-

Posts

518 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by oakheart

-

Could not resist, I started sanding the planking already done. Using 50 grit sandpaper on a small wood block. But I have a problem with the 1.5mm thick planks flexing, while I am sanding the hull fair the planks are bending slightly in between bulkheads, I am not even pressing very hard. This means that the plank on either side gets sanded a little bit more and becomes thinner. This is sort of difficult to photograph, hope you get the an idea of what's happening. On my next build I will use more bulkheads, meanwhile I have glued a small strip behind the planks to stop the flexing. Has anyone else had this problem? What have others done about it? Tim

-

The planking continues. I made a simple jig to aid cutting the planks into the correct taper. here it is with the steel straight edge ready to cut the taper A few planks make it begin to look like a cutter. the shape begins to appear. close up of the bow. Doing the Bounty launch helped me with understanding planking. I want to stain the Alaskan Yellow Cedar to look like the old models in the RMG collection, so I have been testing a water based wood dye. Pleased with the result, also found I could not coat with brush on acrylic as the stain runs, so used a rattle can from Halfords. Tim

-

So here I am back, it's been a long summer, so much to do................. Managed to get a bit done on the Speedy. Garboard plank in place on both sides. while I am plodding away building this 1:48 scale model some people build full size Cutters. Here is the real thing Luke Powell built the 'Pellew' https://www.workingsail.co.uk/pellew?itemId=fihssy98q3833wr2jbjrsb17q7mzt6 loads of videos of it on youtube. and some action video of other Cutters , really shows what it must have been like sailing these craft. anyway, the sun is shining and I have more garden work to do. See you soon Tim

-

Thanks Allan For this build I have just gone with whatever Bill Shoulders has shown on his plans. I have no idea if they are accurate or not. I will try and find somewhere in the UK where I can get things 3D resin printed, I have tried cannons at this scale on my FDM printer and they do not look good. Tim

-

Managed to get some done to the hull over the last few days. Masked up the keel ready for fairing the bulkheads. Noticed a fault ( hole ) in the plywood made a quick and dirty repair I had to add some temporary beams to strengthen the bulkhead tops while I was sanding. they will be removed after I have done the planking. the planks now sit nicely on the bulkheads I now need to make a jig to hold the hull upside down while I do the planking. Off to do some research Tim

-

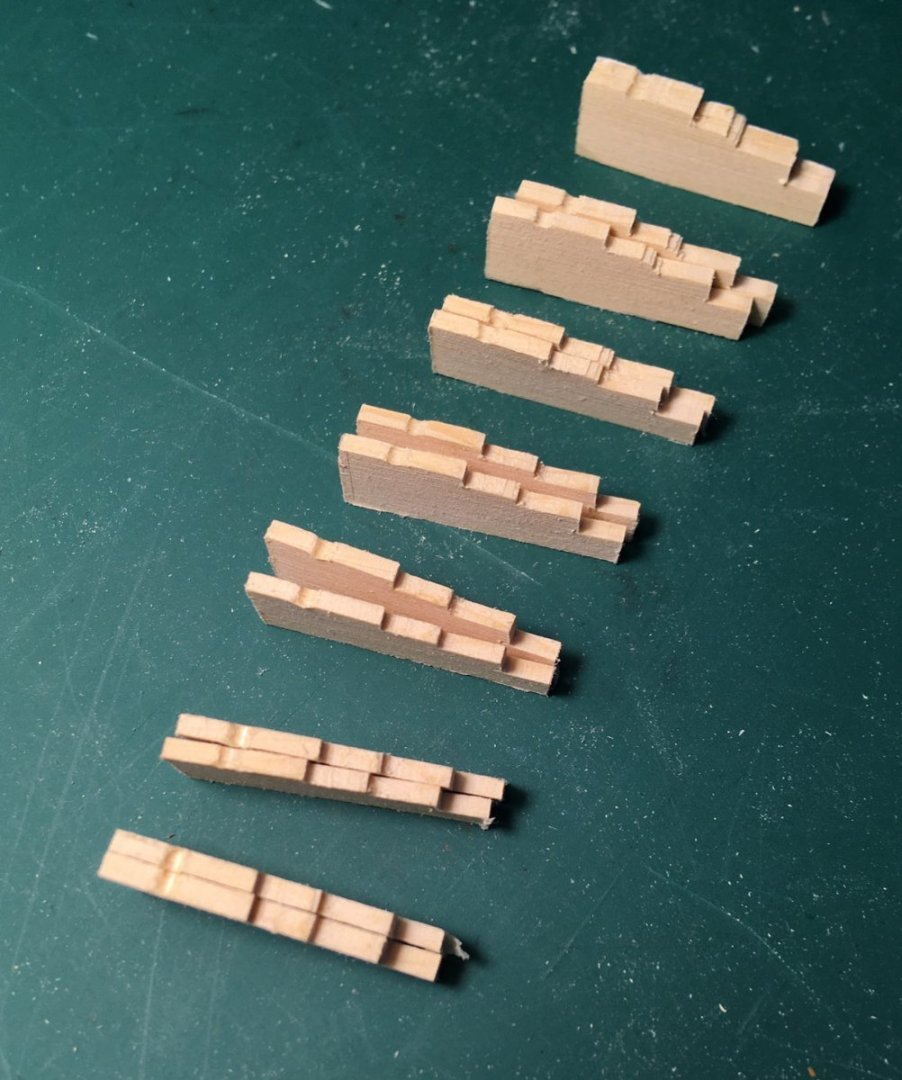

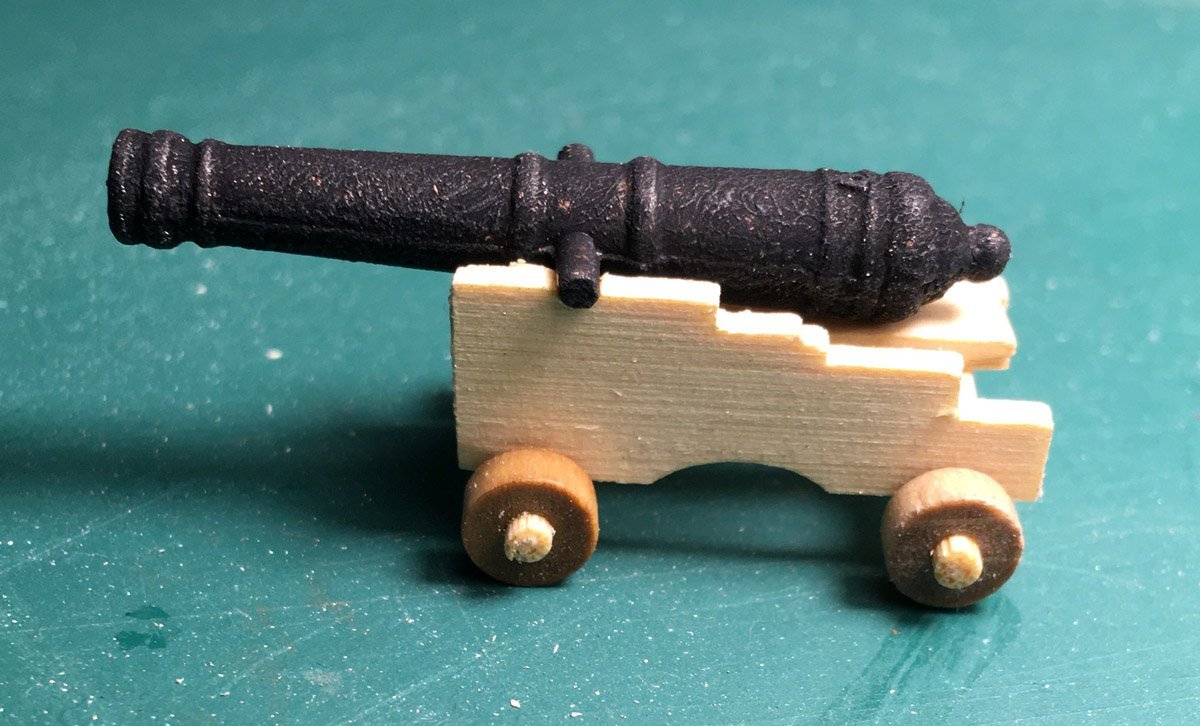

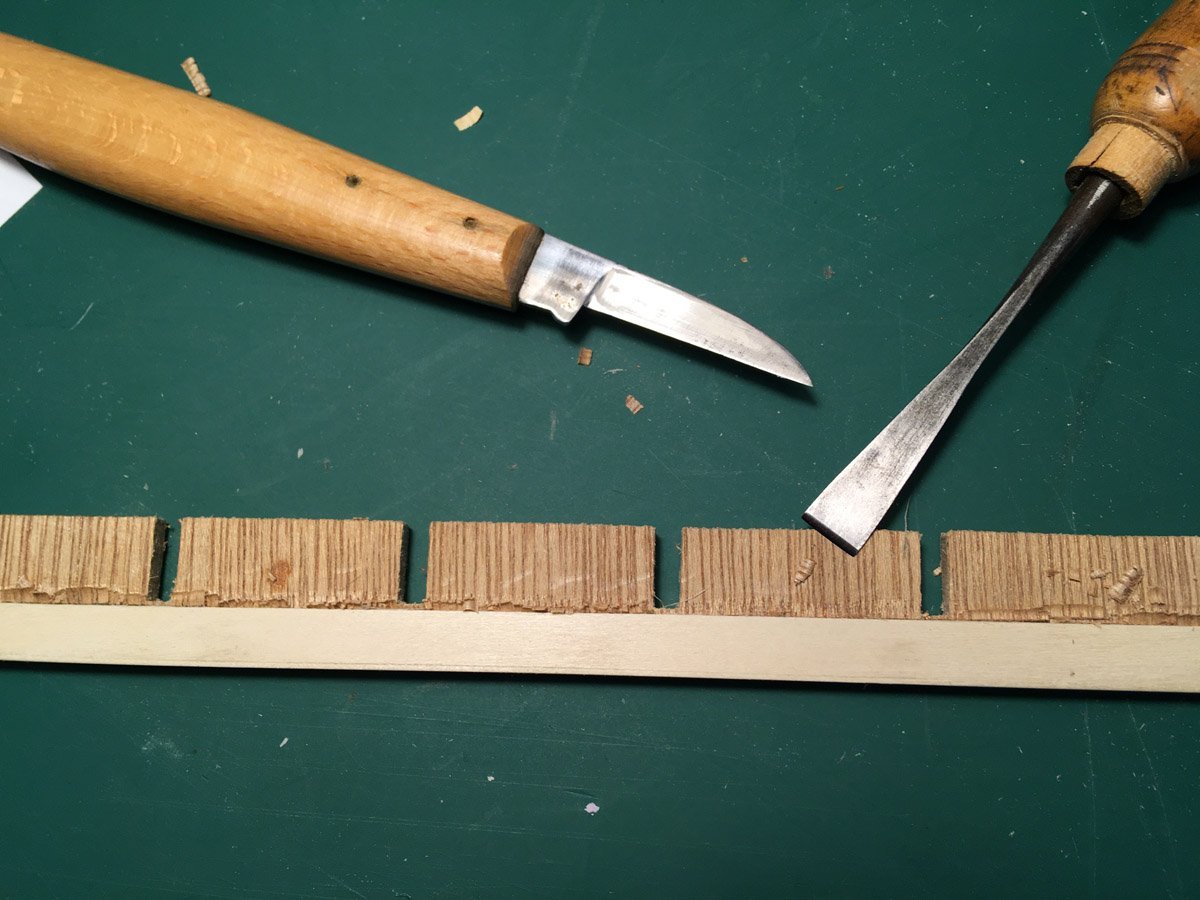

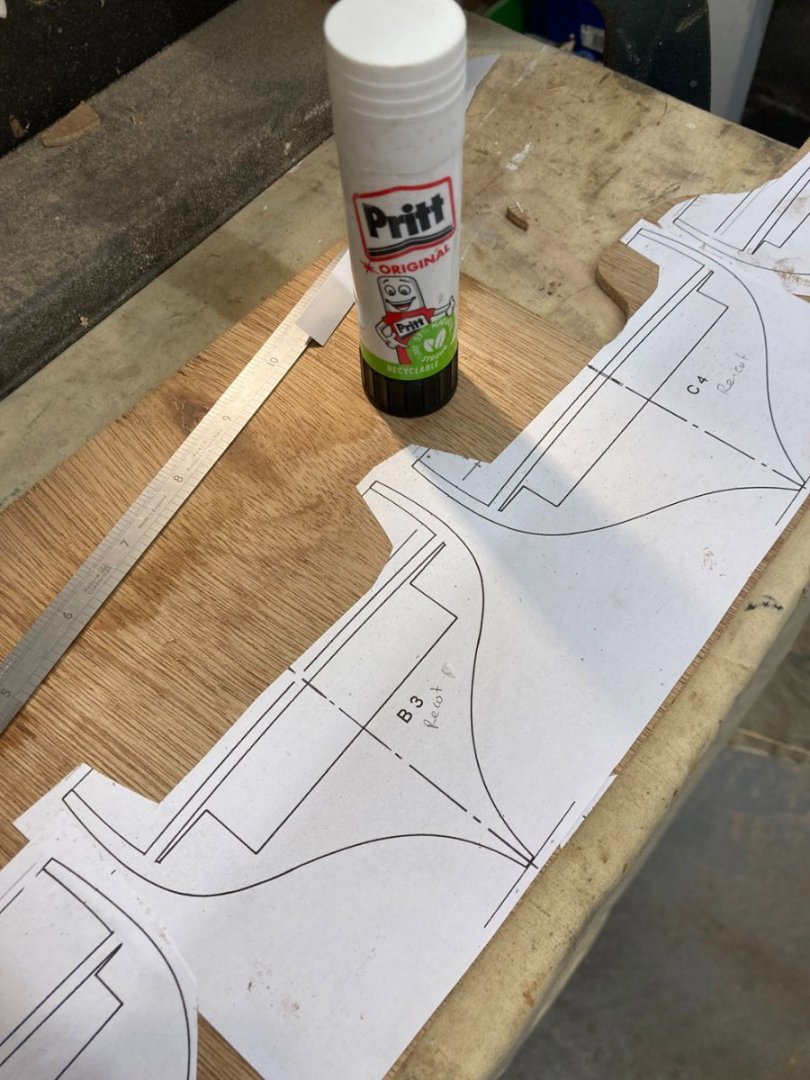

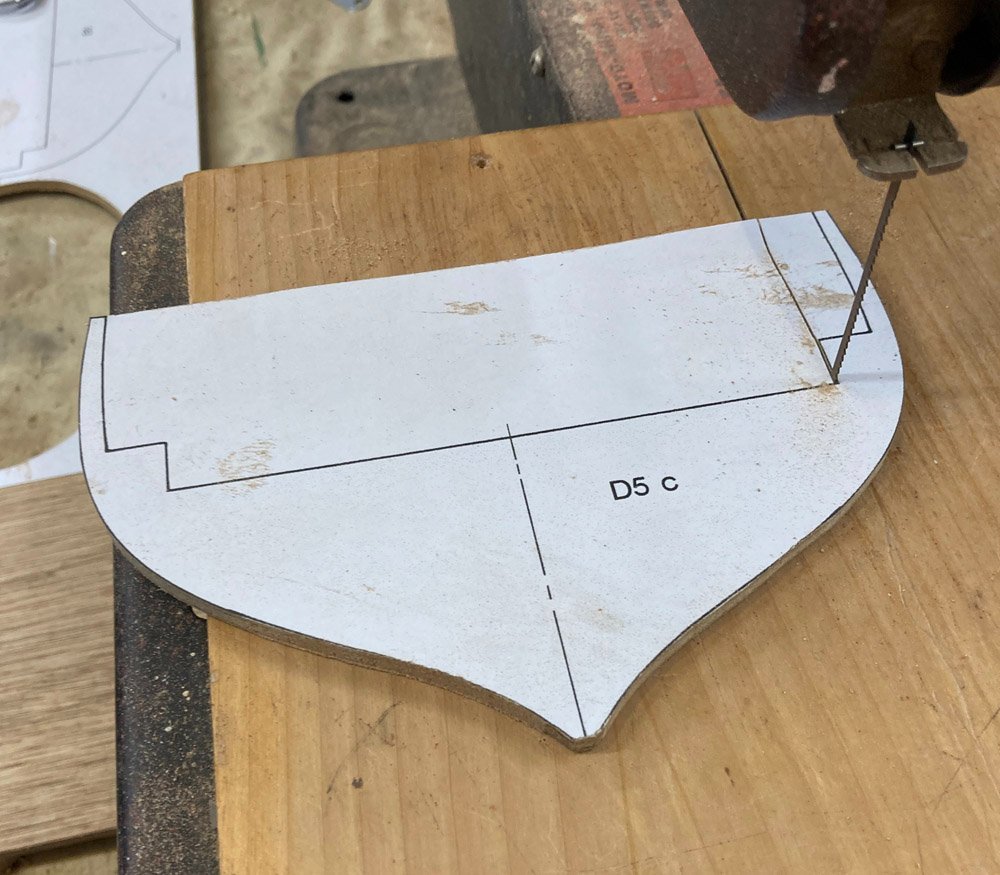

While the glue on the bulkheads was drying, I turned to the cannons. I had ordered a set of Amati barrels and wheels from my favourite model shop https://www.cornwallmodelboats.co.uk/acatalog/amati-cannon-barrels.html I drew out the carriage to scale, printed it out then assembled a stack of 2mm thick wood cut to those dimensions, a small strip was glued along each end to hold the block together. The template was pasted on one side of the block. Then using a jewellers saw cut out the shape of the carriage. There are a few errors with the cuts, but not too bad overall, a quick touch up with a small fine file. I ended up with enough to make the required number of carriages These were assembled and with the barrel in placed look pretty good, the barrels are a bit to garish so gave them a coat of matte black that I dabbed on with an old scrubby brush. Looking good. But I have just realised looking the photo that the wheels are on the wrong way round, should be the larger at the front, lucky I had not glued them in place Tim

-

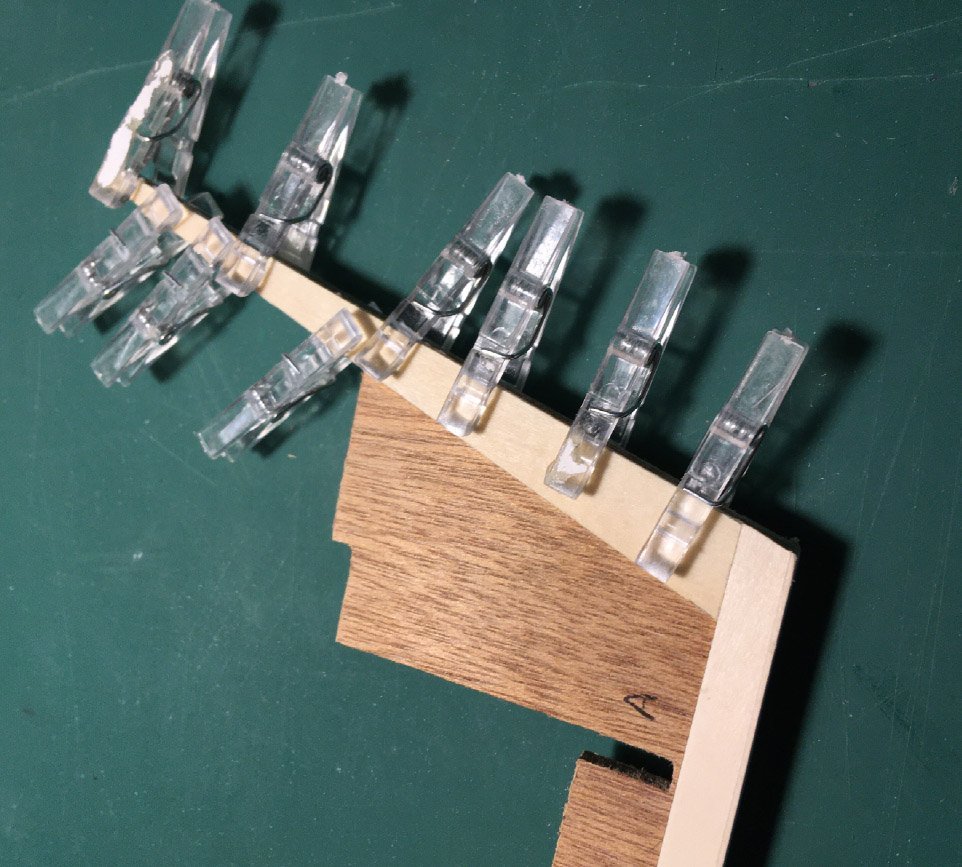

Hi Craig Well spotted, you have a very keen eye, it is high and I did not join it the same as either you, thunder the booklet. I went off on my own and it worked out wrong, I have no idea where those angles came from? So back the the drawing board, printed out new templates and cut some new parts. I now need to sand them to the correct angles and glue them up. Back tomorrow Tim.

-

Just a couple of small jobs to keep the build moving along. Glued on a strip of limewood to cover the raw plywood edge. then added a layer of limewood to the stern. In my next build I really want to make a solid wood stem, keel and stern post. but for this simple cutter model that I am using to get some practice at planking, this will do. Tomorrow I will cut a rabbet. Tim

-

Hi Igmar welcome to MSW I am glad to be retired, I used to build models for customers ( not ships ) Will go and have a look at your YouTube channel Tim

-

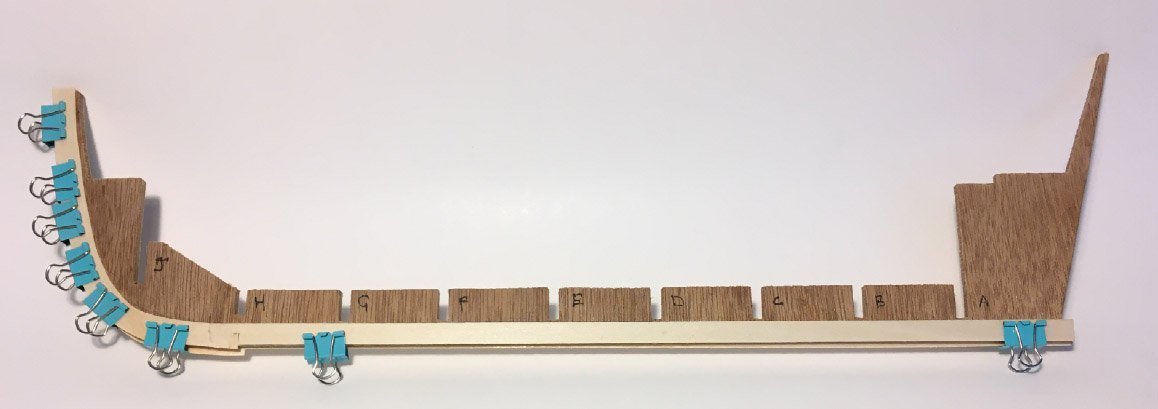

Yesterday in the workshop I managed to get quite a lot done. Pasted the paper templates onto the plywood. then made some sawdust here are the bulkheads and the 'deck' which holds the whole thing together. I then glued the rabbet strip on the keel using some 1mm limewood. I will leave that to dry overnight , then cover the plywood edge grain as well. A good days work Tim

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.