Daniel Kimmer

NRG Member-

Posts

42 -

Joined

-

Last visited

-

Canute reacted to a post in a topic:

Finishing Pear wood

Canute reacted to a post in a topic:

Finishing Pear wood

-

Mahuna reacted to a post in a topic:

Sherline Accessories for sale (Updated 9/10/2025)

Mahuna reacted to a post in a topic:

Sherline Accessories for sale (Updated 9/10/2025)

-

Keith Black reacted to a post in a topic:

Sherline Accessories for sale (Updated 9/10/2025)

Keith Black reacted to a post in a topic:

Sherline Accessories for sale (Updated 9/10/2025)

-

The short 90 degree angle plate arrived by mail this morning, thanks for selling it to me and for a very smooth transaction. It helps to have one for the Sherline Mill and just opens up a new degree of creativity. I already have the other items listed except the Lathe Vertical Milling Column. Since I own both the mill and the lathe not sure how the vertical column would be needed. The prices certainly are very fair and the right angle plate appears as if was never used. Thanks again.

-

Nirvana reacted to a post in a topic:

Ultimation tools

Nirvana reacted to a post in a topic:

Ultimation tools

-

Canute reacted to a post in a topic:

Ultimation tools

Canute reacted to a post in a topic:

Ultimation tools

-

thibaultron reacted to a post in a topic:

Looking for ideas for work area

thibaultron reacted to a post in a topic:

Looking for ideas for work area

-

RossR reacted to a post in a topic:

Ultimation tools

RossR reacted to a post in a topic:

Ultimation tools

-

Looking for ideas for work area

Daniel Kimmer replied to Desertanimal's topic in Modeling tools and Workshop Equipment

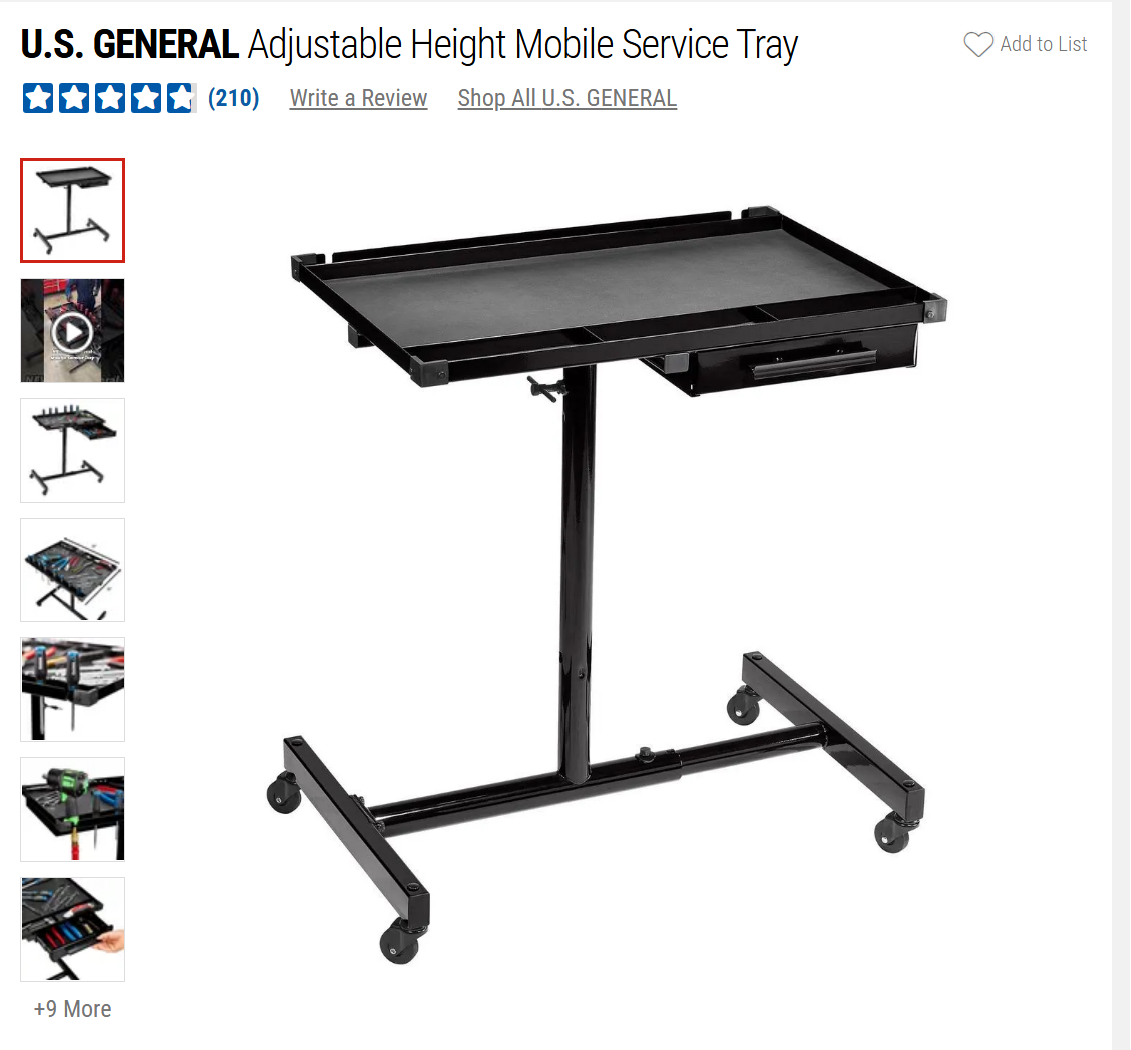

I purchased an Adjustable height mobile service cart from Harbor Freight. It has wheels and I placed a homemade build slip using 3/4 plywood and universal T track from Rockler. Built some slides to support the work. The table rolls and I move it to the position I need it to work. If I need to push it out of the way I do. The 12 x 12 tool tray stores the tools I need for the work I'm doing. Works great for me. -

I own both of them and you will be amazed at how well they work. Did you also purchase the repeater? When I purchased mine I bought the extra mats and the extra replacement blades. The repeater works well when cutting deck planking. Hope you enjoy it, pretty nifty tools. Expensive but I think worth the money. Others will argue they are not but we all have opinions.

-

I'm happy that it works for you. What is the brand? Please keep us posted it it works over the long run. I could use another inexpensive lamp that holds position. The ones I purchased never seemed to hold position. I would move it to a position where I needed it and the lamp, over a few minutes would sag at the joint. and come out of position. I was always having to tighten the wingnut and add tape or wedges to keep it in position. I even tried several of the lamps from different manufactures and always had the same result. I finally gave up and spent way more than I should for a Laguna Tools Chameleon LED Lathe Light. You can mount it with a clamp or you can mount it direct using screws. Very pricey but fully adjustable and always stays in place. The lamp has adjustments for brightness and the type of light from cool to very white. I was able to pick mine up on sale. I now have two of them.

-

Please explain razor saws to me

Daniel Kimmer replied to nheather's topic in Modeling tools and Workshop Equipment

you will enjoy using it, just remember to let the saw do the work. It is very sharp and will make very fine cuts. Just take your time. Great selection on your part. -

Please explain razor saws to me

Daniel Kimmer replied to nheather's topic in Modeling tools and Workshop Equipment

Most of the cutting I do by hand is done by a Ultra Thin Kerf Razor Saw 32tpi. It cost around 10 $. The wood I cut generally is not very thick. I have a small chop / miter saw from Proxxon for any larger wood. I have several of the zona saws but i find the ultra thin kerf razor saw to be my "go-to". -

Keith, You stated " The wood used also comes into play. At times I have to mix lighter woods with darker woods to make a piece." Is there wood you need that you don't have or a shade of wood you require. I have a lot more if you need more. Let me know. I have more mahogany, walnut, yellow cedar, and cherry. After reviewing your latest photos I definitely think you really need to keep building models long enough to build a second donkey pile driver where the boiler engine assembly is not covered by a shed, or at least consider having a side panel open where you can see the works inside. All the detail you put into building an accurate boiler engine assembly should not be covered up. Either way keep up the excellent work, I love the detail. Dan

-

Ras, I am so envious of your skill. I have all the tools, (lathe, milling machine, soldering unit, etc.) but lack your skill. I'm 67 so I have time to improve. I think the brass and all the detailed work truly makes for a great focal point and just looks fantastic. Your model is a great inspiration to the many of us that lack the skill but can dream. Keep up the incredible work.

- 128 replies

-

- zulu

- sternwheeler

-

(and 1 more)

Tagged with:

-

Keith, Awesome build so far, I really like the detail you add to the model. I think you should build two of the floating pile drivers. Have one with the steam engine exposed and the other in a shed, you could then have the best of both worlds. The diorama would be slightly larger, but you could make it work.

-

Keith, I've been following along on your latest project. I took the time to read your entire USS Tennesse log and besides the detail of the build I enjoyed the history. I think your current log is awesome. If you need any more wood let me know. Happy to give you more. If you need a certain dimension also let me know. Like I told you, I enjoy spending time in the basement at the "saw mill" cutting and milling. Dan

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.