-

Posts

807 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Greg Davis

-

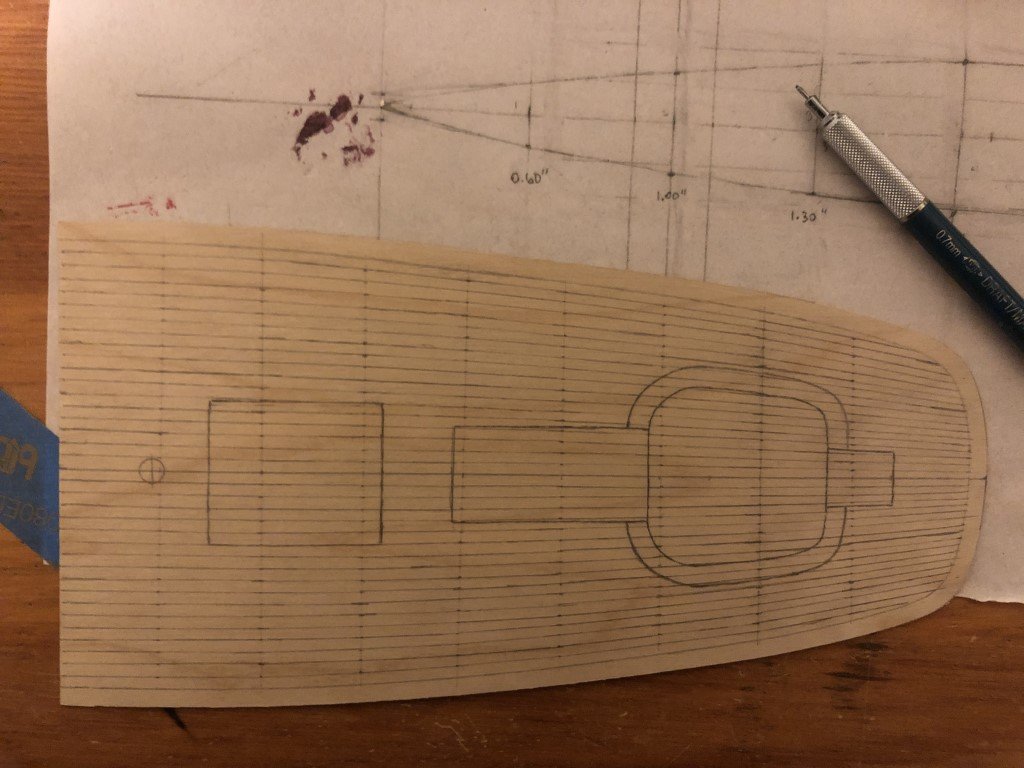

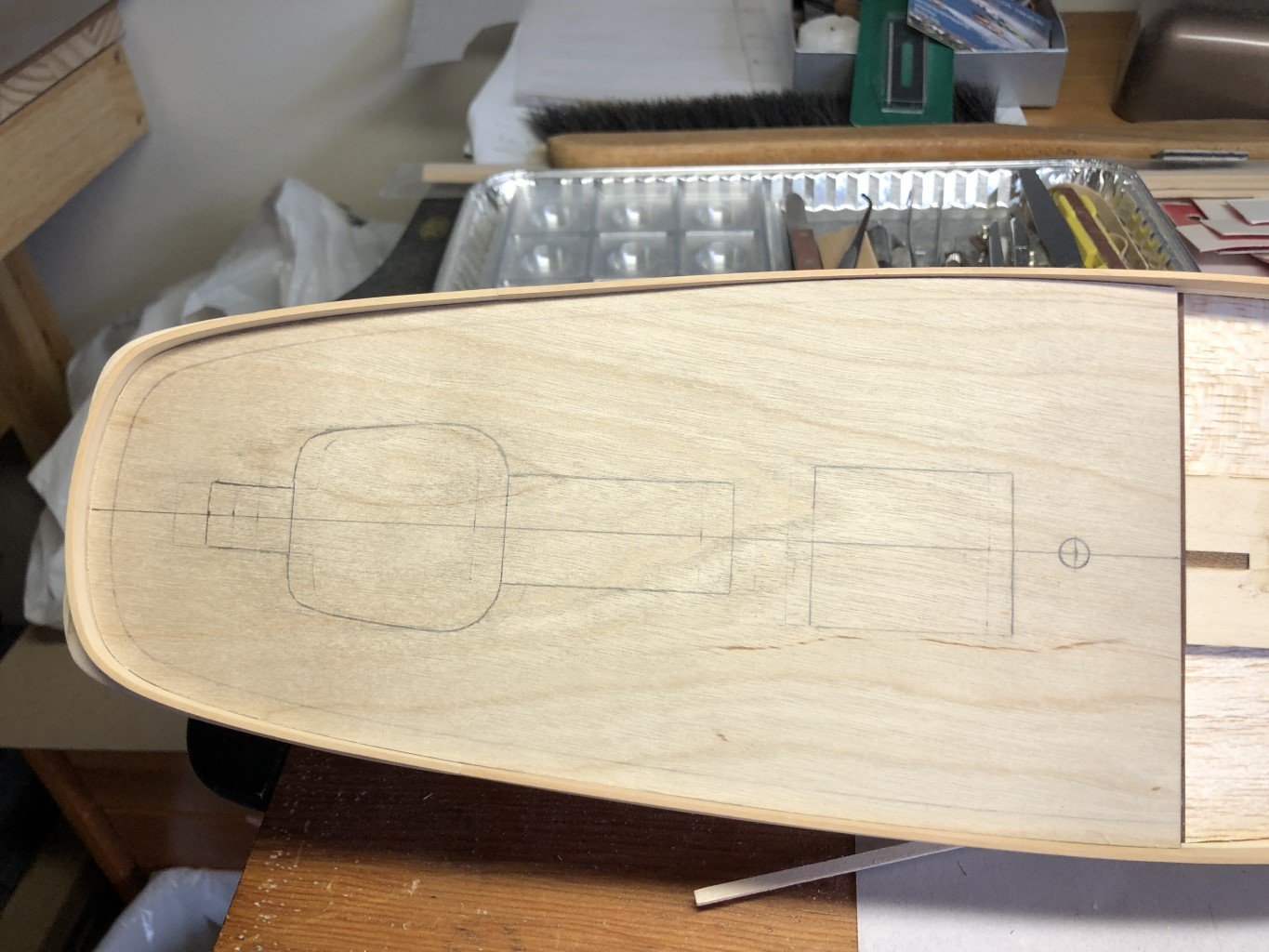

The aft deck template shown a couple of posts ago was actually made on 1/64" plywood - not 1/16" as I typed. After placing it in position on the model and pressing down between the bulkheads I decided that the material was too thin / flexible for its purpose. So here is a new template made from 1/32" plywood. It appears to have the right amount of stiffness yet allows for bending in all necessary directions along the deck profile. Liking this template more, I went ahead and drew in the planking scheme. I should probably mark the timberhead locations on the waterway and then notch them out - the result may be better than gluing them on top of the waterway. (Probably over-doing it - scale back, scale back - the model will probably never leave the house!) The maximum plank width is 1/8"; i.e., 6 scale inches and this conforms well with the plans and information in Chapelle's books 'The American Fishing Schooners 1825-1935' and 'Boat Building'. I am planning on milling the planking material to a thickness of 1mm - just a bit more than 1/16". So once planked and smoothed, the finished decking will be 1/16" or slightly less. Today I'm thinking about trying maple for the planks and swiss pear for the margin plank and timberheads.

-

Thinner planks are certainly an option - I think I may get away with 1/32" planks. As you note, not much room is left for error / sanding! But if I use a subdeck, smoothness of the initial planking job should be reasonably good. As for the overall accuracy of the model when completed - I think a very nice model will be the result, one that will be great to display, and one that is certainly a good value for the investment (both material and time spent). Will it be a perfect replica? - probably not, but this is most often the case with models, especially those from kits. My disappointment is in the discrepancies between the plans and the kit pieces. Quite frankly, I have no good idea if the plans themselves are truly accurate and I don't think there is any way to proof-check them. I believe that right now, I'm doing something I shouldn't be doing - being overly concerned with each and every deviation. I should be reserving these feelings for a 1:48 scale frame model built to ANCRE plans or similar and being made for competition and/or a wealthy client (wish I had one of those!). Its like many Model Expo kits - a really good starting point, with lots of potential, and a good deal of room for frustration because the kit could be so much more for not much more thought and / or production cost. Yes, the ship has a stepped deck, so issues to address up front as well!

-

I am also concerned about the transition between the subdeck and the rest of the ship. Fortunately, it is not quite as extreme as the photograph seems to indicate. I've already gone after the region with a good deal of smoothing to help with the transition. I am considering the plywood deck underlayment partially because it will additionally smooth out some of the junction angle. I might need to add a small amount of material to the top of the bulwark to have a nicer flow.

-

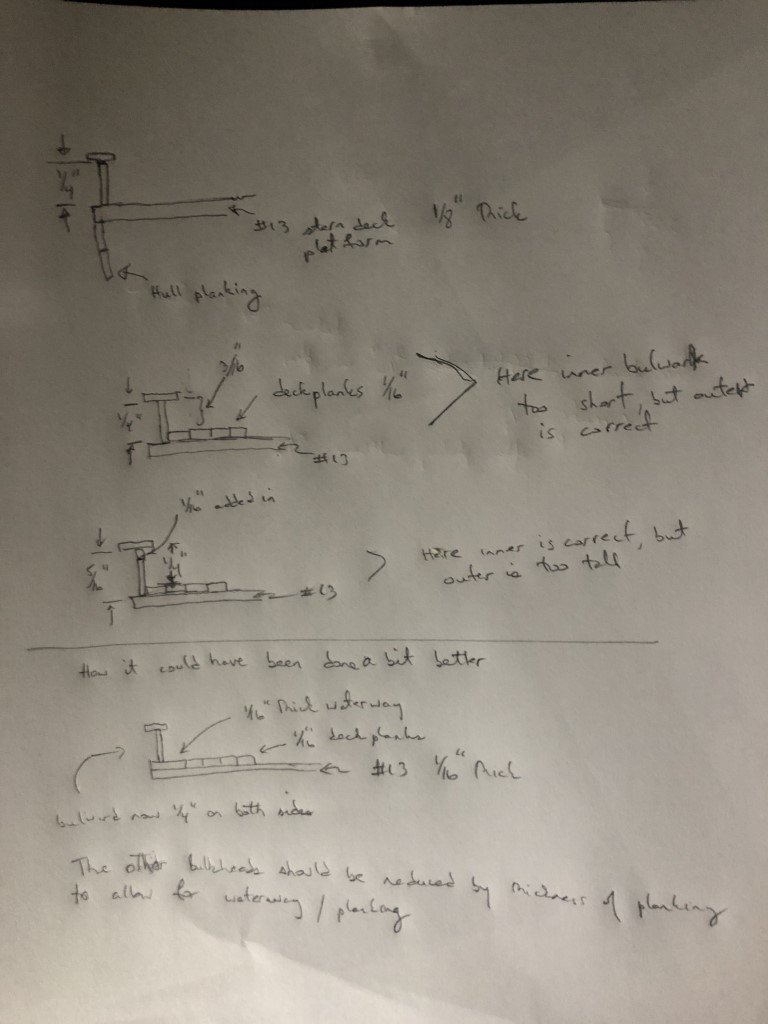

With respect to the bulwarks, I've made a sketch to better explain the situation. According to the plans, the bulwark height - distance from planking to under the rail - should be a constant 1/4" along the aft deck. This measurement is for both the inner and out bulwark . Before planking the aft section this is how the measurements are. If the aft deck is planked with 1/16" material the outer bulwark dimension remains 1/4" but the inner becomes 3/16" and is shorter than it should be. If 1/16" of material is then added to the current bulwark, the inside dimension is corrected, but the exterior dimension becomes too large by 1/16". There are ways to correct this - but it would take more work than I care to do at this point. In the aft portion of the vessel, if part #13 had been made 1/16" thick, then a 1/16" piece could have been used as a waterway and the bulwark planking could have been positioned over it. This would also have required that the remaining bulkheads had been made 1/16" lower to accommodate the planking and waterway. I think this would have been a good place to have used laser-cut parts in the kit. The waterway could have been laser cut with locations for timberheads precut. Due to how the kit was manufactured, the distance between the fore deck and the rails will also be too small. According to the plans, the distance between the deck planking and the bottom of the rail should be 7/16". The way the kit is constructed the distance is 3/8" before planking - this will be reduced to 5/16" after planking with 1/16" material. Down the road there may be some issues due to the missing 1/8" - I am most concerned about what this will mean for locating the hawse holes.

-

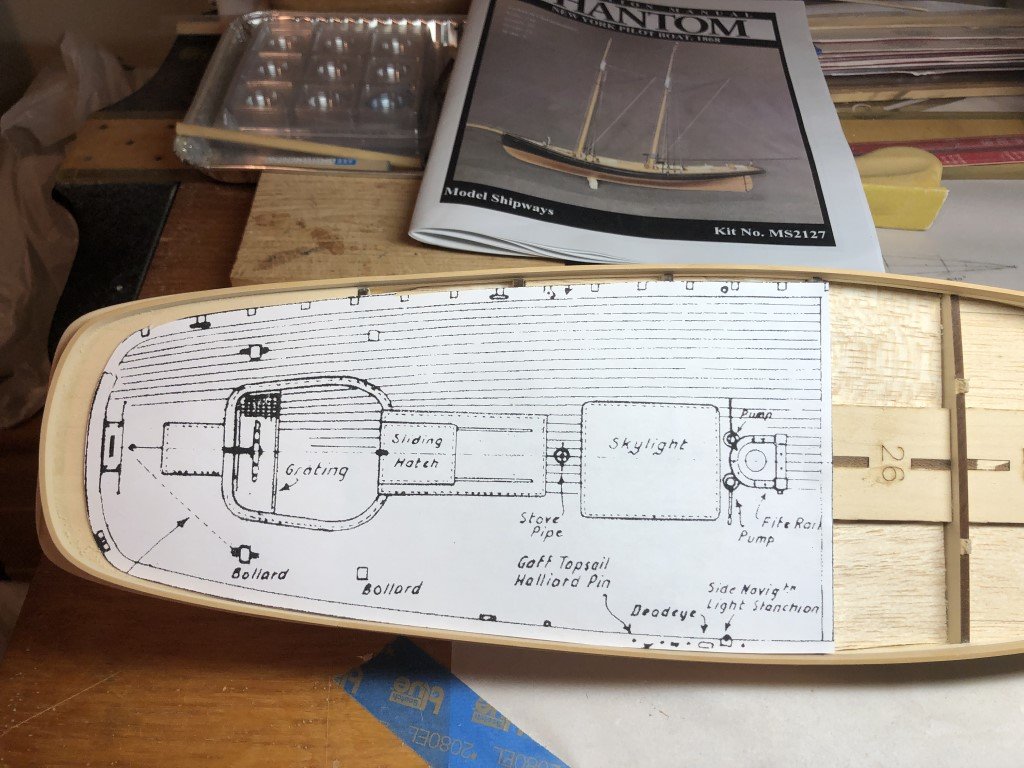

The surprise in #46 is that the deck plan didn't match the deck length by quite a bit - 5/16" in fact. I now realize that a portion of that discrepancy is my own fault - when I planked the transom, the deck length was extended by 1/16". The remaining differential of ~1/4" is a miss between the model and the plans. I was rereading the Volk / Davies-Garner book 'Working techniques for model shipbuilding" and the discrepancy is noted there as well; in fact, it is a discrepancy from the original 1/96 plans that remains after enlargement to 1/48 scale. I made template of the aft deck using 1/16" plywood and have repositioned the deck plan slightly. The mast hole is over the slot in the framing. The space between the mast and skylight was increased by 1/8" and the space between the skylight and deckhouse / cockpit by 3/16". I couldn't move the cockpit / rudder house back any further without having a severe mismatch in location with the rudder post. At the end of the day, it will look OK as the proportions have not changed drastically. I've marked a 3/16" waterway on the template and will probably line off the planking as well. I am considering planking directly on this template and fastening it to the model as opposed to gluing the planking only to the bulkheads in the front portion of this deck.

-

I think I've discovered another 'issue'. This one is a bit more serious and I don't have a good solution. In relationship with the bulwark planking, the top of the bulkheads and part #13, the stern deck underlayment, are already at deck level. That is, no space was engineered into the model for the thickness of the deck planks. Now if the deck is planked with 1/16" material as called for, the inner sides of the bulwarks will be short by that distance. If the bulwarks are then extended, they will be too high on the exterior of the model. The deck profile / height at center and side are clearly marked on the kit plans (drawn by Campbell), but apparently were not conformed to in production of the model. Ideas? Any would be welcome!

-

Popped off the bulwark molds, smoothed out the bulkhead tops along the quarterdeck. I then made a copy of the deck plan provided with the kit. I cut it out to place on the deck to help position the cockpit and other features on this part of the boat. I matched up the mast location and big surprise: Quite a plan / model mismatch! Looks like the 'plans' are going to be a 'guide'. Not insurmountable, but not a good look for Model Expo's new offering - another missed opportunity for a good check before kit release.

-

The case has been stained and given a coat of polyurethane. Here's port and starboard views of the model in the case: A few more steps - fasten the display board to the base board, cut and install the clear acrylic panels, and attach some felt to the feet of the case - then I can make delivery of the project. Completion is coming into view!

- 123 replies

-

- Le Pourquoi-Pas

- Constructo

-

(and 1 more)

Tagged with:

-

The aft portion of the bulwark attachment went well! I think I will now work on the deck for a while. It is either the deck or painting / coppering the hull. I have the feeling that I have a better chance of messing up the hull when working on the deck than messing up the deck when working on the hull!

-

The mid / forward portions of the bulwarks have been installed successfully - this is the part that used two 1/8" high strips of the c. boxwood. The aft portion made from the 1/4" strip came out of the mold nicely (with no char marks) I need to now remove the bulkhead extensions (or at least the last one) so that this piece can be trimmed and mated to fit the rest of the bulwark.

-

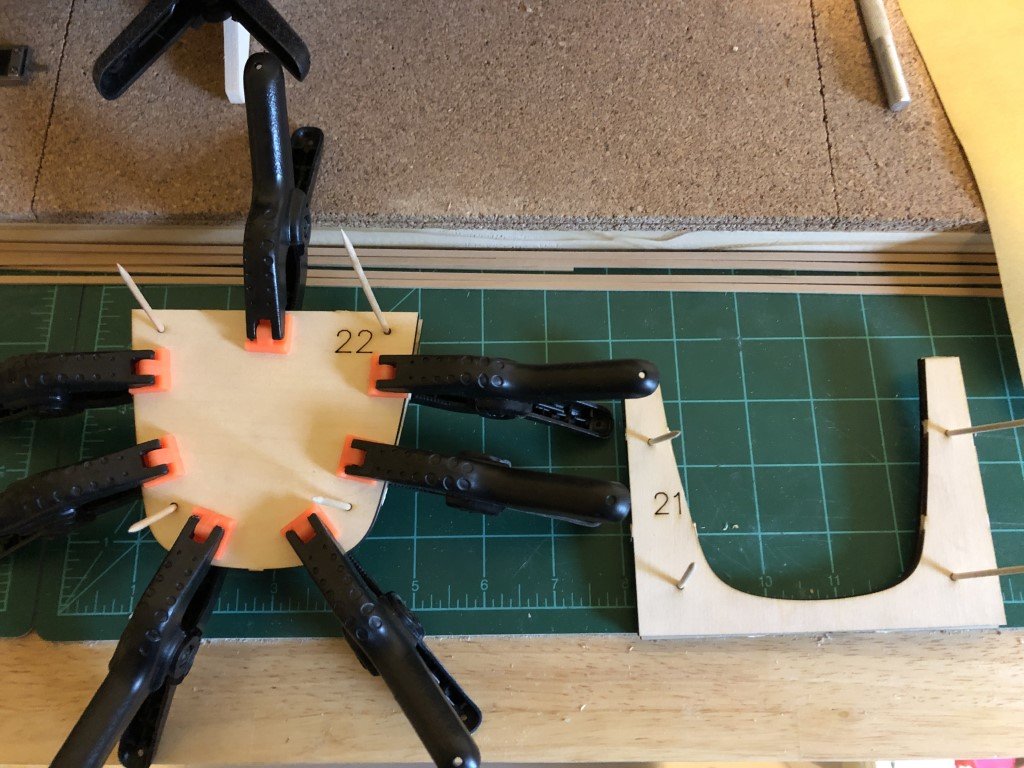

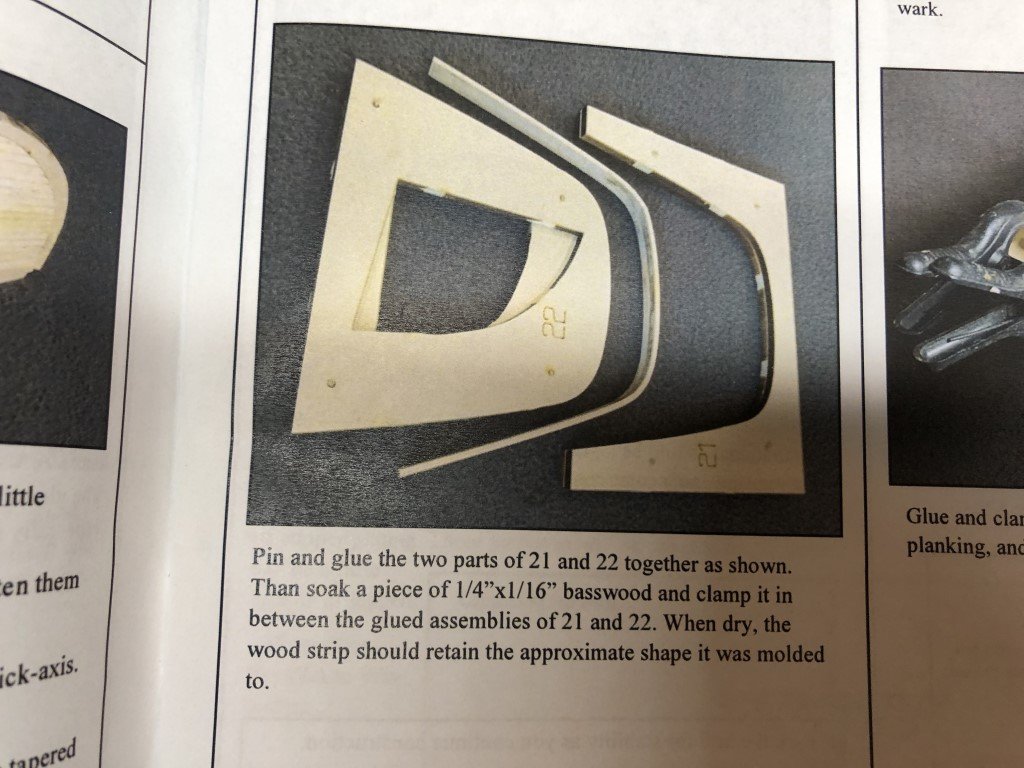

Working on the bulwarks yesterday and today. I have the first strakes of the thinner material attached. It went on quite well - one strake to go. While letting the above work dry, I released the four pieces of material that are to form a mold for the stern bulwark. I was a bit disappointed as I worked on the mold. In each pair of pieces for the mold, there are four registration holes to align the pieces while gluing them together. Unfortunately, the registration holes do not nicely match. I eventually found the best matches that I could by flipping / stacking the pieces. Even then, the holes for the alignment toothpicks is not great - only good enough to sort of get the points in. Thus in this picture you can see the toothpicks pointing in various directions: The edges of the pieces don't make as good a match as expected either: So a bit of sanding / filing to even out and true up the edges and finally I've a got a mold to try out: I cleaned up the laser char quite a bit so that when I mold the bulwark the wood won't get stained by char. The outside doesn't matter so much because it will be painted, but the inside will likely be left natural, so char dye would be bad. You can see in the instruction manual, that the char was not cleaned up and some was transferred to the wood. So the mold is ready - wood is soaking as I write this - but it is a disappointment in the age of CAD and laser cutting, that the pieces that make up the mold needed so much work to get them ready for use.

-

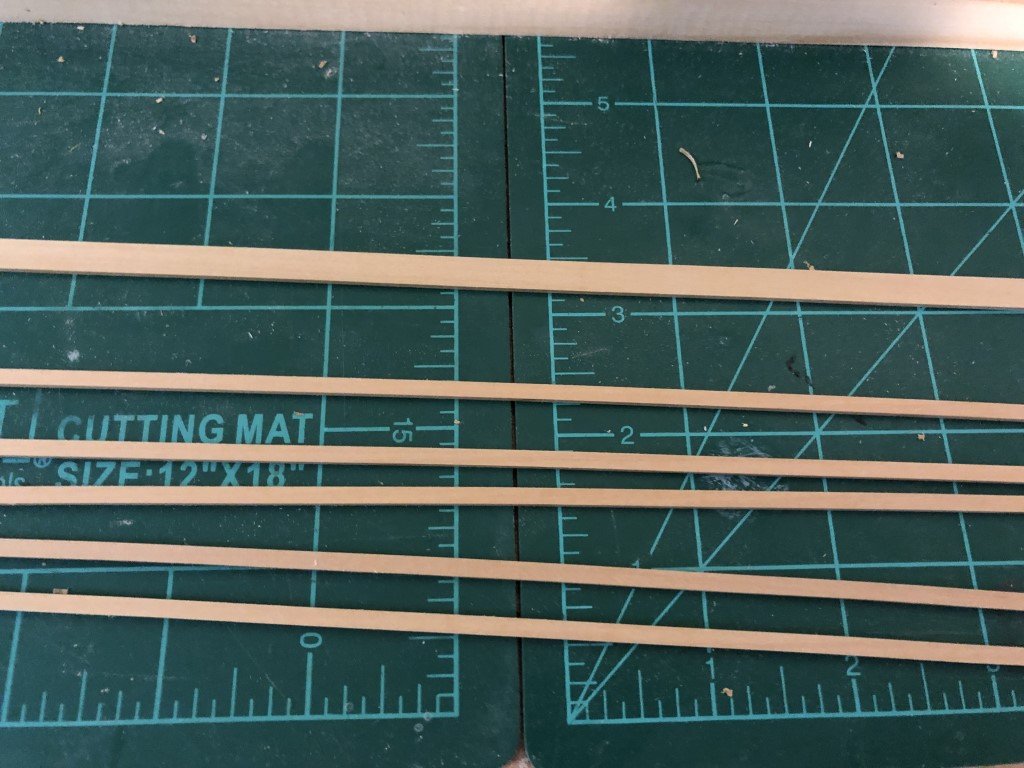

I'm done smoothing the bulk of the hull as I am going to do. Time to install the bulwarks. I did decide to go with Costello Boxwood for this structure. Here is some material that I've milled / cut for the next steps: I need two strakes (each side) of the 1/8" x 1/16" material. This will go from the bulkhead 9 to the front of the ship. The 1/4" x 1/16" material is to be bent into a u-shape that will fit from bulkhead 9 back to the stern region.

-

Thank you very much! The whole frame that holds the plexiglass panels lifts out, so there is some opportunity for some air-exchange between the frame and base inside the molding. Do you think that is enough exchange or should there be more? I have always wished that there was more information on case construction within forum - it always seems to be a bit of a mystery to me! It actually would be a nice topic for NRG to set up a tutorial and / or a nice article in the Nautical Research Journal. Greg

- 123 replies

-

- Le Pourquoi-Pas

- Constructo

-

(and 1 more)

Tagged with:

-

Construction complete, the case is now just about ready for its finish. After the picture was taken, I filled the finishing nail holes and a couple of 'almost perfect joints'. After testing a few finishing methods / colors, I've decided to go with two coats of Minwax cherry stain. I also made a matching cherry display board for the model to be attached to via a pair of brass pedestals. Inching closer to the finish line!

- 123 replies

-

- Le Pourquoi-Pas

- Constructo

-

(and 1 more)

Tagged with:

-

First - thank you for the positive comments! I do plan on opening space for the cockpit prior to planking the deck. I'm not sure exactly how all the work will be done - one thought is to model the cockpit and its enclosure as a unit and then 'dropping' it into the model; this may be easier for me to handle than putting in a floor and then planking the cockpit and finally adding the sides. I have been giving this some thought! I am no expert on the actual workings of this ship but as far as I can see, for anchor handling, there is a small windlass / winch that is attached to the forward bits, it is to have removable hand cranks. From the drawings / plans it appears that raising the anchor would be a two man job. There is a single anchor davit that is removable and can be placed on either side of the ship. It appears that a single anchor was used and that it would be stowed on deck. Some of this can be seen on the plans included with the model, the rest of this information is based on the practicum that Chuck Passaro wrote for building the 1/96 scale Model Shipways kit: https://modelexpo-online.com/assets/images/documents/MS2027-Phantom-Practicum-Complete.pdf - and I'm fairly confident his work is very well fact-checked.

-

I gave the port side of the hull a good sanding today and then brushed on a coat of 50% white glue to seal that side. Soon I can start working toward a nice smooth surface to paint and copper. Thoughts for future steps in the build: Starting to think more about the bulwarks and deck. Currently I am thinking about a natural finish on the inner bulwarks, deck, cabins and such. Because of this, I am planning on replacing the kit supplied wood for the bulwarks and decking with something nicer. Probably Costello boxwood for the bulwarks and timberheads. Swiss pear may make for a nice contrasting margin planks and then C boxwood for the deck planking (I'm also considering maple for the deck). I also want to modify the deck so that the cockpit is dropped under deck level. I understand way this wasn't done on the 1/96 version, but would not have been hard to work in for the 1/48 kit. Also, I not be using the PE brass for the sides of the deckhouse, etc.

-

The transom has been planked and is partially faired with the rest of the hull. I used 3/16" planks for all of this planking except for the top plank which is from 1?4" material. This time I remembered that the top plank needs to be positioned high enough so that the top edge fairs with the deck - been caught out on this type of situation a few times over the years! So the next picture is mostly a personal reminder.

-

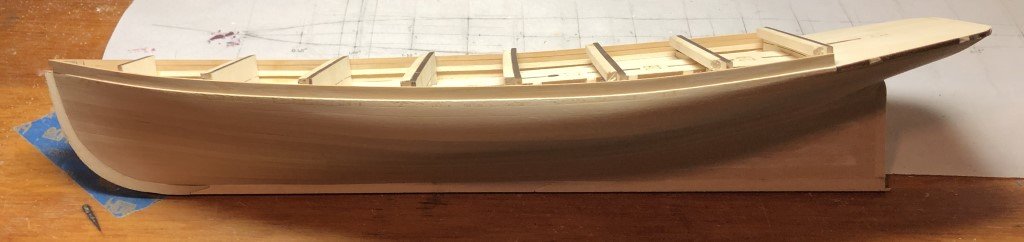

I've completed planking the port side of the ship. Most of the exterior planking work is done. A bit of sanding coming my way! But before that is done, I will be addressing the stern (and that small triangular region). Here I continue to ponder: why the does instructions / prototype build not address planking the stern? In the instruction manual, pictures show the stern smoothed with the aid of filler prior to painting. Personally, I think a few planks would look nice back here, so they will be going on soon. Then the sanding / smoothing process will commence. Bulwark planking will go on once I'm satisfied with the rest of the hull's appearance, but prior to painting.

-

Finally started working on the case today - maybe I really don't want it off my shelf! Fortunately, I'll still be able to see it once it is cased and moved to its destination. This will be the fourth case I have made based on Wes Marden's 'Build Your Own Model Ship Case' PDF. I got most of the base completed today. A nice piece of plywood is the main part of the base. The rest of the wood in this case will be cherry - I wanted a wood that would finish nicely to match the darker hull of the model. So the molding was made from some 1" by stock. It's now 3/4" thick and I routed a Roman Ogee shape into the top of the molding. It is now glued and finish nailed to the plywood. Next I need to make up a lot of 3/4" square material for framing the 'glass'.

- 123 replies

-

- Le Pourquoi-Pas

- Constructo

-

(and 1 more)

Tagged with:

-

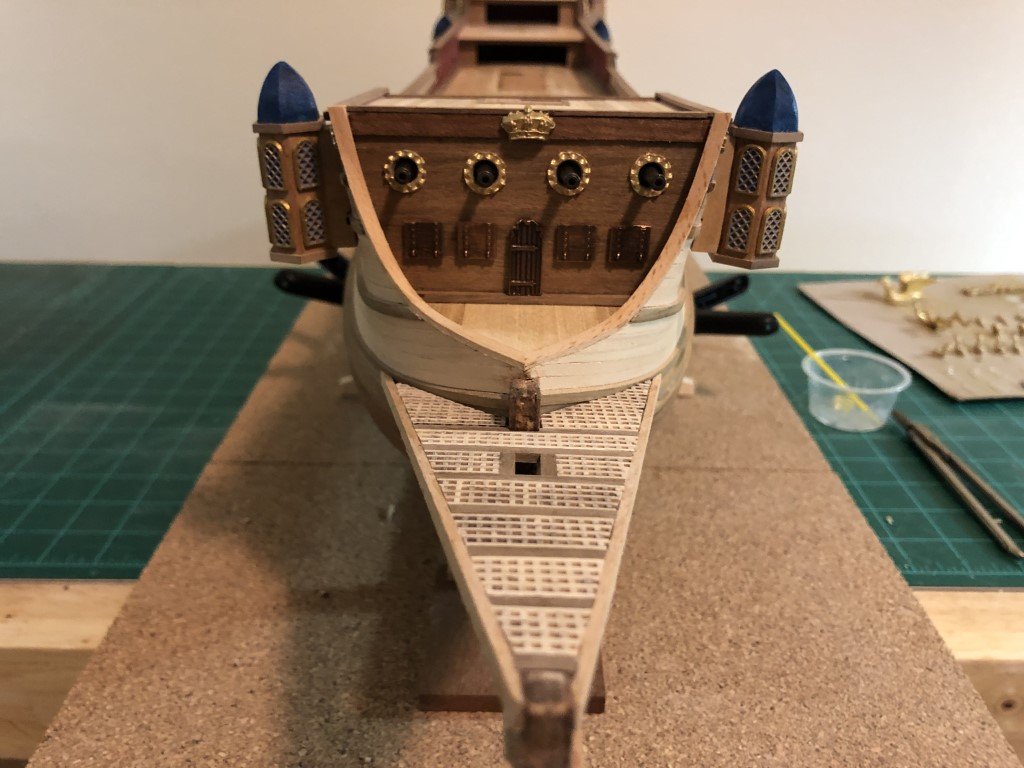

A couple of small steps forward: 1. The head grating has been reduced to the correct thickness and installed 2. All five of the gunport wreaths on the starboard side are in place (there are two more along side the forecastle). I wasn't looking forward to installing these as cutting away space from already installed material always gives me some anxiety! These went in fine - hopefully the port side goes as well.

-

I've completed the starboard planking and given it a first smoothing. The basswood planking is a bit soft / flexible even with the additional material between the bulkheads. I'm going to give the planking a 50% white glue / water treatment to stiffen the material up a bit. For now this should minimize chances of denting the planking while I continue work on the hull and later in the build it should provide an opportunity to get a smoother finish on the wood. On to the port side planking!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.