-

Posts

1,407 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Ferrus Manus

-

I made the 30 cleats that this model will need. There might be a few extras by the time I'm done. The main braces and sheet will belay to kevels, as well as both fore and main lifts. That means 8 kevels, which I have not made up yet. Other than that, not much to report. I hope they look halfway decent when I paint them. I guess they'll be covered in rope anyway.

- 176 replies

-

- la reale de france

- heller

-

(and 2 more)

Tagged with:

-

Also, the loosened shrouds on the lee side of the masts are an accurate detail I have almost never seen correctly depicted in lateeners before. This makes me want to do another caravel kit at some point.

- 508 replies

-

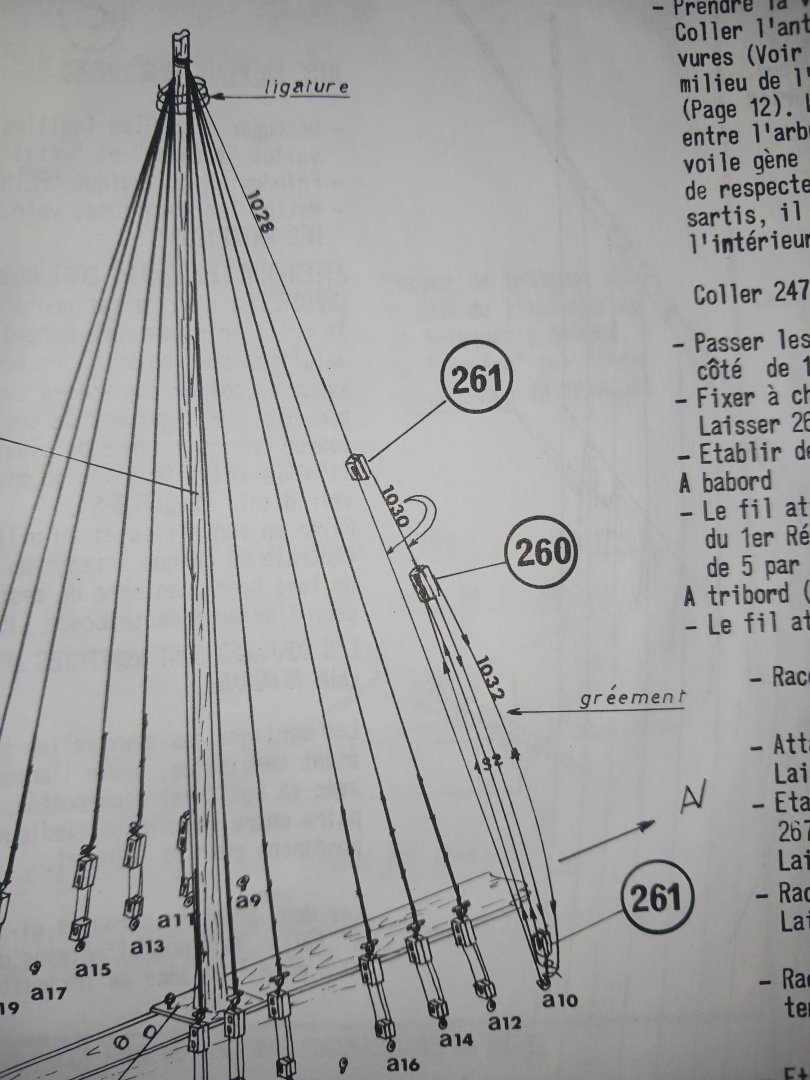

You should simplify the rig. Only one sheet would make tacking the yard simpler, and because the yard swings in front of the mast on a medieval lateener, all lines must be swung around the mast and shrouds. Check out how I rigged my Portuguese caravel. You should have a hook on the one sheet block and an eyebolt and cleat setup on both sides, but only one will be used at a time. The idea of using multiple sheets for a fore-and-aft sail originates with the invention of staysails almost 500 years later. I highly doubt the use of double sheets ever happened on lateeners especially in this era. Moreover, I doubt the use of vangs would make much of a difference, even though I used them on my caravel. The vangs would not be as effective at positioning the yard as the braces/tacking tackle would be. If vangs were used, the blocks would not be positioned right up against the yard. There would be a section of standing line between the blocks and the yard to allow them room to move. Also, vangs would make more sense further forward on the yard, as that gives them the ability to tack the yard to a greater angle. To make a long story short, I would redo most of the rigging of each sail aft of each mast. The lifts and parrels look perfect and the fore rigging makes sense.

- 508 replies

-

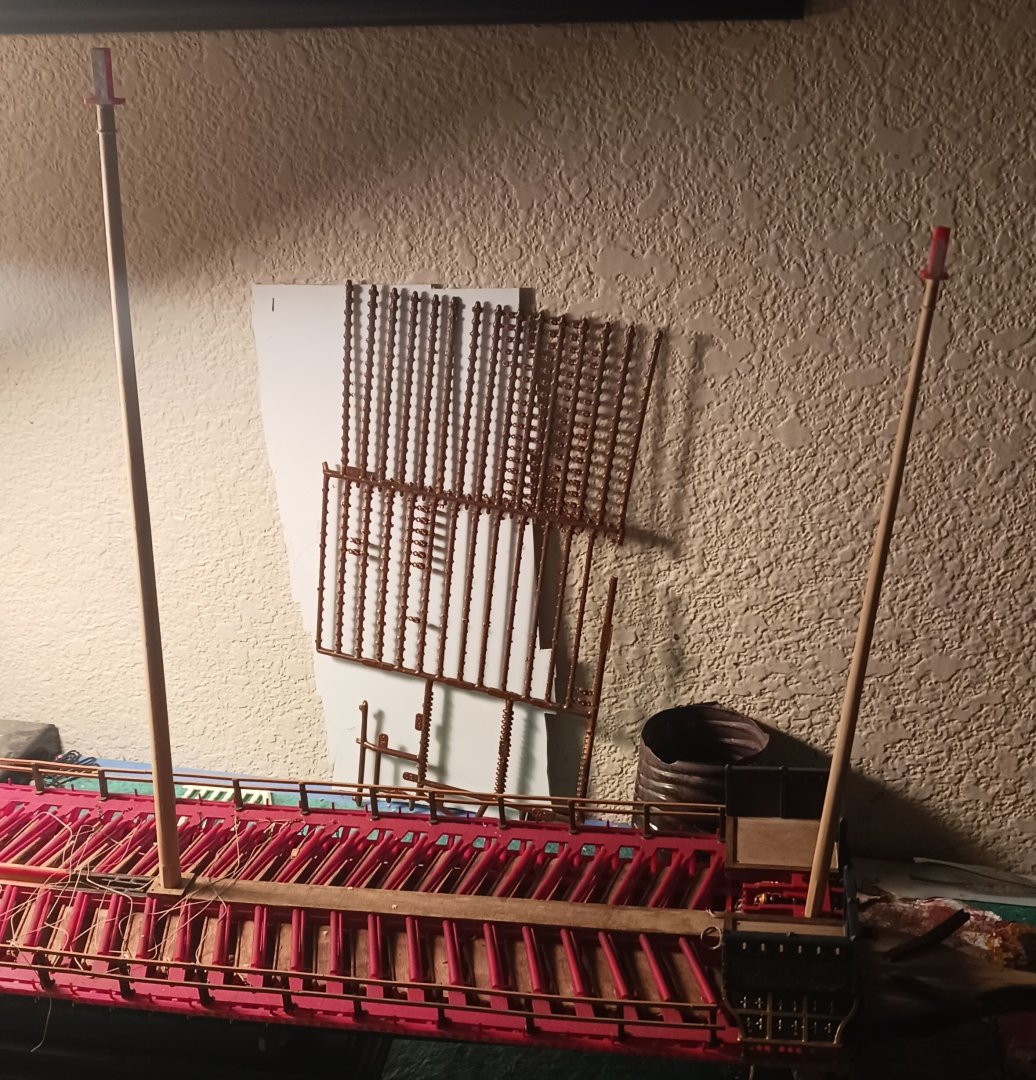

The modelling I have done in the past few days includes making up the yards (including their lashings) and making and installing the ship's ladders. Next up is the construction and mounting of about 30 cleats, plus a few kevels, and a bunch of eyebolts.

- 176 replies

-

- la reale de france

- heller

-

(and 2 more)

Tagged with:

-

I got the fore shrouds done a couple days ago, and I am now working on the yards. In order to complete the rope coils for the fore shrouds, I need to go to the model shop and get medium thickness tan thread, as well as medium brown thread for other stuff, namely the yard lashings. I also need cleats.

- 176 replies

-

- la reale de france

- heller

-

(and 2 more)

Tagged with:

-

I have gotten started with the fore shrouds. Getting the eyebolts to stay in their holes was a challenge, but it worked out fine. I have not taken pictures of the rope coils I made and affixed to the main shrouds, but they did get done.

- 176 replies

-

- la reale de france

- heller

-

(and 2 more)

Tagged with:

-

That's interesting, because I have been trying specifically to take my time and put more effort into the smaller details on this one. I can't sacrifice quality on a model like the Reale, even though I don't think I can get it to truly professional standards.

- 176 replies

-

- la reale de france

- heller

-

(and 2 more)

Tagged with:

-

- 176 replies

-

- la reale de france

- heller

-

(and 2 more)

Tagged with:

-

I added the shrouds after getting the tackles done. The ship is now becoming a "rat's nest" at least temporarily. The work I have done on the aft shrouds has corrected the two issues I talked about earlier. In other news, I made my first proper seizing using Olha Batchvarov's technique. The reason this is my first is I can't seem to get my small line to do this. I would like to get at least most of the rest of the main shrouds done tomorrow.

- 176 replies

-

- la reale de france

- heller

-

(and 2 more)

Tagged with:

-

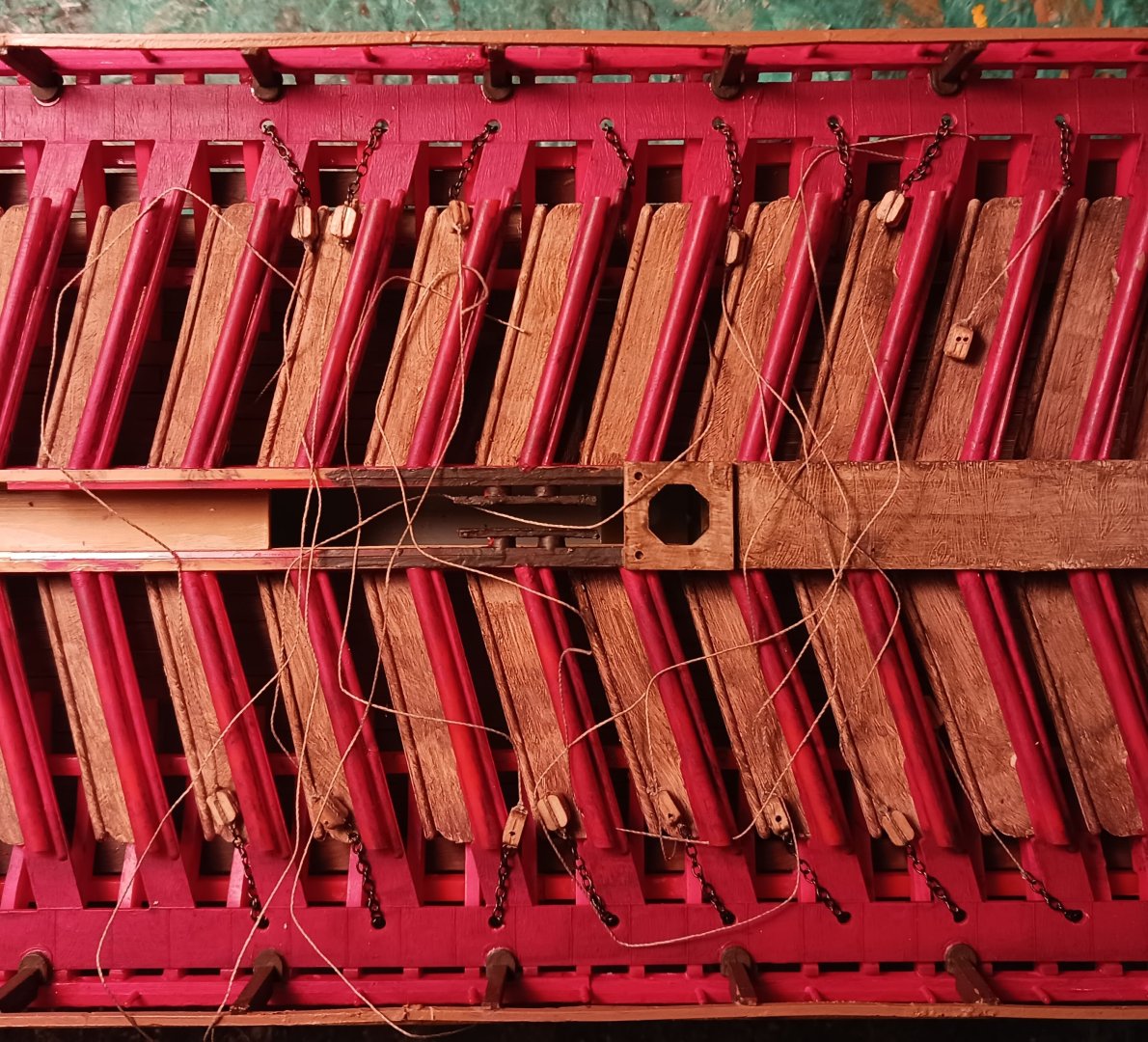

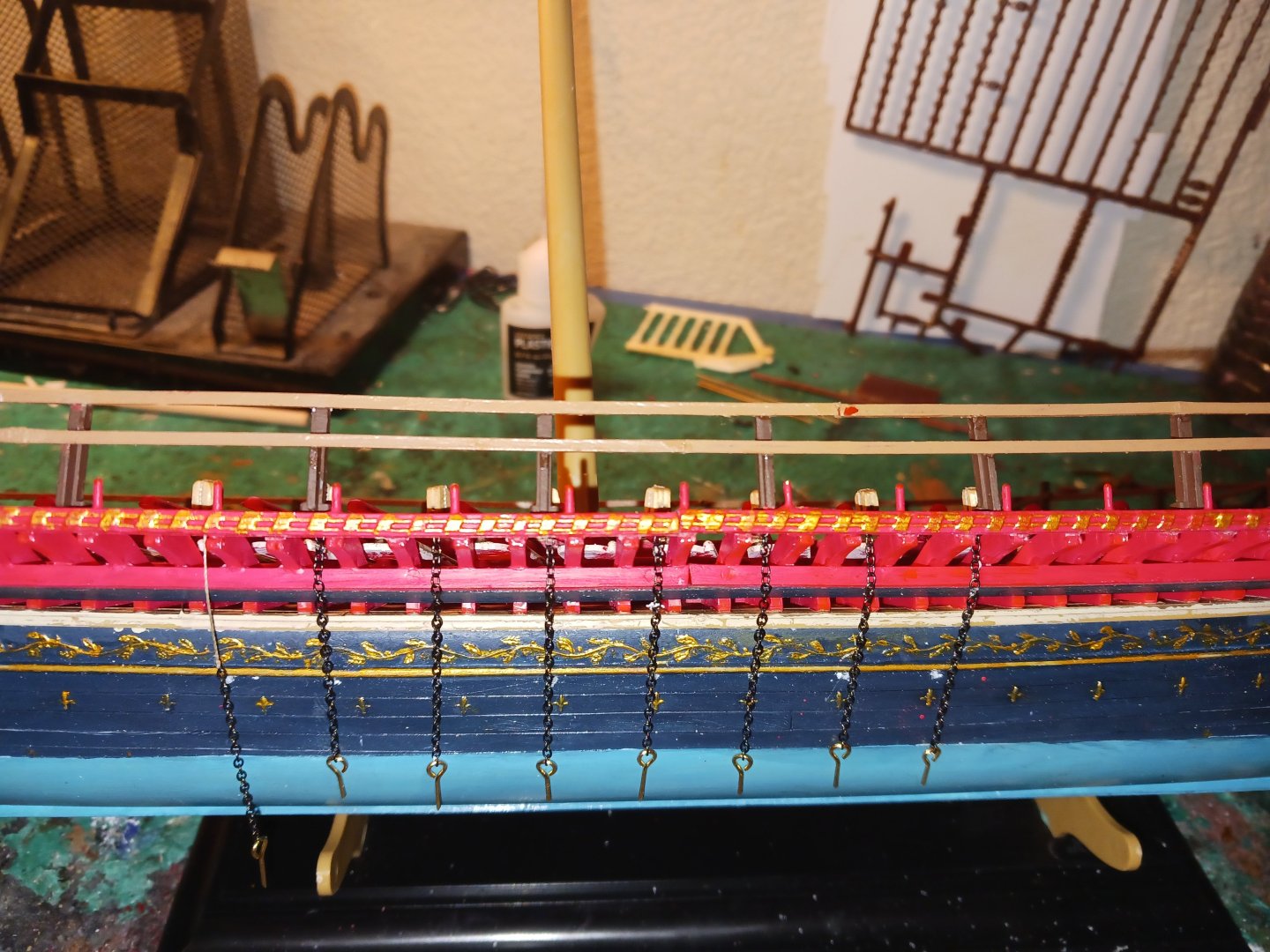

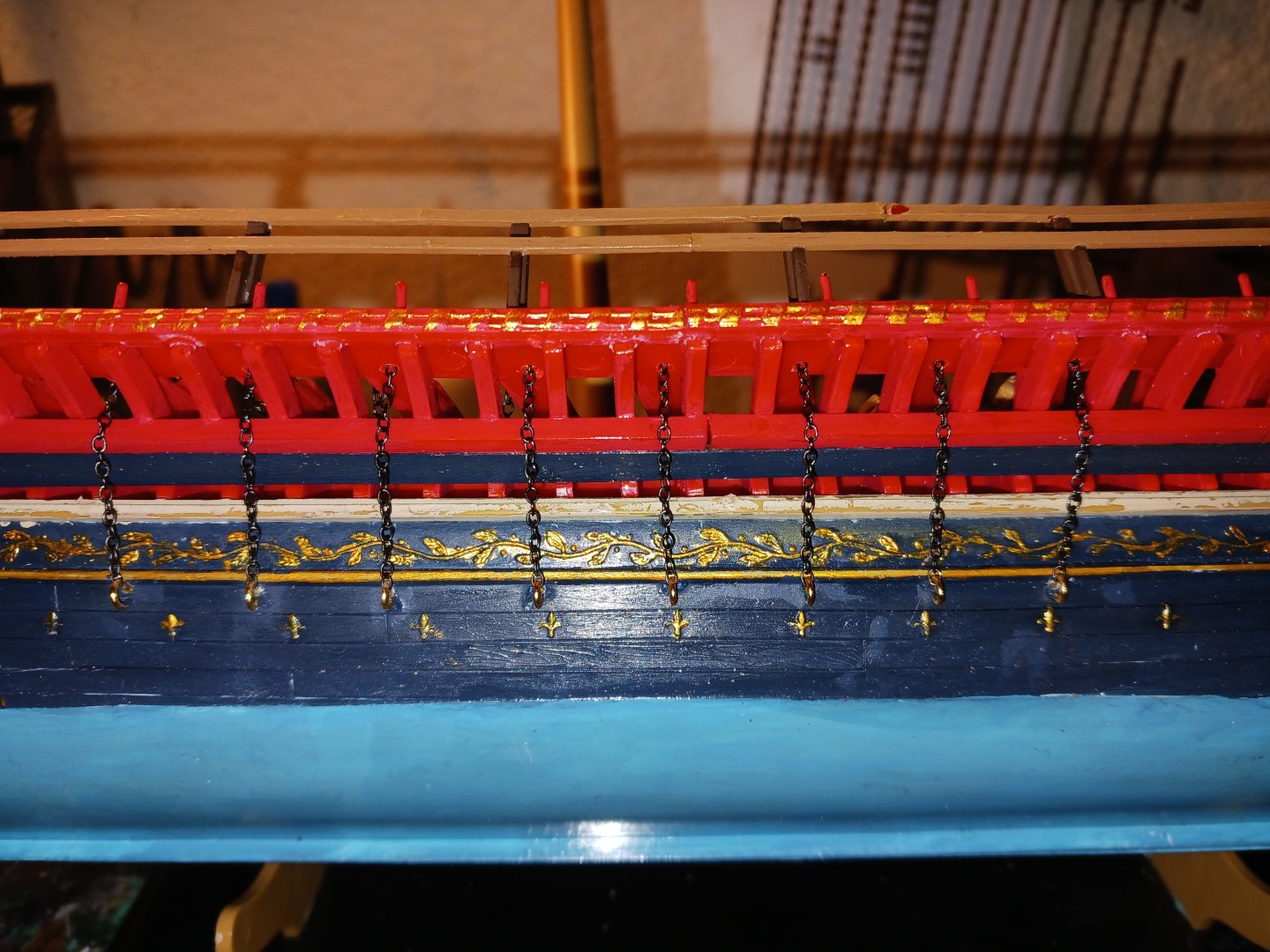

I did a simpler version of this. I chose to go with the logic of the actual shrouds and both hook and belay to the chain itself. This was the result: I think it's not bad. The noticeable curve in the mainmast and now-excessive forward rake will both be rectified by putting in the aft shroud pair first.

- 176 replies

-

- la reale de france

- heller

-

(and 2 more)

Tagged with:

-

It seems as though you belayed the runner on an eyebolt directly aft of the chainplate and the lanyard on a cleat to the fore.

- 176 replies

-

- la reale de france

- heller

-

(and 2 more)

Tagged with:

-

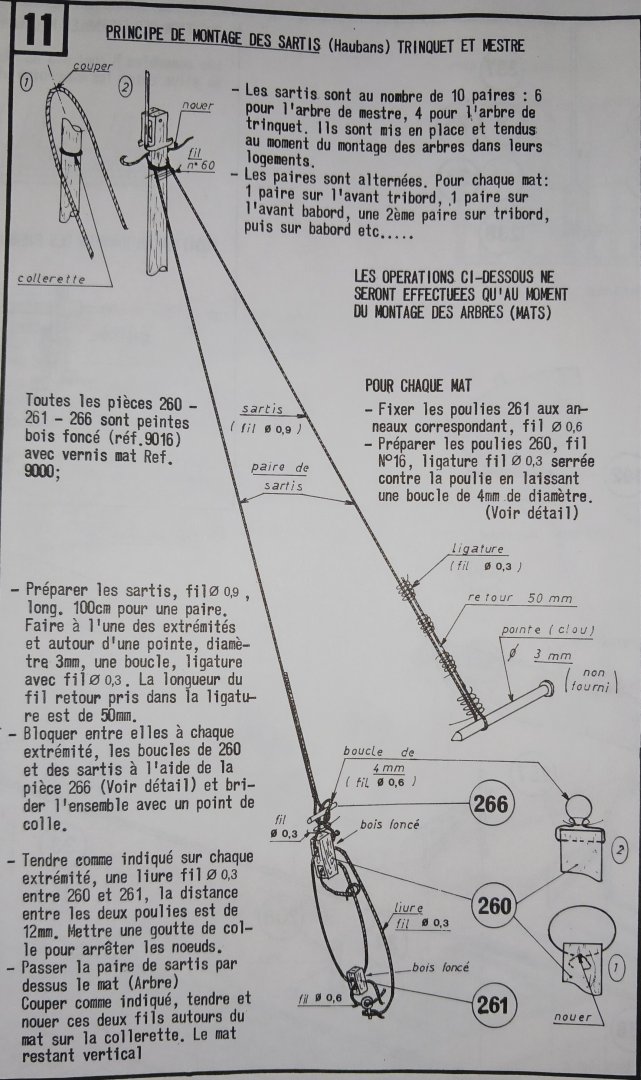

The work on the masts continued today. I took both masts out, assembled and installed their calcets, and put them back in to see how they looked. I fixed up the calcets beforehand by puttying over the ugly indentations. I ran sandpaper over the entirety of the mast assemblies to make my life easier down the road, to my great satisfaction later. Painting the masts was actually not that hard because of my sanding. Now, on to the second issue: This might be the first and only time I have actually agreed with Heller's instructions regarding rigging. This is how Heller sets up the forward shroud: If I remember correctly, 72Nova used a simpler double block tackle without the runner. I think the runner and tackle is more effective for this job because the crew has more control over the tension on the mast. Instead of any change in tension of the double block tackle being applied directly to the mast, it instead has to travel through another block/tackle system first. The only issue is where to belay the standing end of the runner. I can do this one of two ways. I can either make a hook and hook the line onto the uppermost chain link with the line for the lower double block, or I can run the line through the hole and belay it on the eyebolt that attaches to the hull. The problem with this is that the line would foul on the hole and the chain. So, option 1 it is.

- 176 replies

-

- la reale de france

- heller

-

(and 2 more)

Tagged with:

-

Today's work involved the setting up of the starboard chainplates, exactly as was done on the port side.

- 176 replies

-

- la reale de france

- heller

-

(and 2 more)

Tagged with:

-

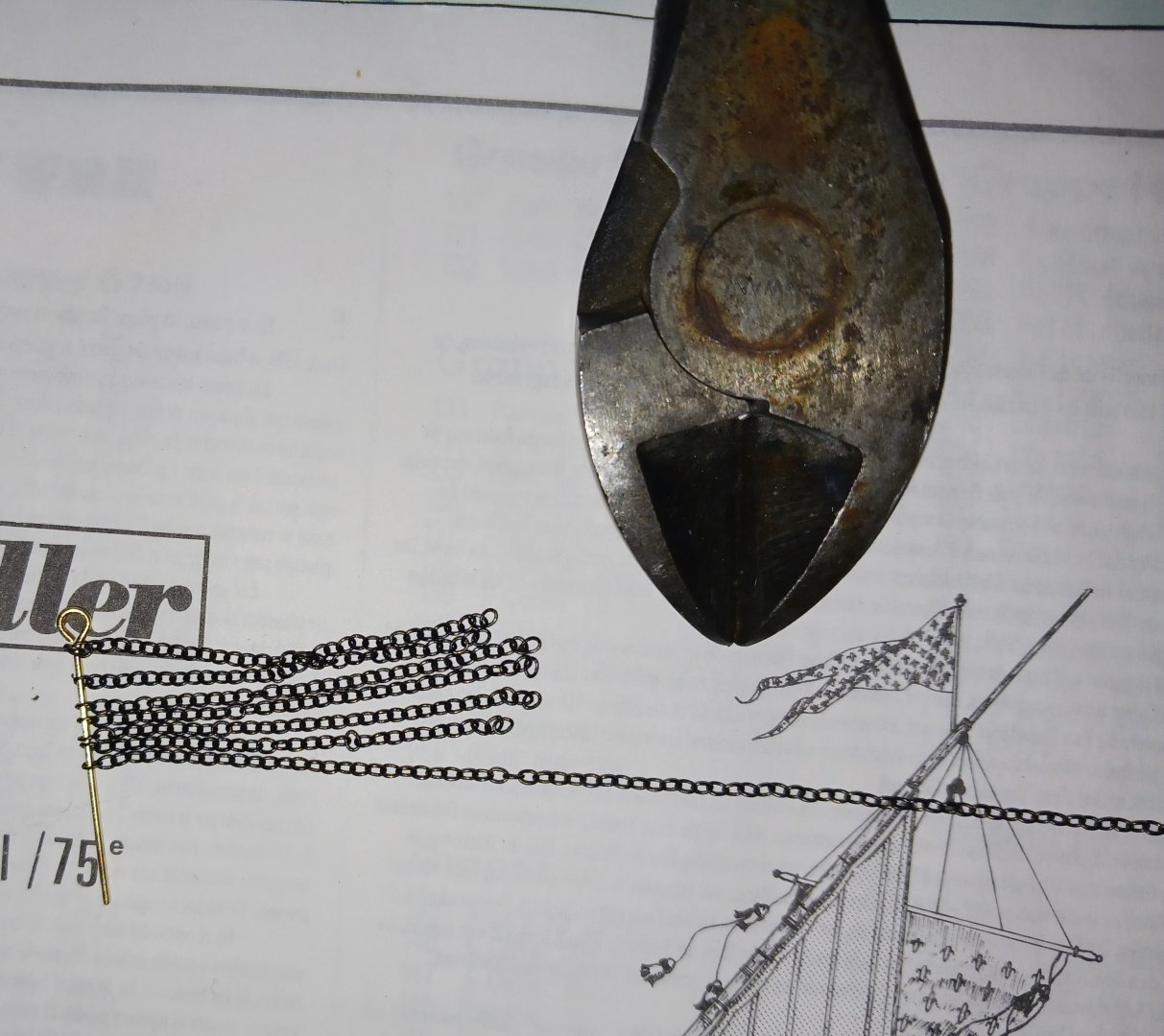

Last bit of weekend work on the Reale. I cut down 16 of my eyebolts (6 pictured) and saved the rest for use as the metal toggles for the upper blocks of the shrouds. After that, I slid the last links of the chains/blocks I had prepared earlier today onto the eyebolts. I proceeded to tie the standing ends of the halyards onto the blocks and anchor everything down into the holes I drilled. Nothing looks as bad in real life as it does in pictures. I only finished the port side today. There are two chainplates that lead to something other than normal shrouds on each side, so 4 in total. The first shroud pair is actually some sort of running whip-and-tackle stay that involves a single block and two double blocks, the standing end of which is not the chainplate. The chainplate anchors the bottom double block. The fifth chainplate from fore anchors the bottom double block for one of the two parrel tackles. You can see these differences in the pictures. Neither of these rigging elements are shown in the painting, but I think something related to a parrel line belays just forward of the main mast. The next job is the anchoring of all the starboard chainplates.

- 176 replies

-

- la reale de france

- heller

-

(and 2 more)

Tagged with:

-

The only other work that needs to be done on the hull that isn't related to rigging is the ladders and the swivel guns, both of which I have elected to save until after the rigging is completed. That means it's time to start working on the masts. Making and dry-fitting the masts was easy: Fitting out the masts will be less easy. This is mostly because of how Heller believes the shrouds work. In the outer catwalks are a grand total of 16 holes. Heller says these holes are for eyebolts that serve as anchors for the shrouds. The issue is the fact that the slightest gust of wind against the mainsail would tear up the shrouds on the windward side. This is why I have a better idea. My idea is to widen the holes and anchor 16 lengths of chain into the hull itself via eyebolts, and connect the other ends of the chains to the bottom blocks of the shrouds. I recognize the fact that most builders use blackened brass strips to make chainplates for this.

- 176 replies

-

- la reale de france

- heller

-

(and 2 more)

Tagged with:

-

The finished canot: The only thing I found frustrating about the canot was the fact that the metal glue I bought specifically for use on the anchor I made worked arguably worse than super glue, which is itself abysmal for metal-on-metal connections. I had to abandon the second set of anchor arms for that reason. The canot will be placed on the gallows angled inward toward the center line, which makes sense for lowering and raising the boat. Heller claims the canot is actually meant to rest on the forward portion of the center catwalk. This makes no sense for two reasons: 1. this makes the catwalk unusable, especially during combat engagements. 2. the Landstrom book claims that both boats were usually towed (which makes sense for the era) and could optionally be raised onto the gallows when not used. I have seen some modelers make a second set of gallows specifically for the canot. I do not believe this was on a Reale model specifically, but large galleys were so standardized by this point that I don't think it would matter.

- 176 replies

-

- la reale de france

- heller

-

(and 2 more)

Tagged with:

-

The canot is painted in the same colors as the caique: There are still a few things to be painted, and then it's on to the hull details.

- 176 replies

-

- la reale de france

- heller

-

(and 2 more)

Tagged with:

-

I made the frames for the canot in the same way as the caique. There are 18 frames grand total, the same number as there are in the caique.

- 176 replies

-

- la reale de france

- heller

-

(and 2 more)

Tagged with:

-

I am getting a good start on the canot. The canot will be getting the same treatment as the caique, with a few exceptions. While one of the thwarts is braced as though there was going to be a mast, there is neither a mast step nor partners. Even then, this boat will be stowed on the gallows, so a mast and its equipment would rest on top tied down to the thwarts. The canot is slightly longer than the caique, but only has six oars. No anchor is provided so I will be making my own, more reasonably sized one.

- 176 replies

-

- la reale de france

- heller

-

(and 2 more)

Tagged with:

-

Now, it would be reasonable to believe that the anchor aboard the caique would actually be some kind of spare/maneuvering anchor for the ship. However, I used it anyway even considering its excessive size. One would wonder, with the anchor stowed in the bow, how this boat would possibly remain level in the water. It must weigh almost half a ton. This is the finished caique: Apart from the anchor and its line, I put two mooring lines on the thwarts, and put in the rudder. The tiller looked sad, so I replaced it. I intend to do the same with the canot, which I might start tonight.

- 176 replies

-

- la reale de france

- heller

-

(and 2 more)

Tagged with:

-

Mediaeval Shipwreck found in England

Ferrus Manus replied to Louie da fly's topic in Nautical/Naval History

Could this be the first nef wreck ever found? -

The positions of the oars on the thole pins: I quickly realized the infeasibility of having the oars sitting on the thwarts, owing to how their size and how many there were. Had they been sitting on the thwarts, the boat would have been unsailable. The other thing I wonder is why a ship's boat that's only slightly larger than a pinnace would need twelve oars? I could see a ship's launch requiring twelve or more rowers, but not this. I would say 3 pairs would be sufficient, but both the kit and the Landstrom book agree on twelve for the caique and six for the canot. The oars are positioned at an upward angle in relation to the waterline.

- 176 replies

-

- la reale de france

- heller

-

(and 2 more)

Tagged with:

-

I finished the rigging of the caique today. I knew before starting work on the stay sail that I had failed to make stay hoops out of rope before rigging the stay. The way I solved this was to tie loops around the stay and a sewing needle (five of them) and then pull the sewing needle out. I also made rope coils for the entire thing. The one issue I have consistently experienced is with the red paint on the exterior. It keeps coming off onto my fingers, at which point I rub it onto various parts of the rigging. It has not been that much of an issue, however. The caique has twelve belayed lines and associated rope coils. Because of the positioning of the sails and rigging, it isn't feasible to have the oars sitting on the thwarts, so I will put them on the thole pins as though they were in use. The way I got the stay sail to billow was to put a tiny dot of glue on the starboard fore upper deadeye, and allowed the sail to rest on that, as shown in the pictures. The rudder and anchor, and maybe some moorings lines, are still in order.

- 176 replies

-

- la reale de france

- heller

-

(and 2 more)

Tagged with:

-

- 176 replies

-

- la reale de france

- heller

-

(and 2 more)

Tagged with:

-

This morning, I put the rigging lines on the sail, before gluing the sail itself to the spritsail yard with wood glue. This is the result:

- 176 replies

-

- la reale de france

- heller

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.