Patrick B

Members-

Posts

74 -

Joined

-

Last visited

Profile Information

-

Gender

Male

Recent Profile Visitors

-

The Gimps Chimp reacted to a post in a topic:

HMS Beagle by Patrick - OcCre - 1/60

The Gimps Chimp reacted to a post in a topic:

HMS Beagle by Patrick - OcCre - 1/60

-

SiriusVoyager reacted to a post in a topic:

HMS Beagle by Patrick - OcCre - 1/60

SiriusVoyager reacted to a post in a topic:

HMS Beagle by Patrick - OcCre - 1/60

-

DanB reacted to a post in a topic:

HMS Beagle by Patrick - OcCre - 1/60

DanB reacted to a post in a topic:

HMS Beagle by Patrick - OcCre - 1/60

-

Patrick B reacted to a post in a topic:

HMS Beagle by Patrick - OcCre - 1/60

Patrick B reacted to a post in a topic:

HMS Beagle by Patrick - OcCre - 1/60

-

Patrick B reacted to a post in a topic:

HMS Beagle by Patrick - OcCre - 1/60

Patrick B reacted to a post in a topic:

HMS Beagle by Patrick - OcCre - 1/60

-

JacquesCousteau reacted to a post in a topic:

HMS Beagle by Patrick - OcCre - 1/60

JacquesCousteau reacted to a post in a topic:

HMS Beagle by Patrick - OcCre - 1/60

-

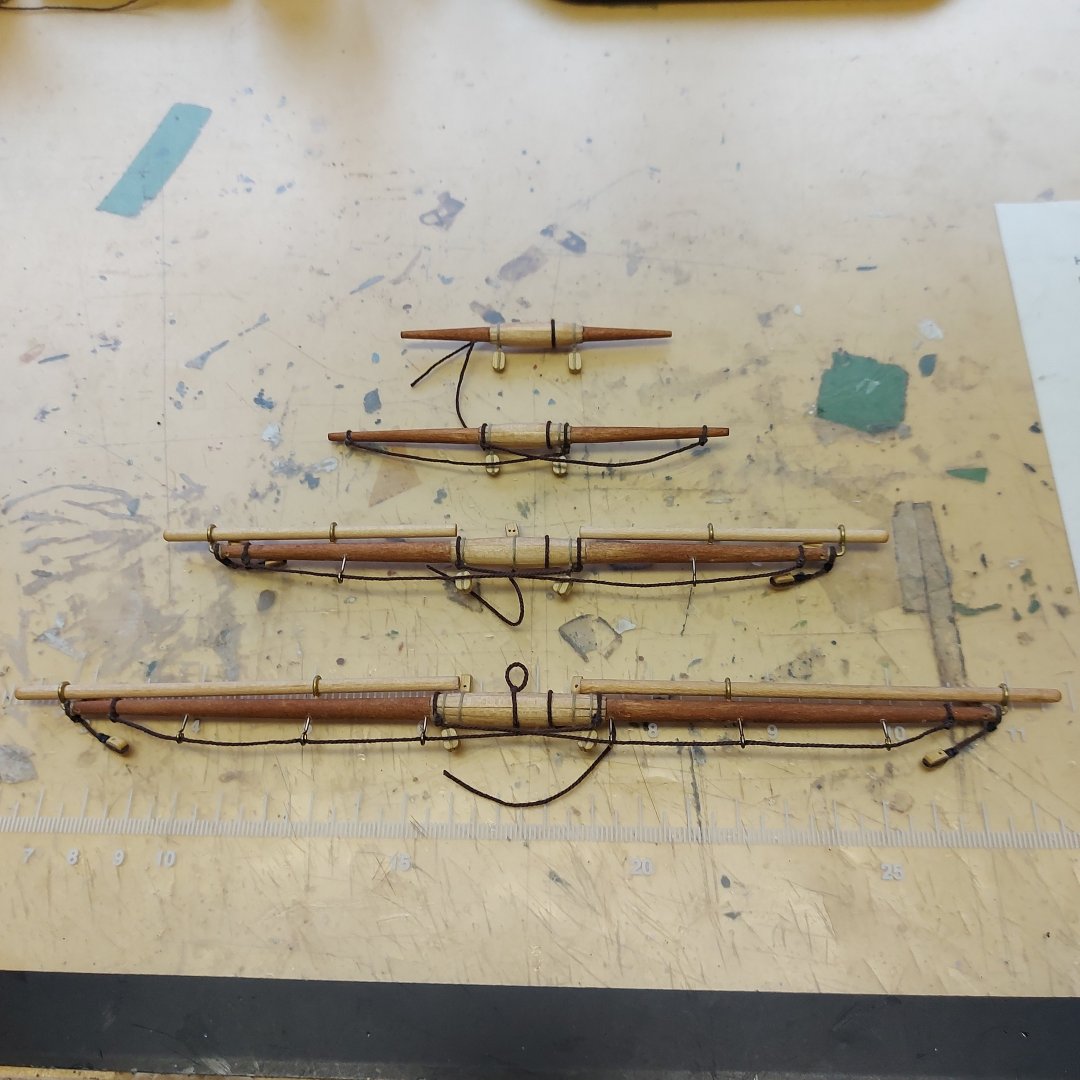

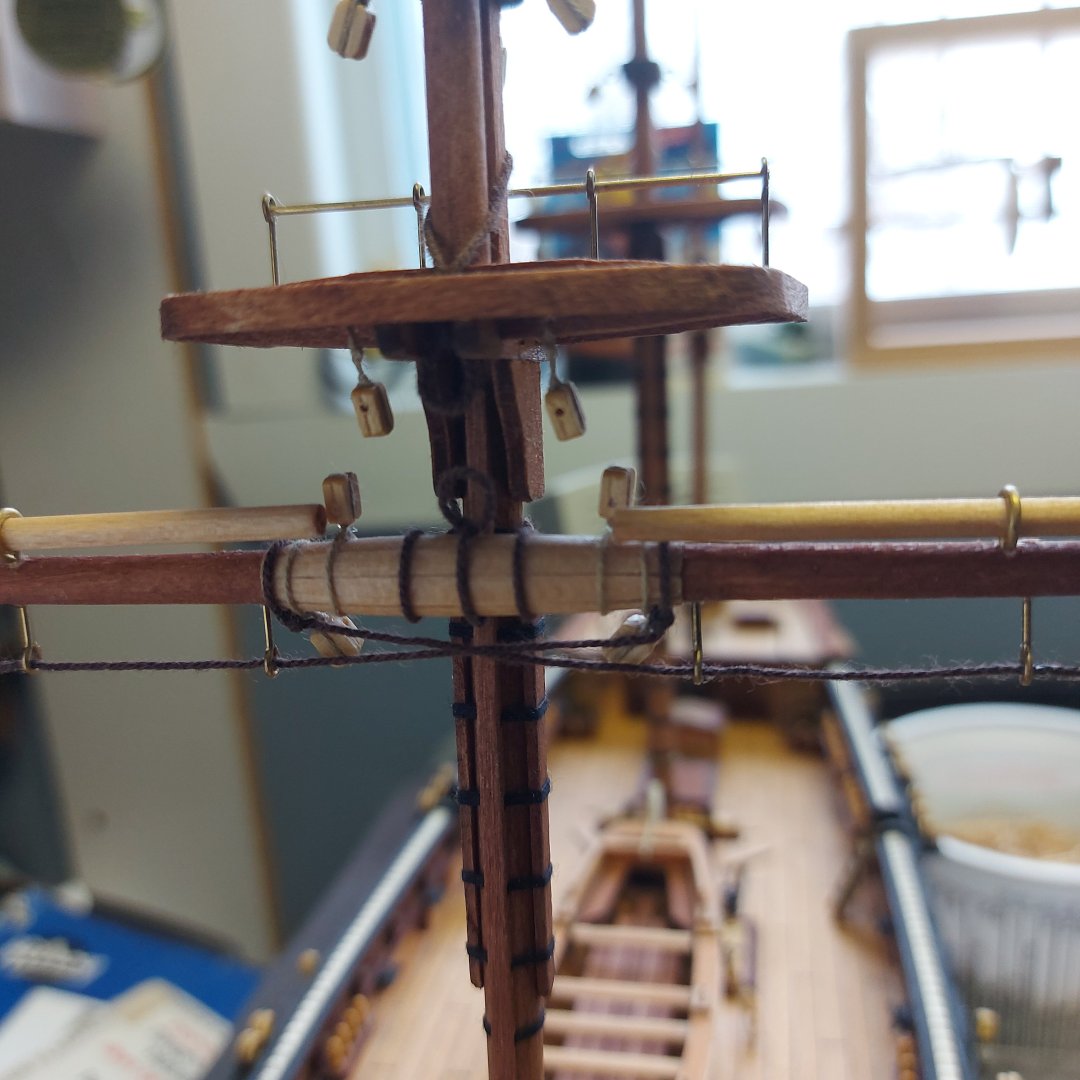

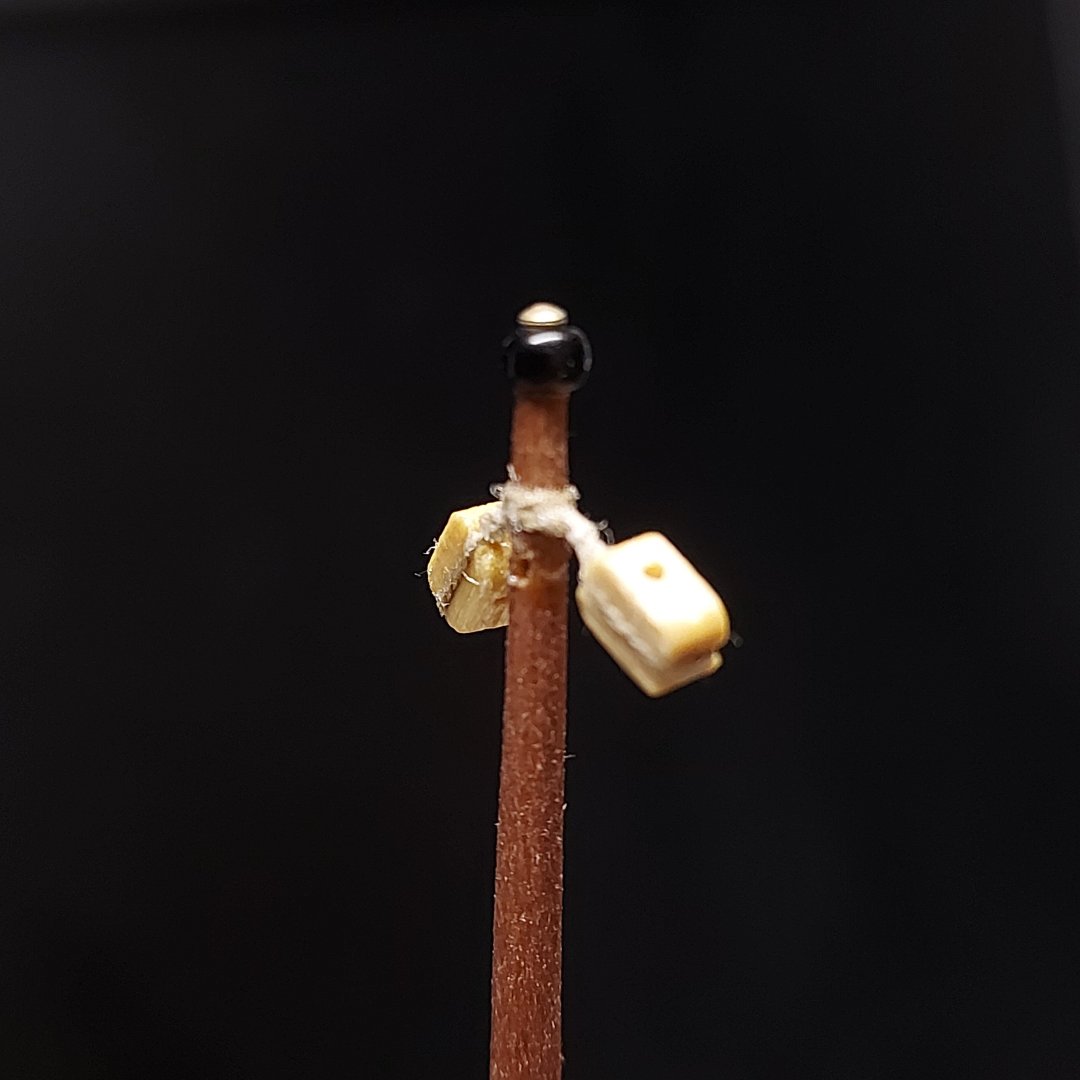

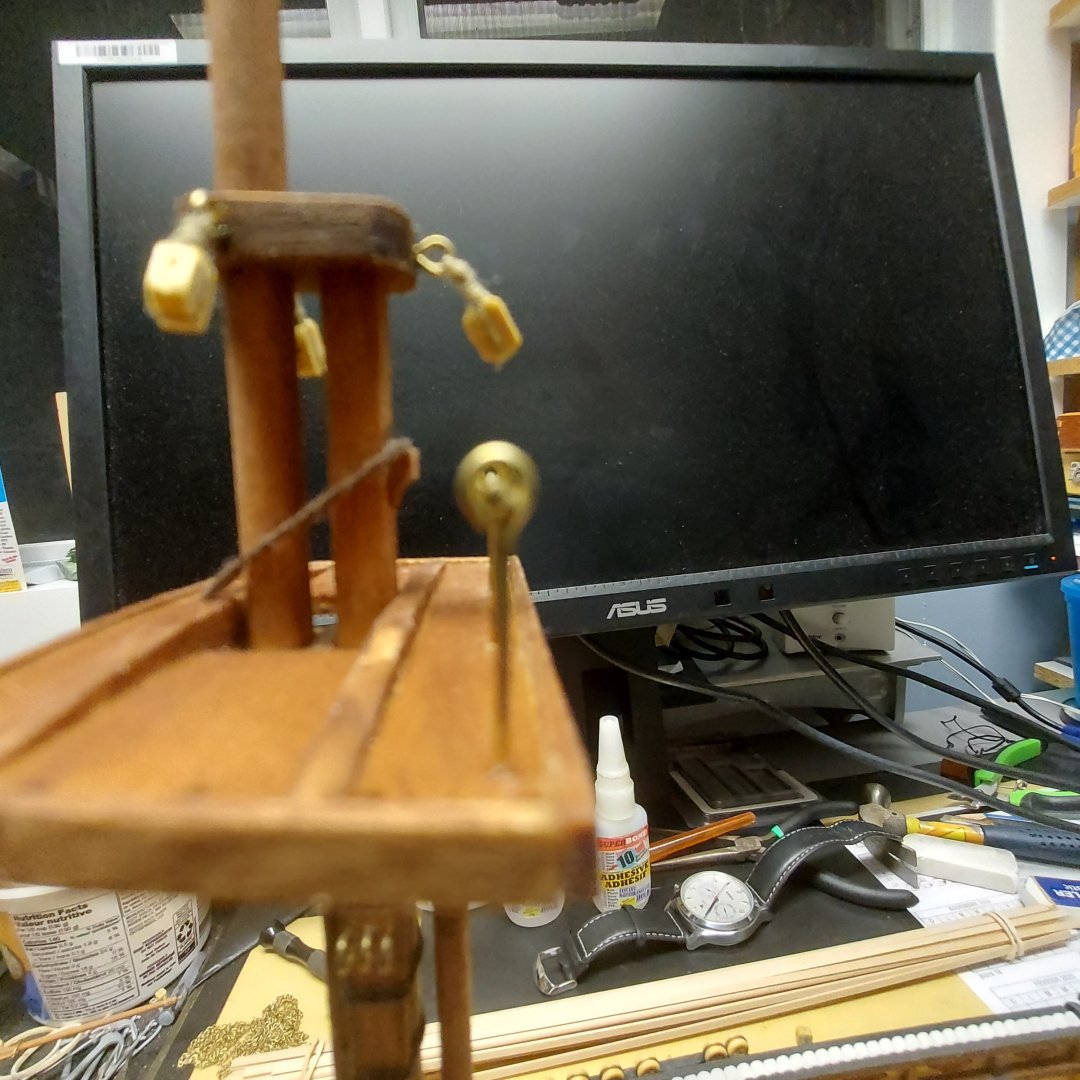

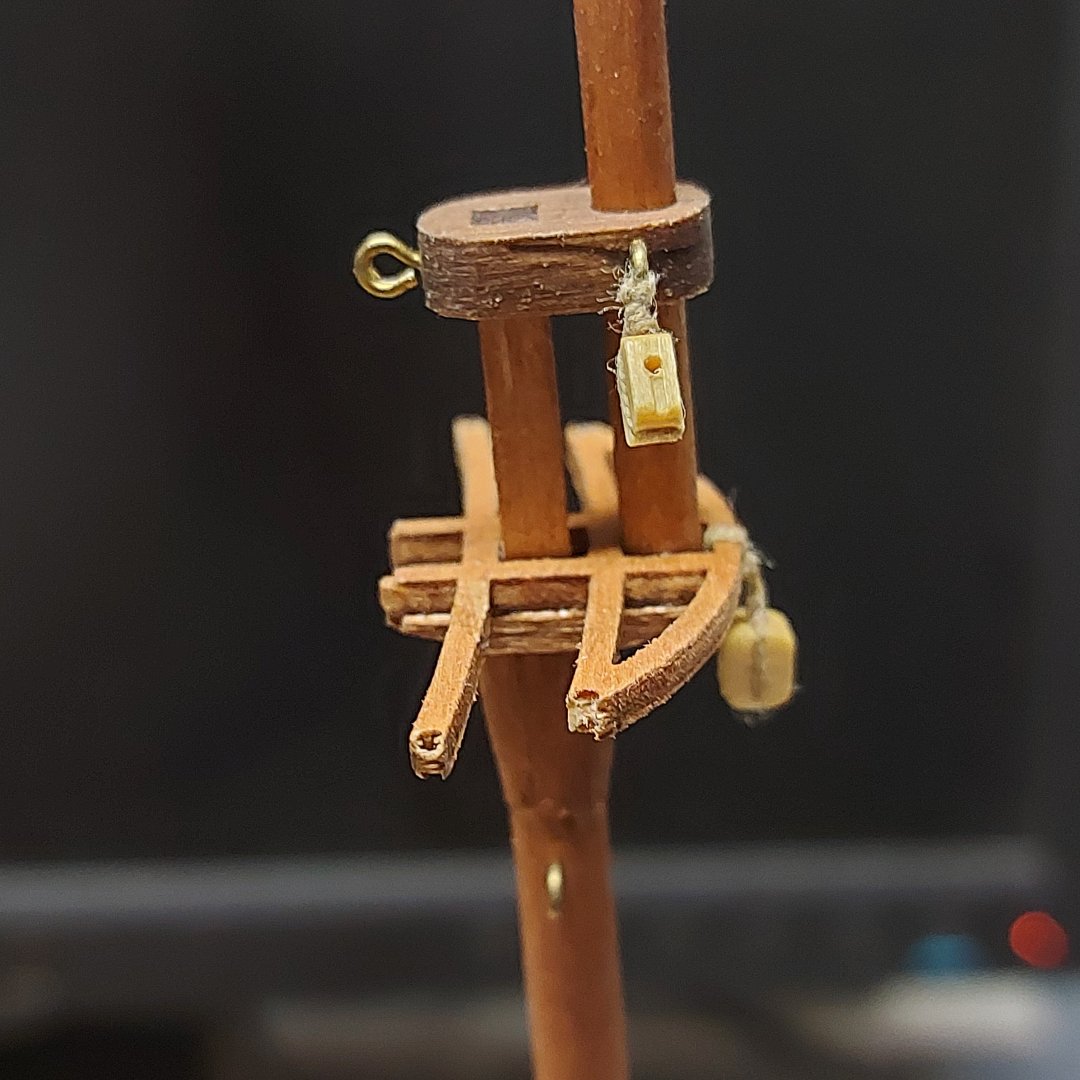

Hello everybody, The spars of the mizzen mast are done. I will not yet install them, as I will wait for the great mast ones to be completed. I am not sure about the utility of the pale beams held by metal rings on the two bigger spars, nor about their position. Some align them straight on top of with the bigger beams. Other pictures propose them resting a bit backwards. I decided to stick to the plans, leaning them forward of some degrees. The pulleys are a bit too spaced out from one another. I saw just after that when attached, they won't be straight. It it tied yet, just a simple knot is holding it for the sake of the picture. I will leave them out for now, to ease the rigging of, most notably, the ratlines. You can see too that I tried my best to emulate weight on the ropes, by giving them some slack. Don't know if it does any difference, but I tried. The rings were the hardest to bend. Especially the endings. Quite a challenge to bend shapes like those at such a small radius, without disrupting any earlier bends. In the end, I'm happy about how it turned out. But the struggle doesn't end yet, as the great mast is still waiting for spars of it's own. I seIzed the blocks with the girthier ropes. Knots would be out of place. Only for the 0.15 mm beige line, I "seize" them with two overhand knots, in alternance. Now that this is done, I am wondering if I should tie the sails on the spars on the mast or on my bench. An other double, or idea if you will, I had about the sails was wether I should soak them in tea to give them a more more look. I am openened to suggestions. I will see you soon. Cheers, Patrick

-

Patrick B reacted to a post in a topic:

HMS Victory by James H - Amati - 1:64

Patrick B reacted to a post in a topic:

HMS Victory by James H - Amati - 1:64

-

DonSangria reacted to a post in a topic:

HMS Beagle by Patrick - OcCre - 1/60

DonSangria reacted to a post in a topic:

HMS Beagle by Patrick - OcCre - 1/60

-

Patrick B reacted to a post in a topic:

HMS Beagle by Patrick - OcCre - 1/60

Patrick B reacted to a post in a topic:

HMS Beagle by Patrick - OcCre - 1/60

-

Snug Harbor Johnny reacted to a post in a topic:

HMS Beagle by Patrick - OcCre - 1/60

Snug Harbor Johnny reacted to a post in a topic:

HMS Beagle by Patrick - OcCre - 1/60

-

brunnels reacted to a post in a topic:

HMS Beagle by Patrick - OcCre - 1/60

brunnels reacted to a post in a topic:

HMS Beagle by Patrick - OcCre - 1/60

-

Patrick B reacted to a post in a topic:

HMS Beagle by Patrick - OcCre - 1/60

Patrick B reacted to a post in a topic:

HMS Beagle by Patrick - OcCre - 1/60

-

Patrick B reacted to a post in a topic:

HMS Beagle by Patrick - OcCre - 1/60

Patrick B reacted to a post in a topic:

HMS Beagle by Patrick - OcCre - 1/60

-

I did consider it Snug Harbor Johnny, but I would like to make my first model at least with the kit ropes, in order to make my own idea out of it. If I haven't worked with bad ropes, I won't apreciate as much third party scale rope. I intend to buy some for my next project, perhaps HMS victory if Amati ever releases it. Or else Maris Stella seems to have impressive material quality. I liked Occre although their rigging plans left to be desired, so the Santisima Trinidad and the Endeavour remain good options. The best ones would be the Sphinx or Indefatigable by Vanguard, with their extremely detailed plans. I always redrill the blocks with a 0,5mm hand drill, but I don't want to sand them in a tumbler, because they would loose their shine and be uneven. I wouldn't want to risk it.

-

Cathead reacted to a post in a topic:

HMS Beagle by Patrick - OcCre - 1/60

Cathead reacted to a post in a topic:

HMS Beagle by Patrick - OcCre - 1/60

-

Paul Le Wol reacted to a post in a topic:

HMS Beagle by Patrick - OcCre - 1/60

Paul Le Wol reacted to a post in a topic:

HMS Beagle by Patrick - OcCre - 1/60

-

The Gimps Chimp reacted to a post in a topic:

HMS Beagle by Patrick - OcCre - 1/60

The Gimps Chimp reacted to a post in a topic:

HMS Beagle by Patrick - OcCre - 1/60

-

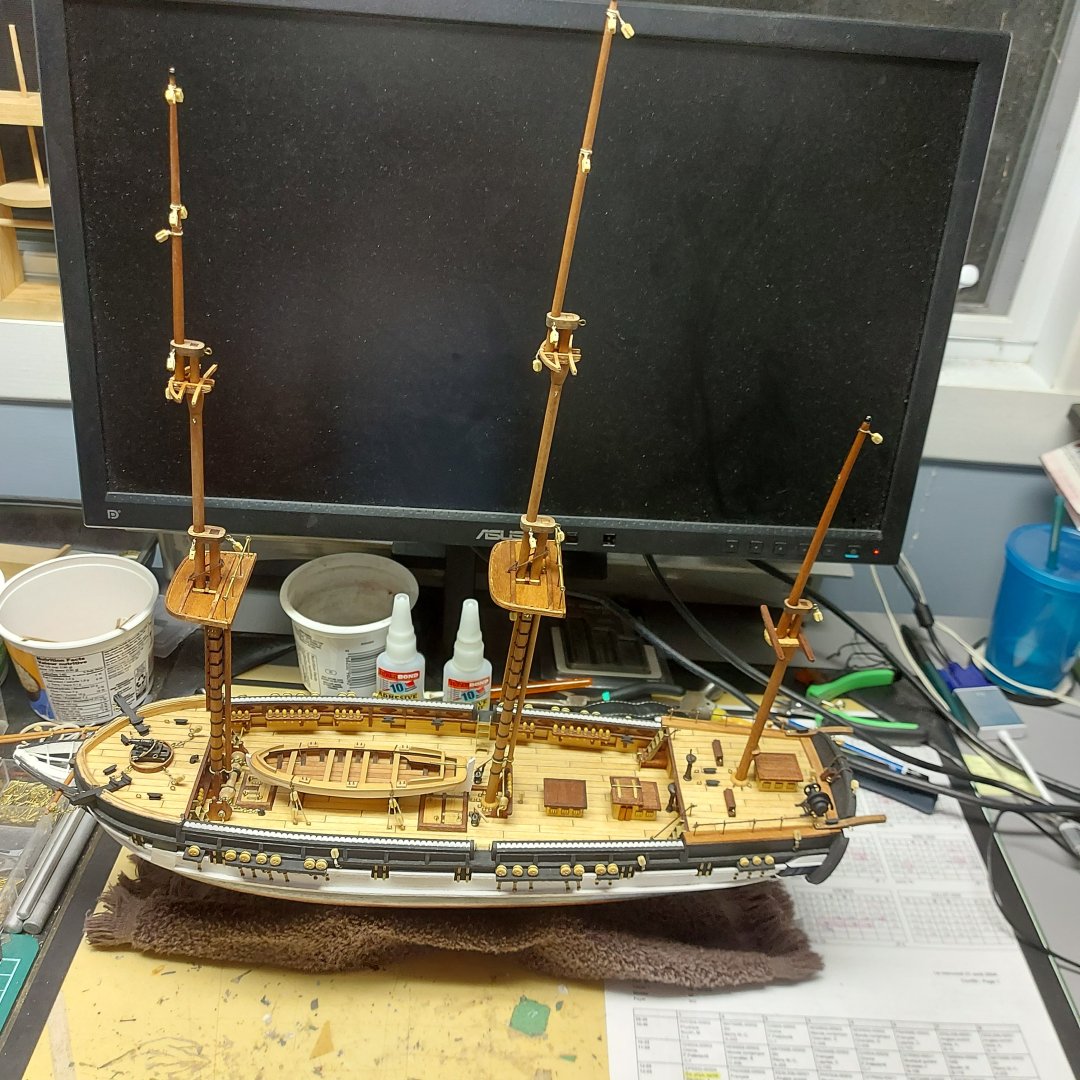

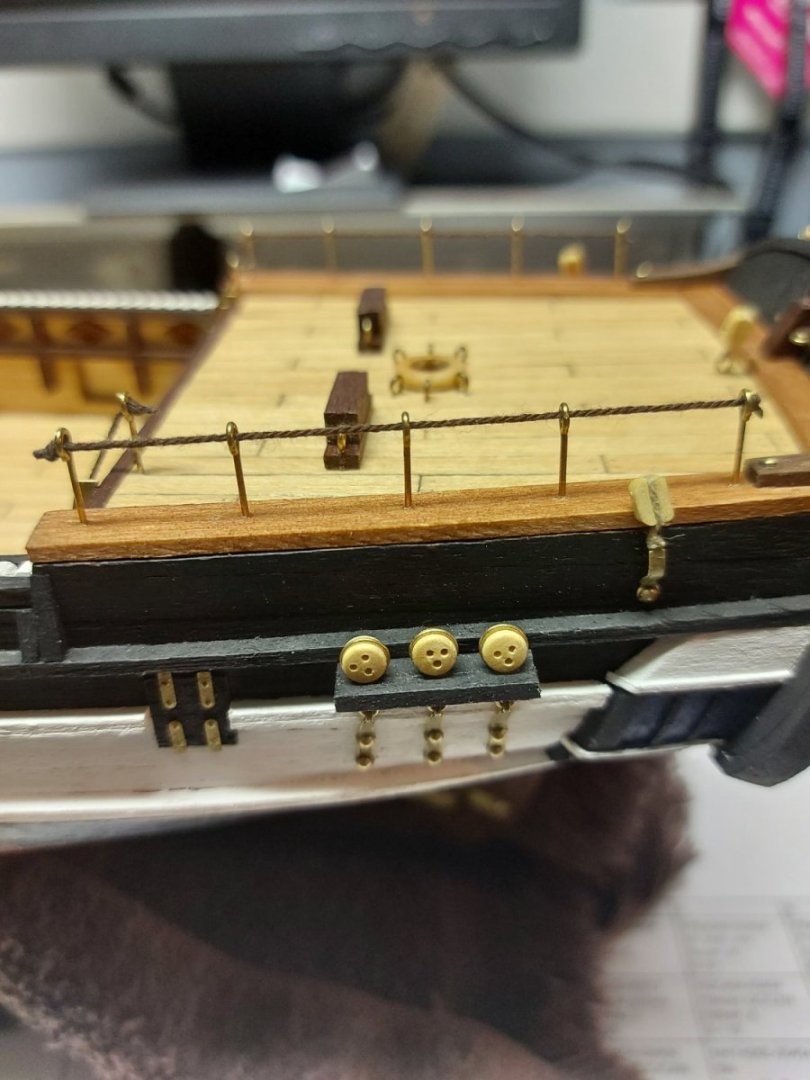

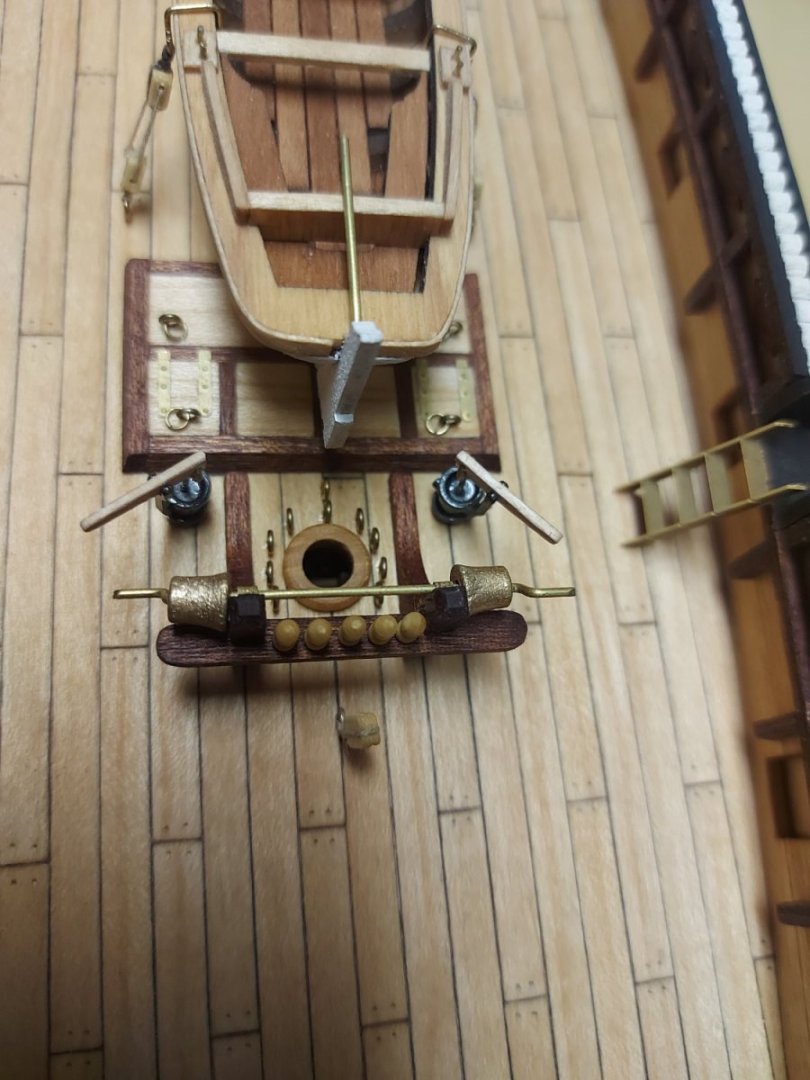

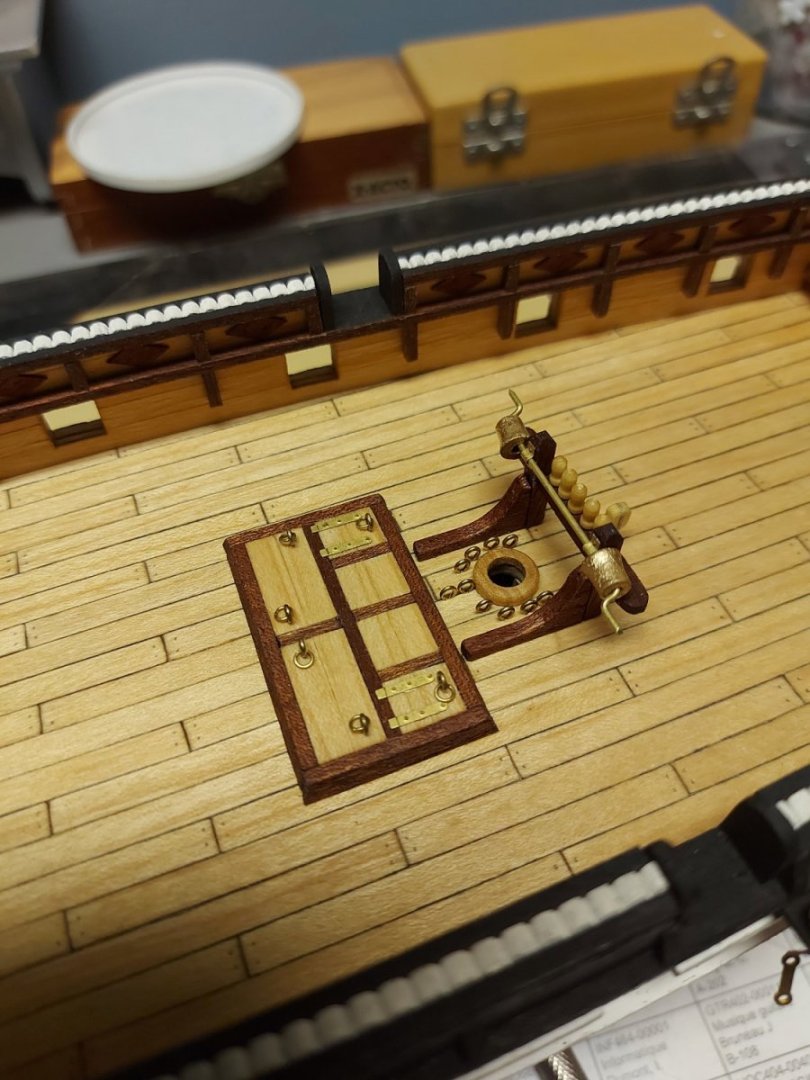

Good evening everybody, I forgot to post in some while, but progress has happened in the mean time. I did the small houses on the deck, with great care to adjust the planks that cover them. The contours have received particular attention, so that the ends match up with the thicker plank around. You may have spotted a new crank, which I plan on passing a rope through, with a simulated lead weight to its end. I struggled on finding a reference for that, so if anyone out there knows how this was done, let me know. I painted and glued to the deck the two small pillards, not sure about their name. I have painted and glued the anchors too. They are glued with CA, but I am not sure if they will hold up with even a small tension on the ropes. The chains on those where so finicky, I think their installment took me 2h, and I lost one link to the carpet monster in the process. Just like the back chains, I counted the number of links so that they sag the same way. Of course, you may have seen already bits of masts here and there. They are finished, the beams will come soon. There were some beads I had to nail to the mast, not sure how historically acurate this is, but it does look good. I broke the tip of it while pushing the nail in. With the hole in the middle and the size of the tip, it wasn't a surprise. I think they are pretty straight. Seeing them aligned this way made me think of Ulysse's Odyssey feat where they align 12 axes and he had to shoot an arrow through them. The three pins were difficult to align this way, and it might not look like at this distance, but they are quite close. Putting a knot through them will be a problem for futur me though. Sanding the char off these pieces was a pain, and breaking these delicate edges was unavoidable. Luckily, from afar it doesn't look too bad. I glued all the mast with wood glue, as its long drying time gave me enough time to align the in the best way I could. I will finish the beams before starting the rigging, unless one of you knows a better order to follow for the shipwright to not contravene with previous installments. See you soon next time, Patrick B.

-

Patrick B reacted to a post in a topic:

HMS Victory by James H - Amati - 1:64

Patrick B reacted to a post in a topic:

HMS Victory by James H - Amati - 1:64

-

Patrick B reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

Patrick B reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

-

Patrick B reacted to a post in a topic:

HMS Beagle by Firs49 - OcCre - 1:60 - First Build

Patrick B reacted to a post in a topic:

HMS Beagle by Firs49 - OcCre - 1:60 - First Build

-

Patrick B reacted to a post in a topic:

HMS Beagle by boerscht - OcCre - 1:60

Patrick B reacted to a post in a topic:

HMS Beagle by boerscht - OcCre - 1:60

-

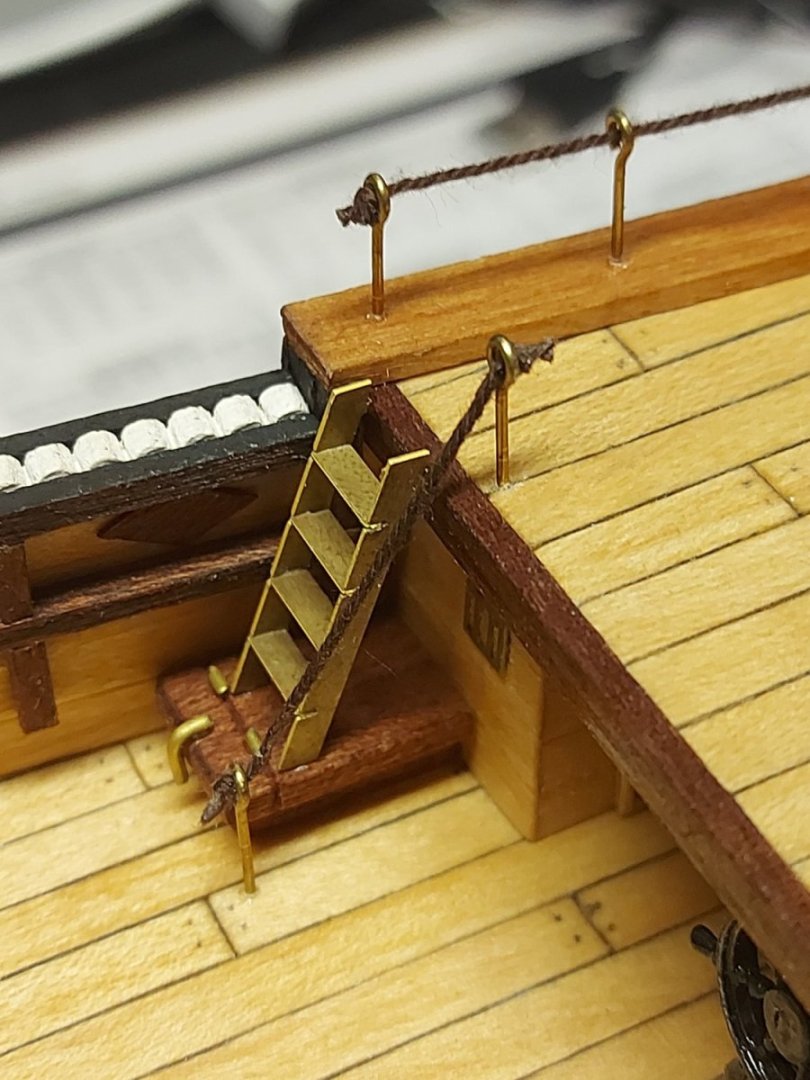

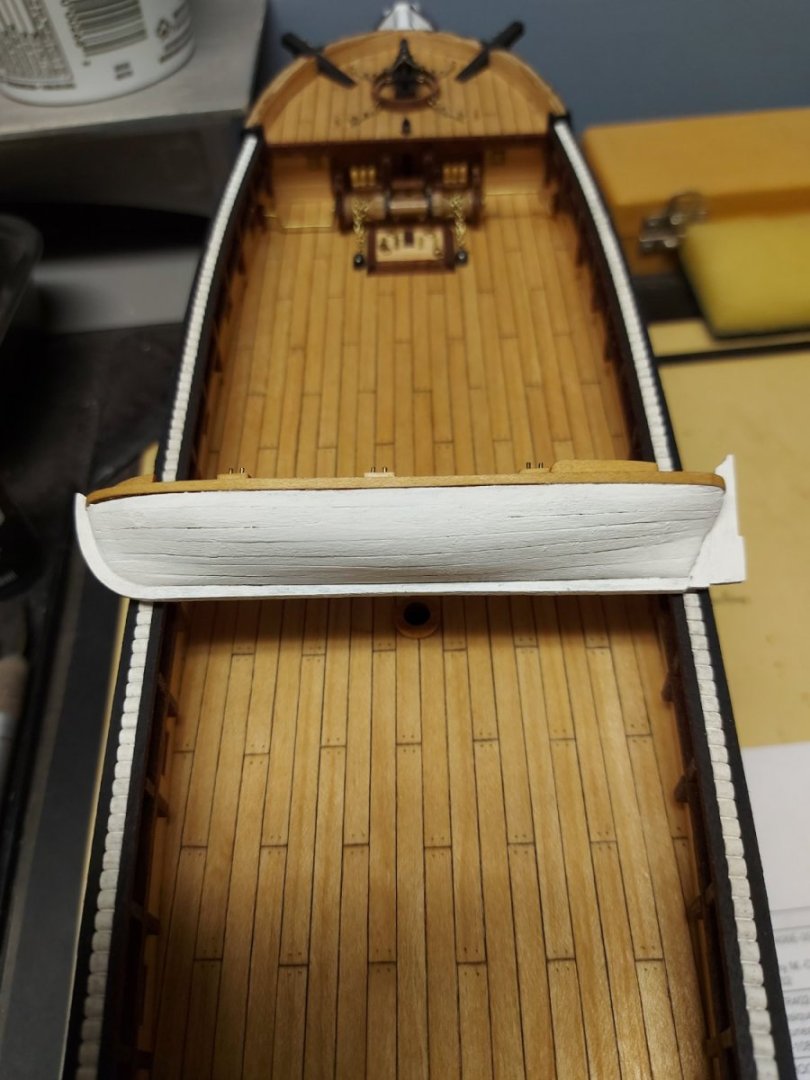

Hi, I haven't posted in some time. This is due to me procrastinating when I should take photos. In the last weeks, I worked on many different small thing on the deck. They didn't seem like worthwhile to make à post about. But when you add them up together, it makes a good chunk to show and talk about. First, I made the rails with eyebolts and rope. It was quite tricky to get the knot at the right place for it to be tight. I also glued the back catheads after removing the char and making pulley holes in them. Then, I secured the launch to to deck, and I'm pretty happy about how that turned out. I was unsure about the rope placement after its knot to the eyebolt. I could have done concentric rings of leftover rope, but it looked weird. I chose to leave it clean after the knot. As you might already have seen through the earlier photos, I made all the ladders, but I opted to leave them unpainted. I find it too Tricky to paint in all those tiny areas between the steps and I felt like this brass color fits the overall deck ensemble pretty well. After that, I focused on the water pumps. I wanted to give an iron look but I failed and it looks too shiny and plastic. Still, it doesn't look too bad. To finish off, I nailed the chain plates along the sides. To do that I placed temporarly the masts to get their angle right. I almost forgot, I also installed the chains at the stern, which drove me crazy. They were so fiddly and kept jumping off from my twizzers. I lost 3 links and for a good 20 minutes I thought the carpet monster had stolen them but after a while, I found them at the complete opposite side of the room where I thought they were. Those efforts were rewarded because in the end, they look great. Thanks for following along guys. The next update will be about the storage compartments on the deck and maybe something else. Patrick

-

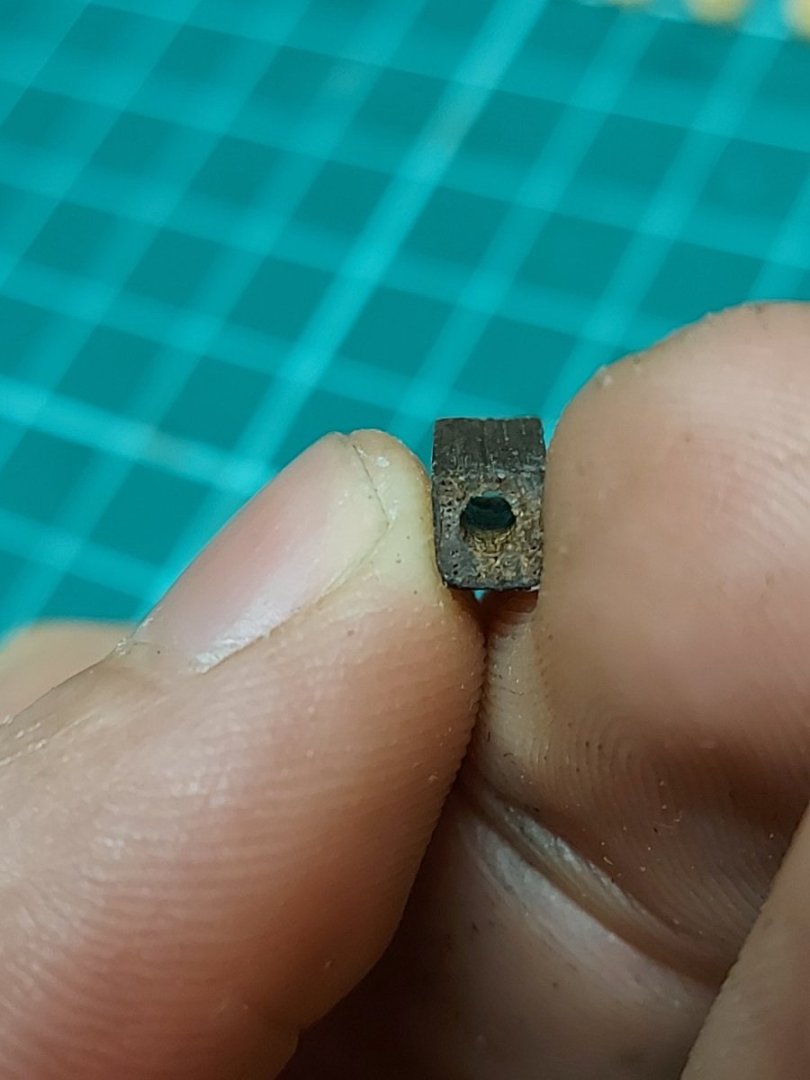

Hi guys, I have a question before gluing a piece in place. Do you know what was the purpose of the beam with a hole in it? I know it has two metal loops to attach some chain, but the hole seem a good place to put a flag pole. The instructions don't show you its purpose and I can't find anything on the internet. I'm sure someone here knows what it is, the time period associated with it, the history of it's name and the specific hole dimensions haha. Thanks, Patrick B

-

Hi, I missed your start a little, but I will join from now on your build. I noticed that occre did some changes lately. It seems that your keel is made of presswood instead of the plywood I received in the kit I purchased a year ago. Quick question: Are your blocks made of boxwood or are they plastic? Also, do you still have a sheet of walnut pieces? Good luck with the rest, Patrick B

-

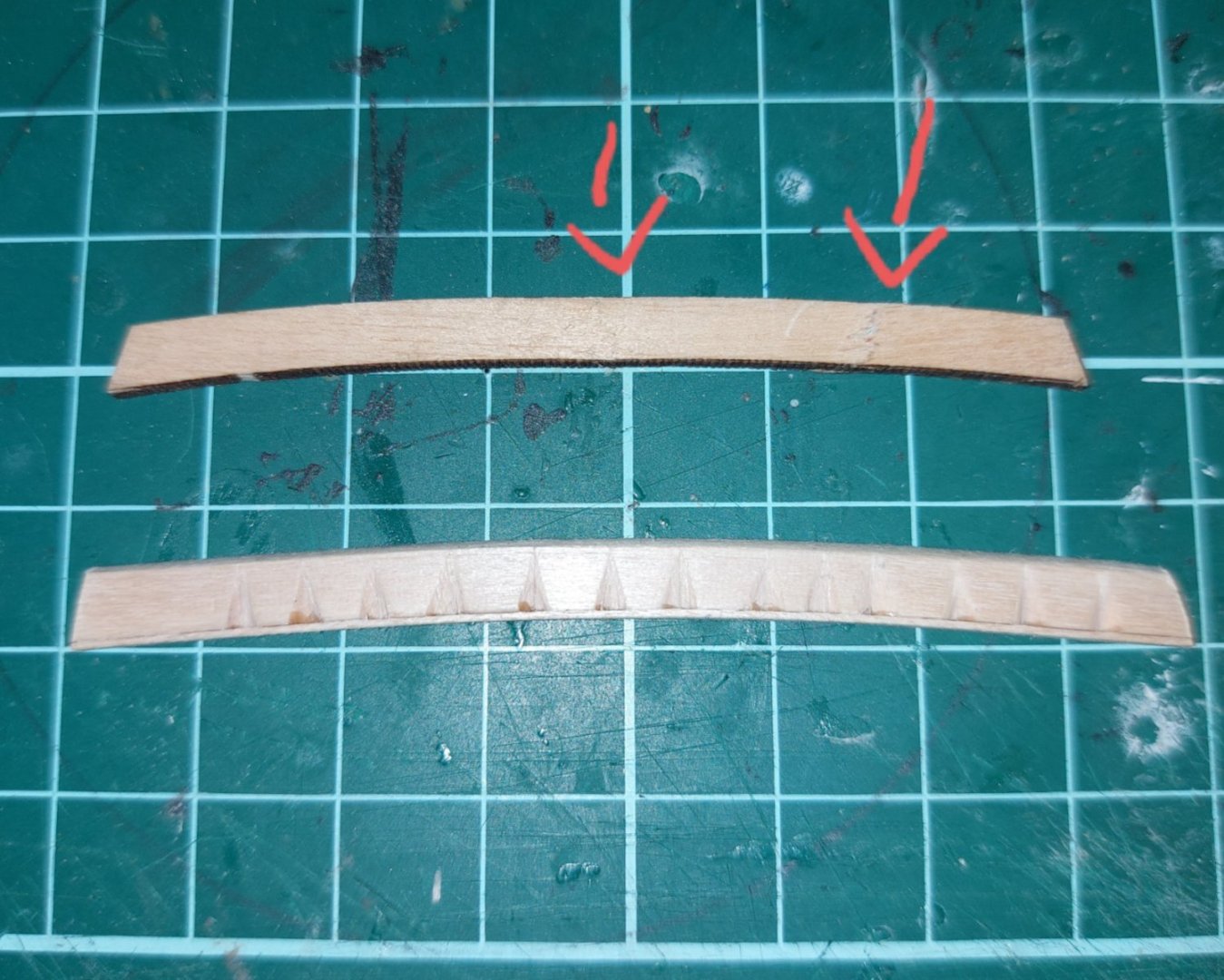

Small update here is a beam that will next be glued on the poop deck. The bend on the CNC machined plywood part was not fitting with my version of the ship. I tried straightening it But it broke in 2 different places. So I replaced it with some leftover wood. Even after putting it in hot water it wouldn't bend. I decided to cut some slots to facilitate the process and mitigate the risk of breakage. In the end, I glued a small veneer strip from leftover wood to cover the holes. A bonus of that is that when I will dye it, it will come out the same color as the strips on the side, as it is the same wood as opposed to the plywood part. I hope you guys had a merry holiday filled with time in the shipyard !

-

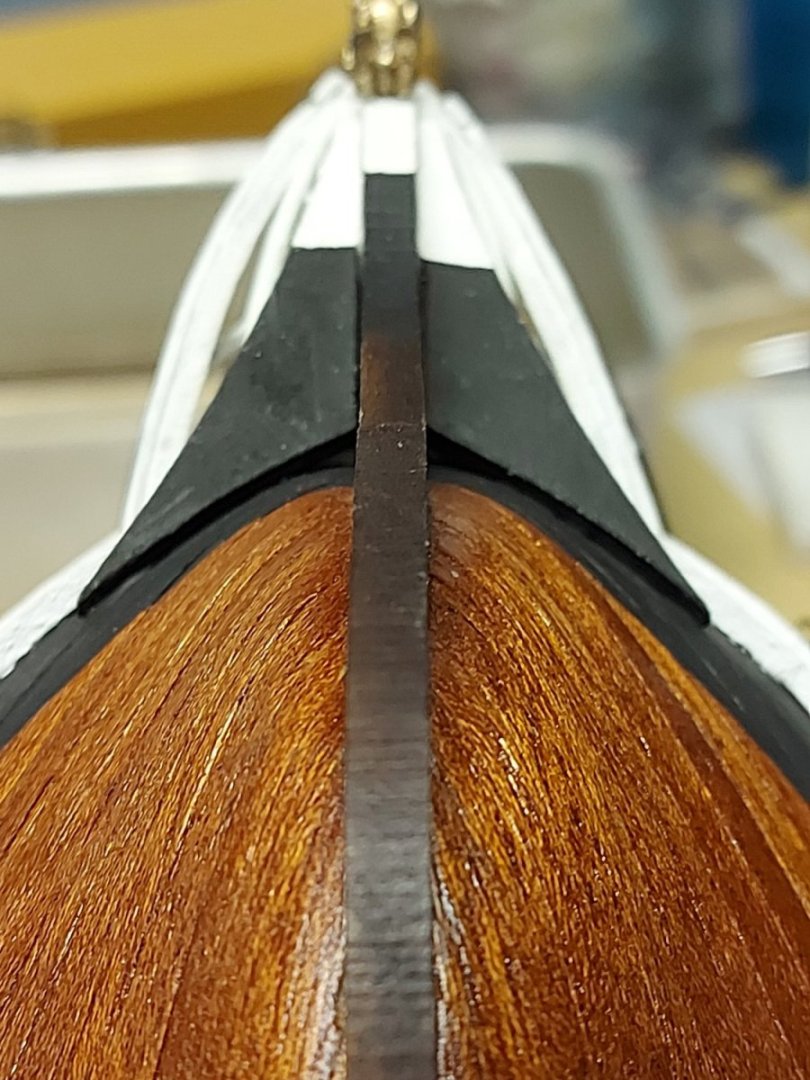

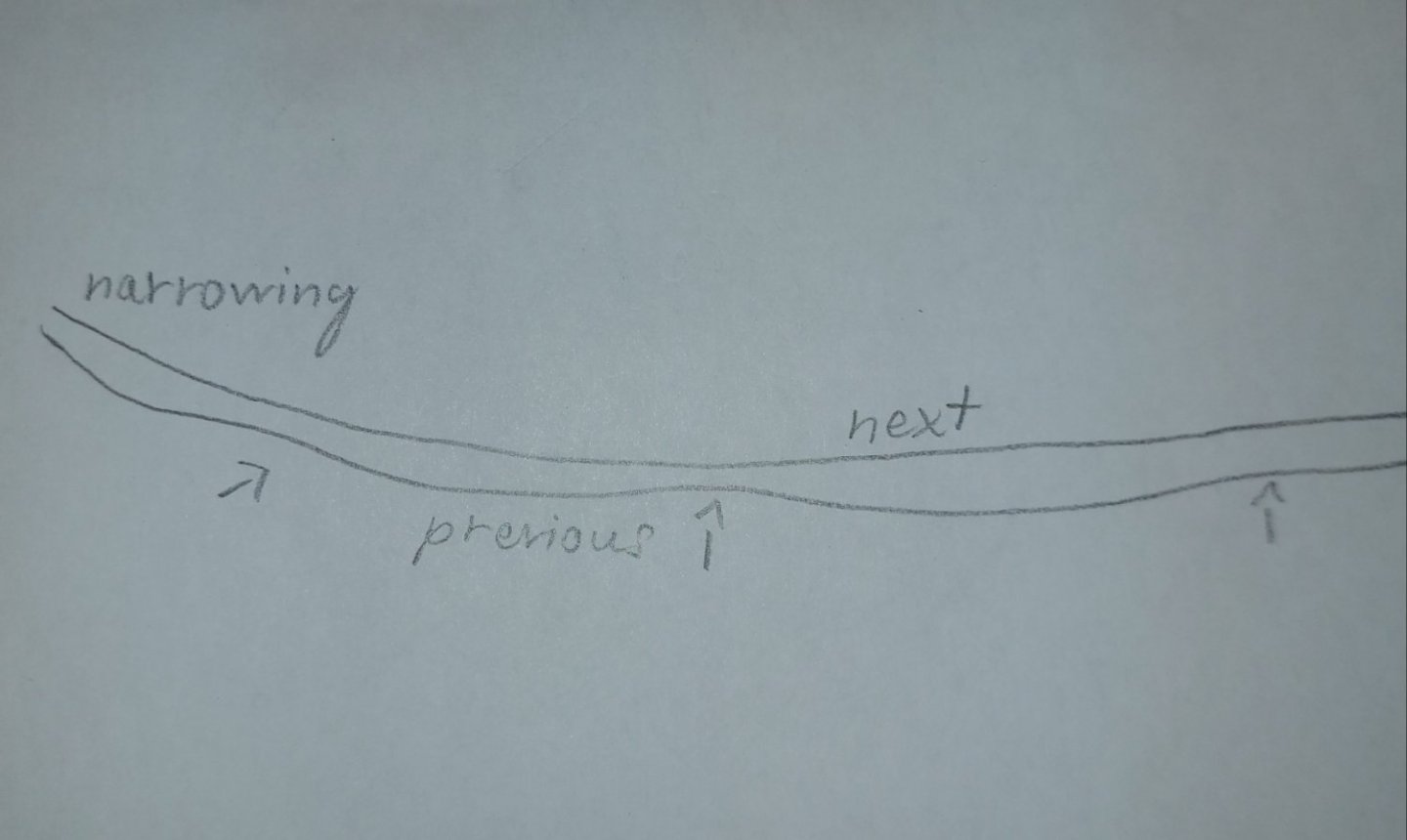

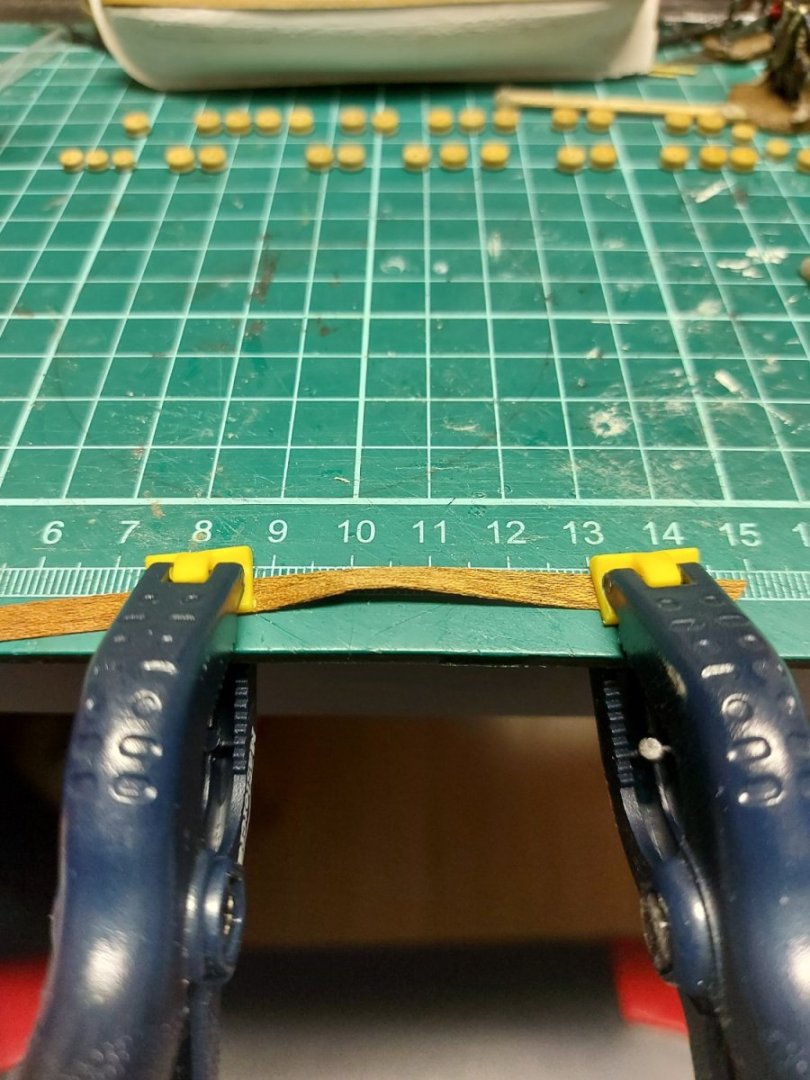

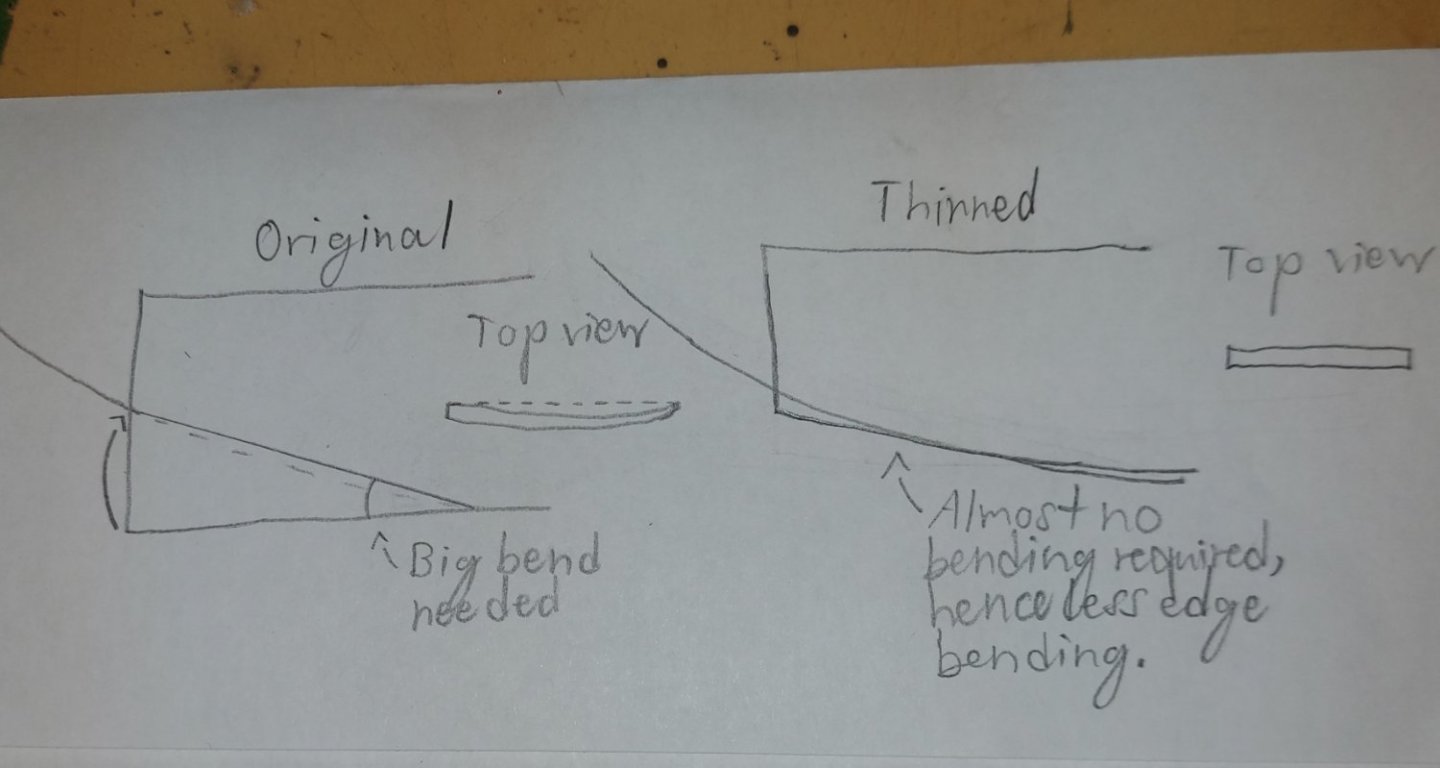

Hi Capella, you asked for tips, so here are the most important things I learned while planking, especially true for second planking. Start at the bottom and make your way to the top. Make sure that any previous plank are exactly the curve you want them to be. Don't be afraid to take some more time to send the edges or else the small errors will end up being harder to correct afterwards. Think of it as a butterfly effect. Here is an analogy to better explain. If you place a small pea on a table and lay several sheets of paper on it after a while the elevated area will cover more space than did the pea initially, causing some more trouble along the way. Count the number of strips needed to cover the belly (the largest part) then measured the front bow section and divide it by the number of strips, to get the width of each strip. Start this process over after every 2 or 3 trips glued, make sure that the width is correct and that you won't end up with too much to lose at the top. If needed, use stealers although if you did the other steps correctly you shouldn't have to use them too much for example, I didn't have to, but sacrificed a lot of time because I edge sanded every strip to make them fit the previous one. Like I just mentioned try to make each strip fit exactly the previous one and make them in the process as straight as possible. Here is a drawing I made to illustrate this. Finally, use CA (cyanoacrylate is the working agent examples : krazy glue, gorilla, Bob Smith industries) glue and press firmly a while to maintain pressure on the whole strip. Unlike the thicker ones, these strips will elevate one side, the one where the bend is made. To counter this effect you should narrow the end. Here is an example. Instead, your strip should be tapered, to decrease the bending needed. If you are unhappy with a plank, correct it now or else later it'll be too late. In fact if you try sanding it afterwards, you risk going trought and revealing the layer underneath. These where my top tips, hope this helped.

-

Thanks a lot Cathead, like you I struggled to find a diagram that put the canons parralel to the sides, like showed occre. This will be helpfull I'm sure. I thanks Snug Harbor Johnny too for his idea, although these many twists seem harder than the half hitch I use. I would like to use the most accurate knots in rigging my ship, but I struggle a lot with holding the knot itself, the working end and the block I'm trying to seize. Inevitably, I release one of the above, having only two hands. I cross my fingers that nothing will slip out of place and, with good luck I'm sometimes able to finish the knot.

-

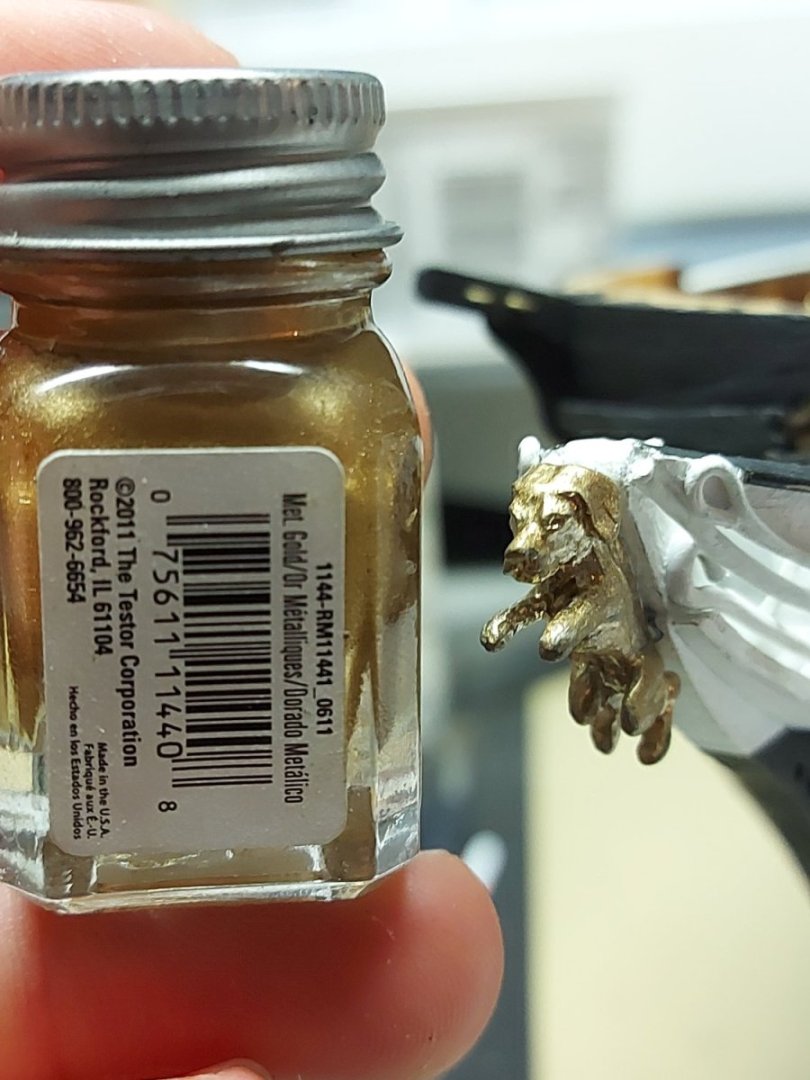

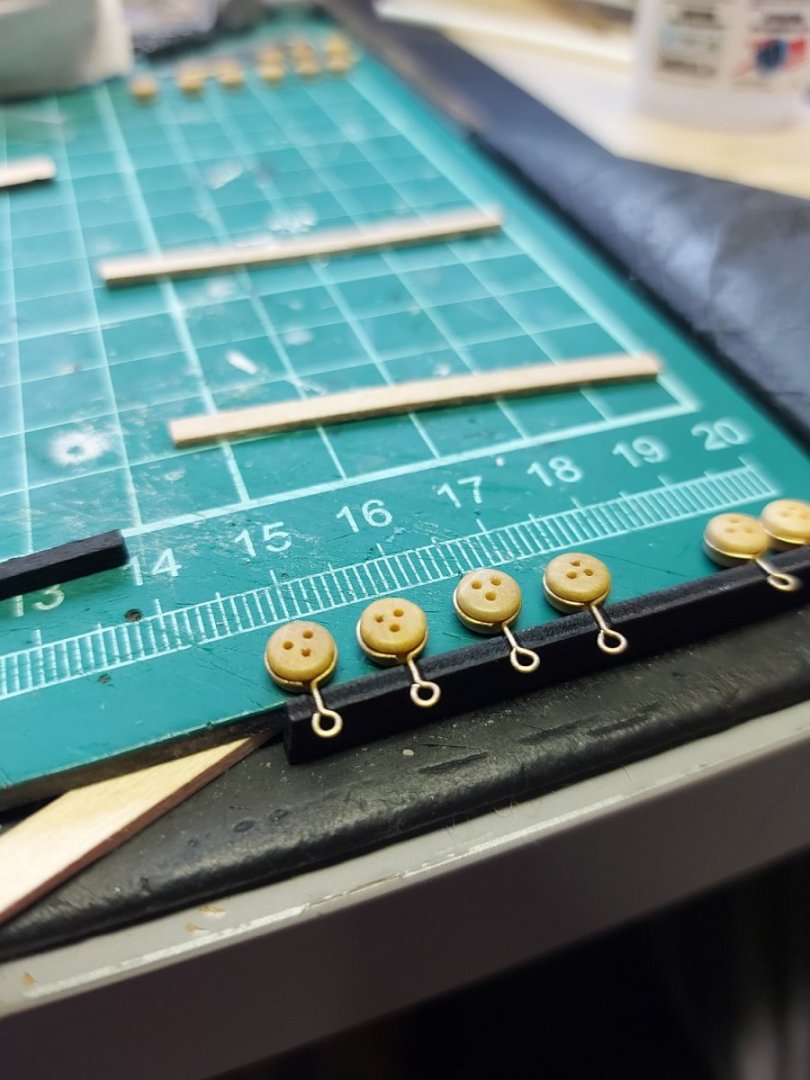

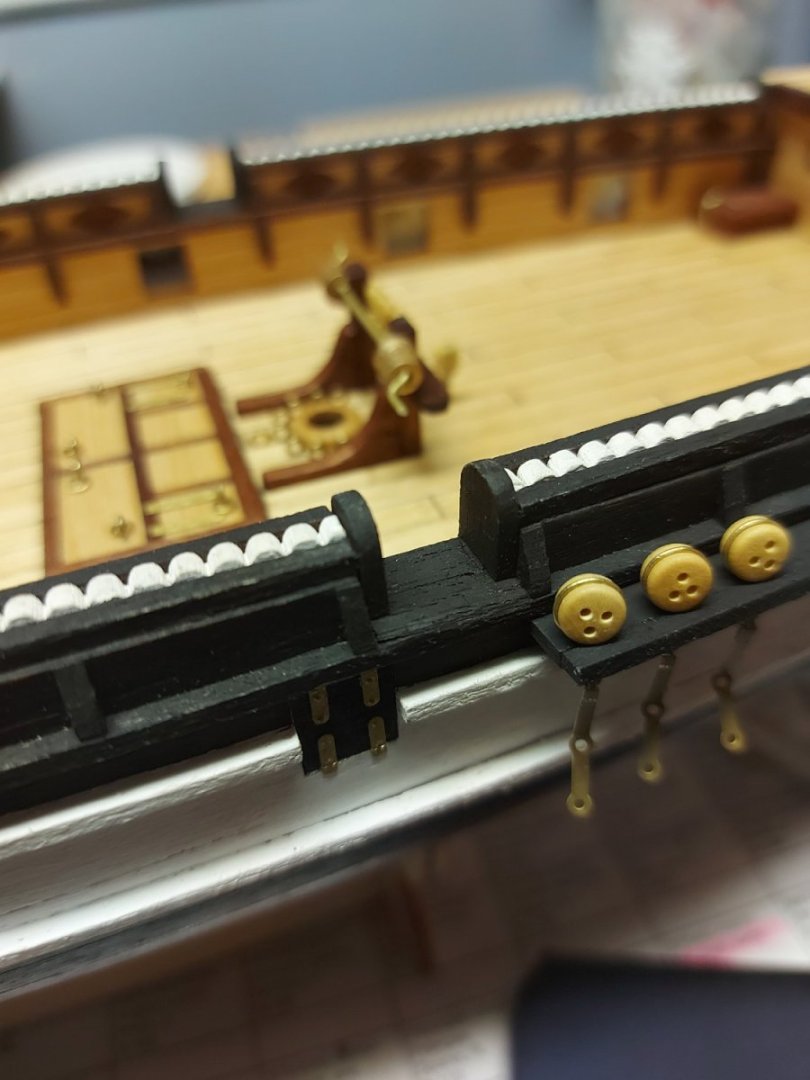

Hi everybody, some progress has been made during the holidays, and more is to come. The central trap doors are finished, as well as a crank, wich I still don't know the use. Since the pins where too far forward, I had to glue it at the back. I also covered the feet with a mahagony veneer I curved around, making them much better looking than the naked plywood. I forgot last time to show you the bow figure, wich I painted with gold testor enamel paint. Then came the chainplates, very fastidius to make the end loops. I invented a method to glue the beam over all at once, consisting of placing a wedge under the cutting mat to elevate the deadeyes. I haven't nailed them to the hull yet, I am waiting to place the mast in, to align them with it. At first, I hadn't realise that the 3 deadeyes at the stern where supposed to be the small size. I realized that a bit too late. I had to open them and replace them. Now nobody could notice that this mistake was made. I attached some blocks to eyebolts on the deck, but made a small mistake. For one of them, the hole was upside down. I managed to take it out of the loop and put it back, without loosening the loop too much I think. The last part where the gun ports. I took some scrap 2 x 5 wood and oiled it to match the inner sides. I covered them with mahagony and painted them. I glued the hinges a bit off the center, to give the impression of real hinges. This is why I also added a small x-acto line to simulate a 2 part organ. You better be carefull with those, as they fly off tweezers easily and they give you only the exact amount necessary. I did a 90 degrees bend, to compensate with the loss of space caused by the deadeyes placement. To finish off, I read somewhere that the gun port at the bow was only painted, to make it seem like they had more canons than they really had. In fact, it lines up with nothing, this door leads to a wall. Maybe this isn't true, I don't know. I do not remember showing some pictures of, well, those. I don't remember the name of the entrances. I know some people put staircase on the hull that lead to them but occre doesn't seem to make us put them. Anyways, I glued mahagony strips there to cover the layer of the sides. One last thing, do you guys know how the canons on the HMS Beagle where rigged to the deck. Altough occre shows a way, it doesn't convince me that this was the way. Otherwise they would be moving back and forth on these ropes. Thank you all again for following me on this journey.

-

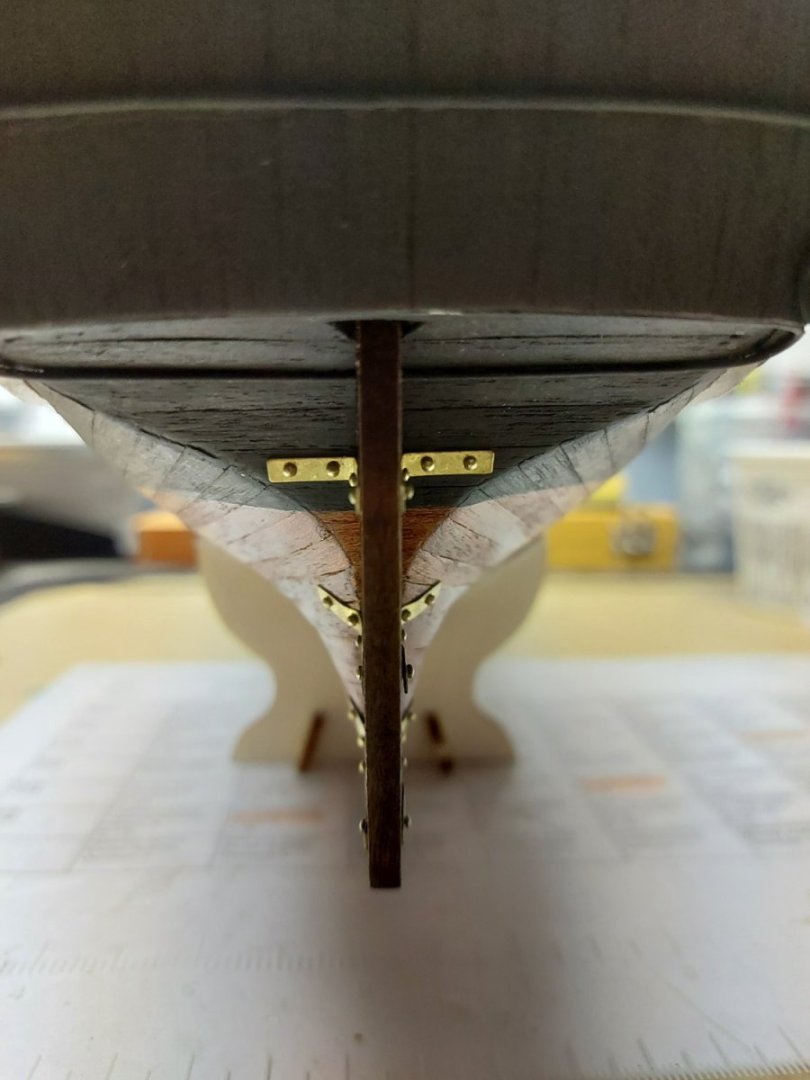

Hi, its been a long time. In the meantime I ordered 5 more brass rods, which weren't the right size. Luckily, occre agreed to send me an other package, for free. While waiting, I drilled the holes for the nails of the keel (is that the word? ), which turned out pretty good. The hard part was to carefully bend the sides to fit the curvature of the stern. Next, I made the windows from leftover wood, because the kit supplied one woudn't fit, because of how flat they where. They still servent as a good guide, to get the size right. I then bended and glued the metal decoration piece. To finish of, I drilled and glued the eyebolts arount the mast hole. I think I might have placed the one at the left a bit too close to the one beside it. After that, I started the trapdoors. bye guys, until next time. I will try to post more often.

-

The bow's decorations are finished. They where hard to do, because of the curves and the end loops you had to give the brass rods. Speaking of them, as some mentionned in their build logs before, this kit doesn't have enough of 1 mm rods. I just commander them, and by occre's police, they should be free of charges. I don't know if there are other material issues you have encountered. If yes, let me know. After that, I painted the barge and the stern.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.