Don Case

Unsubscribed-

Posts

482 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Don Case

-

HMS Discovery 1789 by Don Case - 1:48

Don Case replied to Don Case's topic in - Build logs for subjects built 1751 - 1800

I've been kind of stumped here. Trying to make the transoms and I don't really know what the underwater stern looks like. This is what I get for building a ship with no plans(Insert a rounding course of "I told ya so" here😉) I have the sections and the waterlines which gives me a rough Idea but I'm not experienced enough to get a solid picture of what it looks like. I've used three family sized cereal boxes making patterns. I re-used Longridge's jig that I used for the forward cant frames but it doesn't seem to work as well for the transoms. I've resorted to sticking together a stack of "transoms" that I can just grind away at with the drum sander. It's a lot easier in 3D. I have all the patterns of stations and waterlines to check my progress as I go. Tomorrow should show some progress. Deciding where to cut them off to fit the fashion pieces will be stressful. -

Thanks guys. Yes I am considering casting. I'll have to do a little reading/watching.

-

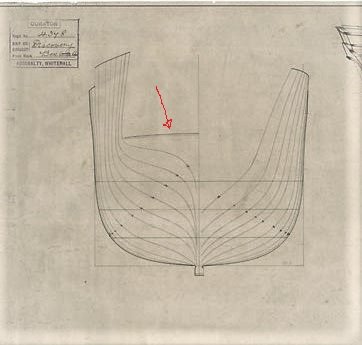

Body plan line

Don Case replied to Don Case's topic in Building, Framing, Planking and plating a ships hull and deck

I've taken a closer look, it's got to be the transom. -

No I don't have a top slide. I'm looking for one as it would make it much easier. One of the problems is that i only have to make 10 guns. A compound slide is about $100 for a cheap one. That's $10 a gun. Now if I was making 100 guns🙂. My glue dried so i haven't worked on this for a few days. I keep thinking that there should be a way. I could turn a taper between centers by using a dog and off centering my tailstock. I'll keep this on a back burner for a while til I come up with a solution. The size of the lathe is a problem too. Everything seems to get in the way.

-

It's a Shoptask lathe/mill. I bought it new in 1990. I'm using .2 dia brass. 1:48 scale. I've done a bit of fiddling with tool height by putting feeler gauges under the tool. I think I've got it working OK now. Very little chatter and a nice finish. I'm using a 1/16" cutoff tool with no rake. Getting the rings to scale is tough. I'm toying with the idea of turning a smooth taper and then wrapping and soldering a very thin copper wire around it for the rings. That may be just as cumbersome.

-

HMS Discovery 1789 by Don Case - 1:48

Don Case replied to Don Case's topic in - Build logs for subjects built 1751 - 1800

Thanks guys. Yeh, blocks, that's going to be a challenge.😕 -

Thanks Bob. I did look but I must have put in the wrong parameters. I thought "turning small brass" would do it but all I got was turning brass on a wood lathe. The internet and I used to get along but lately, not so much. I'll take a peek at those sites.

-

I'm taking a shot at making my own guns. I'm making 10 four pounders. If I figured it right they are 1.75" long and taper from .175 to .11. Any tips for turning brass that small? I seem to remember from high school 60 years ago that the cutting tool should scrape more than cut and maybe the speed should be higher than steel. How about tool height? Any tips at all. Thanks

-

HMS Discovery 1789 by Don Case - 1:48

Don Case replied to Don Case's topic in - Build logs for subjects built 1751 - 1800

While you're waiting for glue to dry or some such thing is there some things that you shouldn't do ahead of time? Obviously some things have to wait but some should be OK. I've made all my timberheads and I was thinking of trying to make the guns. I was going to make a bunch of knees but I have to figure out how many different sizes there is. -

Making Knees

Don Case replied to Don Case's topic in Building, Framing, Planking and plating a ships hull and deck

I'll give that a try, it's still going to be a little cross grained though, isn't it. I guess it doesn't have to be that strong. I've got some Hazel heartwood that was too dark for matching my framing. It seems denser. Thanks -

Making Knees

Don Case replied to Don Case's topic in Building, Framing, Planking and plating a ships hull and deck

Hazel. It seems pretty solid. One of the first things that my father taught me was don't use wood with the grain across the wood. Don't want another "Ajax" here😃 -

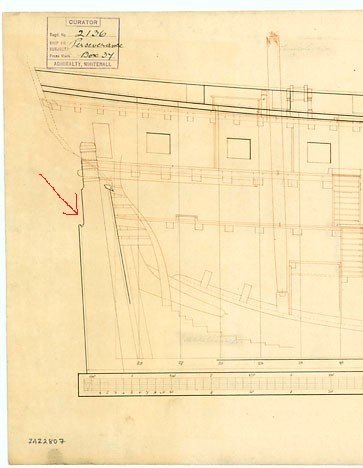

Thanks guys, I guess I'll have to make a decision here. I'm working on the aft cant frames and depending on how they settle in and how the last one(fashion piece) sits will decide where the wing transom goes. Some serious thinkin' and measurin' coming up. Allan, I had that drawing(second one) in my stuff with "unknown" as it's name. Now I know it's the Aquilon. Thanks. Oh, I got your book, nicely done thanks again🙂

-

I'm planning ahead for when I start needing knees. Finding enough natural crooks that small is unlikely so I have to saw them out. In order to make them reasonably strong how do you deal with the grain? Do you laminate them, lap the corners. miter them or just cut them willy nilly in any direction and hope they don't split?

-

I've reached the first real problem on the Discovery1789 build. I have no drawings of the stern. There is a couple of paintings but the old one is very pixelated and the other is recent(2012). The first problem that no drawings is causing me is the wing transom/fashion piece joint. Any drawings of ships of the era are usually of 50 or more guns meaning more decks. The Discovery only has two decks(depending on how you count them sorta) there is just not as much going on in that corner. Steel says that the the wing transom sits on top of the fashion piece with a horizontal knee but is there something that actually ties the transom to the fashion piece? Mortice and tenon maybe? I've done some searching on here and on the web with no luck. Would anyone have a link to a build of the same era/size ship that may have some pictures of the framing of the stern? Thanks

-

Deadwood

Don Case replied to Don Case's topic in Building, Framing, Planking and plating a ships hull and deck

-

Deadwood

Don Case replied to Don Case's topic in Building, Framing, Planking and plating a ships hull and deck

Thanks guys. Allan- a follow up. On the pictures you posted the rudder has that notch close to the top. Some ships have it and some don't. Is it there for a reason? -

I've noticed in drawings that the deadwood is usually made up of two or more pieces. Would this be a set plan or was it just fill up the bow and stern with whatever was kicking around? Of course the end result had to be the right shape but did it matter how they arrived at that shape.

-

Sloping deck

Don Case replied to Don Case's topic in Building, Framing, Planking and plating a ships hull and deck

I was under the impression that cambered was referring to an even curve of the entire deck. Like both ends are a foot lower than the middle. This is not even. The deck has a bit of camber over it's length but then it drops off in the last 8-12" at the stem. -

Home made Drill Press Vise

Don Case replied to RichardG's topic in Modeling tools and Workshop Equipment

Nice job!! Will we be able to hear you scream when you drill the first hole in it?😉 -

HMS Discovery 1789 by Don Case - 1:48

Don Case replied to Don Case's topic in - Build logs for subjects built 1751 - 1800

I was starting to have to be on both sides to measure frame and gun port heights so I made a new bench. I'm working up the miles walking from one side to the other but it's way nicer to be able to get all around. It's 4' tall so it's easier on my back. -

I'm reaching the point in the Discovery build where I have to concern myself with gun ports. Everything I've read says that the Discovery had 10 4 pound guns but all the plans show 14 ports(7 per side). I have a modern painting that shows window panes in the forward two of the ports. How do I decide where the guns go? Since it wasn't a war ship would they maybe try to keep the guns under cover ie. not on the weather deck?

-

HMS Discovery 1789 by Don Case - 1:48

Don Case replied to Don Case's topic in - Build logs for subjects built 1751 - 1800

My first major screw-up. Somehow I managed to get the first three hawse pieces 1/4" to short. Soggy old brain I guess. Removing and replacing was out, they are glued in too well. I tried IPA and they just don't want to move. So I'm scabbing little pieces on the top. It will be planked over but I'll always know😒 -

Electric sanding belt file

Don Case replied to Don Case's topic in Modeling tools and Workshop Equipment

WEN 6307 Variable Speed Detailing File Sander with 1/2-by-18" Belt: Amazon.ca: Tools & Home Improvement There ya go -

Electric sanding belt file

Don Case replied to Don Case's topic in Modeling tools and Workshop Equipment

I know exactly what you're talking about and you can rant all you want on my threads. This was just one of those occasions that I thought a two use tool might fit the bill but but in a recent survey 2 out of 3 said they didn't like this kind of tool and the third was undecided😃😃😃

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.