-

Posts

518 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by oakheart

-

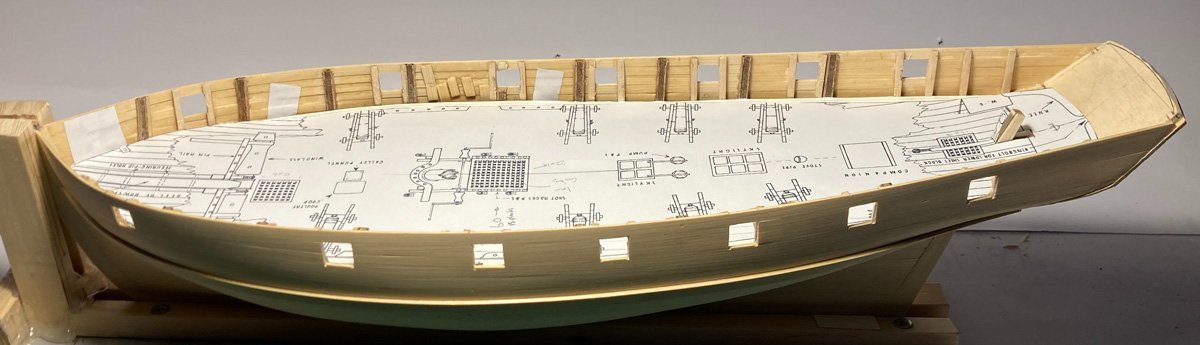

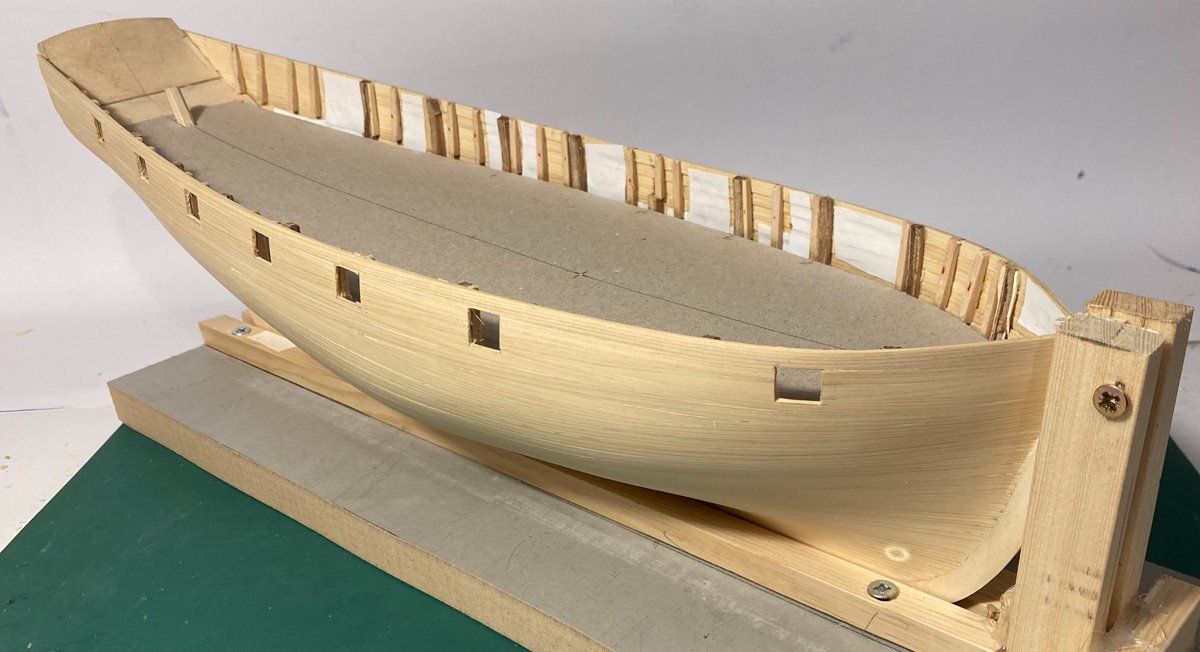

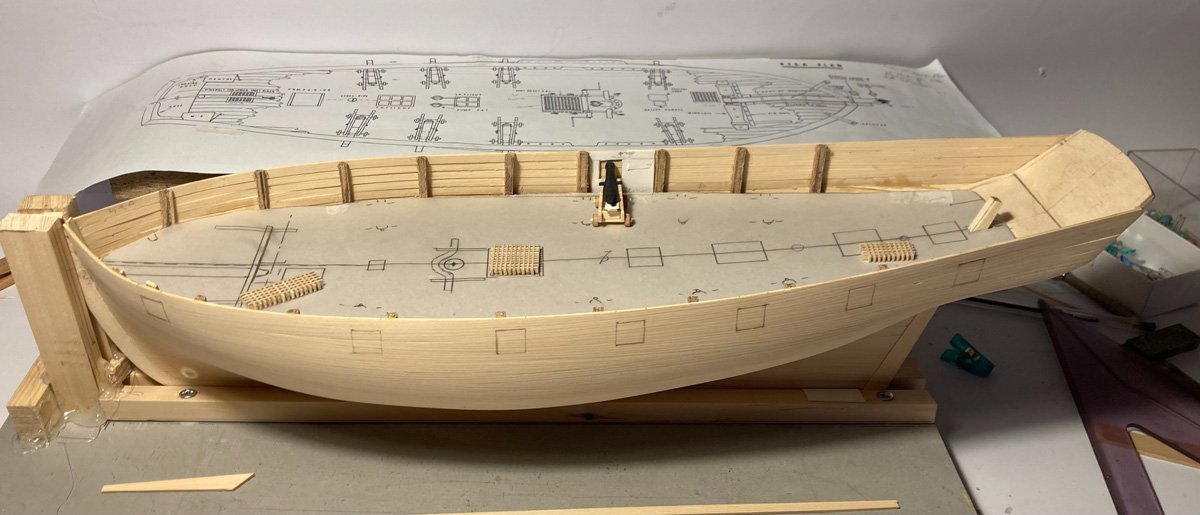

Happy New Year to all onboard. I managed to get the wales cut and glued in place, I was really happy with the result. Then I went back to figuring out the deck. I cut out the deck plan from the original design as drawn by Bill and laid it in place. As I looked, the old saying of "measure twice and cut once" sprang to my mind. How did I managed to do that? I had measured from the transom taking measurements from the side view drawing, it looks like I had got the stern all wrong, it's too long, so that threw out the gun ports. Not a lot I can do about it now, so I will crack on and finish this model knowing that it's wrong, I think it should make a nice looking model all the same. I don't remember who said it, but apparently "we learn nothing from success." Tim

-

Merry Christmas Craig, Hope Santa left some nice pressies ! I have to wait until tomorrow to see what I got.............. Thanks for the drawings they do help to get an idea of the difference, I may just stick with the 5mm planks I have already. They are maple not holly ( wishful thinking ) and too late for the Santa list now. Tim

-

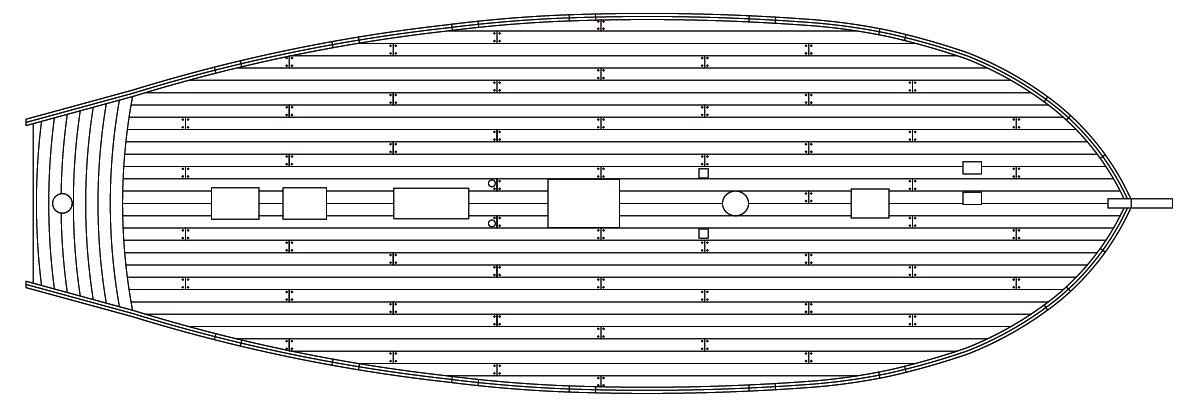

I have been giving this some thought. On the plan drawn by Shoulders the deck planks measure about 5mm wide ( the lines are thick and uneven) At 1:48 scale that equates to a 9.5 inch plank is this too wide? I can get thinner planks in stock sizes so 4 mm = 7.5 inches which would seem to be a bit more realistic Dan Vadas said about his swan class sloop 'most of the planks (apart from the Kingplank) are no wider than 8 inches ' What would be the best for this model of a cutter, I did see another discussion about deck plank widths but can't find it again Tim Hope you all have a good Christmas, see you on the other side.

-

As usual your advice is good. That would make it look better. Is that deck / beam plan of the Speedy or a different cutter? I am tempted at this point to make this build the 'Kite' there is a great painting of her in action off Beachy Head on the south coast of Britain by Montague Dawson I think she was a sister to Lapwing. The painting shows the drama of a chase really well, my model will just be static on the shelf. maybe put a print of the painting behind it. Tim

-

Hi Carter Welcome to this crazy place. What is your current project? Tell us a bit about what you do. Tim

-

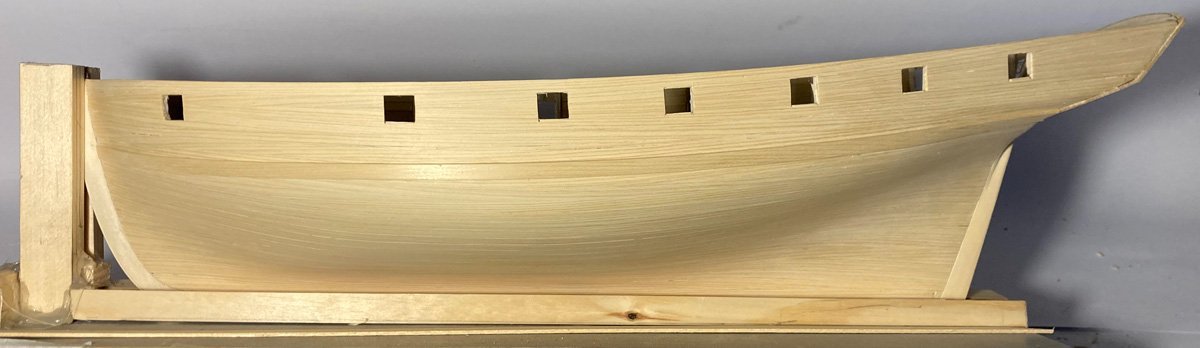

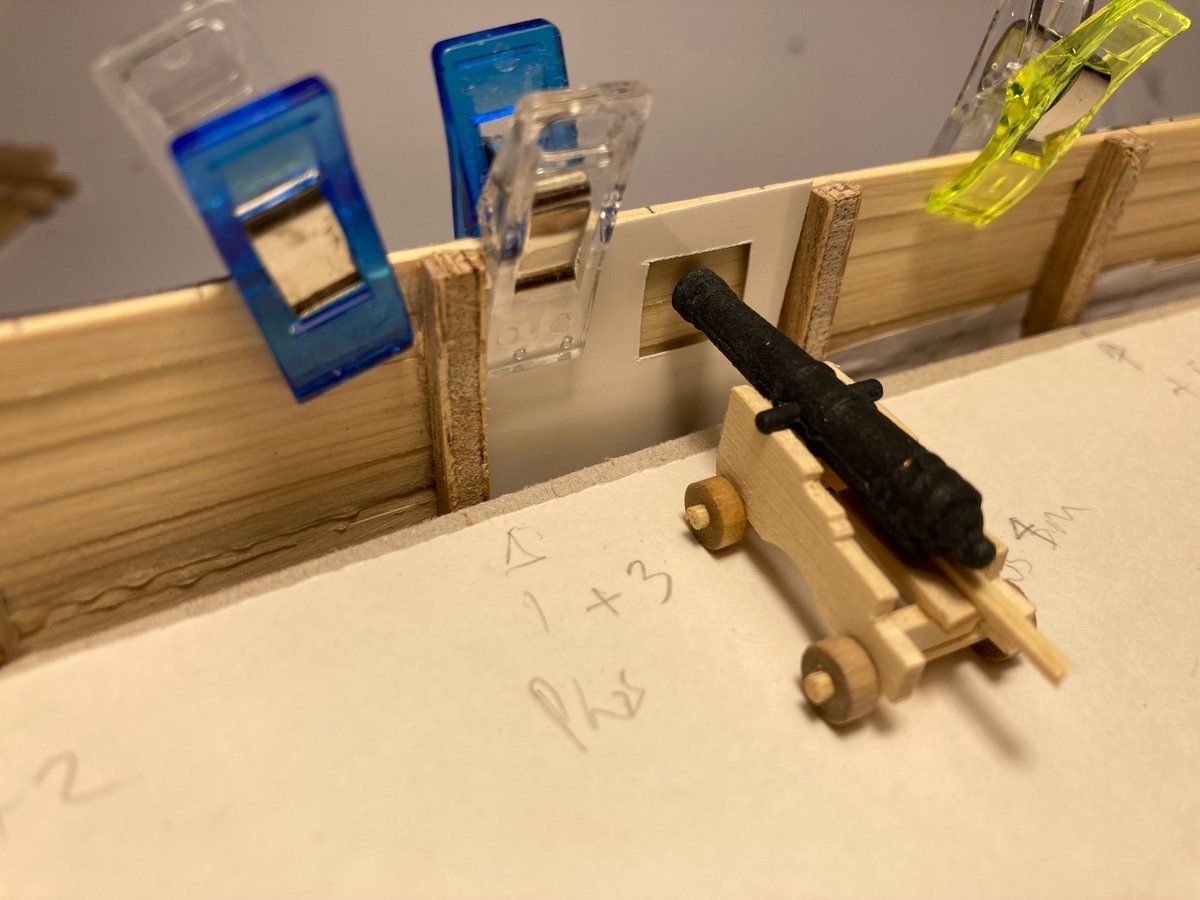

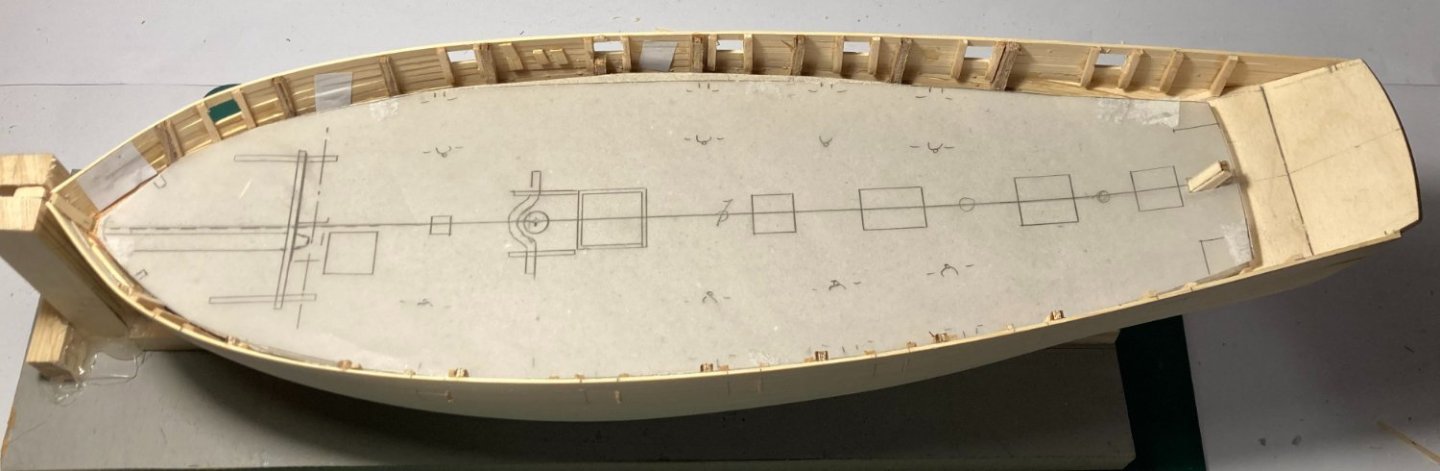

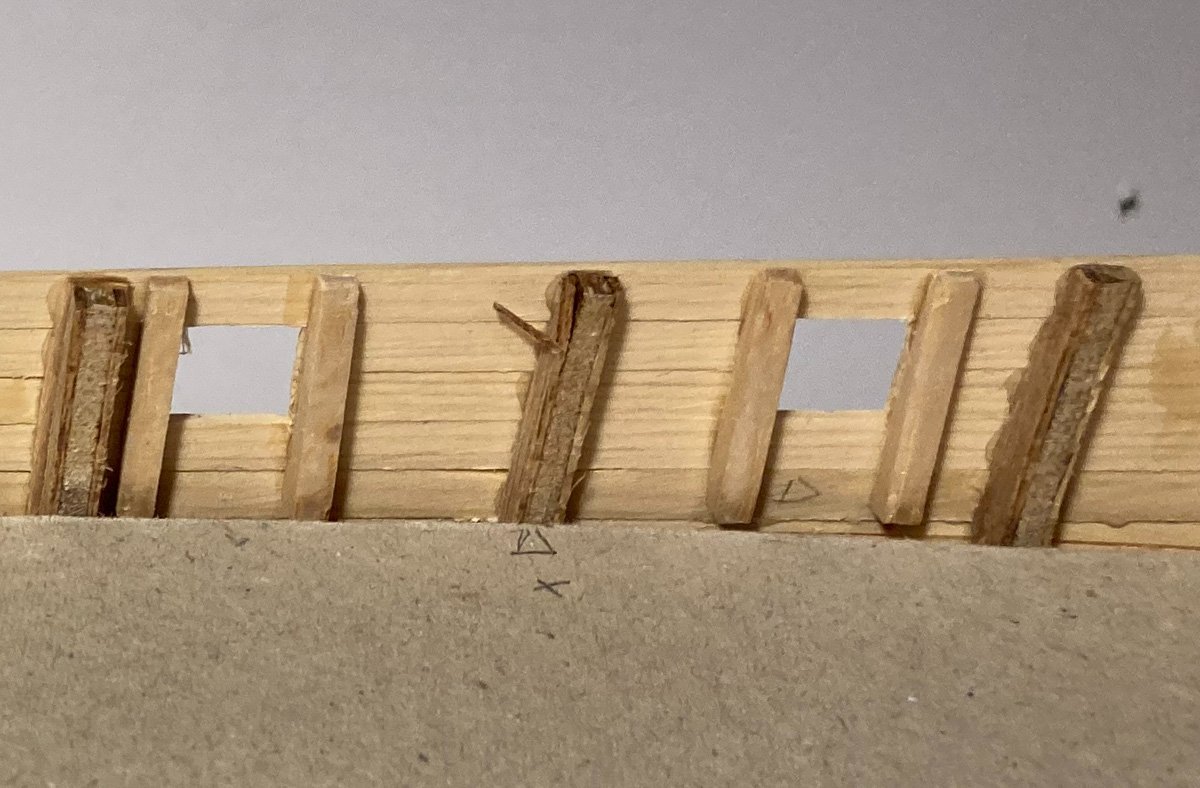

Thanks for all the likes. I have now completed the planking on both sides. The gun ports have been marked out as per the drawings before they are cut, I tested with the cannon and a card template here are the first half cut, I used a 10a scalpel to cut them, the cedar is a joy to cut. here is a test of fitting the lining, not sure if it's too thick? a lot of cleaning up to do before the ports look crisp. I have traced the deck fittings to give me an idea of what it will look like. I now need to plan the deck planking For this I need some advice, what would be the correct plank layout for a cutter like this? Is there a layout I could use, the drawings I have only show part of the deck. Only a few more days until Christmas, hope I can find some spare time to get a bit more done Tim

-

Hi Mark, my 20 year old heat gun has 2 settings, After doing a bit of research The maximum temperature of a hair dryer is 140°C, a heat gun's maximum temperature is upto 700°C Mine does low : 460°C and high : 600°C if I make a snoot for it as well it could work Here is the wet plank clamped in place, I soaked it in boiling water for several minutes then clamped it and left it to dry overnight. here it is clamped and gluing. fingers crossed 🙂 Tim

-

Thanks for that Mark, I too will try to keep it in mind. It also helps that there are not so many tasks that need attending to in the garden. I have just cleared the leaves from a Mulberry tree. The first hard frost and they all come down at once in great drifts. Hi Allan, I just tried this. The plank is keeping the shape nicely. I let it dry out off the hull as you suggested. After my coffee I will glue it in place. Tim

-

I have read that this could be a problem, I had done about 2/3rds of the sides together, do one plank and mirror the other side, then I could not stop myself and rushed ahead, finished one side so I could see what it looked like. ( you know me always rushing to get finished ) So far there is no visible twisting, maybe it only happens if you plank one whole side and leave the other blank. Talking of twisting, I am finding getting the twist of the planks at the stern right very difficult. I'm using a small hot iron the bend the planks and it works well it's getting the twist in the right direction and how much, that gets me all the time. Tim

-

Thanks for all the likes. I have pretty much decided to stain the hull as per the test I did earlier. So have ordered a larger bottle of the water based stain. After it's applied the gaps between the planks ( caulking ) I hope will show much more clearly. Once stained I will apply a coat or 2 of WOP. Onto planking the Port side now Tim

-

Thanks Craig - Task completed for the first plank. It looks a bit of a mess but it will not show. New plank glued in place. I will wait for it to dry and do the next one. I may make some tiny slivers to fill the cracks as well. The sternpost plank was just a sacrificial piece while I sanded the main planks down. I will make up a board as you suggest with the grain running parallel to the aft edge. Thanks again for your help and support. Tim

-

I have now finished one side of the hull really pleased with the overall result. it even looks okay close up. I did not manage to get the correct twist in the planks at the stern with the result that I sanded right through a couple of them. Looks like it may be repairable. I still need to do some clean up round the stem. So when I do the other side I now know what to watch out for. Not so sure if I will stain it, what a shame if it went patchy. all comments welcome, please give me some feed back. is the repair doable? Tim

-

Hi Craig While searching for information on cutters, I found these. some good photos of the replica https://www.britmodeller.com/forums/index.php?/topic/235131538-le-renard-1812-wip-artesania-latina-150-finished/ nice rigging and replica build https://bosco45-eklablog-com.translate.goog/?_x_tr_sch=http&_x_tr_sl=auto&_x_tr_tl=en&_x_tr_hl=fr&_x_tr_pto=wapp tim

-

It feels like winter already. Heating on, managed to get a few more planks done. Not sure about my planking run, do I need to try and correct it. Ignore the hacking on the last two planks near the stem, I got carried away with the scalpel blade I was running out of room for the paper clip clamps, so I made some screw types, they work even better than the clips some number zero self tappers and a bit of ally rod drilled, with an offcut of plank strip. I have a knurling tool for the lathe to give the rod a bit of bite. A drop of glue on the head seems to be holding it okay.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.