-

Posts

2,314 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by chris watton

-

Next batch shipping at the end of next week or beginning of week after, after receiving photo etch delivery confirmation. I put in and paid for (a lot of money) a 'Repeat Order' of Sphinx photo etch sets in August. Due to miscommunication within the Italian PE company, what they sent was one of the 5 sets required, making this my month of hell. Problems now resolved, so all back to normal at the end of next week.

-

I have a feeling the wrong part is glued to the top of the quarter galleries, they look MDF to me, and the parts that should fit are 4mm pear, 481 and 482. They have bevelling lines etched on the tops. It would be much better if you dry fit parts, and check, check and then check again before fixing anything in place. Some parts do need shaping, as this is not a plastic kit. The stern and quarter galleries require much attention to attain a decent result.

-

Damn, that is stunning! I think the black main wales will look great against that hull.

- 345 replies

-

- Duchess Of Kingston

- Vanguard Models

-

(and 1 more)

Tagged with:

-

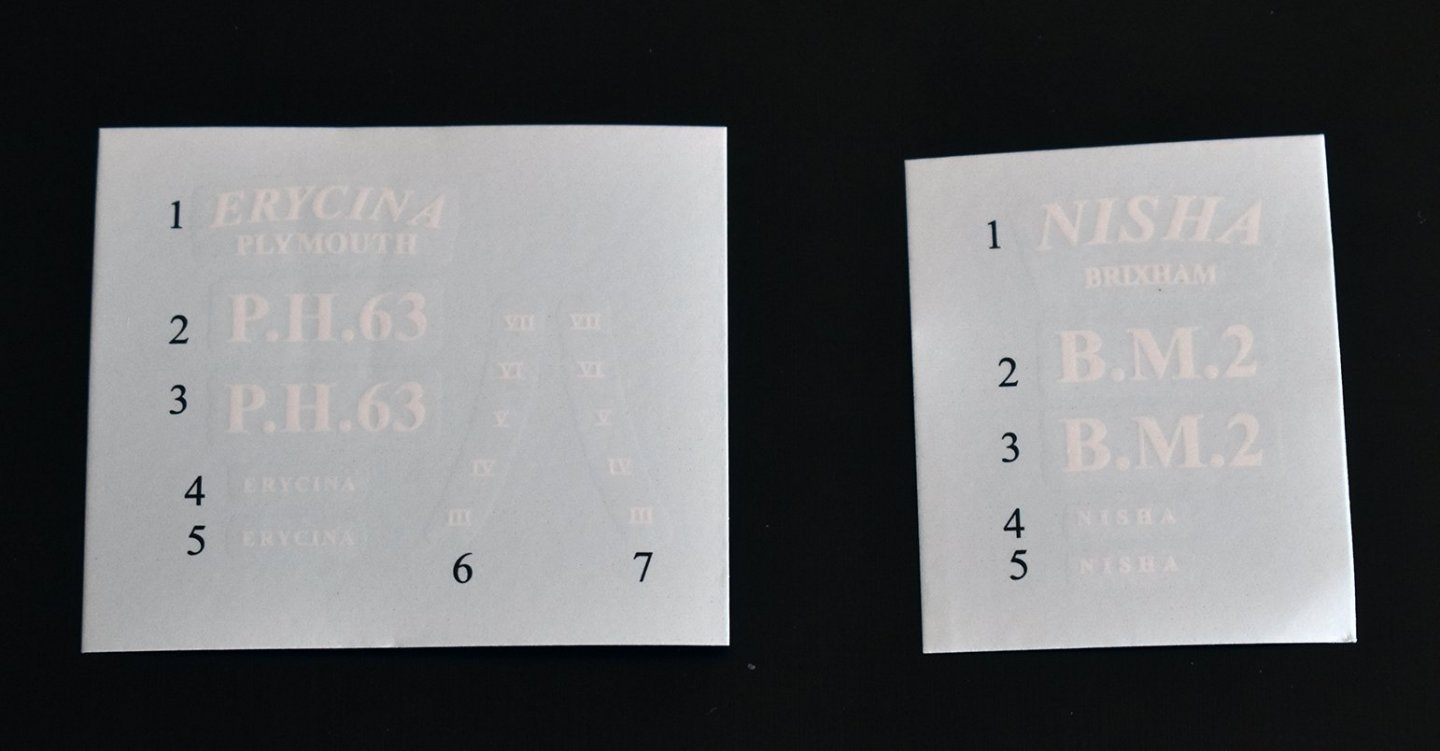

Little update: I am expecting the Sphinx photo etched sheets to be delivered next week. These are all I am waiting for, as the rest of the kit contents have already been done and boxed. Sphinx is now available to pre-order. This is the Revision 2 version, with the thicker manual and revised parts list. Right now, all laser production is stopped for two to three weeks (but all kit laser cut sheets have been done and all is in stock), as our large garage is being converted into a proper unit to house two laser machines and a separate area for materials and packing. I take delivery of my larger second laser machine at the end of next month. This larger machine will allow me develop much larger kits and cut thicker materials faster. The garage conversion and new machine are massive investments for me, but I think ultimately worth it. I am hoping to have the small fishing vessels, Nisha and Erycina out before December. These will have optional sail sets. Tomorrow, I take delivery of the waterslide decals for both fishing boat kits, these include the vessel name and registration number. These are what I am working on now.

-

I am expecting the sample sail sets for both Nisha and Erycina within the next two weeks. Once I have them, I will post over to Jim. Plans will show drawings for both rigged with and without sails. (There are 15 A1 sized plan sheets for Erycina, and am now working on plan sets for Nisha..)

- 36 replies

-

- vanguard models

- Erycina

-

(and 2 more)

Tagged with:

-

I think what I shall do is continue doing what I do. I know I will never please everyone (and the loudest critics are usually the ones who would never buy your product anyway), but I like to think I know enough as to what most would like to see in a kit, I just think of what I would like to see in a kit that I paid my own hard earned on. I will source flags at some point, but right now, I want to concentrate on new kits, this is where my investment money is going.

- 355 replies

-

- vanguard models

- Sphinx

-

(and 1 more)

Tagged with:

-

Nice work, Glenn! Do not worry too much about the pear quarterdeck beam pattern, it is inset slightly, so that char showing is fine. And again, do not worry about breaking a few of the upper tabs, this is almost inevitable - as long as you still have couple left by the time you add the outer skins, that is fine. Even if all of them broken off, you probably still would be fine..

-

Glad you like the coaster! I only do these if I have enough time and after everything else is cut. Each sheet does 24 coasters, and is four and a half hours engraving/cutting time per 600x400mm sheet, as the etched hull drawing has a lot of lines and curves. If I get time, I shall do some in the clear acetate.

- 355 replies

-

- vanguard models

- Sphinx

-

(and 1 more)

Tagged with:

-

It is something I shall look at in the future, I need to find someone that can print in good definition and appropriate materials, yet be cheap enough not to add too much to overall kit cost. Regarding the stand (two in each of my kits), if I put in enough options to please everyone, there wouldn't be enough room in that cavernous box for the actual kit - and then there would be a few who would still not be happy!

- 355 replies

-

- vanguard models

- Sphinx

-

(and 1 more)

Tagged with:

-

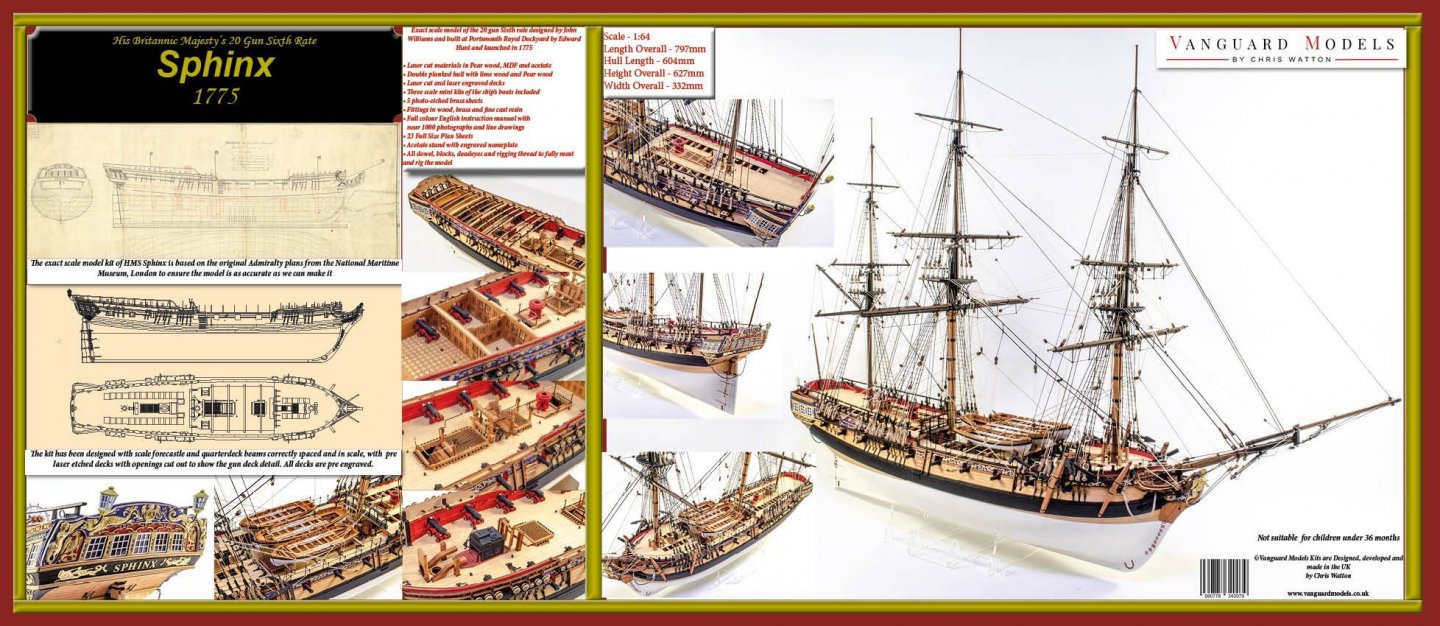

OK, Sphinx Revision 2 manual all done, and will be sent off to printers, along with new box label. The revised manual can be found using the download link at the bottom of the page here: HMS Sphinx – 1775 – VANGUARD MODELS Have attached the new box label, perhaps I will now stop getting enquiries asking if the kit has masts and rig.

-

Strange how customers in the US have very differing times for the parcel to reach them. Some in a couple of days, some in a couple of weeks, and one, in California was fun. I had an email from customs asking me to fill in a 'TSCA Form', in which I had to write down the species and genus of each wood type before they released it to the customer! Didn't realise I needed a doctorate in botany to produce and sell these kits!

-

All the kits I had have already gone. The second batch is being done now. I will have the manuals in for reprint next week. All I had to do was to change the part numbers in the text relating the the first and second planking in the manual, just two minor changes. It really was no big deal, coupled with the fact that you only have two types of planking in the kit, the lime first planking and the pear second planking. It isn't like there's a myriad of different size planks.

-

During wartime, even well before the French Revolutionary Wars, captains ordered their crew to build up the bulwarks. It seems the Admiralty knew about this, but turned a blind eye. But it does seem that when carronades were introduced and were found to be very effective close range weapons, bulwarks were built up to perhaps help counter the recoil effect of the carronades. In peacetime, ships were ordered to have their bulwarks open (don't know why, perhaps for aesthetic reasons), but in wartime, they were closed. It isn't until the very tail end of the 18th Century do we see Admiralty plans showing built up bulwarks, first just aft, and then forward.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.