the can is not a concern. It is readily available in home improvement and hardware stores. It is inexpensive.

I have no connection to the company.

Roger

Roger if I may ask what is Durham water putty like for sanding and painting? I like the idea of just mixing what you use. Sorry for asking a question on someone else post.I not sure if this is allowed.

-

-

23 minutes ago, Jerry said:

Good morning, Dave,

Yes, same time as New York. It's about 7 minutes after 8 am right now

Jerry

Good morning Jerry .We are 5 hours ahead of you I have just finished my lunch after laying a number of second planks which seem to be going ok but not perfect. I have also tapered one or two which seem to be tight next to each other. I have also manged to finish the bulwarks but I am almost out of planks. Unfortunately the ones I received with the kit do not improve with sanding. I may need to use a few before I get to an area which will be covered in paint. Otherwise I have or ordered a few spares which weren't expensive but it will be sometime before I receive them.

-

Just been to the local hardware store to pick up some bits and pieces (pipework) to make a pipe soaker . Thanks to Jerry and Rob for recommending which I will probably need for the second planking . It will definately make life easier if I ever need to do another model with the first planking 6mm x 1.5 mm.

Here is a photo of the finished job, secured in place and in easy reach.

-

Jerry I think that works out at 5 hours behind us. Not much difference .Are you on the same time as New York? My wife and I found tough when travelling to the west coast, The east coast was always a breeze and once we went to Hawaii getting there was a nightmare but well worth the journey.

-

1 hour ago, Jerry said:

Good morning, Dave.

Have you checked to see if the discoloration is permeated? Is it possible that the color change is on the surface only and can be sanded away? Just wondering.

Best,

Jerry

Wow I never thought of that Jerry I will give it a go once I finished my cup of tea. Thanks for your help and quick reply. I am kind of guessing you are anyway between 6 and 10 hours behind us depending up what coast you are on, correct me if I am wrong.

-

Morning guys. I have made a bit of an error and did not check the condition of the second planking when I first received the kit. Upon opening the bundle of second planking I have noticed the colour has faded at one end and looks a bit strange. If they had of been slightly different colours then this would have been not to bad but when all the planks are 50% faded at one end and on both sides, this is a bit much. Fortunately I do have some spare stock and think I have enough for the areas which are not painted, Here is a photo of the planks supplied by Amati. I am wondering if I alternate the different ends forward. Then perhaps it would not look too bad. I am really annoyed with Amati and will probably complain to them at some point.

-

1 hour ago, Rob S said:

Dave - I appreciate all the detail you’ve provided during your planking exercise. Your Bounty looks very nice. While I’m a bit late to the party, I experienced many of the issues you have during the planking of my Vic. As time went on, I assembled a ‘soaker’ tube from PVC piping and ends and used it in conjunction with my plank bender. Also, your second planking will cover up some of your earlier errors:) I look forward to following along on your journey!

Welcome aboard Rob and thanks for your input. I have exactly the same electric plank bender and will definately have to make myself a pipe soaking tube. Yours looks to be just what I need and should be relatively inexpensive to put together. Unfortunately the UK has just gone back into lock down but hopefully there are still some hardware shops open. Best Regards Dave

-

3 hours ago, Jerry said:

Happy Monday, Dave.

From what I can see you've progressed admirably. (No pun intended) You say that your first layer of planking is smooth and that's necessary before attempting the second layer. So you are indeed,ready to roll. As you say it is difficult to sand a 0.5 mm piece of wood so don't do it as when you complete the second planking you'll be lightly sanding again and that should take care of any rough spots. You did a very nice job on the first layer and I'm convinced you know what you're doing and will certainly finish with a fine model. With respect to the planking at bulkhead 15, I would plank the hull up to the transom and then do the transom afterwards so the transom planking will cover the ends of the hull planking . ( see attached photo.) Again, don't be concerned with interim sanding as that will be treated when you sand the completed second layer. I apologize if this sounds confusing but I hope you understand what I mean. Keep up the good work.

Best,

Jerry

Jerry Thanks for your quick reply and clearing that up for me. Your photograph showed me exactly what you mean. Also thank you for your kind words as it gives me the confidence to proceed. What I meant regarding the sanding of the second layer was the edges of the planks to ensure a tight fit and wondered if this is even possible.

I also see by your photo that the rudder hole is in fact a slot rather than a hole which looks very neat. When did you actually cut the slot? Was this cut at the same time as the rudder post or later as per instructions. I have just gone off the Amati video and the rudder post was fitted in between the two layers of planking but does not mention when the hole for the rudder is made. Thanks again for your input Jerry it is really great that you can help me having the experience of this actual model . Best regards Dave

-

Update. First layer of planking completed and gaps filled in with sealer. More sealer than I would have wished however the main thing is I have got what I think is the shape without any bumps or dips. I have also fitted the stem and stern posts and the keel. I now think I am ready for the second planking and here is a couple of photos of my attempt at lining off the hull and once again dividing the hull into 4 bands. I have a couple of questions regards when laying the second planks at the stern. You can see where the first layer of planking stops at bulkhead 15 where it meets the underside of the transom. (First photo) I am thinking of laying the second layer past this join and onto the transom but wonder if any gaps might open up in which case I would have to increase the width of the planks at that point. Another question is ,is there a need to sand these planks after cutting the taper with the a knife. Seems to me it would be be difficult as they are only 0.5mm wide

-

12 minutes ago, amateur said:

I was wondering the small black triangle....

I guess that you will figure out that not only each mast. But essentially each yard has the same rigging.

lifts, braces, clew-lines, sheets (four of the major ropes per sail) ate a rather repetitive system. Once you figured that out for one yard, the others bevome infinitively easier

Jan

Jan The black triangle I think is an arrow. There is also a white or clear arrow which is where I thought would go to the belaying pin I too can,t figure out which belaying pin the black arrow goes to. Best regards Dave

-

19 minutes ago, amateur said:

Good heavens, I thought Corels rigging diagrams of mybuild were a kind of jigsaw-puzzle, but this one is equally, if not more, difficult.

But I guess that it is what youthink it is: numbers in circles refer to the parts-list, squares to the belaying points.

I would have expected also a number of squares referring to the pin-racks after the masts, as some of the ropes are usually taken along the mast to a belaying point near the mast (especialy the tackles that hold the spars and yards)

Jan

Phew! I thought I was going crazy. Thanks for clearing that up and its starting to make a little bit of sense. It would be easier if each mast had the same rigging or if I had a list. Perhaps when I know the names of what each rope does perhaps it will become easier. I have figured out that when a number has a P in front it is the start point and then the same number I am assuming where it ends os the belaying pin.Finding where it is. Once again I thank you for your help and I am slowly getting there. Best regards Dave

-

The model I am working on is the HMS Bounty. I have just finished the first layer of planking so a good while away from the rigging but just trying to get my head around it all. Here is a couple of photos of the belaying pin diagram so hope this helps . Sorry if these photos are not great. The ones of the masts and rigging I notice they have arrow heads which I am assuming go to the belaying pins. However I can,t find the corrisponding numbers on the belaying pin diagramm, some are not even numbered. I am obviously not seeing the obvious so what am I doing wrong? Thanks for everyones input which is much appreciated. Best regards Dave

-

A beginner here trying to make sense of the drawings. I think I am following the instructions on where to fit the blocks, dead eyes but struggling where which ropes go to the belaying pins. I have been trying to work out what some of the numbers mean as they don,t seem to correspond with the drawings in the the instructions.

I am assuming all the belaying pins are for running gear, however there are some ropes that start at a block or ring, on deck and wonder do they then end in a belaying pin or am I getting mixed up. I think the standing rigging is straight forward and I think I can follow the instructions, however I am struggling with the running rigging. This will be my first attempt at rigging and hoping someone can help me make sense of it!

-

On 12/22/2020 at 10:58 AM, allanyed said:

Hi Dave

Looking at the drawings of Bounty on the RMG collections site, it appears that the keel was 12" wide (5mm at 1:60) ) so building it up makes some sense, or make a new keel the proper dimension. If building it up, it might actually be easier to make the rabbet by tapering the top edge of the plank to match the angle of the frames as you go.

Allan

Sorry for the delay in thanking you for your input and can see why making the rabbet might be a very good solution, so thanks for your input. Best regards Dave

-

1 hour ago, Keithbrad80 said:

IMO you can (almost) never go wrong with PVA wood glue. Most people don’t like using CA but sometimes it’s a necessity, I use it some times when planking the decks but most of the time a little bit of wood glue and maybe a minute of finger pressure on that plank should do it, just enough for the glue to start to set.

Bradley

Bradley .I will definately give the PVA glue a go. I used speed bond which is a PVA glue which drys clear I did find that if I use it sparingly it does start to hold quite quickly and wipes off if I over do it a bit. Thanks again for your advice.

- mtaylor and Keithbrad80

-

2

2

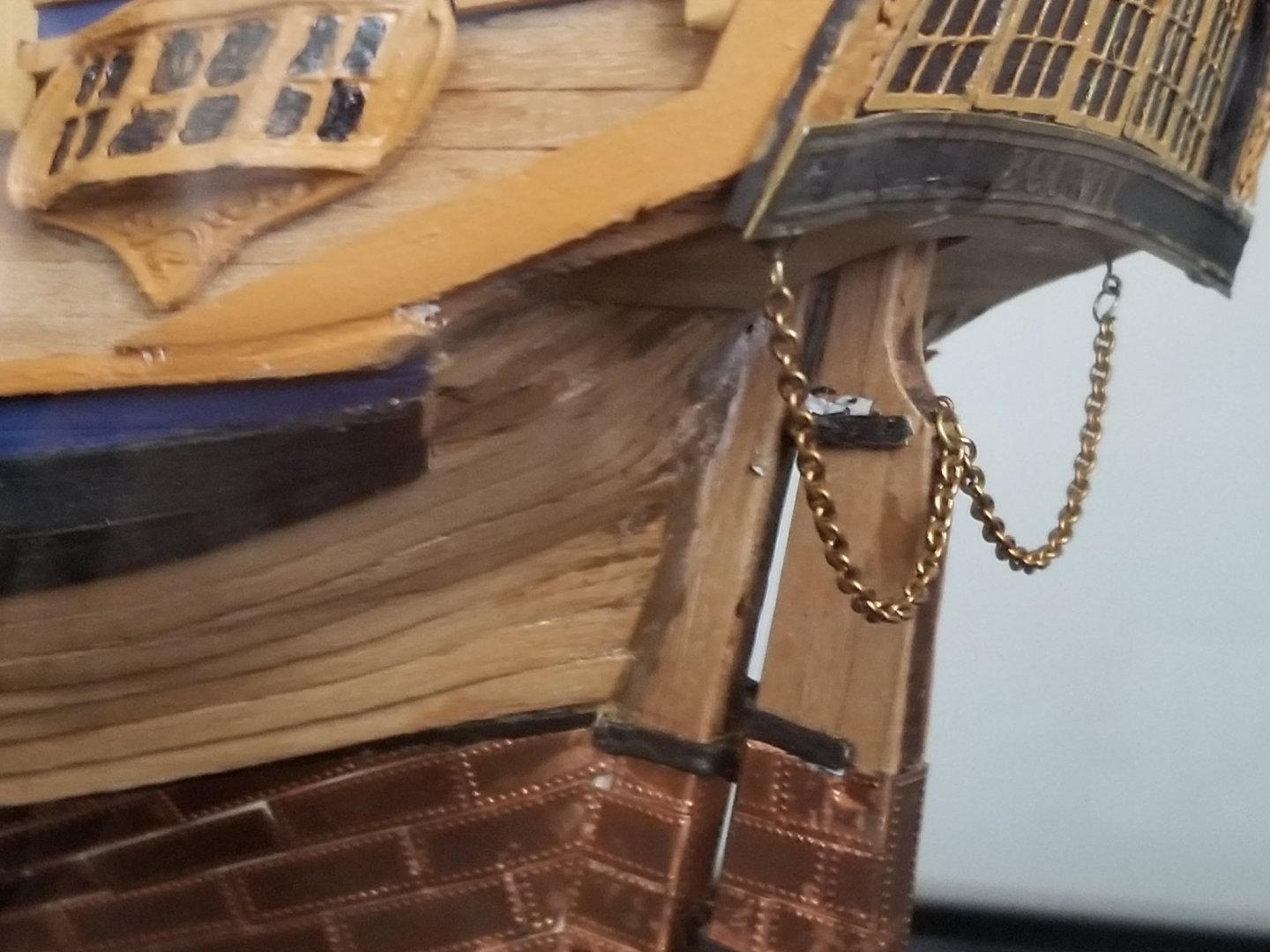

HMS Bounty by DaveBaxt - FINISHED - Amati - 1:60

in - Kit build logs for subjects built from 1751 - 1800

Posted

Thank you for you kind remark and your input is welcome.