-

Posts

240 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by FreekS

-

the model is finished. I've decided on the name Hr Ms Banckert. this destroyer was in dry dock in Soerabaya when the Japanese invaded Java, and was sunk (including drydock) by my other model Hr Ms K-XVIII (herself then destroyed by her crew). All 8 of the class were sunk in WW2, one by the Germans in Rotterdam and the others by the Japanese in the Dutch East Indies. The first time working with PE and with airbrush has not been a disappointment. With a lot of patience it was well doable and the overall level of detail that Boris built into this model is very nice. pacific Crossroads has a set of models of many other Dutch warships that fought in the pacific, and I can certainly recommend then to anyone interested. freek

- 7 replies

-

- admiralen class destroyer

- pacific crossroads

-

(and 2 more)

Tagged with:

-

Last dast day of the holidays Further work towards the stern, starting to look like a real "jager"! Freek

- 7 replies

-

- admiralen class destroyer

- pacific crossroads

-

(and 2 more)

Tagged with:

-

Another day work - a few hand wheels lost and mother few errors but on the whole it's starting to look like a nice destroyer. Freek

- 7 replies

-

- admiralen class destroyer

- pacific crossroads

-

(and 2 more)

Tagged with:

-

The Admiralen class destroyers were a series of eight destroyers built between 1928 and 1931 for the Dutch Navy. All were lost in WW2, one in Rotterdam and seven in the Dutch East Indies. The kit is from Pacific Crossroads, designed by Boris Mulenko, who is Russian and has built models of many of the Dutch ships that fought in the Pacific. The kit is a mix of resin parts and PE, and I have never used either. Here are some of my pictures of the start of the project Started with my (also new) airbrush. I practiced a bit on a small helo project (still visible!) but now started using it in earnest. Waterline is nice and straight and painting the PE before use seems to work. I put the resin parts onto double sided tape. The hull after painting on the box from Boris. First experience with PE - I bought one of those bending tools and read a bit on Internet. Main tool seems to be patience and it's still holiday... The nearly completed bridge, I count only 7 errors (all of them thinking errors - wrong parts on wrong places etc) ! And a start on the 75 mm gun platform between the funnels. All for now - so far I like the work and I very impressed with the extreme detail in the kit. freek

- 7 replies

-

- admiralen class destroyer

- pacific crossroads

-

(and 2 more)

Tagged with:

-

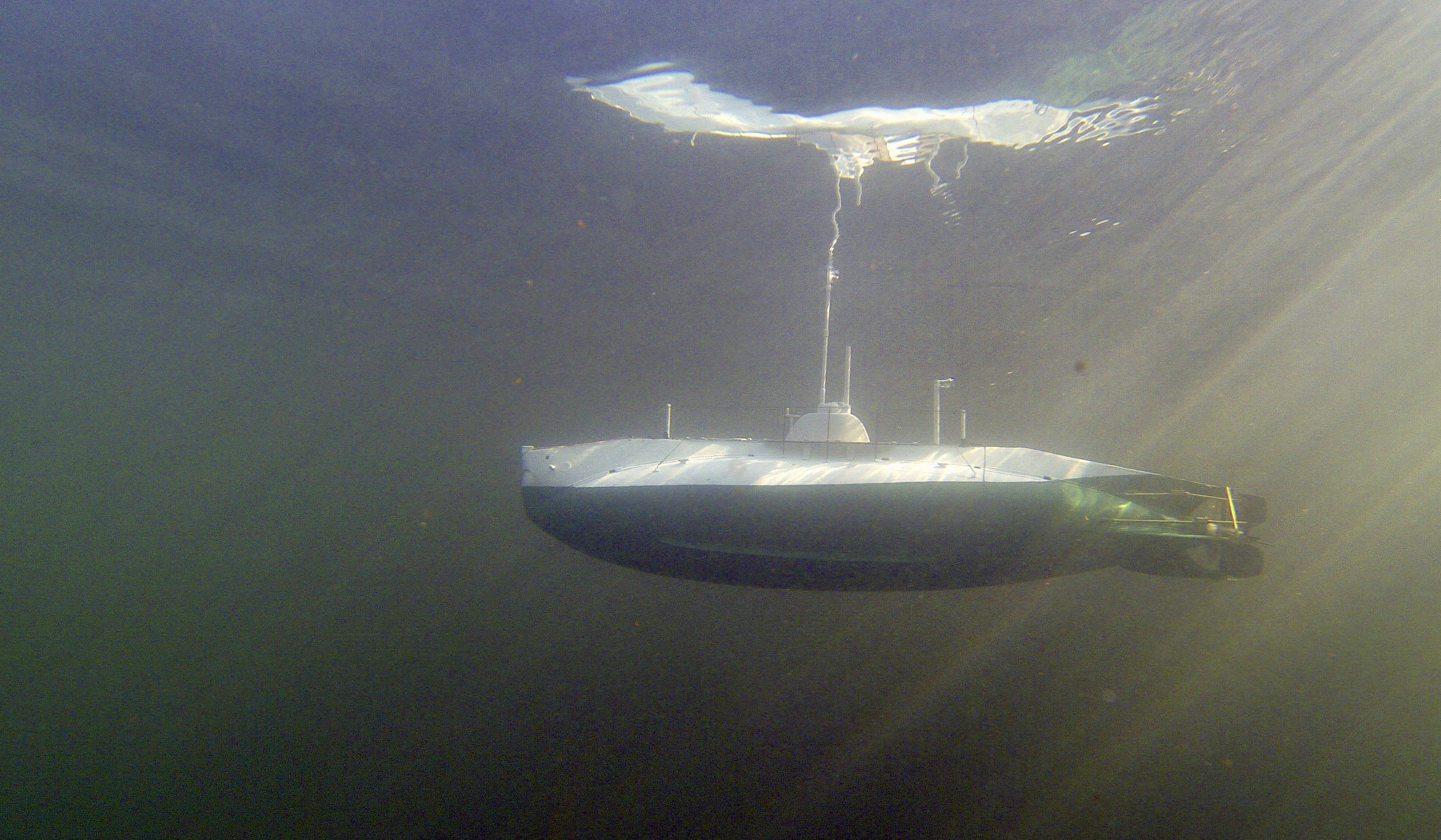

Hi all November 23rd, 12 degrees C outside and sunny! Today I went back to the cologne rowing club waters, my sub was followed under water by an ROV taking pictures. I must say, model subs look fabulous in their own element! Still some work planned, I want to replace the wires to the mast (they stretch too much), install turnbuckles, decals, and a few other things Freek

-

Hello all, Slowly this thread is turning into a sailing rather than a building log! Last weekends trip to a nice clear lake in Cologne, home of the oldest German model sub club. Note slight damage due to underwater collision Also note the even older sub encountered in the last few seconds... Freek

-

After the "shakedown cruise", as Piet called it, some more details were added to the boat. I redid the waterline, though still not as good as I want it. Added supports for the deck, a forward guide bar for the anchor chain, cables on the mast and a flag in top. Also copied one of Piets additions, the "pikhaak". Which was stored under the deck. A flag was used by these boats on exercises so the "enemy" Could keep track of the subs movement and prevent collisions. In the 1909 and 1910 Dutch Navy exercises the boat sank the armoured cruisers of the surface fleet! the boat has now hads its second voyage, in de Vinkeveense plassen, nice and clear water in the centre of holland where this picture was taken. Again unfortunately the photographer did not capture the dozens of other models of Dutch Navy ships that were sailing around!

-

Piet, see here how Paul Burghorn has made the plans for his sloep http://www.modelbouwforum.nl/forums/bouwverslagen-schepen/139613-mijnenlegger-hr-ms-nautilus-1930-1941-a-13.html Freek

-

Boris there is nice model of the O-1 and two of KXVIII in Den Helder. I agree Piets model competes well with them, but musea are not that keen on static model displays anymore, nowadays it has to have buttons, a screen and a theme! Freek

-

Thanks for your kind words! Yes I was very pleased with the boat and it's performance. The trim was perfect and the boat as stable as a rock! Manoeuvrability also much better than expected, hull shape seems to make for a stable and fast boat. Mark, good question on control. The key is a long wavelength transmitter, so the signal will penetrate water. My very old 40 MHz transmitter can penetrate clean water to maybe 5 meters. In US I believe 75 MHz is used. Most model plane people have moved to 2.4 GHz, which is a better frequency for high dat rate transmission, but being microwave won't penetrate water at all. The antenna is inside the boat, under the wooden deck and I guess the wavelength that penetrates water does the same with water and plastic. Freek

-

Well friends, The maiden voyage of Hr ms O-1 went extremely well. The boat was pretty much perfectly trimmed in my bath and todaz was tested in the swimming pool in Zutendaal - beautifully clear water! I had a camera on a tripod under water, and one outside of the pool, and together these captured below 7 minute summary of a day worth of sailing. Yes there were some other boats, but somehow I never saw those - and they 'surprisingly did not show up in pictures'. figure that! I'm certainly happy with the boats performance, now I can get back to redoing the paint job and look for more details to include! Freek (could not find how to embed a video!)

-

I thing THE stanchoins and antennes and some maats are taken down pro to diving, at least in case of K-XVIII thats described in books written by THE XO Freek

-

Hello all, I hereby cordially invite you the maiden voyage of hr ms O-1, to take place in a swimming pool in Zutendaal, Belgium this coming Sunday! Over the past weeks I remade the divetank , so I now have a 300ml bag rather than the 120ml before. Spent significant time with the boat in the bath to balance it, and Im fairly happy with the result. Under water the boat seems to be level with the tank pumped full, and above the water, while it does not quite reach the painted waterline, the decks are nicely above the water. Subs always have 'variable' water lines anyway. The pressure sensor inside the boat switches the pump off when the bag is full, and then the boat just dives. Trimming it with the pump leads to below nice image of a sub 'hanging on the periscope', that's what we aim for! Freek

-

Given the wealth of targets on this forum, I loaded some more shot - now nearly 2 kg on board and total weight of the boat is 3.8 kg; exactly the nominal weight of the RL-boat divided by 32 to the power 3. Seems the hull shape is pretty good to drawing. By the way - I was given the drawing set of this 1905 boat by Fred Huygen, who unfortunately passed away a couple of weeks ago. He built many per-war Model Dutch submarines including Cornelis Drebbel , a beautifull oar powered sub from the 1760s and O-13 - still on patrol, for which he built the model for a TV documentary about her disappearance off the Danish coast in 1941. Both my subs were inspired by Fred's work. Yesterday was a large submarine meeting in Cologne, and we missed him. Back to the present. The pic below shows the wet testing of the boat to determine the volume of the dive-bag. The stern is lying in a container of water, and using the transmitter and some kitchen scales. I could determine the dive tank is only 120 ml. That's much less than the 300-400 I need to get the boat anywhere near the waterline when not submerged. I thus ordered some more of the tough plastic sheeting to try make a bigger one. The shot is pretty much distributed to have the boat level under water (keeping a reserve bag of 250 gram shot in place of the dive tank - which I can reduce if I manage to make a bigger one. As seen in my bath, the boat lies a bit deep and not perfectly level. It's pretty stable though. I took both my boats to the world famous submarine day in Cologne, unfortunately my K-XVIII refused to dive after a nice round on the surface - pump seems to have failed or developed a control glitch. And with so many large (5 foot or more), and FAST subs in the water I was not comfortable trying my small boat with its minute reserve buoyancy. Rather do some more bath work! However here were some of the visitors.

-

With 1.3 kg lead shot glued in the hull, so that the tech rack slides just overtop. With the lead the boat now weighs 3.2 kg (sorry, i don't calculate in pounds!), and based on the displacement I expect the total weight to become 3.8 kg, including 200 gram or so of water in the dive tank/bag. The boat has not been wet (as the paint is still wet) but next step is to carefully balance the boat with the remaining lead shot in a tank, and of course check for leaks. Exiting!

-

Starting mounting the deck covers, and the first set of planks on the deck. The rope is about 0.4 mm, so maybe. 1 cm in RL. the rope is tightened by a 12 mm long tightener, I bought 6 but looking at this picture I think it's a little too big for this scale. I may look for another solution for this. Any ideas how to keep this tight Unobtrusively? The hinges for the deck covers are still missing All for now Freek

-

Hey Piet, those are MUCH nicer torpedo tubes than the two black ones I built for my KXVIII, at the same scale. Really I'm very impressed! can I order a pair, working and able to fire my rubber band Torpedo's? Just kidding !! Yours is the best combination of a superb build, great link to history and personal story - I read it every day! Freek

-

Thanks Piet, My farther was born in Indonesia (well Batavia in Nederlands Indie at that time), so he was one of the Dutch that your father defended! And my wifes mother comes from Surabaya! Its nice to see y'all ( now where did I pick up that term) being even more impatient to getting O-1 wet that I am! But as Piet points out, these old submarines had many details on deck and since I will have to trim her with lead shot to within a gram or so I want nearly everything mounted before I do so. Now working on the deck, where two of my pictures show a nice wooden planked deck, similar to what K-XVIII had. making that is simple and fun work and then comes the hinges to the doors in the deck to load Torpedo's and such. They won't be functional and that's good as my metal working skills are nearly non-existent! Cheers Freek

-

Well, Ian, thanks for your interest in the maiden voyage of hr ms O-1. I am going much faster than my first sub (since i actually follow à fairly conventional build strategy instead of the hair-brained "bread and butter" strategy I used onnhr ms K-XVIII). There are several interesting dates in the diary, including August 16 in cologne with a very distinguished U-boot building club. Also a pool run in Belgium in September. But first I plan I have to finish most of the additions so I can then start to glue 2 kg worth of lead shot inside the hull and balance her fore and aft to a gram or so, in a plexiglass "fishtank" I have. Trimming will be a challenge as I have a "dry hull", and so while I can move weights, I cannot also reposition floating foam pieces in flooded areas of the sub. But then the pictures I have of her sometimes say "O-1 with crew and torpedos moved to the back so the mouth of the torpedo tube can be seen. It's not like this boat had a firm waterline. Thanks for all your interest - I will be sure to post pics and videos of a maiden when it happens! Freek

-

Dear friends, Started painting the boat, in colors close to the model in the Dutch Navy museum in Den Helder (and that I just happened to still have from K-XVIII!). Using normal brush - airbrush did not existing 1905!. "Tjetten" it was called. In spite of professional blue masking tape the waterline needs some correction. Freek

-

Piet, Thanks! I do believe though that the K-XIV to K-XVIII class also did not have bilge keels. Not on my model at least! Freek

-

Dear all, Lots more details made such as the stabilisers (Piet you can translate "kimkielen"!), and the stanchions on the deck, held in particular tiny holders. The stabilisers fins are again mounted with carton flanges impregnated with epoxy resin. Next step is painting of the hull followed by the deck planking. All for now again! Thanks for your interest! Freek

-

@Piet, bedankt voor het compliment! As with most ships, fotos indicate many changes made during the boats life. As this was the first Dutch sub, it was a testbed. In fact the drawings I have are of the "mid-life conversion" when the dangerous petrol engine was replaced by a Diesel. The early photos often show two short masts with stripes fore an aft, I think to help trim the boat. Later fotos seem to have three full masts with navigation lights etc. As my O-1 will be a working model, and those masts were clearly taken down for submerging, I will make the early version with the two "trim masts". As I call them. Another very visible feature of the boat are the flanges that were used to rivet the deck section and the fins to the pressure hull. Rivets themselves are only visible in dock fotos, I think they were probably hammered flat and covered with many layers of paint. I cut the flanges from 0.4 mm carton (so in rl they resemble 12 mm steel), and glued them on the boat. Next they were coated in thin 2 component epoxy resin to make the waterproof.

-

Subsail is over again. The technical bits of hr ms O-1 were finished on time and seem to work. However, the boat has not seen water yet as its unpainted. My other boat (K-XVIII) did get into water and even fired a torpedo but I had little chance to film in the pea-soup like water. On a short holiday in Switserland I took a box of tools, including my 15 W soldering iron. So after mountain hikes I could make some of the details. First the steering wheel, in the case of O-1 mounted outside the conning tower and horizontal. The coin for scale may be unknown to some, as the Dutch have discontinued it but the Germans have not. Here is the completed steering wheel, and the mast. This submarine from 1905 still had three masts (plus two periscopes). Also these old boats had lots of details, here a few thingies for tying ropes to, foundations for the fore and aft-masts, and guide-eyes for the (anchor?) chain (I have not found out yet if the O-1 had an anchor)! Greetings Freek

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.