Don Case

Unsubscribed-

Posts

482 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Don Case

-

Has anyone come up with a great push stick for a hobby table saw? I just started trying to make gratings and and it's kind of tight. When you get down to cutting .020" planks and .040x .040" strips it starts to get dicey as to whether you keep all your fingers. My fence is 1/4" high so that may be one thing I can change. The table is about 12" long so ripping anything less than 6" means that the wood is right in the corner between the fence and the table. Is a consumable push stick maybe the best way to go? Any thoughts? Oh, I just remembered the Byrnes saw post at the top of the page. I'll go read that now.

-

HMS Discovery 1789 by Don Case - 1:48

Don Case replied to Don Case's topic in - Build logs for subjects built 1751 - 1800

I've been making parts and pieces. Nothing is glued in yet. I improved my "tablesaw" so now I can adjust the blade height(actually the table height) and I made a slide for it. Tried making my first ever grating. The spacing isn't right but it was just a test to see if I could even do one. Cutting out the parts isn't too bad but assembling it is tough. I need to come up with a jig or steady hands or something. -

Minimum plank length

Don Case replied to Don Case's topic in Building, Framing, Planking and plating a ships hull and deck

Thanks for the offer Alan but I think I can get what I want from the NMM thumbnails. I haven't compared the frames with the expansion yet, I've been to busy planking and reading Steel. I tried PMing you but it said you can't receive messages Thanks again Don -

HMS Discovery 1789 by Don Case - 1:48

Don Case replied to Don Case's topic in - Build logs for subjects built 1751 - 1800

I got the interior planked up to the lower deck clamps. Big job. I drew up a rough plan but that only lasted a bit. Seven drop planks on each side. A lot of long slow tapers. I don't get a nice pattern. A lot of the butts seem to bunch up in spots but I think I only made one butt spacing mistake. This practice will help a lot when it comes time to do the exterior. There's a little filler in there but no where near as much as I'd be willing to use🙂 -

Minimum plank length

Don Case replied to Don Case's topic in Building, Framing, Planking and plating a ships hull and deck

I was reading Steel's "Elements" and was just getting in to some plank stuff and then fell asleep. I'm going to read it again tonight. Do you know of hand where Steel said that? I've ordered zu Mondfeld but the other one is to steep for me. -

Minimum plank length

Don Case replied to Don Case's topic in Building, Framing, Planking and plating a ships hull and deck

I want to apologize to you guys. I went off the handle and I shouldn't have. I just get frustrated with some of the responses I get when they're not what I'm expecting. I'm green and don't know what I don't know. I have a lot of trouble even formulating questions let alone know what I should include. I figured my build notification at the end of every post would give all the info needed. Even though I don't get all the answers I want I have gotten a ton of info while on here and I thank you for that. Sorry Don -

Minimum plank length

Don Case replied to Don Case's topic in Building, Framing, Planking and plating a ships hull and deck

That's the kind of rule I'm looking for. -

Minimum plank length

Don Case replied to Don Case's topic in Building, Framing, Planking and plating a ships hull and deck

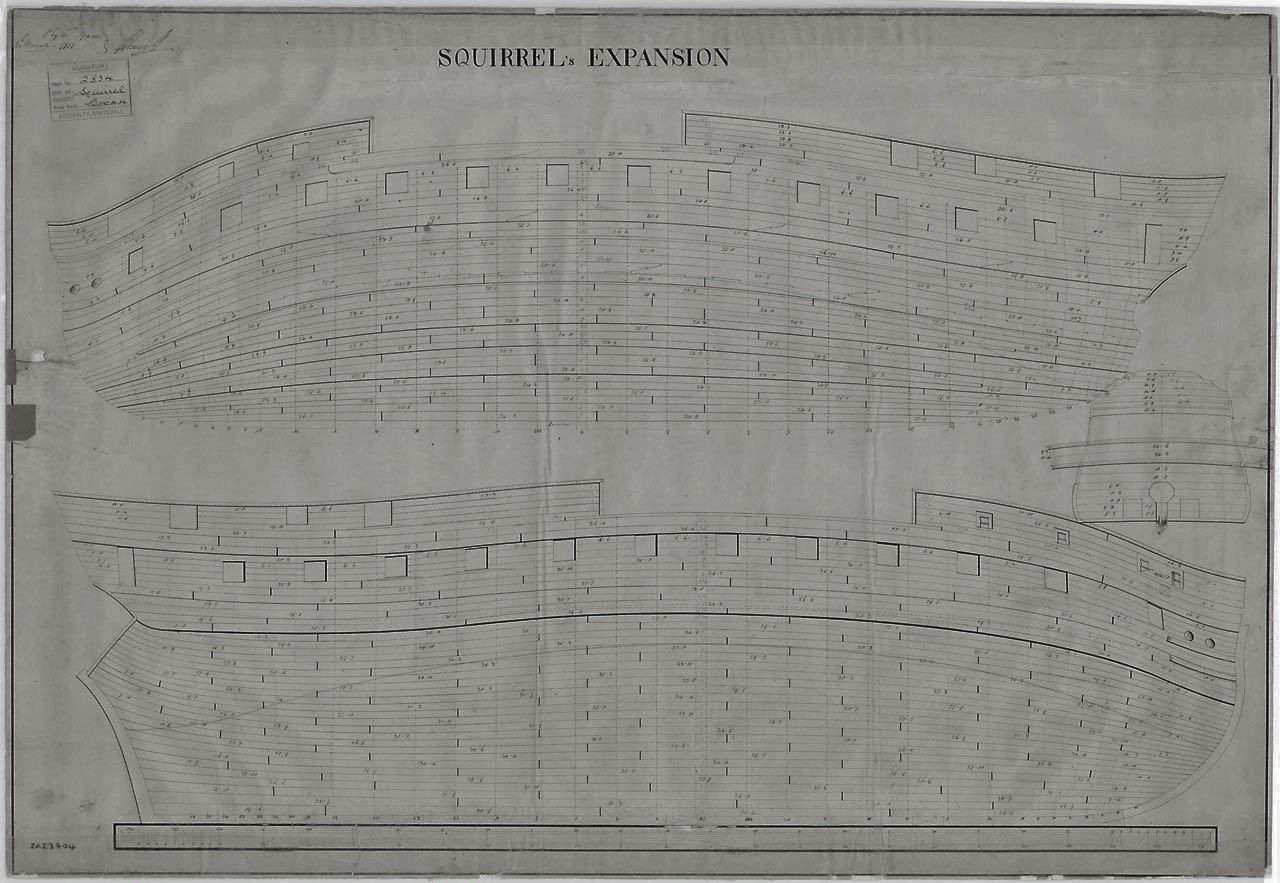

Here is an expansion drawing of the HMS Squirrel that Alan linked for me. Squirrel (1785) - National Maritime Museum (rmg.co.uk) The plank lengths are blurry but you can make out that most of them in midships are in the 25 or so range. The scale at the bottom is clear enough so you can get closer measurements if you want. Now look at the bow and stern. Note the stubby little planks. A lot of single digit lengths. These planks probably don't make the minimum. These are the planks I'm talking about. How short can they be? My logic tells me that there would be a shipwrights rule telling him how many frames it has to be attached to. -

Minimum plank length

Don Case replied to Don Case's topic in Building, Framing, Planking and plating a ships hull and deck

I don't understand. I thought this was a dead straight forward question. It's looking to me like there is no point in asking questions on here. You never get a straight answer. -

Minimum plank length

Don Case replied to Don Case's topic in Building, Framing, Planking and plating a ships hull and deck

How short? -

Minimum plank length

Don Case replied to Don Case's topic in Building, Framing, Planking and plating a ships hull and deck

I guess I asked that wrong. Is it OK to have a plank that's only long enough to contact 2 frames? I need drop plank as close to the stem as I can get it for maximum taper. -

It seems that I've been doing nothing but reading about planking and a lot of places say the minimum length is in the contract ie. 20-25 feet or so. That's not the minimum length I'm looking for. If a ship is 110' long and the contract calls for minimum 25" what do they do when they get to the end and have a 10' gap to fill? Is there be a "plank must cover "X" number of frames or something" rule?

-

How do I end the planks when they run into the clamp? Do they just butt up to it? With the clamp curving around like that I was just thinking that maybe they should be Joggled(right word?) I've noticed that when the limber strakes run their course they just kind of taper out to nothing. I thought that was a no no.

-

Planking options

Don Case replied to Don Case's topic in Building, Framing, Planking and plating a ships hull and deck

Yes I can, and will, but I thought I would check and see if there was anything I'd missed. -

Planking options

Don Case replied to Don Case's topic in Building, Framing, Planking and plating a ships hull and deck

So we don't use HMS? Your way works perfectly. If you put in HMS Squirrel you get crap. Is squirrel not an HMS? Anyhow, thanks. I'll look at the drawing now. -

Planking options

Don Case replied to Don Case's topic in Building, Framing, Planking and plating a ships hull and deck

I went to "collections" and searched for HMS Squirrel and got a "Ships cover" for a 1904 CoasT Guard cutter. I tried "Ships Plans", nothing. I clicked Vessels, nothing. How do you guys find anything on that site? I find nothing but frustration. The only time I've found anything on NMM's site is when Goolle took me in through a side door. -

Planking options

Don Case replied to Don Case's topic in Building, Framing, Planking and plating a ships hull and deck

You should have seen them before I moved them the first time! That's a good point though. I'll look and see if I can improve that. -

HMS Discovery 1789 by Don Case - 1:48

Don Case replied to Don Case's topic in - Build logs for subjects built 1751 - 1800

Whew, thanks Druxey -

HMS Discovery 1789 by Don Case - 1:48

Don Case replied to Don Case's topic in - Build logs for subjects built 1751 - 1800

I have the lower deck clamps in. I had to unglue about 1/4 of both upper clamps as I got a bit of a peak where the clamps joined and the second one wouldn't lay right. IPA loosens Aleene's tacky glue thankfully. The aft end is a bit strange compared to other ships I've seen. The clamp takes a hard turn before it gets to the transom. I managed but it was tricky. Spile and soak and bend. Are some other ships like this or have I done something wrong. Now I can plank up to the clamps I believe. Planking is fun because I get to see my mistakes disappear row by row. Sometimes they get replaced rather than disappear. -

This is truly an education Druxey, thank you🙂

- 433 replies

-

- open boat

- small boat

-

(and 1 more)

Tagged with:

-

Aleenes Tacky glue

Don Case replied to Don Case's topic in Building, Framing, Planking and plating a ships hull and deck

It does stay flexible but I tested it on a couple of scraps of wood and it is plenty strong. I'll use it up and then buy ordinary PVA. -

Treenail holes

Don Case replied to Don Case's topic in Building, Framing, Planking and plating a ships hull and deck

I hadn't really decided much past past drilling the holes. I know they should not be obvious. I was looking a thread that used the "fill with dust" method and another that used filler so I'm seriously considering one of those. I'll probably be planking the whole ship but I thought that I could get some practice doing these things where it won't show. Maybe I'll do a pass on treenails on the interior. I guess Google must be listening to me because when I started thinking about this up pops an add from Banggood for a tiny(about 4" long) USB powered drill. It was $10Can so I ordered one. it's going to take six weeks to get here but we'll see. Most of the comments said it's underpowered which is to be expected but one person said they hopped it up with a 9 volt battery and it works a lot better. As long as you don't let out the factory smoke. -

Aleenes Tacky glue

Don Case replied to Don Case's topic in Building, Framing, Planking and plating a ships hull and deck

It says on their website that it is a PVA glue. Does that change anything?

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.