-

Posts

518 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by oakheart

-

The planking has been ongoing. I am really not sure about it being correct. I need some advice. The way the planks are tapered from the frame towards the stem looks odd, but I cant figure out what it is I've got wrong? should it be more like the penciled in line ? With the photo above , I can also see that I missed the tick mark on the stem one plank up, that can't be helping. Tim

-

Waiting for the 5th plank to dry, trawling through the incredible amount of build logs there are here on MSW. I found this build log : https://modelshipworld.com/topic/3741-queen-annes-revenge-1710-by-shipmodel-finished-136-scale/ Thanks shipmodel ( Dan ) your work on the QAR boats gives me a goal to work towards. It has re-inspired me, my planking was beginning to get to me. I know this is only a tiny model but it is testing me. Reading the QAR log I'm being tempted towards a larger project, like a pirate ship or a Bounty. But I really do need to finish my launch first. I am too easily tempted into a new project, leaving a trail of part finished models in my wake Tim

-

Black Pearl by LFNokia - 1/48 - open hull

oakheart replied to LFNokia's topic in - Build logs for subjects built 1501 - 1750

Thank you for these plans, I may just have to give this a go................. when I finish my small boat of course Tim -

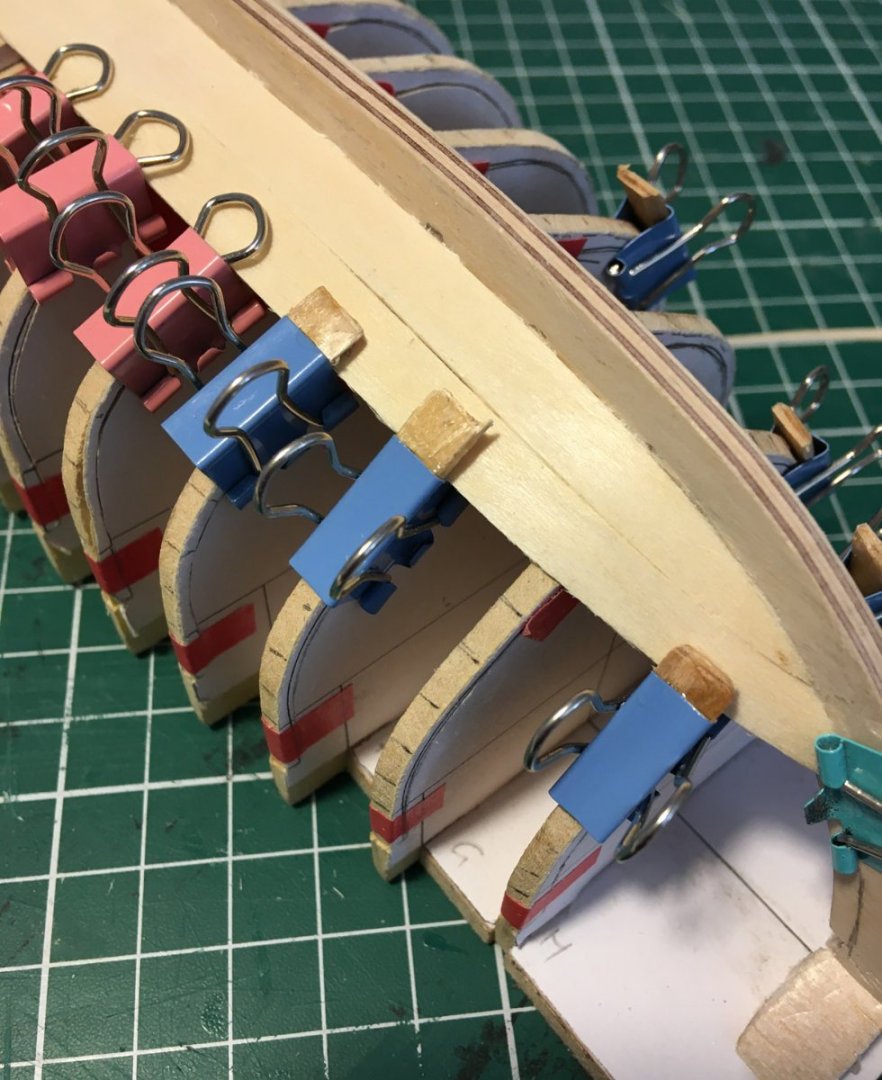

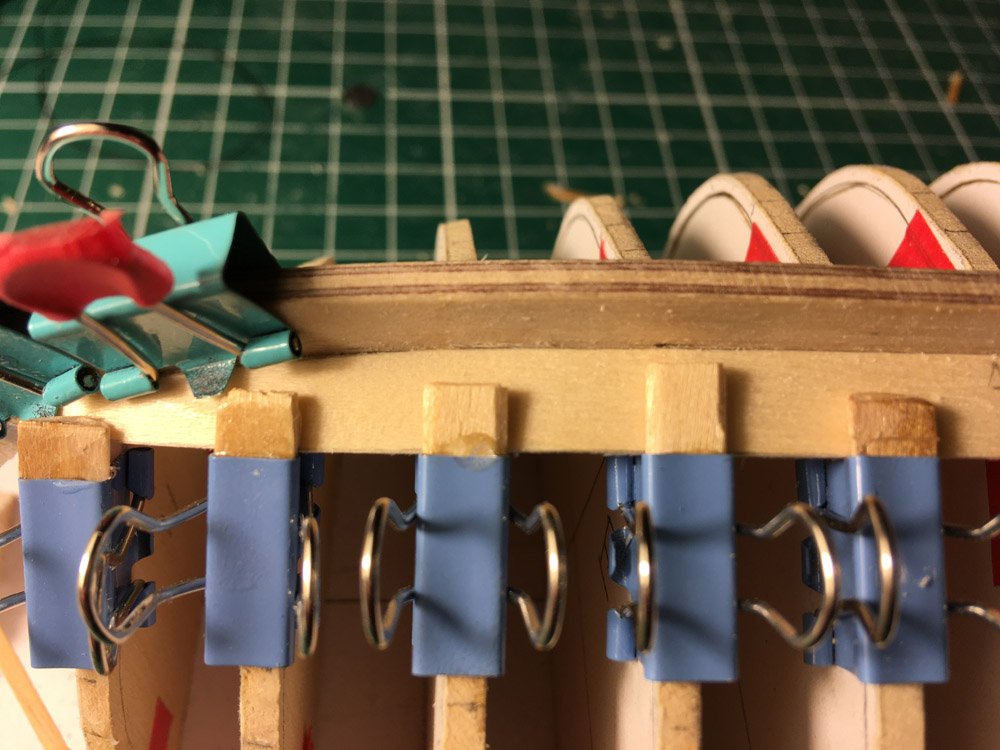

I have now glued up the matching plank pre-bent and faceted the frames. It looks good, so I think I will continue with this technique until I get round the bend, then up the straighter sides go back to normal. I saw some one on this forum ( website ) who had planked straight from the Garboard right up to the gunwale in one run, so on this build that is what I am trying out. As a programmer I was taught "only change one thing at a time" or you won't know what is causing the problem. Here I have just jumped in with all feet first. Tim

-

so my take on those options are : 1: Could I live with the faceted inside - Yes, if it's not to noticeable it could be alright 2 : looks like it would be really difficult to do. 3 : Planks are only 0.8 mm ( 1/32 ") going even thinner may work, worth testing, may break. 4 : This would help but may need a lot of clamping pressure and crush the model. 5 : with the clamps I am using that's the only way they work, will try elastic bands Thanks for all of those ideas, I will see how my faceted frame worked when I un-clamp it later Tim

-

I have now got to, as Craig said - the interesting bit. Moving down the frame, now when I lay the plank on the frame, the plank is flat but the frame is curved ! In the photo, I have used a wider plank to exaggerate what happens, the problem is made worse when you can only clamp from one side of the plank. Sorry - I could not get the phone to focus on the end of the plank, but you can see what's going on. To overcome this I have just tried a test laying of a plank. Firstly between the tick marks on the frame, I sanded that area flat. It's glue up right now, we will see later if it worked. How do others overcome this? Is there a trick I am missing? Tim

-

Thanks for the compliments. Allan and Craig are the experts here, There is a load of information on the their other logs as well. I'm just here having a load of fun doing some research, trying new ideas and learning new skills. Question : Should all of the detailed information be collected together and put it in the "launch details" log. Who started that log ? was it Craig or Allan? my memory is not so good Tim

-

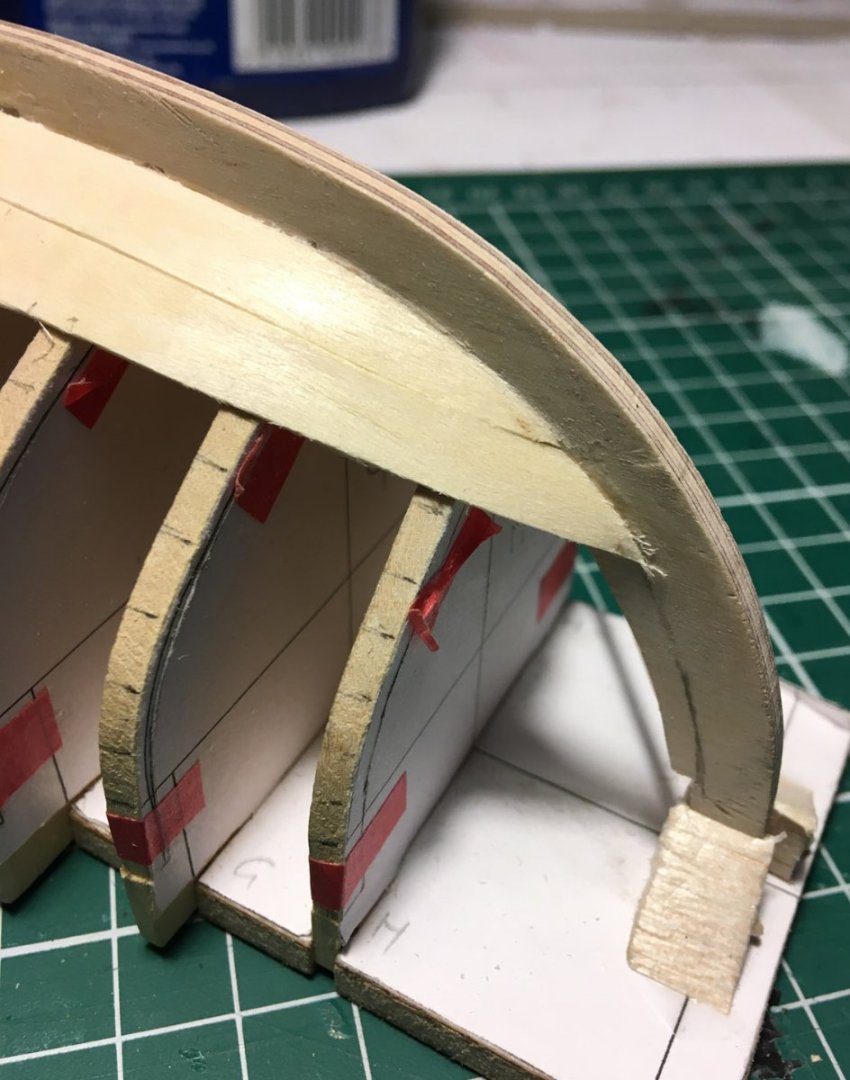

Okay here as promised the next installment. Got three planks in place over the last couple of days, taking it slow. Third plank clamped in place here is a close up after the clamps have been removed, a bit of clean up needed but pleased with it. onto the 4th plank There is a a bit of a step of levels here, I think it's because the first plank did not glue down tight to the frame, hope I can sand the new plank level without sanding right through it. here is a view of the whole thing, pretty pleased so far comments please Tim

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.