Michael_A

Members-

Posts

42 -

Joined

-

Last visited

About Michael_A

- Birthday 02/26/1963

Profile Information

-

Gender

Male

-

Location

Lyndeborough, NH

-

Interests

Ancestral health, fitness, nordic skiing, trail running, working with my hands

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Colin B reacted to a post in a topic:

Marblehead Pond Yacht by Michael_A - 1:1 - RADIO - 1940s design by J Selmer Larson

Colin B reacted to a post in a topic:

Marblehead Pond Yacht by Michael_A - 1:1 - RADIO - 1940s design by J Selmer Larson

-

KeithAug reacted to a post in a topic:

Marblehead Pond Yacht by Michael_A - 1:1 - RADIO - 1940s design by J Selmer Larson

KeithAug reacted to a post in a topic:

Marblehead Pond Yacht by Michael_A - 1:1 - RADIO - 1940s design by J Selmer Larson

-

KeithAug reacted to a post in a topic:

Marblehead Pond Yacht by Michael_A - 1:1 - RADIO - 1940s design by J Selmer Larson

KeithAug reacted to a post in a topic:

Marblehead Pond Yacht by Michael_A - 1:1 - RADIO - 1940s design by J Selmer Larson

-

aechmea reacted to a post in a topic:

Marblehead Pond Yacht by Michael_A - 1:1 - RADIO - 1940s design by J Selmer Larson

aechmea reacted to a post in a topic:

Marblehead Pond Yacht by Michael_A - 1:1 - RADIO - 1940s design by J Selmer Larson

-

aechmea reacted to a post in a topic:

Marblehead Pond Yacht by Michael_A - 1:1 - RADIO - 1940s design by J Selmer Larson

aechmea reacted to a post in a topic:

Marblehead Pond Yacht by Michael_A - 1:1 - RADIO - 1940s design by J Selmer Larson

-

aechmea reacted to a post in a topic:

Marblehead Pond Yacht by Michael_A - 1:1 - RADIO - 1940s design by J Selmer Larson

aechmea reacted to a post in a topic:

Marblehead Pond Yacht by Michael_A - 1:1 - RADIO - 1940s design by J Selmer Larson

-

Roger Pellett reacted to a post in a topic:

Marblehead Pond Yacht by Michael_A - 1:1 - RADIO - 1940s design by J Selmer Larson

Roger Pellett reacted to a post in a topic:

Marblehead Pond Yacht by Michael_A - 1:1 - RADIO - 1940s design by J Selmer Larson

-

G.L. reacted to a post in a topic:

Marblehead Pond Yacht by Michael_A - 1:1 - RADIO - 1940s design by J Selmer Larson

G.L. reacted to a post in a topic:

Marblehead Pond Yacht by Michael_A - 1:1 - RADIO - 1940s design by J Selmer Larson

-

GrandpaPhil reacted to a post in a topic:

Marblehead Pond Yacht by Michael_A - 1:1 - RADIO - 1940s design by J Selmer Larson

GrandpaPhil reacted to a post in a topic:

Marblehead Pond Yacht by Michael_A - 1:1 - RADIO - 1940s design by J Selmer Larson

-

GrandpaPhil reacted to a post in a topic:

Marblehead Pond Yacht by Michael_A - 1:1 - RADIO - 1940s design by J Selmer Larson

GrandpaPhil reacted to a post in a topic:

Marblehead Pond Yacht by Michael_A - 1:1 - RADIO - 1940s design by J Selmer Larson

-

Bitao, a breathtaking model. Really a stunning achievement on so many levels. Thanks for sharing with us all. Michael

- 257 replies

-

- young america

- Finished

-

(and 1 more)

Tagged with:

-

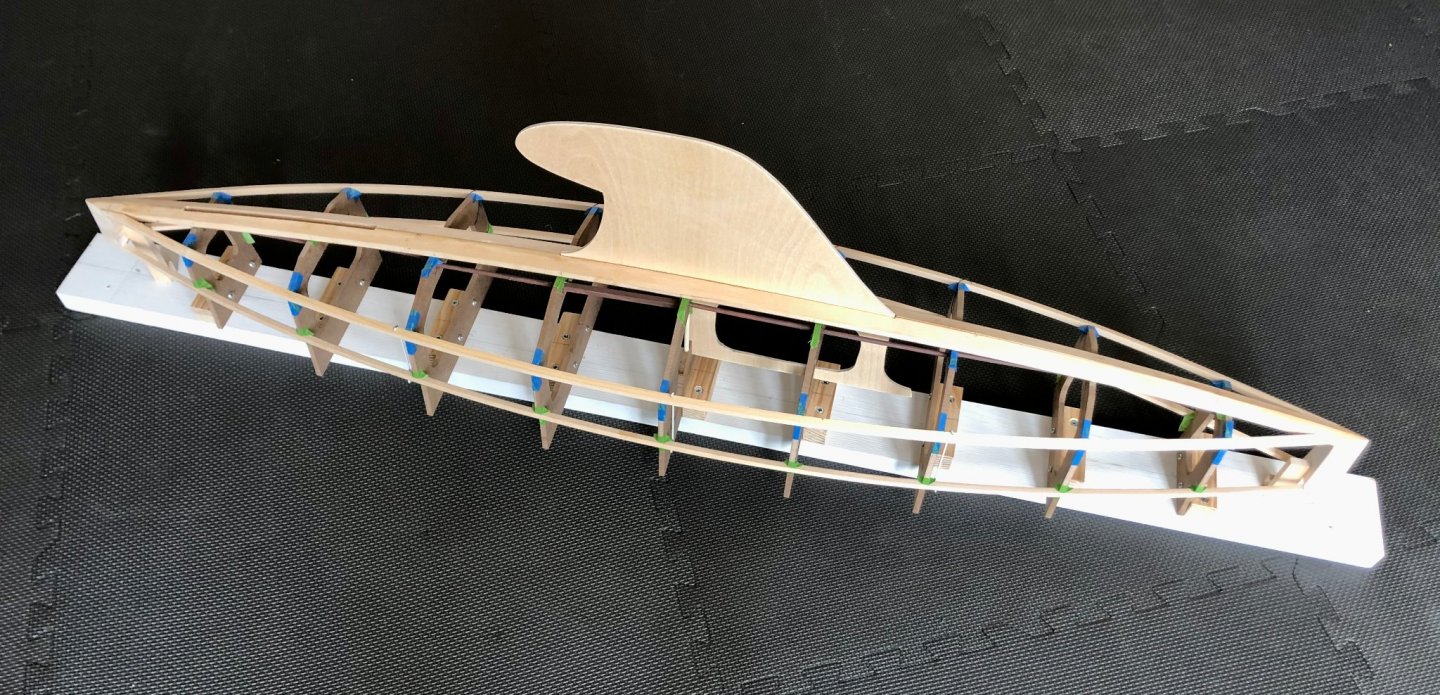

Time to put on the two side planks! These are made from 1/16" 3ply birch plywood, from Boulter Plywood in Boston. It's an amazing material – stiff and very light – and the surface is very clean. Here's my first try at wrapping the ply around the hull: I epoxied the side onto the framework, holding it on with as many clamps as I own. I guess you can never have too many clamps! I pinned the planks to the chine using toothpicks to prevent any shifting as the glue dried. The epoxy has no holding power when it is wet .... Finally, I made a tiny transom to cover the blocks at the stern (and bow). Eventually the bow will have a rounded "bumper" in case there are any collisions. Next step is to put on the bottom. Back to you all soon!

- 10 replies

-

- Marblehead

- radio

-

(and 1 more)

Tagged with:

-

Jond, such a beautiful choice of a boat and the historic photos really add interest to the overall project. I am guessing when the schooner was fully loaded it would sit quite a bit lower in the water? I figure your hull is about 36" long at this point? I enjoy these larger scale builds.

-

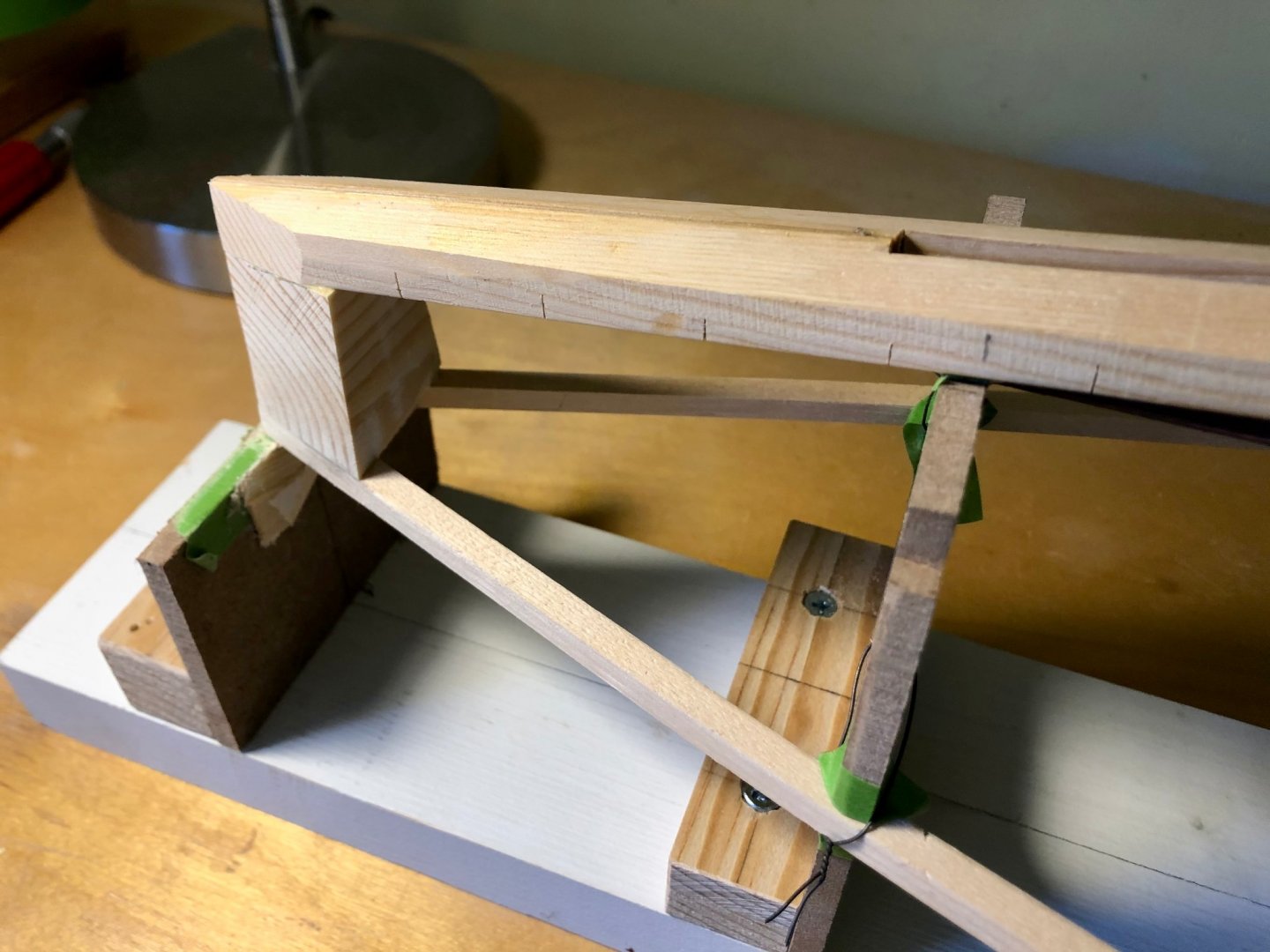

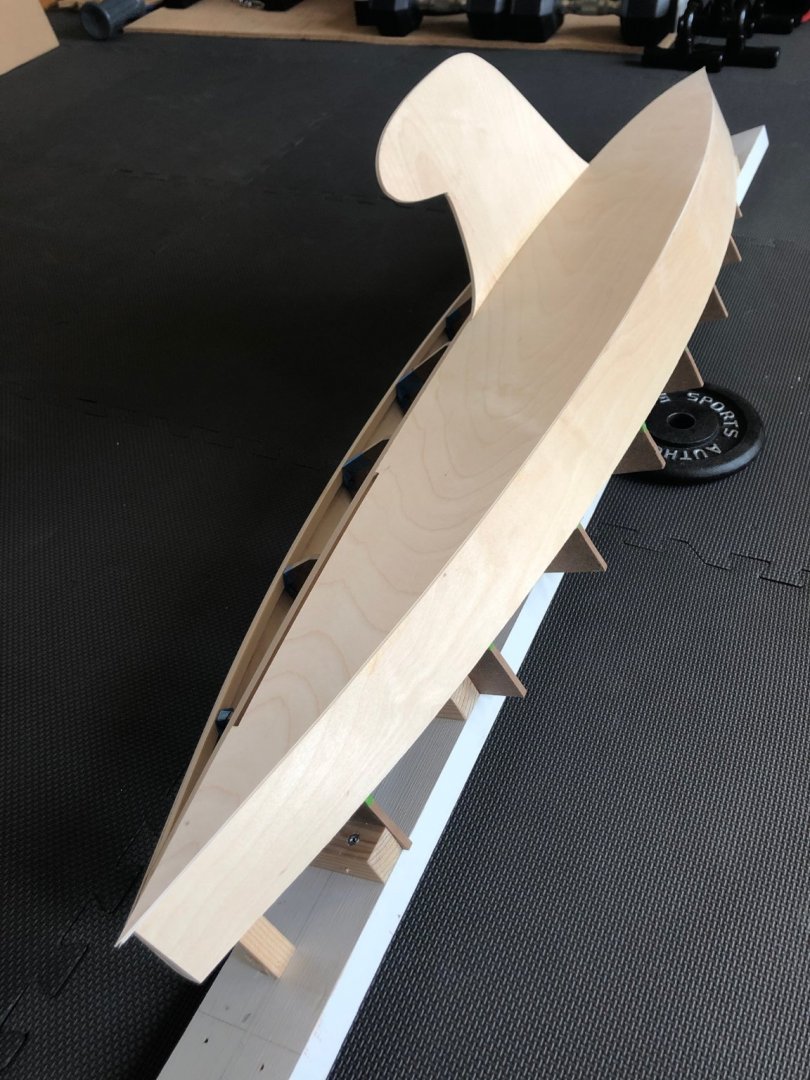

Hello all, Now that I have the molds in place I decided to use a block for the stem and transom. It weighs a little extra but gives me plenty of gluing surface, and I don't think the weight will make a big difference. Fun to get all the angles squared away! I am using the second power tool I purchased for this project; a 12" disc sander from Harbor Freight. It works great. I glued the keelson over the molds and attached it to the sheer clamp using the blocks at both the stem and stern. Twisted wire worked well for the clamps. Here's a view of everything so far, including the chine logs which I bevelled in advance. Note, the spruce keelson was too thick (too stiff) so I had to cut into it every few inches to make it more flexible. Starting to look more like a boat now! I have glued the keel fin into the keelson to make it one solid structure. I will reinforce the keel later as it has to hold a 10lb lead bulb. Thanks for reading and I will post more progress soon. I hope you all had a great weekend!

- 10 replies

-

- Marblehead

- radio

-

(and 1 more)

Tagged with:

-

Ian, Thanks for the encouragement. I've pretty much made up my mind to complete this with RC. I may try to find someone to help me to the RC setup when I reach that point.

- 10 replies

-

- Marblehead

- radio

-

(and 1 more)

Tagged with:

-

Roger, Fascinating! Was the paper you used the thickness of office copy paper? Shellac on both sides? Do you think it would be possible to lay down a long pre-made strip, all at once? Or would that have caused alignment issues. Can't wait to see this once it is painted the final color which I assume will be darker.

-

Exactly! There are a lot of forces on a sailing model so the hull and rig have to be very strong. The bow will have a "bumper" to reduce damage in the case of a collision.

- 10 replies

-

- Marblehead

- radio

-

(and 1 more)

Tagged with:

-

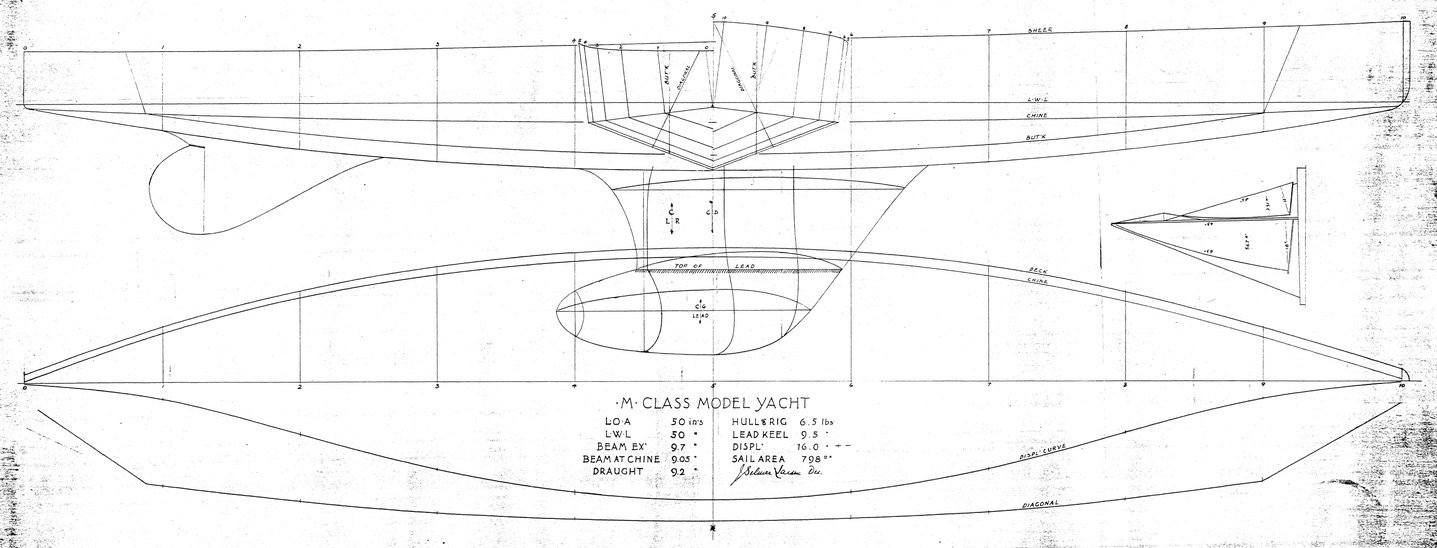

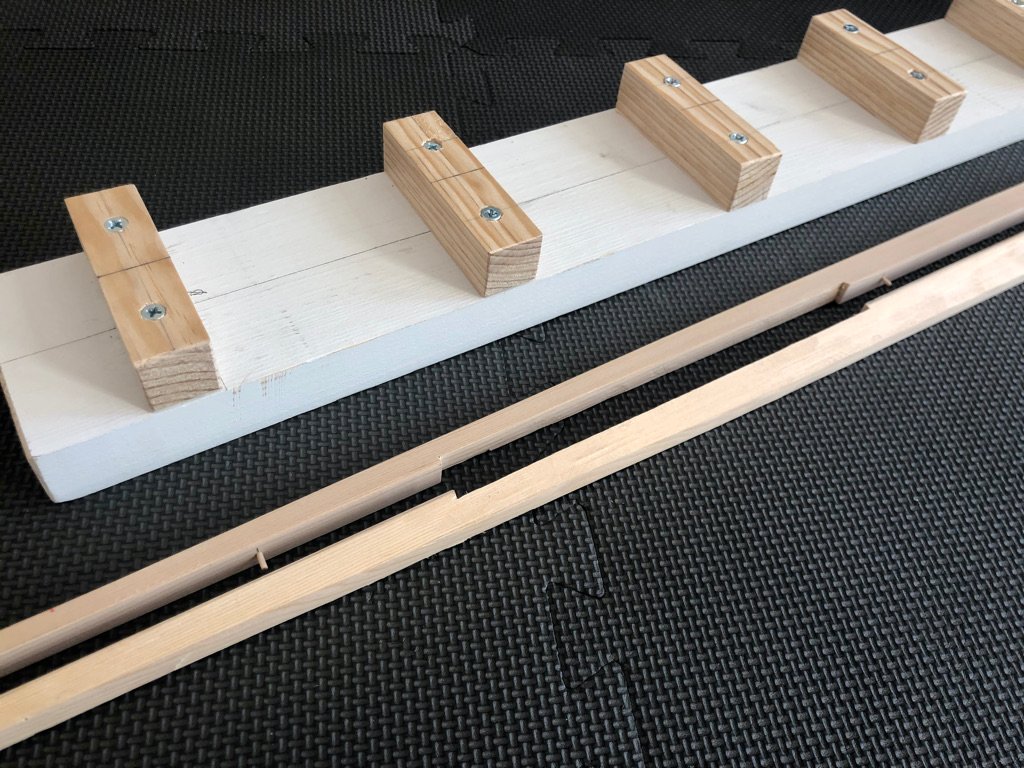

Hello everyone, I started this model a few months ago and am creating this build log (my first) so I can show the progress to date and get advice moving forward. I have to say I am feeling a little nervous! The boat is a 50" model yacht of the Marblehead class. This class was started in the Depression era when, like now, people had more free time on their hands. These models were designed to sail in ponds (like the one in Central Park in NYC). Initially they would sail on their own and be redirected by the owner at the edge of the pond, with a stick. Now, they are mostly radio control. I'm more interested in building than sailing so we'll see how far I progress in that area. The design is by J. Selmer Larson, a well-known sculptor during that time. I love the hull design and am interested in working with aircraft plywood. I am really interested in seeing how well I can do using the tools I already own – I don't want to buy a lot of stuff just for this model. Here's the strongback (materials from Home Depot) and the beginning of the keel. It's in two halves to make it easier to form. I don't own a table saw so most of my timber will be standard dimensional spruce. Here are the molds, and my first pass at the keel fin. Parts of the fin will extend up to the deck to support the mast. Molds are made of MDF and the fin is two layers of 1/16" aircraft plywood epoxied together; to be built up and strengthened later on. I do admit, I bought a nice jigsaw just for this model; even so the molds do not feel very accurate. I can fair up the hull later as I get more into it (I hope). Sheer clamps are now on the molds. If I accomplish nothing else, I am proud of the joint! The hull is double ended so the bow is easy ... but then the stern has to be just right as there's no going back at that point. Here's the framework with the sheer clamps installed. It all feels a bit wobbly so I put some dowels between the molds to add some rigidity. If you look carefully you can see my high-tech twisted wire clamps. The green tape will help keep the boat itself from being glued to the molds. At least that is the plan. I"m not sure how I will get the boat out once it is planked either. That's all for now! My main takeaway so far: A huge amount of thought and planning is required for each step. Once the planning is done the actual "work" takes very little time at all. I was surprised how far you have to think ahead to make sure everything will work out at the end. I'm guessing this is an experience most of you all are very familiar with. Thank you all for your attention and I hope to post more soon.

- 10 replies

-

- Marblehead

- radio

-

(and 1 more)

Tagged with:

-

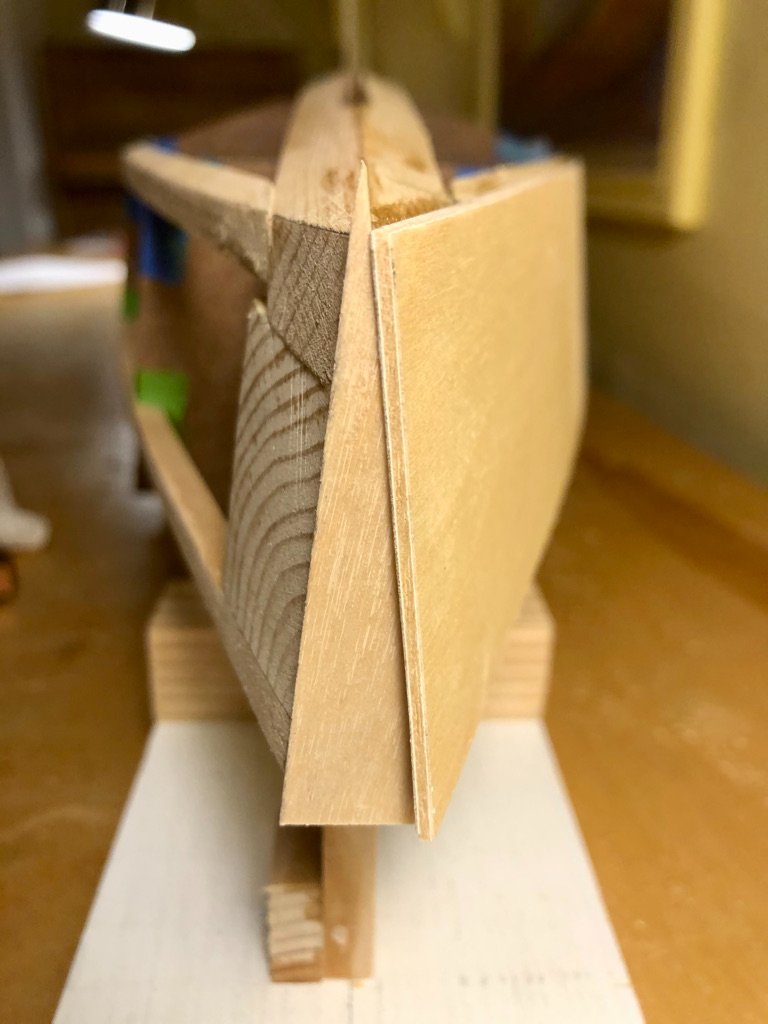

Hello all, I am at a key point in my Marblehead model but am having a crisis in confidence. I have epoxied on a bottom "plank" of 1/16" plywood and it is overhanging the side by about 1/16". I need to bring it flush to the sides without damaging the finish of the plywood side planking which is actually a bit sensitive. The finish is very smooth and hard but it scratches, chips, tears easily if handled too roughly. I can't mask the sides with tape because it lifts off the grain ... Is this just a long slow careful sanding job or is there something I am missing? The bottom is about 50" long and the corner in question is perfectly fair; and I"m wanting to keep it that way. The two photos show a general view and a closeup; hopefully this is enough to see what is going on. Thanks, Michael

-

Nice job with the blocks! I'm working on a v-bottom model myself and have experienced first hand how many different planes intersect in this area. Howard Chapelle's writes about these blocks in "Boatbuilding" but even after reading several times I'm not entirely clear about them. Michael

- 20 replies

-

- Breezin Thru

- Wye River Models

-

(and 1 more)

Tagged with:

-

Shore thing, The V bottom looks nice. Can you show us a side view of your progress? It looks like no side planking is on yet? Seems like you are making the best of it, all things considering! Michael

- 20 replies

-

- Breezin Thru

- Wye River Models

-

(and 1 more)

Tagged with:

-

Roger, I find this fascinating! For the last few weeks I have been reading C. V. Waine's wonderful books on British Steam Coasters and am anxious to hear about both how you will plate this model; and what methods have been discarded as impractical. Please share as much as you can! Your posts are an inspiration for my next model which may well be a steel plated craft. Michael

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.