-

Posts

55 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Ron B

-

starboard all done....not nearly the nasty job I envisioned...all but one went smooth...that one literally disintegrated when I touched it....so trimmed as best I could and made a form around it,filled with plastic wood and will sand tomorrow....luckily its at the very back on N so buried anyway.

-

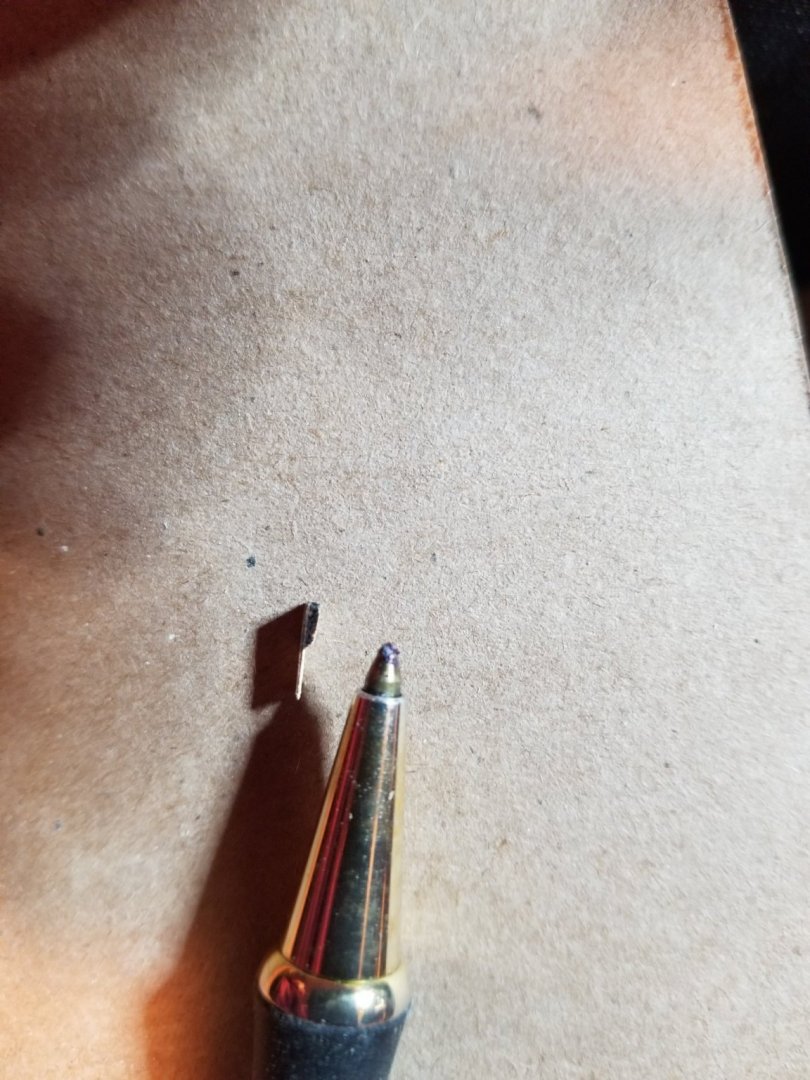

So, I got all the stanchions on port side trimmed...after 1st one which I agonized over, the rest went easy and accurate....no clamping or measuring after 1st.....just ran knife blade to create saw line, soaped edge of razor saw (old carpenter trick), and zoom zoom...all neat clean cuts, leaving 1/8" square posts behind.

-

Thought I would skip to stanchion trimming...oh boy, now this is interesting. I need to go buy some magnifying glasses as these 73 year old eyes can't see the posts well.....arghhh, getting old ain't for sissies . Once this done will add the strake supports between them , and then the strake pieces.

-

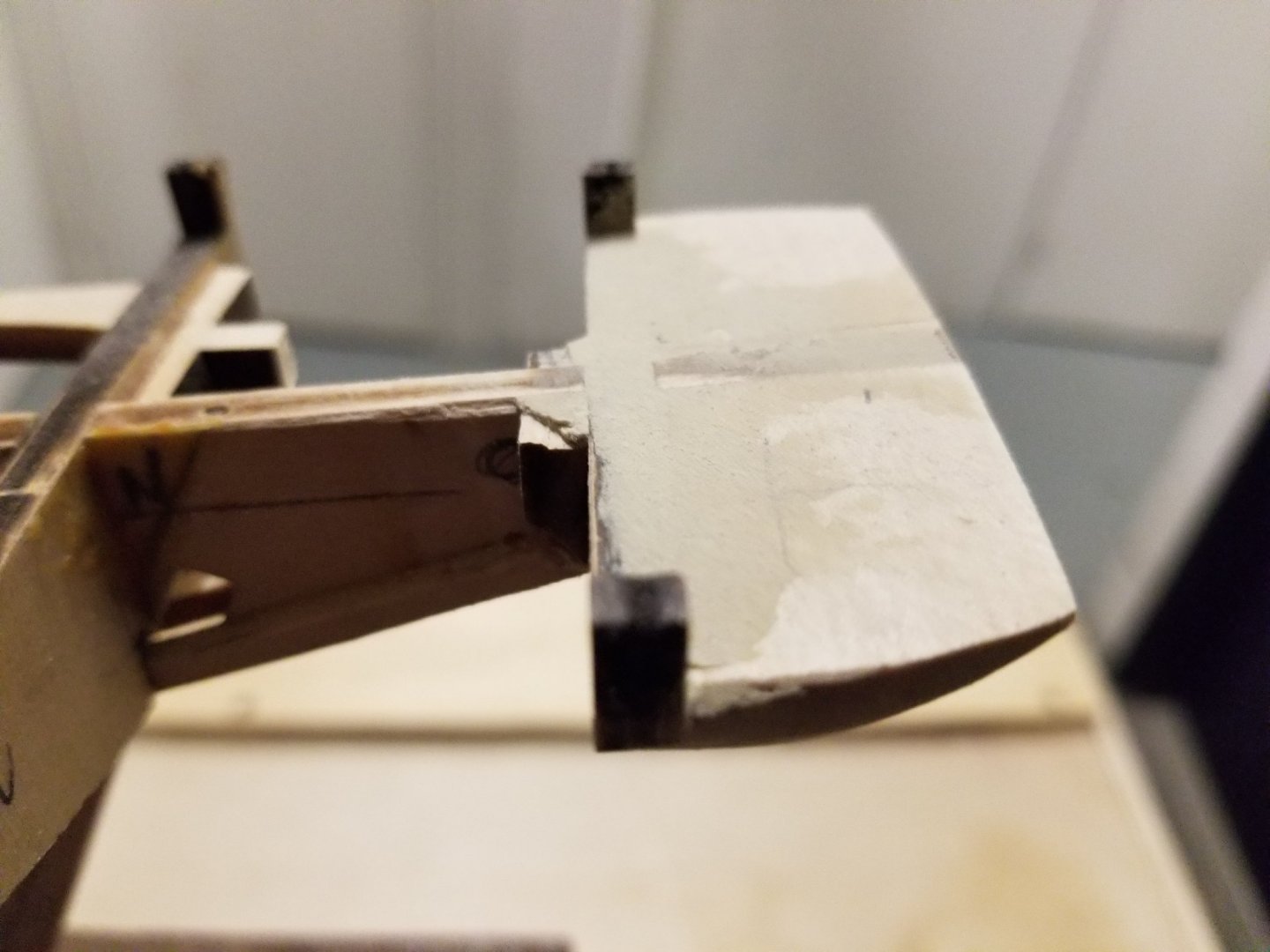

Getting back to to it. Got the transom done with a minimum of fuss.

Think I'll wait to add qtr panels, upright strips, and figure out how to make tumbles, though Nirvana had some really good pics of his efforts that I am studying and will use as a guide (thanks for this,pal). Where does the wood for this come fromas wasn't in my inventory....visit nearby hobby shop?

-

Hi all,

I took a lot of time away from Bluenose as we got crazy busy at work. Seems Covid sparked a lot of riots and crime...as in break and enters at retail stores, and that's my biz...preventing that very thing.

However my uber executive daughter said I was "languishing" , not depressed, but not motivated...kick in the butt did me good.

Back to shipyard.

Some updates (no pics yet)

Upgraded my shipyard which you may remember I built in my condo locker...more logical set up now, with some added shelving.

The internal pin I inserted at that weak spot in the stern part of keel has paid off in spades

I also bought a bunch of wood cubes on Amazon , about 1" cubed, and cut in half and used to true up bulkhead/keel ...worked like a charm...all at perfect 90° and all equidistant....but I over did it as not too neat looking, but admittedly all below decks.Oh well, lesson learned.

Tonight made a bunch of paper templates from the plans so can start working on stern blocks...looks like fun. Only disparity I see when I look at all your great builds is that some blocks are flush with top of keel and "O" bulkhead....others have a "groove" separating the blocks as though the bulkhead is higher than the keel, but might just be photographic shadow as it makes no sense to be like that.

I'll take some pics tomorrow night and post.

Hope everyone came through pandemic OK ( is it over, or even close to being over?)....going for my 3rd shot soon as over 70 and don't want to take any chances. We seem to have it under control here in Toronto ,with almost 90% vaccinated.

And snow flakes this week mixed with rain...yikes.

Have a good night, and talk with you soon.

Ron

.thumb.jpg.382b360cbe5ca25b2e2f1dc8a615678c.jpg)