64Pacific

Members-

Posts

53 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by 64Pacific

-

3D Printing Cannons in Resin

64Pacific replied to thibaultron's topic in 3D-Printing and Laser-Cutting.

Thank you for sharing these tables and the drawing. I am not too particular on the type or style of cannon as it won't go into a ship. Rather it is a small project with the intent of re-igniting my desire for using the resin 3D printer with the added benefit being something neat to put on the shelf afterwards. -

3D Printing Cannons in Resin

64Pacific replied to thibaultron's topic in 3D-Printing and Laser-Cutting.

Awesome, thanks for sharing the drawing! When I am back at the computer in the morning I will take a look. -

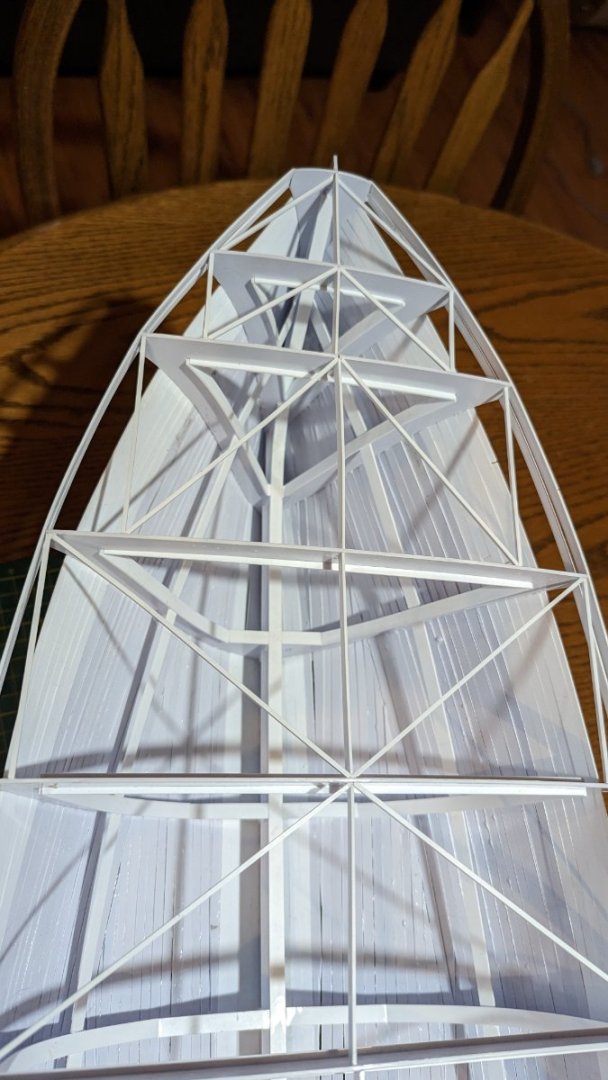

Here the Keel and section lines as taken from the lines plans have been cut out on the paper cutter and glued to 0.06" thick styrene sheets and cut out. The prototype is about 64' long, the keel as shown is roughly 32" overall length. Once the shapes were roughed out notches were cut to allow them to interlock with one another. The paper keel template included a horizontal line (above the pencil tip in the first image), this reference line was used to mark a line. Later this line was used to ensure that the ribs where set at the right location vertically on the keel. Dry fitting the components, a jig would be required to hold everything in line... To hold the keel straight while the ribs were fixed a very simple jig was made up. This consisted of two pieces of MDF with a few scrap chunks of .060" styrene sandwiched between. The shape of this piece was made by tracing the plastic keel onto the wood and offsetting by sketching a line. The offset only needed to be rough, such that once the jig was cut it wouldn't interfere with the ribs, a few tests and adjustments allowed the parts to slide in without interference.

- 11 replies

-

- Malaspina Straits

- plastic

-

(and 1 more)

Tagged with:

-

Hello everyone: This log will go back in time a bit, like a lot of my projects this one started roughly twenty years ago. During the early 2000's this tug, the Malaspina Straits, was listed for sale on a used vessel website. With the posting were a few photos of the tug out of the water along with a few drawings. At the time I was quite into 3D modelling and thought that this would be a fun project to make a few renderings of. One thing led to another and the project never did get off of the ground and the files were tucked away. Fast forward to sometime around 2017 and it was suggested that we build a pond at the local museum; the model ship bug bit, at this same time I was realizing that HO scale model trains, while neat, just won't fit my current living arrangements. The ship bug really bit when the missus and I purchased a property with a small pond, and a pond needs a boat so the search was on for a prototype. While organizing some files I stumbled upon the old drawings and photos saved some twenty years prior. A little looking online showed that she was again for sale and a few queries put me onto the naval architect. After making a call to see about getting a set of drawings the architect noted that this was a common request and asked that I mail a cheque to them, but make it out to another independent society that is rebuilding a steam tug, the SS Master. The Master is British Columbia's last surviving wooden hulled steam tug, once I learned that the "fee" for the drawings was going to help with this restoration I couldn't get the cheque book fast enough. Check out the SS Master here: SS Master The Malaspina Straits was launched in 1964 and was one of a group of three ships, the Rasario Straits and the third escapes me at the moment, all built for Straits Towing Ltd. of Vancouver, BC. Considered a hot rod of a tug it was primarily designed for moving chip barges up and down the West Coast of British Columbia. The tug moved around to various owners over the years and was refit a few times, the model that I am building will be per the original drawings. I've never seen the tug myself so can't post any photos of it but here is a link to a page with a bit more detail: Malaspina Straits - Nauticapedia.ca As far as model ships go, I've never built one, at least from scratch however I have turned heaps of styrene into other buildings, trucks and various model railway related things. As I was more familiar with modelling in styrene and as this model will be used in the water styrene felt like a better fit than wood, it may be, it may not be, time will tell. Just after the ugliness of Covid descended upon the world the model got under way, a few 4' by 8' sheets of styrene were purchased from a local supplier and bits started to be cut out...

- 11 replies

-

- Malaspina Straits

- plastic

-

(and 1 more)

Tagged with:

-

Silver soldering

64Pacific replied to Dziadeczek's topic in Metal Work, Soldering and Metal Fittings

Very interesting, I've never had good luck with soldering, silver or otherwise when it comes to model parts. It always seems to take forever to heat the part that I intend to join, and rarely the parts are fixed together. -

3D Printing Cannons in Resin

64Pacific replied to thibaultron's topic in 3D-Printing and Laser-Cutting.

I have really been struggling with my resin printer lately; I believe the issue to be trying to print too small without first trying bigger models. I wouldn't mind trying one of these cannons and following through with this tutorial. Are there drawings available for the base and details of the cannons? I wouldn't mind making a model for my desk of one of these cannons. -

Informative video about 18th Century Sailing Battleships

64Pacific replied to Peanut6's topic in Nautical/Naval History

Thanks for posting this link, a nice explanation; life on one of those ships for the enlisted would have been near unbearable, it looks like the officers had a much more "luxurious" time. -

Thank you both, really excited to be here!

-

Silver soldering

64Pacific replied to Dziadeczek's topic in Metal Work, Soldering and Metal Fittings

Reading Harold Underhill's Plank-on-Frame Models and Scale Lasting & Rigging Vol. 2, PG 40: He says in reference to making scale chain, touch the area to be soldered (with flux) using a fine brush. Lay the chain on a charcoal block, and from a length of silver wire add fine filings alongside the area to be soldered then move along the chain with the blowpipe. He noted that you will see the silver filings jumping to the joint and when cool it will be soldered. Have been wanting to try this to build anchor chain for my current tug model but I've had no spare time of late. -

This gives me an idea, I'll fire up Solid Edge and the 3D printer this weekend and post some results...

-

3D Ropes/Rigging in Blender

64Pacific replied to 3DShipWright's topic in CAD and 3D Modelling/Drafting Plans with Software

It is really refreshing to see a well put together tutorial that is not a video. I might have to give this a try in Modo, but I have been thinking about a switch to Blender and this may be a good starting point. -

Fiber glass hull, cloth and resin help

64Pacific replied to Riotvan88's topic in RC Kits & Scratch building

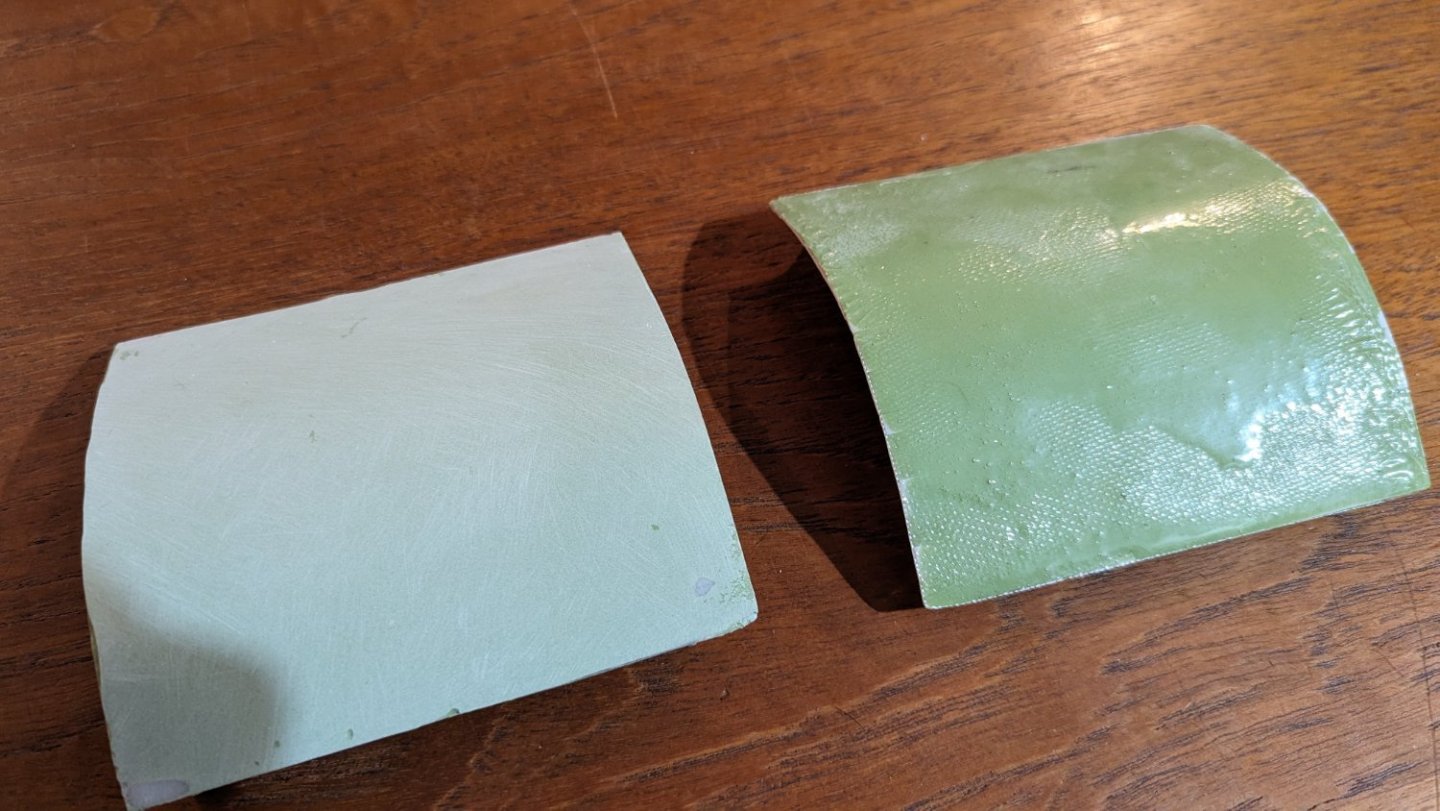

I am about to start putting glass cloth on my hull, at the moment work continues by reinforcing the rib to plank joints with a resin / filler mixture. I am using West Systems products as well, when I called their local distributor he had a lot to say and a lot of tips. My model is styrene and my concern was warping or other reaction issues, which there were none, see below. My process will be to apply body filler on top of the plastic, then lay cloth on top and in some cases add more filler. Another concerned was delamination and warping. To test this a couple of quick models were built using the same method as the plastic tug hull; one had body filler applied and sanded, followed by cloth; the next had cloth applied and then body filler; both test pieces had resin with filler applied on the inside to reinforce the rib to plank connection. Once everything dried it was left outside for a few nights at -40 and then brought back into the house, the idea here was to test extreme temperature differences and the resultant material expansion and contraction rates. I was purposely rough with these to test the inter-layer adhesion, additional rough handling tests (trying to twist the test pieces) yielded no failures. While they could be snapped significant force was applied to them with out failure, the pieces did flex a bit and it was a surprise that no cracks appeared in the filler. No sanding was done at all with the exception of smoothing the body filler, after sanding the filler was wiped down with Acetone which was allowed to evaporate before the glass was laid. My advice is to get some product, find some things with interesting curves and hard edges and try a few tests. Get familiar with the process on something that you have no problem throwing into the trash, nail down your technique before you touch your nice model work. The attached images are my test pieces, quick and messy. The piece at left (light green) has body filler applied over glass cloth, while the one at right is cloth applied over the filler - on this one the cloth actually fell off as I was moving this around, I tossed it back on, added more resin and carried on. One piece (left) has a small strip of cloth inside between the ribs as well, this did add a small bit of rigidity to the structure. While not the nicest work this did let me dip my toes into the fibreglass world and disprove a few concerns that arose. -

Wow, this will be an impressive model to see come together! This has me thinking about the Conveyor or the BX for my next build.

-

What a great model, the CAD work is really cool!

- 454 replies

-

- Union Steamship Company

- Stepcraft 840

-

(and 3 more)

Tagged with:

-

This is quite the project that you have completed, thank you for sharing! I've always wanted to do a ship in 3D but spend way too much time using 3D CAD and have trouble convincing myself to grab the mouse after work, however, this thread makes me want to try it!

- 107 replies

-

- Frigate

- Confederacy

-

(and 1 more)

Tagged with:

-

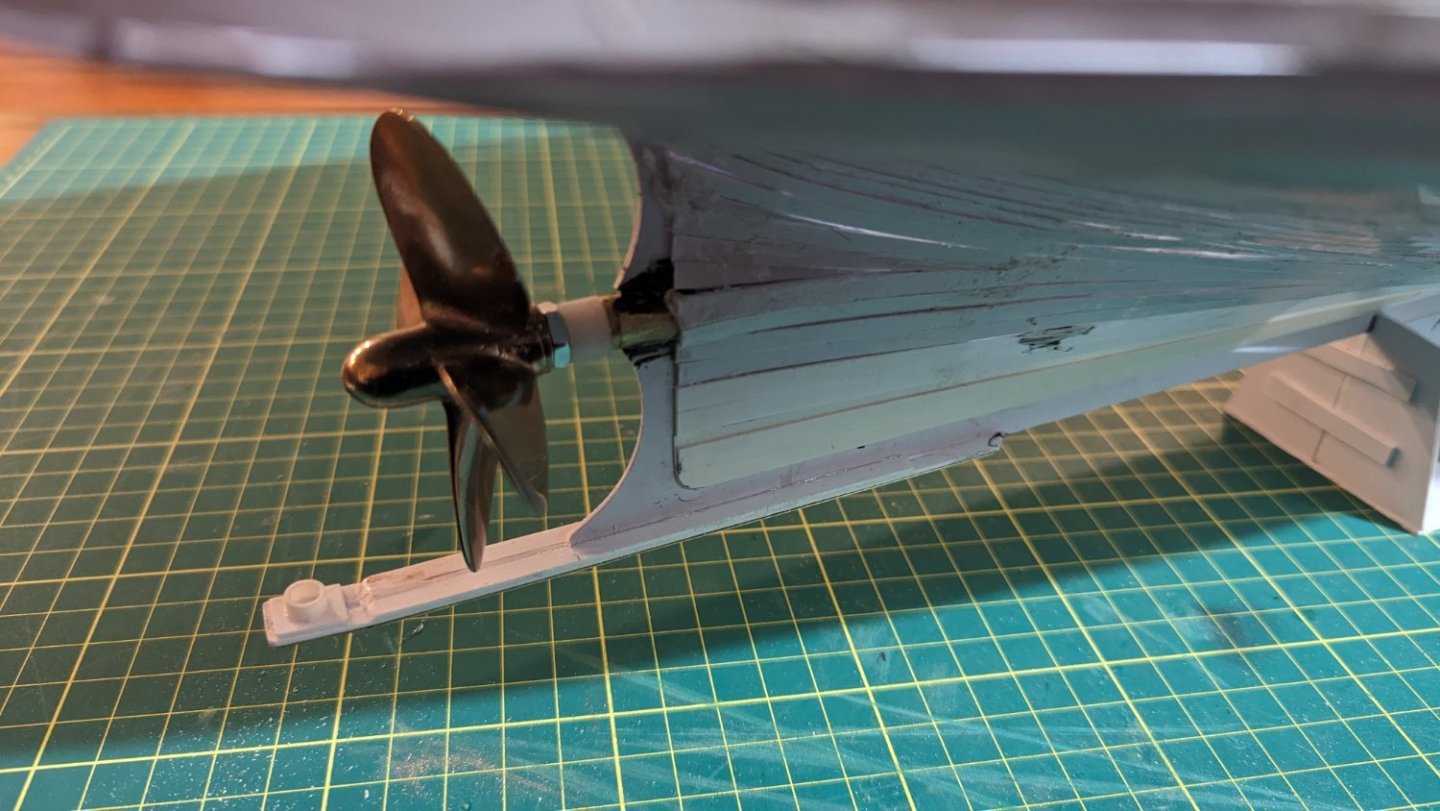

Now that I am back at the computer with a moment to spare here are a few shots of the tug model for those curious:

-

Thank you everyone, I am looking forward to participating here - a lot of impressive projects and it can really be seen that the amount of knowledge is quite impressive!

-

Hello all, I'm new to the hobby and the forums and hail from the Western half of Canada. A few years back an idea was tabled to build a large pond at our local museum. This suggestion got my mind running and before long a fibreglass hull for a 1:96 scale model of the banana boat Afric Star was order from a firm somewhere in the UK; apologies as my recollection of whom or exactly where they were is rather vague. Work took over and the model sat in my office, gathering dust and a nice pile of reference images from FotoFlight. Later, while stuck in a 'hotel' in Tuktoyaktuk I started digging through some old files, in there were drawings and photos of the tug Malaspina Straits saved from the internet nearly 25 years ago. The documents depicted the tug when it was sold about 1998 and was hauled out of the water for service. A few posts on the Facebook lead me to the naval architect and from them a few drawings were purchased. Covid hit and I, for some reason, decided to start another project. A few sheets of styrene later and a hull of my 1/2" model started to take shape... At the moment I've only got the one photo of the model handy, see attached if it comes through. Aside from the model ships, I am a mechanical designer / draftsman; am restoring an old logging truck, a tractor and a forklift; do a bit of fly fishing among other hobbies... Until next time...

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.