-

Posts

2,315 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by chris watton

-

This will be a more conventional kit. I cannot go as far as did with Sphinx for two reasons. The first being that the sheer size of this would make it way too expensive. The second reason is that this kit will be aimed at more experienced modellers, more used to planking. Decks will be planked with strip and most of the outer hull will also be planked from the quarterdeck bulwarks down. This will be more like my Amati Victory designs. There will still be a silly amount of laser cut and PE parts, though.

- 488 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

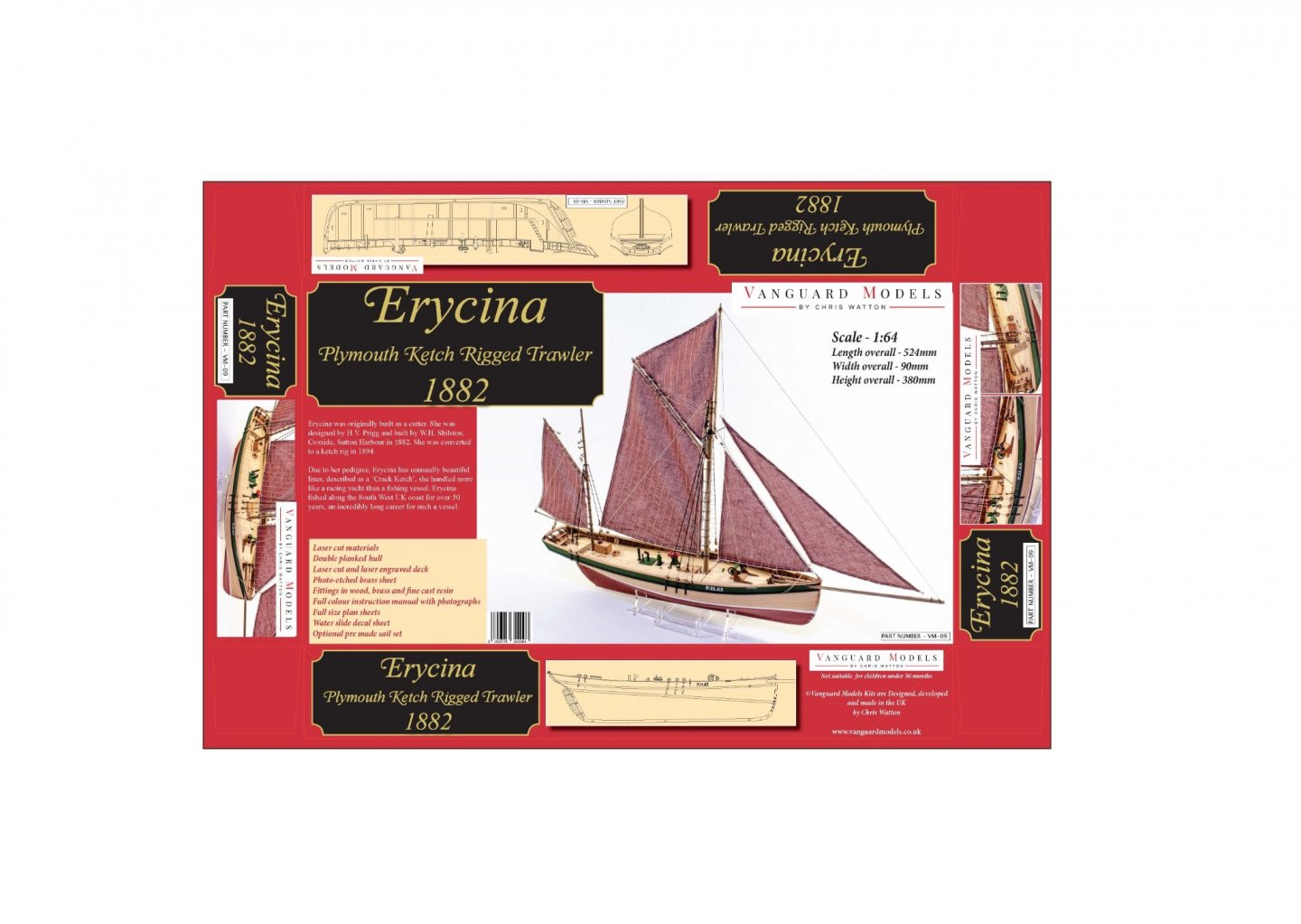

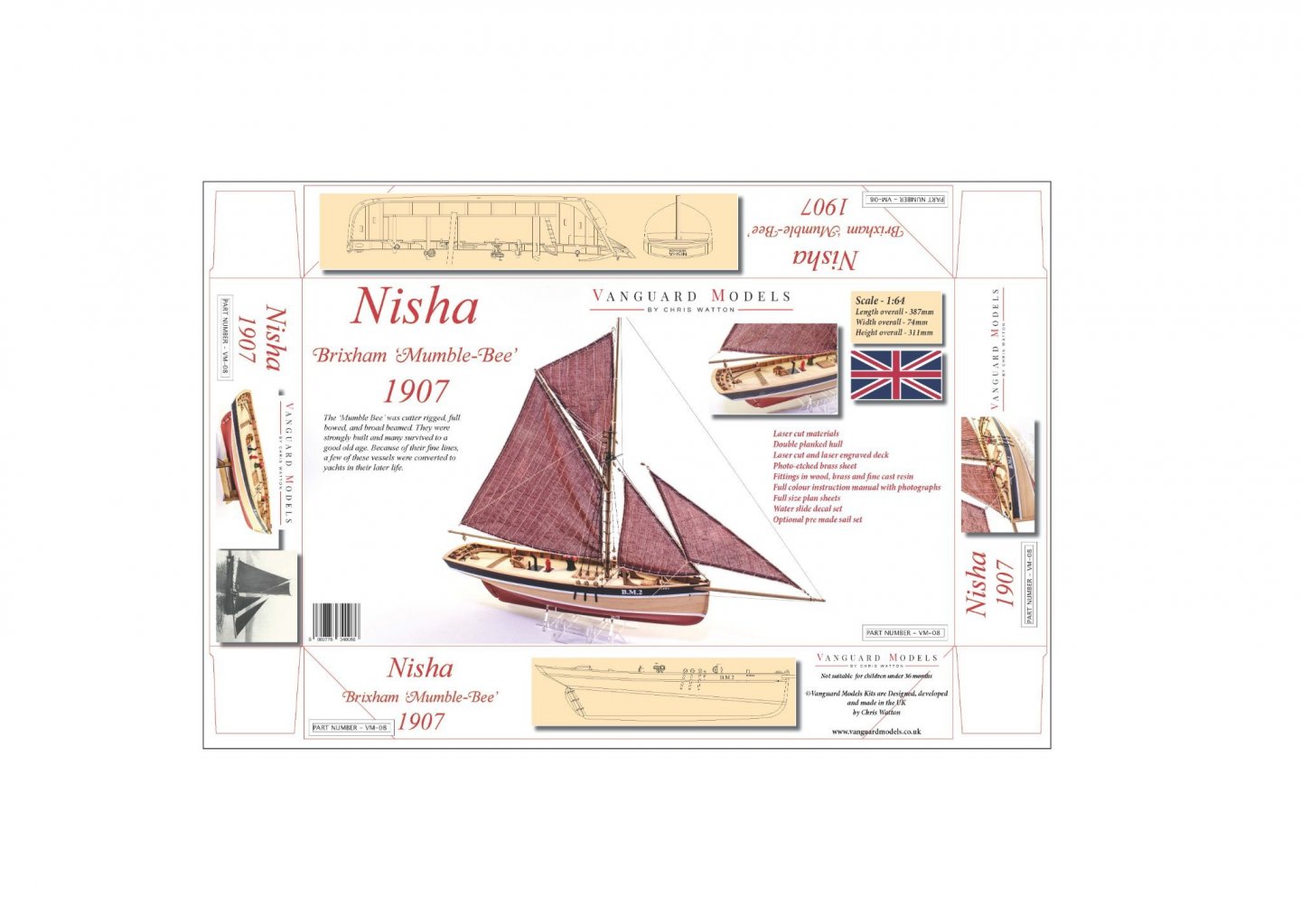

Damn, you have an Erycina coaster, it should be Nisha. My wife is fired....

- 206 replies

-

- Vanguard Models

- Brixham trawler

-

(and 2 more)

Tagged with:

-

Again, very nice work! Amazon Class (1770's) is very much on my To Do list

- 542 replies

-

- Sphinx

- Vanguard Models

-

(and 3 more)

Tagged with:

-

That is Royal George. I have a lot of plan sets I bought from the NMM, for future development purposes. Once scanned, they are often just left in their tubes forever. The Royal George plan is there because it is gorgeous, and I like to look at it The other two plans are future developments, with the one being very near future..

-

Hey Ron Sadly no, the little flash drive contained all the drivers and software for the new machine - but the external HDD also attached has all my files! That is the bed size (actual machine a lot larger), so it could cut up to 960 x610. However, more realistically, I will be cutting materials that are 800x600mm in size. Up until now, I have been restricted to a max material size of 600x400mm, which is fine for all kits I have done thus far.

-

Busy day! New laser machine arrived earlier (LaserPro Laser Engraving Machine Spirit GLS), and it's quite a bit larger than my trusty workhorse. I ordered it from the same company, as the software is identical. But the bed size is a lot larger. My Mercury 3 laser bed is 635x459mm, this one is 960x610mm. It is a big investment, but very necessary if I want to grow the business. The workshop is still a work in progress, as I am waiting for the wiring to be added for the electrics (lighting and plug sockets), and the doors will be changed to insulated roller doors. But it has had a brand new roof, floor levelled and a partition wall added, so this room is narrower than the other side. Bigger kits can now be developed!

-

I would like to do a Restoration warship at some point, but the castings isn't the problem, it's getting the carvings done that is, and they would be very expensive to commission. But one day, I will, I have one in mind. (not Sovereign, though, that's a little too OTT for my mellowing taste) In the meantime, I have just booked the pick up for the Nisha and Erycina printed colour boxes, so should receive these Wednesday or Thursday, and kits go on sale Friday. I wasn't sure these boxes would be ready in time, so I was very pleased to learn they are just awaiting picking up!

-

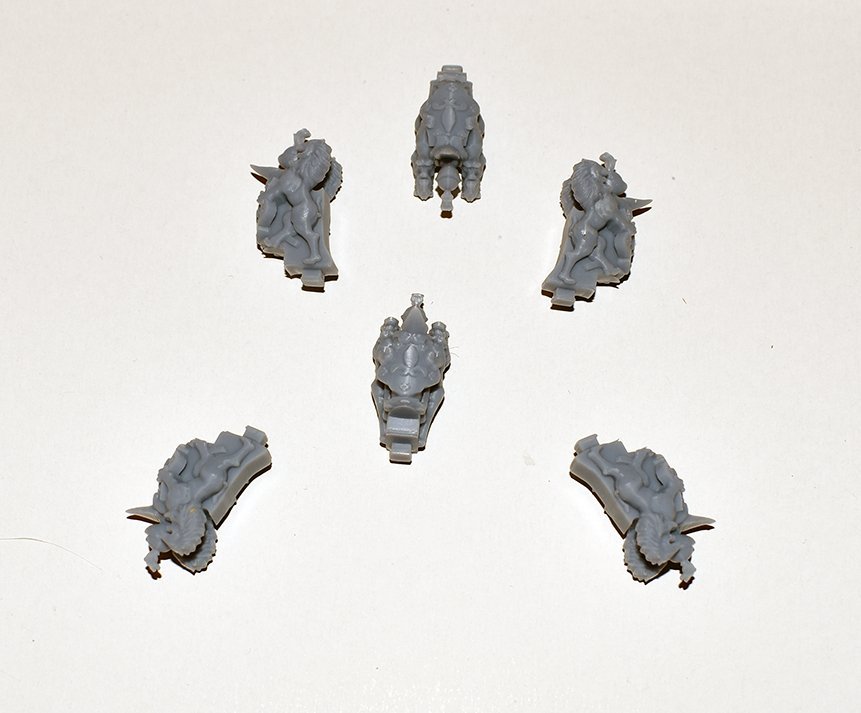

Small update - Things are moving slower than I would like. This is mainly due to shipping delays with my new laser machine (and other items), which has been more than a little frustrating. However, it is being delivered tomorrow, at long last, 15 weeks after placing the order! Nisha and Erycina should be due for release next Friday (3rd December). I am not putting these on pre order due to the problems I had with Sphinx, so I am not putting them on until I have absolutely everything here and they're ready to be boxed. I do have all of PE sets here, though, and the manual and plans are due Wednesday. One item I will need to put on pre order is the sail sets. The company that produces these for me had to shut down for 14 days, due to a Covid outbreak at their place, but I am hoping to have these with me in the next 2-3 weeks. This is equally annoying for me, as the sail sets have all been paid for, but cannot be helped. I do now have Nelson figures in 48th and 96th scale in stock. These are 3-d printed 'In-House'. Most (but not all) future castings like figureheads and stern decoration will also be 3-d printed in house. I have attached some pics of some sample parts I sent to Jim. There are figureheads for Duchess, Sphinx and Bristol, and the sterns are Sphinx and Duchess. Here is the link to the Nelson figures, there are 4 scale choices now: Figure – Lord Nelson 1:48, 1:64,1:72, and 1:96 scales – VANGUARD MODELS

-

I think you are overthinking way too much for this. All of the hard work has already been done in the development stage. All you need to do it put it together and then, when all parts are added as described in the instructions, simply sand the required bevels so the planks have maximum contact with each bulkhead edge . If you do as Glenn Barlow and watch you do not take away too much of the other edge of the bulkheads, that is all you need to do. The lines for Sphinx are pretty nice, so this shouldn't be an issue. (compared to a bluff bow like Endeavour or similar)

- 476 replies

-

- sphinx

- vanguard models

-

(and 1 more)

Tagged with:

-

With this kit, it is very important you follow the instruction stages. For my first prototype, I didn't even think about tackling the sanding of the frames until the inner bulwarks were in place, unifying the structure.

- 476 replies

-

- sphinx

- vanguard models

-

(and 1 more)

Tagged with:

-

I now know about angling the parts, a delicate balance, as I try to use as few supports as I can get away with. This is my very first attempt for the Sphinx stern casting, angled and with all supports at the rear, which came off easily. Plenty of flex in the material, and as it is printed directly from the master file, little to no shrinkage - a world away from white metal.

-

I bought a MSLA 3D Printer last week, as I am trying to do as much in house as I can. It is only a little printer to practise on, with a view to get a larger one if this works out. Here are a couple of pics of my first results, Duchess of Kingston figureheads, and Nelson figures in 48th and 96th scale. Sorry about pic quality, but all my photographic equipment is stowed away at the moment..

-

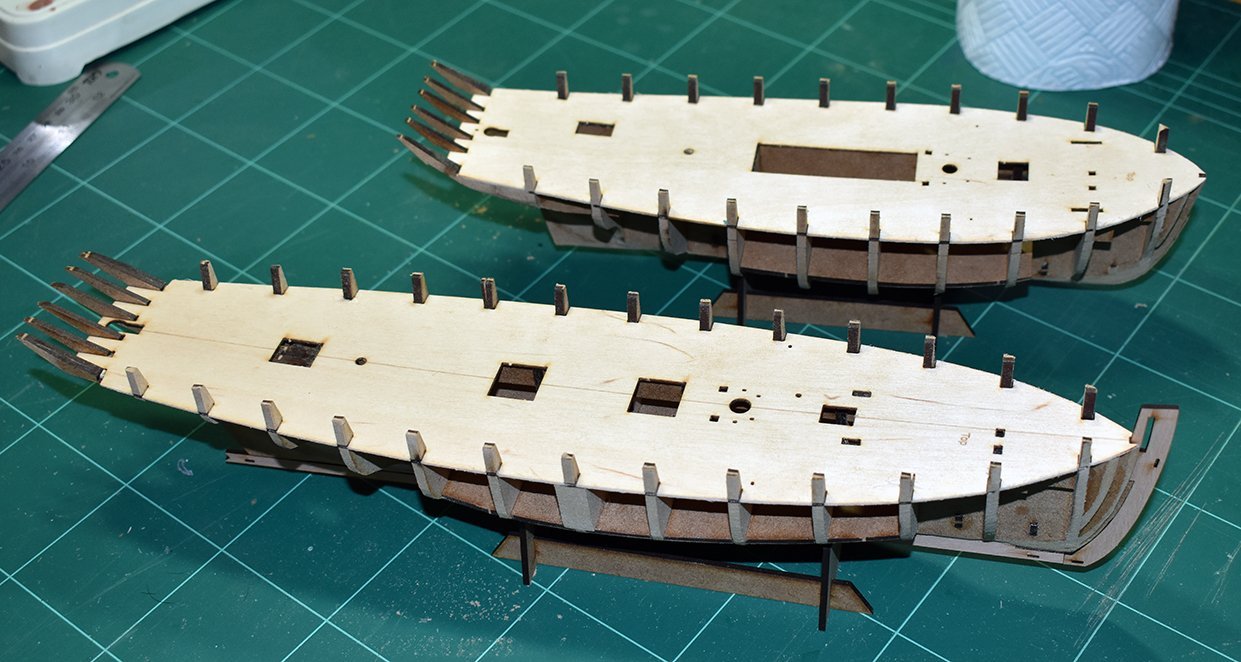

The little one is Saucy Jack, a Barking Well Smack, 1836. This will be the next release, probably the tail end of January. I have already done all plans, and the photo etched sheets will be produced in the next couple of weeks. The larger one is Ranger, a Barking fish carrier, 1864, and designed to be as fast as possible to get the fish to market once picked up from the fishing fleets. I may wait a while to release this, don't know yet - but I do know the development for the next big kit release will take most of 2022. With that in mind, I may save Ranger for April/May.

-

Of course! In the meantime, I am working on my next little kit (or maybe 2, don't know yet, may save one for later...) I have attached a couple of pics of the pre-prototype builds. I show them so you can see the amount I take off when sanding the bulkheads (both just took me just a little over 30 minutes with an improvised sanding stick). I notice on some build logs that some leave way too much un sanded/unbevelled bulkhead edges at the bow and (especially) at the stern, and then wonder why certain parts do not fit as well as they should, almost as if they are too afraid of sanding too much off. If you use a long-ish sanding stick (in my case, just a scrap length of 0.8mm ply with sandpaper wrapped around it), there is little chance of digging into any one bulkhead, as you are sanding across 3, 4 or 5 at a time. I usually sand the whole lot for these small hulls, but for much larger ones, I just make sure bow and stern are properly sanded to follow the run of the planks, with much lighter sanding at the middle section of the hull.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.