-

Posts

518 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by oakheart

-

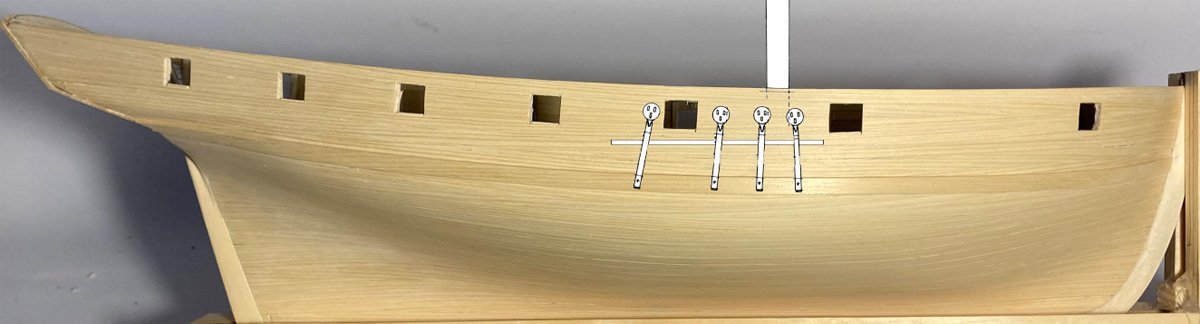

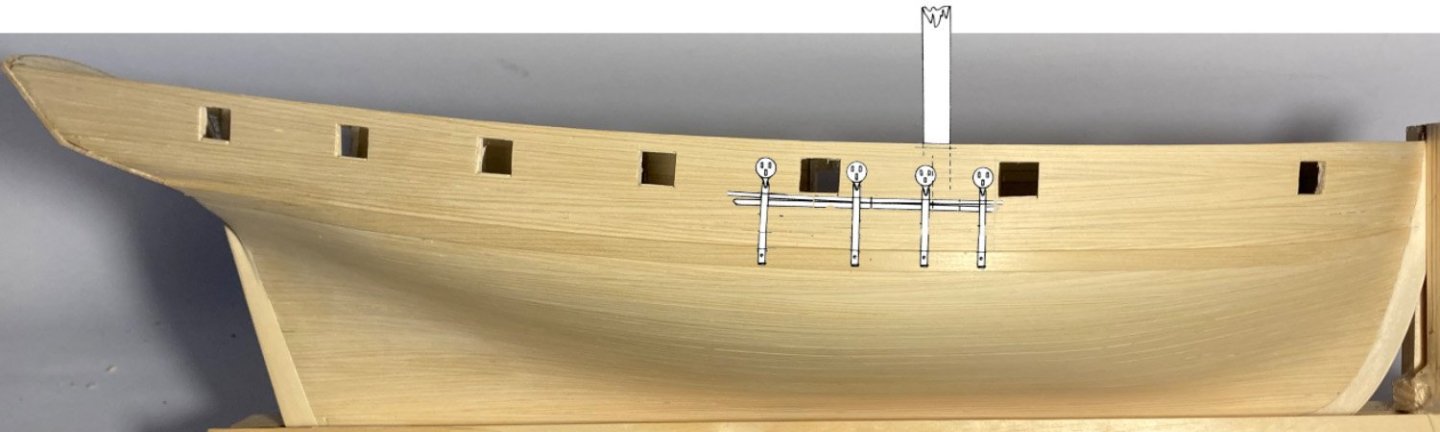

Hi Craig @iMustBeCrazy Not sure which you mean here? I have got it wrong or they are correct? I did make them as per the drawings ( yes I know they are in the wrong place 😞 ) and they are trapezoid in shape. It could be the angle of the photo. You can see it better in the photo in post #123 On a different topic Seeing it coming together I do think that the all pale wood is a bit too bland and needs some variation, so I need to do staining. as was discussed earlier. Tim

-

Log to PDF Tool

oakheart replied to VTHokiEE's topic in Using the MSW forum - **NO MODELING CONTENT IN THIS SUB-FORUM**

Hi VTH what a brilliant idea. so I downloaded the program ( GUI Version ) it runs and says its finished and the pdf has downloaded but there is no sign of the file? Even search of the whole machine does not turn it up? running Windows 10, chrome is installed in correct folder. any ideas? Tim -

Talking about a lot to learn. The drawings in post #105 and #114 show the deadeye straps passing though the board attached to the hull, other drawings show it on the outside? OK now I think I need to do some more research on the names for the parts of what I believe are called the "channel" or "Chains" I found this webpage useful even though it seems aimed at a more general audience http://www.ageofsail.net/aostermi.asp Is there a good reference I can refer too? here comes yet another rabbit hole......................if I don't get too sidetracked I might get some ship building done. Tim

-

Thanks for the advice @druxey, @Thunder and @iMustBeCrazy. have done a new profile view and think I will be able to make it work. This model will not represent any particular cutter but should work visually. I am not sure now if the straps ( don't know what their real name is ) should bolt into the wale? Tim

-

Hi Craig That is a nice idea. I did do some tests earlier using a water based stain which worked well on the cedar. But I am terrified that it will all go horribly wrong and I will end up with patchy tide marks all over the beautifully smooth hull. Someone suggested spraying the stain using a hand spray bottle, not sure if this would work I think more testing is required. Tim

-

Thunder, welcome onboard, glad you like the build so far, it was your original build that inspired me to start this model. Thanks for taking a look and for some very welcome advice. You are right I will have to move everything to match the revised gun ports. I had been considering doing a sort of "admiralty" style with a stub mast and bowsprit, so no rigging, it's above my current pay grade anyway. Could I get away with just moving the things you mention. The anchor will also need moving, that was a costly ( in effort ) mistake I made .............. Tim

-

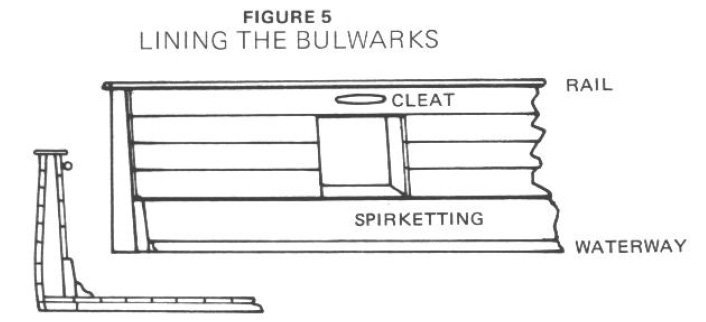

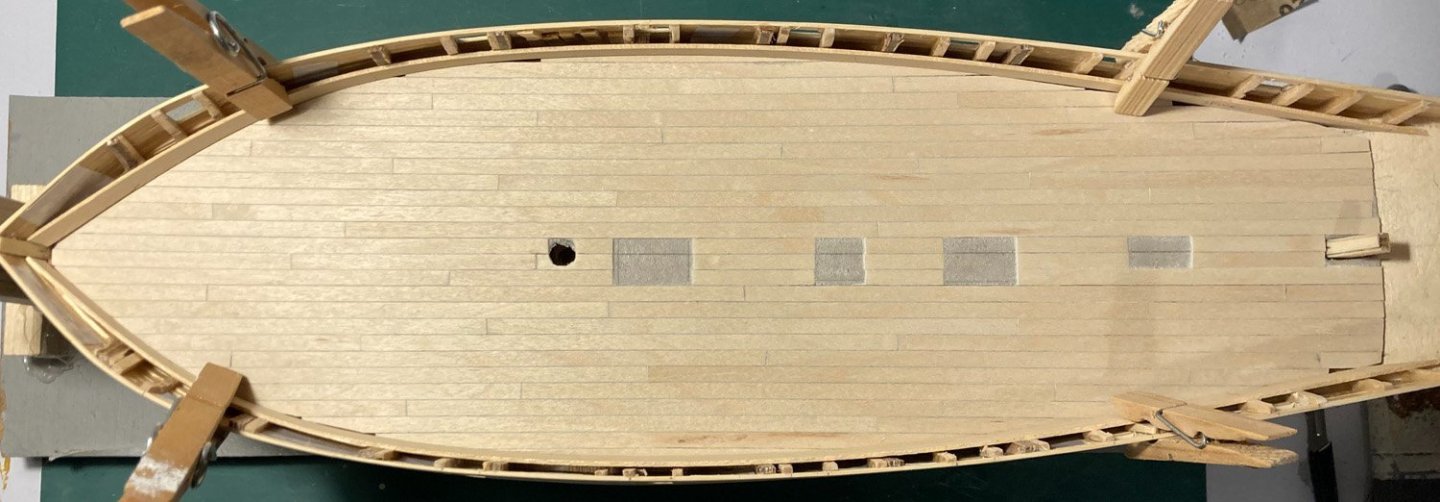

Thanks for the encouragement. I seem to have difficulty even following the ones I do have 🙂 Next jobs, glue down the deck, line the bulwarks, fit the spirketting and waterway, then frame the gunports. I intend to leave it all natural wood so there will be no hiding any ( more ) mistakes.................. Tim

-

Have a look on this website, they have loads of info. http://www.lathes.co.uk/atlas/ Also as others have said search YouTube someone is bound to have fixed one up already Tim

-

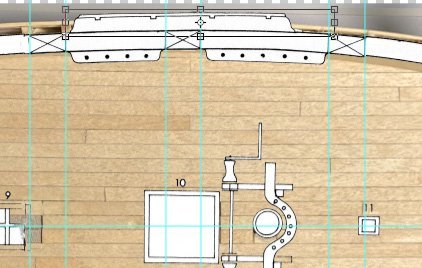

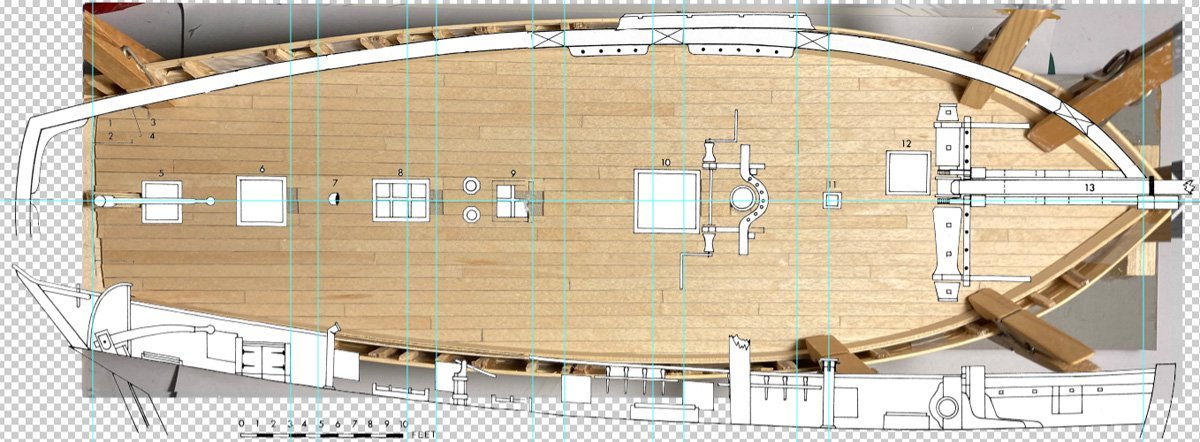

thanks for the compliment @kgstakes. Here it is with blemish removed, a bit more work than with photoshop, but worth doing. a quick coat of WOP ( water based Tamiya matt, thinned). looks much crisper now. width of planks is 5mm which at 1:48 equates to about 9.5 inches. the gap at the stern top right, will be covered by the pantry or the W.C. can't remember which goes on which side. Tim

-

Got quite a bit done yesterday, deck planked with 5mm white maple from Mantua Models. I think it looks good, there are a couple of planks I may replace. I was not taking notice, the brown blemish shows now I have sanded it down. here is a close up used the soft pencil for the caulking, it was glued to 1mm thick grey card, I have left it loose for the time so I can try other decking. what does everyone think of the colour and width? Tim

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.