MajorChaos

NRG Member-

Posts

301 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by MajorChaos

-

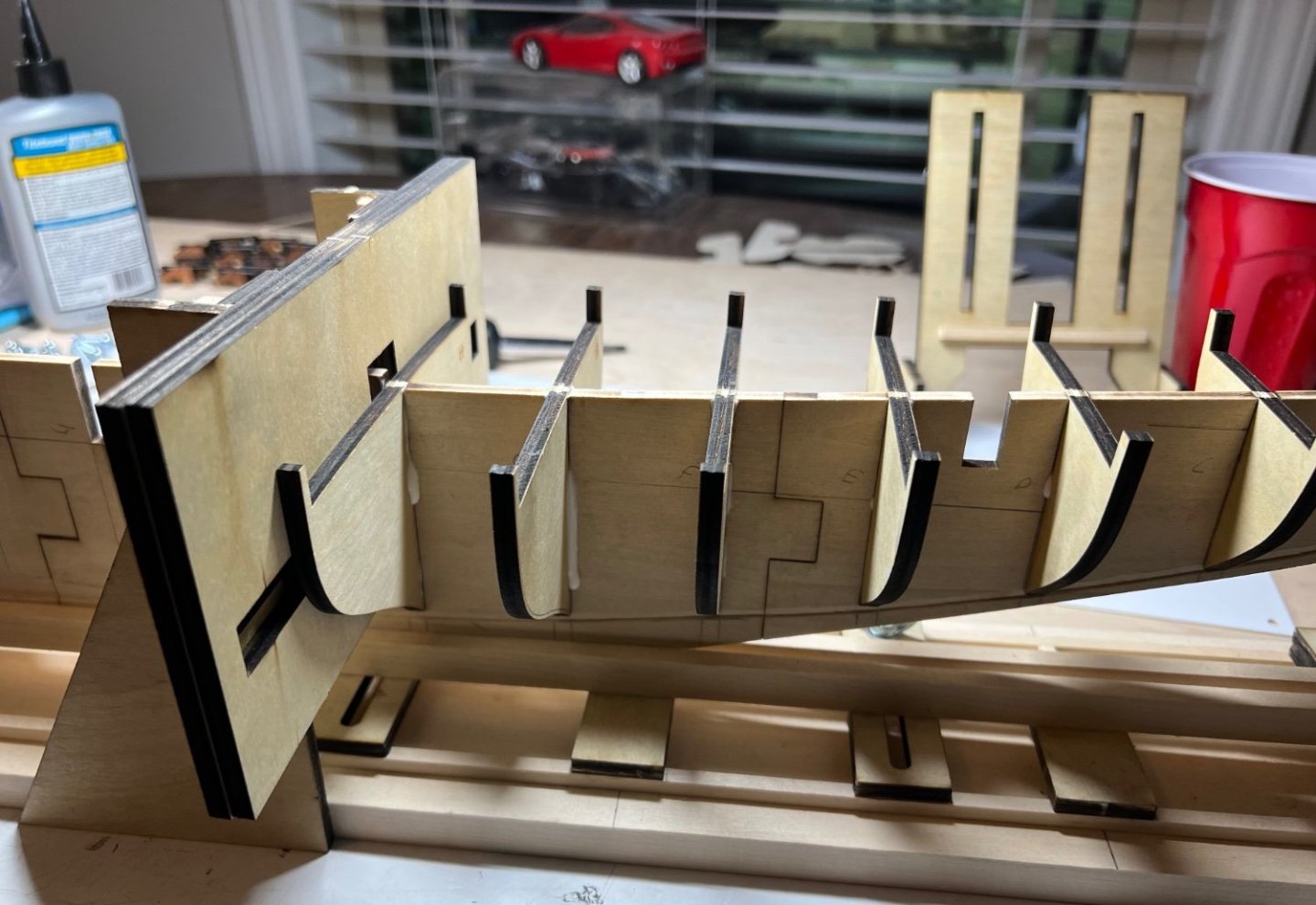

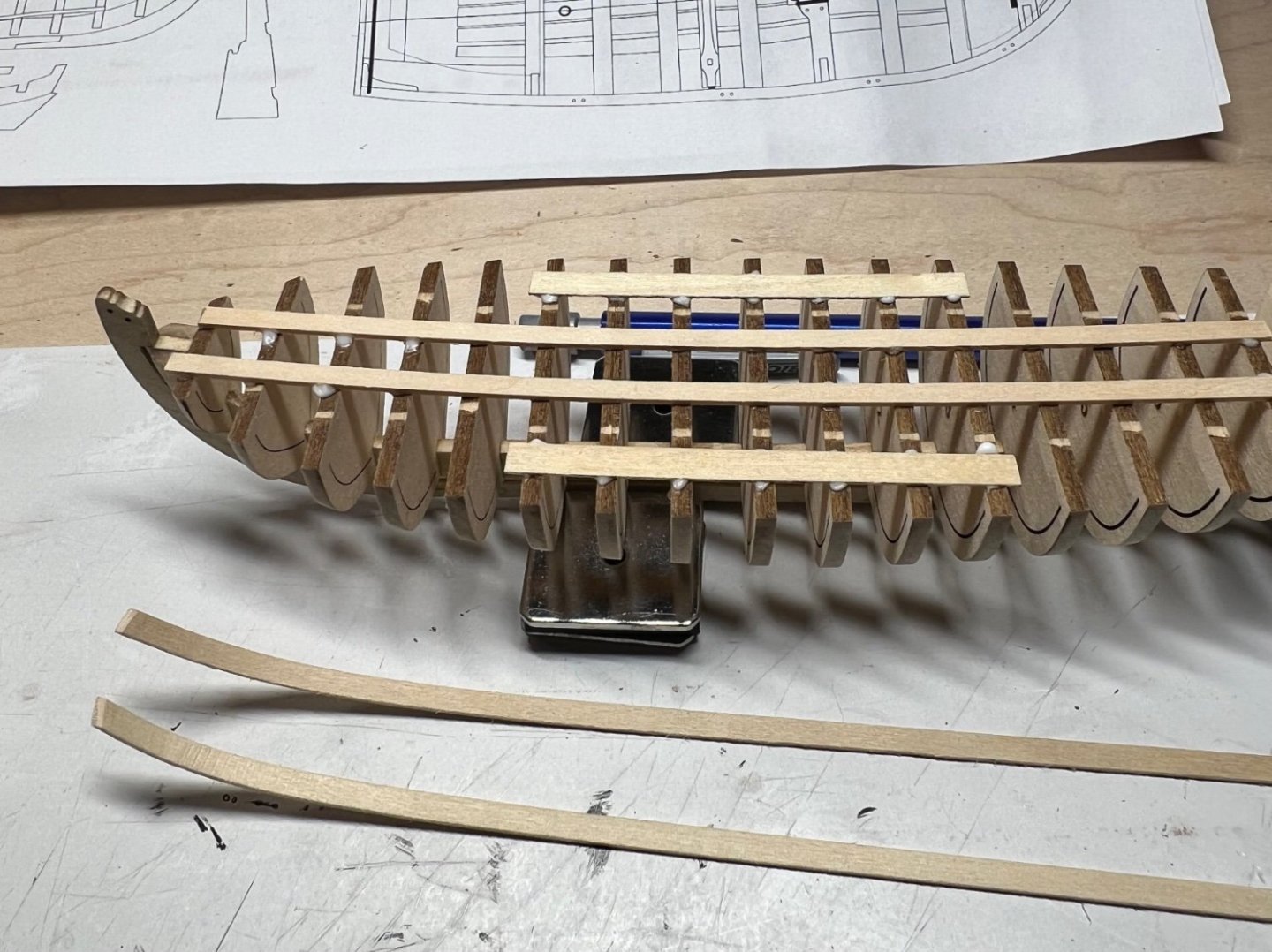

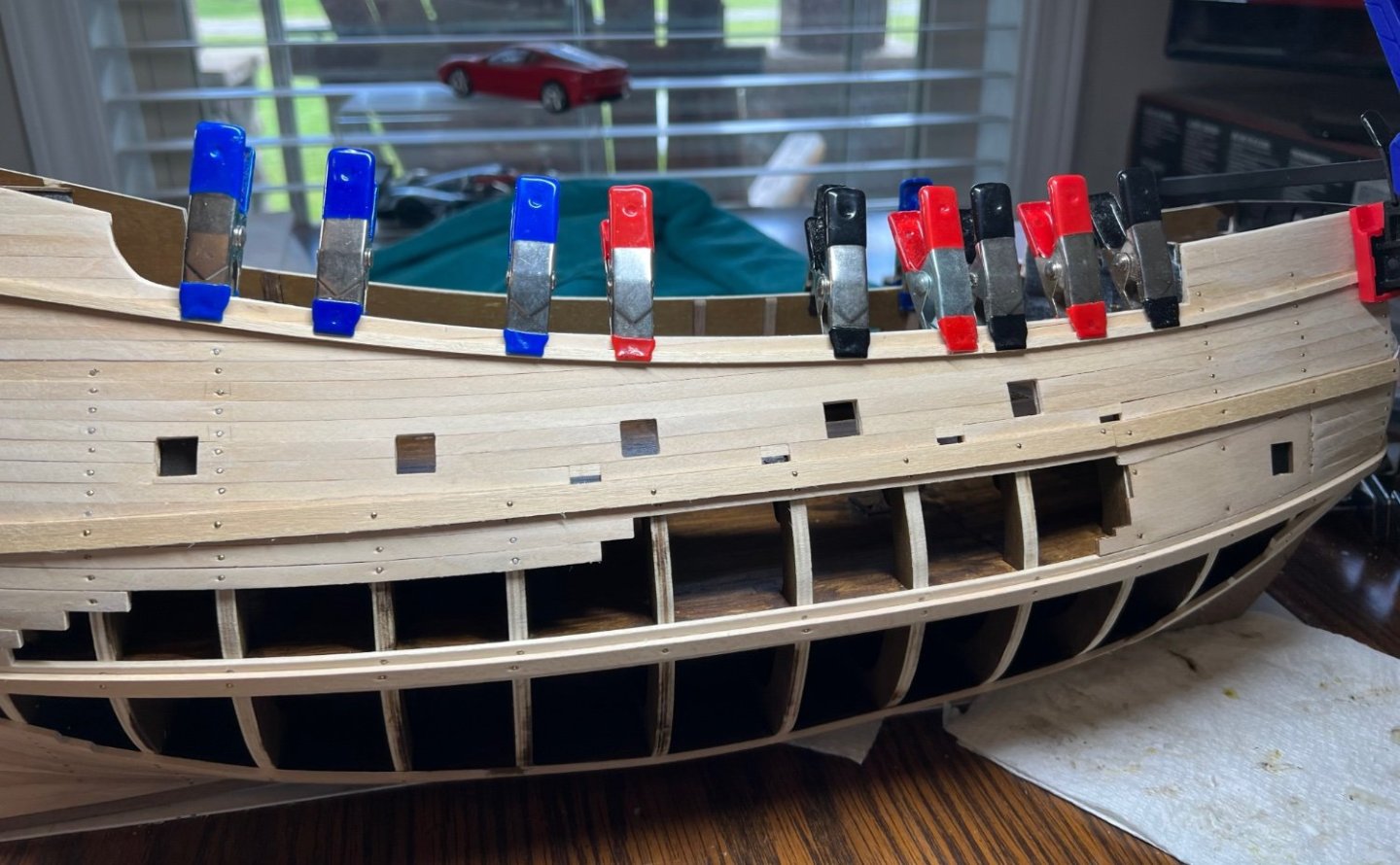

The current goal was/is to plank the sides enough to get the waist installed, to get all the stanchions installed and the main rail on top of that. As many of the instructions and guides state, I’m trying to make each plank a victory in itself. Hundreds more to follow. 😳 The Modena just won’t fall off…..

-

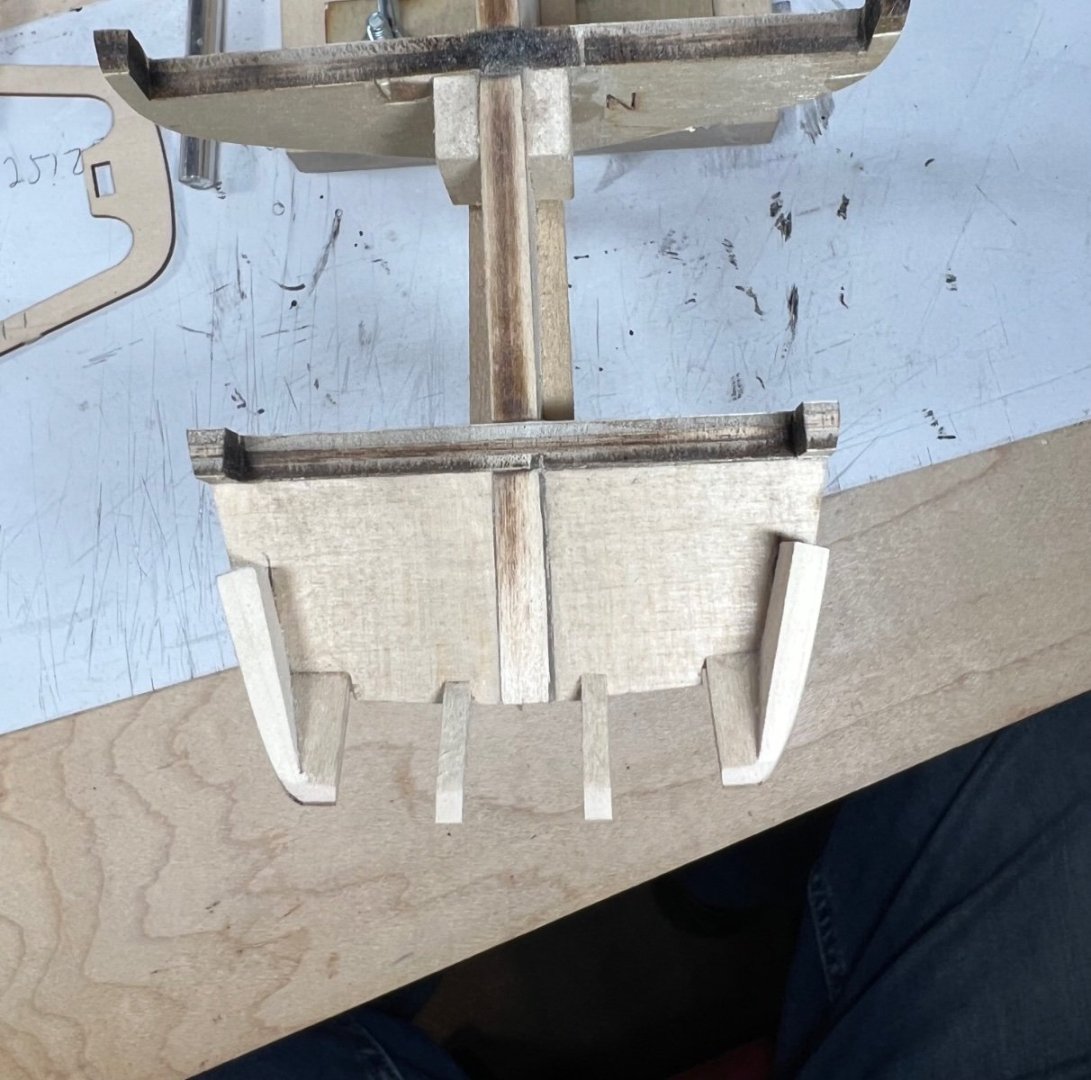

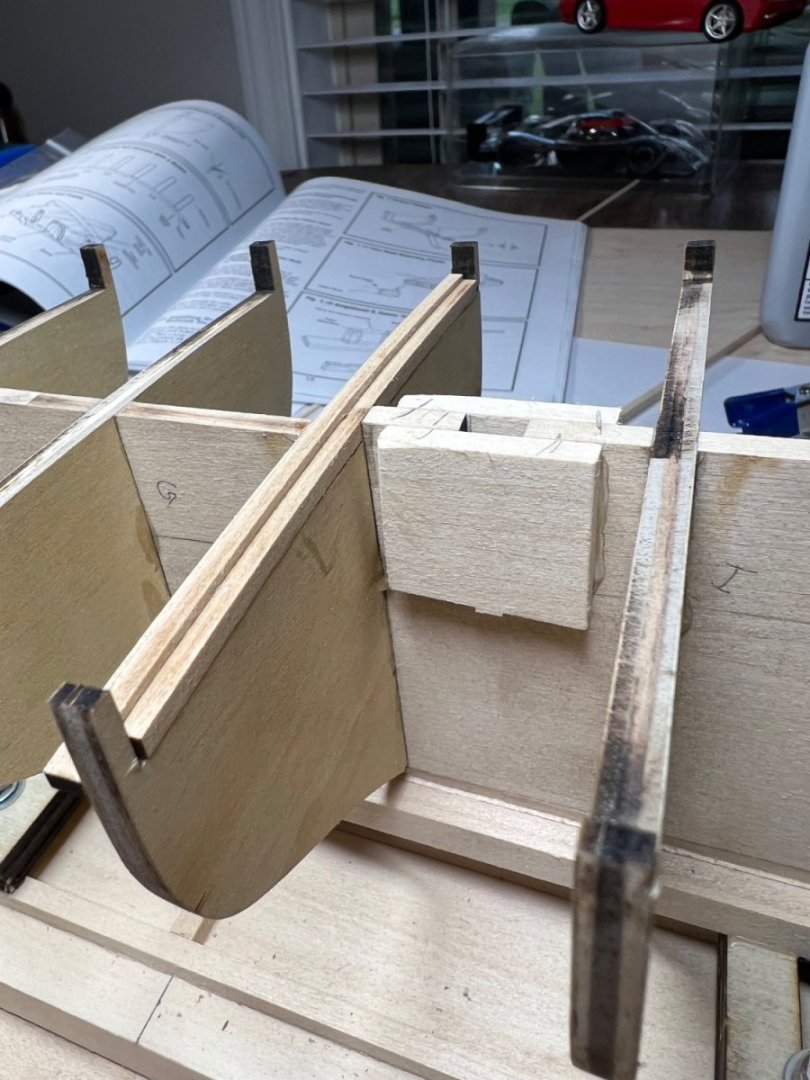

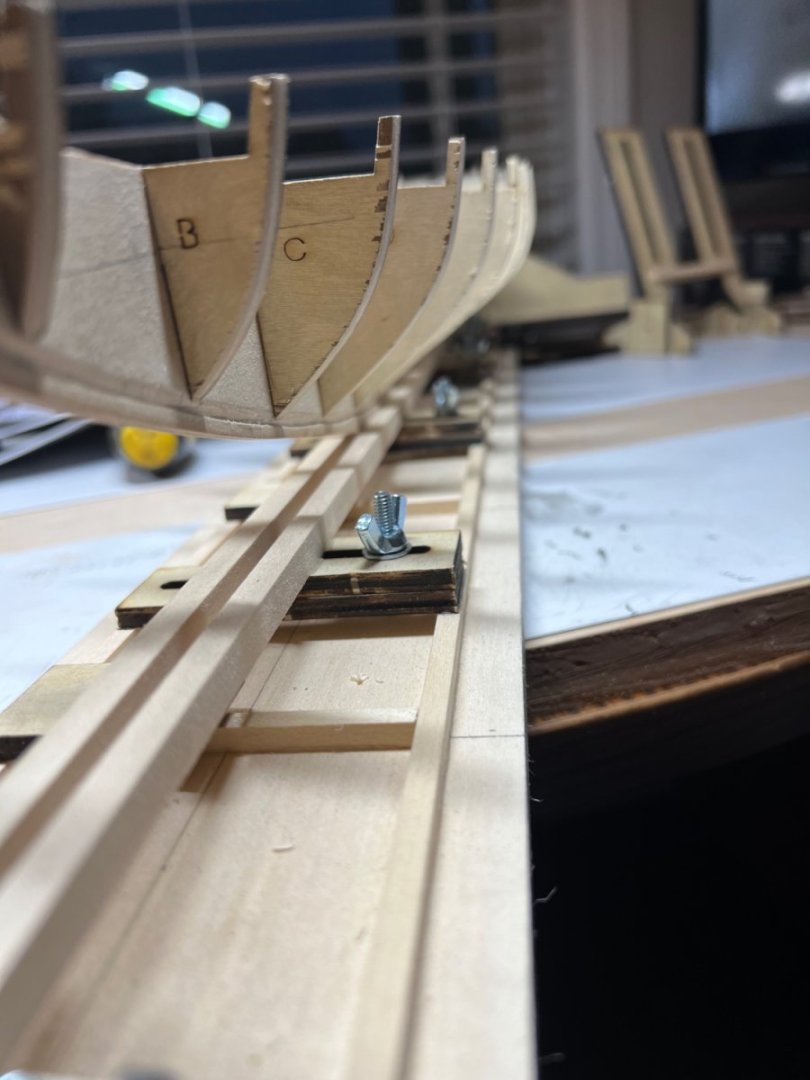

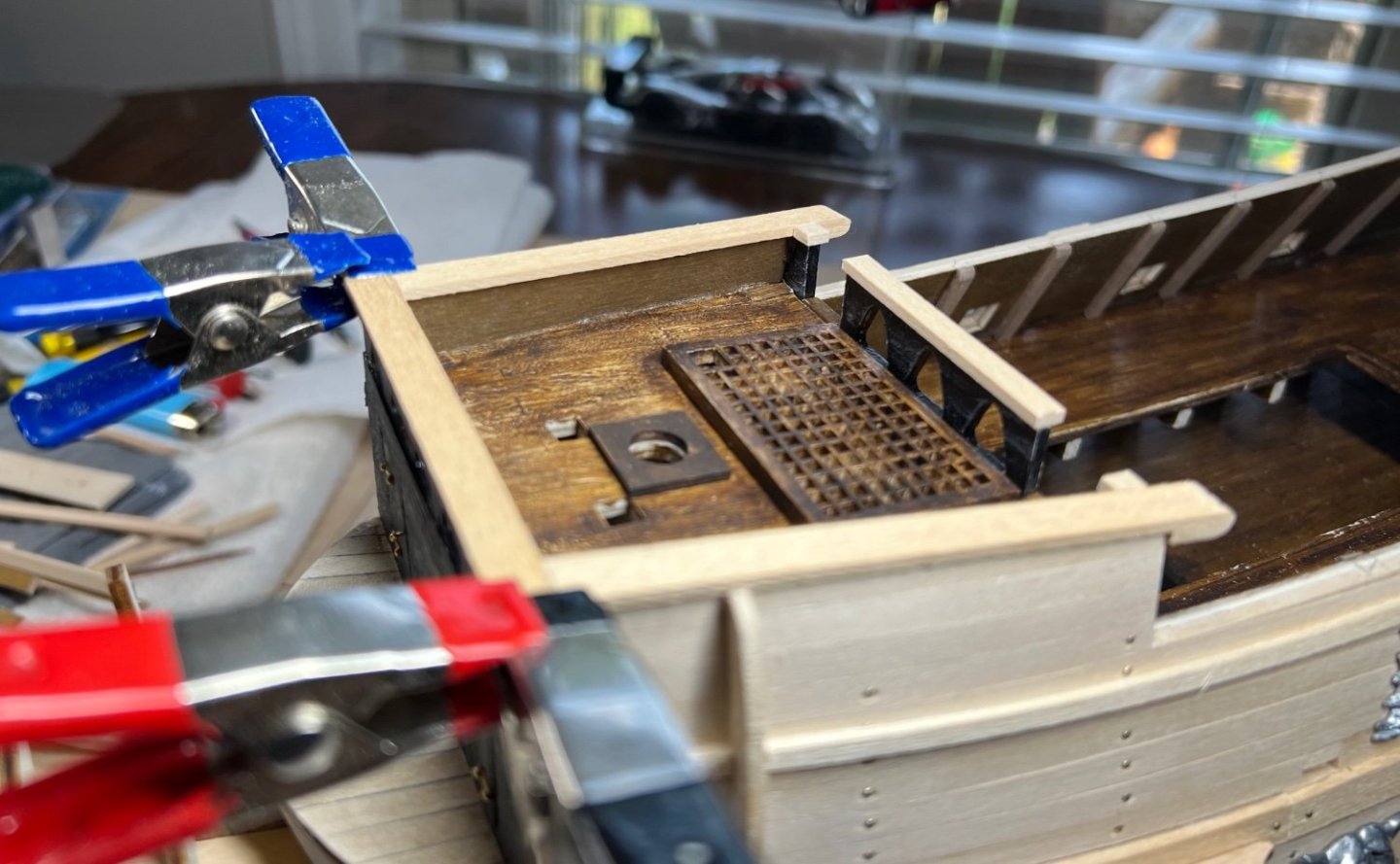

There are certain things to be done in a different order. The great beam it shows last for stage 1. I don’t think that would work out. The water ways rest on the great beam. The main rail on the aft section needs an aft boom sheet buffer fitted before installing. Or at least it looks a lot simpler to do it now. I’ve cleaned up and fitted bulkhead stanchions until it looks like they fit and flow well. I have convinced myself nothing will fit going up to the top rails, we shall see. I have no idea which wood to use for the main rail. There is some 1/16 inch thick 1/2 wide, looks like these would fit the curves every 6 inches. I think I will start a few top side planks before the top rail, so the waist can be fitted nicely before gluing the top rail in place. This should allow fitting of fake stanchions also. Model Expo still hasn’t shipped a small order made last Sunday for some 3/32 x 1/8 sticks and other stuff for the fore waterway. I bought what was missing so I didn’t have to wait until they got around to it.

-

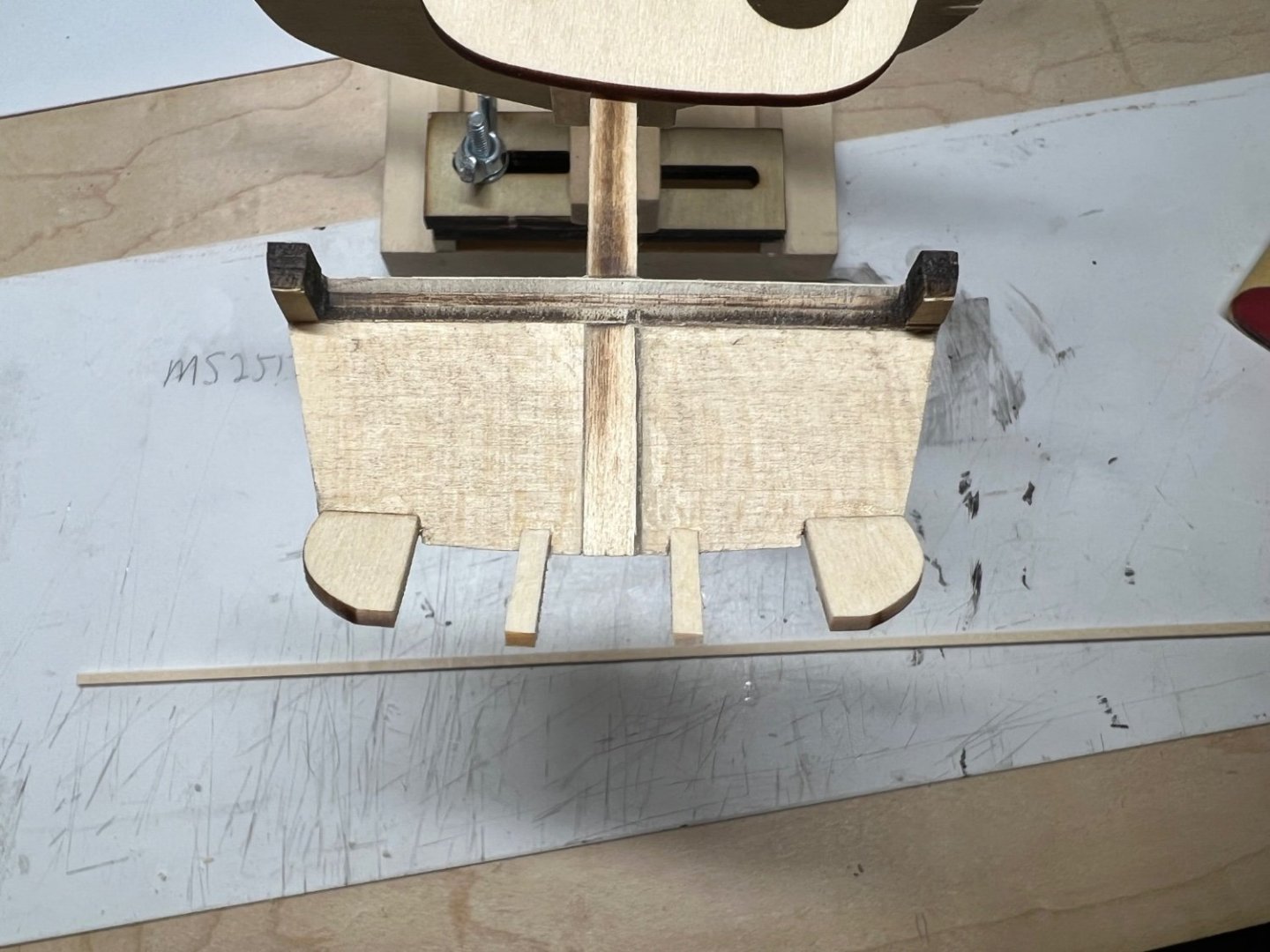

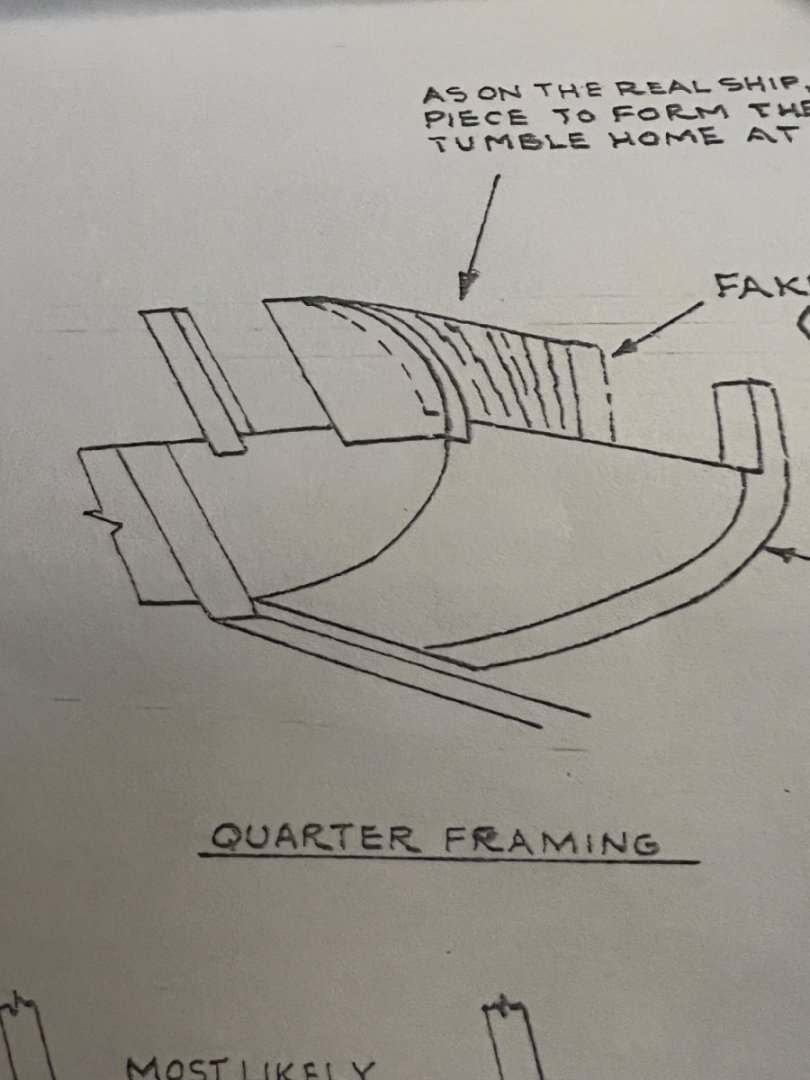

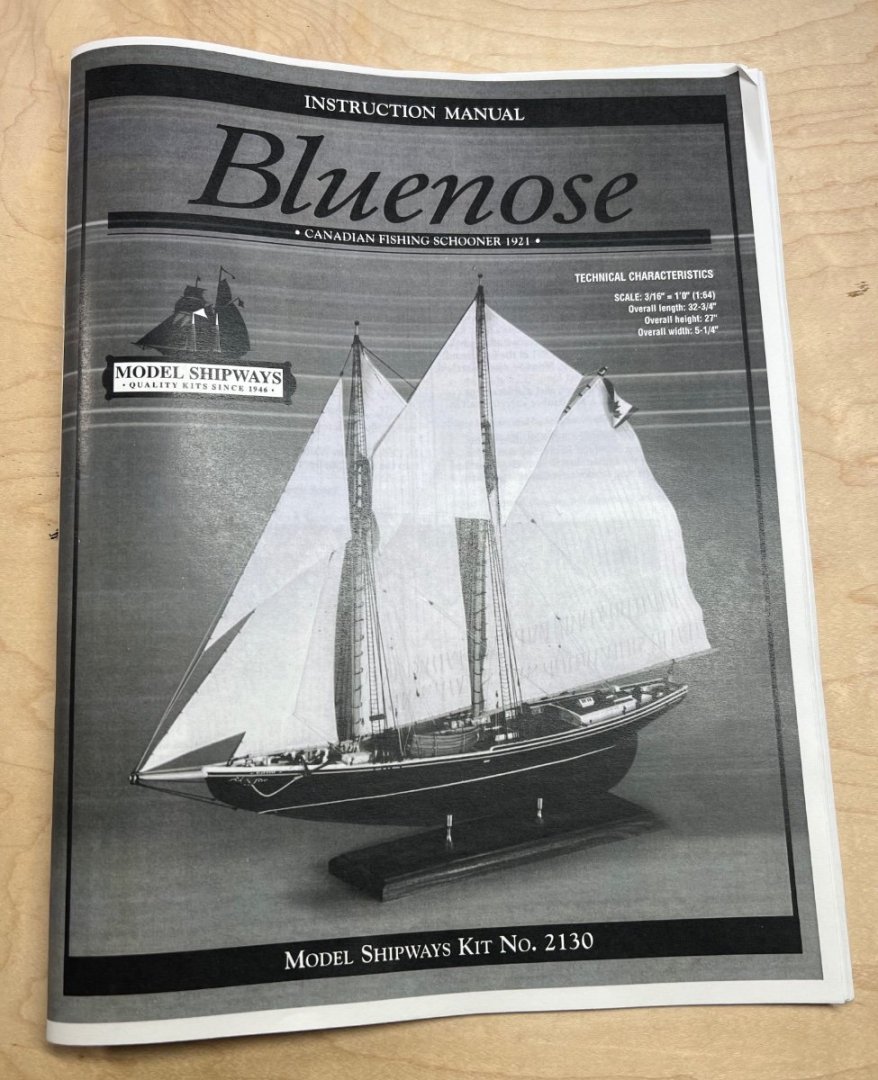

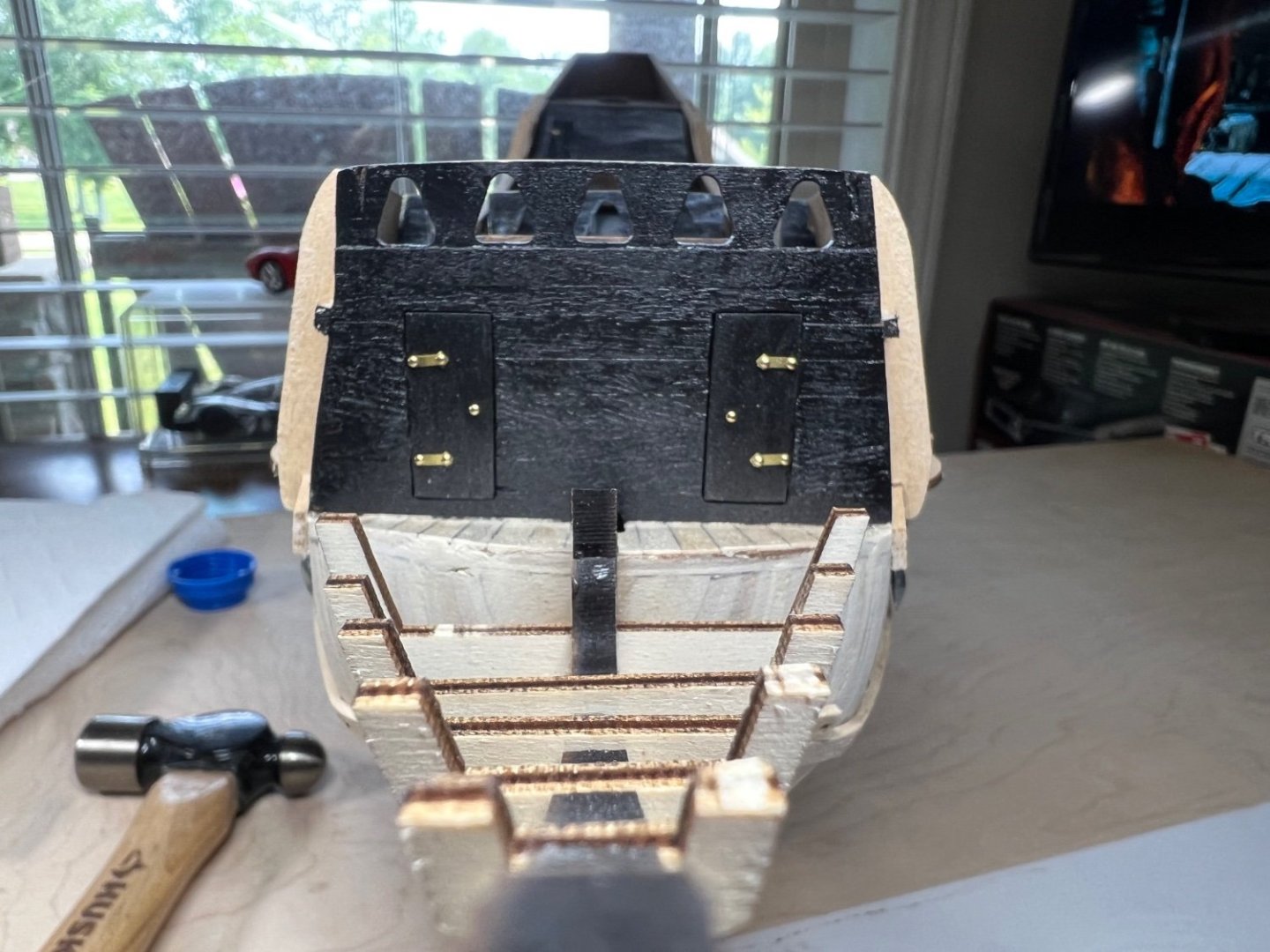

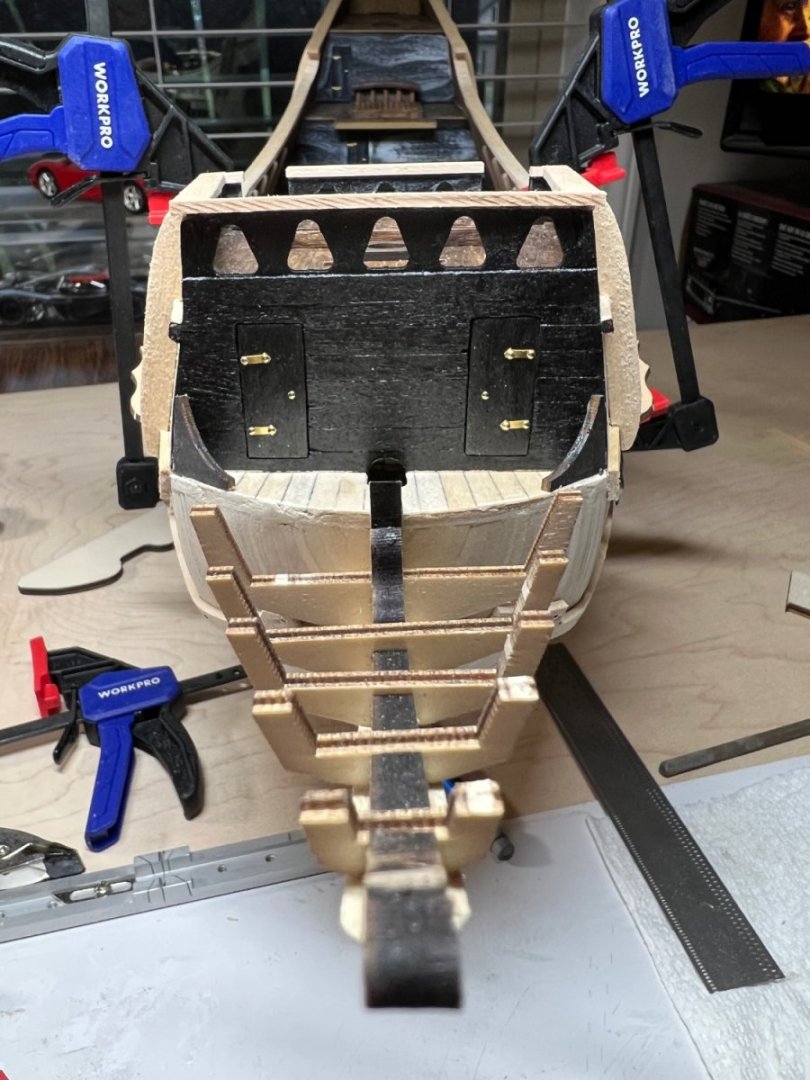

The transom is very close to the picture of the Bluenose II. I’m thrill I got it to look like this. I’ve stopped and studied the plans the instructions, pictures everything I could find. I think I even understand where the fashion piece fits in. Soon to learn how to cove. Then figure out the scuppers, and fake stanchions. Soon I’ll be past the point I got stuck years ago.

-

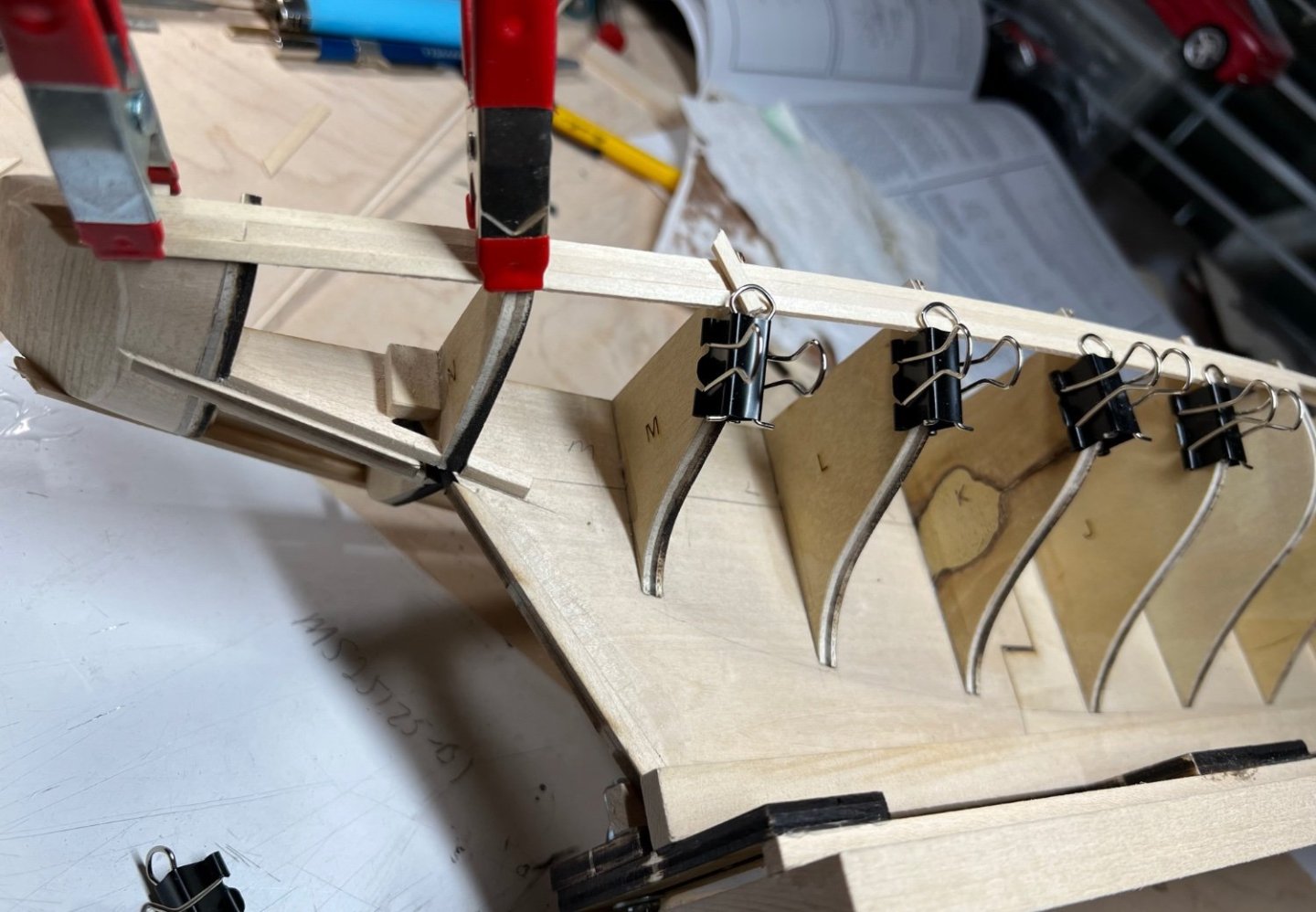

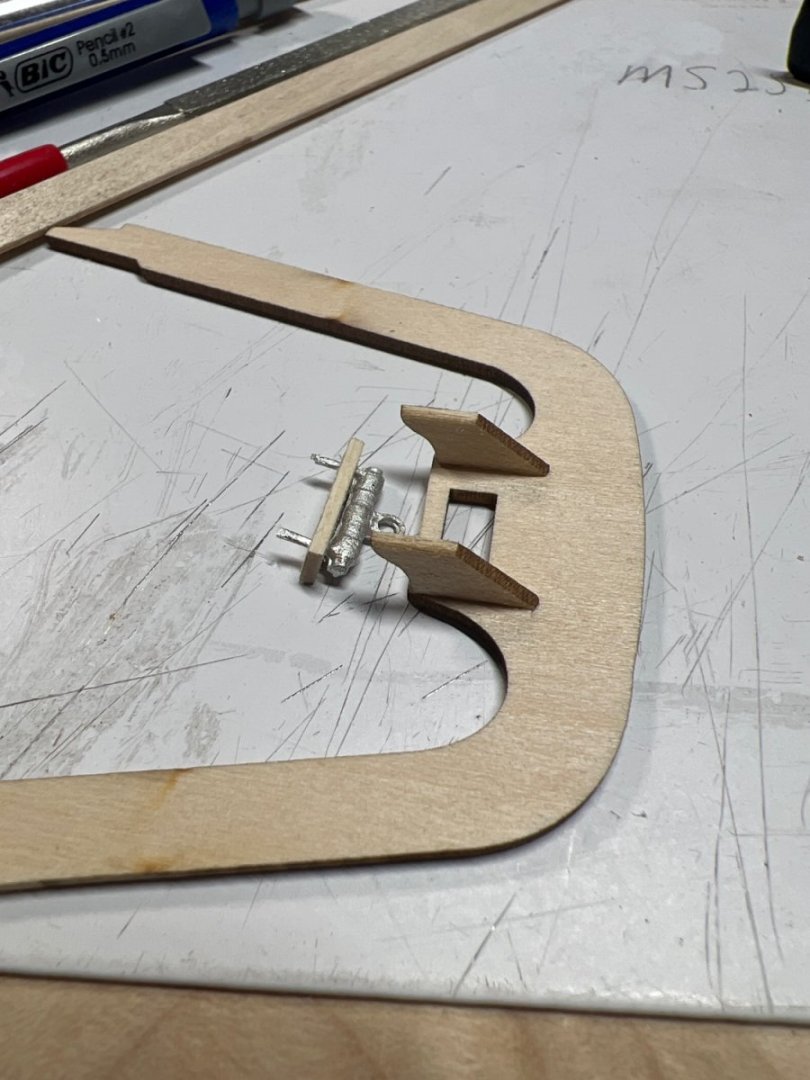

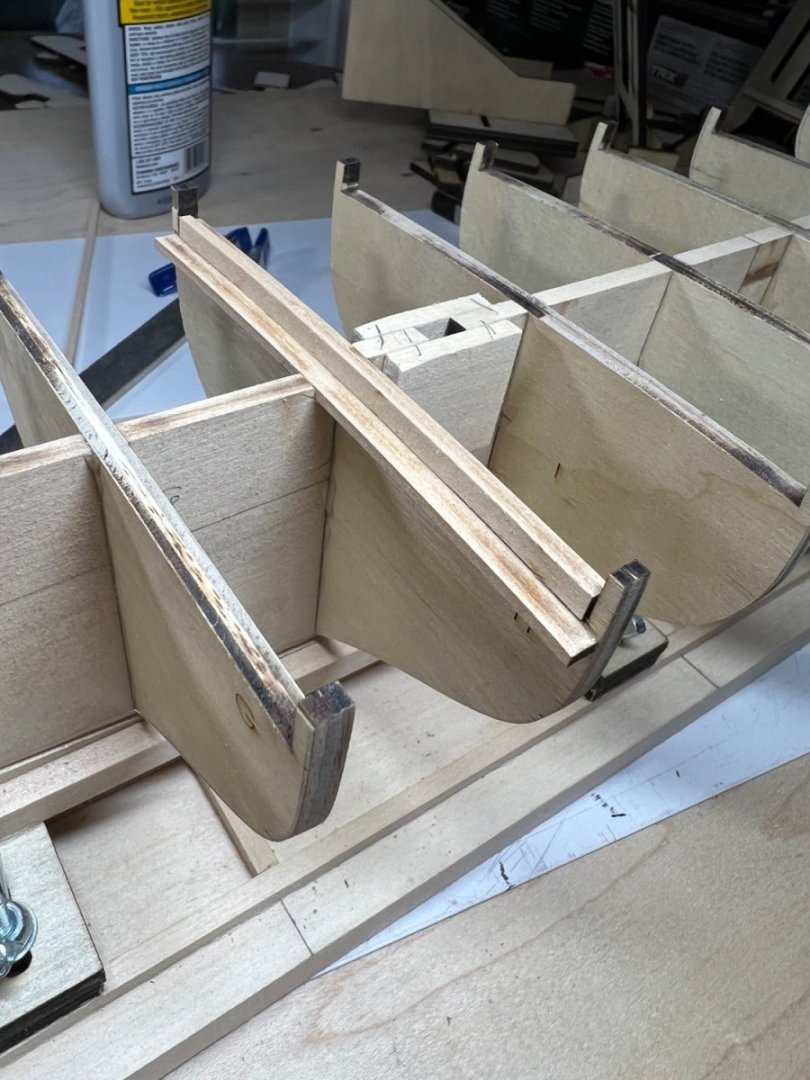

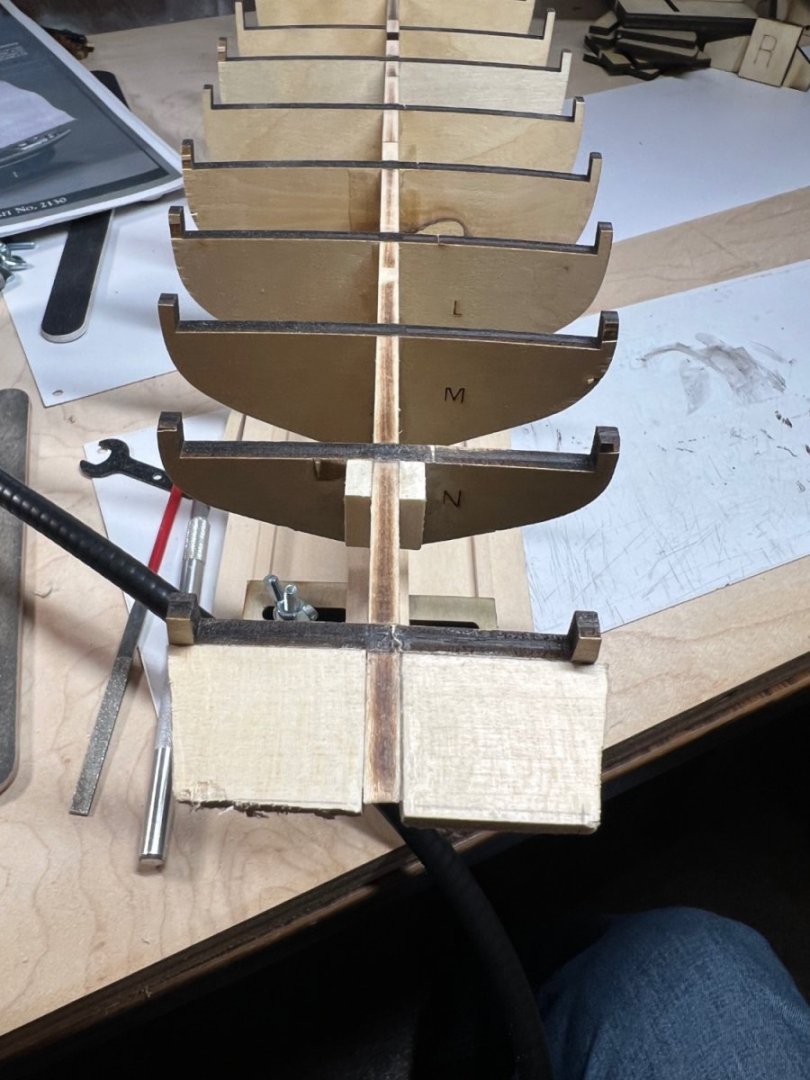

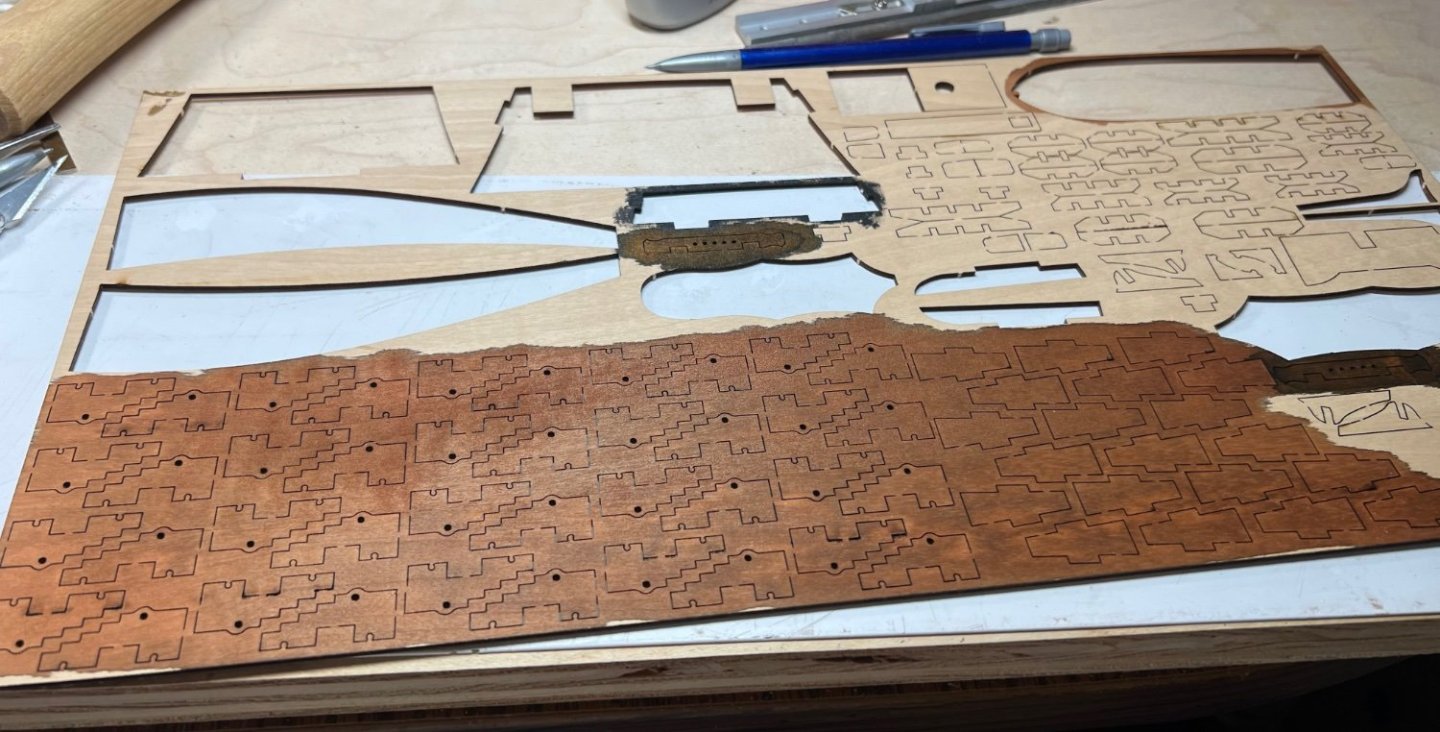

The Bluenose transom is crazy hard for me to figure out. I think I’ve got it 95-97% what it should be. It flows nice. It seems to fit the next piece to go on top. It not clear what to plank it with. The notes seem to not say both parts of the stick size. It does not say to cut a slot for part of the great beam in front of H. But it clearly has it be notched out. It might be on a note on the plans I have not found yet. My kit is missing 3/32 x 1/8 sticks. I have 20 different sticks, the list is 21 items long. What a bit of fun to figure out what size everything is without dial calipers, ordered those and on the way. I’ve faired it well. I see more stuff to sand as I study it. It should plank well.

-

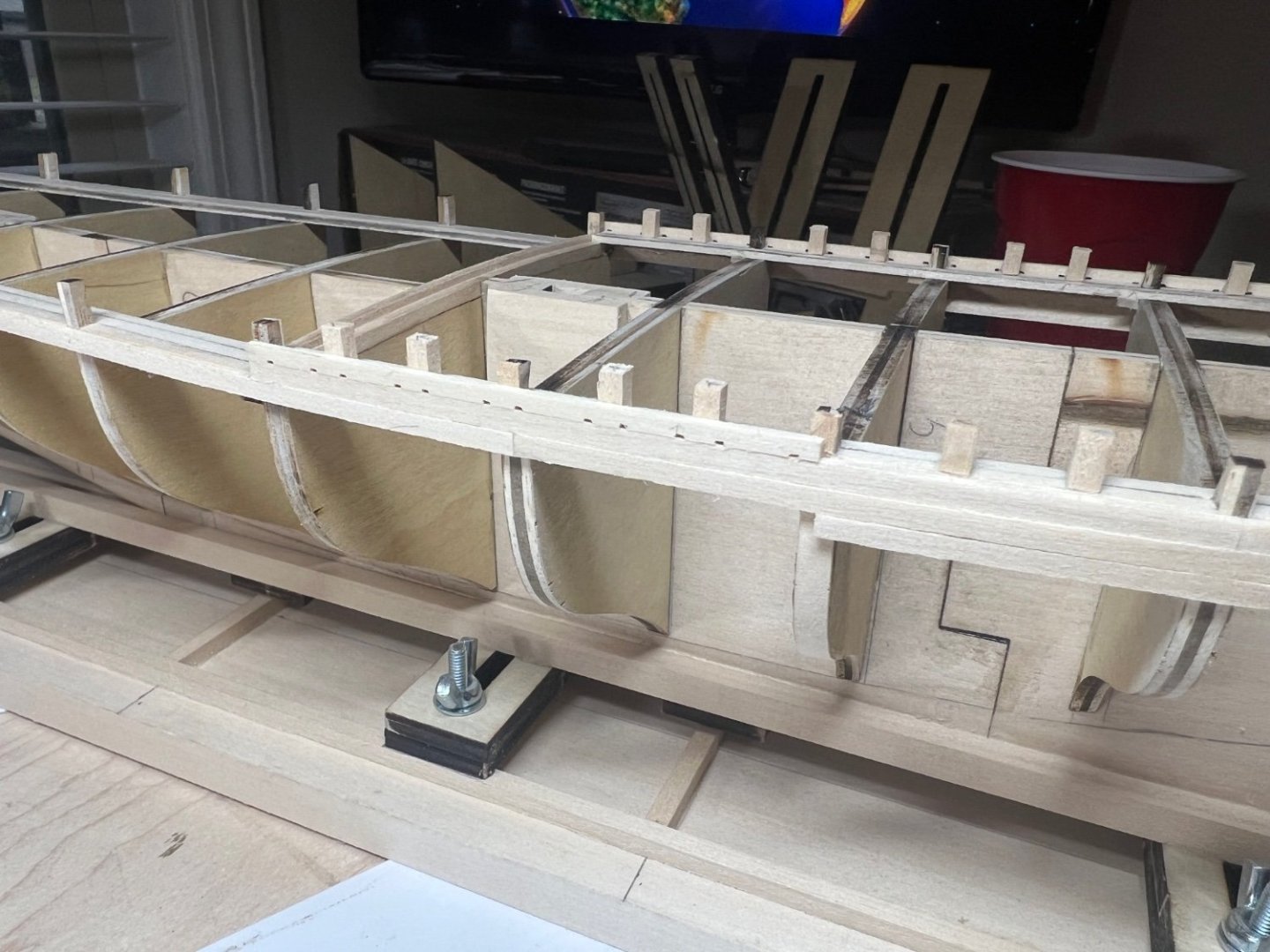

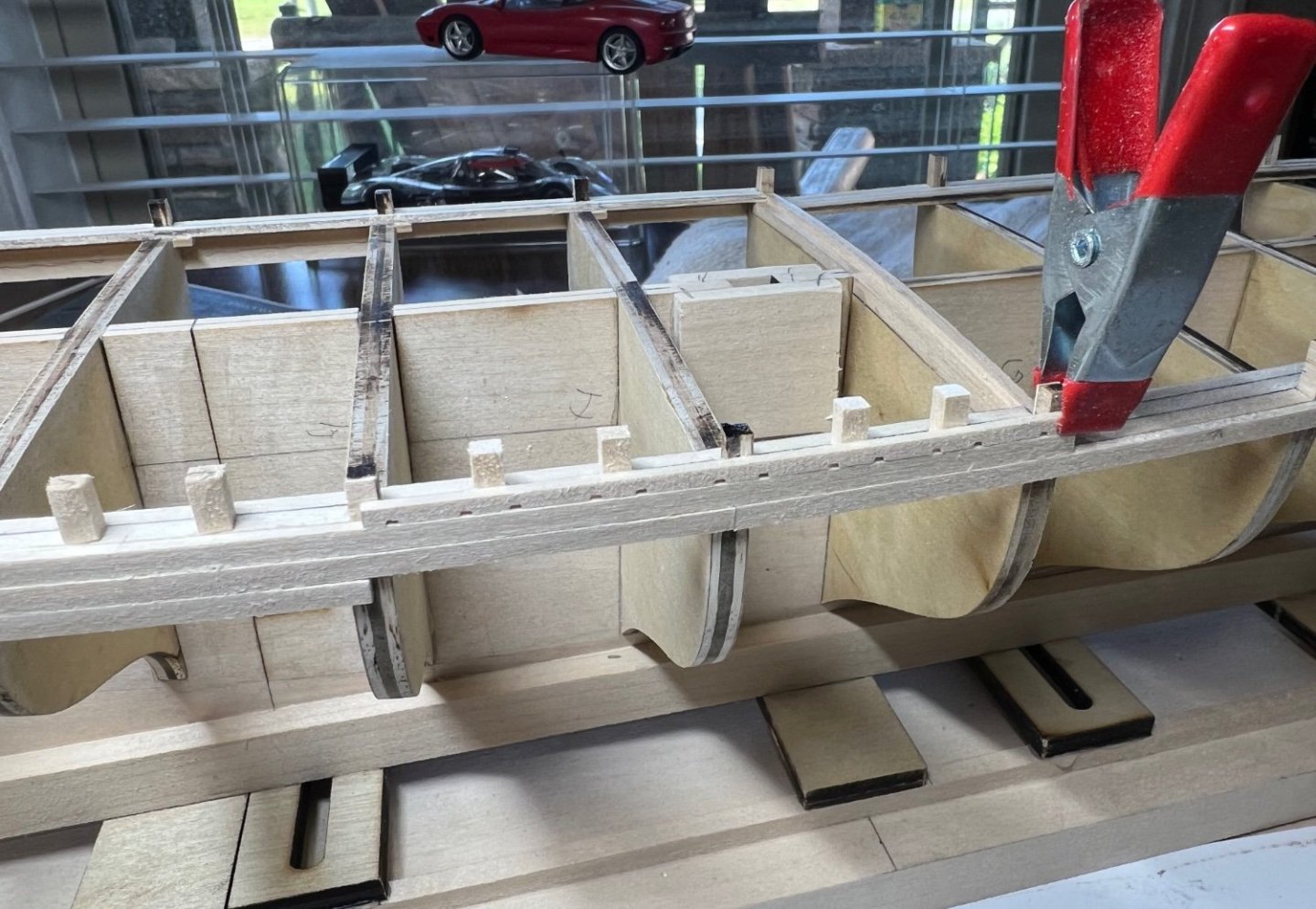

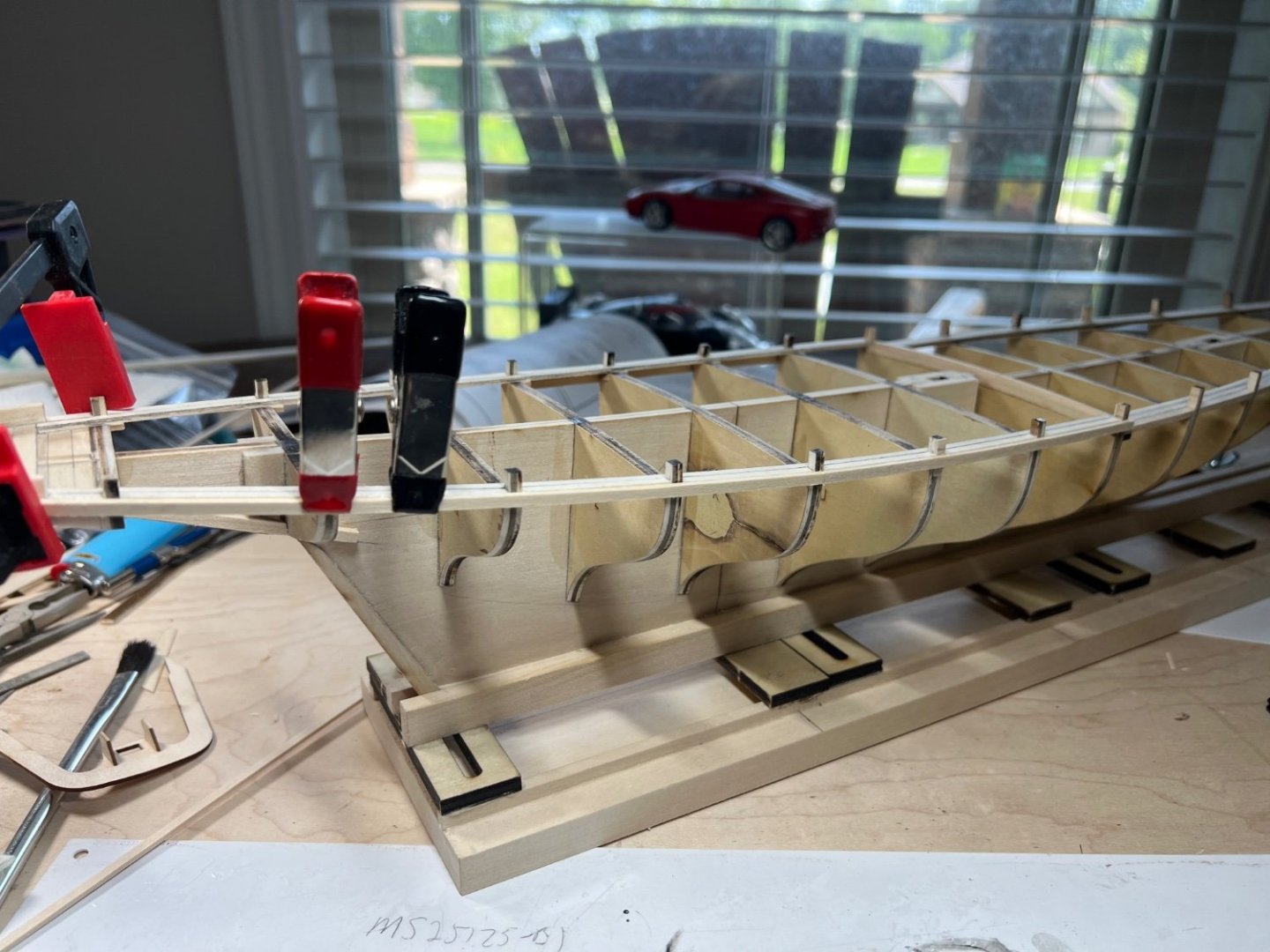

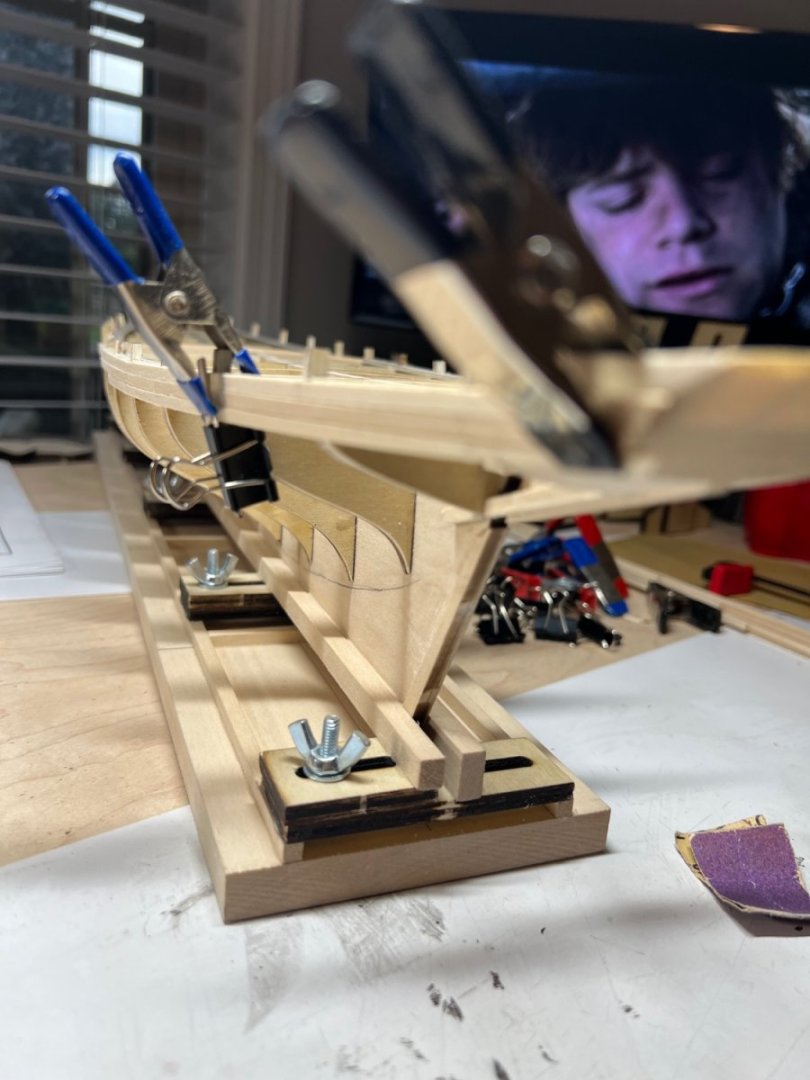

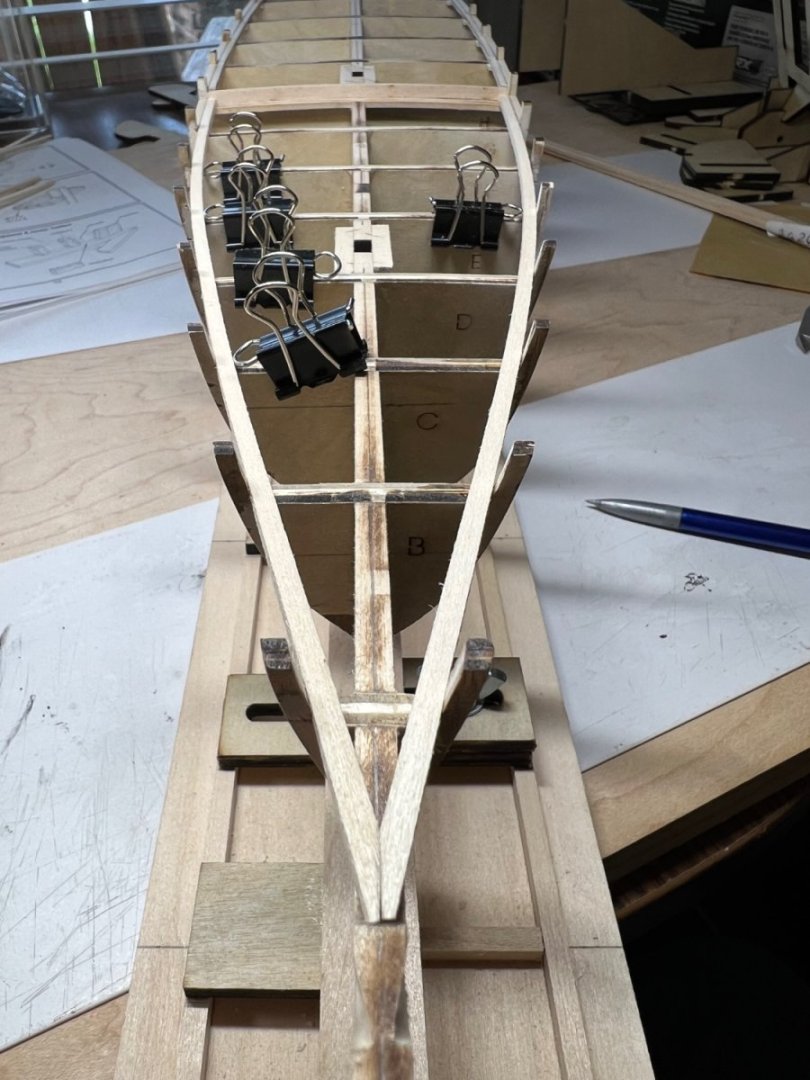

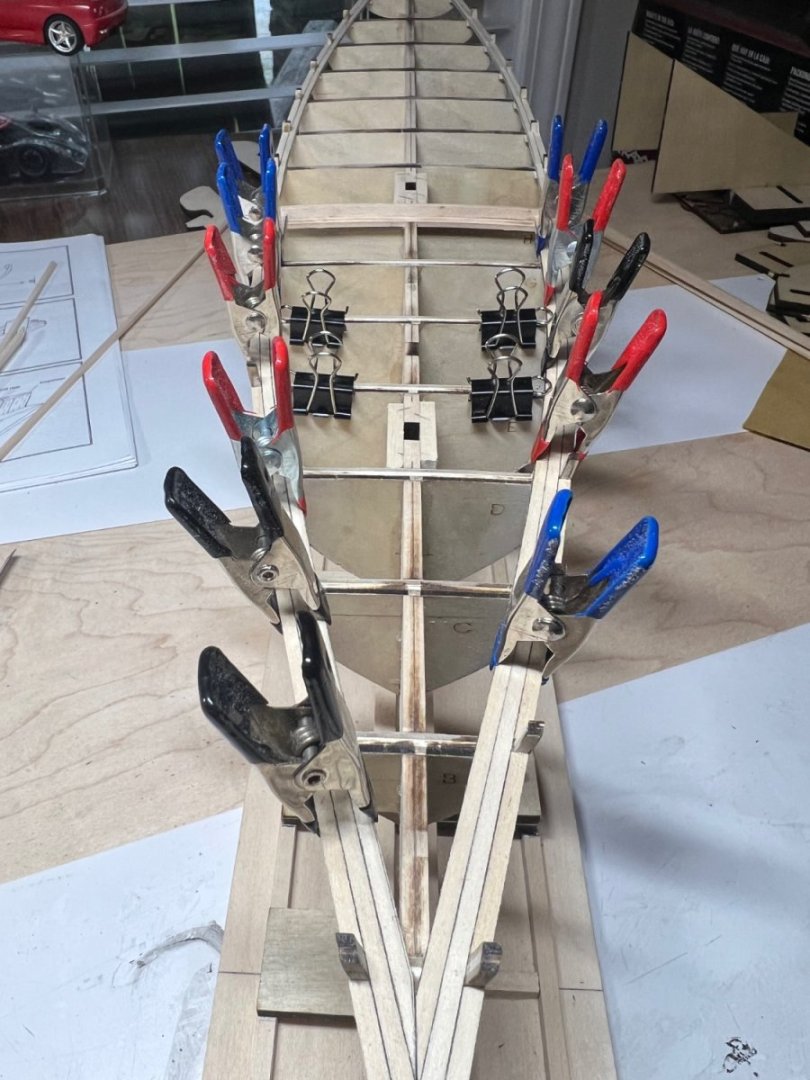

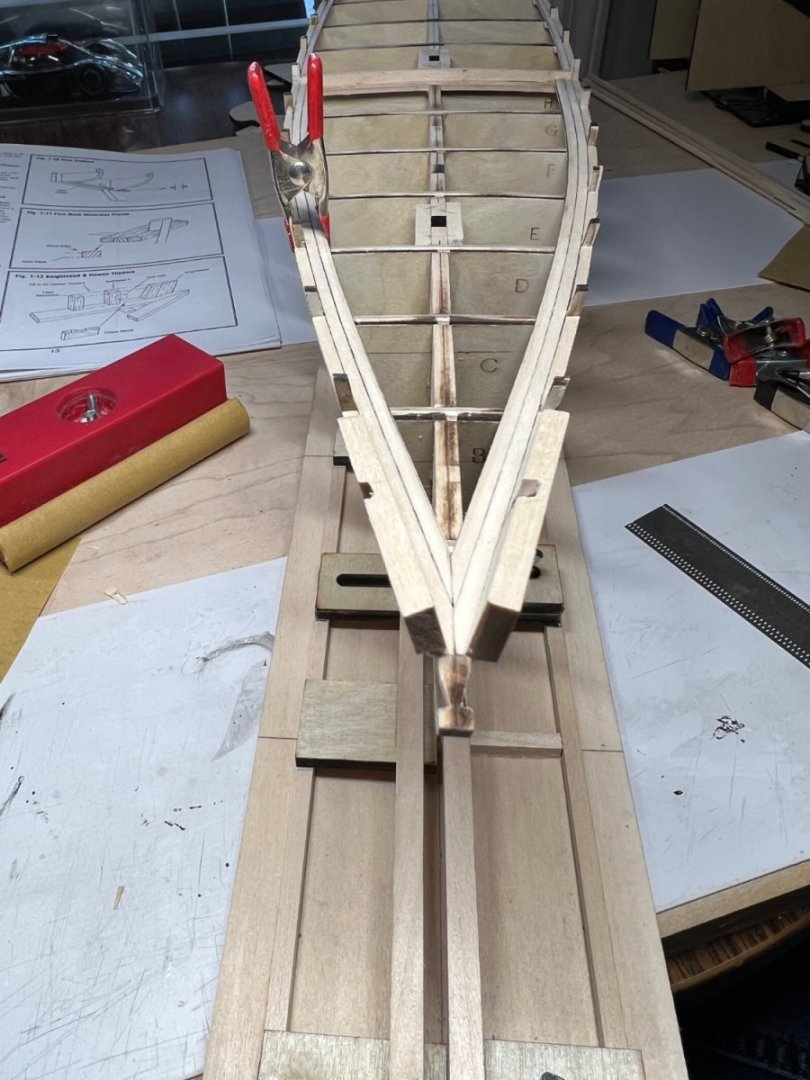

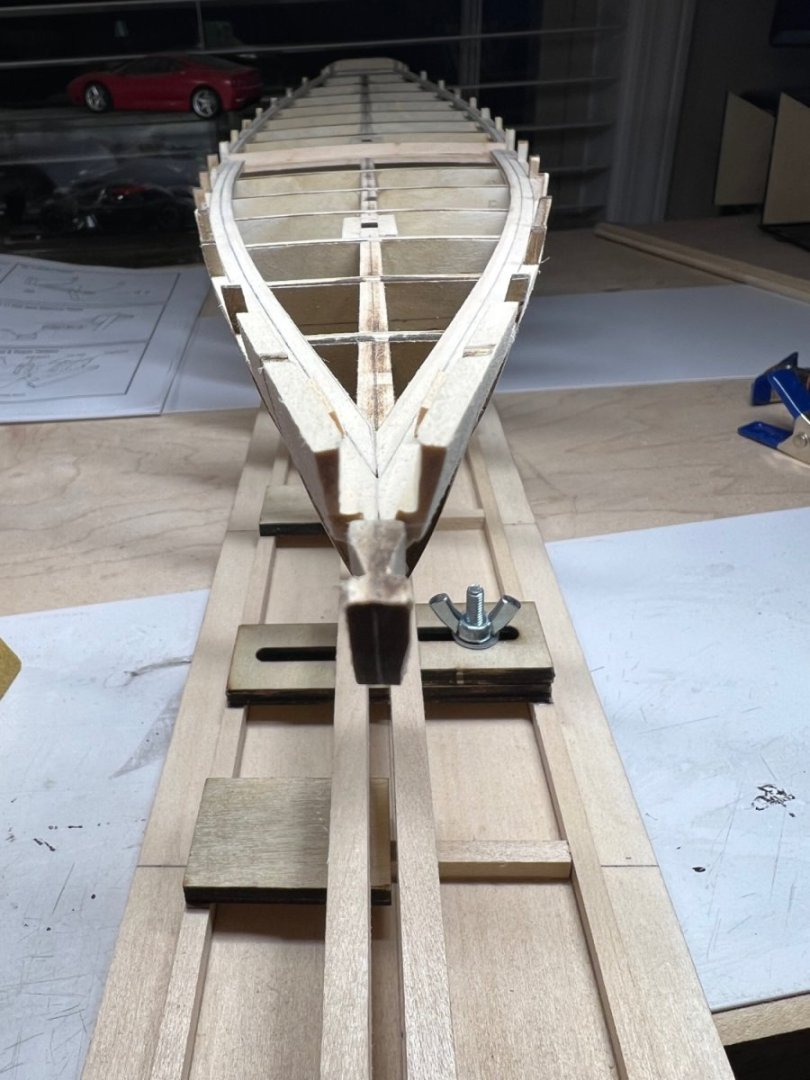

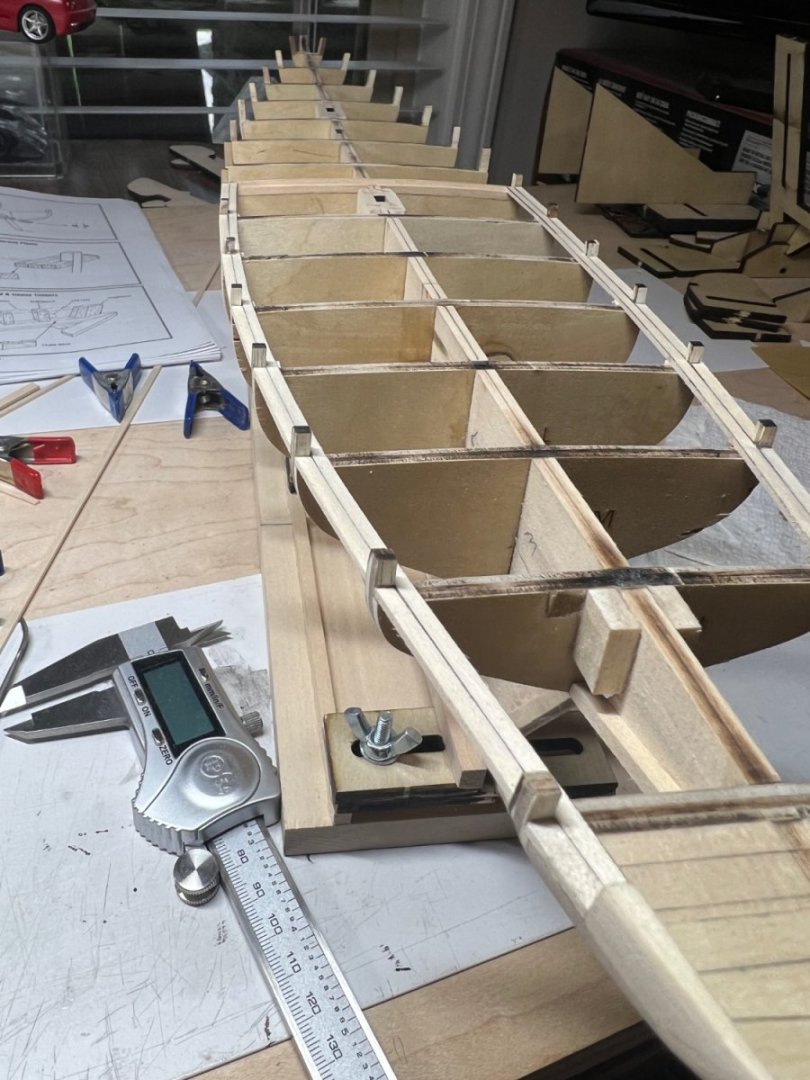

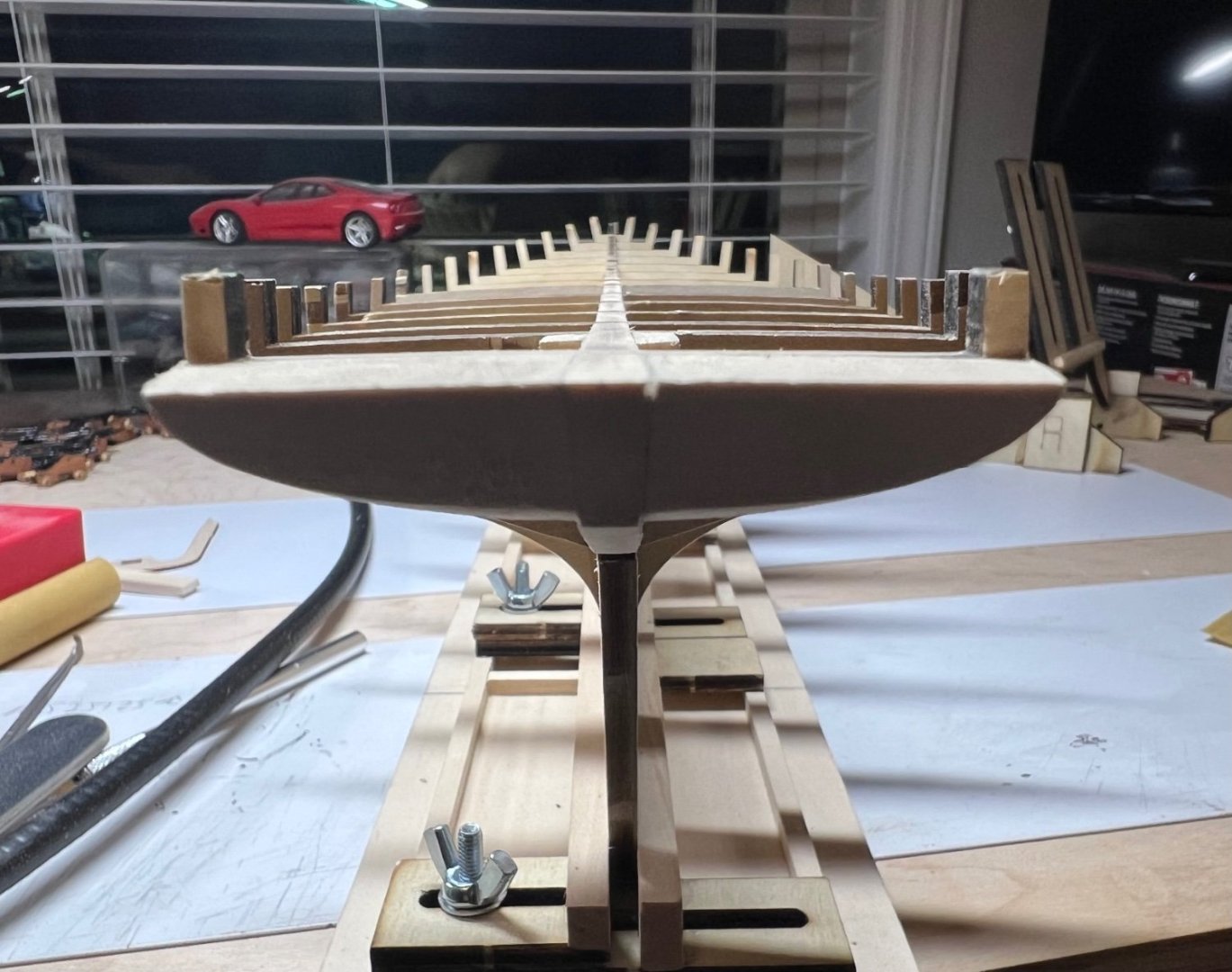

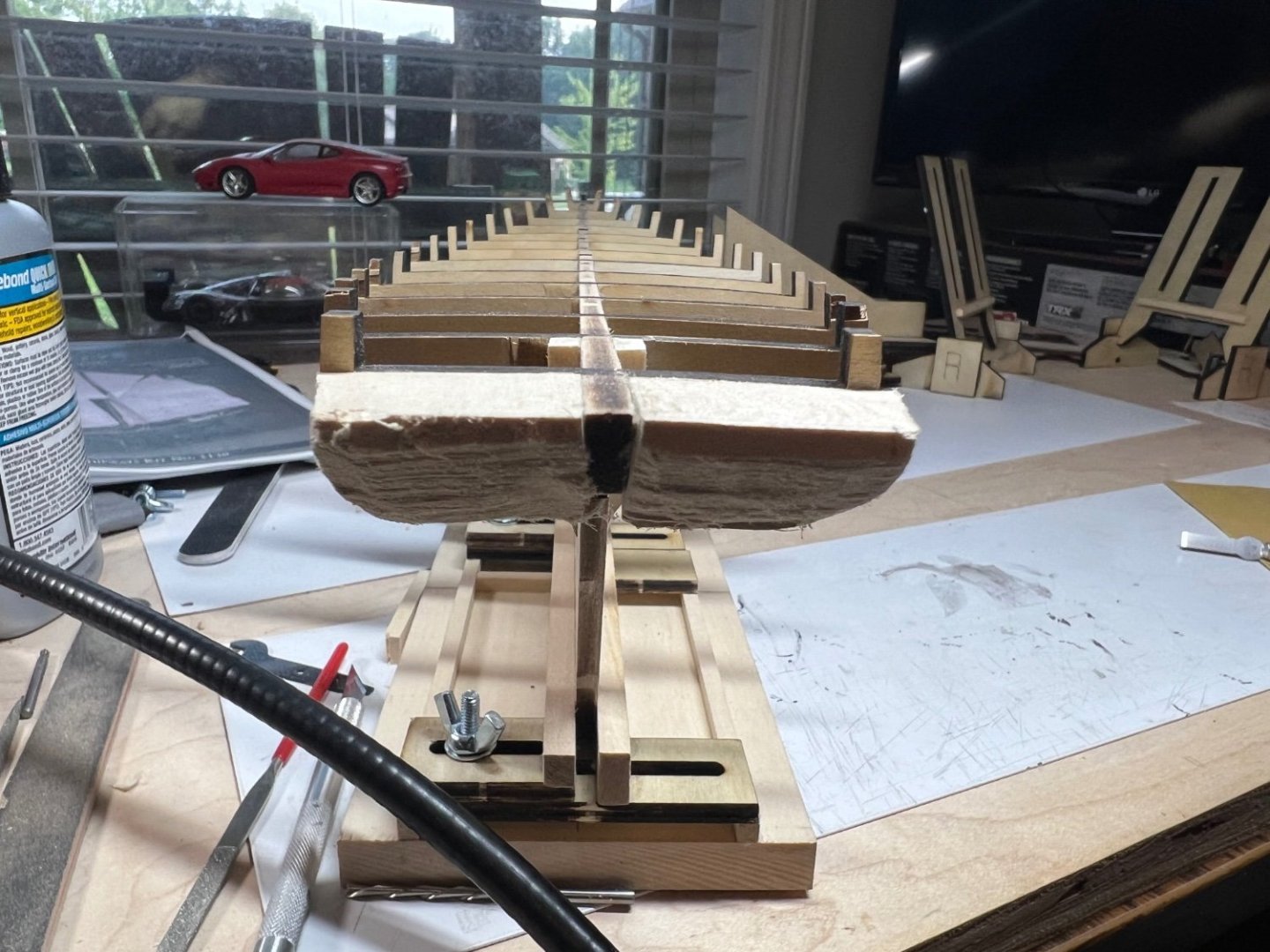

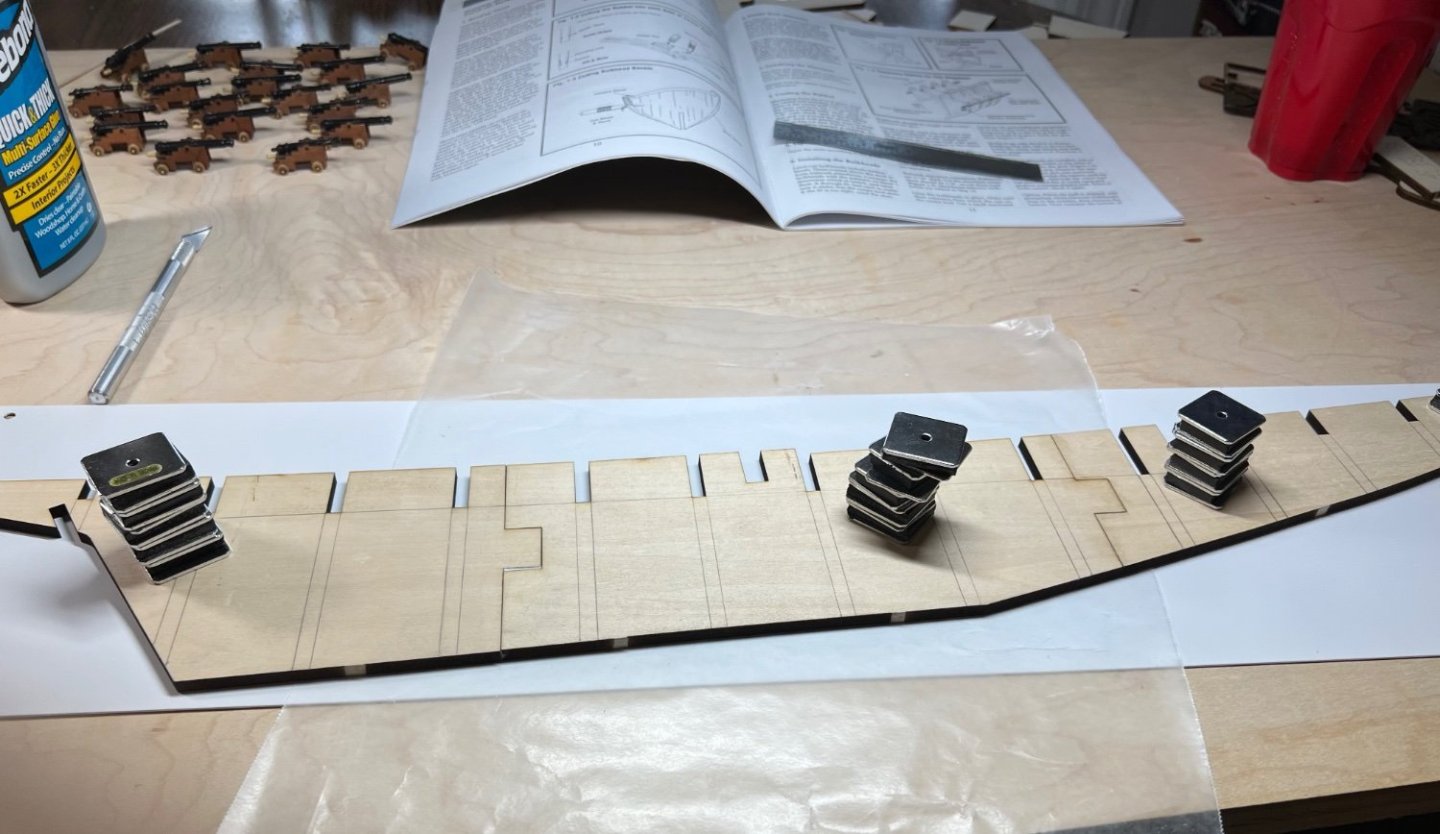

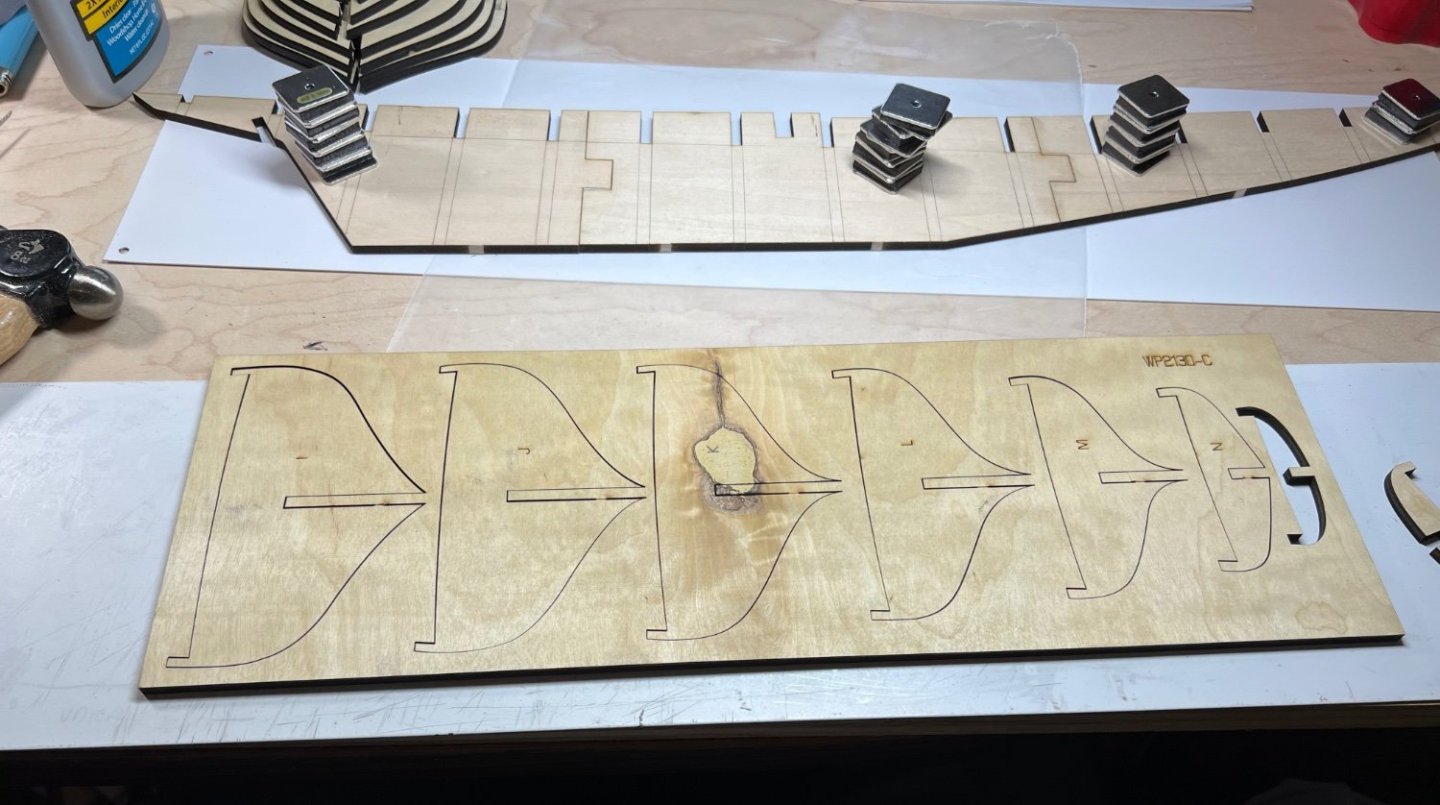

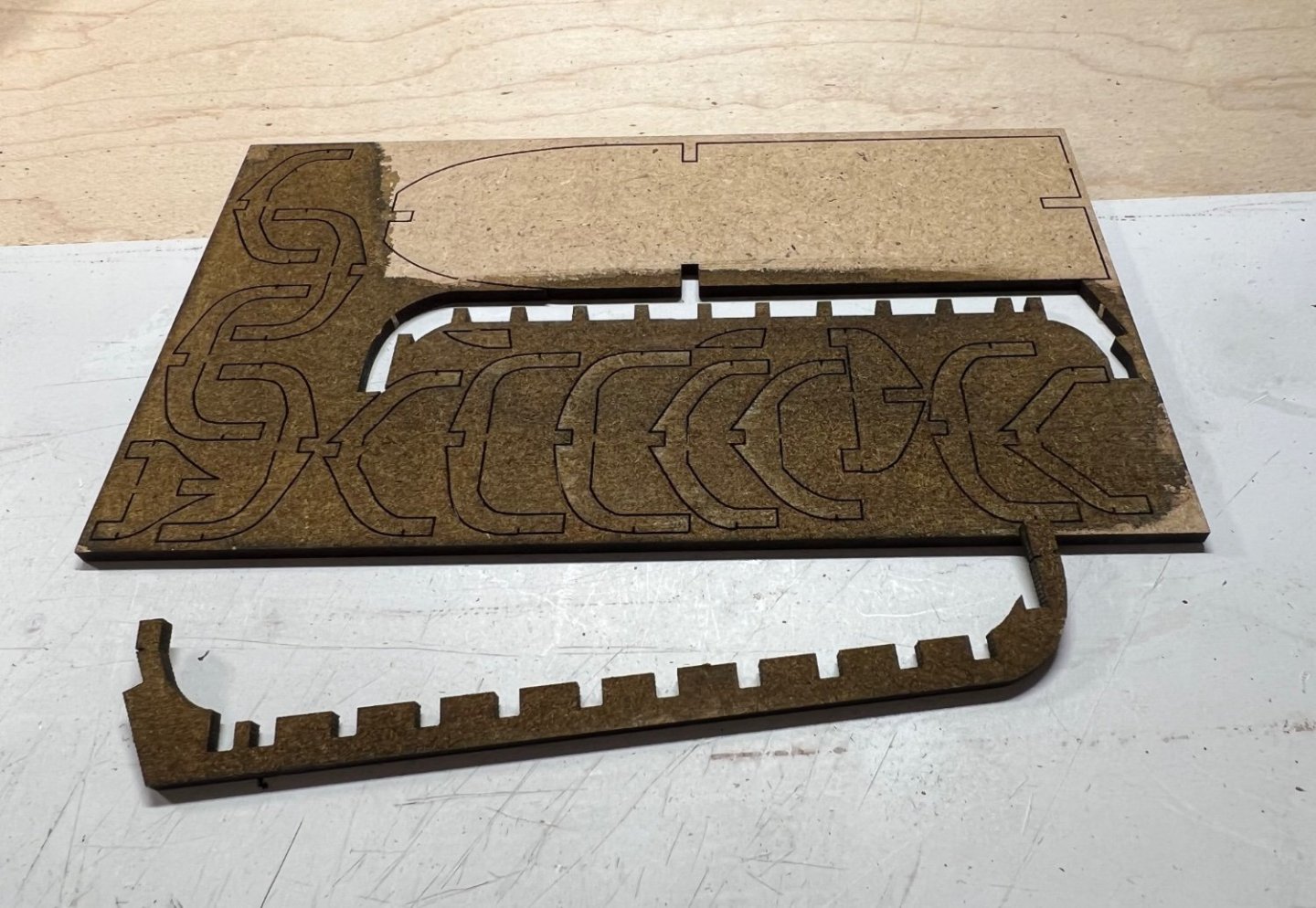

I remember this taking much longer the first time. It’s been so long I’m not really sure where I got to. Now that I have a better understanding of fairing the hull this part may go better. Fair a frame MS105 was good enough to square up the bulkheads. I built it to hold the hull. I got it a try for it’s intended purpose. Not my favorite tool, but it did the job.

-

My attempt at paint. Step 36. The goal is to finish. Not to be perfect. Tamiya masking tape works good.

- 40 replies

-

- Model Shipways

- Muscongus Bay Lobster Smack

-

(and 1 more)

Tagged with:

-

- 40 replies

-

- Model Shipways

- Muscongus Bay Lobster Smack

-

(and 1 more)

Tagged with:

-

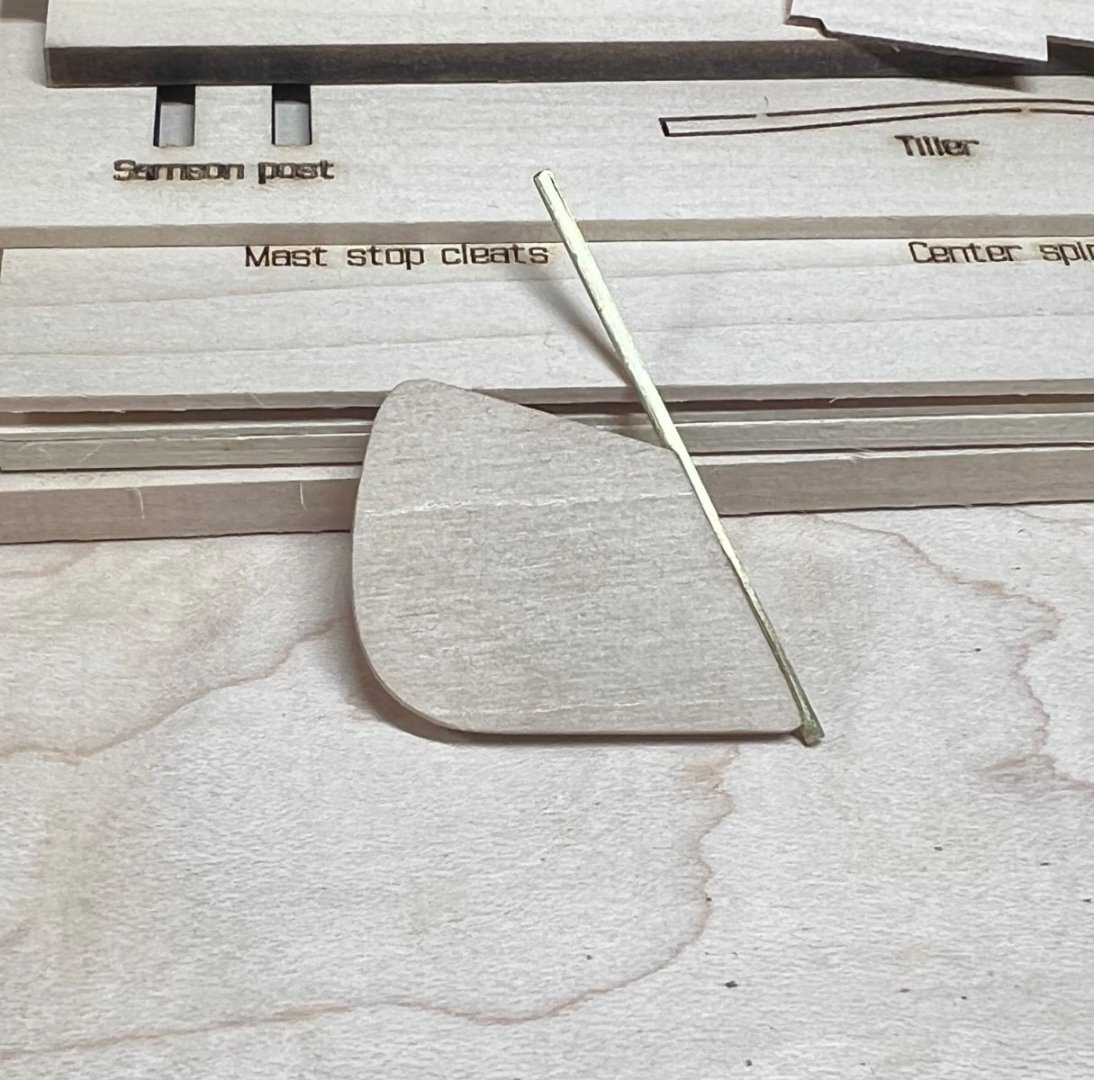

Completed thru Step 32 Rudder I’ve taken pictures of strategic spots from 19 thur 31. No picture of the rudder was taken with this batch. The oarlock pads from the punch out didn’t seem right. The instructions show oarlock pads like made with the Dory. They should be 1/8 in tall, mine are to short, I’ll leave them like I have them, I want to finish, not achieve perfection. I’m sure I’ll regret not painting something at this time, but I’ll deal with that later. I had to add material to the beakhead, not sure why it was angled down and was not tall enough. Working on 3 kits at the same time I’ve got all kinds of scrap around me now haha.

- 40 replies

-

- Model Shipways

- Muscongus Bay Lobster Smack

-

(and 1 more)

Tagged with:

-

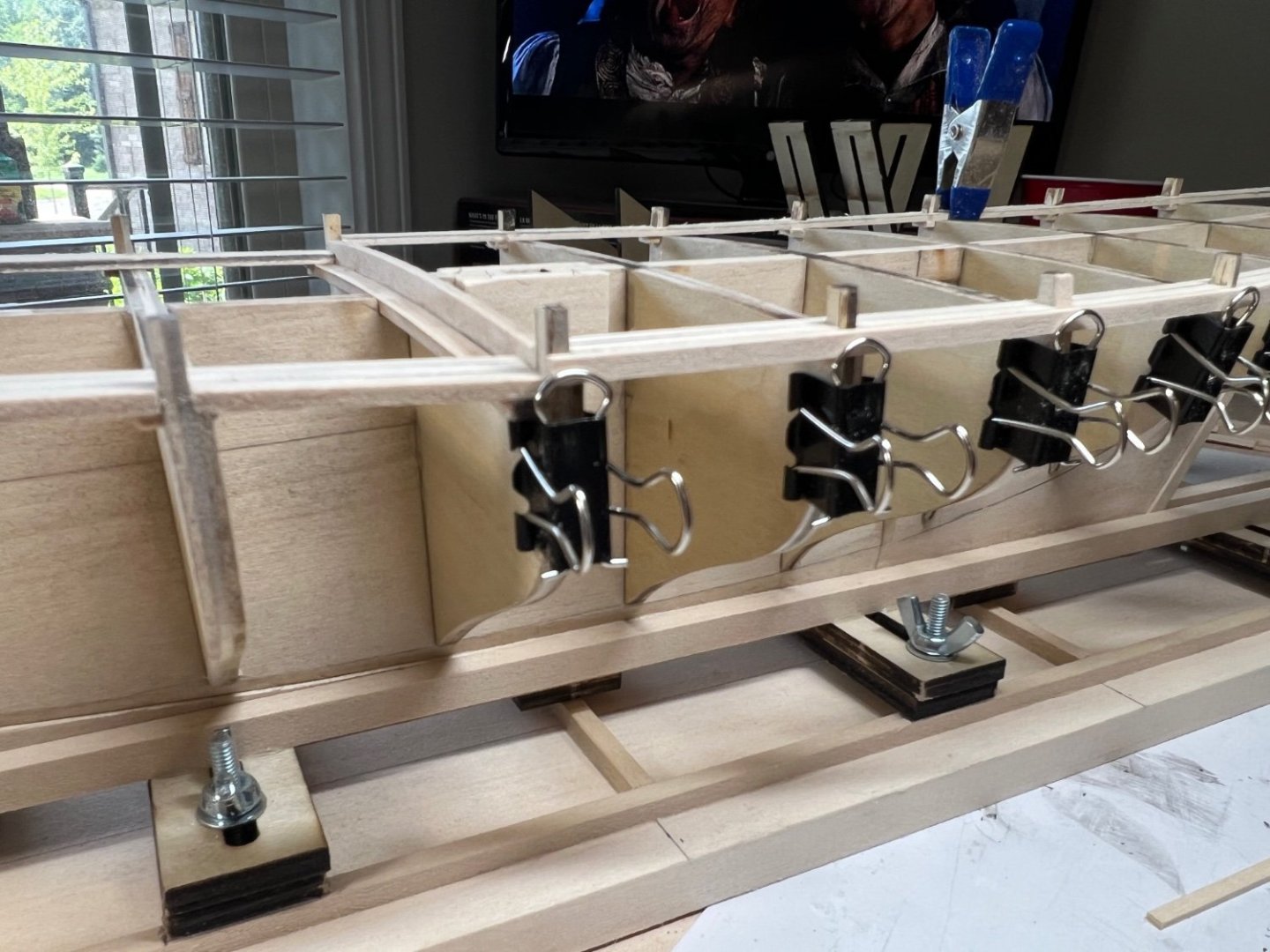

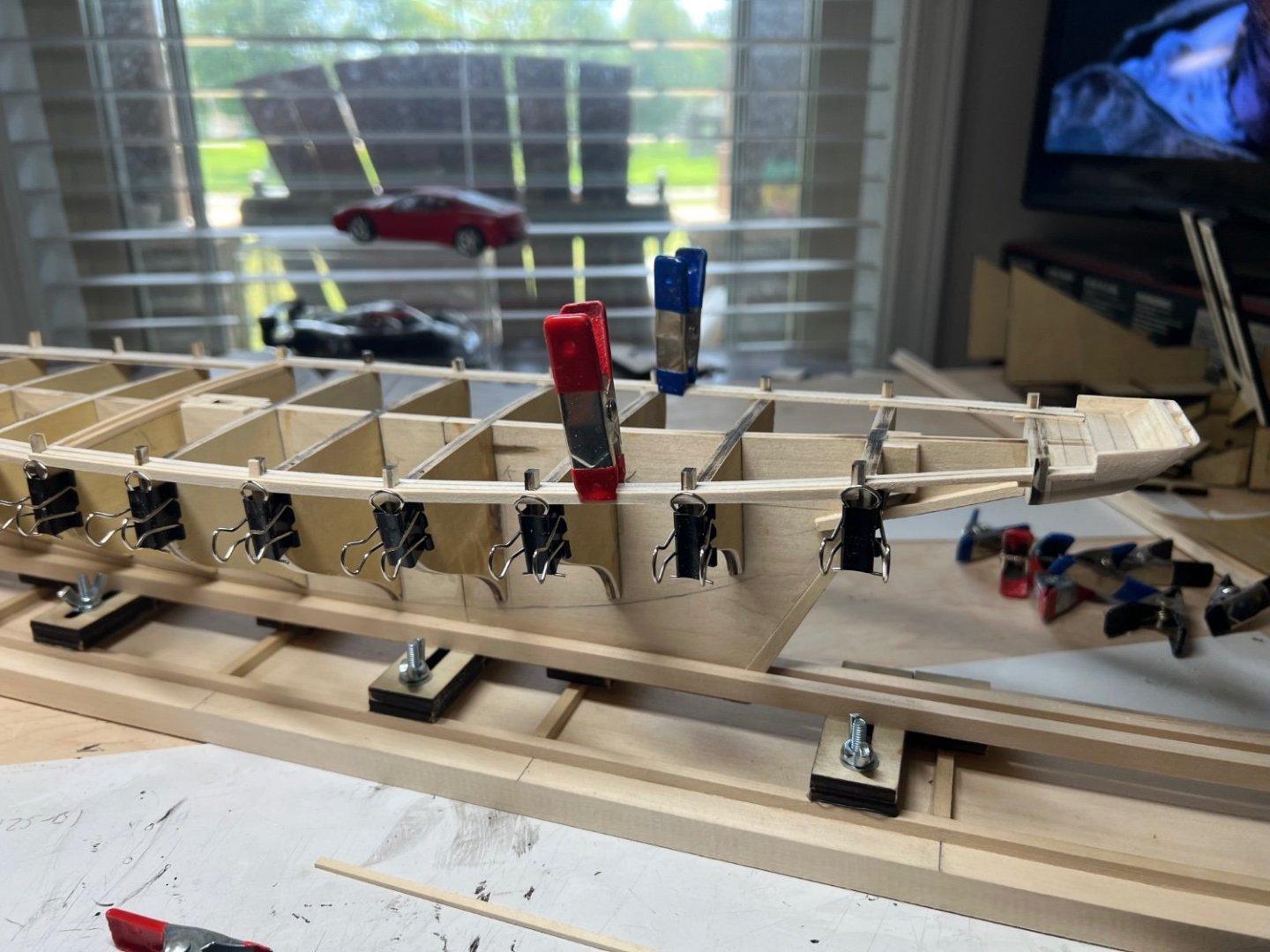

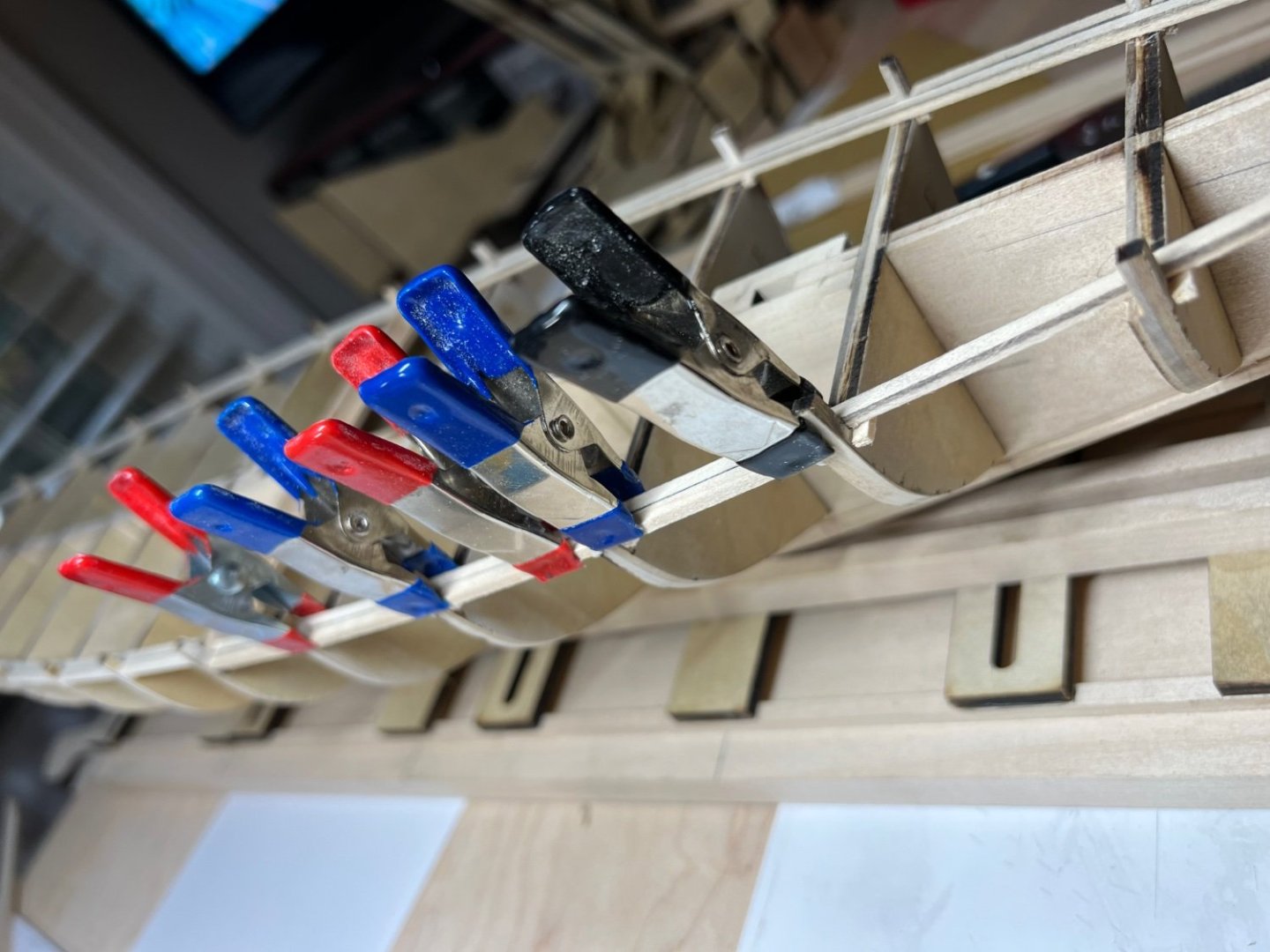

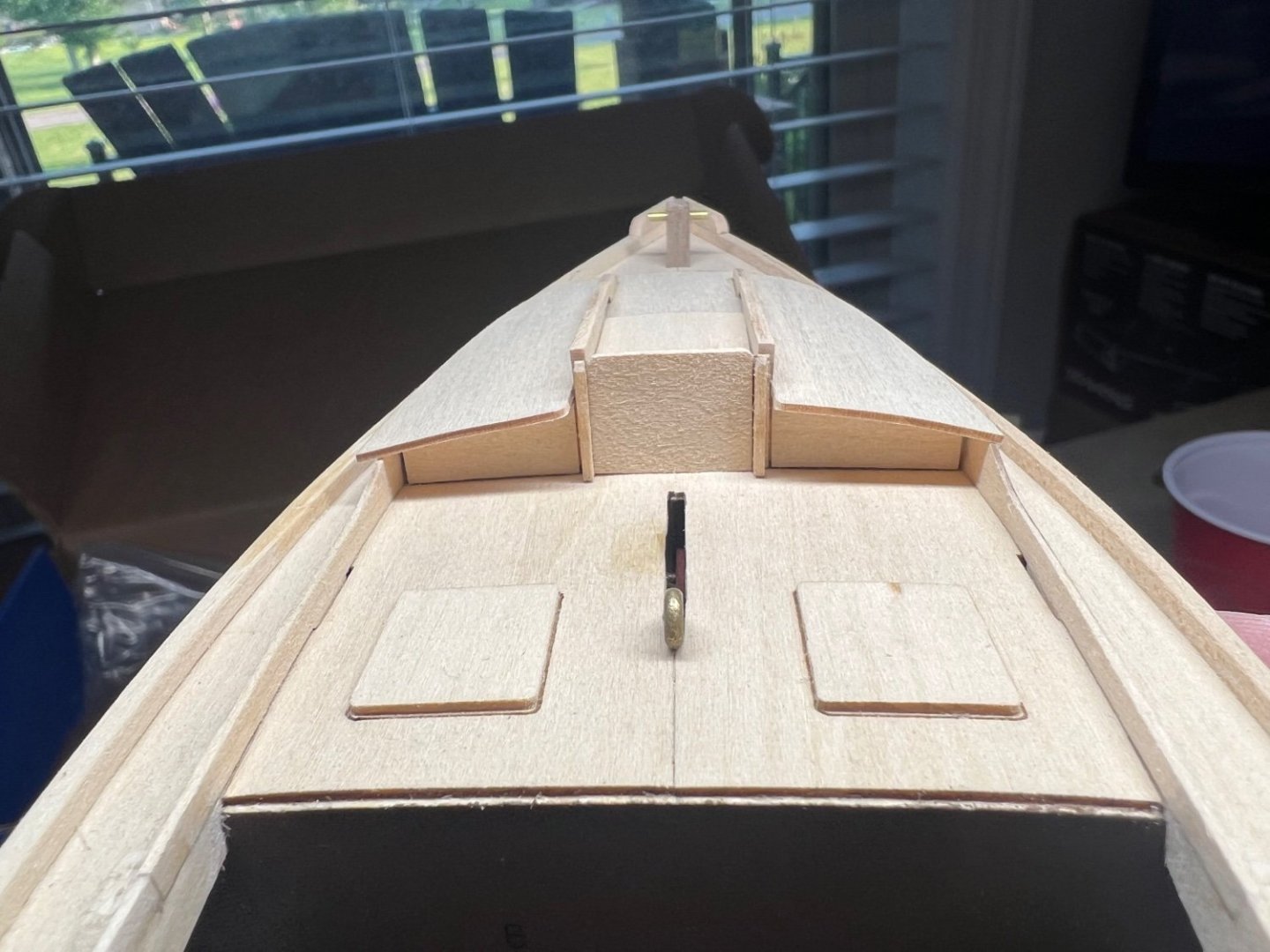

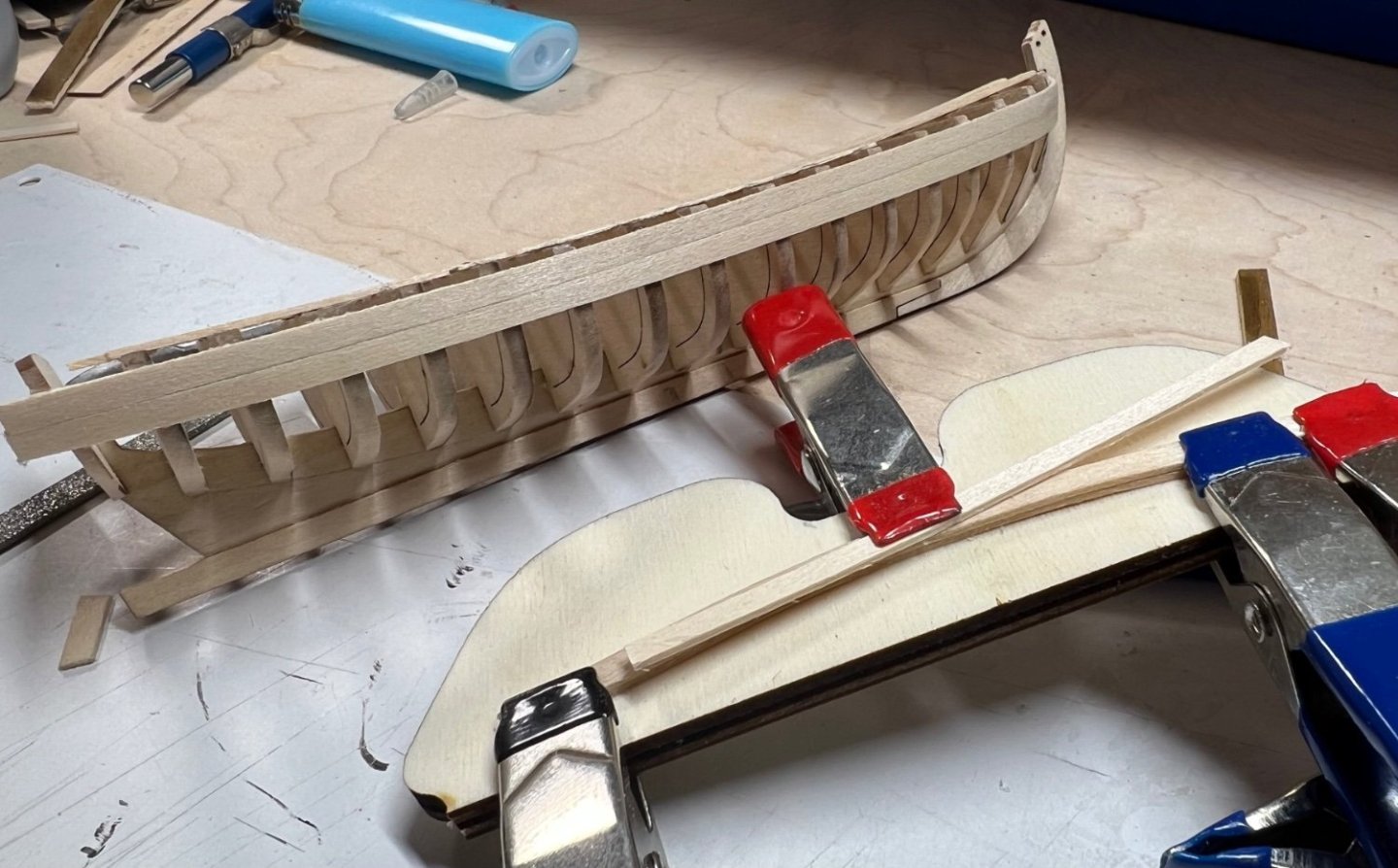

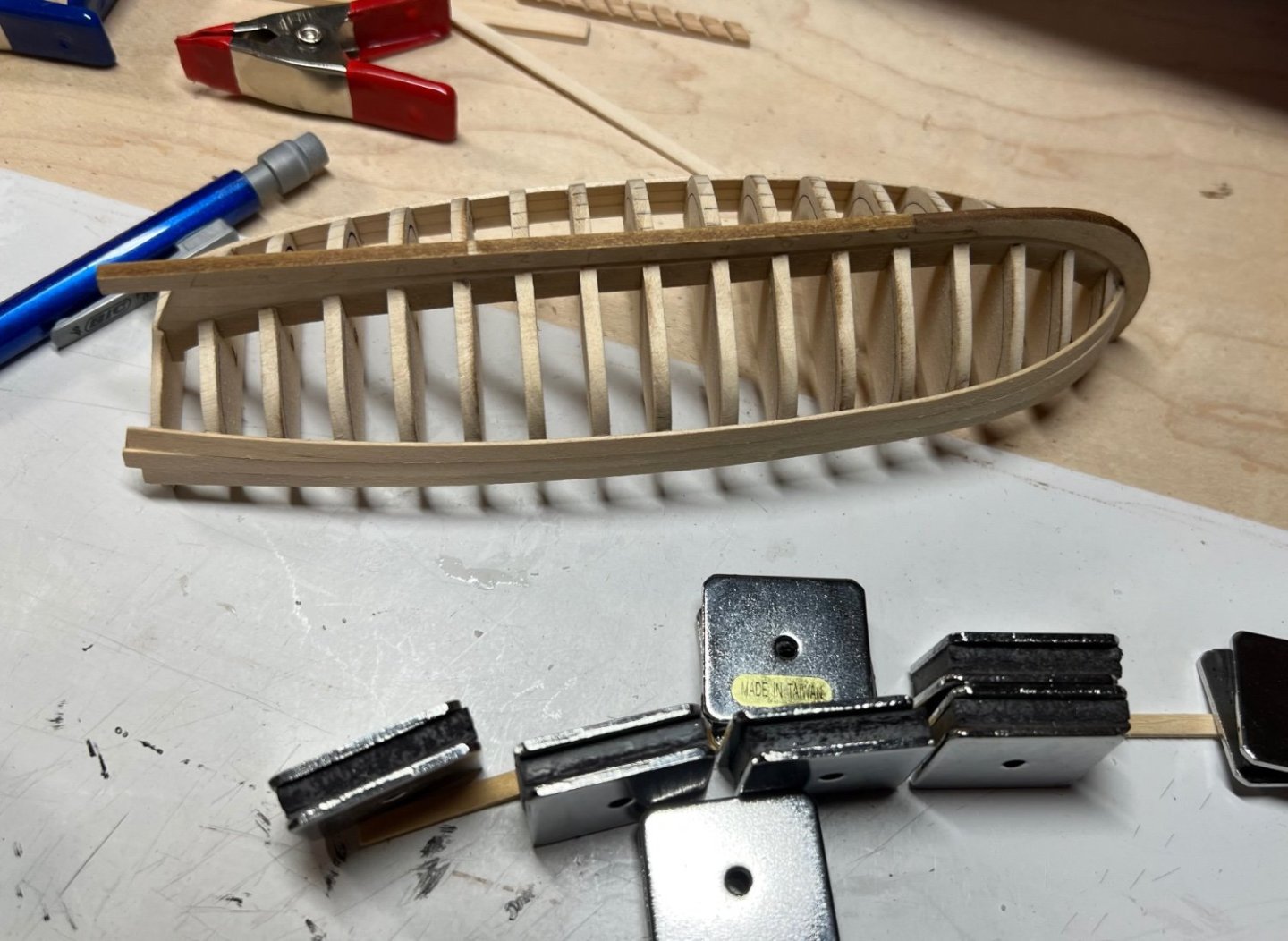

I looked at this project a few times over the last few weeks. I could not figure out how to stabilize the hull so I could plank it. I found another build log to see what others have done. Someone mentioned straps across the top. It worked great. Bending the planks around a cap worked great too. Top planks in place. It’s so small, it’s easier and harder to work with being so small.

-

The aft balcony needs its clear windows installed. All hull parts are installed, complete thru stage P. it’s easier and harder than it looks. It’s far from perfect but it’s a run out ghost ship, so I’m not looking for being perfect. The next step for the hull is full black paint. One tiny container of black paint and one big boat. I bought extra of the full paint set, just in case. I'm following the instructions and the videos closely. No two builds will be the same that’s for sure.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.